Page 1

Single-zone snow

melt control

installation and

operation manual

The Uponor Single-zone Snow Melt Control

(A3040654) is designed to operate hydronic

equipment to melt snow or ice from any

surface including driveways, walkways,

patios, business entrances, parking ramps,

loading docks, hospital entrances, helipads

or car wash bays.

The surface temperature for snow melting

is controlled automatically to reduce

operating energy costs. The control has

an automatic start and stop function when

used with the Pavement Snow and Ice

Sensor (A3040090).

Automatic start with a timed stop is

available when used with the Aerial

Snow Sensor (A3040095). The control

can operate a dedicated hydronic boiler.

Isolation relays are required to operate

line voltage pumps.

Features

• Automatic snow/ice detection

• Supports both in-slab and retrot aerial

snow sensors

• Mixing with modulating boiler

• Manual start with timer

• Warm weather shut down

• Cold weather cut out

• Idling

• Slab protection

• EconoMelt

• Manual override

• Exercising

• Alert output

Page 2

2 | uponorpro.com

Important safety information

Warning

It is your responsibility to ensure that this control is safely installed according to all applicable codes

and standards. Uponor is not responsible for damages resulting from improper installation and/or

maintenance.

Radio frequency interference

The installer must ensure this control and its wiring

are isolated and/or shielded from strong sources of

electromagnetic noise. Conversely, this Class B digital

apparatus complies with Part 15 of the FCC Rules and

meets all requirements of the Canadian InterferenceCausing Equipment Regulations. However, if this

control causes harmful interference to radio or television

reception, (determined by turning the control off and

on) try to correct the interference by re-orientating or

relocating the receiving antenna, relocating the receiver

with respect to this control, and/or connecting the control

to a different circuit connected to the receiver.

Single-zone snow melt control installation and operation manual is published by

Uponor Inc.

5925 148th Street West

Apple Valley, MN 55124

USA

T 800.321.4739

F 952.891.2008

uponorpro.com

© 2017 Uponor. All rights reserved.

Second Edition

Second printing August 2017

Printed in Canada

Uponor Ltd.

6510 Kennedy Road

Mississauga, ON L5T 2X4

CANADA

T 888.994.7726

F 800.638.9517

uponorpro.com

Uponor has used reasonable efforts in collecting, preparing and

providing quality information and material in this manual. However,

system enhancements may result in modication of features or

specications without notice. Uponor is not liable for installation

practices that deviate from this manual or are not acceptable

practices within the mechanical trades.

To avoid serious personal injury and damage to the equipment:

• Read manual and all product labels before

using the equipment. Do not use unless

you know the safe and proper operation

of this equipment.

• Keep this manual available for easy access

by all users. Replacement manuals are

available at uponorpro.com.

• Disconnect all power before opening

the control.

• Safely install this control according to all

applicable codes and standards. Improper

installation and operation of this control

could result in damage to the equipment

and possibly even personal injury or death.

• Only place controls that are intended and

certied as safety limits into the control

circuit. This electronic control is not intended

for use as a primary limit control.

• Do not attempt to service the control. There

are no user serviceable parts inside the control.

Attempting to do so voids the warranty.

Page 3

Single-zone snow melt control installation and operation manual | 3

Table of contents

Important safety information ................. 2

Installation .............................................. 4

Preparation ............................................. 4

Physical dimensions ............................... 4

Installation location ................................. 4

Rough-in wiring ...................................... 4

Sizing the transformer ........................... 5

Control wiring ........................................ 5

Sensor wiring ........................................ 7

Testing the sensor wiring ....................... 9

Testing the control wiring ....................... 9

Manual override — maximum heat ........ 10

Manual override — test .......................... 10

Manual override — purge ..................... 10

Manual override — off .......................... 11

Switch settings ....................................... 11

User interface ......................................... 12

Display .................................................... 12

Operation eld ........................................ 12

Status eld.............................................. 12

Symbols .................................................. 12

Programmable settings .......................... 13

Programming menus .............................. 13

Access levels and access level lock ...... 14

View menu ............................................. 14

Set Temp menu ..................................... 16

Monitor menu ......................................... 17

Display menu ......................................... 18

Toolbox menu ........................................ 18

Override menu ....................................... 19

System menu ......................................... 20

Boiler menu ............................................ 21

Sequence of operation ........................... 22

Snow melting overview .......................... 22

Slab temperature control ........................ 22

Melt operation ........................................ 22

Manual start and timed stop .................. 23

Automatic start and stop ....................... 23

Automatic start and timed stop .............. 24

EconoMelt .............................................. 24

Additional melting time ........................... 25

Idle operation ........................................ 25

Warm weather shut down ...................... 26

Cold weather cut out ............................. 26

Away key ................................................ 27

Slab protection ....................................... 27

Application modes .................................. 27

Electric operation ................................... 28

Pulse width modulation operation .......... 28

Boiler operation ...................................... 28

Exercising ............................................... 30

Alert relay ............................................... 30

Pump post purge .................................... 30

Troubleshooting...................................... 30

Error messages ...................................... 30

Symptoms and solutions ........................ 32

Job record .............................................. 33

Technical data ....................................... 34

Getting started

Congratulations on the purchase of your new Uponor Single-zone Snow Melt Control.

This manual covers installation, programming, sequence of operation, instruction on

testing, commissioning and troubleshooting.

Page 4

4 | uponorpro.com

Installation

Preparation

Tools required

• Jeweller screwdriver

• Phillips head screwdriver

• Needle-nose pliers

• Wire stripper

Materials required

• 18 AWG LVT solid wire

(low-voltage connections)

• 24 VAC transformer

Physical dimensions

Installation location

When choosing the location for

the control, consider the following:

• Interior wall

• Keep dry; avoid potential leakage onto

the control

• Relative humidity less than 90%;

non-condensing environment

• No exposure to temperatures below -4ºF

(-20ºC) or above 122ºF (50ºC)

• No draft, direct sun or other cause for

inaccurate temperature readings

• Away from equipment, appliances or other

sources of electrical interference

• Easy access for wiring, viewing

and adjusting the display screen

• Maximum wire length of 500 feet (150m)

• Approximately 5 feet (1.5m) off the

nished oor

• Strip wire to ⅜" (10mm) for all terminal

connections

• Use standard 8-conductor, 18 AWG wire

Rough-in wiring

Low-voltage wiring

Pull each cable from the equipment to the

control’s plastic enclosure. All low-voltage

wiring connections enter the enclosure

through the square knockout on the rear.

Uponor recommends labeling each cable

for easy identication. Strip all low-voltage

wires to a length of ⅜" (9mm) to ensure

proper connection to the control.

Front view

5"

Side view Mounting base

Brn

slab

Mod

+

Aux Ht R C

-

Out

Blk

com

Yel Blu Red Sup

No power

CL

CL

CL

3¼"

(82mm)

15

⁄16"

(23mm)

13

⁄16"

(20mm)

29

⁄32"

(23mm)

1½"

(38mm)

4"

(102mm)

9

⁄16"

(14mm)

1⅞"

(47mm)

2½"

(64mm)

¾"

(19mm)

3¼"

(83mm)

Page 5

Single-zone snow melt control installation and operation manual | 5

Pull 4-conductor, 18 AWG LVT cable up to

500 feet (150m) for the Aerial Snow Sensor

(A3040095).

Pull 5-conductor, 18 AWG LVT cable up to

500 feet (150m) for the Pavement Snow

and Ice Sensor (A3040090).

Pull 2-conductor, 18 AWG LVT cable up to

500 feet (150m) for the following equipment:

• 24 VAC power from transformer

• Outdoor temperature sensor

• Supply sensor (if applicable)

• On/off boiler (if applicable)

• Modulating boiler 0-10 VDC or 4-20 mA

(if applicable)

• Alert output (if applicable)

Sizing the transformer

The control requires an external transformer.

The total power capacity of the power supply

should be larger than the total load of all the

devices connected to the control. This total

load must not exceed 100 VA.

Control wiring

Pavement Snow and

Ice Sensor (A3040090)

Aerial Snow Sensor

(A3040095)

Slab Sensor

for Aerial

Snow Sensor

(A3040073)

Snow

Sensor

095

Pavement Snow and Ice Sensor (A3040090)

Outdoor and supply sensors Modulating boiler output

Aerial Snow Sensor (A3040095) and Slab Sensor

for Aerial Snow Sensor (A3040073)

Outdoor

sensor

Supply

sensor

– +

Modulating boiler

Brn

slab

Mod

+

Aux Ht R C

-

Out

Blk

com

Yel Blu Red Sup

No power

Brn

slab

Mod

+

Aux Ht R C

-

Out

Blk

com

Yel Blu Red Sup

No power

Brn

slab

Mod

+

Aux Ht R C

-

Out

Blk

com

Yel Blu Red Sup

No power

Brn

slab

Mod

+

Aux Ht R C

-

Out

Blk

com

Yel Blu Red Sup

No power

Page 6

6 | uponorpro.com

Control wiring

Alert relay output

Alert

equipment

Brn

slab

Mod

+

Aux Ht R C

-

Out

Blk

com

Yel Blu Red Sup

No power

Transformer and relays

Alert

equipment

24 VAC relay 24 VAC relay

System

pump

2

1

8

7

3

4

5

6

2

1

8

7

3

4

5

6

Transformer

L

N

C

R

On/off boiler

TT

LNG

115 VAC

Brn

slab

Mod

+

Aux Ht R C

-

Out

Blk

com

Yel Blu Red Sup

No power

Brn

slab

Mod

+

Aux Ht R C

-

Out

Blk

com

Yel Blu Red Sup

No power

Brn

slab

Mod

+

tN4

-

Out/

bret

Blk

com

Yel Blu Red Sup

No power

Page 7

Single-zone snow melt control installation and operation manual | 7

Wiring the outdoor sensor

Wires from

outdoor sensor to

controlʼs outdoor

sensor and sensor

common terminals

Sensor is built into

the enclosure

Sensor wiring

Mounting the outdoor sensor

Note: The temperature sensor (thermistor)

is built into the sensor enclosure.

• Remove the screw and pull the front cover

off the sensor enclosure.

• Mount the outdoor sensor directly onto a

wall or a 2" x 4" electrical box. When wall

mounting the outdoor sensor, the wiring

should enter through the back or bottom of

the enclosure. Do not mount the outdoor

sensor with the conduit knockout facing

upward as rain could enter the enclosure

and damage the sensor.

• To prevent heat through the wall from

affecting the sensor reading, it may be

necessary to install an insulating barrier

behind the enclosure.

• Mount the outdoor sensor on a wall

which best represents the heat load

on the building (a northern wall for most

buildings and a southern-facing wall for

buildings with large south-facing glass

areas). Do not expose the outdoor sensor

to heat sources such as ventilation or

window openings.

• Install the outdoor sensor at an elevation

above the ground that will prevent

accidental damage or tampering.

Wiring the outdoor sensor

• Connect 18 AWG or similar wire to the two

terminals provided in the enclosure and

run the wires from the outdoor sensor to

the control. Do not run the wires parallel to

telephone or power cables. If the sensor

wires are located in an area with strong

sources of electromagnetic interference

(EMI), use shielded cable or twisted pair or

run the wires in a grounded metal conduit.

If using shielded cable, connect the shield

wire to the Com or Com Sen terminal on

the control and not to earth ground.

• Follow the sensor testing instructions

in this manual and connect the wires

to the control.

• Replace the front cover of the

sensor enclosure.

Sensor with

bottom-entry wiring

Sensor with

rear-entry wiring

Sensor mounted

onto 2" x 4"

electrical box

Mounting the outdoor sensor

Page 8

8 | uponorpro.com

Strapping to pipe

Strap the sensor directly to the pipe using

the cable tie provided. Place insulation

around the sensor to reduce the effect of

air currents on the sensor measurement.

Immersion well

If mounting a sensor onto 1" (25mm)

diameter, Type L copper pipe, there is

approximately an 8-second delay between

a sudden change in water temperature

and the time the sensor measures the

temperature change. This delay increases

considerably when using mild steel

(black iron) pipe. Uponor recommends

using a temperature well for steel pipe

of diameter greater than 1¼" (32mm).

Uponor also recommends temperature

wells when using large-diameter pipes

and uid stratication is present.

Sensor mounted

onto 2" x 4"

electrical box

Wires from outdoor

sensor to control’s

outdoor sensor

and sensor

common terminals

Sensor is built into

the enclosure

Mounting the sensor

Sensor

Cable tie

Sensor well

Retaining

clip

Sensor

Bottom of

enclosure

Mounting the slab sensor

Note: The Slab Sensor for Aerial Snow

Sensor (A3040073) can mount on a pipe

or in a temperature immersion well.

Place the sensor downstream of a pump

or after an elbow or similar tting. This is

especially important if the system uses

large-diameter pipes, as the thermal

stratication within the pipes can result in

erroneous sensor readings. Proper sensor

location requires the uid is thoroughly

mixed within the pipe before it reaches

the sensor.

Page 9

Single-zone snow melt control installation and operation manual | 9

Conduit connection

The slab sensor and slab sensor

enclosure (sold separately) are specically

designed to mount onto a ⅜" (10mm) I.D.

temperature well that is supplied with an

end groove. To install the well, plumb a ‘T’

into the pipe and x the well into the ‘T’.

Remove the ⅞" (22mm) back knockout to

place the enclosure over the temperature

well. Then insert the universal sensor

into the well and snap the retaining clip

supplied with the enclosure onto the well

end groove. If the well has a threaded end,

add a standard threaded conduit retaining

ring. The two wires from the sensor are

connected to the terminal block provided

in the enclosure. The other side of the

terminal block is used to connect wires

from the control.

Testing the sensor wiring

A good-quality test meter capable of

measuring up to 5,000 kΩ (1 kΩ = 1000

Ω) is required to measure the sensor

resistance. In addition to this, the actual

temperature must be measured with either

a good quality digital thermometer, or if

a thermometer is not available, a second

sensor can be placed alongside the one to

be tested and the readings compared.

First measure the temperature using

the thermometer and then measure the

resistance of the sensor at the control. The

wires from the sensor must not be connected

to the control while the test is performed.

Using the chart below, estimate the

temperature measured by the sensor. The

sensor and thermometer readings should

be close. If the test meter reads a very high

resistance, there may be a broken wire, a

poor wiring connection or a defective sensor.

If the resistance is very low, the wiring may

be shorted, there may be moisture in the

sensor or the sensor may be defective. To

test for a defective sensor, measure the

resistance directly at the sensor location.

Testing the control wiring

Testing the power

1. Remove the front cover from

the control.

2. Use an electrical test meter to

measure AC voltage between the

R and C terminals. The reading

should be 24 VAC +/– 10%.

3. Install the front cover.

Temp. Resistance Temp. Resistance Temp. Resistance Temp. Resistance

ºF ºC Ω ºF ºC Ω ºF ºC Ω ºF ºC Ω

-50 -46 490,813 20 -7 46,218 90 32 7,334 160 71 1,689

-45 -43 405,710 25 -4 39,913 95 35 6,532 165 74 1,538

-40 -40 336,606 30 -1 34,558 100 38 5,828 170 77 1,403

-35 -37 280,279 35 2 29,996 105 41 5,210 175 79 1,281

-30 -34 234,196 40 4 26,099 110 43 4,665 180 82 1,172

-25 -32 196,358 45 7 22,763 115 46 4,184 185 85 1,073

-20 -29 165,180 50 10 19,900 120 49 3,760 190 88 983

-15 -26 139,403 55 13 17,436 125 52 3,383 195 91 903

-10 -23 118,018 60 16 15,311 130 54 3,050 200 93 829

-5 -21 100,221 65 18 13,474 135 57 2,754 205 96 763

0 -18 85,362 70 21 11,883 140 60 2,490 210 99 703

5 -15 72,918 75 24 10,501 145 63 2,255 215 102 648

10 -12 62,465 80 27 9,299 150 66 2,045 220 104 598

15 -9 53,658 85 29 8,250 155 68 1,857 225 107 553

Do not apply voltage to a

sensor at any time as damage

to the sensor may result.

Page 10

10 | uponorpro.com

Testing the relay outputs

The control includes an Override menu to

check if the control’s relays are operating

and that the control is wired correctly to the

snow melting equipment.

1. Press and hold the Home button for

3 seconds.

2. Press NEXT to navigate to the Override

menu.

3. Press ENTER to enter the Override

menu.

4. Select Manual Override to Hand.

5. For hydronic systems, set System Pump

to On. The system pump should now be

operating.

6. Set Heat Relay to On. The boiler or

electric heating cables should start

heating.

7. For modulating boilers, change the Boiler

Percent from 0 to 100%. The boiler

should be ring.

8. Select the Override Time after which the

control resumes normal operation.

9. Exit the Manual Override by selecting

Auto.

Manual override —

maximum heat

In hydronic application modes, the control

includes a Maximum Heat operation where

the control operates the snow melting

system to maintain the maximum allowed

heating setpoints. This allows testing of the

snow melting system during warm weather.

1. Press and hold the Home button for

3 seconds.

2. Press NEXT to navigate to the Override

menu.

3. Press ENTER to enter the Override

menu.

4. Select Manual Override to Max.

5. Select the Maximum Heat Time after

which the control resumes normal

operation.

6. Exit the Manual Override by selecting

Auto.

Manual override — test

When operating an electric snow melting

system, the control includes a Test

operation where the electrical heating

cables can be energized for 10 minutes

after which the control resumes normal

operation. This allows testing of the electric

snow melting system during warm weather.

1. Press and hold the Home button for

3 seconds.

2. Press NEXT to navigate to the Override

menu.

3. Press ENTER to enter the Override

menu.

4. Select Manual Override to Test.

5. Exit the Manual Override by selecting

Auto.

Manual override — purge

When operating a hydronic snow melting

system, it is necessary to purge and

bleed all air out of the system. The control

includes a Purge operation where the

System Pump is turned on to assist in

purging air from the system.

1. Press and hold the Home button for

3 seconds.

2. Press NEXT to navigate to the

Override menu.

3. Press ENTER to enter the

Override menu.

4. Select Manual Override to Purge.

5. Select the Maximum Purge Time

after which the control resumes

normal operation.

6. Exit the Manual Override by

selecting Auto.

Page 11

Single-zone snow melt control installation and operation manual | 11

Switch settings

Back of control

Power: 24 V (ac) ±10%, 60 Hz, Class 2,

16 VA standby, 100 VA fully loaded

Relays: 24 V (ac) 2 A, 3.5 A combined

1058-05

Switch

settings

Designed and assembled in Canada

Meets Class B: ICES & FCC Part 15

Lock

Unused

Unlock

ON

1

2

HxxxxA

Single-zone

Snow Melt Control

Switch Position Action

1

ON

Lock access level – The control

is locally locked and the access

level cannot be changed. Set to

Lock when installation has been

completed.

OFF

Unlock access level – The

control is unlocked and the

access level may be changed. Go

to the Toolbox menu to change

the access level. Set to Unlock

during the installation process.

2

ON Not used

OFF Not used

Manual override — off

The snow melting system can be manually

turned off and the control remains off until

manually changed back to Auto. This allows

the installer or end user to permanently

disable the snow melting system without

removing power from the control.

1. Press and hold the Home button for

3 seconds.

2. Press NEXT to navigate to the Override

menu.

3. Press ENTER to enter the Override

menu.

4. Select Manual Override to Off.

5. Exit the Manual Override by selecting

Auto.

Page 12

12 | uponorpro.com

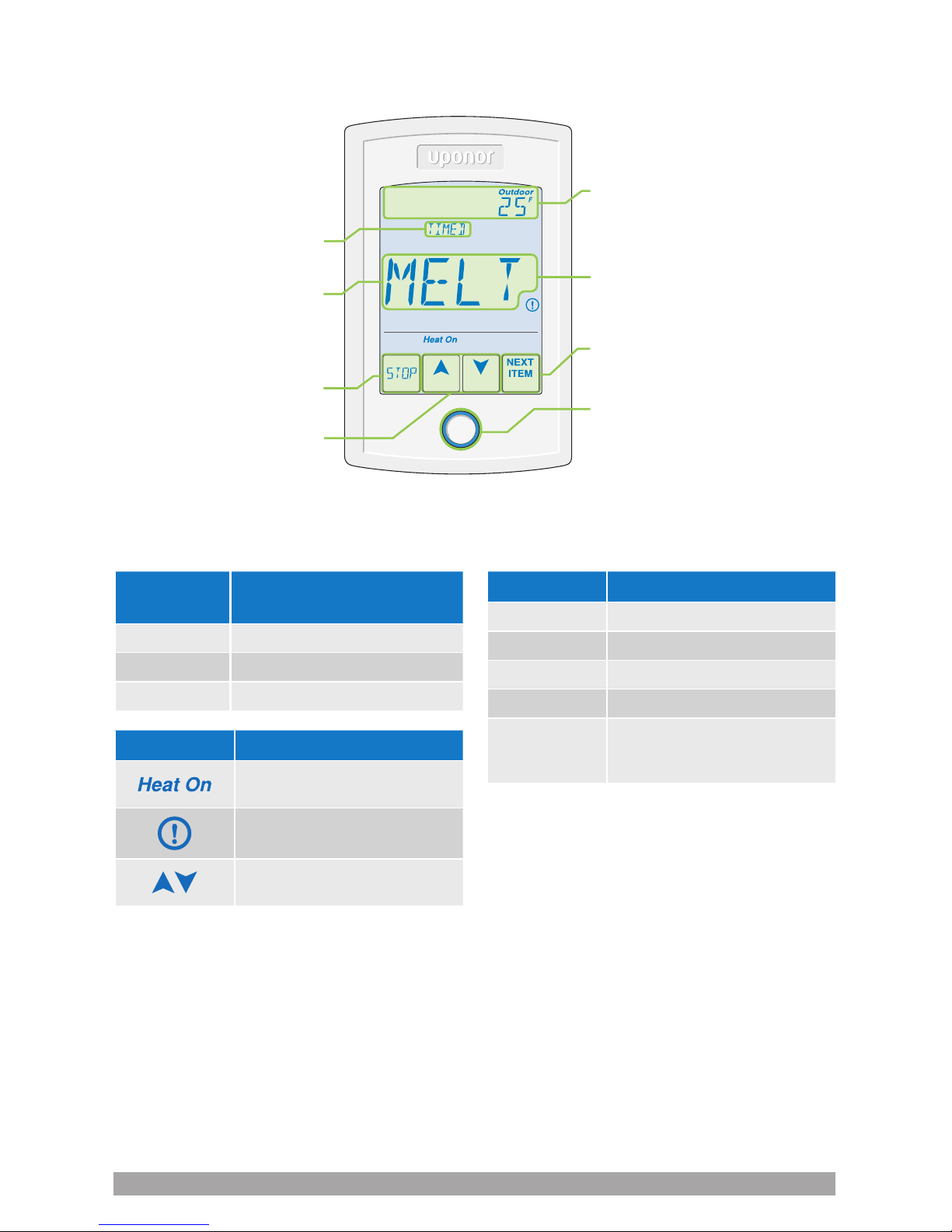

Home

button

ENTER

Status field

Touch to display

run time, outdoor

and slab temperature

Touch to quickly

enter the view menu

Touch to go to the next setting

Home button returns to the

Home screen; press and hold

for 3 seconds to access

programming menus

Operation field

Touch to melt or stop

Touch to adjust settings

User interface

Display

Operational

field

Action

MELT System is melting snow or ice.

IDLE System is idling.

OFF System is off.

Status field Action

WWSD System is melting snow or ice.

CWCO System is idling.

TIMED System is in storm operation.

WARM System is off.

PEND

Pending; the system has

detected water, but it is too

cold to operate.

Symbols Definition

HEAT ON

Heat is turned up.

WARNING SYMBOL

An error is present.

ARROWS

Adjusts the displayed setting.

Page 13

Single-zone snow melt control installation and operation manual | 13

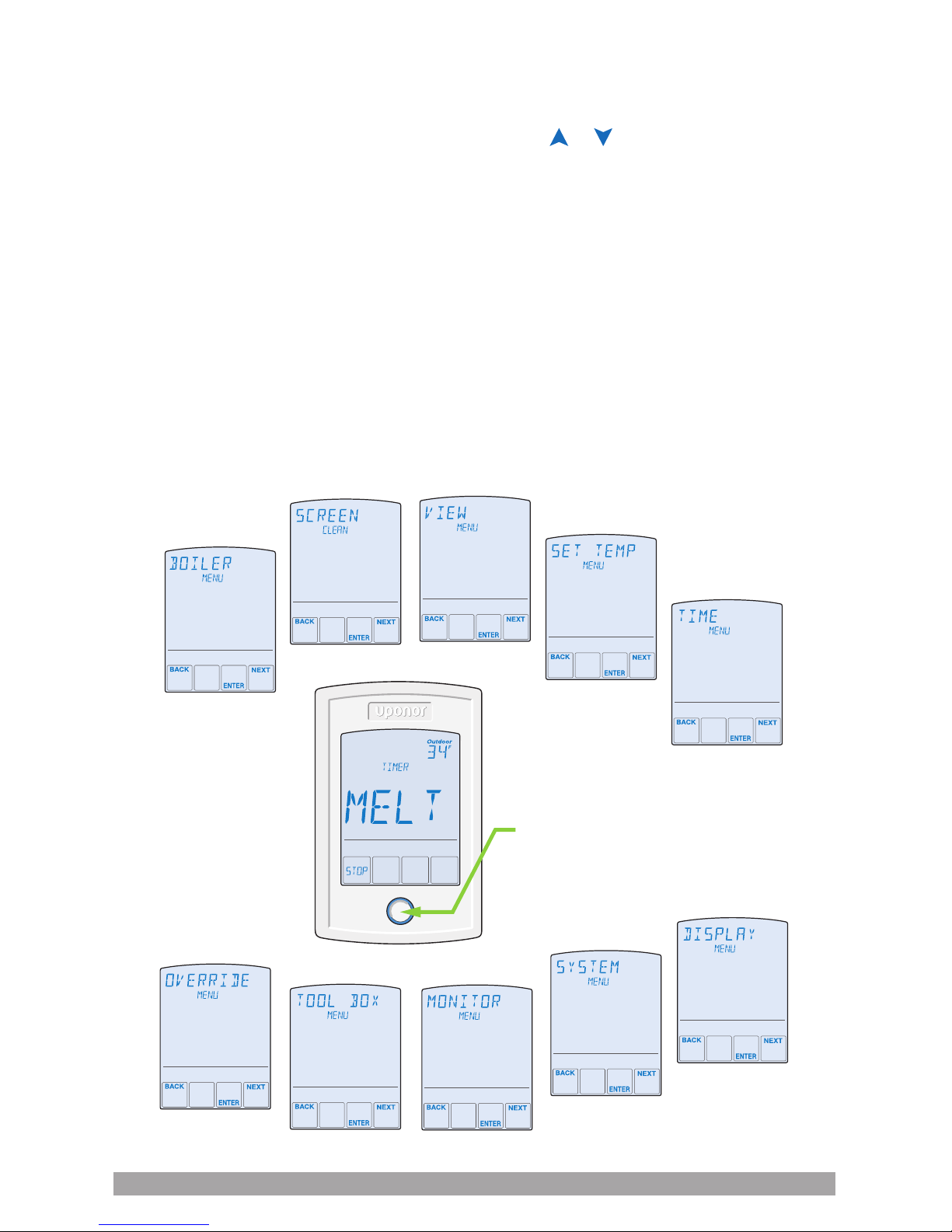

Programmable settings

Programming menus

Press and hold the Home button for 3

seconds to enter the programming menus.

The control returns to the last programming

menu previously used.

Select a programming menu

• Touch NEXT to advance

(clockwise in below illustration)

to the next menu.

• Touch BACK to go backwards

(counterclockwise in below illustration)

through the menus.

• Touch ENTER to enter a menu.

Setting items

• Touch or arrows to adjust the setting

if required.

• Touch NEXT ITEM to advance to the next

item within the menu.

• Touch BACK ITEM to go backwards to

the previous item within the menu.

• To return to the parent menu after

changing a setting, press and release

the Home button.

• To return to the Home screen, press and

release the Home button twice or wait

30 seconds to automatically return to

the Home screen.

Press and hold for

3 seconds to access

the programming menus.

Page 14

14 | uponorpro.com

Access levels and access

level lock

The control is shipped pre-programmed

with common settings. The control has an

Installer access level that allows full access

to all settings and a user access level that

restricts the number of settings available.

The control defaults to the User access

level after 12 hours of operation.

To change to the Installer access level:

• In the Toolbox menu, locate Access.

• Adjust the access level to Installer by

pressing the up or down button. This will

permit setting changes to the control.

View menu (1 of 2)

The View menu displays the current operating temperatures and status information

of the system.

Field

Range Access Description Set to

– – –,

-76 to 149ºF

(-60 to 65ºC)

User

Installer

OUTDOOR — Current outdoor air temperature

as measured by the local outdoor sensor.

Conditions: Application Mode is set to PWM,

Boil or Elec.

– – –,

-76 to 149ºF

(-60 to 65ºC)

Installer

SLAB TARGET — This field displays the

calculated slab target of the snow melting

system. Three dashes (– – –) display when

the snow melt control is off.

Conditions: Application Mode is set to PWM,

Boil or Elec and a snow/ice sensor or slab

sensor is installed.

-76 to 149ºF

(-60 to 65ºC)

User

Installer

SLAB — Current slab temperature as

measured by the control.

Conditions: Application Mode is set to PWM,

Boil or Elec and a snow/ice sensor or slab

sensor is installed.

DRY or WET

User

Installer

WATER SENSOR — Current status of the

water detection sensor.

Conditions: A snow/ice sensor or snow

sensor is installed.

– – –,

70 to 200ºF

(21.0 to 93.5ºC)

Installer

BOILER TARGET — This field displays

the calculated boiler target of the snow

melt system. Three dashes (– – –) display

when the snow melt control is not operating

the boiler.

Conditions: Application Mode is set to Boil.

-58 to 212ºF

(50.0 to

100.5ºC)

Installer

SUPPLY — Shows the current system supply

temperature as measured by the control.

Conditions: Application Mode is set to PWM

or Boil.

Page 15

Single-zone snow melt control installation and operation manual | 15

View menu (2 of 2)

The View menu displays the current operating temperatures and status information

of the system.

Field

Range Access Description Set to

0 to 100% Installer

BOILER RATE — Shows the current firing

rate of the modulating boiler.

Conditions: Application Mode is set to Boil

and Boiler Type is set to Mod (modulating

boiler).

OFF or ON

User

Installer

HEAT RELAY — Shows the current status of

the heat relay. The boiler or pump is on when

ON is displayed. The boiler or pump is off

when OFF is displayed.

Conditions: Application Mode is set to PWM,

Boil or Elec.

0 to 100% Installer

PWM RATE — Shows the current duty cycle

rate of the zone or boiler for each 20 minute

cycle.

Conditions: Application Mode is set to PWM

or Elec. Not visible when Manual Override is

not Auto.

OFF or ON

User

Installer

SYSTEM PUMP RELAY — Shows the current

status of the system pump relay.

Conditions: Application Mode is set to PWM

or Boil and Auxiliary Relay is set to SYS

(system pump).

OFF or ON

User

Installer

ALERT RELAY — Shows the current status

of the alert relay.

Conditions: Application Mode is set to PWM

or Boil and Auxiliary Relay is set to ALRT

(alert) or Application Mode is set to Elec.

00:00 to

24:00 hours

User

Installer

MANUAL MELT TIME — When manually

started, the display shows the remaining run

time before shutting off.

Conditions: Application Mode is set to PWM,

Boil or Elec.

00:00 to

6:00 hours

User

Installer

ADDITIONAL MELT TIME — When

automatically started by the Pavement

Snow and Ice Sensor, the display shows the

remaining run time before shutting off.

Conditions: Application Mode is set to PWM,

Boil or Elec and the Pavement Snow and Ice

Sensor (A3040090) is installed.

Page 16

16 | uponorpro.com

Set Temp menu

The Set Temp menu selects the operating temperatures of the snow melt system.

Field

Range Access Description Set to

32 to 95ºF

(0.0 to 35.0ºC)

Default = 36ºF

(2.0ºC)

User

Installer

MELTING — Selects the desired surface

temperature of the snow melt surface

when melting.

Conditions: Application Mode is set to PWM,

Boil or Elec.

OFF, 20 to

95ºF

(-6.5 to 35.0ºC)

Default = OFF

Installer

IDLING — Selects the desired surface

temperature of the snow melt surface when

idling. Idling pre-heats the slab when the

slab is dry but cold and allows faster reaction

time to reach the melting temperature.

(Recommended for commercial use only.)

Conditions: Application Mode is set to PWM,

Boil or Elec.

0:30 to

24:00 hours

Default =

4:00 hours

User

Installer

MANUAL MELT RUN TIME — Selects

the amount of running time when manually

starting the system.

Conditions: Application Mode is set to PWM,

Boil or Elec.

0:00 to

6:00 hours

Default =

0:00 hours

Installer

ADDITIONAL MELT TIME — Selects the

amount of additional melting time after the

Pavement Snow and Ice Sensor is dry. This

allows low spots on the slab to fully dry before

the snow melting system is shut off.

Conditions: Application Mode is set to

PWM, Boil or Elec and a Snow/Ice Sensor

is set to 090.

AUTO, MIN, -2,

-1, MID, +1, +2,

MAX

Default = AUTO

Installer

WATER SENSITIVITY — Selects how

sensitive the Pavement Snow and Ice

Sensor or the Aerial Snow Sensor is to

water detection.

Conditions: Snow/Ice Sensor is set to the

Pavement Snow and Ice Sensor or Aerial

Snow Sensor.

AUTO, 32 to

95ºF

(0.0 to 35.0ºC)

Default =

AUTO

Installer

WARM WEATHER SHUT DOWN — Selects

the temperature at which to shut down the

snow melting system during warm weather.

This allows the snow or ice to melt off the

slab naturally.

Conditions: Application Mode is set to PWM,

Boil or Elec.

OFF, -30 to

50ºF

(-34.5 to

10.0ºC)

Default = 10ºF

(-12.0ºC)

Installer

COLD WEATHER CUT OUT — Selects the

temperature at which to shut down the snow

melting system during extremely cold weather.

Below this temperature, the heat loss of the

slab exceeds the capacity of the boiler or

heating appliance.

Page 17

Single-zone snow melt control installation and operation manual | 17

Monitor menu

The Monitor menu provides information about the system’s operation and performance.

The Monitor menu is not available when the Application Mode is set to the Pavement

Snow and Ice Sensor.

Field

Range Access Description Set to

0 to 9999

hours

User

Installer

HEAT HOURS — Records the number of running

hours since the item was last reset. Touch the

number and then the ENTER key to reset to zero.

0 to 9999

hours

Installer

HEAT CYCLES — Records the numbers of

cycles of the heat relay since the item was last

reset. Touch the number and then the ENTER

key to reset to zero.

0 to 9999

hours

User

Installer

SYSTEM PUMP HOURS — Records the system

pump running hours since the item was last reset.

Touch the number and then the ENTER key to

reset to zero.

Conditions: Auxiliary Relay is set to SYS

(system pump).

-58 to 167ºF

(-50.0 to

75.0ºC)

Installer

SLAB HIGH — Records the highest slab

temperature since the item was last reset. Touch

the number and then the ENTER key to reset.

Conditions: Sensor is set to the Pavement Snow

and Ice Sensor or Slab Sensor is set to On.

-58 to 167ºF

(-50.0 to

75.0ºC)

Installer

SLAB LOW — Records the lowest slab

temperature since the item was last reset. Touch

the number and then the ENTER key to reset.

Conditions: Snow/Ice Sensor is set to the

Pavement Snow and Ice Sensor or Slab Sensor

is set to On.

-58 to 212ºF

(-50.0 to

100.0ºC)

Installer

OUTDOOR HIGH — Records the highest outdoor

temperature since the item was last reset. Touch

the number and then the ENTER key to reset.

-58 to 212ºF

(-50.0 to

100.0ºC)

Installer

OUTDOOR LOW — Records the lowest outdoor

temperature since the item was last reset. Touch

the number and then the ENTER key to reset.

-58 to 212ºF

(-50.0 to

100.0ºC)

Installer

SUPPLY HIGH —Records the highest supply

temperature since the item was last reset. Touch

the number and then the ENTER key to reset.

Conditions: Application Mode is set to PWM

or Boil.

-58 to 212ºF

(-50.0 to

100.0ºC)

Installer

SUPPLY LOW — Records the lowest supply

temperature since the item was last reset. Touch

the number and then the ENTER key to reset.

Conditions: Application Mode is set to PWM

or Boil.

Page 18

18 | uponorpro.com

Toolbox menu

The Toolbox menu is a location for system information and Test functions. If any errors are

present on the system, they will be located at the beginning of this menu.

Field

Range Access Description Set to

Installer (INST)

User (USER

Default = INST

User

Installer

ACCESS LEVEL — Selects the access level

of the control, which determines which menus

and items are available.

Conditions: Adjustable only when control

switch setting is set to UNLOCK.

Software

J1236A

Type 1058

User

Installer

SOFTWARE VERSION AND TYPE

NUMBER — Selects the access level of the

control, which determines which menus and

items are available.

Not applicable Installer

FACTORY DEFAULTS — Loads the factory

default settings. Press ENTER to load defaults.

See

Troubleshooting

Guide on p. 30

Installer

HISTORY - 1 THROUGH 5 — Displays a

history of any past errors that have occurred

on the system. Will clear after 30 days, or

press Up and Down buttons for one second to

manually clear. The last five history items will

display if present.

Display menu

The Display menu selects the temperature units and backlight options.

Field

Range Access Description Set to

or ºC

Default = ºF

User

Installer

UNITS — Selects Fahrenheit or Celsius as the

temperature units.

ON,

ON MELT,

OFF

Default =

ON MELT

User

Installer

BACKLIGHT — Selects how the display

backlight operates.

ON = Always on

ON MELT = On when melting, off when not

melting

This provides a visual indicator to occupants that

the snow melting system is currently melting.

OFF = Always off

Page 19

Single-zone snow melt control installation and operation manual | 19

Override menu

The Override menu allows an operator to manually test each relay and manually start the

system.

Field

Range Access Description Set to

Hydronic

AUTO,

HAND,

MAX,

PRGE, OFF

Electric

AUTO, AND,

TEST, OFF

Default =

AUTO

Installer

MANUAL OVERRIDE — Manually overrides

the normal automatic operation of the control to

test the equipment or operate the system at the

maximum temperature limits.

AUTO = Normal operation

HAND = Manual override of each relay output

MAX = Operate hydronic system at maximum heat

TEST = Operate electric system for 10 minutes

PRGE = Hydronic system purge operates pumps

to help bleed air from the system

OFF or ON

Default =

OFF

Installer

SYSTEM PUMP RELAY — Manually turns on the

system pump during the HAND Manual Override.

OFF or ON

Default =

OFF

Installer

HEAT RELAY — Manually turns on the heat

during the HAND Manual Override.

0 to 100%

Default =

0%

Installer

BOILER PERCENT — Manually sets the

modulating boiler firing rate during the HAND

Manual Override.

Conditions: Application Mode is set to Boil.

OFF or ON

Default =

OFF

Installer

ALERT RELAY — Manually turns on the alert

relay during the HAND Manual Override.

Conditions: Application Mode is set to PWM or

Boil and Alert Relay is set to ALRT (alert) or the

Application Mode is set to Elec.

0:10 to

72:00 hours

Default =

0:10 hours

Installer

OVERRIDE TIME — Selects the amount of time

that the HAND Manual Override is in effect before

returning to Automatic operation.

0:10 to

72:00 hours

Default =

24:00 hours

Installer

MAXIMUM PURGE TIME — Selects the amount

of time that the PURGE Manual Override is in

effect before returning to Automatic operation.

Conditions: Application Mode is set to PWM

or Boil.

0:10 to

72:00 hours

Default =

24:00 hours

Installer

MAXIMUM HEAT TIME — Selects the amount

of time that the MAX HEAT Manual Override is in

effect before returning to Automatic operation.

Conditions: Application Mode is set to PWM

or Boil.

Page 20

20 | uponorpro.com

System menu

The System menu provides settings on how to congure and operate the mechanical

equipment.

Field

Range Access Description Set to

PWM, BOIL,

ELEC,

Default =

PWM

Installer

APPLICATION MODE — Select the control

application mode.

PWM = Hydronic pulse width modulation

BOIL = Hydronic boiler heats snow melting system

ELEC = Electric snow melt

NONE, 090,

095

Default =

090

Installer

SNOW/ICE SENSOR — Selects if a Pavement

Snow and Ice Sensor or Aerial Snow Sensor is

installed.

OFF or ON

Default =

ON

Installer

SLAB SENSOR — Selects if a Slab Sensor for

Aerial Snow Sensor is installed to measure the

slab temperature.

Conditions: Application Mode is set to PWM,

Boil or Elec and Snow/Ice Sensor is set to None

or 095.

OFF or ON

Default =

ON

Installer

SLAB PROTECTION — Select if the slab should

be protected from large temperature differentials

to avoid cracking the concrete due to high tensile

stress.

Conditions: Application Mode is set to Boil and

Snow/Ice Sensor is set to 090 or Slab Sensor is

set to On.

OFF or ON

Default =

OFF

Installer

ECONOMELT — EconoMelt allows the user to

mechanically remove snow then manually start

the system to melt the thin snow layer or ice.

Conditions: Application Mode is set to PWM,

Boil or Elec.

SYS

(System

Pump)

or ALRT

(Alert)

Default =

SYS

Installer

AUXILIARY RELAY — Select if the auxiliary

relay should function as system pump or as

an alert.

Conditions: Application Mode is set to PWM

or Boil.

0.5 to 7.0

days, OFF

Default = 3.0

days

Installer

MAXIMUM MELT TIME — Select to limit

the amount of melting run time after snow is

automatically detected by the Pavement Snow

and Ice Sensor or Aerial Snow Sensor.

Conditions: Application Mode is set to PWM,

Boil or Elec.

Page 21

Single-zone snow melt control installation and operation manual | 21

Boiler menu

The Boiler menu provides settings on how to congure and operate the boiler.

Field

Range Access Description Set to

App mode =

Boil

MOD,

1STG,

EMS1,

EMS2

Default =

MOD

Installer

BOILER TYPE — Shows the type of boiler

connected to the control.

MOD = Modulating boiler

1STG = Single one-stage on-off boiler

EMS1 = Boiler staging controls

EMS2 = Viessmann modulating boilers with 0-10

V OpenTherm Module

0-10 or 4-20

Default =

0-10

Installer

BOILER MODULATION TYPE — Selects if the

modulating boiler accepts a 0-10 VDC or 4-20

mA input signal to control the boiler firing rate.

Conditions: Boiler Type is set to MOD

(modulating boiler).

0 to 50%

Default =

0%

Installer

BOILER MINIMUM MODULATION — Shows the

minimum-percent modulation of the boiler burner.

Conditions: Boiler Type is set to MOD

(modulating boiler).

OFF, 10 to

180 seconds

Default =

OFF

Installer

BOILER MODULATION DELAY — Shows the

delay time between the burner firing and the

boiler releasing to modulation.

Conditions: Boiler Type is set to MOD

(modulating boiler).

30 to 230

seconds

Default =

30 seconds

Installer

BOILER MOTOR SPEED — Shows the time

required for the modulating actuating motor to

fully open the gas valve or ramp the burner fan

from off to full speed on a modulating boiler. Set

to 30 seconds unless otherwise recommended

by the boiler manufacturer.

Conditions: Boiler Type is set to MOD

(modulating boiler).

AUTO, 2 to

42ºF

(1.0 to

23.5ºC)

Default =

AUTO

Installer

BOILER DIFFERENTIAL — Shows the

temperature differential that the control is to use

to cycle the boiler on and off (half above and half

below target).

Conditions: Boiler Type is set to MOD

(modulating boiler) or 1STG (one stage).

OFF, 50 to

180ºF

(10.0 to

82.0ºC)

Default =

OFF

Installer

BOILER MINIMUM — Shows the minimum

allowed boiler target temperature. Check the

boiler manufacturer’s manual for recommended

supply water temperatures.

Conditions: Application Mode is set to Boil.

Page 22

22 | uponorpro.com

Sequence of operation

Snow melting overview

A snow melting system can offer a safe,

convenient and cost-effective way to

remove snow and ice from surfaces.

Activating the snow melting system as

soon as the snow falls rather than waiting

for mechanical snow removal after snow

has accumulated is a safer alternative.

This eliminates slip hazards and reduces

the risk of injury by mechanized snow

melting equipment, thereby reducing

potential liability costs. Eliminating snow

plow equipment and corrosive salts also

reduces damage to the slab surface and to

the environment. Additionally, snow melting

systems, when controlled correctly, can be

cost competitive compared to mechanical

snow removal.

The snow melting control can operate in

one of three different ways:

• Melt: Heats the slab to melt snow or ice

• Idle: Pre-heats the slab just below freezing

to shorten the time required to melt snow

• Off: Snow melting system is off

The control display shows the control

operation in the home screen.

Slab temperature control

Controlling the slab temperature is critical

to minimizing the cost of snow melting. This

requires installation of the Pavement Snow

and Ice Sensor (A3040090) or Slab Sensor

for Aerial Snow Sensor (A3040073).

The sensor contains a built-in slab

temperature sensor. While the control

will continue to operate without a slab

sensor installed, operating costs will

be much higher.

The slab is operated using slab outdoor

reset. As the outdoor temperature gets

colder, the heat loss of the slab increases.

In order to keep the slab surface at a

constant temperature while operating, the

inner core of the slab must be heated above

the melt or idle temperature setting.

The amount that the slab inner core

temperature is above the melt or idle setting

is proportional to the outdoor temperature.

Since the slab sensor is installed below the

surface of the slab, it is not measuring the

true slab surface temperature, but rather the

inner core temperature.

The control automatically compensates for

this temperature difference. However, the

slab item in the View menu displays the

actual measured temperature, so it

is normal to view slab temperatures that

exceed the melt or idle temperature settings.

Melt operation

The snow melting system operates the

heating equipment to heat the slab from

a cold start or from the idle temperature

to reach the melt temperature setting to

melt snow or ice.

Melt operation can be triggered automatically

using the Pavement Snow and Ice Sensor,

the Aerial Snow Sensor or manually by

pressing a button. The melt temperature

setting affects calculated targets such as

the slab target and boiler target.

Surface temp. = 35˚F (1.7˚C)

Slab outdoor reset

Core (sensor) is warmer.

Decreasing air temperature

Slab surface temperature is constant.

Increasing slab core temperature

Page 23

Single-zone snow melt control installation and operation manual | 23

Manual start and timed stop

The snow melting system can be started

manually by touching the Melt key on the

control display.

Once manually started, the snow melting

system continues to operate until the time

set by the Manual Melt Run Time setting in

the Set Temp menu elapses.

If a manual start has been provided and a

sensor detects water, the control changes

from manual melt to automatic operation.

The snow melting system will continue

to operate until the sensor is dry and the

Additional Melt Time elapses.

Automatic start and stop

Automatic start and stop operation requires

the installation of a Pavement Snow and Ice

Sensor (A3040090). The control continually

monitors the sensor for the presence of

moisture and slab temperature conditions

in which snow or ice may be present. When

moisture is detected, the control will show

Sensor Water Wet in the View menu. When

the sensor is dry the control will show

Sensor Water Dry. The control includes a

Sensitivity setting in the Set Temp menu

that allows the installer to adjust the amount

of moisture required to start and stop

the melting operation. In areas with low

amounts of dust and/or air pollution, the

sensitivity may need to be increased.

The Sensitivity setting default is Auto,

and the control will automatically determine

the best suitable sensitivity setting for

the installation.

When moisture is detected and the slab

and outdoor temperatures are at or below

freezing, the control will automatically start

the snow melting system. As the snow or ice

melts and the slab dries off, the sensor also

dries off at the same time. When the sensor

is dry, the snow melt system automatically

shuts off. If there are low spots on the slab

surface that dry off slower than the sensor,

additional melting run time can be included

by adjusting the Additional Melt Time setting

in the Set Temp menu.

WWSD

Touch STOP key

Aerial Snow Sensor and slab dry

and MELT time elapses

Aerial Snow Sensor detects water

Touch MELT key

CWCO

Timed

melt

Idle

or

off

Touch

MELT

Melt

suspended

Enters

CWCO

Exits

CWCO

Pavement Snow

and Ice Sensor

(A3040090)

Pavement sensor and slab dry and

ADD MELT time elapses

Pavement sensor detects water

WWSD

Touch STOP key

Timed

melt

Idle

or

off

Touch MELT key

Page 24

24 | uponorpro.com

Melt

suspended

Enters

CWCO

Exits

CWCO

Pavement sensor and slab dry and

ADD MELT time elapses

Pavement sensor detects water

WWSD

Touch STOP key

Timed

melt

Idle

or

off

Touch MELT key

If the snow melting system is manually

stopped, the sensor must fully dry

before it is able to detect a new snow

fall and automatically start the snow

melting system.

EconoMelt

When a Pavement Snow and Ice

Sensor is installed, the installer can

choose to select to either automatically

or manually start the snow melting

system. Selecting EconoMelt to On

provides the option to remove the snow

using a snow plow or shovel and then

use the snow melting system to melt the

remaining thin layer of snow or ice that

mechanical snow removal methods are

unable to remove. The snow melting

system stops when the sensor is dry.

The factory default for EconoMelt is Off.

Melt

suspended

MeltOff

Enters

CWCO

WWSD

Touch STOP key

Touch START key

Pavement sensor and slab dry

and ADD MELT time elapses

Exits

CWCO

Automatic start and timed stop

Automatic start with a timed stop operation

requires the installation of an Aerial Snow

Sensor (A3040095). It is also highly

recommended to install a Slab Sensor for

Aerial Snow Sensor (A3040073) to regulate

the slab temperature and operate the snow

melting system at the highest possible

efciency.

The control continually monitors the sensor

for the presence of moisture and slab

temperature conditions in which snow

or ice may be present. When moisture

is detected, the control will show Sensor

Water Wet in the View menu. When the

sensor is dry the control will show Sensor

Water Dry. The control includes a Sensitivity

setting in the Set Temp menu that allows the

installer to adjust the amount of moisture

required to start and stop the melting

operation. In areas with low amounts of dust

and/or air pollution, the sensitivity may need

to be increased. The factory default is for

the Sensitivity setting is Auto. The control

automatically determines the best suitable

sensitivity setting for the installation.

Aerial

Snow Sensor

(A3040095)

Aerial

snow

sensor

Page 25

Single-zone snow melt control installation and operation manual | 25

Additional melting time

A Pavement Snow and Ice Sensor

(A3040090) automatically shuts off the snow

melting system when the water sensor is

dry. Due to the construction of the slab and

the layout of the heating pipe or electrical

cable, there may be areas that do not

melt completely. The Additional Melt

Time setting in the Set Temp menu allows

the installer to set additional melting time

after the sensor is dry.

Idle operation

When the snow melting system starts

from a cold temperature, there may be a

long time delay before the slab is warm

enough to melt snow. This time delay allows

snow to accumulate on the slab which is

not acceptable in some commercial and

institutional applications. To decrease the

start-up time, the slab can be pre-heated to

maintain a minimum temperature.

This is known as the Idle temperature.

Idling requires large energy consumption

and is generally recommended for

institutional and/or commercial installations

where safety concerns are paramount.

Idle is shown on the display when the

control is in idle operation.

When designing a snow melting system, an

engineer may specify the amount of allowed

snow accumulation as the Snow-free Area

Ratio. There are three different levels. A

Snow-free Area Ratio of 1 is dened as a

system that melts all snow as it falls with

no allowed accumulation. This requires

that the Idle temperature be set just below

freezing. Examples of these types

of applications include:

• Hospital emergency areas

• Helicopter landing pads

• Parking garage ramps

A Snow-free Area Ratio of 0.5 is dened

as a system with partial snow accumulation

on the slab but not in all areas.

These types of systems may also use idling

but usually set at a temperature several

degrees below freezing to reduce energy

consumption. Applications may include:

• Steep residential driveways

• Commercial sidewalks

• Loading docks

When moisture is detected and both

the slab and outdoor temperatures

are below the Melting setting, the

control automatically starts the snow

melting system. The snow melting

system operates to heat the slab

to the slab target temperature and

continues to operate until the time set

by the Manual Melt Run Time in the

Set Temp menu elapses.

Pavement snow

and ice sensor

Dry

WWSD

Touch STOP key

Aerial Snow Sensor and slab dry

and MELT time elapses

Aerial Snow Sensor detects water

Touch MELT key

CWCO

Timed

melt

Idle

or

off

Page 26

26 | uponorpro.com

A Snow-free Area Ratio of 0 is dened as

a system that allows snow accumulation.

These systems operate the snow melting

system from a cold start resulting in the

lowest energy consumption costs and the

longest times to start melting snow.

In this case, set the Idle to off. This

is recommended for most residential

applications:

• Flat residential driveways

• Patios

• Residential sidewalks

Some systems are designed for keeping

a slab surface free of ice rather than free

of snow. The most common applications

include:

• Car wash bays and aprons

• Aircraft hanger aprons

• Turf conditioning on golf course greens

These systems require the use of idling at

or near freezing throughout the winter and

may result in high energy consumption.

Warm weather shut down

During warm weather, the slab is warm

enough to naturally melt snow or ice. The

control has a Warm Weather Shut Down

(WWSD) setting in the Set Temp menu that

prevents the control from entering Melt or

Idle operation in order to conserve energy.

The control shows WWSD on the display

when WWSD is in effect.

Automatic (Auto)

The control enters WWSD when both

the slab temperature of the zone and the

outdoor temperature exceed the Melt

temperature setting by more than 2ºF (1ºC).

Manual WWSD

The control enters WWSD when the

outdoor air temperature exceeds the

WWSD setting by 1ºF (0.5ºC) and when

the slab temperature exceeds 34ºF (1ºC).

The control exits WWSD when the outdoor

air temperature falls 1ºF (0.5ºC) below the

WWSD setting or if the slab temperature

falls below 34ºF (1ºC). This allows the Melt

temperature setting to be set higher than

the WWSD. This is useful when high slab

temperatures are required to melt the snow

or ice. An example of this are installations

using paving bricks on top of sand and

concrete layers.

Cold weather cut out

Maintaining the melting or idling

temperature during extremely cold

temperatures is not only expensive but may

be impossible if the heat loss of the slab

exceeds the input capacity of the heating

plant or electric cable. The control turns the

snow melting system off when the outdoor

air temperature drops below the Cold

Weather Cut Out (CWCO) temperature

and the slab is below freezing. This is a

safety and energy-saving measure. The

control shows CWCO on the display when

CWCO is in effect. When the temperature

reaches the CWCO setting in an actively

melting system with a Pavement Snow and

Ice Sensor, melting is suspended until the

outdoor temperature rises above the CWCO

setting. If a Pavement Snow and Ice Sensor

is not installed, melting is permanently

stopped when CWCO is in effect. Melting

does not resume when the temperature

rises above the CWCO setting.

Page 27

Single-zone snow melt control installation and operation manual | 27

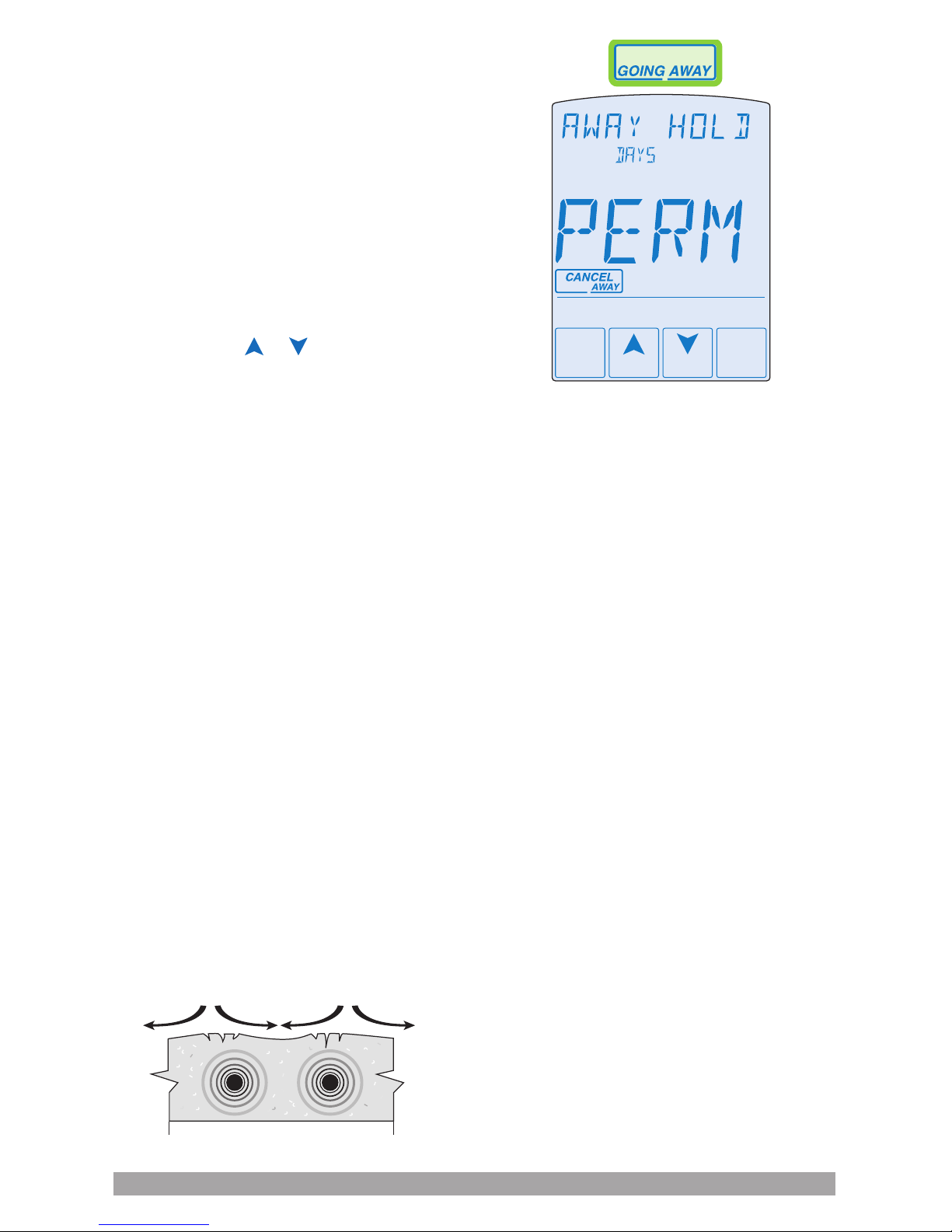

Away key

Disable the snow melting system with the

Away Key. To turn on the Away Key, go to

the Display menu.

• Select AWAY KEY.

• Select ON.

To activate the Away Override (once the

Away Key has been activated).

• Touch “Going Away” on the screen.

• Select PERM (permanent) or a number of

days using the or arrow. Range is 1

to 180 days.

• Press the home button to accept the

setting or leave the screen

untouched for several seconds.

• “Away” is displayed on the home screen

until the number of days expires.

• Touch “Cancel Away” to cancel at any time

Slab protection

In a hydronic snow melting system, the

boiler or heating plant capacity may be

much larger than the load of the snow

melting zones. This can result in large

temperature differentials between the

supply water temperature and the slab,

creating large tensile stresses on

the slab.

Concrete is weak to tensile forces and when

repeatedly exposed to tensile loads the

concrete may crack. This may be prevented

by selecting the Protect Slab setting in the

System menu to On. The control measures

and limits the temperature differential

between the supply water and the slab.

Application modes

The snow melting control can operate either

an electric or a hydronic snow melting

system. A hydronic system can be further

categorized as either boiler or pulse width

modulation (PWM) zone operation as well

as whether the boiler plant is dedicated or

non-dedicated for the snow melting system.

A dedicated boiler only provides heat from

the snow melting system. A non-dedicated

boiler provides heat for the snow melting

system in addition to the space heating and/

or domestic hot water system. The control

requires that one of the following Application

Modes is selected in the System menu:

• PWM: Pulse width modulation

• BOIL: Boiler operation

• ELEC: Electrical operation

Tensile stresses

Page 28

28 | uponorpro.com

Electric operation

The control operates the heat relay on

a 20-minute PWM cycle. The heat relay,

in turn, activates a line voltage electrical

contactor to energize the electrical cable

heater installed in the slab. The heat relay

on time is determined by the calculated

slab target and by the measured slab

temperature reading.

As the slab temperature reaches the

slab target, the on time per cycle of the

heat relay is reduced to prevent the slab

temperature from overshooting. If no

slab sensor is installed, the heat relay

remains on 100% of the time until the Melt

operation has completed. Idle operation

is not available when a slab sensor is not

installed. The electric operation requires

the installation of an outdoor sensor. A slab

sensor is highly recommended to reduce

operating costs.

Pulse width modulation

operation

The Application Mode should be set to

Pulse Width Modulation (PWM) when the

boiler or heat source is non-dedicated to

the snow melting system and there is no

mixing system. The snow melting system

is considered to be a zone together with

space heating and the domestic hot water

system. The control operates the heat

relay on a 20-minute PWM cycle. The

heat relay, in turn, activates the hydronic

heating system zone pump or zone valve.

The heat relay on time is determined by the

calculated slab target and by the measured

slab temperature reading. As the slab

temperature reaches the slab target, the on

time per cycle of the heat relay is reduced

to prevent the slab temperature from

overshooting. If no slab sensor is installed

the heat relay remains on 100% of the time

until the Melt operation has completed.

Idle operation is not available when a slab

sensor is not installed.

The hydronic PWM operation requires the

installation of an outdoor sensor and a

supply sensor. The supply sensor is

installed on the glycol antifreeze system

supply pipe and allows the control to

provide slab protection and as well as

supply zone priority. A slab sensor is highly

recommended to reduce operating costs.

Boiler operation

The Application Mode should be set to

Boil when the snow melting system has a

dedicated boiler or heat source. The boiler

is piped primary-secondary to the snow

melting loop, allowing the boiler to re

on and off while allowing continuous ow

through the snow melting system loop.

The control calculates a Boiler Target

based upon the Slab Target which,

in turn, is based upon the measured

outdoor temperature and the Melt or Idle

temperature setting. The control can

operate a boiler in one of four different

methods: single stage, modulating boiler,

EMS1 or EMS2. The Boiler Target is shown

in the View menu. Settings for the boiler

operation are located in the Boiler menu.

Note: The boiler operator, or aquastat,

remains in the burner circuit and acts

as a secondary upper limit on the

boiler temperature. The boiler aquastat

temperature setting must be adjusted

above 200ºF (93.5ºC) in order to

prevent short cycling of the burner.

Page 29

Single-zone snow melt control installation and operation manual | 29

Single stage on/off boiler (1STG)

The control turns the heat relay on or off

to re the boiler in order to maintain the

Boiler Target temperature. The boiler supply

temperature operates on a differential that is

half above and half below the boiler target.

The status of the boiler is shown by the Boil

Relay item in the View menu.

Modulating boiler (MOD)

The control can operate a single hot-water

modulating boiler using the Mod output and

the Heat contact. The control operates the

boiler by rst switching the heat contact to

allow the modulating boiler to go through

the ignition sequence (the heat contact may

not be required on all modulating boilers).

A 0-10 VDC or 4-20 mA analog signal is

then used to modulate the boiler ring rate

starting at 50% (5 VDC or 12 mA signal)

for 30 seconds. After the 30-second delay

has elapsed, the control will then allow the

boiler to modulate down to the Minimum

Modulation setting and hold it there for the

Modulation Delay time setting.

After the modulation delay has elapsed,

the control uses PID logic to change the

boiler ring rate signal in order to satisfy the

boiler target temperature. When the ring

rate signal is reduced down to the minimum

modulating setting and the boiler supply

temperature exceeds the boiler target by half

the differential, the control will shut off the

boiler burner. The modulating signal output

is shown by the Boil Rate in the View menu.

The Modulation Delay setting is determined

by the boiler manufacturer. It is the amount

of time that the burner must operate before

the internal boiler control allows an external

signal to operate the burner.

The Motor Speed sets the rate at which the

modulating electrical signal can change. For

most modulating boilers with an ECM fan,

the motor speed can be set to 30 seconds.

For commercial boilers with a mod motor,

set the motor speed according to the time

required by the mod motor to travel from the

closed to the open position.

EMS1

The EMS1 signal is a method for the snow

melting control to send the boiler target

temperature to a compatible boiler control

(if used). The control provides a 0-10 VDC

signal proportional to the boiler target and

turns on the heat relay to operate the boiler

to maintain the Boiler Target temperature.

EMS2

The EMS2 signal is a method for the snow

melting control to send the boiler target

to a Viessmann boiler that supports the

OpenTherm temperature targeting. Typical

boilers include the Viessmann Vitodens

100-W and 200-W. The boiler may require

an OpenTherm Input Module 0-10V.

Contact Viessmann for details.

The control provides a 0-10 VDC signal

proportional to the boiler target and turns

on the heat relay to operate the boiler to

maintain the Boiler Target temperature.

EMS1 conversion table

0-10 VDC Boiler target

0 – – – (Off)

1 50ºF (10ºC)

2 68ºF (20ºC)

3 86ºF (30ºC)

4 103ºF (39ºC)

5 121ºF (49ºC)

6 139ºF (59ºC)

7 157ºF (69ºC)

8 174ºF (79ºC)

9 192ºF (89ºC)

10 210ºF (99ºC)

Page 30

30 | uponorpro.com

Exercising

In a hydronic snow melting system, the

control operates the system pump every

three days to prevent pump seizure.

Alert relay

The control includes an auxiliary relay that

can be congured to be either a system

pump or an alert output. When the Auxiliary

Relay setting in the System menu is set to

Alert, the relay closes whenever there is a

local error code. The Alert Relay is connected

to the input power R and provides a 24 VAC

powered signal when closed. An isolation

relay may be installed if a dry contact switch

is required on the third-party equipment.

Pump post purge

After a zone has nished heating, the boiler

or heat source is shut off and the zone

continues to operate for 20 seconds to

post purge heat from the boiler to the zone.

Troubleshooting

It is recommended to complete all wiring to ensure trouble free operation. Should an error

occur, simply follow these steps:

1. Find: If the control ashes on the screen, it is indicating a problem on the system.

2. Identify: Hold the Home button for 3 seconds, touch the NEXT key to locate the Toolbox

Menu, then touch the ENTER key. The error code should appear as the rst item.

3. Solve: Use the chart below to match the error code to the one on the control. Use the

description to solve the problem

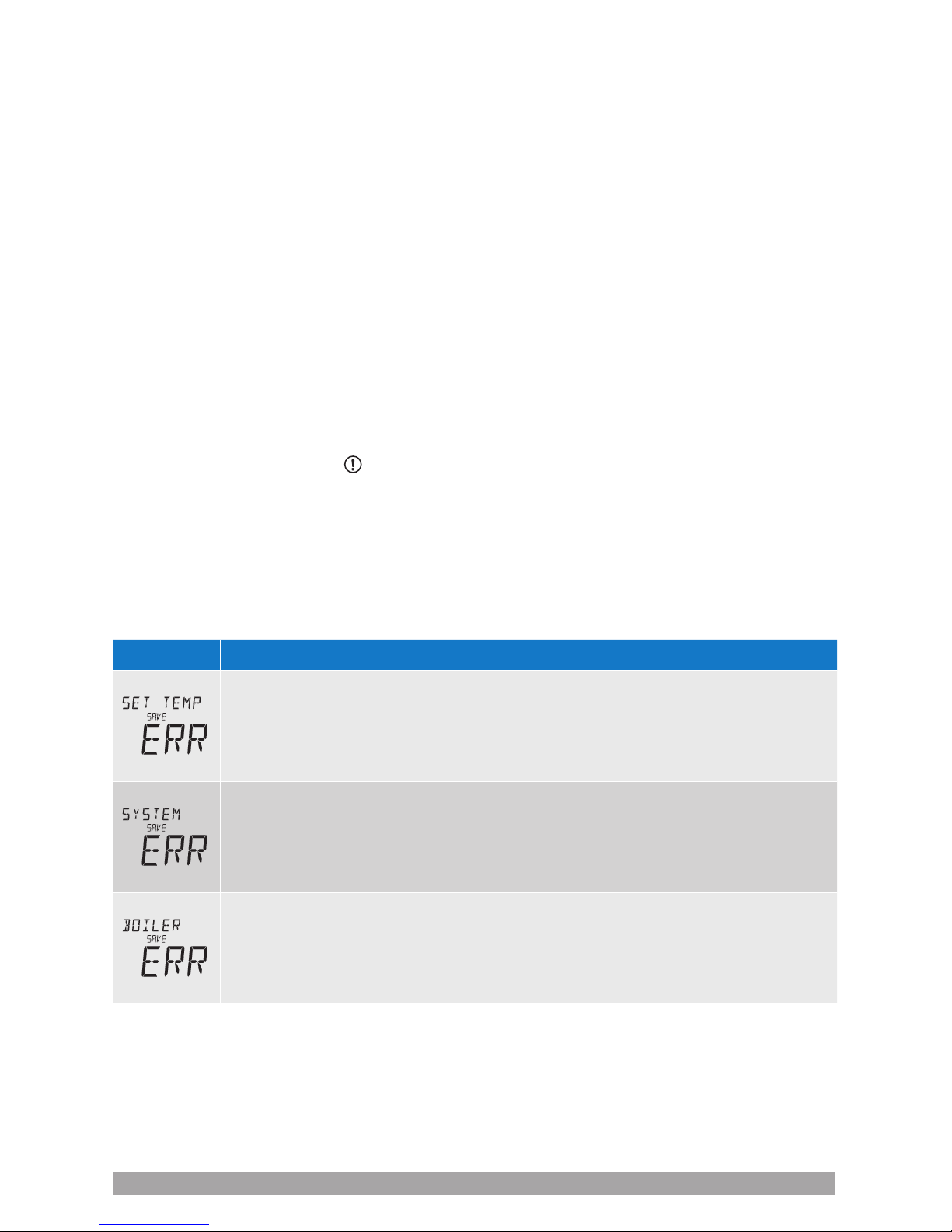

Error messages

Field

Description

SET TEMP MENU SAVE ERROR — The control failed to read the Set Temp menu

settings from memory and has reloaded the factory default settings. The control stops

operation until all settings in the Set Temp menu are checked.

To clear the error, set the access level to Installer and check all settings in the Set

Temp menu.

SYSTEM MENU SAVE ERROR — The control failed to read the System menu

settings from memory and has reloaded the factory default settings. The control

stops operation until all settings in the System menu are checked.

To clear the error, set the access level to Installer and check all settings in the

System menu.

BOILER MENU SAVE ERROR — The control failed to read the Boiler menu settings

from memory and has reloaded the factory default settings. The control stops

operation until all settings in the Boiler menu are checked.

To clear the error, set the access level to Installer and check all settings in the

Boiler menu.

Page 31

Single-zone snow melt control installation and operation manual | 31

Error messages

Field

Description

MAXIMUM MELT TIME ERROR — The control has operated in melting for the time

set by Maximum Melt Days setting located in the System menu. This error is usually

created when there is a mechanical system failure resulting in the snow melt slab not

heating correctly.

Clear the error message by touching the Cancel key while viewing the error

message. Use the Manual Override menu to manually check that each component of

the mechanical system is operating correctly.

If necessary, change the Maximum Melt Days setting to a longer time period or to Off.

OUTDOOR SENSOR SHORT CIRCUIT ERROR — Due to a short circuit, the control

is unable to read the outdoor sensor. The control continues to operate and assumes

an outdoor temperature of 32ºF (0ºC). Energy saving features such as Warm

Weather Shut Down (WWSD) and Cold Weather Cut Out (CWCO) are disabled.

Check the outdoor sensor wire for short circuits according to the sensor installation

manual. It may be necessary to replace the outdoor sensor. Once the error has been

corrected, the error message automatically clears.

OUTDOOR SENSOR OPEN CIRCUIT ERROR — Due to an open circuit, the control

is unable to read the outdoor sensor. The control continues to operate and assumes

an outdoor temperature of 32ºF (0ºC). Energy saving features such as Warm

Weather Shut Down (WWSD) and Cold Weather Cut Out (CWCO) are disabled.

Check the outdoor sensor wire for open circuits according to the sensor installation

manual. It may be necessary to replace the outdoor sensor. Once the error has been

corrected, the error message automatically clears.

SUPPLY SENSOR SHORT CIRCUIT ERROR — Due to a short circuit, the control

is unable to read the supply sensor. When set to App Mode Boiler, the control stops

operation and does not provide any heat. When set to App Mode PWM the control

continues melting or idling.

Check the supply sensor wire for short circuits according to the sensor installation

manual. It may be necessary to replace the supply sensor. Once the error has been

corrected, the error message automatically clears.

SUPPLY SENSOR OPEN CIRCUIT ERROR — Due to an open circuit, the control

is unable to read the supply sensor. When set to App Mode Boiler, the control stops

operation and does not provide any heat. When set to App Mode PWM the control

continues melting or idling.

Check the supply sensor wire for open circuits according to the sensor installation

manual. It may be necessary to replace the supply sensor. Once the error has been

corrected, the error message automatically clears.

SLAB SENSOR SHORT CIRCUIT ERROR — Due to a short circuit, the control is

unable to read the Slab Sensor for Aerial Snow Sensor (A3040073). Idling is disabled

and energy saving features such as Warm Weather Shut Down (WWSD) and Cold

Weather Cut Out (CWCO) are operated using the outdoor temperature only.

Check the slab sensor wire for short circuits according to the sensor installation

manual. It may be necessary to replace the slab sensor. Once the error has been

corrected, the error message automatically clears.

Page 32

32 | uponorpro.com

Symptoms and solutions

Symptom

Look for… Corrective action

LCD display is off Power to control Use electrical meter to measure 24 VAC voltage on input

power R and C terminals.

System pump

always on

Display shows idle Idle operation requires that the system pump operate

continuously while below the melting temperature setting.

Blue short Dirt or salt on

sensor

The sensor requires regular cleaning. Avoid using road

salt on the snow melting slab.

Slab is above melt

temperature

Slab target The slab is heated to the slab target.

Heat on not shown Check wiring of the system pump. The system pump

operates continuously during melt and idle operation.

The heat source must be wired to operate together with

the heat relay.

System running

with no snow

Idle Idling heats the slab when the temperature falls below

the Idle temperature.

Melt During Cold Weather Cut Out (CWCO), the system

is shut off. If shut off during a melt cycle, the system

resumes melting once the outdoor temperature is above

CWCO.

Timed melt System manually started.

Snow on slab but

system did not start

Off System has been manually stopped and the Pavement

Snow and Ice Sensor or the Aerial Snow Sensor never

dried, thereby preventing the system to automatically start.

Page 33

Single-zone snow melt control installation and operation manual | 33

Job record

Set Temp menu settings

Item

Setting

Melting

Idling

Manual melt run time

Additional melt time

Water sensitivity