Uponor Climate Control Zoning System II, A3800167, A3801165, A3800165, A3080301 Installation And Operation Manual

...Page 1

Climate Control Zoning System II

installation and operation manual

Page 2

Climate Control Zoning System II

installation and operation manual

is published by

Uponor, Inc.

5925 148th Street West

Apple Valley, MN 55124 USA

T 800.321.4739

F 952.891.2008

Uponor Ltd.

2000 Argentia Rd., Plaza 1, Ste. 200

Mississauga, ON L5N 1W1 CANADA

T 888.994.7726

F 800.638.9517

uponorpro.com

© 2016 Uponor

All rights reserved.

First Edition October 2016

Printed in the United States of America

Uponor has used reasonable efforts in collecting, preparing

and providing quality information and material in this manual.

However, system enhancements may result in modication of

features or specications without notice.

Uponor is not liable for installation practices that deviate from

this manual or are not acceptable practices within the mechanical trades.

Page 3

Table of contents

Foreword ...................................iii

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Safety symbols .................................... iv

Safety measures ................................... iv

Power ........................................... iv

Technical constraints ...............................iv

Limitations for radio transmission ...................... iv

Compliance ....................................... iv

Proper disposal .................................... iv

Chapter 1: System overview ...................1

System example ................................... 1

System components ................................ 1

Base unit ......................................... 2

Main characteristics ............................... 2

Options ........................................ 2

Components .................................... 2

Thermostats ......................................3

Dial thermostats ................................... 3

Main characteristics ............................... 3

Components .................................... 3

Digital thermostats .................................3

Main characteristics ............................... 3

Components .................................... 3

Expansion module .................................. 4

Main characteristics ............................... 4

Components .................................... 4

Uponor actuators ................................... 4

On/off control .................................... 4

PWM control .................................... 4

Autobalancing ..................................... 4

Low hysteresis temperature .......................... 4

MicroSD card .....................................4

Removing the expansion module ...................... 10

Connecting components to the base unit ................ 10

Connecting actuators to the base unit .................. 11

Connecting a circulation pump to the base unit ........... 11

Connecting a boiler (optional) ......................... 12

Connecting a boiler to the base unit .................... 12

Connecting the base unit to AC power .................. 12

Testing actuators ................................... 13

Chapter 4: Installing thermostats and sensors ....15

Thermostat placement .............................. 15

Labeling thermostats ................................ 15

Inserting batteries .................................. 15

Connecting an external sensor to a thermostat (optional) ... 15

Digital thermostats .................................16

Attaching a thermostat to a wall ..................... 16

Using a wall bracket (recommended) ................. 16

Using a screw and wall plug ........................ 16

Using an adhesive strip (not included) ................ 16

Attaching to a table stand .......................... 17

First setup of digital thermostats ....................... 17

Select thermostat control mode .....................17

Temperature setpoint ............................. 17

Registering thermostats in the base unit ................ 18

Finishing installation ................................ 19

Chapter 5: Operating the base unit ..............21

Sequence of operation .............................. 21

Normal operation ................................... 21

Run mode ........................................ 21

Exit to run mode ................................. 21

Resetting the base unit .............................. 21

Unregistering channels in the base unit ................. 21

Unregistering all channels ............................ 22

Chapter 2: Installation setup ...................5

Installation procedure ............................... 5

Installation preparation .............................. 5

Placement ...................................... 5

Installation example ................................6

Chapter 3: Installing the base unit ..............7

Placement ........................................ 7

Modular placement ............................... 7

Attaching and detaching components ................... 7

Installing the antenna ............................... 8

Attaching the antenna to a base unit ................. 8

Attaching the antenna to a wall ...................... 8

Connecting the antenna cable ......................8

Attaching the base unit to a wall ....................... 9

Mounting brackets ................................ 9

Screws and wall plugs ............................. 9

Connecting the expansion module (optional) ............. 9

Chapter 6: Operating dial thermostats ...........23

Thermostat components ............................. 23

Adjusting the temperature ............................ 23

Replacing batteries ................................. 23

Factory reset ...................................... 24

Chapter 7: Operating digital thermostats .........25

Thermostat components ............................. 25

Display layout ..................................... 25

Operating buttons .................................. 26

Start up .......................................... 26

Adjusting temperature ............................... 26

Run mode ........................................ 26

Settings .......................................... 26

Sensor options .................................... 27

Adding a sensor ................................... 27

High oor temperature limitation ....................... 27

Low oor temperature limitation ....................... 28

Climate Control Zoning System II installation and operation manual | Table of contents l i

Page 4

Display unit ....................................... 28

Room temperature calibration ......................... 28

Replacing batteries ................................. 28

Factory reset ...................................... 28

Chapter 8: Maintenance .......................29

Manual preventive maintenance ....................... 29

Automatic preventive maintenance ..................... 29

Corrective maintenance ............................. 29

Fallback mode ................................... 29

Resetting the controller ............................ 29

Controller LEDs .................................... 29

Restore from backup ................................ 30

Preparation ..................................... 30

Restore from backup to new base unit ................ 30

Chapter 9: Troubleshooting ....................31

General troubleshooting ............................. 31

Troubleshooting after installation ...................... 32

Digital thermostats .................................32

Dial thermostats ................................... 33

Base unit alarms ................................... 33

Contact the installer ................................ 33

Installer instructions ............................... 33

Appendix A: Technical data ....................35

General ........................................ 35

Thermostats ..................................... 35

Antenna ........................................ 35

Base unit ....................................... 35

Technical specications ............................. 36

Cables ......................................... 36

Base unit layout .................................... 36

Base unit wiring .................................... 37

Expansion module wiring ............................ 37

Dimensions ....................................... 38

Base unit and antenna ............................ 38

Base unit with expansion module and antenna ......... 38

Thermostats ..................................... 38

Appendix B: Installation report .................39

ii | uponorpro.com

Page 5

Foreword

Uponor has prepared this document and all the content

included solely for information purposes. The contents of this

document (including graphics, logos, icons, text, and images)

are copyrighted and protected by worldwide copyright laws

and treaty provisions. Modication or use of any of the contents

of the document for any other purpose is a violation of Uponor's

copyright, trademark and other proprietary rights.

The presumption for the document is all safety measures have

been fully complied with and, further, that the Climate Control

Zoning System II, including any components that are part of

such system, covered by the manual:

• Is selected, planned and installed and put into operation by

a licensed and trained installer in compliance with current

(at the time of installation) installation instructions provided by

Uponor as well as in compliance with all applicable building

and plumbing codes and other requirements and guidelines;

• Has not been (temporarily or continuously) exposed to

temperatures, pressure and/or voltages that exceed the

limits printed on the products or stated in any instructions

supplied by Uponor;

• Remain in its originally installed condition and is not

repaired, replaced or interfered with, without prior written

consent of Uponor;

• Is connected to potable-water supplies or compatible

plumbing, heating and/or cooling products approved or

specied by Uponor;

• Is not connected to or used with non-Uponor products,

parts or components except for those approved or

specied by Uponor; and

• Does not show evidence of tampering, mishandling, insufcient

maintenance, improper storage, neglect or accidental damage

before installation and being put into operation.

While Uponor has made efforts to ensure the document is

accurate, Uponor does not guarantee or warrant the accuracy

of the information contained herein. Uponor reserves the right

to modify the specications and features described herein, or

discontinue manufacture of the Climate Control Zoning System

II described at any time without prior notice or obligation. The

manual is provided "as is" without warranties of any kind, either

expressed or implied. The information should be independently

veried before using it in any manner.

To the fullest extent permissible, Uponor disclaims all

warranties, expressed or implied, including, but not

limited to, the implied warranties of merchantability,

tness for particular purpose and non-infringement.

This disclaimer applies to, but is not limited to, the accuracy,

reliability or correctness of the manual.

Under no circumstances shall Uponor be liable for any

indirect, special, incidental or consequential damages

or loss that result from the use of or the inability to use

the materials or information in the manual, or any claim

attributable to errors, omission or other inaccuracies in

the manual, even if Uponor has been advised of the

possibility of such damages.

This disclaimer and any provisions in this document do not

limit any statutory rights of consumers.

Climate Control Zoning System II installation and operation manual | Foreword l iii

Page 6

Overview

Uponor strongly recommends reading this entire installation

and operation manual before installing the control system.

Safety symbols

The following symbols are used in this document to indicate

special precautions when installing and operating any

Uponor equipment.

Warning! Ignoring warnings can cause injury or

damage to components.

Caution: Ignoring cautions can cause

equipment malfunctions.

Safety measures

Conform to the following measures when installing and

operating any Uponor equipment.

• Read and follow all instructions in this document.

• Ensure a trained installer performs all work in accordance

with local regulations.

• Do not make changes or modications not specied

in this document.

• Switch off all power supply before starting any wiring work.

• Do not use water to clean Uponor components.

• Do not expose Uponor components to ammable

vapors or gases.

Uponor cannot accept any responsibility for damage or

breakdown that can result from ignoring these instructions.

Power

Warning! The Uponor system uses 24 VAC, 60 Hz

power. In case of emergency, immediately disconnect

the power.

Technical constraints

Compliance

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received,

including interference that may cause undesired operation.

Note: The grantee is not responsible for any changes or

modications not expressly approved by the party responsible

for compliance. Such modications could void the user’s

authority to operate the equipment.

This device complies with Industry Canada licence-exempt RSS

standard(s). Operation is subject to the following two conditions:

(1) This device may not cause interference, and

(2) This device must accept any interference, including

interference that may cause undesired operation of

the device.

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

Caution: To avoid interference, keep installation/data

cables away from power cables of more than 50 VAC.

Limitations for radio transmission

The Uponor Climate Control Zoning System II uses radio

transmission. The frequency used is reserved for similar

applications, and the chances of interference from other radio

sources are very low.

However, in some rare cases, it might not be possible to

establish perfect radio communication. The transmission

range is sufcient for most applications, but each building has

different obstacles affecting radio communication and maximum

transmission distance. If communication difculties exist, Uponor

recommends relocating the antenna to a more optimal position

and ensuring radio sources are at least 16" (40 cm) apart for

solving exceptional problems.

iv | uponorpro.com

Consult the dealer or an experienced radio/TV technician for help.

Proper disposal of waste electrical and

electronic equipment

This marking shown on the product or its literature

indicates it should not be disposed with other household

waste at the end of its working life. To prevent possible harm

to the environment or human health from uncontrolled waste

disposal, please separate this form from other types of wastes

and recycle it responsibly to promote the sustainable reuse of

material resources.

Contact your installer or local government ofce for details

about environmentally safe recycling.

Page 7

Chapter 1

System overview

The Uponor Climate Control Zoning System II is for use

with underoor heating installations and combines comfort,

user friendliness and temperature control for each individual

room of a home.

The system consists of a base unit, thermostats and actuators.

The base unit manages the operation of the actuators when

the thermostats detect a demand for the heating.

The system is controlled by different types of thermostats.

Designed for maximum comfort, the thermostats communicate

with the base unit by radio link. It is possible to mix the

different types of thermostats in the same installation.

System example

The illustration below shows the system with several installation

options and thermostats.

24V

60Hz

Figure 1-2: Installation examples

C

A

B

Figure 1-1: Installation options

Item Part no. Description

A A3800167 Wireless Digital Thermostat (T-167)

B A3800165 Wireless Dial Thermostat (T-165)

C A3801165 Wireless Base Unit, 6 zones (X-165)

D A3010100/

A3080301

External relay for pumps

115V

60Hz

D

Note: The oor sensor can connect to both digital and

dial thermostats.

System components

Item Part no. Description

A A3801165 Wireless Base Unit, 6 zones (X-165)

B A3801160 Wireless Base Unit Expansion Module,

6 zones (M-160)

C A3800167 Wireless Digital Thermostat (T-167)

D A3800165 Wireless Dial Thermostat (T-165)

C

D

A

B

Figure 1-3: System components

Climate Control Zoning System II installation and operation manual | Chapter 1 – System overview l 1

Page 8

Base unit

The base unit operates the actuators, which in turn affect the

ow of the supply water, to change the indoor temperature

using information transmitted from registered thermostats

and system parameters.

Up to six channels and eight actuators can be operated by the

base unit, which is typically located near the radiant manifolds.

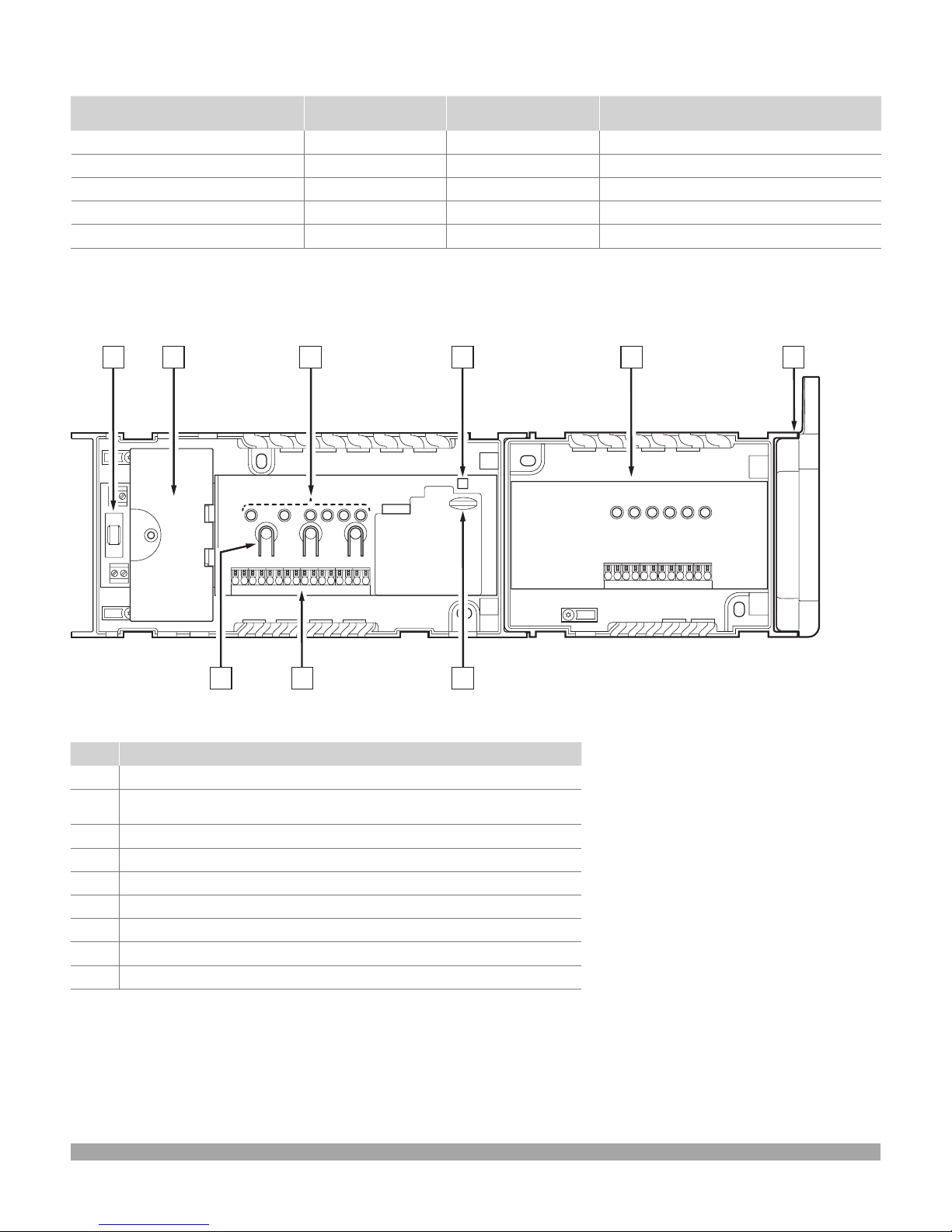

Components

D

The radiant illustration below shows the base unit with the

antenna and actuators.

24

VAC

24

VAC

24

VAC

Figure 1-4: Base unit

Caution: Only 24 VAC Uponor actuators are

compatible with the controller.

Main characteristics

• Autobalancing energy-management function

• Electronic control of actuators

• Connection of maximum eight actuators

• Two-way communication with up to six room thermostats

• Separate relays for control of pump and boiler

• Valve and pump exercise

• Logging, backup and updates via microSD card

A

B

C

E

F

Figure 1-5: Base unit components

Item Description

A Wireless Base Unit (A3801165)

B Antenna

C Antenna connection cable

D MicroSD card

E Mounting bracket

F Mounting hardware

Options

• Expand base unit with optional expansion module (A3801160)

which adds an extra six channels and six actuator outputs

• Modular placement (detachable antenna)

• Cabinet or wall mounted (with mounting bracket or

supplied screws)

• Free placement and orientation when installing the base unit

(except the antenna which must be installed vertically)

2 | uponorpro.com

Page 9

Thermostats

The thermostats communicate with the base unit through radio

transmissions and can be used individually or in combination.

All the thermostats use AAA batteries.

Important! The thermostat is affected by the

temperature of the surrounding surfaces as

well as the ambient air temperature.

Dial thermostats

Main characteristics

• Adjust temperature setpoint with large dial

• 70ºF (21°C) position is marked on the dial

• LED ring indication when twisting the dial

(changing temperature setpoint)

• Setpoint range is 41°F to 95°F (5°C to 35°C)

• LED in lower-right corner indicating

whether a heating demand exists

• Can be placed up to 98 ft. (30 m) away from the controller

Components

Digital thermostats

Main characteristics

• Shows ambient, set temperature or relative humidity

on the display

• Temperature settings adjusted using +/- buttons on the front

• Backlit display, dims after 10 seconds of activity

• Displays Celsius or Fahrenheit

• Heating demand as well as low battery indication on display

• Displays software version during power up sequence

• Setpoint range is 41°F to 95°F (5°C to 35°C)

• Room temperature regulation with use of optional external

temperature sensors

• Displays optional temperature sensor values if sensors

are connected and relevant room temperature regulation

is activated

• Relative humidity limit indicated in display

• Can be placed up to 98 ft. (30 m) from the controller

Components

C

A

Figure 1-6: Dial thermostat components

Item Description

A Wireless Dial Thermostat (A3800165)

B Wall bracket

C 2 AAA 1.5 V batteries

D Mounting hardware

B

C

D

E

A

Figure 1-7: Digital thermostat components

Item Description

A Wireless Digital Thermostat (A3800167)

B Wall bracket

C Stand

D 2 AAA 1.5 V batteries

E Mounting hardware

F Connection terminal

B

D

F

Climate Control Zoning System II installation and operation manual | Chapter 1 – System overview l 3

Page 10

Expansion module

Main characteristics

• Adds six channels and actuator outputs to an existing base unit

• Easy plug-in installation on existing base unit with additional

wiring needed

• Register up to six extra thermostats to the system

• Electronic control of actuators

• Valve exercise

Important! Only one expansion module is supported

per controller.

PWM control

PWM control is used when the Autobalancing function is active.

When installing a system with PWM control, the system is

balanced automatically.

A

B

Components

B

A

C

Figure 1-8: Expansion module components

Item Description

A Wireless Base Unit Expansion Module (A3801160)

B Mounting bracket

C Mounting hardware

Uponor actuators

Uponor actuators are mounted on top of the manifold valves

and operated using either on/off signals or pulse width

modulation (PWM) signals.

On/off control

When installing a system with on/off control, manual balancing

of the system is required.

As soon as the temperature measured at a thermostat is lower

(heating mode) than the setpoint temperature, a demand to

change the room temperature is created and sent to the base

unit. The base unit will open the actuators according to current

settings. Once the set temperature is reached, this information

is sent and the actuators are closed. The indicator window on

the actuator shows, with a white bar, how much it is opened.

If the window is completely lled with white it is fully opened,

no white bar shown means the actuator is closed.

Figure 1-9: Actuator valve status

A Actuator has closed the valve (empty indicator)

B Actuator has opened the valve (white indicator)

Autobalancing

The base unit can operate the actuator outputs by either on/off

signals or by Autobalancing (on by default), using PWM signals.

Autobalancing is a function where the system calculates the

actual energy need of single rooms and adapts the output

power of each loop to its length. This means a short loop

might get 20% on time while a long loop might get about 60%.

The automatic balancing continues through the seasons

and throughout the household’s changing lifestyle and

usage patterns, removing the need of manual balancing.

This gives more even oor temperatures and faster system

reaction times with lower energy consumption than any

standard on/off system.

Low hysteresis temperature

Uponor uses a low hysteresis temperature for best performance

of the system. It is used for high-control accuracy by deciding

when to start and stop heating and cooling, based on information

from sensors and setpoint values.

MicroSD card

The system uses a microSD card for cloning automatic backup

(settings and thermostat registration data), manual restoration

of backup, data logging (room data, controller data, system data

and events) and upgrading software.

Time to open and close an actuator is one minute.

4 | uponorpro.com

Page 11

Chapter 2

Installation setup

Installation procedure

Uponor recommends following the process described below

to guarantee the best possible installation results.

Step Procedure

1 Installation preparation

2 Installing the base unit

3 Connecting the expansion module (optional)

4 Installing themostats

5 Finish installation

Installation preparation

Before starting the installation:

• Verify the contents of the package with the packing list.

• Check whether an external temperature sensor is

to be installed with a compatible thermostat.

• Study the wiring diagram in the end of this manual or

inside the base unit.

Figure 2-1: Base unit with wiring diagram

Placement

To determine where to best place the Climate Control

Zoning System II components, follow these guidelines:

• Ensure the base unit can be installed close to the manifold.

Note: Each manifold must have its own controller

(unless proximity of second manifold allows for it).

• Ensure the base unit is supplied by a 24 VAC,

50 VA transformer.

• Ensure all installed components are protected from

running or dripping water.

Climate Control Zoning System II installation and operation manual | Chapter 2 – Installation setup l 5

Page 12

A3800165 A3800165A3800167

A3800167

A3800165

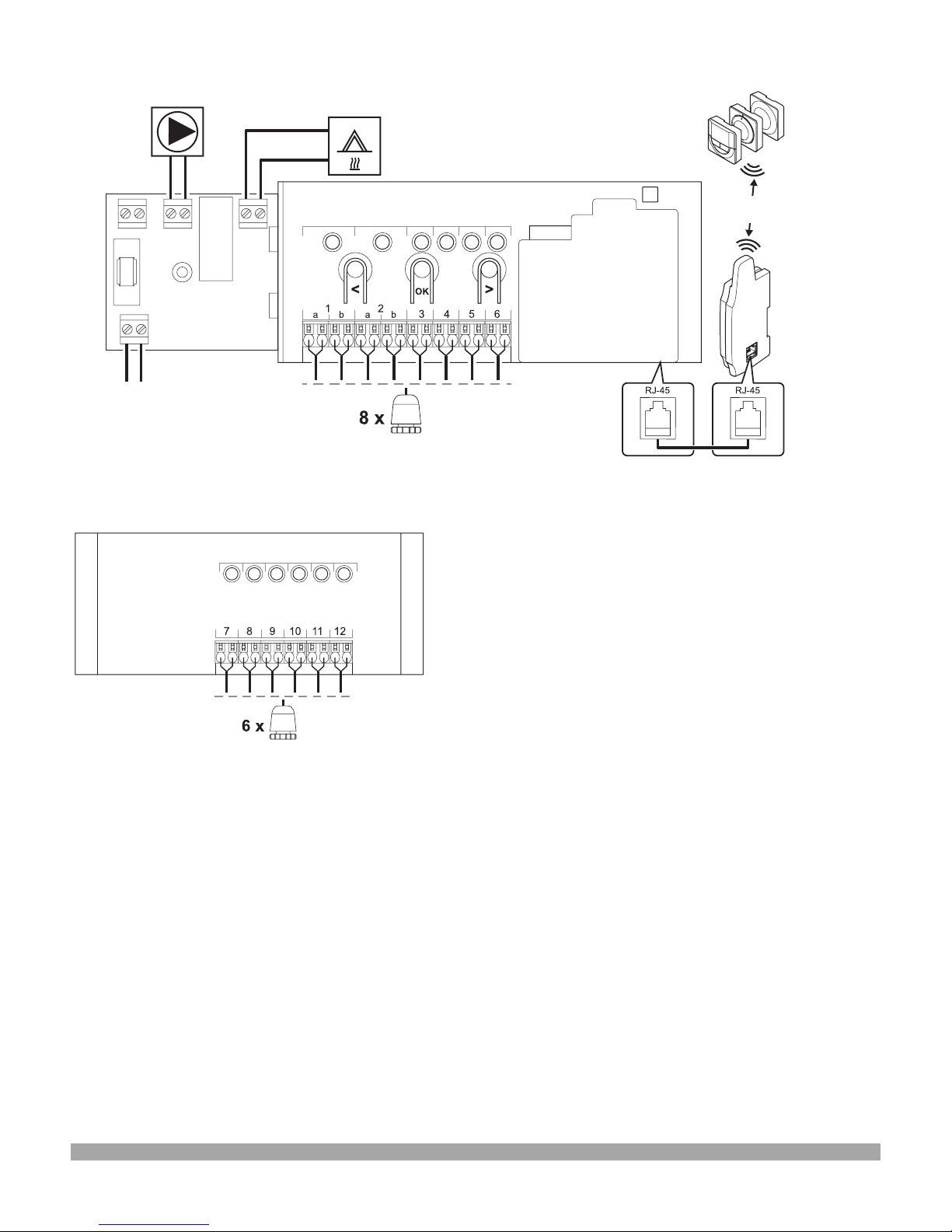

Installation example

The gure below shows an installation example of the

base unit (six channels) with an optional expansion module

(six extra channels) using thermostats and actuators.

Thermostats will regulate each room according to their set

temperatures.

• Thermostat 01 controls the actuators on channels

01a, 01b, 02a and 02b with an optional AC sensor.

• Thermostat 03 controls the actuators on channels 03 to 05.

• Thermostat 06 controls the actuators on channels 06 and 07.

• Thermostat 08 controls the actuators on channels 08 to 10

with an optional AC sensor.

• Thermostat 12 controls the actuators on channels 11 and 12.

Option A

• External temperature sensor

• Floor temperature sensor

Option B

• Outdoor temperature sensor

01 08 1203

Option

A or B

06

T

T TT T

Option

A or B

3801165 A3801160

S

T

24

VAC24VAC24VAC24VAC24VAC24VAC24VAC24VAC24VAC24VAC24VAC24VAC

02a 02b01b01a 09 10 11 12080704 05

030201 04 05

03

06

Note: Refer to page 37 for additional

wiring information.

Caution: Only 24 VAC

Uponor actuators are

compatible with the

base unit.

Option A Option B

Figure 2-2: Installation example

6 | uponorpro.com

Page 13

Chapter 3

Installing the base unit

Placement

• Position the base unit just above the manifold, ensuring

24 VAC, 50 VA power is available.

• Check that the cover of the base unit can be easily removed.

• Check that connectors and switches are easily accessible.

Modular placement

The base unit is designed with the option of modular

placement in mind. This means that all major parts are

detachable and can be placed separately (some extra

wiring may be required depending on placement).

Attaching and detaching components

The components can either snap on or off without having

to remove the covers.

Figure 3-2: Attaching and detaching base unit components

Caution: Be sure to attach the expansion module

by snapping it into place via the connection pins on

the module.

Figure 3-1: Base unit

Important! Wires between transformers and

base unit must be disconnected prior to detaching

the transformer.

Climate Control Zoning System II installation and operation manual | Chapter 3 – Installing the base unit l 7

Page 14

Installing the antenna

The antenna can be attached to the right-hand side of the

base unit or to the wall. If the base unit is installed inside a

metal cabinet, the entire antenna must be placed vertically

outside the cabinet, as illustrated below.

Attaching the antenna to a wall

The illustration below shows the antenna attached to a wall

with screws (A) or double-sided adhesive strips (B).

Figure 3-3: Antenna installation options

Important! The antenna must be installed

vertically for best coverage.

Attaching the antenna to a base unit

The ilustration below shows the antenna attached to the

right-hand side of the base unit.

A

70 mm

B

Figure 3-4: Attaching the antenna to a base unit

8 | uponorpro.com

Figure 3-5: Attaching the antenna to a wall

Connecting the antenna cable

Connect the antenna to the base unit using the supplied

antenna cable.

Figure 3-6: Connecting the antenna cable

Page 15

Attaching the base unit to a wall

The base unit is delivered in a kit that includes screws, wall

plugs and a mounting bracket.

Screws and wall plugs

The gure below shows base unit mounting hole positions

and how to attach it to the wall using screws and wall plugs.

Mounting brackets

Attach the mounting bracket to the wall using the screws and

wall plugs, then attach the base unit to the mounting bracket.

The gure below shows how to attach (A) and detach (B)

the base unit using a mounting bracket.

B

A

A

B

110 mm

80 mm

Figure 3-8: Attaching base unit with screws and wall plugs

Connecting the expansion module (optional)

The illustration below shows how to connect the expansion

module to the base unit.

1

2

1

Figure 3-7: Attaching the base unit to a wall

Caution: Make sure the controller cannot slide

off the bracket if mounting it in any other position

than horizontal.

Figure 3-9: Connecting optional expansion module

Important! Only one expansion module is supported

per base unit.

Climate Control Zoning System II installation and operation manual | Chapter 3 – Installing the base unit l 9

Page 16

Removing the expansion module

B D G H

C E F

A

AB

The illustration below shows how to remove the expansion

module from the base unit.

1.2 mm

8 mm

1

2

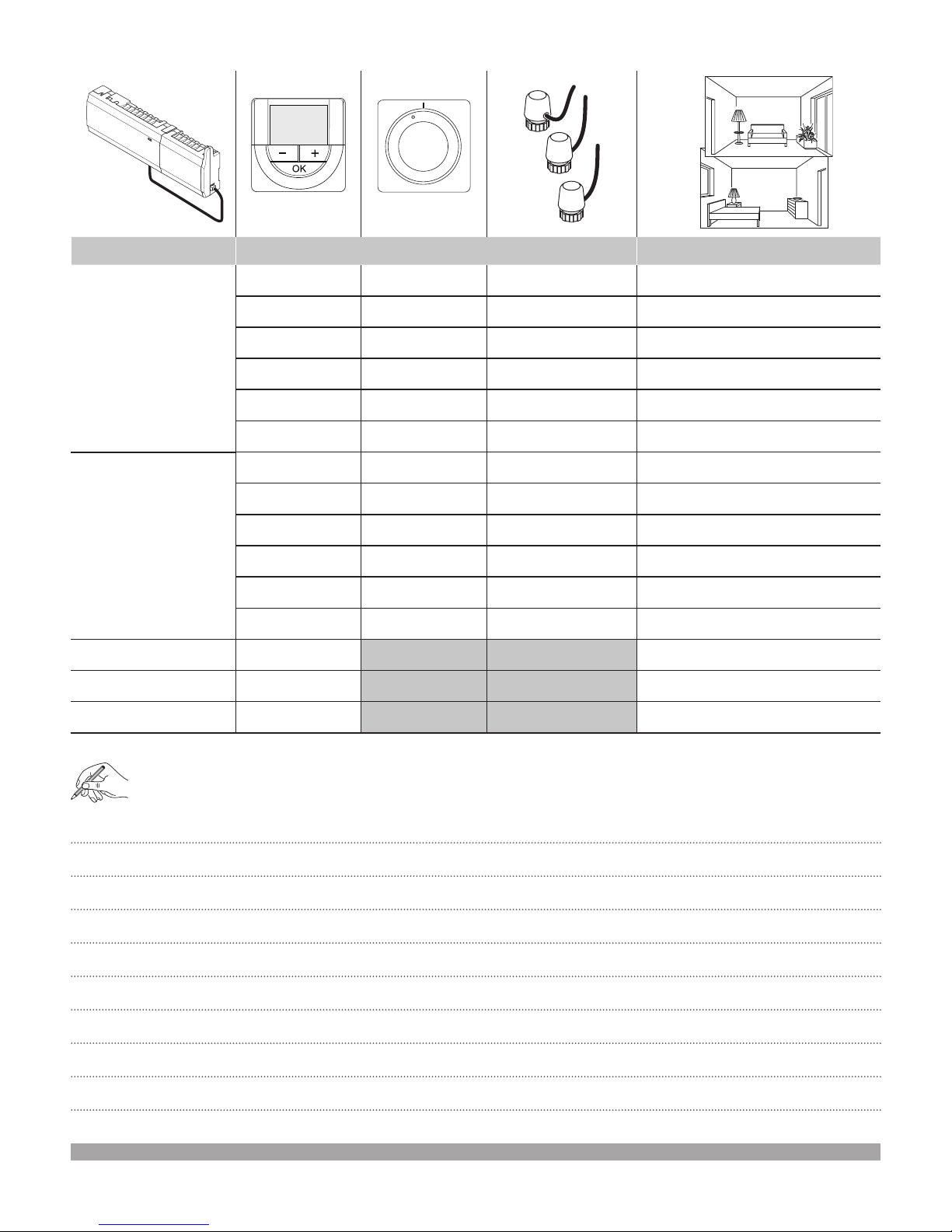

Connecting components to the base unit

Refer to the wiring diagram found at the end of this document.

The illustration below shows the inside of the base unit.

Figure 3-10: Removing the expansion module

1. Place a wide, at-head screwdriver in the slot between

the expansion module and the other unit and twist until

the snap-in lock releases. Repeat for the other side.

2. Remove the expansion module. Use caution not to bend

the connection pins.

Figure 3-11: Connecting components to the base unit

Item Description

A Fuse

B Optional inputs and outputs for pump management,

boiler managment

C Channel registration buttons

D LEDs for channels 01 to 06

E Quick connectors for actuators

F MicroSD card

G Power LED

H Wireless antenna

I LEDs for channels 07 to 12

J Wireless Base Unit Expansion Module (A3801160)

10 | uponorpro.com

Page 17

Connecting actuators to the base unit

Each thermostat can control one or more channels.

To simplify installation and maintenance, Uponor

recommends that actuators controlled by the same

thermostat wired in sequence to the channels.

Connect the actuators to the base unit as follows.

Connecting a circulation pump to the base unit

A3010100

R/T

W/T

A3080301

1. Lead the cables from the actuators through cable entries

in the bottom of the base unit frame (see Figure 3-12).

1

Figure 3-12: Connecting actuators to the base unit

2. Press, without turning, with a thin screwdriver,

on the white button of the quick connector.

3. Insert a wire in the quick connector.

4. Remove the screwdriver.

Important! Identify the room supplied by each loop

on the manifold and determine which channel it must

be connected to.

PUMP

PUMP

Figure 3-13: Connecting a circulation pump to the base unit

1. Study the wiring diagram in the end of the manual or inside

the cover of the base unit, to locate the connector positions.

2. Ensure power is disconnected from both the base unit and

the circulation pump.

3. Remove the screw and open the cover for the optional

connections compartment.

Climate Control Zoning System II installation and operation manual | Chapter 3 – Installing the base unit l 11

4. Route the wires to/from the pump relay via a cable entry.

5. Connect the wires to/from the pump relay as shown and

connect to the terminals labeled PUMP.

Important! There is no power in the controller to

supply the pump. The pump connector in the base unit

provides only a dry contact to switch off and on the

power connection to the pump.

6. Secure the wires properly inside the enclosure.

7. Close and secure the lid to the optional

connections compartment.

A circulation pump is now connected to a relay module

and activated.

Page 18

Connecting a boiler (optional)

BOILER

The controller includes a boiler relay that can be used to

send a signal to either re the heat source or to open a

two-port motorized zone valve positioned on the ow to

the underoor heating manifold. If the relay is used to open

a zone valve, the dry contact on the zone valve should

be used to re the heat source.

Alternatively, the boiler relay can be used to send a demand

signal to the water temperature controller. The additional

contacts on the water temperature controller should then be

used to re the heat source.

The boiler can be connected either on the base unit or by

using a wireless relay module.

Connecting a boiler to the base unit

The illustration below shows how to connect a boiler to

the base unit.

4. Route the wires from/to the boiler via a cable entry.

5. Connect the boiler to the connection labeled BOILER.

Important! There is no power in the base unit to

supply the boiler. The boiler connector in the controller

provides only a dry contact to switch on and off the

power connection to the boiler.

Connecting the base unit to AC power

Refer to the instructions below to conclude the installation

of the base unit.

1. Check that all wiring is complete and correct.

• Actuators

• Heating device

• Circulation pump

2. Ensure the 24 VAC compartment of the base unit is

closed and the xing screw is tightened.

3. Connect the power cable to a 24 VAC, 50 VA transformer

as required by local codes.

BOILER

Figure 3-14: Connecting a boiler to the base unit

Important! This connection requires a dry contact

sensing input in the boiler.

1. Study the wiring diagram in the end of the manual or inside

the cover of the base unit to locate the connector positions.

2. Ensure power is disconnected from both the base unit

and the boiler.

3. Remove the screw and open the cover for the optional

connections compartment.

12 | uponorpro.com

Page 19

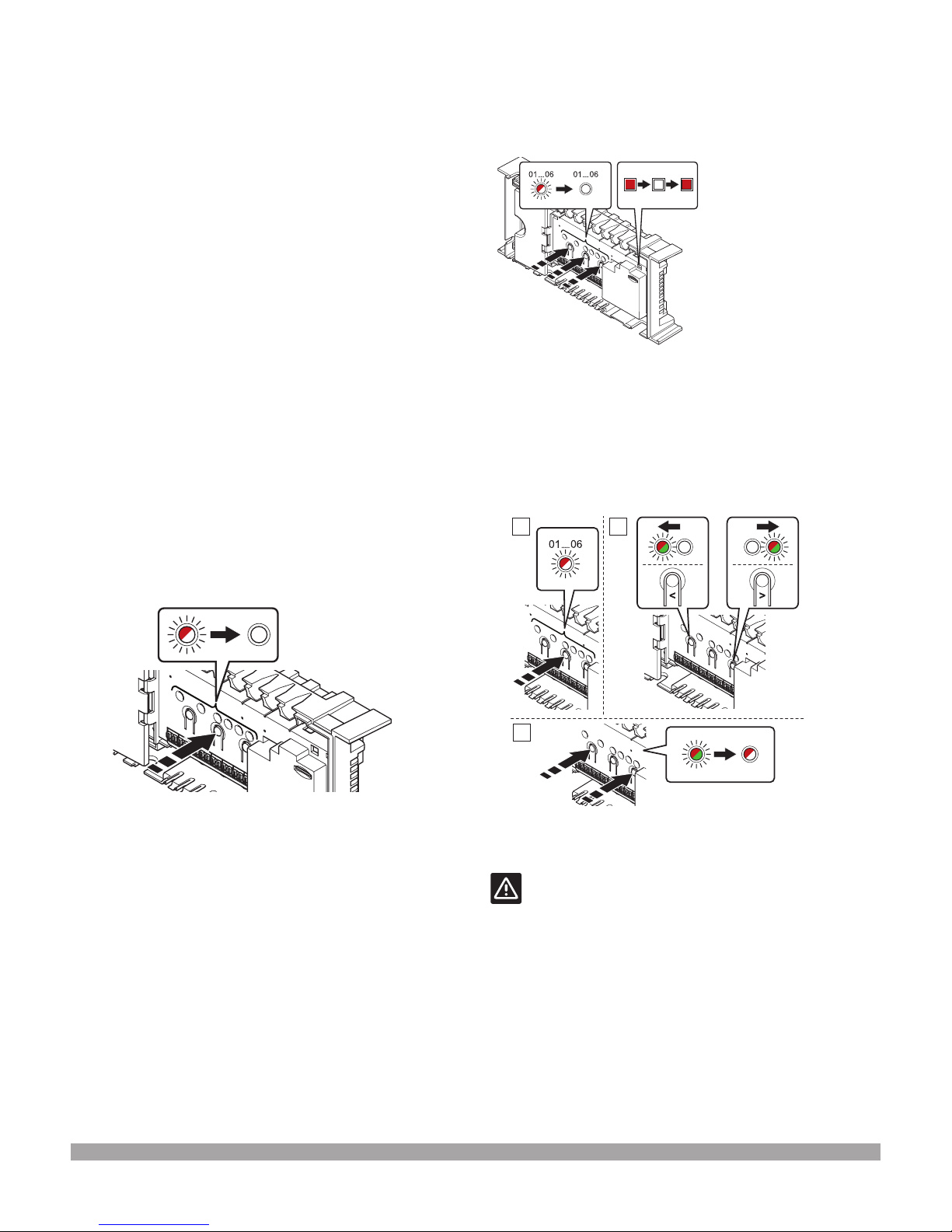

Testing actuators

It is possible to manually open or close an actuator connected

to a channel when testing the system. Testing an actuator takes

about 10 minutes and the base unit automatically returns to run

mode when nished.

1 2

43

10 min

10 min

Important! Activated test/cycle mode for a channel is

indicated with a lit LED, when in forced mode.

Refer to the instructions below to test the actuators.

1. Enter test/cycle mode by pressing the > button while

in run mode.

2. Use the < or > buttons to select a channel. Selected channel

is indicated with a LED ashing red.

3. Press the OK button to activate test/cycle mode for the

selected channel. The LED of the channel turns solid red,

which means the base unit opens the actuator on the selected

channel, and the system exits to run mode. If the LED keeps

ashing, the channel cannot be chosen for forced operation.

If the LED does not turn solid red, it might be the actuator

management delaying the actuator if more than eight

channels is opened at the same time. Otherwise refer to

the troubleshooting section.

4. Wait for 10 minutes, or enter forced mode again, choose

the activated channel and press the OK button for the

system to end the test.

A test/cycle operation can always be canceled by entering

forced mode, selecting the active channel and pressing

the OK button.

Figure 3-15: Testing actuators

Climate Control Zoning System II installation and operation manual | Chapter 3 – Installing the base unit l 13

Page 20

14 | uponorpro.com

Page 21

Chapter 4

Installing thermostats and sensors

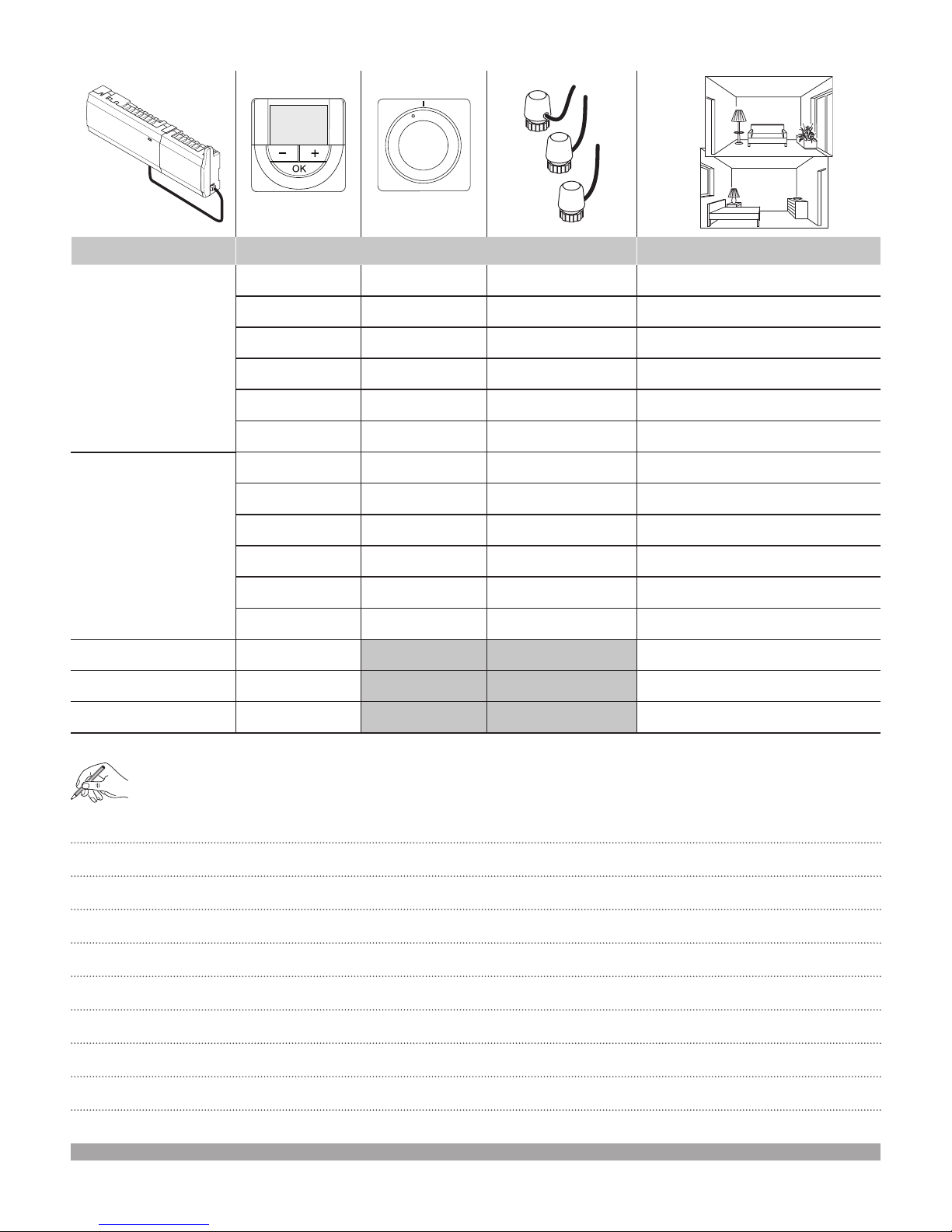

The following thermostats can be connected to the system:

• Wireless Dial Thermostat (A3800165)

• Wireless Digital Thermostat (A3800167)

Thermostat placement

Refer to the following guidelines when positioning

the thermostats:

1. Select an indoor wall and a distance 5 ft. (1.5 m)

above the oor.

2. Ensure the thermostat is away from direct solar radiation.

3. Ensure the thermostat will not be heated through the wall by

sunshine.

4. Ensure the thermostat is away from any source of heat

(e.g. television set, electronic equipment, replace, spotlights).

5. Ensure the thermostat is away from any source of humidity

and water contact.

6. Ensure the thermostat is positioned at least 1.3 ft. (40 cm)

away from the controller to avoid interference.

Inserting batteries

All thermostats use two alkaline 1.5 V AAA batteries which

provides about two years of battery life, as long as they are

positioned within radio range of the base unit. Ensure the

batteries are correctly inserted into the thermostats.

After inserting the batteries, the thermostat will perform a

self test for about 10 seconds. The system will block for input

and the thermostat LED ashes during this period.

The illustration below shows where to insert the batteries.

Figure 4-2: Inserting batteries

Connecting an external sensor

to a thermostat (optional)

An optional external sensor can be connected to the digital

thermostats (A3800167) for extra functionality.

5 ft./1.5 m

Figure 4-1: Thermostat placement

Labeling thermostats

Label the thermostats, where suitable, with the channel

numbers they are to control (e.g. 02, 03). For a system

with several controllers, add the ID of each controller

(e.g. 1.02, 1.03, 2.02, 2.03).

If the thermostat can connect to an external sensor,

add information about sensor type when applicable.

Available thermostat and sensor combinations:

• Room temperature

• Room and oor temperature

• Room and outdoor temperature

• Remote sensor temperature

Important! For accurate temperature, attach the

outdoor sensor to the north side of the building

where it is unlikely to be exposed to direct sunlight.

Do not place it close to doors, windows or air outlets.

Connect the sensor to the terminal located at the back of

the thermostat, as shown in the illustration below.

1

2

Figure 4-3: Connecting an external sensor

1. Insert the two wires from the sensor cable (non polarized)

into the removable connector.

2. Tighten the screws, xing the wires in the connector.

3. Insert the connector on the input pegs on the thermostat.

3

Climate Control Zoning System II installation and operation manual | Chapter 4 – Installing thermostats and sensors l 15

Page 22

Digital thermostats

1

The external temperature sensor input can be used for either

a oor, outdoor or remote temperature sensor. Use the software

on the thermostat to select a control mode which corresponds to

the use of the sensor and thermostat.

Using a wall bracket (recommended)

The illustration below shows thermostat mounting hole positions

and how to attach it to a wall using a wall bracket.

60 mm

ON DIP

1 2 3 4

Figure 4-4: Switch location

Function

Used as a standard room

thermostat

Used as a standard room

thermostat together with a

floor temperature sensor

Used as a standard room

thermostat, or system

device, together with

an outdoor temperature

sensor

Switch

1 2 3 4

Off Off Off Off

On Off Off Off

Off On Off Off

2

1

3

Figure 4-6: Wall bracket installation

Using a screw and wall plug

The illustration below shows how to attach the thermostat to a

wall using one screw and wall plug.

2

5

3

Caution: The switches must be set before the

thermostat is registered.

Caution: The switches must be set to one of the

available functions, otherwise the thermostat

cannot be registered.

Attaching a thermostat to a wall

The thermostats come with screws, wall plugs and a wall

bracket, allowing several options for attaching to a wall.

Figure 4-5: Attaching a thermostat to a wall

4

Figure 4-7: Screw and wall plug installation

Using an adhesive strip (not included)

The illustration below shows how to attach the thermostat

to a wall using an adhesive strip.

60x10

4

3

1

5

Figure 4-8: Adhesive strip installation

16 | uponorpro.com

Page 23

Attaching to a table stand

Temperature setpoint

The illustration below shows how to attach the thermostat

to a table stand.

3

1

4

2

Figure 4-9: Attaching to a table stand

First setup of digital thermostats

Select thermostat control mode

If an external sensor is connected to the thermostat, a control

mode must be selected to accommodate the extra functionality

of the sensor.

Important! If no button is pressed for about 8 seconds,

while in a submenu, the current values will be saved

and the software exits to the settings menu. About

60 seconds later, it exits to run mode.

1. Press and hold the OK button until the settings icon and

menu numbers are displayed in the top-right corner of the

display (about 3 seconds).

2. Use buttons – or + to change the numbers to 04 and

press OK.

3. Current control mode is displayed (RT, RFT, RS or RO).

The thermostats are delivered with a default setpoint

of 70°F (21°C).

The illustration below shows how to adjust the thermostat

temperature setpoint.

Figure 4-10: Temperature setpoint

To adjust the thermostat temperature setpoint of the current

control mode:

1. Press the – or + button once.

The screen shows the current setpoint ashing.

Figure 4-11: Current setpoint screen

2. Press the – or + button repeatedly to adjust the setpoint

temperature. It will change with increments of 0.5.

When the new setpoint is set, the screen returns to run mode

after a few seconds, showing the room temperature.

4. Use buttons – or + to change control mode (see list below)

and press OK.

RT = Room temperature

RFT = Room temperature with external oor sensor

RS = Remote sensor

RO = Room temperature with remote outdoor sensor

5. Press and hold the OK button for about 3 seconds to exit the

settings menu.

Climate Control Zoning System II installation and operation manual | Chapter 4 – Installing thermostats and sensors l 17

Page 24

Registering thermostats in the base unit

3 second

1. Press and hold the OK button on the controller until the LED

for channel 1 (or the rst unregistered channel) ashes red.

2. Use buttons < or > to move the pointer (LED ashes red)

to a preferred channel.

3. Press the OK button to select the channel for registration.

The LED for the selected channel starts ashing green.

4. Repeat steps 2 and 3 until all channels to be registered

with the thermostat are selected (LEDs ashing green).

Note: Uponor recommends registering all channels to the

thermostat at the same time.

5. Select a thermostat.

Wireless Dial Thermostat (T-165) (A3800165)

Gently press and hold the registration button on the

thermostat, release when the LED on the front of the

thermostat starts ashing. The selected channel LED in the

controller turns xed green and the registration is complete.

Wireless Digital Thermostat (T-167) (A3800167)

Press and hold both - and + buttons on the thermostat until

the text CnF (congure) and a communication icon is

displayed. The selected channel LED in the controller turns

xed green and the registration is complete.

1 2

s

3 4

5

2

3

6. Repeat steps 2 through 5 until all used room thermostats

are registered.

7. Press and hold the OK button on the controller until the green

LEDs turn off to end registration and return to run mode.

A3800167 A3800165

5 seconds

5 seconds

6

2

5

7

18 | uponorpro.com

3 seconds

Figure 4-12: Registering thermostats

Page 25

Finishing installation

1. Ensure the thermostats are working correctly.

Turn thermostat setpoints to maximum to obtain a heating

demand and make sure the actuators are running.

2. Set the thermostats to the dened operating settings.

3. Close the base unit cover.

3

5

4. Attach the thermostats to the wall.

5. Print out and complete in the "Installation report"

located at the end of this manual.

6. Give the manual and all system information to the user.

1

1

2

4

6

Figure 4-13: Finishing installation

Climate Control Zoning System II installation and operation manual | Chapter 4 – Installing thermostats and sensors l 19

Page 26

20 | uponorpro.com

Page 27

Chapter 5

3 seconds

1 2

Operating the base unit

The Climate Control Zoning System II controls the underoor

heating installation according to customer needs.

Sequence of operation

As soon as the temperature measured at a thermostat is lower

(heating mode) than the setpoint temperature, a demand

to change the room temperature is created and sent to the

controller. The controller will open the actuators according

to current operating mode and other settings. Once the set

temperature is reached, this information is sent and the

actuators are closed.

Normal operation

When the system is running in normal mode, the actuators are

open when room temperatures are lower than the temperatures

set on the thermostats.

Run mode

During normal operation, the controller is in run mode.

Exit to run mode

Figure 5-2: Resetting the base unit

3. Installation and registration are required after resetting

the controller.

Unregistering channels in the base unit

When a channel is inaccurately registered or if a thermostat

registration needs to be remapped, it is possible to remove

the current registration from the controller.

If the controller is in registration or forced mode, exit to run

mode by pressing the OK button until the LEDs turn off

(about 5 seconds).

Figure 5-1: Exit run mode

Resetting the base unit

It may be necessary to reset the base unit if problems, such

as inaccurate channel registration exist. The following illustration

shows the location of the reset button in the base unit.

To reset the controller:

1. Make sure the controller is in run mode. If it is in registration

or forced mode, press and hold the OK button for about

5 seconds or until the LEDs turn off.

2. Press the <, OK, and > buttons simultaneously (for about

10 seconds) until the power LED ashes, and all channel

LEDs turn off. All parameters are erased and run mode

has been activated.

3

Figure 5-3: Unregistering channels

Caution: Make sure the base unit is in run mode.

Refer to the instructions below to unregister a channel.

1. Press and hold the OK button on the base unit until

the LED for channel 1 ashes red/green, or the rst

unregistered channel ashes red.

2. Use buttons < or > to move the pointer (LED ashes

red) to the selected channel (ashes green if registered)

to unregister.

3. Press the < and > buttons simultaneously until the LED for

the selected channel starts ashing red (about 3 seconds).

Climate Control Zoning System II installation and operation manual | Chapter 5 – Operating the base unit l 21

Page 28

Unregistering all channels

When one or more channels are inaccurately registered,

it is possible to remove all registrations at the same time.

Caution: Make sure the base unit is in run mode.

Refer to the instructions below to cancel all

channel registrations.

1. Press and hold the OK button on the base unit until

the LED for channel 1 ashes red/green, or the rst

unregistered channel ashes red.

2. Press the < and > buttons simultaneously until the LEDs

for all channels except one turn off (about 10 seconds).

The one remaining ashes red.

22 | uponorpro.com

Page 29

Chapter 6

CFDEA

BF

2

Operating dial thermostats

Thermostat components

During normal operation, if there is a demand for heating, a

descreet LED on the dial thermostat is lit for about 60 seconds.

Figure 6-1: Dial thermostat components

Item Description

A Room temperature setpoint dial control

B Heating demand LED

C Backlight

D Registration button

E Disable timer switch (not used)

F Batteries

Adjusting the temperature

The temperature is changed by adjusting the setpoint on

the thermostat to a value between 41°F to 95°F (5°C to 35°C).

Use the dial on the thermostat to adjust the temperature.

A backlight will light up when twisting the dial. It shuts off

after about 10 seconds of inactivity.

The illustration below shows how to adjust the thermostat

temperature setpoint.

Figure 6-2: Adjusting the thermostat setpoint

To adjust the thermostat temperature setpoint:

• Twist the dial clockwise for a higher temperature.

• Twist the dial counter-clockwise for a lower temperature.

Replacing batteries

Replace the batteries of the thermostat when the

LED ashes twice during a heating or cooling demand.

The thermostat will perform a self test, for about

10 seconds, when the batteries have been inserted.

The system will be blocked for input and the thermostat

LED ashes during this period.

The illustration below shows how to change batteries.

3

Figure 6-3: Replacing batteries

1. Angle the thermostat from the bracket.

2. Remove it from the wall.

Climate Control Zoning System II installation and operation manual | Chapter 6 – Operating dial thermostats l 23

3. Replace the batteries.

1

Page 30

Factory reset

2

Important! Do not factory reset the thermostat

if not absolutely needed. A factory reset removes

the registration data from the thermostat.

3

1

4

A3800165

Figure 6-4: Factory reset instructions

Refer to the following instructions to factory reset

a dial thermostat.

1. Angle the thermostat from the bracket.

2. Remove it from the wall.

3. Gently press and hold the registration button on the

thermostat, release when the demand LED starts ashing.

4. Change the Disable timer switch twice, regardless

of starting position.

5. The thermostat is now reset to factory default.

24 | uponorpro.com

Page 31

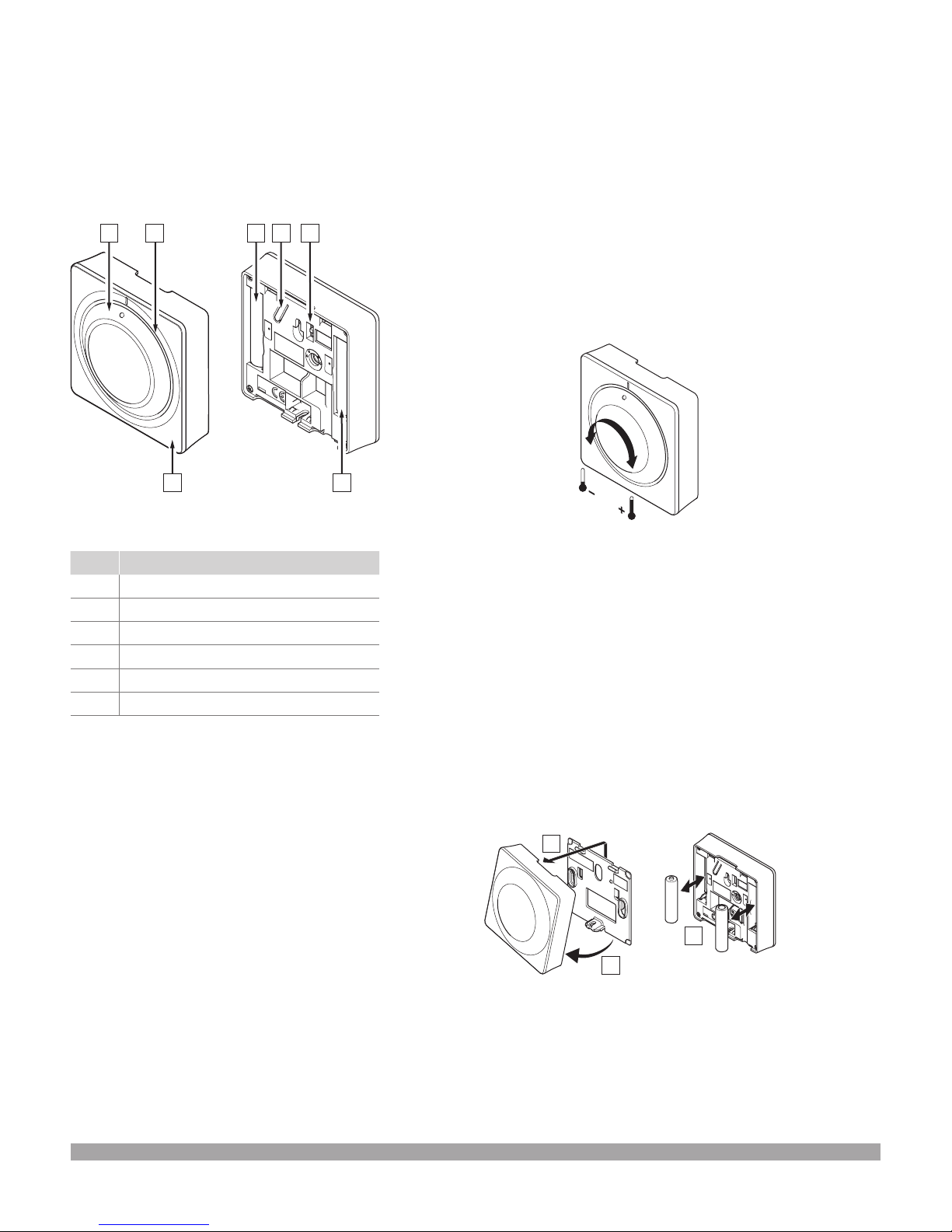

Chapter 7

A D

B C D

H F

A

Operating digital thermostats

Thermostat components

The illustration below shows the parts of the thermostat.

Figure 7-1: Digital thermostat components

Item Description

A Display

B Buttons

C Terminal for external sensor (non-polarised)

D Batteries

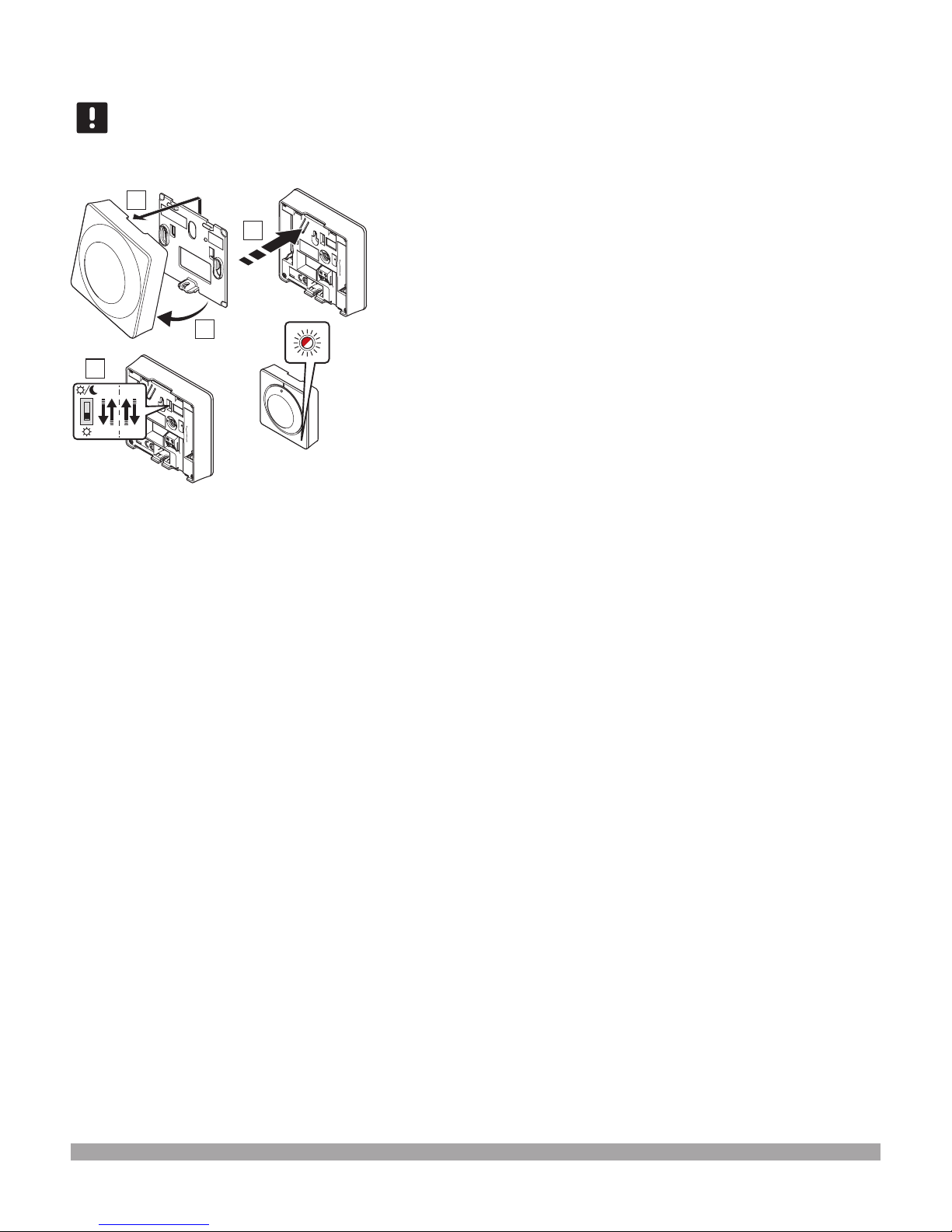

Display layout

The gure below shows all possible symbols and characters that

can be shown on the display.

Item Icon Description

A

Message field using three

alphanumerical characters

Temperature reading using a – or + sign,

two digital characters, a decimal point

and a character showing either 0 or 5

Relative humidity reading using two digital

characters, indicated with a “%” character

B

Low battery indicator

C

Temperature unit, shown when the character

group A shows a temperature

D

Communication indicator

E

Indoor temperature indicator

Remote sensor temperature indicator

(RS mode)

The text Err and a flashing sensor icon

indicates a faulty sensor.

Indoor temperature with floor temperature

limitation indicator

The text Err and a flashing floor sensor icon

indicates a faulty sensor.

Floor temperature indicator

The text Err and a flashing floor sensor icon

indicates a faulty sensor.

G

Figure 7-2: Display layout

Climate Control Zoning System II installation and operation manual | Chapter 7 – Operating digital thermostats l 25

Outdoor temperature indicator

The text Err and a flashing outdoor sensor

icon indicates a faulty sensor.

D

C

F

Settings menu

B

E

G

H

Settings menu number

Heating demand

Comfort mode

Page 32

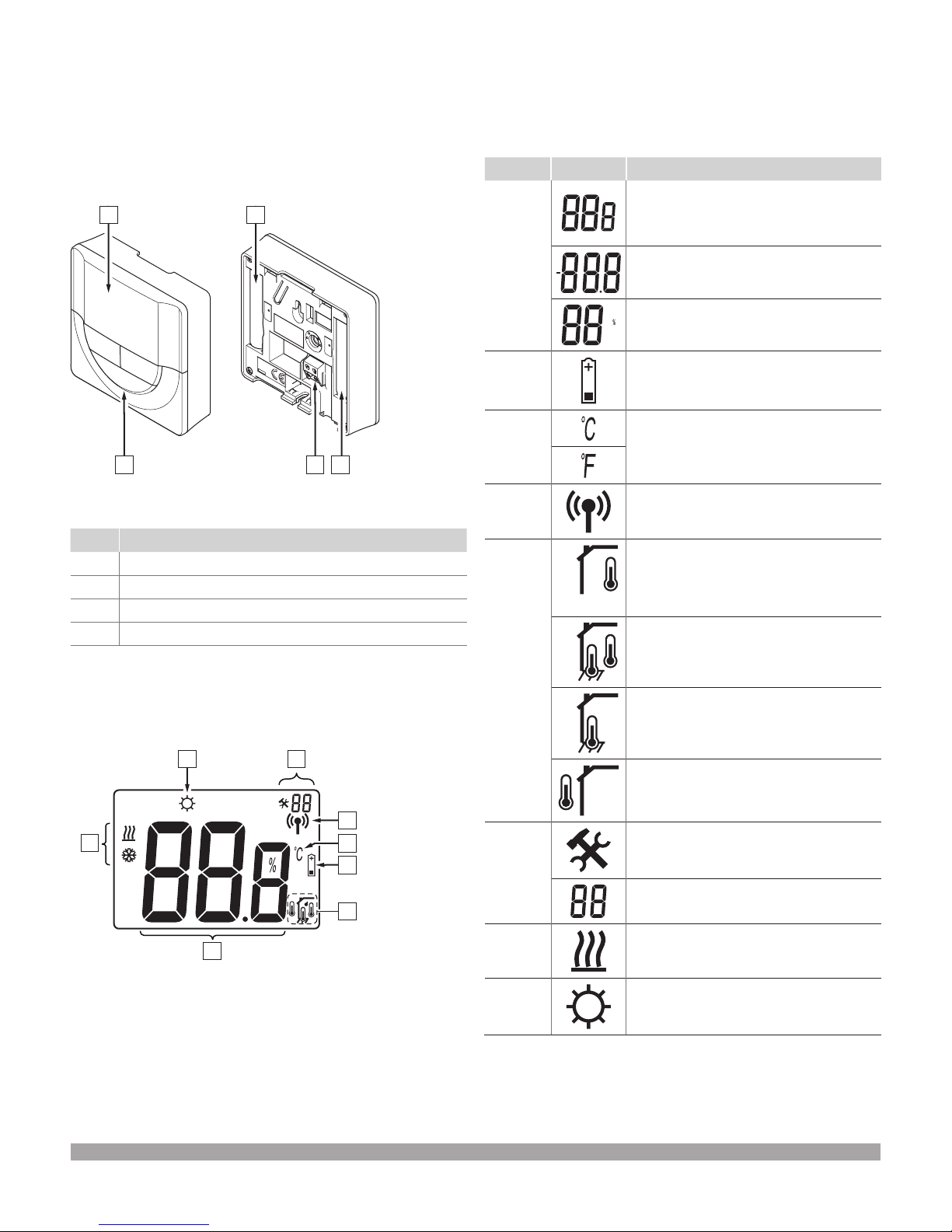

Operating buttons

The gure below shows buttons used to operate the

digital thermostats.

To adjust the thermostat temperature setpoint of the current

control mode:

1. Press the – or + button once.

The screen shows the current setpoint ashing.

A

B

C

Figure 7-3: Digital thermostat operating buttons

Item Description

The – and + buttons are used to:

A

• Adjust setpoint temperature

B

• Modify parameters in the settings menus

The OK button is used to:

C

• Toggle between current status data as well as values of

available sensors connected to the thermostat

• Enter and exit the settings menu

• Confirm a setting

Start up

When starting up, the software version is shown in the display

for about 3 seconds. Then the thermostat enters run mode.

Note: The rst time the thermostat is started, or after a factory

reset, the software requires the time and date to be set.

Adjusting temperature

Change the temperature by adjusting the setpoint

on the thermostat.

Use the buttons on the thermostat to adjust the temperature.

The display will light up when pushing a button. It shuts off

after about 10 seconds of inactivity.

The illustration below shows how to adjust the thermostat

temperature setpoint.

Figure 7-5: Temperature setpoint screen

2. Press the - or + button repeatedly to adjust the setpoint

temperature. It will change with increments of 0.5.

When the new setpoint is set, the screen returns to run

mode after a few seconds, showing the room temperature.

Run mode

During normal operation, the thermostat is in run mode.

While in run mode the display shows specic information.

Settings

This menu sets thermostat parameters.

Note: If no button is pressed for about 8 seconds, while

in a submenu, the current values will be saved and the

software exits to the settings menu. About 60 seconds later, it

exits to run mode.

To enter the settings menu:

1. Press and hold the OK button for about 3 seconds.

2. The settings icon and menu numbers is displayed

in the top right corner of the display.

3. Use buttons – or + to change the numbers to locate a

submenu (see list below) and press OK.

00 = Program1

02 = Heating/cooling changeover

03 = ECO mode setback temperature1

04 = Sensor options

05 = High oor temperature limitation

06 = Low oor temperature limitation

07 = Cooling allowed1

08 = Display unit

09 = Climatic controller integration1

10 = Time and date1

11 = Room temperature calibration

1

Not active in this release.

2

This menu is not visible if the thermostat is registered to a controller.

1, 2

Figure 7-4: Adjusting temperature

26 | uponorpro.com

4. Change parameters in the submenus.

5. Press and hold the OK button for about 3 seconds to

exit the settings menu.

Page 33

Sensor options

The thermostat has four different sensor options that can be

set in the settings menu.

• RT = Room temperature

• RFT = Room temperature with external oor sensor

• RS = Remote sensor

• RO = Room temperature with remote outdoor sensor

Different types of information can be shown in the display

depending on the sensor setting.

Adding a sensor

If connecting an external sensor, choose the sensor type to

accommodate the extra functionality.

Note: If no button is pressed for about 8 seconds, while in a

submenu, the current values will be saved and the software

exits to the settings menu. About 60 seconds later, it exits

to run mode.

1. Press and hold the OK button for about 3 seconds.

2. The settings icon and menu numbers are displayed in the

top-right corner of the display.

Use the OK button to toggle between the information available.

RT = Room temperature

1. Room temperature (default)

2. Relative humidity

RFT = Room oor temperature

1. Room temperature (default)

2. Relative humidity

3. Floor temperature

RS = Remote sensor

1. Room temperature (default)

2. Relative humidity

RO = Remote outdoor sensor

1. Room temperature (default)

2. Relative humidity

3. Outdoor temperature

3. Use buttons – or + to change the numbers to 04 and

press OK.

4. Current control mode is displayed (RT, RFT, RS or RO).

5. Use buttons – or + to change control mode (see list below)

and press OK.

• RT = Room temperature

• RFT = Room temperature with external oor sensor

• RS = Remote sensor

• RO = Room temperature with remote outdoor sensor

6. Press and hold the OK button for about 3 seconds to

exit the settings menu.

High oor temperature limitation

This menu sets the limit on the maximum allowable

oor temperature.

To change this setting:

1. Press OK and the parameter starts ashing.

2. Use buttons – or + to change the parameter.

Default: 78.8ºF (26ºC)

Setting range: 68ºF to 95ºF (20ºC to 35ºC), 0.5 increments

Important! This parameter cannot be set lower

than the set value in the Low oor temperature

limitation settings menu.

3. Press OK to conrm the change and return to

the settings menu.

Climate Control Zoning System II installation and operation manual | Chapter 7 – Operating digital thermostats l 27

Page 34

Low oor temperature limitation

2

This menu sets the limit on the minimum allowable oor

temperature.

Replacing batteries

Replace the batteries of the thermostat when the low battery

icon appears in the display.

To change this setting:

1. Press OK and the parameter starts ashing.

2. Use buttons – or + to change the parameter.

Default: 68ºF (20ºC)

Setting range: 50ºF to 86ºF (10ºC to 30ºC),

0.5 increments

Important! If this parameter is set lower than

60.8ºF (16ºC) the cooling icon will start ashing,

warning for risk of condensation in the system.

Important! This parameter cannot be set higher

than the set value in settings menu High oor

temperature limitation.

3. Press OK to conrm the change and return to the

settings menu.

Display unit

This menu sets the temperature display unit.

To change this setting:

1. Press OK and the parameter starts ashing.

2. Use buttons – or + to toggle between Celsius and Fahrenheit.

DEg ºC: degrees Celsius

DEg ºF: degrees Fahrenheit

The illustration below shows how to change batteries.

3

1

Figure 7-6: Replacing batteries

1. Angle the thermostat from the bracket.

2. Remove it from the wall.

3. Replace the batteries.

Factory reset

Factory reset sets all parameter values to default settings.

Important! Do not factory reset the thermostat

if not absolutely needed.

3. Press OK to conrm the change and return to the

settings menu.

Room temperature calibration

This menu calibrates the room temperature.

To change this setting:

1. Press OK and the parameter starts ashing.

2. Use buttons – or + to change the parameter.

Default: 0.0 ºC

Setting range: -6.0 to 6.0 ºC, 0.1 increments

3. Press OK to conrm the change and return to

the settings menu.

Important! A factory reset removes the

registration data from the thermostat.

1. Press and hold the –, + and OK buttons for about 5 seconds

until the screen goes blank.

2. The thermostat is now reset to factory default.

28 | uponorpro.com

Page 35

Chapter 8

AB

Maintenance

Manual preventive maintenance

The system requires no preventive maintenance except

cleaning with a dry, soft cloth.

Warning! Do not use any detergents to clean

the Climate Control Zoning System II.

Automatic preventive maintenance

The system is equipped with an automatic exercise function

that consists of a test run designed to prevent the pump and

actuators from seizing up due to inactivity.

This exercise is run every six days ±24 hours at random.

• The pump exercise operates only if the pump has not been

activated since the last exercise. The pump is activated for

3 minutes during the exercise.

• The actuator exercise operates only if the actuators have not

been activated since the last exercise. The exercise consists

of opening and completely closing the actuators periodically.

Corrective maintenance

Fallback mode

If a thermostat is malfunctioning or not detected, the controller

executes the fallback mode to maintain the temperature in the

room until the problem is resolved.

Resetting the controller

If the controller does not work as expected, for example

due to a hang-up, it can be reset to solve the problem.

1. Disconnect and reconnect the controller to AC power.

Controller LEDs

Uponor recommends occasionally checking the power

LED on the controller for alarms. The power LED ashes

continuously for general alarms. Determine which thermostats

are issuing alarms by removing the cover. If a channel

LED is indicating an error, check the function and batteries

of the registered thermostat.

The controller power LED is on during normal operation.

All the channel LEDs are off when there is no current or

waiting actuator activity. The LEDs turn on when the

corresponding actuators are activated or start ashing

when they are awaiting activation.

The illustration below shows the position of the controller LEDs.

Figure 8-1: Controller LEDs

Item Description

A Power LED

B Channel LEDs

The table below describes the status of the base unit LEDs.

LED Status

Power The base unit power LED is always on and ashes

when a problem occurs, such as:

• Loss of radio transmission from a thermostat

for more than 1 hour

• Loss of radio transmission from a timer or an

interface for more than 15 minutes

Channel during

run mode

Channel during

registering

mode

Channel during

forced mode

• Red, on – actuators activated

• Red, ashing – thermostat communication

error or low battery indication

• Off – no demand for heating or cooling

• Red, on – thermostat registered but with

communication errors

• Green, on – thermostat registered and

communication is OK

• Red, ashing – selector pointing at channel

• Green, ashing – channel selected to

be registered

• Off – channel not pointed, nor registered

• Red, on – actuators activated

• Red, ashing – selector pointing at channel

• Off – channel not pointed, nor activated

Up to eight actuators in six rooms can be in the opening process

at the same time. If a slave module is installed, the LEDs of the

seventh and subsequent actuators ash while they are waiting

for the previous actuators to be fully open.

Climate Control Zoning System II installation and operation manual | Chapter 8 – Maintenance l 29

Page 36

Restore from backup

If an existing base unit has been replaced, installation data

(including thermostat registration data) from the replaced

base unit can be reused to setup the base unit.

Caution: Make sure the base unit is powered off

before ejecting the microSD card.

Important! When replacing a base unit, the microSD

card from the replaced unit must be used in the new

base unit. Otherwise all registrations must be redone.

Important! When a base unit has been replaced,

no additional units can be added to the system

without redoing the whole installation. Replace the

microSD card with the new one again, or format the

existing one, and redo the installation procedure

with the additional units.

3 41

Figure 8-2: Replacing the microSD card

Preparation

1. Eject the microSD card from the malfunctioning base unit.

Restore from backup to new base unit

2. Power off the new base unit.

3. Eject the existing microSD card from the new base unit.

4. Insert the microSD card containing the installation data from

the malfunctioning controller into the new one.

5. Power on the new base unit.

The new base unit is now setup with the installation data from

the malfunctioning one.

30 | uponorpro.com

Page 37

Chapter 9

Troubleshooting

The table below shows problems and alarms that can occur and describes solutions. Note that common issues may be due to

incorrectly installed loops or mixed up thermostats. In the case of mixed up thermostats in a system, use the room check function.

General troubleshooting

Problem Indication Probable cause Solutions

Fluctuating floor temperature Floor temperature is changing

The room is too cold Press – or + buttons to display the

The room is too warm

(or too cold in cooling mode)

The floor is cold The room temperature is okay, but

No communication Communication error

abnormally between hot and cold in

heating mode.

Room temperature does not

match setpoint on the thermostat,

and actuators shut on/off on a

fixed interval.

Room temperature does not match

setpoint on thermostat.

temperature setpoint on the thermostat

Temperature setpoint is displayed

on the interface, in the room

information menu.

The temperature displayed on

the thermostat changes after the

thermostat is moved.

See installation report and

controller/channel numbering

on the thermostat label.

White indicator cannot be seen in the

window of an actuator.

Setpoint temperature displayed in the

room information menu is lower than

the temperature set on the thermostat.

Corresponding loop is warm even

after a long period without a heat call.

the floor is cold.

Software versions incompatible

Supply water temperature is

too high.

Heating fall back function

is activated due to lost

communication with thermostat.

The thermostat is placed in

direct sunlight or close to other

heat sources.

The thermostat is placed in the

wrong room.

The thermostat setting is too low. Change the temperature setpoint.

The thermostat may be influenced

by an external heat source.

The thermostats of individual

rooms are incorrectly registered

An actuator does not open Replace the actuator

Incorrect minimum/maximum

limitation

An actuator is not closing. Check that the actuator is

No heat demand from the

underfloor heating system.

The room is heated by another

heat source.

Registration is lost. Contact the installer.

Check the boiler or pump.

Check the connection of the room

thermostat.

Check the batteries in the room

thermostat.

Check placement of the thermostat

according to installation instructions

and change location if needed.

Check the placement of the

thermostats and change rooms

if needed.

Change the location of the thermostat.

Place the thermostat in the correct

room or change the thermostat

registration in the controller.

Contact the installer.

Change the minimum/maximum

limitation in the interface.

correctly installed.

Replace the actuator.

Contact the installer.

Table 9-1: General troubleshooting

Climate Control Zoning System II installation and operation manual | Chapter 9 – Troubleshooting l 31

Page 38

Troubleshooting after installation

Problem Indication Probable cause Solutions

The system does not start The power indicator in the controller

is off.

There is no AC power to the

controller.

1. Check that the controller is

connected to AC power.

2. Check the wiring in the 24 VAC

compartment.

3. Check that there is 115 VAC power

to the transformer.

There is no 24 VAC power in the

wall socket.

Poor radio reception Repeated radio alarms The antenna is installed inside

The thermostat is faulty Channel LEDs in the controller

continue flashing

Blown controller fuse or faulty

wiring

a metal cabinet, or too close to

other shielding objects.

Building structure is unfavorable

for radio transmission.

The antenna is not correctly

installed or positioned.

Replace the fuse and/or correct the

wiring issue.

Change the antenna location. If the

problem persists, contact the installer.

Check the wiring and the antenna

connection.

Table 9-2: Troubleshooting after installation

Digital thermostats

An alarm is sent when more than one hour has elapsed since the controller received the last radio signal from the thermostat. The

table below shows problems that can occur with digital thermostats.

Indication Probable cause Solutions

Battery icon is displayed.

The display is off. The batteries are discharged or wrong

Radio transmission icon is displayed but

the signals are received only when the

thermostat is close to the antenna.

No radio transmission icon is displayed

on thermostat screen when –/+ buttons are

pressed.

Relative humidity icon is displayed.

The icon for floor temperature

sensor flashes.

The icon for outdoor temperature

sensor flashes.

The icon for indoor temperature

sensor flashes.

Table 9-3: Troubleshooting digital thermostats

Thermostat battery power is running low. Replace the batteries.

type of batteries are used.

The batteries are installed upside down

(reverse polarity).

Transmitter working with reduced

signal intensity

New installations in building shield radio

signals (for example, metal door safe)

The transmitter broken in the thermostat. Force the thermostat to transmit by changing the

The relative humidity limit is reached. Lower the humidity level by increasing the ventilation

Faulty temperature sensor Check the connection of the floor sensor.

Faulty temperature sensor Check the connection of the outdoor sensor.

Faulty temperature sensor Contact the installer or replace the thermostat.

Replace the batteries.

Install the batteries correctly.

Force the thermostat to transmit by changing the

temperature setpoint.

Replace the thermostat.

Try to find a new position for the thermostat and/or

the antenna, or, if possible, move the shielding object.

temperature setpoint.

Replace the thermostat.

or temperature setpoint.

Disconnect the floor temperature sensor and

check it with an ohmmeter. The value must be around

10k ohms.

Disconnect the outdoor sensor and check it with an

ohmmeter. The value must be around 10k ohms.

Disconnect the remote temperature sensor

(if connected) and check it with an ohmmeter.

The value must be around 10k ohms.

32 | uponorpro.com

Page 39

Dial thermostats

An alarm is sent when more than one hour has elapsed since the controller received the last radio signal from the thermostat.

The table below lists problems that can occur with dial thermostats.

Indication Probable cause Solutions

The LED on the thermostat flashes twice. The thermostat battery power is running low. Replace the batteries.

Table 9-4: Troubleshooting dial thermostats

Base unit alarms

An alarm is sent when more than one hour has elapsed since the base unit received the last radio signal from the thermostat.

The table below lists problems that can occur in the base unit.

Indication Probable cause Solutions

The power LED and channel LED on the

controller flashes.

Alarm in the interface

The battery icon is displayed in room

information on the interface or thermostat.

Radio alarm in interface