Ural Classic Motorcycles, BC75, LC75 Owners Manual

URAL Classic Motorcycles

Owner’s Manual

2002 Models (All States)

BC-75 (Bavarian Classic)

LC-75 (Luxury Cruiser)

Tourist, Adirondac & Patrol

Classic Motorcycles & Sidecars, Inc.

P.O. Box 969

Preston, WA 98050

www .ural.com

1

2

Contents

Introduction ............................................................................................................................................................. 7

W arnings, Cautions, Notes....................................................................................................................................... 9

Chapter 1 Specifications

Specifications .........................................................................................................................................................11

T orque Specifications............................................................................................................................................. 14

Conversions .......................................................................................................................................................... 14

Chapter 2 Motorcycle Controls & Instrumentation

Motorcycle Controls & Instrumentation.................................................................................................................. 15

Controls ................................................................................................................................................................ 16

Chapter 3 Engine Operation & Maintenance

Engine Operation and Maintenance ........................................................................................................................ 19

Pre-Trip Preliminaries ............................................................................................................................................ 19

Starting the Engine ................................................................................................................................................. 19

Operating Precautions............................................................................................................................................ 21

Running-In the New Motorcycle ............................................................................................................................ 22

Chapter 4 Design & Maintenance

Brief Description of Design & Maintenance .......................................................................................................... 23

Engine ................................................................................................................................................................... 23

Lubrication System ................................................................................................................................................ 23

Fuel System........................................................................................................................................................... 24

Ignition System ...................................................................................................................................................... 25

Chapter 5 Carburetors

Carburetors ........................................................................................................................................................... 25

Chapter 6 Power T ransmission

Power Transmission............................................................................................................................................... 27

Clutch ................................................................................................................................................................... 27

Gearbox ................................................................................................................................................................ 27

Fi na l Dr ive............................................................................................................................................................. 27

Chapter 7 Running Gear

Running Gear......................................................................................................................................................... 29

3

Motorcycle and Sidecar Frames ............................................................................................................................ 29

Spring-Loaded Hydraulic Shock Absorber............................................................................................................. 29

Adjustment of Sidecar Installation ........................................................................................................................ ..30

Front Fork ............................................................................................................................................................ 31

Steering Head Bearings.......................................................................................................................................... 31

Chapter 8 Wheel & Tires

Wheels and Tires ................................................................................................................................................... 33

Tire Data ................................................................................................................................................................34

Running Gear Maintenance .................................................................................................................................... 35

Chapter 9 Controls & Instruments

Handle Bar and Controls ....................................................................................................................................... 37

Brakes .................................................................................................................................................................. 37

Brake Adjustment .................................................................................................................................................. 37

Control Cable Adjustment...................................................................................................................................... 38

Control Cable Maintenance ................................................................................................................................... 39

Speedometer ......................................................................................................................................................... 39

Chapter 10 Electrical

Electrical Equipment .............................................................................................................................................. 41

Electrical Symbols ................................................................................................................................................. 42

Electrical Circuits.....................................................................................................................................................42

Electrical Equipment Maintenance .......................................................................................................................... 43

Electronic Ignition .................................................................................................................................................. 43

Ignition Timing ....................................................................................................................................................... 44

Electronic Ignition Components .............................................................................................................................. 45

Electrical Wiring Diagram ....................................................................................................................................... 47

Chapter 11 Maintenance

Maintenance of Motorcycle ................................................................................................................................... 49

List of Recommended Lubricants ........................................................................................................................... 49

Lubrication Chart................................................................................................................................................... 50

Required Lubrication ............................................................................................................................................. 52

Care of Motorcycle Paint....................................................................................................................................... 52

Preservation and Storage ....................................................................................................................................... 53

Battery .................................................................................................................................................................. 53

List of Individual T ool Set, Spare Parts, Accessories & Documents......................................................................... 54

Chapter 12 Patrol Motorcycle With Engageable Sidecar Drive

Patrol Motorcycle with Engageable Sidecar Drive ................................................................................................. 57

Description ............................................................................................................................................................ 57

Handling Differences from the Single Wheel Drive .................................................................................................. 57

Sidecar Maintenance ............................................................................................................................................. 58

4

Chapter 13 Learning to Ride the URAL

Learning to Ride the Ural Motorcycle with Sidecar Accessory ................................................................................ 59

Safe Operating Rules ............................................................................................................................................. 60

Chapter 14 Warranty

Warranty ............................................................................................................................................................... 63

T erms Used in this W arranty Section .................................................................................................................. 63

W arranty Responsibilities ..................................................................................................................................... 63

W arranty Disclaimers, Limitations & Exclusions .................................................................................................. 65

Distributors Limited W arranties - New Motorcycle............................................................................................. 66

W arranty Time Period .......................................................................................................................................... 67

Distributor’s Limited W arranties - Motorcycle T ires............................................................................................ 67

Distributor’s Limited W arranties Emission Control System.................................................................................. 69

Distributor’s Limited W arranties - Noise Control Systems.................................................................................. 70

Distributor’s Limited W arranties - Replacement Parts ......................................................................................... 71

Distributor’s Limited W arranties - Ural Accessories............................................................................................ 71

EP A Noise Regulations......................................................................................................................................... 72

Classic Motorcycles Emission Control System W aranty...................................................................................... 73

Classic Motorcycles Noise Control System W arranty........................................................................................ 75

Reporting Safety Defects...................................................................................................................................... 75

Manufacturers W arranty Coverage ...................................................................................................................... 75

Chapter 15 Service Coupons

Service Coupons ................................................................................................................................................... 79

New Address Form ............................................................................................................................................... 89

New Owner Form ................................................................................................................................................. 91

URAL S tarting and Running Tips .................................................................................................... Inside Back Cover

5

6

INTRODUCTION

Welcome to the URAL Motorcycling Family! Y our new Ural motorcycle conforms to all applicable US

Federal Motor Vehicle Safety S tandards and US Environmental Protection Agency regulations effective

on the date of manufacture. This manual covers the Tourist, BC-75 LC-75 Adirondac, and Patrol.

This manual has been prepared to acquaint you with the operation, care and maintenance of your motorcycle, and to provide you with important safety information. Follow these instructions carefully for maximum motorcycle performance and for your personal motorcycling safety and pleasure. Please pay

particular attention to the section “Learning to Ride the Ural Motorcycle with Sidecar” and the separate

manual “Driving the Ural Sidecar Motorcycle.” It is critical that a beginning sidecar driver becomes

thoroughly familiar with the special operating characteristics of sidecar outfits before venturing out on the

roads.

Y our Owner’s Manual contains instructions for operation, maintenance and minor repairs. Major repairs

require the attention of a skilled mechanic and the use of special tools and equipment. Y our Authorized

Ural Dealer and Ural certified Service Center has the facilities, experience and genuine Ural parts neces-

sary to properly render this valuable service.

The Ural represents an important piece of German and Russian history since it has been continually

manufactured with the same general arrangement and outward appearance for the past 60 years after

Russian engineers initially copied the BMW’s of 1939. It truly is an “instant antique” as many of our

owners have said.

Since the Ural weighs 700 lb. empty with the attached sidecar , has a large frontal area and is powered by

an old fashioned 745cc engine, it is not a fast motorcycle. The Ural T ourist s’ top speed is 65 mph with a

cruising speedsof 55 mph but only after faithful adherence to the break-in period.

If you are a vintage enthusiast, collector , local commuter, hunter , fisherman, have children, grandchildren

or a dog that likes to ride, or you just like to be noticed on a rig that draws a crowd wherever you park,

welcome aboard!

The classic boxer twin has a German heritage. So effective, simple and powerful is this design that

Porsche, V olkswagen, and even Harley (during the war with the XA model) made this design their choice.

The reliability and torque of this elegant motor is due to its original design in 1912 by Max Friz, a brilliant

German aircraft-engine builder . He devised a compact and rugged engine that delivered significant

torque for its displacement, at low and constant rpms, without the gyro effects of other twins. The military

and civilian uses became legendary . The German motorbike builder BMW , began sing the design in their

motorcycles in 1922.

Because of its opposed cylinder layout the “Boxer” as it was dubbed, turns the crankshaft in line with the

motorcycle (or airplane!). This allows for a straight-through shaft connection from the engine, through the

7

gearbox and through a stainless steel driveshaft to a rear wheel final drive gear in the wheel hub. This

drivetrain design is exactly like the millions of rear wheel drive automobiles built over the past eighty

years! It is a time tested, proven drive system made elegantly simple by the “Boxer” opposed cylinder

engine.

T oday the “Boxer” engine has evolved into the high tech and electronically sophisticated and complicated

versions that can be found not only in BMWs but also in Porsches, Hondas and others. These are wondrous engines at wondrous prices! But they still retain the basic “soul” of Max Friz’s first engines. And

although it is not as evolved as the most modern “boxers”, the IMZ 750 cc is true to the earlier versions in

looks, but also has many modern internal components. These parts, like pistons, rings, valves, valve

seats and oil seals are modern and western made. The carburetors are made in Japan. These parts

make the engine more reliable and cleaner.

However , the “boxer” is still an air cooled power plant. As such it must be carefully monitored during

operation to prevent overheating. As the gear making and other machine tools in the Ural plant are

“vintage” ones, a careful break-in of the engine is very important. Neglecting to follow the prescribed

speeds during break-in or the frequent oil changes will cause this wonderful engine to rebel against its

“abusing” owner. However , by treating the “boxer” with respect and raising it well, you will be rewarded!

So its true that sometimes simple is better , and old fashioned ideas and designs have strong reasons for

the ability to continue for a long time. It is the main reason why over millions of Urals have been sold

around the world.

Any suggestions or comments are welcome! Write to us or post an e-mail on the Ural Discussion bulletin board at www.ural.com.

Happy Riding!

8

Important Notice!

St atements in this manual preceded by the following words are of special importance:

WARNING: MEANS THERE IS THE POSSIBILITY OF PERSONAL INJURY TO

YOURSELF

OR OTHERS.

CAUTION: Means there is the possibility of damage to the vehicle.

NOTE: Other information of particular importance has been placed in

italic type.

CAUTION! During the initial 2,500 km, a fundamental bedding-in of parts for all the mecha-

nisms of the motorcycle takes place. During this period do not overload the engine or race the

motorcycle in excess of the speeds specified in the section “Running-In of New Motorcycle.”

Doing so will void the warranty.

Maintenance intervals recommended are based on operational experience under various climatic and

road conditions. However, these intervals may be extended or reduced following repeated checks of the

lubricant condition and general technical condition of the motorcycle.

Carefully study this Owner’s Manual before starting the motorcycle.

Specifications and design are subject to change without notice.

9

10

Chapter 1

SPECIFICATIONS

GENERAL

T ourist, Patrol BC-75 & LC-75

& Adirondac

Maximum speed of motorcycle 120 km/h 74 mph 120 km/h 74 mph

Reference fuel consumption at 85% of 12.5 km/L 29 mpg 14 km/L 33 mpg

maximum speed

Dry mass of motorcycle 700 lb 680 lb.

Maximum load-carrying capacity 500 lb. / 485 lb. 400 lb.

Noise level below 80db

OVERALL DIMENSIONS

Length 2500 mm / 8 ft

Width 1700 mm / 5 ft 6 in

Height 1 100 mm / 3 ft 6 in

Road Clearance 125 mm / 5 in

Seat height 840 mm / 33 in

Wheel base 1470 mm / 58 in

ENGINE

T ype 4 stroke, overhead valves, opposed twin-cylinder

Displacement 745 cc

Cylinder bore 78 mm

Piston stroke 78 mm

Compression ratio 8.6 :1

Rated horsepower 26 KW / 35 BHp

Rated rotational speed 5600 RPM

Rated torque 35 ft.-lbs @ 3750 RPM

Lubrication system Dual system of forced lubrication and splashing

Lubricant SAE 20W/50

CARBURETOR

Carburetor type 32 CVK Keihin

Number of carburetors 2

Air cleaner Paper Filter Element

Fuel 91 octane premium unleaded gasoline

PCV V alve Internal Breather

11

ELECTRICAL

Ignition system 135.3734.COM-2 (CDI)

Ignition coil 135.3705-2

Sp ark plugs Autolite 273

Ignition timing Automatic spark timer

Alternator 35 amp / 12 V olt

Battery Interstate #YTX20L-BS or equivalent

Headlight Sylvania Halogen 6024, 7" round sealed beam

TRANSMISSION

Clutch Dry double-disk clutch

Gearbox 4 speed gearbox with reverse gear lever

GEAR RA TIOS

I gear 3.6

II gear 2.28

III gear 1.5

IV gear 1.19

Reverse gear 4.2

Speedometer drive ratio 0.4

Final drive ratio 4.62

FLUID CAP ACITIES

T ourist, BC-75 Patrol

LC-75 Adirondac

Fuel tank 5 Gal / 19L 5 Gal / 19L

Reserve .5 Gal / 2L .5 Gal / 2L

Engine 68 oz / 2L 68oz / 2L

Transmission 34 oz / 1 L 34oz / 1 L

Final drive 3.5 oz / 105 ml 4.5 oz / 135 ml

T elescopic Forks N/A on T ourist N/A on Patrol

(LC-75 & BC-75) 135ml / 4.5 oz

Shock Absorbers 105 ml / 3.5 oz 105ml / 3.5 oz

12

RUNNING GEAR

T ourist, Patrol & BC-75 & LC-75

Adirondac

Frame Tubular welded Tubular Welded

Rear wheel suspension Swing arms with Same

spring shock absorbers

Front fork Leading link T elescopic spring

Sidecar Cushioned body (on rubber

cushions) and wheel with

hydraulic spring shock absorber

Brakes Shoe-type with mechanical drive on front, rear and sidecar

wheels, front wheel has dual cams.

Tires 4” x 19” 3.5” x 18”

Front 22 psi cold (1.5 Bar / 150 kPa) Front 22 psi cold

Side 22 psi cold (1.5 Bar / 150 kPa) Side 22 psi cold

Rear 36 psi cold (2.5 Bar / 250 kPa) Rear 36 psi cold

CLEARANCES

mm in

V alves with engine cold 0.05 to 0.1 0.002 to 0.004

Between spark plug electrodes 1.016 0.040

Backlash between tooth faces of

bevel gears in final drive 0.1 - 0.3 0.004

FREE TRA VEL / ADJUSTMENTS

mm in

Hand brake control lever 5 - 8 0.2 - 0.3

Clutch control lever 5 - 8 0.2 - 0.3

Foot brake drive pedal ¼ of full stroke of pedal,

25 - 30 1.0 - 1.2

T oe-in dist ance 10 m m 3/8 inch

Lean-out 1° away from sidecar

13

TORQUE SPECIFICA TIONS

Metric US Equivalent Location on Bike

54 to 61 Nm 40 ft/lb to 45 ft/lb cylinder heads

237 to 251 Nm 175 ft/lb to 185 ft/lb fly wheel tightening screws

19 to 30 Nm top 14 ft/lb to 22 ft/lb shock absorber

38 to 49 Nm bottom 28 ft/lb to 36 ft/lb shock absorber

30 to 35 Nm 22 ft/lb to 26 ft/lb bearing nut

30 to 35 Nm 22 ft/lb to 26 ft/lb final drive to swing arm bolts

16 to 19 Nm 12 ft/lb to 14 ft/lb oil pump bolt

6.7 to 11 Nm 5 ft/lb to 8 ft/lb engine sump

14 to 19 Nm 10 ft/lb to 14 ft/lb final drive case nuts

25 to 30 Nm 18 ft/lb to 22 ft/lb nut fastening the pinion bearing

(Patrol rear axle only)

68 to 90 Nm 50 ft/lb to 66 ft/lb nut fastening the pinion bearing

22 to 27 Nm 16 ft/lb to 20 ft/lb reverse gear brake lever

19 to 22 Nm 14 ft/lb to 16 ft/lb generator gear nut

136 to 163 Nm 100 ft/lb to 120 ft/lb steering stem nut

CONVERSIONS

T o convert from mm to in, divide by 25.4 (there are 25.4 mm per inch).

T o convert from liters to gallons, divide by 3.785 (there are 3.78 liters per gallon).

T o convert from liters to quarts, multiply by 1.056 (there are 1.056 quart s per liter).

T o convert from liters to pint s, multiply by 2.1 12 (there are 2.112 pints per liter).

T o convert from km to miles, multiply by .62 (there is .62 mile per km).

T o convert from km/hr to mph, multiply by .62.

T o convert from Newton-meter (Nm) to inch-pound, multiply by 8.86.

T o convert from Newton-meter (Nm) to foot-pound, multiply by .7376.

T o convert from cm3 (cc) to pints, divide by 473 (there are 473 cc per pint).

T o convert Celcius to Fahrenheit: F° = C° x 1.8 + 32.

T o convert Fahrenheit to Celcius, C° = (F° − 32) divide by 1.8.

14

Chapter 2

MOTORCYCLE CONTROLS & INSTRUMENTATION

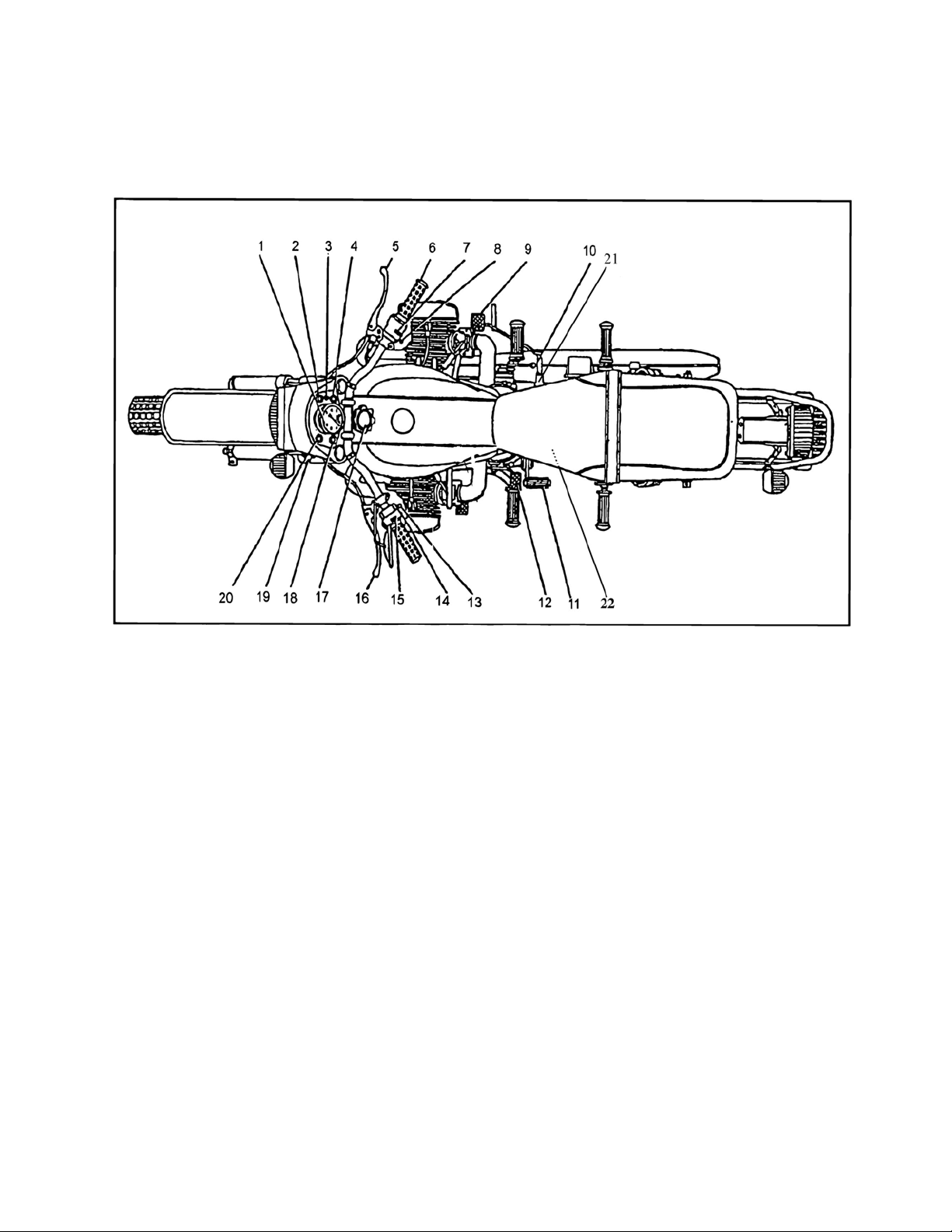

Figure 1. Controls and Instrumentation

1 - Speedometer 12 - Gear shift (foot) pedal

2 - Turn indicator lamp 13 - Turn signal switch

3 - Trip odometer reset knob 14 - Horn push-button

4 - Neutral and reverse gear engagement 15 - “High-low” beam switch

indicator lamp 16 - Clutch control lever

5 - Front brake control lever 17 - Steering damper tightening bolt

6 - Throttle control twist grip 18 - High-beam indicator lamp

7 - Ignition cutoff switch 19 - Ignition Switch

8 - Electric Start Button 20 - Battery discharge warning lamp

9 - Rear brake pedal & sidecar wheel brake 21 - Parking brake

10 - Reverse gear lever 22 - Master battery switch (under seat)

1 1 - Kick st art lever

15

CONTROLS

Clutch control lever (Fig.1, #16) . When the clutch lever is squeezed, the engine is disengaged

from the gearbox. When the lever is released, the engine and gearbox are engaged.

W ARNING: M

OR OPERATION OF VEHICLE COULD BE IMPAIRED.

GRIPS

AKE SURE FINGERS ARE NOT POSITIONED BETWEEN HAND CONTROL LEVERS AND HANDLEBAR

W ARNING: BEFORE STARTING ENGINE, ALWAYS SHIFT TRANSMISSION TO NEUTRAL TO PREVENT ACCIDENTAL

MOVEMENT

WHICH COULD CAUSE POSSIBLE DAMAGE TO MOTORCYCLE AND PERSONAL INJURY.

Front brake control lever (Fig.1, #5). When the lever is squeezed, the front wheel brake is

actuated. The front brake should be used together with rear brake.

When the brake lever is squeezed, the stop signal lamps are switched on.

Kick lever (Fig.1, #1 1) is designed to start the engine. On pressing the lever the crankshaft of the

engine is actuated through the gearbox. The lever is returned to its initial position by the spring

inside the gearbox. Note: this is a backup to the electric starter .

Gear shift foot pedal (Fig.1, #12) is a two-arm type. When the front arm is pressed, shifting

from high to lower gears takes place. When the rear arm is pressed, shifting from low to higher

gears takes place. Since the heel-toe shift lever is short-coupled, you will find it easier to shift up if

you rotate the heel of your left foot in towards the rear arm before stepping on it with your heel.

The neutral position is fixed between the I and II gears.

IMPORT ANT! The green pilot lamp glows when the transmission is in neutral and when

the reverse gear is engaged (see “Starting the Engine”).

Reverse gear engagement lever (Fig.1, #10) Forward for neutral and/or forward running and

back for reverse.

The reverse gear may be engaged only after the motorcycle is completely

stopped!

T o engage reverse gear , shift into neutral (or first), then push back the reverse lever.

T o disengage the reverse gear , press lever up (forward) to the limit, then the gear shift mechanism

is reset to the neutral position. Now you can shift into first gear .

If desired, neutral may be selected by shifting into reverse when the first gear is engaged, and then

moving the reverse gear lever forward into neutral.

16

The rear brake pedal (Fig.1, #9) applies the rear wheel and sidecar wheel brakes simultaneously.

W ARNING: DO NOT APPLY EITHER BRAKE STRONGLY ENOUGH TO LOCK THE WHEELS BECAUSE THIS MA Y

CAUSE

FRONT

POSSIBLE LOSS OF CONTROL OF THE MOTORCYCLE. ALWA YS USE BOTH BRAKES. NEVER STOP WITH

OR REAR BRAKE ONLY.

W ARNING: AN IMPROPERLY ADJUSTED REAR BRAKE PEDAL COULD INTERFERE WITH PROPER REAR BRAKE

OPERATION

RESULTING IN POOR BRAKE ACTION.

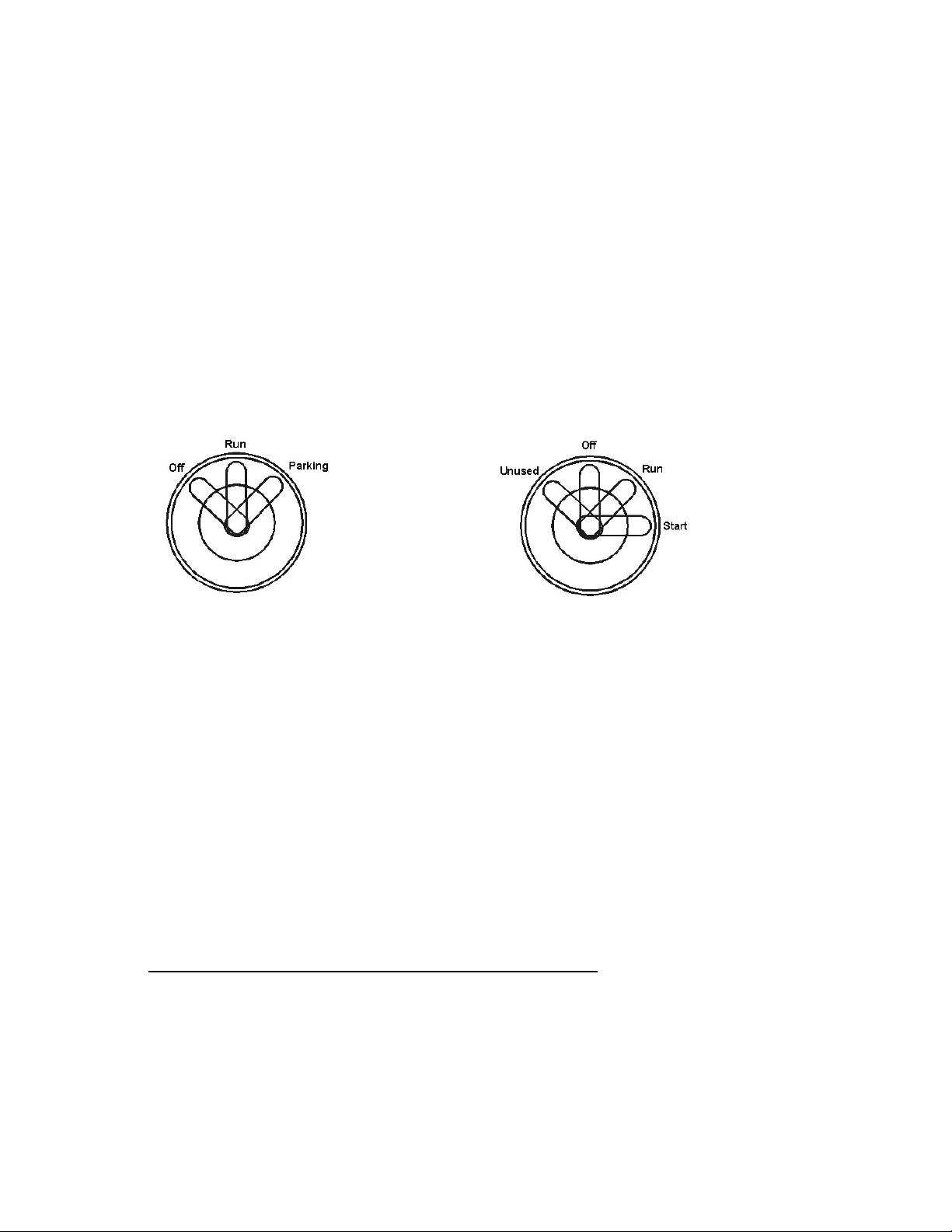

Ignition Switch (Fig.1, # 19) has three fixed positions of the key . The position and switching

diagram of the ignition locks are shown above.

Tourist, Patrol BC-75

Adirondac & LC-75

Off All electrical systems are off.

R un Volt age is supplied to all electrical systems.

Parking Voltage is supplied to running lights only .

Unused All electrical systems are off.

Note: Leaving the key in the Run or Parking position will discharge the battery .

Always return the key to the Off position before taking it out.

Speedometer is on the dash board, with trip (Note..BC-75 has no trip odometer)

and total odometer . The trip odometer is reset to zero by rotating push-button (Fig.1, # 3) counterclockwise. Note that the odometer reads in kilometers not miles.

17

The indicator lamps are mounted on the instrument board:

(Fig. 1, # 2) — turn indicator pilot lamp, (orange)

(Fig. 1, # 4) — gearbox neutral and reverse gear engagement, (green)

(Fig. 1, # 18) — head lamp high beam indicator , (dark blue)

(Fig. 1, # 20) — alternator fault indicator lamp, (red)

Note: If the red alternator fault light stays on continuously during normal operation above approximately 1500 RPM, there is a problem with the charging system or battery .

Throttle Control (Fig.1, # 6) is on the right handlebar . Turning the twist grip counterclockwise

increases engine speed.

Ignition Cutoff Switch (Fig.1, # 7) has two positions, ignition off (up), and ignition on (down).

Low and High Beam Light Switch (Fig.1, # 15), turn indicator switch (Fig.1, #13) and horn

push-button (Fig.1, # 14) are combined in one unit on the left-hand handle bar control housing.

Master Battery Switch (Fig.1, # 21) is under the seat.

Electric Start Button (Fig. 1, # 8) is located on the right-hand twist grip, below the kill switch.

The Steering Damper absorbs lateral kicks on the front wheel. T urning tightening bolt (Fig.1, # 17)

clockwise increases friction. This can be used while riding over bad roads.

W ARNING: DO NOT TIGHTEN THE DAMPER TO THE POINT WHERE THE STEERING BECOMES STIFF. DOING SO

ADVERSELY AFFECT HANDLING QUALITIES.

WILL

Parking brake (Fig. 1, # 22) is located on the right side of the motorcycle next to the foot peg. It is

engaged by applying the foot brake pedal fully and turning the handle and pushing it down to hold

the foot brake lever in the applied position.

Always disengage the parking brake before moving the motorcycle.

18

Chapter 3

ENGINE OPERATION AND MAINTENANCE

PRE-TRIP PRELIMINARIES

Before each trip, attend to all the requirements of the everyday maintenance as outlined in this

manual. When adding fuel and oil to the motorcycle, take all precautions to keep everything neat

and clean.

Gasoline level in the tank fully filled should be 10 - 15 mm / ½ - ¾ in. below the lower edge of the

tank filler . Do not overfill the tank, especially on California models where overfilling can cause fuel

contamination of the charcoal cannister . See that the

than the top and not lower than the bottom marks on the dipstick with the filler plug undone.(See

chapter 4 Lubrication System)

CAUTION: When draining and refilling oil , be careful that dirt and debris does not contaminate the fresh oil. Do not allow draining oil to get on the rear wheel, tire, or brake compo-

nents.

oil level in the engine crankcase is not higher

ST ARTING THE ENGINE

W ARNING: BEFORE STARTING THE ENGINE, MAKE SURE THAT THE GEAR SHIFT MECHANISM IS IN THE NEU-

TRAL POSITION (BETWEEN 1

POSSIBLE

ADVISABLE TO USE NEUTRAL GEAR.)

IS

When the ignition is switched on, the green & red lamps on the instrument board should light up.

Make sure that the reverse gear engagement (lever) is set to the front position. This is important

since the green lamp will also be lit if the motorcycle is in reverse gear . Moving the reverse gear

lever forward will put the gearbox in neutral.

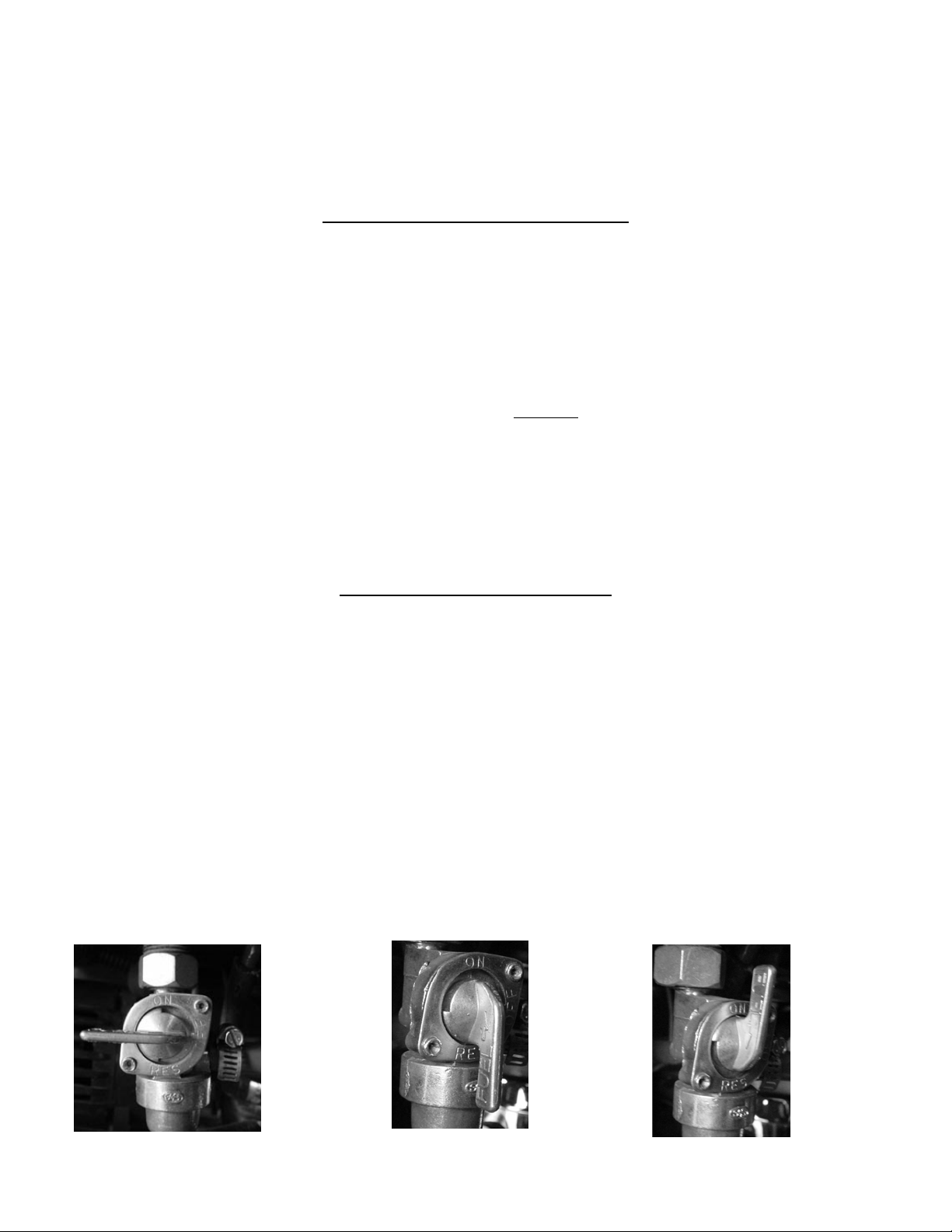

Gasoline petcock positions are as follows:

OFF ON RESERVE

DAMAGE TO MOTORCYCLE AND PERSONAL INJURY. ( FOR MORE THAN JUST STARTING, I.E. IDLING, IT

ST

AND 2ND GEARS) TO PREVENT ACCIDENTAL MOVEMENT WHICH COULD CAUSE

19

Depending on the engine and ambient temperature, use the carburetor enricheners and starting

procedure as follows:

Manual S tarting (without electric starter)

1. T urn on the ignition and depress the kick lever (see Fig. 1) about

1/4 of its travel (enough to firmly get the ball of your foot on the lever) with either your left

foot or right foot, depending on what position is most comfortable with your right hand on the

throttle. T ake up the slack in the throttle until you can feel some slight resist ance from the

return springs in the carburetors. However , do not advance the throttle, since this may flood

the engine.

Note: Y ou may find it more comfortable to stand on the lef t passenger foot peg with your right

foot and kick with your left foot.

Give the kick lever a swift kick. When the engine starts, tickle the throttle (quickly increase

and decrease it) to keep the engine running, but not too fast. If the engine doesn’t start,

repeat the kicking procedure. A properly adjusted warm engine should start within a few

kicks. If the engine doesn’t start, try the procedure described below in item 3. If it still

doesn’t start or fire, it may be flooded.

Note: Do not open the throttle while kicking the engine over since it may flood the spark plugs.

Electric St arting

1. Set carburetor enricheners as with kick starting. Unlike manual starting, however , the

gearbox does not have to be in neutral as the electric starter may be engaged with the clutch

lever pulled in, or with the gearbox in neutral. Make sure the Ignition Cutoff Switch is set to

“ Ignition On” and push the starter button to turn over the engine.

2. When the engine has been standing for several hours but the ambient temperature is

high (60°F/15°C degrees or above), try starting it without any enricheners. If it doesn’t fire,

then use the procedure described below.

3. When the engine is cool or cold and the ambient temperature is between40°F-60°F/5°C-

15°C, depress both enricheners to start. As soon as the engine starts, immediately retract

the enricheners. Run the engine at moderate speed for 30-60 seconds. If it starts to die,

blip the twist grip throttle (rapidly twist part way towards full throttle and then back off) to

keep the engine running. After 1 to 3 minutes, depending on ambient temperature, the

engine should run smoothly without “blipping” the throttle.

4. If the engine is cold and ambient temperature is below 40°F , first, give the engine 5-10

(depending on how cold it is) priming kicks with the ignition off. This will get some oil circulated to key internal parts. Engage the enricheners on both carburetors. The engine should

20

then fire, depending on how cold it is. For example, when the ambient temperature is 0°F, it

typically takes about 5-10 rotations to start the engine. As soon as the engine starts, retract

both enricheners (after a few seconds).

Note: It is very important to back off on the enricheners as soon as the engine will sustain itself

without stalling. Since the Ural is a classic engine design, the plugs will foul quickly (as soon as

one minute) if the engine mixture is too rich. If one plug fouls and the other doesn’t, the engine

will run very unevenly and have greatly reduced power.

When the engine is hot, do not choke or enrichen the carburetors. T o do so risks flooding

the engine.

T o st art an engine that is flooded, first open the throttle fully, hold it there and give the engine

up to 10 swift kicks. If it still doesn’t fire, take the spark plugs out to see if they are wet with

gasoline. If they are wet, dry them. Clear excess gasoline from the cylinders by kicking the

engine over 10 times with the plugs out and the throttle closed. Then replace the plugs and

repeat the starting procedure described at the beginning of this section (1).

W ARNING: SUSTAINED OPERATION ON ONLY ONE CYLINDER FOR EVEN JUST A FEW MINUTES COULD OVER-

HEAT THE CYLINDER AND CAUSE IRREVERSIBLE DAMAGE TO EITHER THE VAL VES OR PISTON. THUS IT IS CRITI-

CAL TO IMMEDIATELY SHUT THE ENGINE DOWN IF IT APPEARS TO BE RUNNING ON ONLY ONE CYLINDER.

Additional Warnings: Once the engine start s, do not allow it to run at a high speed as this could

cause abnormal wear of the parts and may lead to seizure of the piston pin and pistons in the

cylinders since cold oil flows through the oil ducts with difficulty and fails to ensure sufficient lubrication.

A correctly adjusted warm engine should run steadily at low speed with the throttle control twist grip

fully closed.

Do not let the motorcycle sit at idle for more than three minutes, as overheating could result.

OPERATING PRECAUTIONS

W ARNING: MAKE SURE THAT SIDECAR WINDSHIELD IS IN THE FULL BACK POSITION SO IT DOESN’T INTER-

FERE WITH THE RIGHT HANDLEBAR.

T o move the motorcycle from rest, shift to 1st gear only . A void releasing the clutch suddenly , because the engine is liable to stall or the motorcycle will start with a jerk. Do not drive the motorcycle at speeds below the recommended speeds with the 2nd, 3rd or 4th gears engaged. It is not

advisable to use the 1st and 2nd gears for a long time, unless so required by road conditions.

W ARNING: WHEN SHIFTING TO LOWER GEARS WITH THE MOTORCYCLE IN MOTION, DO NOT DOWNSHIFT AT

SPEEDS

HIGHER THAN THOSE LISTED IN THE TABLE. SHIFTING TO LOWER GEARS WHEN SPEED IS TOO HIGH MAY

21

SEVERELY DAMAGE THE TRANSMISSION OR CAUSE THE REAR WHEEL TO LOSE TRACTION.

CAUTION: Do not run the engine at extremely high rpms with clutch disengaged or transmission in neutral. Do not idle the engine unnecessarily for more than a few minutes with

the motorcycle standing still.

An engine which has run long distances at high speed must be given closer than ordinary attention

to avoid overheating and consequent damage. Have the engine checked regularly and keep it well

tuned. V alve seating and good compression are particularly important. This applies particularly to

a sidecar motorcycle equipped with windshields, carrying heavy loads, or operating in hot weather .

W ARNING: WHEN RIDING ON WET ROADS OR UNDER RAINY CONDITIONS, BRAKING EFFICIENCY IS GREATLY

REDUCED

ESPECIALLY

WITH

AND CAUTION SHOULD BE USED WHEN APPLYING THE BRAKES, ACCELERATING OR TURNING. THIS IS

TRUE IMMEDIATELY AFTER THE RAIN BEGINS AND THE OIL FROM THE ROAD SURF ACE COMBINES

THE WA TER.

When descending a long, steep grade, downshift and use engine compression together with intermittent application of both brakes to slow the motorcycle. Avoid continuous use of brakes to reduce overheating of the brakes and reduced efficiency .

While using the motorcycle in summer, p ay special attention to the condition of the tires. Keep

them inflated up to pressures specified in this manual.

RUNNING IN THE NEW MOTORCYCLE

The running-in period for the motorcycle is the first 2,500 km.

Since the Ural engine is a classic design, it is critical to observe this running-in procedure. Failure

to do so could cause engine damage and void the warranty .

During the running-in period, a new motorcycle requires the most careful attention. In the course

of this period, do not overload the machine. A void traveling on freeways and climbing steep hills.

Do not race the engine or overheat it at any time. V ary the throttle setting frequently , so as to avoid

constant RPMs. Allow the new engine frequent rest periods for cooling down.

22

Chapter 4

BRIEF DESCRIPTION OF DESIGN & MAINTENANCE

ENGINE

The motorcycle is equipped with a twin-cylinder four-stroke carburetor-type air-cooled engine.

Opposed arrangement of cylinders in the horizontal plane is the outstanding feature of the motorcycle design which ensures proper cooling and balancing of the crank gear . The engine valves

are located in the cylinder heads.

In summer, carefully observe the heating condition of the engine, power transmission unit s and the

running gear mechanisms. Under normal heating conditions of the engine, the temperature of the

cylinder heads should not be over 356°F-428°F/180°C-220°C.

Engine maintenance. During everyday preventive maintenance, clean the engine of mud and

dust, paying special attention to the cooling fins as their fouling will impair the efficiency of the

engine cooling. Check engine crankcase, cylinders and cylinder heads for leaks of oil and fuel.

Completely follow all maintenance intervals specified in the Service Coupons.

LUBRICATION SYSTEM

The motorcycle engine features a dual lubrication system, some parts are force-lubricated by

pressure built up by the oil pump, while others by splashing . A full-flow paper oil filter is provided

in the lubrication system to prolong the engine life.

Maintenance of lubrication system. During the daily inspection, check the oil level in the engine

crankcase and top off the oil if necessary .

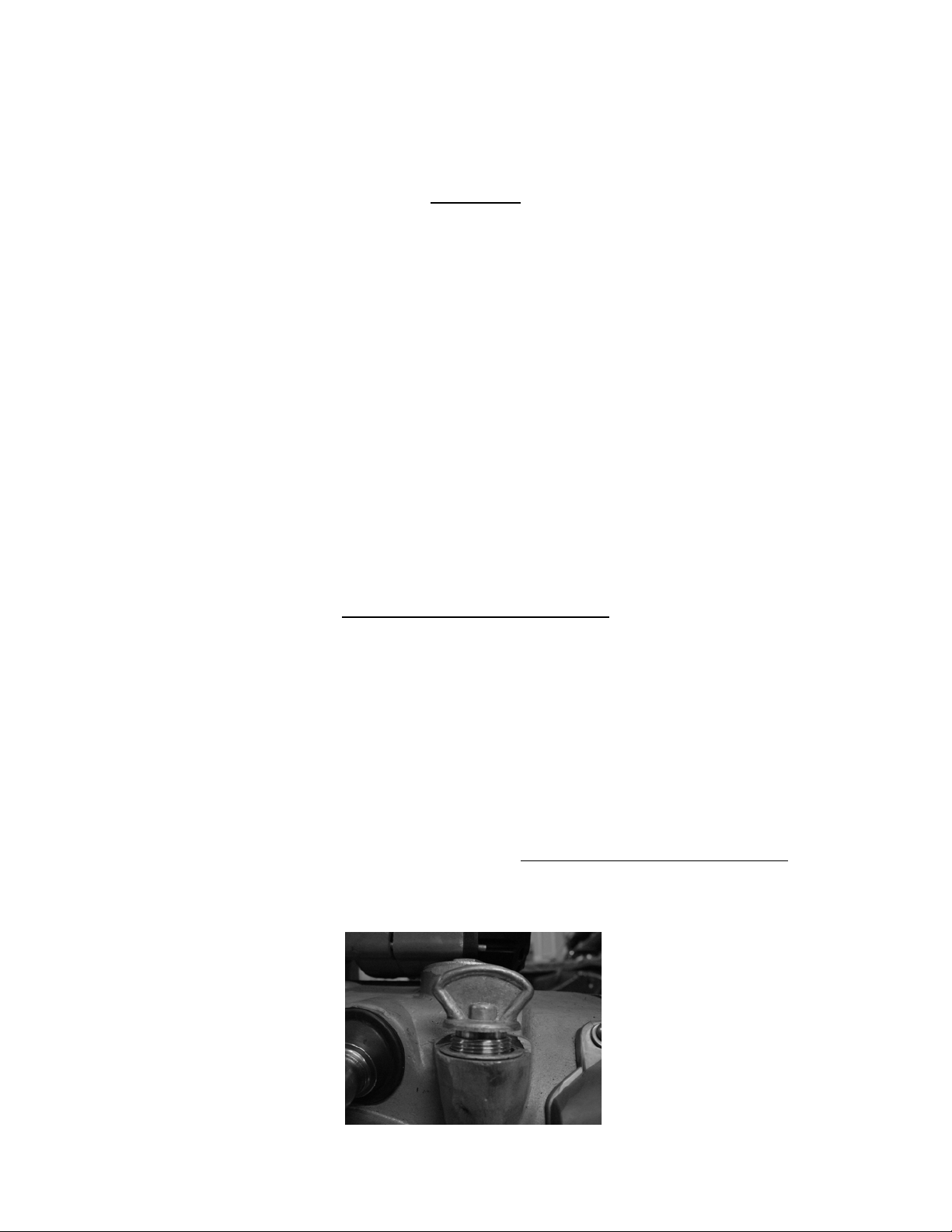

The oil dipstick has two grooves showing the lower and the upper oil level limits. In checking the oil

level, wipe the dipstick and insert it into the crankcase without screwing in the dipstick.

The dipstick is positioned

for correct oil level

measurement.

23

Warm up the engine before changing the oil. Drain used oil from the engine and the oil filter cavity

after having unscrewed the drain plug and filter plug. Change oil filter at the intervals shown in the

service coupons. Set the rubber sealing bushing into the filter and fit the filter with the bushing

onto the adapter of plug, then screw the latter into the front cover . Now screw in the plug. Fill the

engine with 68 oz. oil, or until the top mark of the dipstick is reached.

Let the engine run for 3 - 5 min. Check the oil level again adding oil up to the top groove of the

dipstick if needed. During motorcycle service, keep oil level in the engine crankcase close to the

top groove of the oil dipstick. Don’t ride the motorcycle if the oil level is below the lower mark of the

dipstick, until sufficient oil is added to raise the oil level to the top mark.

Make sure that the dipstick is screwed down securely after measuring the oil level.

FUEL SYSTEM

The fuel system includes the gasoline tank, the three-way fuel valve with filter and two carburetors.

Fuel valve (petcock). The top threaded portion of the valve is screwed into the gasoline tank.

The lever has three positions: (See Pg. 16)

Down - Reserve

Horizontal - Off

Up - On

W ARNING: FUEL VALVE SHOULD ALWAYS BE CLOSED WHEN ENGINE IS NOT RUNNING TO ENSURE AGAINST

ACCIDENTALLY

FLOODING ENGINE OR SURROUNDINGS WITH GASOLINE.

Note: T o maintain a reserve supply , operate the motorcycle with the valve in the on position

after refueling.

W ARNING: FILL FUEL TANK SLOWLY TO PREVENT FUEL SPILLAGE. DO NOT OVERFILL ABOVE THE BOTTOM OF

FILLER

OVERFLOW

FILLER

NECK INSERT. LEAVE AIR SPACE TO ALLOW FOR FUEL EXPANSION. FUEL EXPANSION CAN CAUSE

THROUGH THE FILLER CAP VENT ONTO SURROUNDING AREAS. AFTER REFUELING, MAKE SURE

CAP IS SECURELY TIGHTENED.

Fuel system maintenance. Before a trip, check the tightness of gasoline piping joints, & proper

functioning of throttle cables.

Check fastening and condition of the carburetor flanges. Run the engine and check for proper idle

adjustment of the carburetors.

24

IGNITION SYSTEM

The ignition system incorporates the power supplies, ignition coil, Hall Effect pickup, electronic

module, two spark plugs, a set of low and high voltage wires and the ignition switch.

For the electric circuit diagram of the motorcycle with electronic ignition system refer to Ignition

System schematic diagram.

Ignition coil The ignition coil has two high voltage terminals, each supplying one of the cylinder

spark plugs and operating in conjunction with the Hall Effect pickup.

Periodically , check all wires to be sure they aren’t crimped or have loose connections.

Spark plugs. In certain situations, spark plugs can quickly foul with carbon or soot. The plugs can

be cleaned but it is easier to put in a new set of plugs when on the road. We recommend that you

purchase an extra set of these plugs from your Authorized Ural Dealer and carry them in the motorcycle at all times.

W ARNING: D

DAMAGE

Functioning of ignition system. Both plugs fire simultaneously on the left and right-hand cylinders, one spark being formed when the compression stroke terminates in one of the cylinders and

the other during the exhaust stroke.

THE CYLINDER HEAD.

O NOT OVER-TIGHTEN THE SPARK PLUG WHEN MOUNTING IT ON THE ENGINE, SINCE THIS COULD

Chapter 5

CARBURETORS

32mm CVK Keihin Seike carburetors are used on of the Ural motorcycle for compliance with US

EP A requirement s. They are preset with fixed mixture jetting and adjust automatically for altitude

variations. This is due to the vacuum activation mechanism of these constant velocity type carburetors.

W ARNING: TO AVOID SEVERE ENGINE DAMAGE, DO NOT MODIFY CARBURETOR SYNCHRONIZATION, JETS, OR

THROTTLE

FEDERAL OFFENSE AND MAY SUBJECT THE OFFENDER TO CIVIL PUNISHMENT AND FINES. THIS AIR COOLED

ENGINE

FIRING

LINKAGE. TAMPERING WITH THE CARBURETORS OR OTHER CRITICAL EMISSION ELEMENTS IS ALSO A

MUST ALWAYS RUN ON BOTH CYLINDERS AS EVENLY AS POSSIBLE. WHENEVER ONE CYLINDER IS NOT

, STOP THE ENGINE AND DETERMINE THE CAUSE AND CORRECT IT BEFORE PROCEEDING.

25

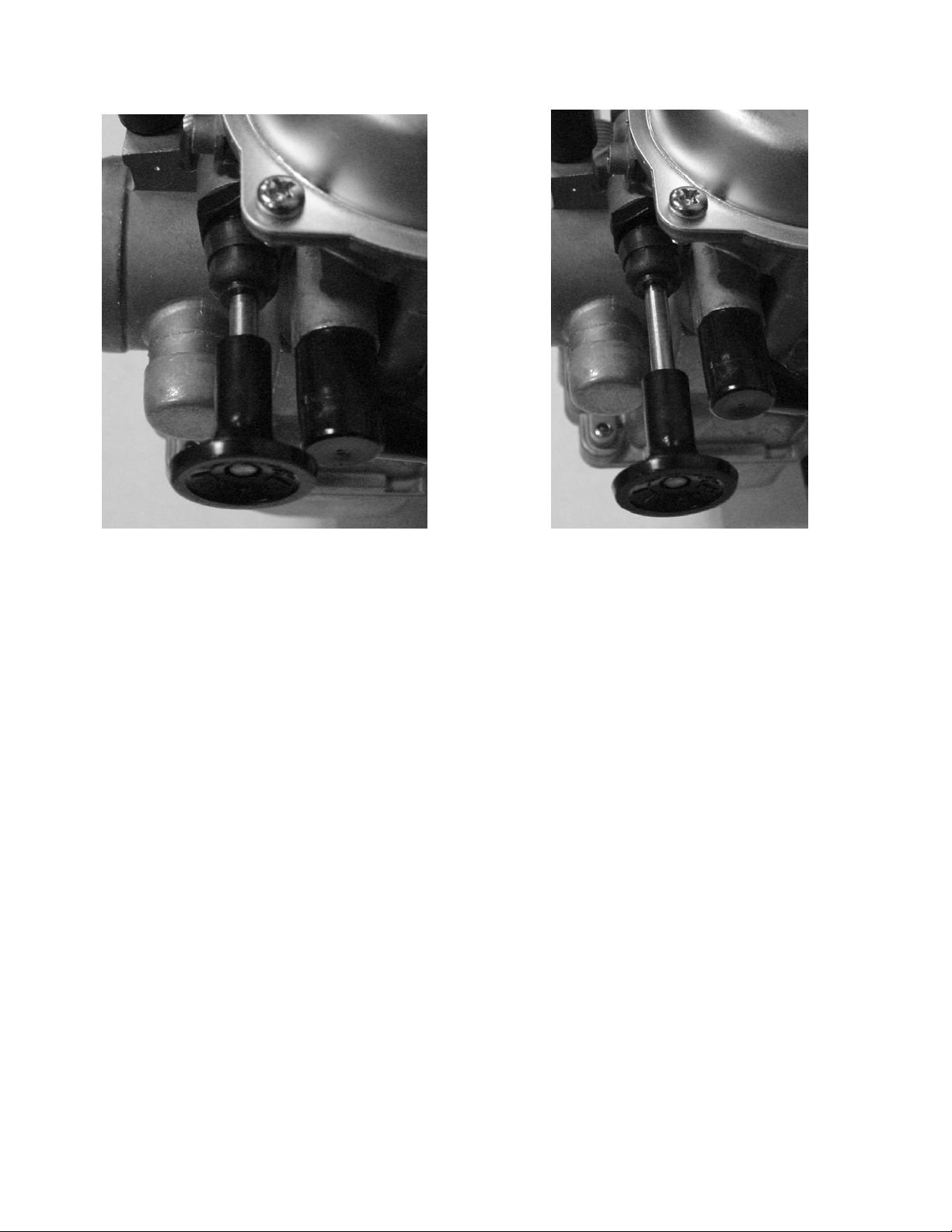

Enrichener off Enrichener on

Use the enricheners only if needed to start a cold engine. T urn the enricheners off as soon as the

engine has started to prevent the possible fouling of the spark plugs.

26

Chapter 6

POWER TRANSMISSION

The power transmission of the motorcycle is comprised of the clutch, gearbox, drive shaft and the

final drive.

CLUTCH

The clutch transmits torque from the engine to the gearbox. Disengage the engine from the gearbox during shifting of the gears and during braking to a stop. The clutch provides for smooth

starting of the motorcycle from rest, protects the power transmission parts against damage when

the engine speed or drive wheel speed is suddenly changed. The clutch is of dry double-disk

design. The clutch release mechanism is controlled by the lever on the left grip of the handle bar .

With the clutch lever released, the engine is engaged to the gearbox. When the clutch lever is

squeezed, the engine is disengaged from the gearbox. Use the clutch lever for starting from

rest and for gear shifting. Under conditions of heavy traffic, when gears frequently have to be

shifted, do not slip the clutch too much, as this will accelerate wear of the disks.

GEARBOX

The reverse gear should be engaged from neutral or first gear when the bike has come to a stop.

Shifting the gears is best accomplished by pushing down on the toe piece for first gear and to

downshift from higher gears. To shift up into second, third and fourth gear , use the heel plate (with

either heel or toe) and push down quickly and firmly .

CAUTION: Severe damage due to insufficient lubrication of gears, shafts and bearings can

result if the oil level is allowed to get lower than the specified level.

FINAL DRIVE

Maintenance of propeller shaft splines and final drive.

Remove the final drive from the swing arm and pull the final drive towards the rear of the bike.

When the drive shaft is free, coat the drive shaft splines with grease. At the same time, use a

grease gun to force grease into the drive shaft universal joint.

T ypical final drive maintenance includes tightening the nuts which fasten the final drive to the

swinging fork arm. Failure to tighten the nuts may result in loose joints and the destruction of the

final drive cover . Change the final drive oil as determined by the service coupons. Undo the filler

and drain plugs and drain the used oil. Fill the casing with fresh 20w / 50 Castrol oil and flush the

final drive by turning the rear wheel several times. Drain the 20w / 50 Castrol oil and then refill the

final drive with the specified lubricant. ( See lubrication list, chapter 1 1 )

27

28

Loading...

Loading...