Installation Guide

KoldLok® 60” Extended

Raised Floor Grommets

Part Numbers

3” x 60” - 10097

6” x 60” - 10098

Table of Contents

Tools & Preparation Required for Installation Page 2

Product Components Page 3

Modications of Grommets Page 4

Installation Procedures Page 5

General Information Page 6

Warranty Page 7

Each carton contains the following items:

KoldLok Extended Raised Floor Grommets (10)

Installation Guide (1)

Optional mounting tape or screws are available for custom installations.

Minimum order may apply. Please call for details.

• Non-Particulating Double Sided Adhesive Tape - 36 Yard Roll: Part No. 20107

• Self-Tapping Screws - 600 Pieces: Part No. 20197

Designer & Manufacturer

(888) 982-7800 www.upsite.com

1

Designer & Manufacturer

(888) 982-7800 www.upsite.com

Tools and Preparation Required for Installation

Tools Required:

• Bandsaw, table saw, miter saw or other appropriate non-ferrous metal cutting tool

(Warning: Do not attempt to cut aluminum with wood cutting blades.)

• Hand tools, including bolt cutters, pliers, hammer (or mallet), stake and metal le

Dimensions and Cutting Requirements Inches (W x D) Millimeters (W x D)

Part No. 10097 (3”x60”) - Overall size 60” x 5.998” 610 x 152mm

Maximum cutout size sealed 60” x 4” 610 x 102mm

Usable cable area 60” x 2.5” 610 x 64mm

Product height above the raised oor 1” w/ adhesive option 25mm w/ adhesive option

Part No. 10098 (6”x60”) - Overall size 60” x 9.025” 610 x 229mm

Maximum cutout size sealed 60 ” x 7” 610 x 178mm

Usable cable area 60” x 5.5” 610 x 140mm

Product height above the raised oor 1” w/ adhesive option 25mm w/ adhesive option

Preparation:

Determine the maximum dimensions of the trimmed cutout or opening in the raised oor. To

ensure stability and proper sealing, the KoldLok Extended Raised Floor Grommet should have

a minimum surface-to-oor contact of 1 inch (25mm) on three sides of the cutout (Does not

apply when grommet is installed facing down - See Install Procedures for more information)

Accurately measure and mark the desired length on the metal extrusion for cutting.

Determine whether to install grommets by screwing the product directly to the oor using

self-tapping screws or by applying double sided adhesive tape. Optional mounting screws or

non-particulating adhesive tape are available for custom installation. Minimum order may

apply. Please call for details.

Clean the tile and bottom surface of the grommet using an alcohol wipe or a clean cotton

cloth, damp with a solution of at least 50 percent isopropyl alcohol.

HELPFUL TIP: When choosing your cleaning cloth, do not use fabric or paper that will disin-

tegrate or leave particles that could interfere with the adhesive or contribute to airborne

contamination.

Designer & Manufacturer

(888) 982-7800 www.upsite.com

2

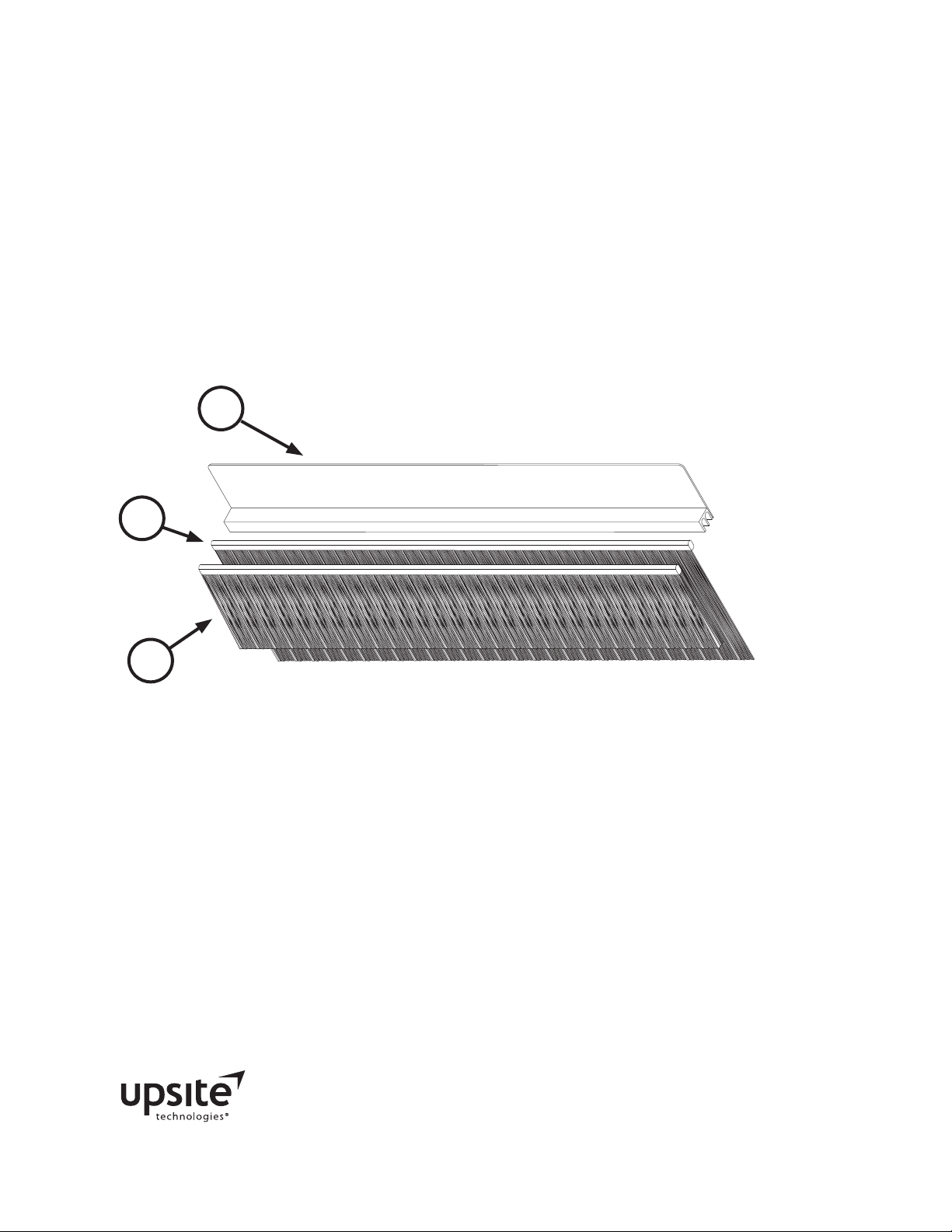

Product Components (see Figure 1)

1. KoldLok Extended Raised Floor Grommet Metal Extrusion

2. Removable Long Filament Brush

3. Removable Short Filament Brush (support brush)

Not Shown

Optional Non-Particulating Double Sided Adhesive Tape - 36 Yard Roll: Part No. 20107

Optional Self-Tapping Screws - 600 Pieces: Part No. 20197

Figure 1

1

2

3

Designer & Manufacturer

(888) 982-7800 www.upsite.com

3

Designer & Manufacturer

(888) 982-7800 www.upsite.com

Modication of Grommets

KoldLok Extended Grommets can be modied to seal large and unique openings in the

raised oor. The KoldLok 60” Extended Grommet will come complete with a removable

short lament brush (support brush), a removable long lament brush and the metal extru-

sion. The metal extrusion and brushes may be cut to a desired length.

*IMPORTANT: Data center best practices indicate that metal should not be cut within the

raised oor environment in order to protect equipment from harmful particulates. However, quick clean up of any debris or loose particulates is always recommended.

1. Cut the metal extrusion with an appropriate cutting tool. File any rough or sharp

edges.

2. Measure and cut both long and short lament brushes with bolt cutters. Crimp the

ends of the channels with pliers or a vice to prevent bristles from falling out.

3. Bend brush lament frames slightly, in order to secure them in the metal extrusion

channels.

4. Use a hammer (or mallet) to maneuver the brush into the metal extrusion so that all

components are ush. NOTE: Short lament brush should be installed in the bottom

extrusion channel in all installations.

Step 1

Step 2

Step 4

Designer & Manufacturer

(888) 982-7800 www.upsite.com

4

Installation Procedure with Self-Tapping Screws

*IMPORTANT: If the KolkLok Extended Raised Floor Grommets are being installed in an active data center, if possible, remove the oor tile and install the grommet outside of the

data center to prevent the risk of particulates.

1. Position the grommet over the cable cutout, with the metal extrusion resting on the

oor tile and grommet brush laments covering the cutout.

2. Ensure the metal extrusion does not rest on top of any cutout trim. If the grommet

cannot be placed without resting on the cutout trim, install the grommet with double

sided adhesive tape. See Installation Procedure with Double Sided Adhesive Tape

below.

3. Once the grommet is positioned as desired, drive a self-tapping screw through the

metal extrusion to attach the grommet to the raised oor.

4. Grommet may be installed with the extrusion facing up (surface mount) or down

(ush mount) depending on specic site placement requirements.

5. If the grommet is installed ush mount (with the metal extrusion facing down), then

place the short brush lament (support brush) on the bottom.

NOTE: Short lament brush should be installed in the bottom extrusion channel in all installations.

Installation Procedure with Double Sided Adhesive Tape

1. Measure double sided adhesive tape and cut to appropriate length with scissors. Re-

move one layer of adhesive backing and place tape rmly onto grommet frame.

2. Remove the second layer of adhesive backing from the tape. Position the grommet on

the oor tile and over the cable cutout.

3. Adhere the unit to the oor. Press down rmly on all portions of the unit to ensure a

secure connection to the raised oor surface.

4. If the grommet is installed ush mount (with the metal extrusion facing down), then

place the short brush lament (support brush) on the bottom.

Designer & Manufacturer

(888) 982-7800 www.upsite.com

5

Designer & Manufacturer

(888) 982-7800 www.upsite.com

General Information

Effective Installation of Cables

In order to minimize any air loss from under the raised-oor plenum, allow for adequate

slack in the cables. If the cables are under too much tension, the grommet laments may

be pulled apart, resulting in a V-shaped gap that will cause an increase in the volume of air

escaping from under the raised oor.

Cutting Raised Floor Tiles

Each raised oor tile manufacturer provides instructions to properly and safely modify their

products. Installers must be familiar with and observe tile manufacturer’s recommendations

with regard to applicable tools, cutting procedures, the design load capacity of the cut tile,

and any additional underoor support requirements for cut raised oor tiles.

When installing the KoldLok Extended Raised Floor Grommet on a newly cut hole, trim

the cutout prior to installation to protect cables from damage.

Maintaining Proper Cooling of Equipment

Failure to follow computer manufacturer’s guidelines for maintaining proper cooling may

result in the overheating of equipment. Ensure that there is adequate airow to the intake

side of the computer equipment or cabinets through devices such as perforated oor tiles or

grates. Achieving proper airow to the intake side of computer equipment and/or cabinets is

the responsibility of the customer.

Safety Requirements

Installers must be familiar with standard safety and risk management practices when work-

ing on server rack equipment or in data center environments.

Customer Support

If you have any questions, please

contact us direct at (505) 798-0200

or Toll Free at (888) 982-7800

Email us at info@upsite.com

P/N 60227 Rev. A © 2012

Printed on

Recyclable Paper

Designer & Manufacturer

(888) 982-7800 www.upsite.com

6

Limited Warranty

Upsite Technologies, Inc. (the Company) warrants to the original purchaser that products delivered

hereunder will be free of defects in materials and workmanship for a period of twelve (12) months

from the date of purchase (the “Warranty Period”).

The Company shall, at its option, within the Warranty Period, either repair or replace free of charge,

any product or part thereof found, upon the Company’s inspection, to be defective in materials and

workmanship, and will return the repaired or replaced product to the purchaser at Company’s expense.

For warranty service and shipping instructions, contact the Company at the telephone number shown

below. If the product is under warranty and the defect appears to be covered by this Limited Warranty, the Company will issue to the purchaser a Notice of Authorization For Warranty Return. Products

returned to the Company for warranty service must be accompanied by a statement of defect, the

Notice of Authorization for Warranty Return provided by the Company, and proof of purchase.

This Limited Warranty is conditioned on the following:

1. The Company must be notied within 12 months of purchase and have been given the opportunity

of inspection by return of any alleged defective product free and clear of all liens and encumbrances to the Company or its manufacturer; and

2. The product must not have been abused, misused, or improperly maintained, and/or repaired during such period; and

3. Such defect has not been caused by corrosion or exposure to other than ordinary wear and tear;

and

4. The installation and use of the product has been in accordance with the manufacturer’s instruc-

tions and not been modied or customized to include but not limited to cut, resized, burned,

glued, bent, re-shaped, disassembled, attachments added to, improperly installed or used in a

manner other than intended.

The company makes no other express or implied warranty or representation of any kind whatsoev-

er including any warranty of merchantability or tness for a particular purpose and all such other

warranties are hereby included.

The Company’s maximum liability hereunder is limited to the purchase price of the product. In no

event shall the Company be liable for any consequential, indirect, incidental, or special damages of

any nature arising from the sale or use of the product, whether based in contract, tort, strict liability,

or otherwise.

Note: Some jurisdictions do not allow limitations on incidental or consequential damages or how long

an implied warranty lasts, so that the above limitations may not fully apply. This warranty gives specic legal rights and you may also have other rights which may vary from jurisdiction to jurisdiction.

For complete warranty and repair information Call (888) 982-7800 or visit upsite.com

U.S. Patent No. 6,632,999 and International Patents Pending

Designer & Manufacturer

(888) 982-7800 www.upsite.com

7

Loading...

Loading...