Installation Guide

HotLok® Rack Airow Management Kit

Mounting Extrusion Part Numbers

90°Profile @ 105’ - 10132 45°Profile @ 105’ - 10134

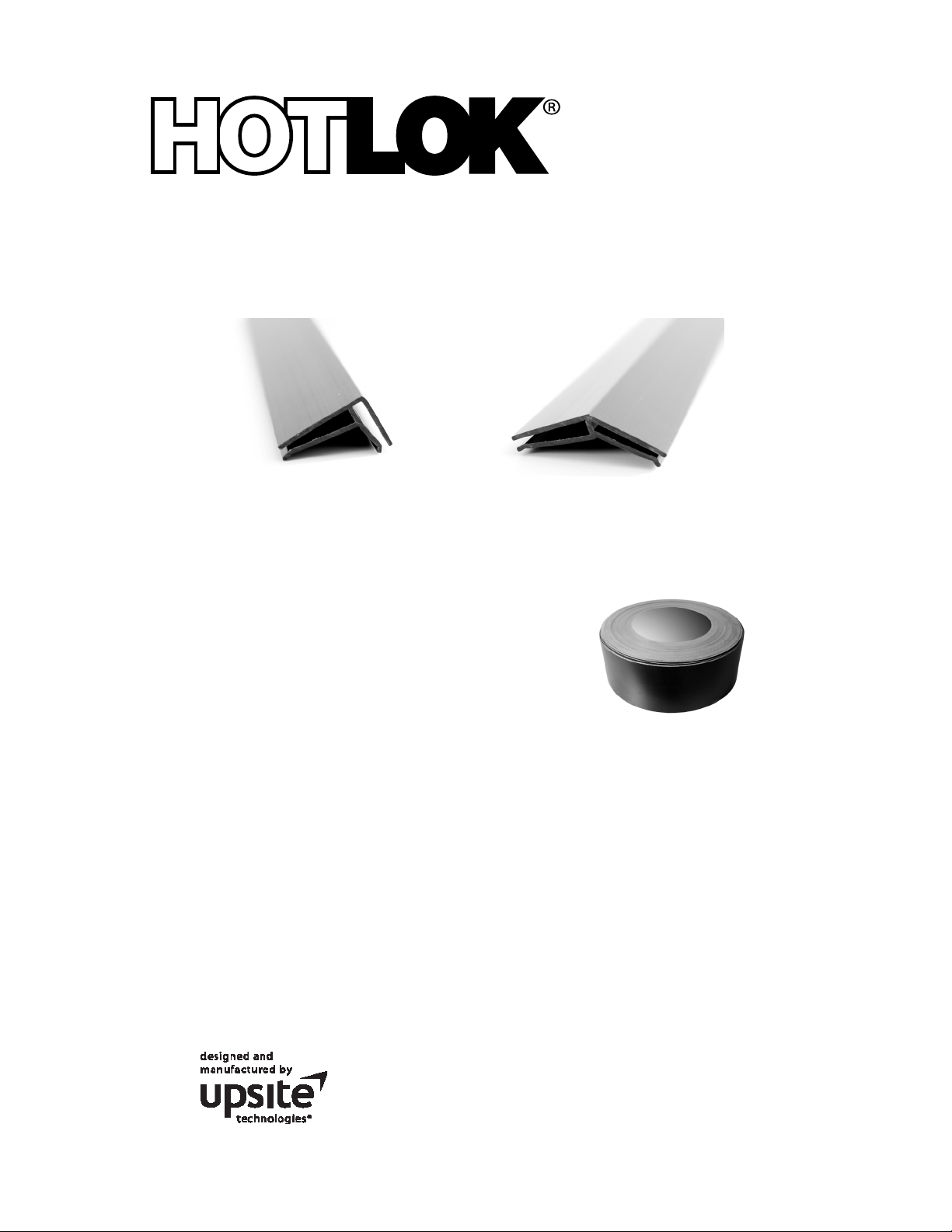

90º Prole - Part No. 10132 45º Prole - Part No. 10134

Sealing Membrane Part Numbers

2.5” Wide Roll @ 100’ - 10139

4.0” Wide Roll @ 100’ - 10140

5.5” Wide Roll @ 100’ - 10141

2.5” Roll @ 100’ - Part No. 10139 4” Roll @ 100’ - Part No. 10140

5.5” Roll @ 100’ - Part No. 10141

Table of Contents

Tools Required for Installation Page 2

Installation Procedures Page 3-4

General Information Page 5

Safety Information Page 5

Warranty Page 6

Each kit contains the following items:

Mounting Extrusions (15)

Roll of Sealing Membrane 100 feet in length (1)

Roll of 3M

TM

double sided adhesive (1)

888.982.7800

www.upsite.com

1

Installation Guide

HotLok® Rack Airow Management Kit

Proles - Mounting Extrusion Proles - Sealing Membrane

Part No. 10132 90

Part No. 10134 45

Note: 105 feet (32m) of Prole is provided in fteen 7 foot (2.1m) long pieces. Sealing panel material is provided in the

selected width (2.5”, 4.0” or 5.5”) in a single 100 foot (30.5m) long roll. Extrusion Prole and Sealing Membrane sold

separately.

º Profile @ 105’

º Profile @ 105’

Tools Required for Installation

• For cutting the Mounting Extrusions, you will need a chop saw, miter saw, tin snips or other cutting

instrument

• For cutting the sealing membrane, you will need scissors, box cutter or a sharp blade

• Tape measure

Preparation Required For Installation

1. Determine the best method to customize your data rack.

Part No. 10139 2.5” Wide Roll @ 100’

Part No. 10140 4.0” Wide Roll @ 100’

Part No. 10141 5.5” Wide Roll @ 100’

a. No external lip will require internal installation of Mounting Extrusions to the inside panel

or side wall of the rack system using the supplied double sided adhesive.

b. External “lip” on the rack system allows for clip-on method to the extended or protruding

area on the rack.

2. For the Mounting Extrusions, use the tape measure to take measurements for the internal/exter-

nal area where the mounting extrusions will be placed (sides, top and bottom of rack). Measure

around any obstacles, mounting brackets or interferences, as you will place Mounting Extrusions

around these on the rack systems.

3. Cut the Mounting Extrusions to your size specications.

4. For the Sealing Membrane, measure the area where the Membrane will be placed.

a. Special Note: Measure the length, top and bottom and add 1/2 to 1 inch to measurement

for extra material. The corner areas will be addressed in the installation.

b. Cut out any special notches, customized to your rack system as needed.

888.982.7800

www.upsite.com

2

Installation Guide

HotLok® Rack Airow Management Kit

Installation Procedures

The HotLok® Rack Airow Management Kit ts most rack congura-

tions based upon your measurements taken during the preparation

directions. The design is to be easy for removal and reuse as needed

for your rack systems.

Surface for

Adhesive

1. Clean rack surface to be free of dust, lint or dirt particles where

the Mounting Extrusions will be installed. This is especially critical

when using the adhesive material, as any dirt or debris will impact

the adhesive.

a. Use an alcohol wipe or a clean cotton cloth, damp with a

solution of at least 50% isopropyl alcohol.

i.Helpful Hint: When choosing your cleaning cloth,

do not use fabric or paper that will disintegrate or

leave particles that could interfere with the adhe-

sive.

2. Install the Mounting Extrusion

a. External clip-on method:

i. Install each piece that is cut on the “lip” of the

rack using the proper clip.

Special Note: See Figures 1 and 2 for the

proper retention clip to use for the rack and

for the Sealing Membrane.

b. For adhesive (inside of the rack method):

i. Attach the adhesive to the Rack Lip Retention Clip

face (see Figures 1 and 2) but leave the adhesive

backing on until the product is ready to install.

ii. When ready to install, peel off the backing and

place inside of your rack system.

Helpful Hint: Press rmly along the full

length of the extrusion to secure in place

Sealing Membrane

Retention Clip

Sealing Membrane

Retention Clip

Rack “Lip”

Retention Clip

(gure 1)

Surface for

Adhesive

Rack “Lip”

Retention Clip

(gure 2)

888.982.7800

www.upsite.com

3

Installation Guide

HotLok® Rack Airow Management Kit

Installation Procedures

3. Sealing Membrane installation for both internal and external Mounting Extrusions.

a. Start the sealing membrane into the retention clip using one corner and then press along the length of the

mounting extrusion to insert the full length of the membrane.

i. Helpful Hint: Take small sections at a time to help push into the extrusion

ii: Alternate Assembly: The Sealing Membrane can be inserted into the Mounting Extrusion before plac-

ing inside of the cabinet. This may require good spacing of the Mounting Extrusions on the sealing membrane.

b. The Sealing Membrane should rest ush with the rack system, with no gaps, to minimize airow inside of the

rack system.

c. If your Sealing Membrane is not sitting ush due to an obtrusion, obstacle and/or notch, it may be helpful to

cut the membrane around the obstruction or attempt to work out the “kinks” by repositioning the Sealing Membrane in

the Mounting Extrusion. Additionally, the double sided adhesive can be used to secure the membrane to adjacent parts.

888.982.7800

www.upsite.com

4

Installation Guide

HotLok® Rack Airow Management Kit

General Information

The maintenance of the manufacturers’ guidelines for proper cooling may result in the overheating of equip-

ment. Before minimizing rack airow, ensure proper airow to the intake side of your computer equipment or

cabinets is feasible through the use of devices such as perforated oor tiles. Achieving proper airow to the

intake side of the computer equipment and or cabinets is the responsibility of the customer.

Safety Requirements

Installers must be familiar with standard safety and risk management practices when working in raised oor

environments and when modifying racks and cabinets.

Customer Support

If you have any questions, please

contact us at 505-982-7800

Monday – Friday, 7AM–4PM MT

Email us at info@upsite.com

Patents Pending | P/N 60239 Rev. A © 2012

Upsite Technologies, Inc.

4900 Lang Avenue NE, Suite 204

Albuquerque, NM 87109

888.982.7800

www.upsite.com

5

Limited Warranty

HotLok® Rack Airow Management Kit

Upsite Technologies, Inc. (the Company) warrants to the original purchaser that products delivered hereunder will be free

of defects in materials and workmanship for a period of twelve (12) months from the date of purchase (the “Warranty

Period”).

The Company shall, at its option, within the Warranty Period, either repair or replace free of charge, any product or part

thereof found, upon the Company’s inspection, to be defective in materials and workmanship, and will return the repaired

or replaced product to the purchaser at Company’s expense.

For warranty service and shipping instructions, contact the Company at the telephone number shown below. If the product

is under warranty and the defect appears to be covered by this Limited Warranty, the Company will issue to the purchaser

a Notice of Authorization For Warranty Return. Products returned to the Company for warranty service must be accompanied by a statement of defect, the Notice of Authorization for Warranty Return provided by the Company, and proof of

purchase.

This Limited Warranty is conditioned on the following:

1. The Company must be notied within 12 months of purchase and have been given the opportunity of inspection by

return of any alleged defective product free and clear of all liens and encumbrances to the Company or its manufacturer; and

2. The product must not have been abused, misused, or improperly maintained, and/or repaired during such period; and

3. Such defect has not been caused by corrosion or exposure to other than ordinary wear and tear.

4. The installation and use of the product has been accordance with the manufacturer’s instructions and has not been

modied or customized to include but not limited to cut, resized, burned, glued, bent, re-shaped, disassembled, attachments added to, improperly installed or used in a manner other than intended.

The company makes no other express or implied warranty or representation of any kind whatsoever including any

warranty of merchantability or tness for a particular purpose and all such other warranties are hereby included.

The Company’s maximum liability hereunder is limited to the purchase price of the product. In no event shall the Company be liable for any consequential, indirect, incidental, or special damages of any nature arising from the sale or use of

the product, whether based in contract, tort, strict liability, or otherwise.

Note: Some jurisdictions do not allow limitations on incidental or consequential damages or how long an implied warranty

lasts, so that the above limitations may not fully apply. This warranty gives specic legal rights and you may also have

other rights which may vary from jurisdiction to jurisdiction.

For complete warranty and repair information Call (888) 982-7800 or visit upsite.com

888.982.7800

www.upsite.com

6

Loading...

Loading...