Page 1

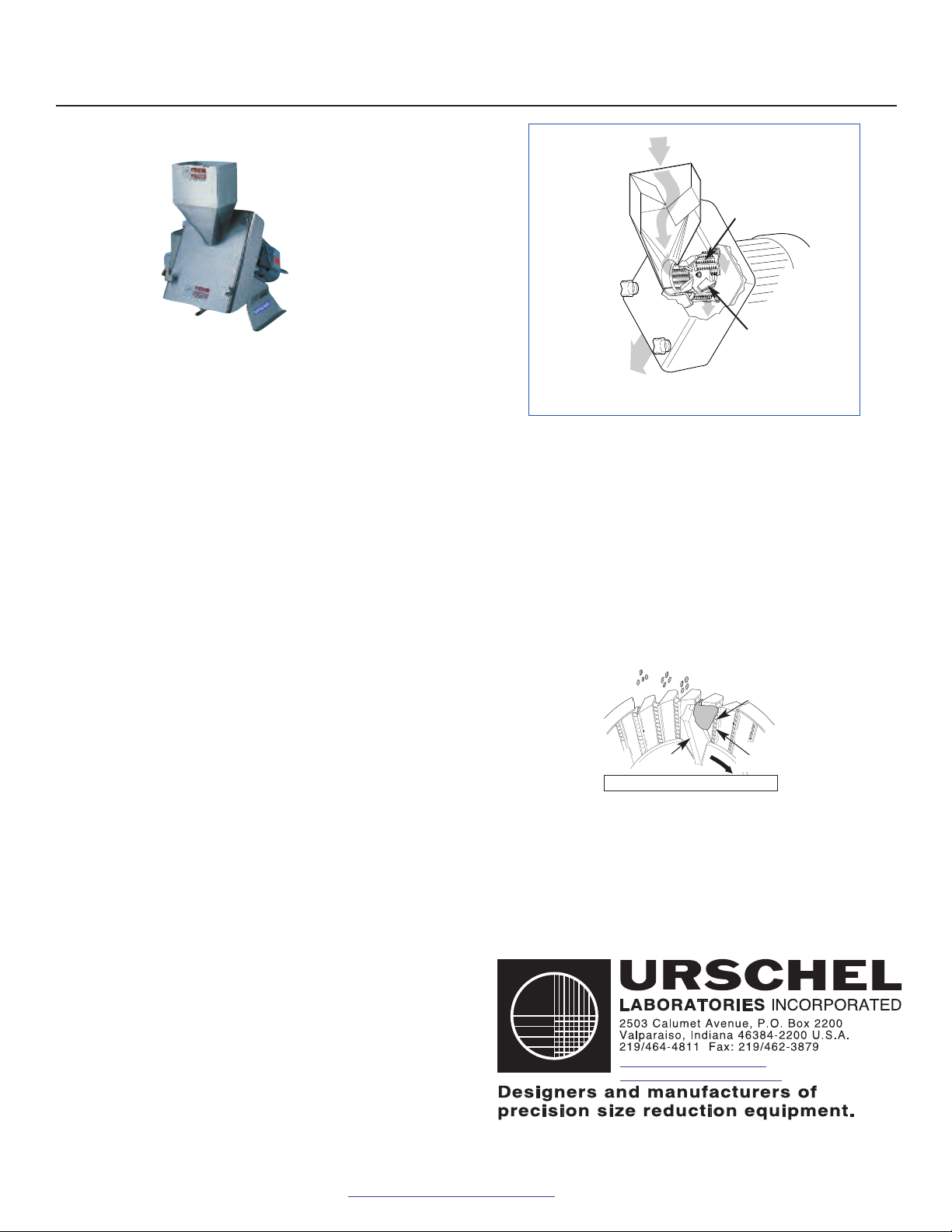

Comitrol® Processor Slant Model 3600

Controlled Particle Size Reduction

Cutting

Head

Comitrol® Processor

Model 3600 Slant

SPECIFICATIONS

Comitrol® Processor Model 3600 Slant:

Length: . . . . . . . . . . . . . . . . . . . . . . . 35.69" (907 mm)

Width: . . . . . . . . . . . . . . . . . . . . . . . . 29.21" (742 mm)

Height: . . . . . . . . . . . . . . . . . . . . . . . 38.64" (981 mm)

Net Weight: . . . . . . . . . . . . . . . . . . . . . 400 lb (181 kg)

Motor: . . . . . . . . . . . . . . . . . Impeller - 10 HP (7.5 kW)

APPLICATIONS

The compact size of the Comitrol Processor Slant Model 3600

makes the machine ideal for a wide range of small volume to high

capacity production environments.

Processors benefit from the wide selection of cutting heads and

impellers that are available for diverse applications such as chopping,

flake cutting, granulating, pureeing, and emulsifying.

Foods such as meats, poultry, fruits, vegetables, and cheeses can

be processed as well as many chemical and pharmaceutical products.

The machine features continuous operation for uninterrupted production, and simplified design for easy cleanup and maintenance.

Impeller

Product

COMITROL® PROCESSOR MODEL 3600 SLANT

OPERATING PRINCIPLE

Product is guided to the high speed, rotating impeller. When product reaches the impeller, it revolves at a high speed inside the cutting

head. Centrifugal force propels the product outward past the cutting

edges of the stationary reduction head. The cutting head has uniformly

spaced thin horizontal bars, or separators. Small portions of product

projecting into the spaces between the separators are cut off into

flakes by spaced columns of vertical knives. These flakes quickly travel outward and away from the cutting head. The wall surfaces between

the vertical knives are relieved to eliminate rubbing friction that would

produce heat.

Product

Impeller

CUTTING HEAD ASSEMBLY

Horizontal

Separators

Vertical

Knives

TYPES OF CUTS

Particle sizes ranging from coarse to fine emulsions are possible. To

ensure the proper combination of cutting parts, Urschel Laboratories, Inc.

recommends your product be tested in one of our worldwide Product Test

Cutting Facilities free-of-charge to find the most efficient solution to your

size reduction needs.

®Comitrol and Urschel are registered trademarks of Urschel Laboratories, Inc.

If your product application is not mentioned on this page, contact your local Urschel representative to

determine the most effective solution to your size reduction needs.

http:// w w w . u rschel.co m

E-mail: in f o @ u r schel.com

L2188 (s.s. L2065) JULY 2008

Page 2

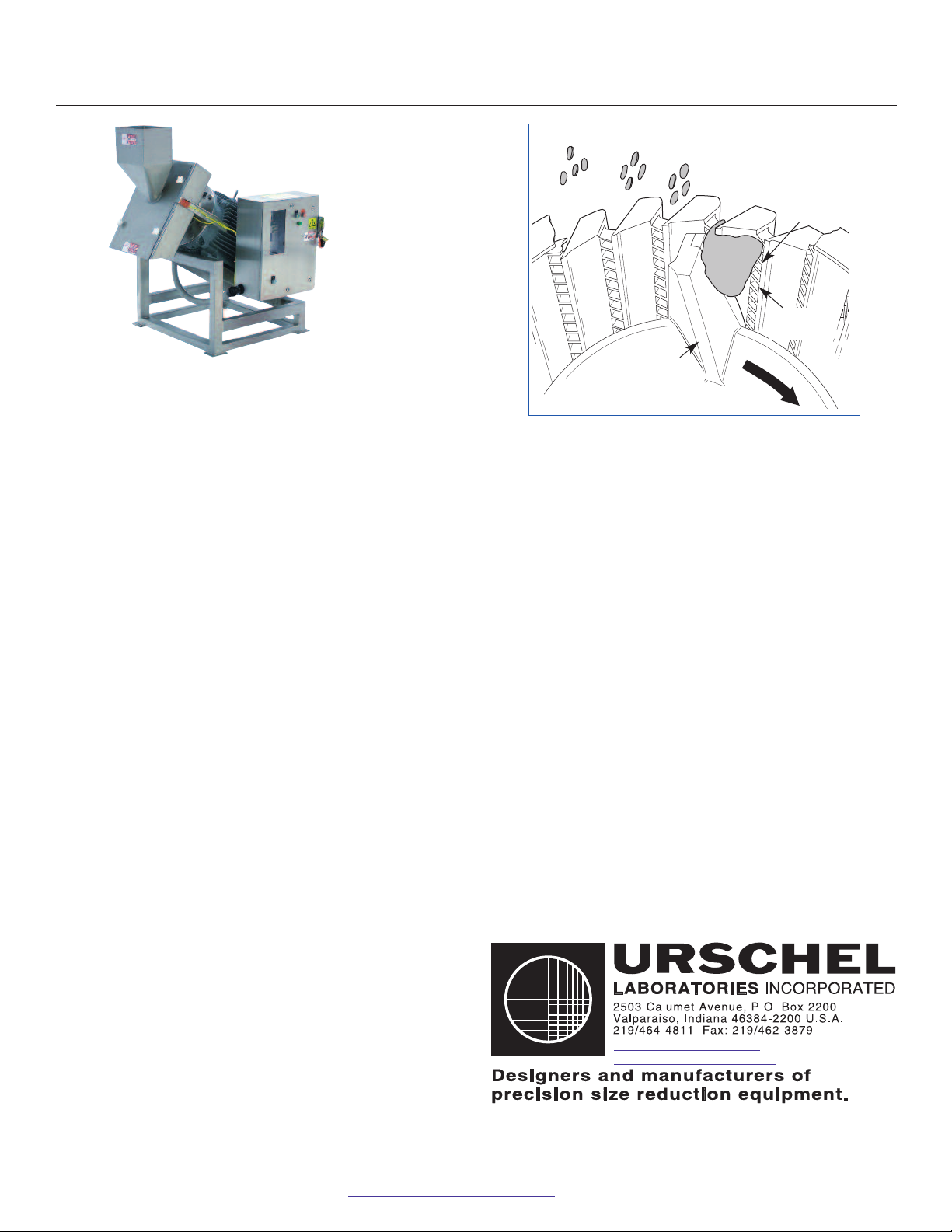

Comitrol® Processor Slant Models 3640, 3660 & 3675

Controlled Particle Size Reduction

roduct

P

Comitrol® Processor

Model 3640 Slant

SPECIFICATIONS

Impeller

Horizontal

Separators

Vertical

Knives

Comitrol® Processor Model 3640 Slant:

Length: . . . . . . . . . . . . . . . . . . . . . . 51.30" (1303 mm)

Width: . . . . . . . . . . . . . . . . . . . . . . . 40.98" (1041 mm)

Height: . . . . . . . . . . . . . . . . . . . . . . 62.43" (1586 mm)

Net Weight: . . . . . . . . . . . . . . . . . . . . 1196 lb (542 kg)

Motor: . . . . . . . . . . . . . . . . Impeller - 40 HP (29.8 kW)

Comitrol® Processor Model 3660 Slant:

Length: . . . . . . . . . . . . . . . . . . . . . . 59.36" (1508 mm)

Width: . . . . . . . . . . . . . . . . . . . . . . . 42.88" (1089 mm)

Height: . . . . . . . . . . . . . . . . . . . . . . 62.43" (1586 mm)

Net Weight: . . . . . . . . . . . . . . . . . . . . 1400 lb (636 kg)

Motor: . . . . . . . . . . . . . . . . Impeller - 60 HP (44.8 kW)

Comitrol® Processor Model 3675 Slant:

Length: . . . . . . . . . . . . . . . . . . . . . . 63.54" (1614 mm)

Width: . . . . . . . . . . . . . . . . . . . . . . . 42.88" (1089 mm)

Height: . . . . . . . . . . . . . . . . . . . . . . 62.43" (1586 mm)

Net Weight: . . . . . . . . . . . . . . . . . . . . 1500 lb (681 kg)

Motor: . . . . . . . . . . . . . . . . Impeller - 75 HP (56.0 kW)

APPLICATIONS

The compact size of the Comitrol Processor Slant Models 3640,

3660, and 3675 makes each machine ideal for a wide range of small

volume to high capacity production environments. Each model varies

in dimension, weight, and horsepower.

Processors benefit from the wide selection of cutting heads and

impellers that are available for diverse applications such as chopping,

flake cutting, granulating, pureeing, and emulsifying.

Foods such as meats, poultry, fruits, vegetables, and cheeses can

be processed as well as many chemical and pharmaceutical products.

The machine features continuous operation for uninterrupted production, and simplified design for easy cleanup and maintenance.

OPERATING PRINCIPLE

Product is guided to the high speed, rotating impeller. When product reaches the impeller, it revolves at a high speed inside the cutting

head. Centrifugal force propels the product outward past the cutting

edges of the stationary reduction head. The cutting head has uniformly

spaced thin horizontal bars, or separators. Small portions of product

projecting into the spaces between the separators are cut off into

flakes by spaced columns of vertical knives. These flakes quickly travel outward and away from the cutting head. The wall surfaces between

the vertical knives are relieved to eliminate rubbing friction that would

produce heat.

TYPES OF CUTS

Particle sizes ranging from coarse to fine emulsions are possible. To

ensure the proper combination of cutting parts, Urschel Laboratories, Inc.

recommends your product be tested in one of our worldwide Product Test

Cutting Facilities free-of-charge to find the most efficient solution to your

size reduction needs.

http:// w w w . u rschel.co m

E-mail: in f o @ u r schel.com

®Comitrol and Urschel are registered trademarks of Urschel Laboratories, Inc.

If your product application is not mentioned on this page, contact your local Urschel representative to

determine the most effective solution to your size reduction needs.

L2189 (s.s. L2065) JULY 2008

Loading...

Loading...