Page 1

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 1/58

INSTALLATION

AND OPERATION MANUAL

G6 EVO

AUTOMATIC RETRACTABLE BOLLARD

Page 2

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 2/58

i. INTRODUCTION ............................................................................................................................................................... 4

ii. FIELD OF APPLICATION AND AIM S ............................................................................................................................... 4

iii. DECLARATION OF CONFORMITY ................................................................................................................................. 4

iv. GUARANTEE AND RESPONSIBILITIES ........................................................................................................................ 4

1. WARNINGS ...................................................................................................................................................................... 6

1.1. Recommendations ................................................................................................................................................. 6

1.2. Health and safety ................................................................................................................................................... 6

1.3. Residual risks ......................................................................................................................................................... 6

1.4. Conditions of use ................................................................................................................................................... 6

1.5. Limits of use ........................................................................................................................................................... 7

1.6. Tools and materials ............................................................................................................................................... 7

2. GENERAL DESCRIPTION ............................................................................................................................................... 8

2.1. Presentation ........................................................................................................................................................... 8

2.2. G6EVO bollard general description ..................................................................................................................... 9

2.3. G6EVO bollard main components ...................................................................................................................... 10

2.4. G6EVO bollard technical details ........................................................................................................................ 11

2.5. G6EVO bollard configuration .............................................................................................................................. 12

2.5.1 G6EVO bollard configuration codes description ............................................................................................. 12

2.5.2 G6EVO bollard configuration codes details .................................................................................................... 13

2.5.3 G6EVO bollard configuration example ........................................................................................................... 16

2.6. G6EVO bollard options detail ............................................................................................................................. 17

3. INSTALLATION .............................................................................................................................................................. 18

3.1. Installation site study .......................................................................................................................................... 18

3.1.1 Standard installation of a complet and safe access control solution .............................................................. 19

3.1.2 G6EVO bollard concrete foundation dimensions ........................................................................................... 20

3.1.3 Place of installation protection ........................................................................................................................ 21

3.2. Receipt of the material ........................................................................................................................................ 21

3.3. Unpacking and handling the bollard .................................................................................................................. 21

3.3.1 Unpacking the bollard ..................................................................................................................................... 21

3.3.2 Handling the bollard ....................................................................................................................................... 22

3.4. Civil works ............................................................................................................................................................ 22

3.4.1 Bollard positioning .......................................................................................................................................... 22

3.4.2 Bollard position marks and excavation ........................................................................................................... 23

3.4.3 Building the draining system .......................................................................................................................... 24

3.4.4 Positioning the lost casing (if used) ................................................................................................................ 25

3.4.5 Pour the concrete foundation ......................................................................................................................... 25

3.4.6 Checking the capacity of the lost casing or the excavation to receive the bollard ......................................... 26

3.4.7 Positioning the bollard .................................................................................................................................... 26

3.4.8 Leveling and finishing the final top layer ........................................................................................................ 27

3.5. Connections ......................................................................................................................................................... 27

3.5.1 Run cables and hoses into the sheaths ......................................................................................................... 27

3.5.2 Bollard connections ........................................................................................................................................ 28

3.5.3 Technical control unit connections ................................................................................................................. 28

4. COMMISSIONING .......................................................................................................................................................... 29

4.1. Preliminary operations to be done before powering the system ................................................................... 29

4.2. Operating test – commissioning of the system ................................................................................................ 30

4.3. Removing site protections .................................................................................................................................. 30

5. MAINTENANCE .............................................................................................................................................................. 31

5.1. G6EVO Bollard’s preventative maintenance program ..................................................................................... 31

5.2. Common check points details ............................................................................................................................ 32

5.2.1 Cover well fastened ........................................................................................................................................ 32

5.2.2 Guides are cleaned ........................................................................................................................................ 32

5.2.3 Cylinder well positioned .................................................................................................................................. 32

5.2.4 Limitswitch sensors controlled ....................................................................................................................... 33

5.2.5 Solenoide valve controlled ............................................................................................................................. 33

5.2.6 Drainage efficiency control ............................................................................................................................. 33

5.2.7 After vehicul impact control ............................................................................................................................ 34

5.3. Pneumatic motorization check points details ................................................................................................... 34

5.3.1 No contact between bollard head and pneumatic hose ................................................................................. 34

5.3.2 No air leak ...................................................................................................................................................... 34

5.3.3 Proper solenoide-valve connection ................................................................................................................ 34

5.3.4 Components properly fastened onto the braket ............................................................................................. 35

SUMMARY

Page 3

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 3/58

5.4. Standard hydraulic motorization check points details .................................................................................... 35

5.4.1 No contact between bollard head and hydraulic hose .................................................................................... 35

5.4.2 No oil leak ....................................................................................................................................................... 36

5.5. Built-in hydraulic motorization check points details ....................................................................................... 36

5.5.1 No contact between bollard head and hydraulic hose .................................................................................... 36

5.5.2 No oil leak ....................................................................................................................................................... 36

5.5.3 Proper solenoide-valve connection ................................................................................................................ 36

5.5.4 Tighten up the fastening screws of the hydraulic pump and support ............................................................. 36

6. CORECTIVE ACTIONS .................................................................................................................................................. 37

6.1. Correctiver actions list ........................................................................................................................................ 37

6.2. Commun corrective actions details ................................................................................................................... 38

6.2.1 Cover and/or covering (sleeve and/or top plate) changing ............................................................................. 38

6.2.2 Plastic frictionless ring changing .................................................................................................................... 40

6.2.3 Guides are cleaned ........................................................................................................................................ 40

6.2.4 LED light changing ......................................................................................................................................... 41

6.2.5 Sleeve holding system changing .................................................................................................................... 41

6.2.6 Magnet changing ............................................................................................................................................ 42

6.3. Pneumatic motorization corrective actions details .......................................................................................... 42

6.3.1 Cover and/or covering (sleeve and/or top plate) changing ............................................................................. 42

6.3.2 Pneumatic cylinder changing ......................................................................................................................... 43

6.3.3 Pneumatic compnents bracket changing ....................................................................................................... 43

6.4. Standard hydraulic motorization corrective actions details ........................................................................... 44

6.4.1 Limitswitch sensors changing ........................................................................................................................ 44

6.4.2 Hydraulic cylinder changing ........................................................................................................................... 44

6.4.3 Standard hydraulic components braket changing .......................................................................................... 45

6.5. Built-in hydraulic motorization corrective actions details ............................................................................... 46

6.5.1 Limitswitch sensors changing ........................................................................................................................ 46

6.5.2 Hydraulic cylinder changing ........................................................................................................................... 47

6.5.3 Hydraulic pump changing ............................................................................................................................... 47

6.5.4 Solenoid valve changing ................................................................................................................................ 48

7. SPARE PARTS ............................................................................................................................................................... 49

7.1. G6EVO - COMMON PIECES ................................................................................................................................ 49

7.2. G6EVO - PNEUMATIC SOLUTION ...................................................................................................................... 50

7.3. G6EVO - STANDARD HYDRAULIC SOLUTION ................................................................................................. 50

7.4. G6EVO - BUILT-IN HYDRAULIC SOLUTION ...................................................................................................... 51

7.5. G6EVO - COVERING ............................................................................................................................................ 52

8. FIRST LEVEL CORRECTIVE ......................................................................................................................................... 55

9. MAINTENANCE LOG ..................................................................................................................................................... 56

10. DISMANTLING AND DISPOSAL .................................................................................................................................. 57

Page 4

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 4/58

i. INTRODUCTION

Thank you to have been relying to URBACO by purchasing the G6EVO access control bollard.

In addition to provide details on operating instructions, this installation a n d operation manual is design to assist the

Users, Installers, Maintainers and Operators Staff.

Should you require any further information or specific assistance, please contact us.

ii. FIELD OF APPLICATION AND AIMS

This manual is covering all steps that must be carefully follow while installing, maintaining and operating the equipment,

to ensure the good functioning and safe of product and personne.

It is intended for specifying implementation site and adequate equipment, design the secure en try system, install,

connect, test and maintain the whole equipment.

The purpose is to insure that all risks are controlled to keep safe any individual, owner, users or any personnel that

could carry out any installation, maintain or repair task on this equipmen t.

This symbol indicates strict attention must be given to the instructions.

The product must be used only for its intended use. Any other use is considered dangerous. The company U RBACO

S.A. is not liable for any damage caused by improper, wrong or unreasonable use.

The product's safety and, consequently, its proper installation are tied to the respect of it technical characteristics and

of its installation and use, which are specifically s h own in this manual.

iii. DECLARATION OF CONFORMITY

URBACO, 457 avenue du Clapier, 84320 Entra ig ues sur la Sorgues, certify that the G6EVO bollard is intended to be

incorporated into other equipment or to be assembled to other machinery, for the purpose of constituting machinery

that complies with EC Machinery Directive 2006/42/CE.

URBACO also certify that the G6EVO bollard complies with the fundamental safety requirements of the following

Directives:

2004/108/CE - Electromagnetic Compatibility Directive (CEM),

2006/95/CE - Low Voltage Directive

And that it is forbidden to commission the bollard until the machinery into which it will be integrated or of which it will

become a component is identified and until the declaration of conformity to the conditions established by Directive

2006/42/CE.

As well as the following regulations:

NF P 98 310,

NF EN 124 Class F

EN 61000-6-2 and EN 61000-6-3 - Electromagnetic compatibility,

EN1050 - Risk assessment principles,

EN60529 - Methods for testing the IP protection rating equipment,

EN11201 - Method for measuring machinery's sound power levels,

EN60068-2-1 and EN60068-2-2 - Machinery's environmental testing methods,

Decree PMR No. 2006-1657,

EN13849-1 and EN13849-2 - Machinery safety.

iv. GUARANTEE AND RESPONSIBILITIES

The owner of the system is responsible for the proper performance of the associate works, as well as the proper use,

and must check that the instructions in this manual will be follow strictly.

Warning! For the safety of people, it is important to strictly follow all of the instructions contained in this installation and

operation manual. Before installing, carefully read all instructions and recommendations.

It is the responsibility of th e owner of the equipm en t to establish which legislation is applic a b le to the c oun try in which

the equipment is installed, an d to ensure compliance with all national and local regulations.

Where associated equipment is supplied or fitted by others, the owner of the equipment is responsible for insuring that

the equipment complies with all safety requirements, norms and compliance and any associated equipment does not

adversely affect the operation or safety of equipment supplied by URBACO.

URBACO is not liable for any consequences resulting from installation, commissioning and system maintenance jobs

that are non compliant with the instructions in this manual.

URBACO warrants this system for 12 months from the delivery date. This guarantee ca n b e exte n d ed with a specific

agreement.

Page 5

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 5/58

URBACO undertakes, within the limits of the guarantee, to replace, free of charge, any faulty components that are

returned to the factory, provided that:

1 - The owner informs URBACO in writing about any system anomalies during the guarantee period.

2 - No element has been damaged due to improper installation, us e , maintenance, negligence or accident.

3 - No non-approved by URBACO components have been used.

NO OTHER WARRANTY IS EXPRESSED AND NONE SHALL BE IMPLIED, INCLUDING WITHOUT THE

WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR USE.

THE FOREGOING STATES THE ENTIRE LIABILITY OF URBACO WITH RESPECT TO THE PRODUCTS.

IN NO EVENT SHALL URBACO BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES

WHICH RESULT FROM USE BY BUYER OR ANY OTHER PARTY, OF THE PRODUCTS, AND IN NO EVENT SHALL

URBACO LIABILITY EXCEED THE AMOUNTS PAID BY THE OWNER FOR THE PRODUCTS THEREUNDER.

Page 6

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 6/58

1. WARNINGS

1.1. Recommendations

• Before installing and commissioning the bollard, carefully read the present manual.

• Improper fitting may result in serious damage. Carefully fo ll o w all instruction.

• This manual is exclusively intended for professional installers or authorized person n el.

• It is also a maintenance log that must be kept up to date a fter ea c h maintenance task performed after

commissioning.

• Keep all of the instructions and documents suplied together with the system.

• Install the bollards in compliance with the Country installation laws and rules. Please, make sure that the

grounding connections have been made in complying with the acknowledged rules-of-the-art.

• To install our bollards, we suggest you to hire skilled technicians that can ensure of safe and proper operation.

• Before starting the job, read paragraph 3.1 for installation site study.

1.2. Health and safety

• All the safety precautions mentioned in present manual are important and are related to both, people and

material.

• The bollards are made of very heavy elements including moving parts that could result in severe injuries unless

the safety provisions are met.

• The technical control units are powered with 230 V. it is definitely forbidden to unauthorized staff to access them.

Before performing any kind of job on the installation, double check that main power supply is shut off.

• The electrical installation must include upstream of power supply line, a protection circuit breaker able to ab sorb

the current, in compliance with the laws and rules of the country where the system is to be installed with the

country's laws where the system is install. All electrical connections must be performed by skilled electric ia n s.

• Respect the general safety provision for hoisting and handling the bollard (doc.: NT-CGS).

• Make sure that no object obstructs the area of operation of any of devices and that vegetation does not hide the

vertical signage.

• Do not enter into the field of action of the bollard when it is moving.

• Do not work close to bollards in movement.

• Do not touch the moving element while it is in movement.

• Do not obstruct the operator's movements as this could result in hazardous situa ti o ns.

• Please, prevent unauthorized persons from accessing to the retractable bollards' manoeuvre field, and also

prevent them to activate the fixed control actuators. Keep also any remote control device, such as transmitters,

away from unauthorized persons.

• If the system needs any maintenance, repair or adjustment, close the access and do not use it until safety

conditions have been restored. Always cut off the power supply before any intervention.

• In case of malfunction, first of all turn off power, and then call skilled personnel for technical assistance.

• Users are ABSOLUTELY PROHIBITED from performing any kind of JOB THAT IS NOT EXPRESSLY

REQUESTED TO THEM in present manual. For any repairs, modifications and adjustmen ts, as well as, any

extraordinary maintenance jobs, EXCLUSIVELY CALL SKILLED TECHNICA L A SSISTANCE.

• When using a hold-to-run control, constantly check, that no person is inside the operating field of the bollard,

during all duration of the movement.

• In automatic operating mode, the bollard may move at an y time, without warning.

• The system must be fitted with warning lights to warn the user about the bollard's position.

• All excavation must be protected by a safety barrier.

1.3 Residual risks

• This equipment has been designed and built in conformity with the current MACHINERY DIRECTIVE. The risk

analysis has resulted in the following residual risks, which are the risks that cannot be eliminated:

o Rick of tripping for pedestrian.

o Danger of collision if visibility is limited, or when the presence of the bollards is not clearly signalled.

o Danger of dragging along the vertical axis whe n passing over the m o ving bollard.

1.4 Conditions of use

• To warn users of the presence of the obstacle and tell them about the travel directions, fit a vertical sign that

reads "retractable bollard".

• Adding red and yellow flashing warning-lights increases safety. Installing magnetic loops into the ground that are

associated to an operating logic, protects the perimeter around the bollard.

Page 7

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 7/58

• Unauthorized users must never try to enter the area squeezing in behind an authorized vehicle because they risk

colliding with the bollard.

• For safety reasons, URBACO recommends that vehicles, before passing through, should stop in front of the

bollard and wait for it to be totally retracted (when the red light turns to flashing yellow, if the access point is fitted

with light).

• Those managing the access point must inform users on the way to use it and how it works, as URBACO cannot

be held liable for improper installation or non-respect of safety rules.

• The bollard must not be operated unless it can be plainly seen, directly or via CCTV (closed-circuit television) for

example.

• Frequently check the system, refer to the periodic maintenance manual, to check for any anomalies, signs of wear

and tear or damage to the moving parts of the operator and all of the fastening points and devices. Keep clean

and grease the area between the fixed and moving part of the bollard.

• Every six months check the detection loops to see if they work properly.

1.5 Limits of use

• This product must be used only for the purpose it was designed for.

• Any other use is considered improper and therefore dangerous.

• Any use other than the one described in this manual is forbidden.

• URBACO declines any liability in case of improper use of the system.

• URBACO declines any liability as concerns the security and proper functioning of the operator if non URBACO

components are used (unless otherwise stated in writing by URBACO).

• Never modify the original components of the system.

It is expressly prohibited to use this device to lift weights and for any other uses that is not expressly stated.

The manufacturer declines any liability for any damage caused by people or things in case of "improper use" of the

whole system.

1.6 Tools and materials

Here after are the necessary tools for assembling/disassembling the bollard.

Plastic hamer

Allen keys size 2.5 ; 3 ; 4 ; 6 and 8

Spanner size 10 ; 13 ; 17 and 19

Crosshead screwdriver

Heater (for heat shrinkable tune)

Wire stripper

Wire cutter

The bollard's weight means that you must use a suitable hoisting method to ensure people safety and prevent the

bollard from being damaged during installation or maintenance. Choose equipment that is compliant with the law and

that has suitable characte ristics:

There is an optional hoisting kit available for handling all heavy elements (bollard head, cover, casing).

See appendix No. NT-CGS - of the general safety conditions for hoisting and hadling products.

Page 8

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 8/58

2. GENERAL DESCRIPTION

2.1 Presentation

URBACO's G6EVO access control bollards are designed to prevent and/or select the passage of vehicles or trucks in

areas, such as town centers, private areas or building access, while keeping free access to pedestrian or bicycle traffic.

Access points equipped with automatic retractable bollards are generally composed by three systems that are

interconnected by electric cables and/or hydraulic/pneumatic hoses.

These three systems are:

• Safety magnetic detec tion loops - positioned into the ground in front of and behind the bollard, form a safety

perimeter around the bollards.

• Automatic retractable bollards - installed on the vehicles passage way, either authorizes or prevents access

(one or more bollards).

• Management system (access control unit) - It is the technical control unit where all com ponents are install to

control the bollard, the security and can integrate multiple control device such as badge reader, radio receiver,

etc.

For safety loops installation please refer to the corresponding manual: NT-BCL - Instruction on laying the magnetic

detection loops.

The positioning of the safety loops determines the proper functioning of the access point. Also, URBACO suggests that

you first establish the position of the loops, then the bollards and lastly the technical control unit.

Recommendations to respect the proper use of an access point that is controlled by automatic retractable bollards:

To ensure proper functioning of the access point, URBACO suggests:

• To install a vertical sign that warns people of the obstruction and that reads "Retractable bollard";

• To add to the automatic systems, a bollard’s position lights (red and yellow flashing light)

For safety reasons, URBACO recommends that vehicles, before passing through an access control systems, should

stop in front of the bollard and wait for it to completely retract (when the light turns from red to flashing yellow, if the

system is fitted with lights).

When the bollards operate in automatic mode, veh ic les must not go through the access point in single file without

stopping in front of the bollard. They must check that it is fully retracted before driving through and must respect the

bollard’s position lights (if installed).

USER INFORMATION AND TRAINING

The access point manager is held to inform users about the use and procedure of the access point given that URABCO

cannot be held liable for its improper use or non compliance with the local safety regulations.

To enable the access point managers to know the safety rules and the latest updates as concerns URBACO proposed

solutions, training courses are available.

Page 9

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 9/58

2.2 G6EVO bollard general description

The G6EVO bollard is designed to control access when associated with a full automation solution.

Consequently, the bollard pr o vides a high level of impact res is ta nc e and an inten sive rate of use.

Also, the G6EVO bollard maintenance is limited due to the use of simple and sturdy elements.

The bollard is made up of:

1 - Cast iron casing

2 - Cast iron bollard head

3 - Painted cast iron cover

4 - Cylinder

5 - Removable components bracket

6 - Bollard covering (Top plate and sleeve)

Figure 1: Example of a G6EVO Ø250 H750, Chateauneuf

version, with LED light ring, light diffusers on top and hidden

screws.

3

Page 10

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 10/58

2.3 G6EVO bollard main components

The G6EVO bollard is made of 4 main components

1

Base

Structure

C 2 Energy

Motorization (part integrated into the bollard)

C

3

Covering

Sleeve

C

Top plate

C

With or without LED light ring

C

4

Options

Tamper-proof screws

O

Fail secure (1)

O

Hoisting kit (for installation and maintenance)

O

Standard anti-freeze device up to -20 °C (1)

O

High anti-freeze device up to -50 °C (1)

O

Movement warning sound-buzzer (1)

O

Lost casing

O

C = Multiple-Choice; O = Optional

(1): Involved changes and/or additional components into the technical control unit.

The multiple choices (C) are detailed in §2.5

Option (O) are detailed in §2.6

Figure 5: Top plate with screws and light diffusers

Figure 3: Motorization (components bracket and cylinder)

Figure 2: Structure (Casing, cover and

bare bollard’s head)

Figure 4: Bollard’s covering

(top plate and sleeve)

Page 11

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 11/58

2.4 G6EVO bollard technical details

G6EVO Monobloc automatic retractable bollard:

Mechanical characteristics:

Size

Ø250 H750

Ø200 H750

Ø250 H550

Material

Ductile cast iron: head, casing and cover / Galvanized sheeting: supports / stainless steel: screws

Load class as per EN124

E600 (60 tons)

Impact resistance

241 kJ

96 kJ

241 kJ

Height above ground

750 mm

750 mm

550 mm

Head diameter

250 mm

200 mm

250 mm

Casing dimensions (AxCxD)

450 x 385 x 972

390 x 317 x 972

450 x 385 x 687

Head weight

57 Kg

45 Kg

41 Kg

Motorization

Hydraulic standard

Pneumatic

Built-in hydraulic

-

Other technical characteristics:

Ø250 H750

Ø250 H550

Ø200 H750

Motorization

Pneumatic

Hydraulic

standard

Built-in

hydraulic

Pneumatic

Hydraulic

standard

Pneumatic

Hydraulic

standard

Built-in

hydraulic

Code

BPEVOF75

BHEVOF75

BHEEVOF75

BPEVOF55

BHEVOF55

BPEVOE75

BHEVOE75

BHEEVOE75

Bollard power

supply

24 V – 50 Hz

-

24 V - 50 Hz

and 230 V -

60 Hz

24 V – 50 Hz

-

24 V – 50 Hz

-

24 V - 50 Hz

and 230 V -

60 Hz

Operating pressure

7 bar

35 bar

35 bar

7 bar

35 bar

7 bar

35 bar

35 bar

Standard operating

temperature

>0 °C / 50 °C

Operating

temperature (with

standard anti-freeze

device)

-20 °C / 50 °C

Working

temperature (with

high anti-freeze

device)

-50°C / 50°C

Rising time

4 - 5 s

5.3 s

5.3 s

2 - 3 s

3.5 s

4 - 5 s

5.3 s

5.3 s

Lowering time

2 - 4 s

3 - 6 s

3 - 6 s

1.5 - 3s

2 - 4 s

3 - 6 s

4 - 7 s

4 - 7 s

Intensive use

2000 cycles / 24 h

Protection rating

IP45

IP67

IP45

IP67

IP45

IP67

A B C

D

Figure 6: Front view

Figure 7: Top view

Page 12

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 12/58

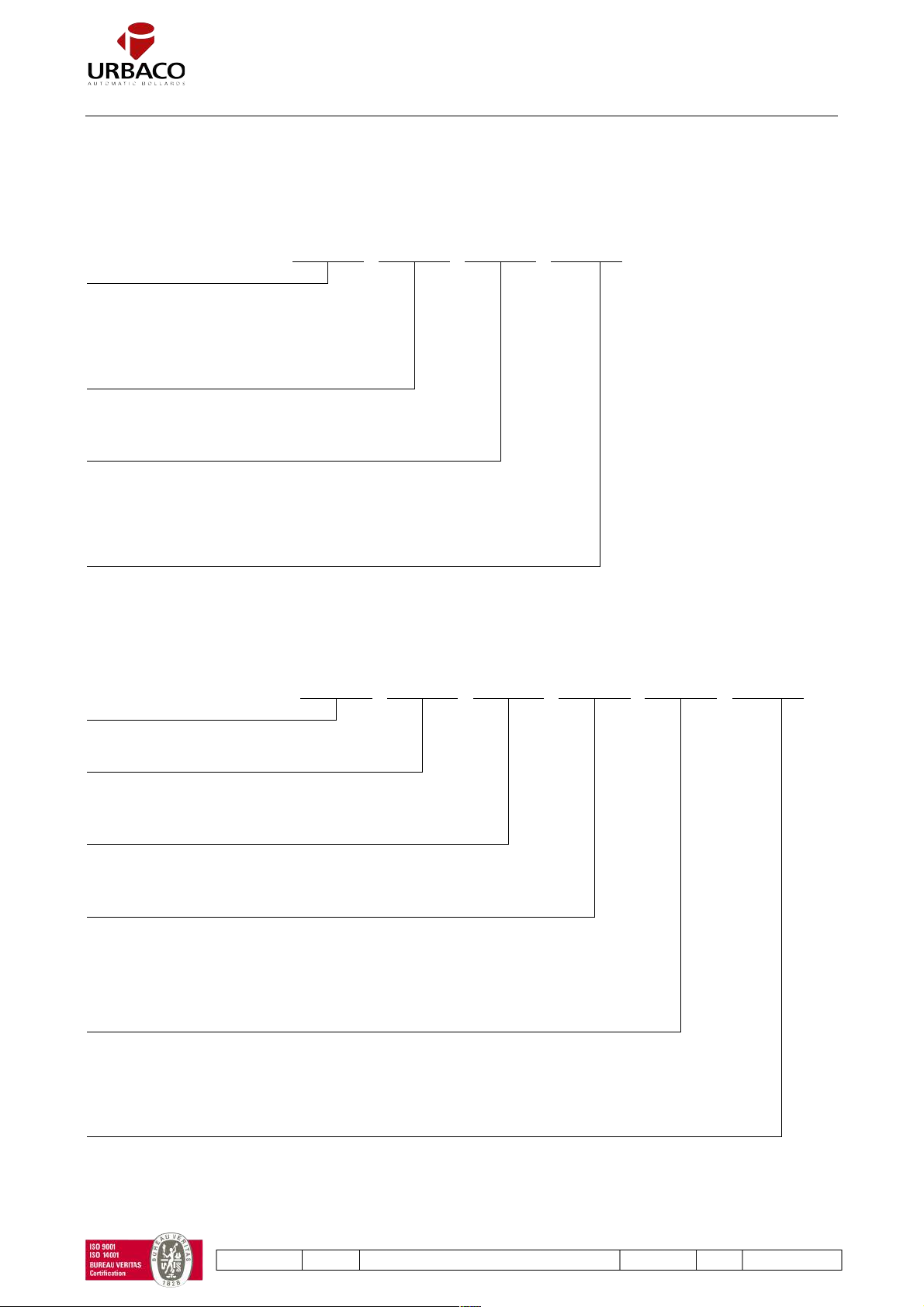

2.5 G6EVO bollard configuration

2.5.1. G6EVO bollard configuration codes description

G6EVO Monobloc automatic retractable bollard can be configured using the following codes:

4 to 5 codes are necessary to fully set a G6 EVO Bollard.

1 – Code to choose bollard motoriz a tio n a nd size

2 – Code to choose bollard covering (sleeve)

3 – Code to choose LED light ring

4 – Code to choose Top pla te appearance

Codes are detailed in §2.5.2

1

2 3 4

5

Figure 8: G6EVO Bollard configuration code exploded view

Page 13

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 13/58

2.5.2. G6EVO bo llard configuration codes details

Each configuration codes are detailed below.

1 – Choose G6EVO Bollar d size (diameter and height) and Motorization

Example: BPEVOF75 – Pneumatic Bollard G6EVO Ø250 H750

2 – Choose G6EVO Bollar d covering (sleeve)

Example: BOEVOHF75-VDM – Stainless Steel Sleeve for G6EVO Bollard Ø250 H750

!

!

BO!

EVO!H!F!

75!*!VDM!

Bollard!Option!

!!!!!!!!!!!!!!

!!!!!!!!!!

Product!family!!

!!!!!!!!!!!!!!!!!!

EVO!:!G6EVO!

!!!!!!

!!

!!!!!!

!!

Option!type!

!!!!!!!!!!!!!!!!!!!!!!

H!:!Habillage!(sleeve ) !

!!!!!!

!!!!!!

Bollard!diameter!

!!!!!!!!!!!!!!!!!!!!!!!!!!

E!:!Ø200mm!

F!:!Ø250mm!

!!!!!!!!!!!!!!!!

!!!!

!!

!!

Bollard!Height!above!

ground!

!!!!!!!!!!!!!!!!!!!!!!!!!!

!!

!

!!!!

50!:!500mm!

55!:!550mm!

!!!!!!!!!!!!!!!

!!!!

75!:!750mm!

!!!!!!!!!!!!!!!!!!!!

Covering!type!

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

CL!:!Cylinder!

VDM!:!Vendôme!

CHP!:!Chateauneuf!

CUSxxx!:!Customized!!

!!!!!!!!!!!!!!!!!

!

BP!

EVO!F!75!

Motorization!!

!!!!!!

!!

BP#:#Pneumatic##

BH#:#Hydraulic#standard#

BHE#:#Built4in#Hydraulic#

!!!!!!

!!!!

!!!!

!!!!!!!!!!!!Product!family!

!!!!!!!!!!!!EVO!:!G6EVO!

!!

!!

!

!!

!!

Bollard!diameter!

!!!!!!!!!!!!!!

!!

E!:!Ø200mm!

F!:!Ø250mm!

!!!!!!!!!!!!

!

Bollard! Height!above!

ground!

!!!!!!!!!!!!!!!!!!

!!!55!:!550mm!

75!:!750mm!

!!!!!!!!!!!

Page 14

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 14/58

3 – Choose G6EVO Bollar d Led light ring

Example: BOEVOSFCL – Led light ring for G6EVO bollard Ø250

!!!

BO!

EVO!S!F!

CL!

Bollard!Option!

!!!!!!!!!!!!!!

!!!!!!

!!

Product!family!

!!!!!!!!!!!!!!!!!!

EVO!:!G6EVO!

!!!!!!

!!!!!!

Option!type!

!!!!!!!!!!!!!!!!!!!!!!

S!:!Signalling!system !

!!!!!!!!!!!!!!!

!

!!

!!

Bollard!diameter!

!!!!!!!!!!!!!!!!!!!!!!!!!!

E!:!Ø200mm!

F!:!Ø250mm!

!!!!!!!!!!!!!

!!!!!!Signalling!type!

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

CL!:!LED!linght!ring!

SB!:!Without!LED!

!!!!!!!!!!!!!!!

!

4 – Choose top plate appearance

Example: BOEVOCFAV – Steel top plate with visible screws and no diffusor

!!!

BO!

EVO!C!F!

AV!

Bollard!Option!

!!!!!!!!!!!!!!

!!!!!!

!!

Product!family!

!!!!!!!!!!!!!!!!!!

EVO!:!G6EVO!

!!!!!!

!!!!!!

Option!type!

!!!!!!!!!!!!!!!!!!!!!!

C!:!Chapeau!(top !p la te )!

!!!!!!!!!!!!!!!!!!

!!

Bollard!diameter!

!!!!!!!!!!!!!!!!!!!!!!!!!!

E!:!Ø200mm!

F!:!Ø250mm!

!!!!!!!!!!!!!

!!!!!!Appearance!type!

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

AV!:!Painted!Steel!+!visible!

screws!

AVD!:!Painted!Steel!+!visible!

screws!+!light!diffuser!

IV!:!Stainless!Steel!+!visib le!

screws!

IVD!:!Stainless!Steel!+!vis ib le !

screws!+!light!diffuser!

!

!

A!:!Painted!Steel!

AD!:!Painted!Steel!+!light!

diffuser!

I!:!Stainless!Steel!

ID!:!Stainless!Steel!+!Ligh t !

diffuser!

!!!!!!!!!

Page 15

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 15/58

5 – Choose LED light color (only wh en led light option code finish by CL)

Example: BOEVOSCLGR – Green led light

!

!

BO!

EVO!S!CL!

GR!

Bollard!Option!

!!!!!!!!!!

!!

!!!!!!

!!

Product!family!

!!!!!!!!!!!!!!

!!

!!!!!!

Option!type!

!!!!!!!!!!!!!!!!!!!!S!:!Signalling!system!

!!

!!

!!

!!

LED!light!ring!!

!!!!!!!!!!!!!!!!!!!!!!!!!!!!LED!color!choice!

!!!!!!!!!!!!!!!!!!!!!!!!!!

!!

GR!:!Green!

YE!:!Yellow!

PU!:!Purpul!

BL!:!Bleu!

CY!:!Cyan!

WH!:!White!

!

!!!!!!!!!!!!!!!

Page 16

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 16/58

2.5.3. G6EVO bollard configuration exa mple

To configure the bellow G6EVO Bollard example, here are the codes that must be chosen:

Pneumatic G6EVO Bollard Ø250 H750, painted Chateauneuf sleeve, White LED light ring, stainless steel top plate with

light diffusers and hidden screws.

1 – BPEVOF75 Pneumatic G6EVO Bollard Ø250 H750

2 – BOEVOHF75CHP G6E VO covering with painted chateauneuf sleeve

3 – BOEVOSFCL G6EVO Lid light ring

4 - BOEVOID G6EVO Stainless steel top plate with light diffusers and hidden screws

5 – BOEVOSCLWH G6EVO LED light color = White

Figure 9: Example of a G6EVO Ø250 H750, painted

Chateauneuf version, with white LED light ring, stainless steel

top plate with light diffusers on top and hid d en screws.

Page 17

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 17/58

2.6 G6EVO bollard options detail

Below are all G6EVO Bollard options that could be choosen:

Independently of the G6EVO bollard siz e a n d motorization choosen, the following options are compatible with the

product.

Tamper-proof screws

Tamper-proof screws require specific tool to be desassembled.

Figure 10 : Example of a tramper-proof screw

Fail secure (1)

The fail secure option means that the bollard remains up if the power is cut off

The bollard could then be manually retracted

Hoisting kit (for installation and maintenance)

See hoisting security manual NT-CGS

Standard anti-freeze device up to -20 °C (1)

High anti-freeze device up to -50 °C (1)

Any anti-freeze option is easy to install into the bollard.

Movement warning sound-buzzer (1)

The sound-buzzer will make a sound at any bollard movement

Lost casing

The lost casing has been designed for easy bollard installation – See manual NT-COFG6

(1) Involve changes and/or additional components into the technical control unit.

Page 18

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 18/58

3. INSTALLATION

This product must be exclusively used for its intended use. Any other use is considered dangerous. The company

Urbaco S.A. is not liable for any damage caused by improper, wrong or unreasonable use.

The product's safety and consequently its installation depend on the respect of its proper installation and usage modes,

which are clearly detailed in this manual.

Installation, control and testing operations, as well as, preventive maintenance jobs, must be made by skilled technical

staff and authorized in agreement with the person responsible of the system.

3.1. Installation site stud y

When choosing the installation site, it is recommended to firstly:

• Check the solidity and compactness of the ground (to prevent from sinking on its foundation).

• Check the condition of the ground where the bollard will be intalled and adopt the necess ary precautions to prevent the

ground from caving in the bollard’s excavation.

• Make sure there are no underground pipes that could impede excavation and underground cable laying operations.

• Check that the site chosen for the technical control unit is sufficiently protected from vehicle collisions.

• Check that the distance between the bollard and the technical control unit does not exceed 25 meters.

• Check that the maximum length of the electrical connecting cables and pneumatic/hydraulic hose between the control

unit and each bollard does not exceed 25 meters.

• Check that the maximum length of the twisted connecting cable between the loops and the loop detector does not

exceed 50 meters.

• Check that the sheaths between the control unit and the bollards are buried at the legal depth according to the country's

laws in force.

• Check that all sheaths are installed without sharp angle to pull through electrical cables and hoses.

• Check that there are no obstructions that may impede the normal movement of the bolla rd .

• The safety loops shape and position could affect the proper functioning of the access-point. Read the Technical manual

NT-BCL for safety loops installation and ensure proper loops installation and lay a safe and secure access-point.

• Position the loops. Then, position the bollards.

• If needed, install additional optical and/or sound systems to warn people of the p r esence o f a moving sys tem an d the

resulting risk. You may also need both horizontal and vertica l w a rn ing s ign al, to comply with the traffic rules where the

system is anstall.

• Check that the power supply and voltage are adapted to the whole system.

• Check that the bollard and surrounding fixed parts are not constitutes an obstacle and become a tripping risk for

pedestrians or cyclists when the bollard is fully retracted.

• Check that the components have been properly installed and that they are stable. In case of problems, contact Urbaco

S.A. for understanding proper corrective actions to be performed.

• Check that the bollard is always vertical, even if the ground is sloped.

• CAREFULLY check the technical manuals, before starting any work.

Page 19

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 19/58

3.1.1. Standard installation of a complete and safe access control solution

Bellow is an example of a standard installation layout of a complete solution with a retractable bollard, magnetic

loops, technical control unit and traffic lights. Please refer to the manual N° NT-BCL and NT-for all types of

installation layouts including specific safety solutions.

1

Automatic retractable bollard

4

safety loop

2

Automatic exit loop

5

Technical control unit

3

Safety loop

6

Traffic light

1 3 2

4 6 5

Figure 11: Standard installation skecth

Page 20

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 20/58

16

Lost casing width*

Figure 12: Standard safety loops installation diagram

3.1.2. G6EVO bollard concrete foundation dimensions

It is recommended to install the bollard using concrete foundation as shown below.

Traffic Way

*For lost casing dimensions, refer to the appendix N°COFG6

Lost casing length*

200

Lost casing

height*

200

200

Figure 13: Cross section view of an installed G6EVO bollard

(with lost casing)

Page 21

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 21/58

3.1.3 Place of installation protection

Public access to installation site is restricted. It must be clearly demarcated with appropriate means during the

installation works and tes tin g d ura tion . Remove protections only after the success of the commissioning tests.

3.2. Receipt of the material

Each bollard is supplied on a pallet (Pallets are treated in compliance with ISPM15).

The technical control unit is supplied on another pallet (also treated in com p lian ce with ISPM15) with separate options

and accessories.

The material is packaged with straps, wrapped in heat-shrinkable film and identified.

Upon delivery, the material must be checked (items, quantities, conditions) and stocked on the original p allets, in a clean

and dry room until its installation.

3.3. Unpacking and handling the bollard

3.3.1. Unpacking the bollard

Unpacking precautions:

Before cutting the straps that bind the bollard on the pallet, chec k that the b ollard stands stable on the pallet and th at

the pallet is in good condition, con sidering the bollard's significant weight.

Each bollard is wrapped, at the top and bottom with yellow adhesive tape mentioning "Do not remove plastic film"., in

five different languages.

THE PACKAGING PLASTIC FILM MUST BE LEFT AROUND THE CASING so that, later, when the polyurethane

foam is injected b e tw e en casing and excav a tion inner wall, the bollard stands protected from the polyurethane foam.

Cut the plastic as shoon below and remove both plastic extremities.

To unpack, use a cutter to cut the

plastic film at the top, just above

the yellow adhesive tape.

In the same way, cut th e plastic

film at the bottom, just under the

yellow adhesive tape.

Figure 14: Bollard wrapped in heat-shrinkable

film upon receiving

Page 22

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 22/58

3.3.2. Handling the bollard

PRECAUTIONS to take when hadling the bollard

Considering that the bollard weighs more than 100 Kg, there is an inherent risk of crus hing. Staff working must be

carefully follow the specified procedures for the safety of p e op le (see manual N° NT-CGS for more details).

The bollard must be positioned using suitable hoisting devices, such as, cranes and winches that can handle loads

exceeding 500 Kg.

Hoist the bollard using suitable harnesses.

From the cover, remove two diagonally opposite screws. Fit the two hoisting rings that are supplied with the bollard.

3.4. Civil works

Building the concrete foundation is the most challenging part of the installation.

Special recommendations:

- The reinforcing steel rebars must exclusively be of the HLE type (TOR steel).

- Rebars fastened must be done with either steel wire or welded.

- The concrete must be carefully checked. It should have a density of at least 350 to 4 5 0kg of cement per m3and

the cure times must be respected (a t lea st 28 days for standard concrete).

- To reduce the job duration, we suggest using a fast curing concrete blend, for example Lafarge Chronolia

45Mpa with a 10-day drying period.

- Besides requesting a certificate of conformity for the concrete, it is always best to take a sample and check it.

3.4.1. Bollard positioning

POSITION THE BOLLARD PROPERLY, RESPECTING THE TRAFFIC WAY

(THE TRAFFIC WAY IS SHOWN ON THE BOLLARD’S COVER)

Figura 15: Removing two cap screws

(diagonally opposed)

Figure 16: Fitting two hoisting rings to the cover

Figure 17: Cover traffic way

marking (FR)

Figure 18: Cover traffic way

marking (EN)

Page 23

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 23/58

• The lost casing of the G6EVO bollard must be positioned so that the axis of the side holes is parallel with the

traffic way.

• See the "Lost casing assembly process" in the technical document N° NT- COFG6

• The chosen bollard place must not be under the vehicle’s wheels.

• The recommended distance between centers of two bollards is 1.45 meters.

• Safety loops must be installed according to the technical document N° NT-BCL instructions.

• The sheath linking the bollard to the side pit, or directly to the technical control unit, is a Ø90 sheath. The

trench where this sheath is buried in must not be too close to the loop's cable (never less than 100 mm) and

must not sharply change of direction.

• The trenches depth must comply with the country's laws in force.

3.4.2. Bollard position markings and excavation

After defining the position and direction of the bollard, trace measurements X and Y of the excavation.

Then, depending on the ground type, cut the top layer or concrete using a circular saw or remove the paving.

When several bollards are fitted side by side, a trench may be done.

Important: traffic way must be respected

Figure 19: Lost casing with top finishing frame

Figure 20: Mark the Bollard

possition before the excavation

Figure 21: Cut top-layer

Figure 22: Excavation

Traffic Way

Side holes axis (for

connecting sheath)

Traffic way

Page 24

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 24/58

3.4.3. Building the draining system

Build a drainage system (well) that suits the permeability of the soil (from 200 to 300 mm). In the lower part of the

foundation, add the geotextile lining and fill it with grav el up to ab o ut 250 mm in height. The drainage system must be

able to evacuate 20 liters of water in five minutes. Place a section of 100 mm diameter PVC pipe and pour the first

concrete layer.

When the ground is not very permeable, it is best to link the bottom of the excav ation to an additional drainage

network/system..

Figure 23: Excavation cut view

Figure 24: Drainage with PVC pipe

Figure 25: First concrete layer

Page 25

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 25/58

3.4.4. Positioning the lost casing (if used)

Position the lost casing inside the hole and reinforce the inside. Check that it is properly positioned (vertically,

horizontally and with respect to the traffic way. We suggest using a bubb le lev el).

3.4.5. Pour the concrete foundation

Steel elements must be covered by at least 5 cm of concrete.

It is recommanded to vibrate the concrete fo r a h o mogeneous fill.

Figure 27: Wooden reinforcement installed into the

lost casing

Figure 28: Concrete poured

Figure 26: Lost casing installation

Figure 29: Reinforcement removed after

concrete cure time

Page 26

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 26/58

3.4.6. Check the capacity of the lost casing or the excavation to receive the bollard

Check the entire height a nd length of the embedded lost casing. It must comply with the foundation dra wing. Make

sure that there is no missing concrete underneath the lost casing. Check that the drainage system is efficient and that

it drains 20 liters in 5 minutes, that is, 4 liters / minute.

Make sure the inside of the lost casing is clean. It must be free of concrete residues which could com promise the

proper positioning of the bollard or even the mechanic a l movement.Check the depth at the bottom of the lost casing.

It must comply with the dimensional chara cteristics detailed in the foundation drawing.

If the lost casing is embedded too low, the bollard will not rest on the bottom of the lost casing but will hang the edge

of the cover up on the ground surface. And this is prohibited.

If the lost casing is embedded too high, the bollard will overhanging the ground surface and creates a dangerous

obstacle for pedestians. And this is proh ib ited.

Clean the surroundings of the excavation. Remove anything that may damage the bollard coating.

Important: the height of the concrete foundation must be under the finishing floor level, so it lea v es enough space for

the top layer. This space must not exceed 6 cm.

Before using the access point, the concrete must cure for at least 28 days.

3.4.7. Bollard positioning

Before bollard positioning, make sure that the unpacking and handling actions have been executed properly.

- Place the bollard onto the excavation or in the los t c asing and check that it is positioned correctly.

- Pass the sheath extremities through the casing’s hole and leave a few centimeters inside the bollard.

- For a good bollard’s stability, inject the polyurethane foam between the casing and the excavation (lost casing).

Figure 31: Bollard installed

Figure 30: Bollard positioning

Page 27

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 27/58

3.4.8. Leveling and finishing the final top layer

3.5. CONNECTIONS

To reach a bollard's connection area, first remove the cover.

3.5.1. Run cables and hoses into the sheaths

Once the technical control unit is installed, run the electric cables and hoses (pneumatic or hydraulic depending on

the chosen motorization) between the bollard a n d the tech n ical con trol unit.

For the hydraulic standard solution (the hydraulic pump is installed into the technical control unit), be very careful with

the following two points:

The hydraulic hose must be run inside the sheath in one single way, from the bollard to th e tec hnical

control unit. The U-bend end shape of the hose must stand on the bollard side for connection.

The hydraulic hose must remain as straight as possible, to prevent any pressure loss.

Do not roll up the hydraulic hose. It must be ordered at proper length.

Figure 32: Finished top layer completed

with asphalt

Connection area

Figure 33: Removing the cover for bollard connection

Page 28

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 28/58

3.5.2. Bollard connections

Depending on the motorization used, refer to the corresponding connection scheme in the appendix NT-RACC.

Leave enough cable length into the bollard (at least 2 m ). Th e ca b le excess can be reinserted into the

sheath to free up space into the bollard.

3.5.3. Technical control unit connections

All automatic bollards are supplied with an access control unit. This access control unit could be installed independently

from the bollard. The technical control unit connection will depend on the global solution choosen. Here are the

controllers compatible proposed by URBACO:

U200

U202H

AT224

LOGO

ZELIO

Industrial Computer

Please refer to the technical documentation of the used controller.

Page 29

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 29/58

4. COMMISSIONING

4.1. PRELIMINARY OPERATIONS TO BE DONE BEFORE POWERING THE SYSTEM

The electrical connections must be made as detailed in para g ra p h 3 .5.3 .

General Check Points (GCP)

Checked

Connect the lower limit-switch to the terminal block (for several bollards access, respect the connection order).

Connect the upper limit-switch to the terminal block (for several bollards access, respect the connection order).

Connect the safety loops cables to the loop detector (if not included, the three inputs must be bridged).

Fastening the "loop tail" cables inside the technical control unit to pre v ent them from moving during bollard

operation.

Connect the bollard's LED light ring (if inc luded).

Clean the ground around the bollard to prevent scratching caused by gravel during testing.

Standard Hydraulic Check Points (HSCP)

Checked

Replace the transpor t c ap of the hydraulic unit's tank with th e v ent cap (IMPORTANT). See the technical

manual N°NT-RGRPH-STD.

Connect the hydraulic hose to t he cylinder into the bollard and t o the hydraulic pump inside the tech nical

control unit.

Connect the solenoid valve wire into the bollard, to the wire run into the sheath for this purpose. The other wire

extremity will be connected to the right terminal block (refer to the technical control unit docum en ta tion).

Check the oil level in the hydraulic tank.

Check that there is no oil leak.

Check that there is no contact between the hydraulic hose and the bollard head.

Built-In Hydraulic Check Points (HECP)

Checked

Connect the solenoid valve wire into t he bollard, to the wire run into the sheath for this purpose. The other wire

extremity will be connected to the right terminal bloc k (re fer to the technical control unit documentation).

Connect the electrical powering cables to the hydraulic unit.

Check the oil level in the hydraulic tank.

Check that there is no oil leak.

Check that there is no contact between the hydraulic hose and the bollard head.

Pneumatic Check Points (PCP)

Checked

Connect the air hose to the s ole n o id v alve into the bollard and to the air compressor inside the technical

control unit.

Connect the solenoid valve wire into the bollard, to the wire run into the sheath for th is purpose. The other wire

extremity will be connected to the right terminal block (refer to the technical control unit docum en ta tion).

Check the network pressure on the compressor gauge.

Check for any air leaks.

Check that there is no contact between the pneumatic hose and the bollard head.

Page 30

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 30/58

4.2. OPERATING TEST - COMMISSIONING OF THE SYSTEM

The operating tests to perform depend on the global solution and allocated controller chosen. Therefore please refer to the

used controller befor e commissioning the sytem.

4.3. REMOVING SITE PROTECTIONS

After performing all operating tests with success and making the access point functional and safe, the protections and

signs can be removed.

Page 31

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 31/58

5. MAINTENANCE

5.1. G6EVO BOLLARD'S PREVENTATIVE MAINTENANCE PROGRAM

This preventive maintenance program is intended to ensure the continuous operation and maintenance of the equipment.

Please refer to the preventive maintenance program of the technical control unit to perform maintenance tasks.

All maintenance actions must be done as planned in order to keep the whole system in proper condition of use.

The below check points are detailed in § 5.2.

Common yearly maintenanc e p rogra m

Checkpoints

Action

type*

§

check-ups and maintenance actions

When installing

1st month

2nd month

3rd month

4th month

5th month

6th month

7th month

8th month

9th month

10th month

11th month

12th month

1

PA

5.2.1

Cover well Fastened

C C C 2 PA

5.2.2

Guides are cleaned

C C C 3 PA

5.2.3

Cylinder well positioned

C C C 4 PA

5.2.4

Limit-switch sensors control

C C C 5 PA

5.2.5

Solenoid valve control

C C C 6 PA

5.2.6

Drainage efficiency control

C C C 7 PA

5.2.7

After vehicle impact control

C C C

Specific yearly maintenance program for the PNEUMATIC motorization

Checkpoints

Action

type*

§

check-ups and maintenance actions

When installing

1st month

2nd month

3rd month

4th month

5th month

6th month

7th month

8th month

9th month

10th month

11th month

12th month

8

PA

5.3.1

No contact between bollard head and pneumatic hose

C C C

9

PA

5.3.2

No air leaks

C C C

10

PA

5.3.3

Proper solenoid-valve connection

C C C

11

PA

5.3.4

Components properly fastened onto the bracket

C C C

Specific yearly maintenance program for the HYDRAULIC STANDARD motorization

Checkpoints

Action

type*

§

check-ups and maintenance actions

When installing

1st month

2nd month

3rd month

4th month

5th month

6th month

7th month

8th month

9th month

10th month

11th month

12th month

12

PA

5.4.1

No contact between bollard head and hydraulic hose

C C C

13

PA

5.4.2

No oil leaks

C C C

Specific yearly maintenance program for the BUILT-IN HYDRAULIC motorization

Checkpoints

Action

type*

§

check-ups and maintenance actions

When installing

1st month

2nd month

3rd month

4th month

5th month

6th month

7th month

8th month

9th month

10th month

11th month

12th month

14

PA

5.5.1

No contact between bollard head and hydraulic hose

C C C

15

PA

5.5.2

No oil leak

C C C

16

PA

5.5.3

Proper soleniod-valve connection

C C C

17

PA

5.5.4

Tighten up the fastening screws of the hydraulic pump onto

support and support onto casing

C C C

All maintenance jobs must be performed every six months even if the system is unused.

* - Action type: Preventive Action: PA; Corrective Action: CA

Page 32

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 32/58

5.2. COMMON CHECK POINTS DETAILS

5.2.1. Cover well fastened – Check Point N°1

Remove the hoisting rings, clean the casing threading holes (using compressed air) and apply grease (Molykote

CU7439 Molykote or equivalent) before pla cin g b a c k the screws. Firmly tighten all screws.

5.2.2. Guides are cleaned – Check Point N°2

Make sure the casing's guides and the bollard head guides are cleaned and freed from deposits. Before reassembling

the bollard, spray the guides with Molykote 3402C or equivalent lubrication.

5.2.3. Cylinder well positioned – Check point N°3

NOTE: to perform this action, remove the cover and action the bollard in the ra is ed position (without dismantling the

bollard head).

Check that the cylinder is properly centred in the cross-bar on the bottom of the casing.

Figure 36: Guide rails view

Figure 38: Casing crossbar

Figure 37: Cylinder position

Figure 35: Put the two screws back in place

Figure 34: Remove the two hoisting ring

Page 33

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 33/58

5.2.4. Limit-switch sensors control – Check point N°4

The bollard is equipped with two limit-switch sensors (one at the top and one at the bottom) mounted into the casing

using the components bracket. Each sensor transmits to the management system's PLC the information on the

bollard’s position and contributes to the access point safe functioning. The limit-switch is a normally open contact.

The bollard head is equipped with a detection magnet.

See appendix N° NT-REG for more detail.

Check the faste ning and positio ning of each limit-switch sensor: they must never touch the magnet. Check that they

properly detect at the top and bottom.

In cas e of malfunction, check the connection s on the technical control unit and inside the bollard and, if the problem

continues, replace the limit switch sensor.

5.2.5. Solenoid valve control – Check point N°5

The solenoid-valve must work. Check the wiring and connections into the Bollard and inside the technical control unit.

See appendix NT-REVB.

5.2.6. Drainage efficiency control – Check poin t N °6

The drainage system must be able to evacuate 20 liters of water in five minutes.

To run the test:

Remove the cover and the bollard head, check that th e inside of the casing is free of a n y sand , dirt or other foreign

bodies (if necessary, clean it). Pour 20 liters of water into the casing and check that it evacuates in five minutes.

If a n y drain a g e proble m oc c urs , clean the draina ge conduit by liquid suction and repea t the operation sev er a l times

until the drainage system works correctly.

Figure 39: Components bracket

Figure 40: Limit-switch sensor assembling

Page 34

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 34/58

5.2.7. After vehicle impact control – Check point N°7

After important vehicle impact, it is recommended to quickly inspect the ac cess point very carefully.

Check the bollard as following:

- No deformation or crack of any structural part.

- The bollard is rising and lowering without any friction point.

Check the concrete foundation as following:

- Original position (the foundation hasn’t moved due to the collision). Check the connection between foundation and

road surface on the impact side.

- Good concrete solidity around the bollard.

If the bollard and foundation can b e used again, it is recommanded to perform preventive maintenance by replacing

all screws.

5.3. PNEUMATIC MOTORIZATION CHECK POINTS DETAILS

5.3.1. No contact between bollard head and pneumatis hose – Check Point N°8

Make sure that the pneumatic hose hasn’t moved during the transport. The pneumatic hose must stay in center position

and have no contact with the bollard head part at any time.

5.3.2. No air leak – Check Point N°9

Check the air pressure into the air circuit. Adjust it if lower tha n requested. If the air circuit doesn’t keep the pressure

check eventual leak on each connections.

5.3.3. Proper solenoid-valve connection – Check Point N°10

Make sure that the soleniod-valve is properly connected.

See appendix N° NT-REVB for more detail.

Figure 41: Inner bottom view. Pneumatic hose

passing through the bollard head

Figure 42: Solenoide-valves mounted

onto the components bracket

Page 35

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 35/58

5.3.4. Components prope r ly fastened onto the bracket – Check Point N°11

Make sure that all components are well fastened onto the bracket.

See appendix N° NT-REG for more detail.

When replacing the braket into the bollard casing, make sure the bottom part is locked into the bottom casing h ole.

5.4. STANDARD HYDRAULIC MOTORIZATION CHECK POINTS DETAILS

5.4.1. No contact between bollard head and hydraulic hose – Check Point N°12

Make sure that the hydraulic hose hasn’t moved during the transport. The hydraulic hose must stay in center position and

have no contact with the bollard head part at any time.

Figure 43: Bracket position

identification

Figure 44: Bracket extraction

Figure 45: Bracket positioning view

Figure 47: Inner bottom view. Hydraulic hose

passing through the bollard head

Figure 46: Bracket positioning zoom

Page 36

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 36/58

5.4.2. No oil leak – Check Point N°13

Check that there is no oil leak from the hydraulic hose and the cylinder.

5.5. BUILT-IN HYDRAULIC MOTORIZATION CHECK POINTS DETAILS

5.5.1. No contact between bollard head and hydraulic hose – Check Point N°14

Make sure that the hydraulic hose hasn’t moved during the transport. The hydraulic hose must sta y in center position and

have no contact with the bollard head part at any time. It is guided and protected by the hydraulic unit support.

5.5.2. No oil leak – Check Point N°15

Check that there is no oil leak from the hydraulic hose and the cylinder.

5.5.3. Proper solenoid valve connection – Check Point N°16

See NT-REVB

5.5.4. Tighten up the fastening screws of the hydraulic pump onto support and support onto casing – Check Point N°17

Check that all assembly screws are well tightened.

Figure 48: Inner bottom view. Hydraulic

hose passing through the bracket

Figure 49: Solenoid valve

indentification

Figure 50: Built-in hydraulic pump

top view

Page 37

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 37/58

6. CORRECTIVE ACTIONS

6.1. CORRECTIVE ACTIONS LIST

For any reason of replacement of a component, follow the below p ro ce d ure to make sure the disassembly/assembly step

are well undertaken.

Common corrective tasks

Operation date

Checkpoints

Action

type*

§

Task name

1

CA

6.2.1

Cover and/or covering(Sleeve and/or top plate) replacement

2 CA

6.2.2

Plastic frictionless ring and/or cover replacement

3 CA

6.2.3

Guide rails cleaning

4 CA

6.2.4

Led light replacement

5 CA

6.2.5

Sleeve holding system replacement

6 CA

6.2.6

Magnet replacement

Specific corrective tasks for the PNEUMATIC motorization

Checkpoints

Action

type*

§

Task name

7

CA

6.3.1

Limit-switch sensors replacement

8

CA

6.3.2

Cylinder replacement

9 CA

6.3.3

Pneumatic components bracket replacement

Specific corrective tasks for the HYDRAULIC STAN DA RD mo toriz a tion

Checkpoints

Action

type*

§

Task name

10

CA

6.4.1

Limit-switch sensors replacement

11

CA

6.4.2

Cylinder replacement

12

CA

6.4.3

Standard hydraulic components braket replacement

Specific corrective tasks for the BUILT-IN HYDRAULIC motorization

Checkpoints

Action

type*

§

Task name

13

CA

6.5.1

Limit-switch sensors replacement

14

CA

6.5.2

Cylinder replacement

15

CA

6.5.3

Hydraulic pump replacement

16

CA

6.5.4

Solenoid valve replacement

Operation date

Operation date

Operation date

Page 38

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 38/58

PRECAUTIONS TO FOLLOW

Considering the weight of the bollard that is over 150 Kg., the people taking charge of this job must be particularly careful

when performing the following procedures, especially regarding their ow n safety, that is, they must wear protective

clothing and safety boots. Also, it is necessary to keep the site closed to traffic, by fitting legal signage dedicated to this

type of construction site. Before starting works, always check that the power supply has b een c ut off.

"NT-CGS“

6.2. COMMON CORRECTIVE ACTION DETAILS

6.2.1. Covering (sleeve and/or top plate) replacemen t – Task N°1

For the visible screws top plate version

Figure 51: Bollard retracted

Figure 52: Screws and cover

removing

Figure 55: Removing covering

Figure 54: Screws and top plate

removing

Figure 53: Raised up bollard

Figure 56: Sleeve removed

Page 39

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 39/58

or the invisible screw top plate version – Action to be made with bollard in raised position.

Figure 57: Place the specific

disassembly tool

Figure 58: Specific disassembly

tool in position

Figure 59: Insert the handling tool to

catch the sleeve’s compression system

Figure 60: Push down to free up the

sleeve and slide it down

Figure 62: When the sleeve has

slid down, a gap between top

plate and sleeve appears

Figure 63: Remove the top plate

using an Allen key

Figure 64: Sleeve removed

Figure 61: Handling tool

positioning view

Page 40

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 40/58

6.2.2. Frictionless plastic ring replacement – Task N°2

The frictionless plastic ring prevents the c y lin d e r from scratching against the bollard casing. This piece must be replaced

after any significant collisions or after it wears down.

Remove the old frictionless ring. After having scrapped off all glue residues, fit the new ring with poly ureth a n e g lue.

6.2.3. Guide rails cleaning – Task N°3

The casing guide rails must be dust free

Before reassembling the bollard, spray the guides with Molykote 3402C or equivalent lubrication oil.

Figure 66: dismounted cover and frictionless ring

Figure 65: cover with mounted frictionless ring

Surface to be cleaned

Figure 67: Guide rails view

Page 41

11/2015

NT

BEA-G6EVO

V3.0

EN

p. 41/58

6.2.4. LED light replacement – Task N°4

There is a direct access to the LED light just under n e a th the top plate.

See §6.2.1. for invisible screw top plate vers ion disassembly.

Led light can be connected by welding and protected with heat-shrinkable sheath or with waterproof electrical