Page 1

TranSlicer® 2510 Cutter

Designers and manufacturers ofDesigners and manufacturers of

precision size reduction equipment.precision size reduction equipment.

LABORATORIESLABORATORIES

2503 Calumet Avenue, P.O. Box 2200

Valparaiso, Indiana 46384-2200 U.S.A.

219/464-4811 Fax: 219/462-3879

http://www.urschel.com

E-mail: info@urschel.com

INCORPORATED

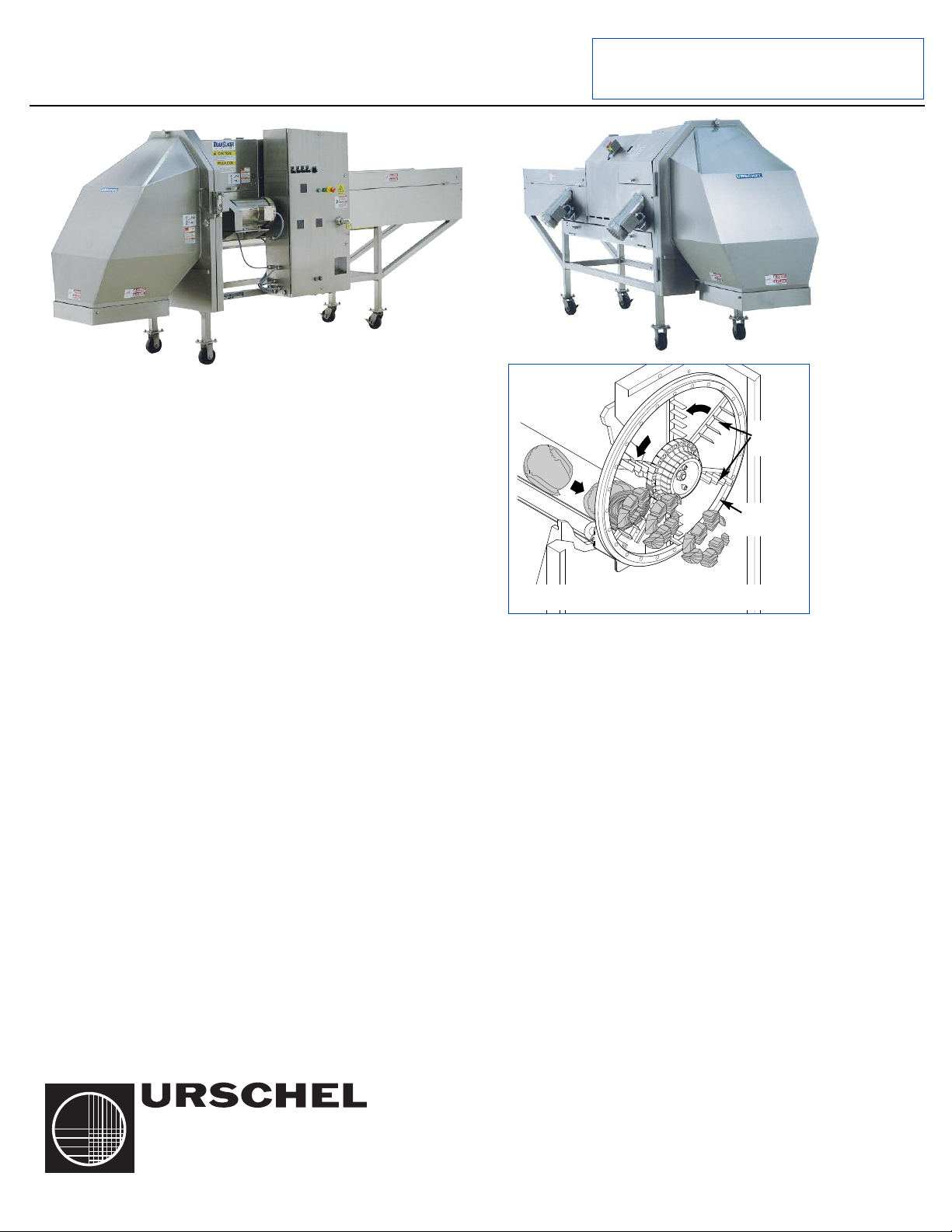

Large Product, High Capacity Slicer/Shredder

New Machine!

The TranSlicer 2500 Newly Designed for

oday's Food Industry Demands.

T

SPECIFICATIONS

Length: . . . . . . . . . . . . . . . . . . . . . 150.82" (3831 mm)

Width: . . . . . . . . . . . . . . . . . . . . . . . 49.88" (1267 mm)

Height: . . . . . . . . . . . . . . . . . . . . . . 66.75" (1695 mm)

Net Weight: . . . . . . . . . . . . . . . . . . . 1,500 lb (680 kg)

Cutting Wheel Motor: . . . . . . . . . . . . . . . . 3 HP ( 2.2 kW)

Feed Belt Motor(s):. . . . . . . . . . . . . . . . . . . 1 HP (.75 kW)

APPLICATIONS

The new TranSlicer® 2510 design combines the production-proven

features of the 2500 with today's industry-driven demands. The TranSlicer

2500 Cutter revolutionized the leafy vegetable industry when it was

introduced in 1995. The TranSlicer 2510 Cutter replaces the TranSlicer

2500 Cutter in the Urschel line-up with valuable features to ease

maintenance, increase positive product flow, and decrease operational

costs. The new machine accepts the same types of products: input of

compressible food products up to 8" (203 mm) in diameter, or firm, round

products such as cabbage up to 6-3/4" (171 mm) in diameter (larger

cabbage heads if cut in half). The TranSlicer 2510 offers:

• New, larger discharge chute simplifies product flow and reduces product

damage.

• Increased accessibility with more hinged compartments and panels ease

maintenance and reduce cleaning time.

• More sloped surfaces including redesigned electrical enclosure and

bottom feed pan to simplify cleaning.

• All stainless steel motors including dynamic brake used on the cutting

wheel motor that enables the motor to smoothly stop.

• Quick feed belt release levers simplify servicing and belt changeovers.

• Additional stop button conveniently positioned opposite the electrical

enclosure.

• Sturdy stainless steel guardlocks permit opening of access panels after

all moving parts have come to a complete stop.

• Positive product feed and increased yield results from overlapping belt

guards with optional lead-ins and belt slide extensions. These components

help guide product on a clear path to the cutting wheel.

• Replaceable feed belt guide supports offer cost-savings by eliminating the

need to replace an entire assembly.

OPERAT I N G

PRINCIPLE

Julienne

Knives

Cutting

Wheel

Product

TRANSLICER® 2510 CUTTER

the second set of belts. The second set of belts are synchronized with the

cutting wheel to insure proper advance of product per revolution of the

wheel. Top belt assemblies are also available to assist in feeding product.

Slightly twisted knives placed under tension serve as uniform-pitched

spokes positioned between the hub and rim. The pitch, number of knives

and belt speed maintain the advance of product which determines cut

thickness. One slice is made at a time which prevents any crushing of the

product. The cut slices are then released into a hinged discharge chute to

reduce their speed before exiting the machine.

The mod e l

TRS 2510 utilizes

two sets of high

speed feed belts

sloped to form a

“V” cross section.

Product delivered

to the first set of

belts is oriented

and accelerated

for p a ssage to

TYPES OF CUTS

Flat Slices

Flat slices ranging from 1/32 to 3-1/2" (0.8 to 88.9 mm) can be produced by

using standard knives on the cutting wheel. Knives must be evenly spaced

around wheel, three knives minimum.

Julienne Cuts

Julienne cuts ranging from 1/4 x 1/4" to 3 x 2" (6.4 x 6.4 mm to 76.2 x 50.8

mm) can be produced by using julienne knives on the cutting wheel.

Shreds

Shred cuts ranging from 3/8" (9.5 mm) to approximately 3" (76.2 mm) in

length and 1/32 to 9/32" (.8 to 7.1 mm) in slice thickness can be produced

by using a combination of julienne and slicing knives to make up the

shredding wheel. Identical knives must be evenly spaced around the wheel

to maintain correct balance.

®TranSlicer and Urschel are registered trademarks of Urschel Laboratories, Inc.

L2237A JUNE 2009 (s.s. L2237)

Loading...

Loading...