Page 1

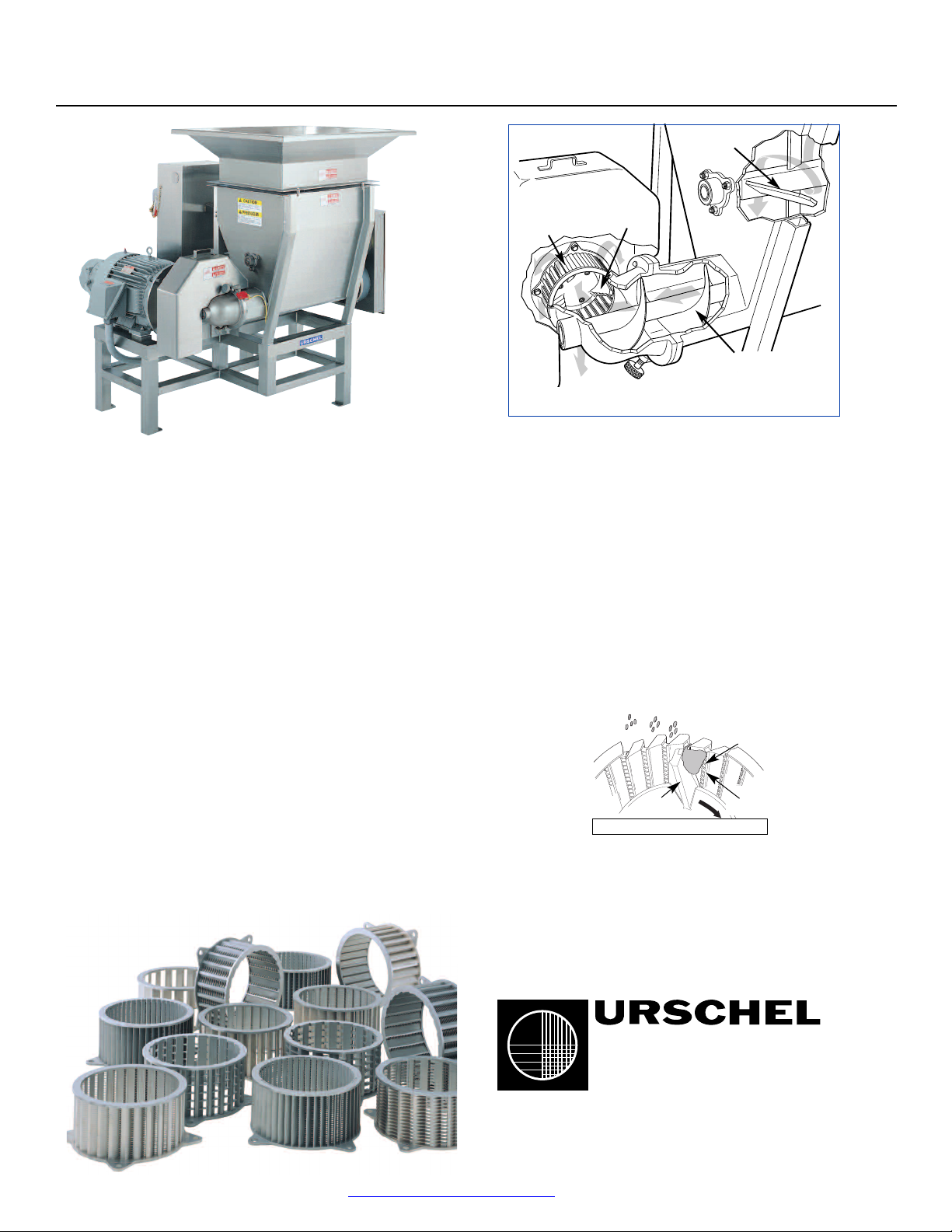

Comitrol® Processor Model 2100

LABORATORIESLABO RATOR IES

INCORPORATED

Designers and manufacturers ofDesigners and manufacturers of

precision size reduction equipment.precision size reduction equipment.

LABORATORIESLABORATORIE S

2503 Calumet Avenue, P.O. Box 2200

Valparaiso, Indiana 46384-2200 U.S.A.

219/464-4811 Fax: 219/462-3879

http://www.urschel.com

E-mail: info@urschel.com

INCORPORATED

LABORATORIESLABO RATOR IES

2503 Calumet Avenue, P.O. Box 2200

Valparaiso, Indiana 46384-2200 U.S.A.

219/464-4811 Fax: 219/462-3879

http://www.urschel.com

E-mail: info@urschel.com

INCORPORATED

Controlled Particle Size Reduction

gitator

A

SPECIFICATIONS

Length: . . . . . . . . . . . . . . . . . . . . . . 69.04" (1754 mm)

Width: . . . . . . . . . . . . . . . . . . . . . . *65.00" (1651 mm)

Height: . . . . . . . . . . . . . . . . . . . . . . 70.24" (1784 mm)

Net Weight: . . . . . . . . . . . . . . . . . . . 2260 lb (1025 kg)

Motors: . . . . . . . . . . . . . . . Impeller - 40 HP (30 kW) or

. . . . . . . .optional 30 or 60 HP (22.4 or 44.7 kW)

. . . . . . . . . . . . . . . . Feed Screw - 5 HP (3.7 kW)

. . . . . . . . . . . . . . . . . . . Agitator - 2 HP (1.5 kW)

APPLICATIONS

Cutting

Head

Impeller

Feed Screw

Product

COMITROL® PROCESSOR MODEL 2100

OPERATING PRINCIPLE

Product received by a hopper is delivered by an agitator and feed

screw to the cutting head and impeller. Once in the stationary cutting

head, the heart of the Comitrol unit, product is revolved by the rotating

impeller at high speed with the resultant centrifugal force propelling the

product outward. The impeller tips force the product against uniformly

spaced horizontal separators. Small portions of product projecting into

the spaces between the separators are cut off into particles by spaced

columns of vertical knives. These particles fly outward and away from

the cutting head. The wall surfaces between the vertical knives are

relieved to eliminate friction that would produce heat. Motor power is

effectively utilized to cleanly sever the product into uniform particles

instead of producing destructive heat.

The Comitrol Processor Model 2100 features large hopper capacity and positive product feeding for cutting fresh and frozen tempered

meat through a wide range of sizes.

The Model 2100 provides maximum utilization of all types of meat

for flaked and formed products, as well as other applications including

bakery rework. A wide range of cutting heads and impellers are available for tailor-made particle size requirements.

continuous operation for uninterrupted production, and simplified

design for easy cleanup and maintenance.

If your product application is not mentioned on this page, contact your local Urschel representative to

determine the most effective solution to your size reduction needs.

The machine features

Product

Horizontal

Separators

ertical

V

Impeller

CUTTING HEAD ASSEMBLY

Knives

TYPES OF CUTS

Particle sizes ranging from coarse to fine emulsions are possible. To

ensure the proper combination of cutting parts, Urschel Laboratories, Inc.

recommends your product be tested in one of our worldwide Product Test

Facilities free-of-charge to find the most efficient solution to your size reduction needs.

®Comitrol and Urschel are registered trademarks of Urschel Laboratories, Inc.

L2086 NOV 2006 (s.s. L1590)

Loading...

Loading...