Page 1

EN Instructions for fitting and use

Occupant Restraints

Unwin User Manual

Page 2

2

Wheelchair & Occupant Restraints Occupant Restraints

The following manual is an important part of the product, providing you with

information on how to achieve maximum performance and safe operation.

Keep the manual in a safe place so that you can refer to it when necessary.

If you have any questions about your equipment, please contact Unwin.

Once again, thank you for placing your confidence in our products!

Unwin

Thank you for choosing

Safe vehicle adaptation solutions

For your safety Unwin products are

designed and tested according to current

directives and standards.

Occupant Restraints

from Unwin!

Page 3

Safety information

4

6

8

Fit and use

10

14

16

18

After care

20 Equipment storage and maintenance

21 Warranty

Limitations of use

General guidance

Before installing and using the occupant restraints

Fitting & using the 2 & 3 point double inertia occupant restraint - Rail Floor

Fitting & using the 2 & 3 point double inertia occupant restraint - Bolted

Fitting & using the 3 point static occupant restraint

Fitting & using the 3 Point WAV retractable occupant restraint

3

Wheelchair & Occupant Restraints Occupant Restraints

EN

Index

“Declaration of conformity” at the end of the manual.

Page 4

Limitation of use

Safety information

The development of Unwin occupant restraint is a continuous process. Applications

are added on a regular basis. For more detail contact Unwin or look on the Unwin

website.

4

Wheelchair & Occupant Restraints Occupant Restraints

Page 5

Occupant Restraints

5

Wheelchair & Occupant Restraints Occupant Restraints

EN

Safety information

Page 6

General guidance

• Wheelchair Accessories that have not been approved by the Wheelchair Manufacturer must be

removed from the wheelchair and secured in the vehicle during transport to reduce the potential for

injury. Refer to ‘Instructions For Use in Transport’ provided with the wheelchair or contact wheelchair

manufacturer for further guidance.

• These occupant restraints comply with all applicable requirements of ISO 10542, including a 48km/h,

20g frontal impact test using a forward facing 85kg surrogate wheelchair and an ATD (test dummy) with

a mass of 76.3kg. The test dummy was restrained by both a pelvic and upper-torso restraint. Use of a

pelvic only belt may compromise the performance of the system and should be avoided.

• If the installation is to be used with an occupant head rest anchored to the vehicle, then a vehicleanchored back rest must be provided to minimise rearward deflection of the wheelchair seatback,

preventing neck injury.

• Regular inspection of all parts is recommended and the equipment should be used only if all

components are in good condition.

• Warning: protect webbing from contacting sharp edges and corners. Replace equipment if the

webbing does becomes cut, contaminated or frayed.

6

Wheelchair & Occupant Restraints Occupant Restraints

Page 7

• Any restraints which have been subjected to a crash situation from which the vehicle must be towed

should, in the interest of safety, be replaced.

• Do not attempt to modify the equipment. For further advice on the installation and use of this occupant

restraints, please contact Unwin. Please read this manual fully before use.

• Avoid contact with corrosive liquids. Care should be taken to prevent contamination of the webbing

with polishes, oils and chemicals.

• The anchorages should be installed by an experienced technician/vehicle converter. Anchorages should

not be installed into unsound materials such as corroded metal, wood, plastic and fibre glass panels,

without additional and suitable reinforcement.

7

Wheelchair & Occupant Restraints Occupant Restraints

EN

Safety information

Page 8

Before installing and using the occupant restraints

• Ensure that the wheelchair is correctly maintained and that the settings of any adjustable parts are made

according to ‘Instructions for Use in Transport’.

• Whenever possible remove any items of luggage etc that may be attached to the wheelchair and secure

or store separately during transport in order to reduce the potential for injury to other passengers

travelling in the vehicle.

• Extra care must be exercised when using vehicle boarding aids such as passenger lifts or ramps during

the loading process. Refer to ‘Instructions For Use’ for information on safe slopes.

• Position the wheelchair facing forward - centrally in the designated region of the vehicle. Ensure the

wheelchair brakes are applied.

• To minimise the potential for head injuries in an impact, allow a clear space of at least 400 mm behind

and 650 mm, (FCZ, front clear zone), in front of the head of the wheelchair user, (Fig A). The shoulder

belt anchorage must be roof or side-wall anchored at a height level such that the belt webbing passes

over the midpoint of the occupant shoulder and at a height that is at or just above the level of the

occupants shoulders so as not to impose downward loads on the spine.

• A height provision (HHT) ranging from 1000mm to 1550mm should be made, depending on the size

of the passenger. There should also be 200 mm of clear space either side of the wheelchair centre line.

If these clear space dimensions cannot be provided then any should be adequately padded and comply

with impact performance requirements of ECE Regulation 21 ‘FMVSS 201’. All vehicle padding should

comply with the flammability requirements of ECE Regulation 118 ‘FMVSS 302’.

Note: seated head

height (HHT)

ranges from as low

as 1000mm for a

6-year-old child to

1550mm for a tall

adult.

8

Wheelchair & Occupant Restraints Occupant Restraints

Page 9

• Wheelchair users, their carers and family are advised to check vehicle

specifications to ensure that sucient floor space is available to accommodate

the wheelchair and tie-down system. These occupant restraint distances are

based upon the desire to maintain clear zones for potential head excursions of

occupants provided with both upper and lower torso restraints.

• Users of heavy powered wheelchairs are also advised to check vehicle carrying

capacity. If in doubt consult the vehicle supplier for further details.

• Any airbag, as fitted to the vehicle, shall be used only as a supplementary

occupant restraint if designed to be used in combination with the occupant

restraint.

• Installers of these occupant restraints should take note of any vehicle airbag

position when planning the installation. Airbags can cause serious injury if a

wheelchair-seated occupant is seated too close to an airbag position. If in doubt

contact the vehicle manufacturer or your National Automotive Regulatory Body

for advice.

Figure A

9

Wheelchair & Occupant Restraints Occupant Restraints

EN

Safety information

Page 10

Fitting and using the 3 point double inertia occupant restraint

Fit and use

Rail floor

1. The rail will have been installed in the vehicle in accordance with their own and the vehicle

converter’s instruction. Position wheelchair within vehicle as required.

2. Wheelchair tie-downs (not supplied with these restraints) should be fitted first to secure

the wheelchair, before any occupant restraint is fitted.

3. Position the occupant restraint behind the wheelchair tie-down, with reel housing (Fig. 1A)

on the window side of the vehicle and reversible/fixed stalk (Fig.1B) on the aisle side.

4. Fit the occupant restraint ATF (aluminium track fitting) into the rail by aligning the ATF feet

with the cut-out sections of the rail. Locate into the rail, (Fig 2).

5. Press on the ribbed part of the ATF, (Fig 2A), and push firmly towards the wheelchair until

the yellow plunger drops and locks into the rail.

6. Position the third point fixing into the cant rail (Fig 3) so that it is vertically above the inertia

reel casing fixed onto the floor fixing. Unfasten the tongue and buckle.

7. Pull the webbing upwards and unfasten the tongue from the grey webbing buckle.

8. Position the black webbing to form the lap belt and insert the tongue into the buckle stalk.

Ensure that the lap belt lays low on the pelvis of the occupant, running as close as possible

over the hips on both sides.

9. Remove the black plastic cover on the grey shoulder belt tongue and fit into the third

point fixing. Position the grey webbing to form the shoulder belt and insert the buckle

into the tongue. Adjust the height of the shoulder belt to clear the occupant’s shoulder by

approximately 25mm (1 inch) Fig 4.

10. The lap belt anchor points should be positioned to achieve belt angles of 30° or more to

the horizontal and preferably between 45° and 75° in order to fit low across the pelvis

reducing the possibility of the belt loading the abdomen (Fig 5). The pelvic restraint is

designed to bear upon the bony structure of the body and should be worn low across the

front of the pelvis with any junctions between the pelvic and shoulder restraints located

near the wearers hips.

Removing occupant restraints

1. Release the grey shoulder belt from

the lap belt section, then from the

third point fixing and carefully allow the

shoulder belt to return to the retractor.

2. Disconnect the black lap belt from

the buckle stalk on the aisle side and

carefully allow the lap belt webbing to

return onto it’s retractor.

3. Connect the shoulder belt buckle to the

lap belt tongue above the opening of

the retractor box.

4. The wheelchair tie-down must now be

removed.

10

Wheelchair & Occupant Restraints Occupant Restraints

Page 11

Figure 5

A

A

Figure 4

Figure 2

A

Figure 3

Figure 1

A

B

11

Wheelchair & Occupant Restraints Occupant Restraints

EN

Fit and use

Page 12

Fitting and using the 2 point double inertia occupant restraint

Fit and use

Rail floor

1. The rail will have been installed in the vehicle in accordance with their own and the vehicle

converter’s instruction. Position wheelchair within vehicle as required.

2. Wheelchair tie-downs (not supplied with these restraints) should be fitted first to secure

the wheelchair, before any occupant restraint is fitted.

3. Position the occupant restraint behind the wheelchair tie-down, with reel housing (Fig. 1A)

on the window side of the vehicle and reversible/fixed stalk (Fig.1B) on the aisle side.

4. Fit the occupant restraint ATF (aluminium track fitting) into the rail by aligning the ATF

feet with the cut-out sections of the rail. Locate into the rail, (Fig 2).

5. Press on the ribbed part of the ATF, (Fig 2A), and push firmly towards the wheelchair until

the yellow plunger drops and locks into the rail.

6. Ensure the Comfort Clip is released (Fig 7) and press the buckle to release the lap belt.

7. Pull the metal tongue on the black webbing upwards to release the webbing from both

inertia reels. Position the webbing across the occupant with the black webbing forming the

lap belt and the grey webbing forming the shoulder belt (Fig 6).

8. Insert the tongue fixed to the black webbing into the stalk buckle.

9. Adjust for comfort by raising the webbing on the shoulder by two finger widths, unlock

the Comfort Clip to take up the slack, then re-lock the clip so that it rests on the reel

cov e r.

10. The lap belt anchor points should be positioned to achieve belt angles of 30° or more to

the horizontal and preferably between 45° and 75° in order to fit low across the pelvis

reducing the possibility of the belt loading the abdomen (Fig 5). The pelvic restraint is

designed to bear upon the bony structure of the body and should be worn low across the

front of the pelvis with any junctions between the pelvic and shoulder restraints located

near the wearers hips.

Removing the occupant restraints

1. Release the Comfort Clip.

2. Release the grey shoulder belt from the

lap belt section, and carefully allow the

shoulder belt to return to the retractor.

3. Disconnect the black lap belt from

the buckle stalk on the aisle side and

carefully allow the lap belt webbing to

return onto it’s retractor.

4. Connect the shoulder belt buckle to the

lap belt tongue above the opening of

the retractor box.

5. The wheelchair tie-down must now be

removed.

12

Wheelchair & Occupant Restraints Occupant Restraints

Page 13

Figure 5

Figure 6

Figure 7

A

Figure 2

A

A

Figure 1

A

B

13

Wheelchair & Occupant Restraints Occupant Restraints

EN

Fit and use

Page 14

Fit and use

Fitting and using the 3 point double inertia occupant restraint

Bolted

1. The occupant restraints will have been installed in the vehicle in accordance with their

own and the vehicle converter’s instruction.

2. Wheelchair tie-downs (not supplied with these restraints) should be fitted first to secure

the wheelchair, before any occupant restraint is fitted.

To fit 3 point double inertial seatbelt, please see instruction on page 10, bullet point 6 onwards.

To fit 2 point double inertial seatbelt, please see instruction on page 12, bullet point 6 onwards.

A

14

Wheelchair & Occupant Restraints Occupant Restraints

Page 15

15

Wheelchair & Occupant Restraints Occupant Restraints

EN

Fit and use

Page 16

Fitting and using the 3 point static occupant restraint

Fit and use

Rail floor

1. The occupant restraint should be installed in accordance with the previous safety information

section using the supplied hardware (Fig 8). Note: if fitting hardware, other than that provided

in this kit, is to be used then the fixing bolts should be of an equivalent cross section and an

equivalent grade namely B.S. Grade ’S’ (ISO 8.8).

2. The componentry is assembed as shown opposite, (Fig 8), with the upper 3rd point bolted to

an approved anchorage position on the vehicle body. Bolts should be tightened to a torque

of 40Nm. If installing the ATF of the removable 3rd point, then a suitable rail section, known

as a cant rail, should be installed in the vehicle. Note: all vehicle anchorage points may require

reinforcement as necessary to meet any required minimum strength recommendations for the

vehicle.

3. Install the static lap belt section— tongue side ATF, (aluminium track fitting), into the rail furthest

away from the 3rd point anchorage, (Fig 9A). Align the ATF feet with the cut out sections of the

rail, press down into the rail and slide forward until the yellow plunger drops and locks, (Fig 2).

Install the static lap belt— buckle side ATF fitting into the rail nearest to the 3rd point anchorage,

(Fig (9B). Draw the lap belts around the occupant and clip the lap belt adjustable tongue into the

lap belt buckle, adjust as firmly as possible consistent with user comfort such that the lap belt sits

low over the front of the pelvis and bears over the bony par t of the body.

4. Disconnect the shoulder belt snap clip from its storage position, and draw across the upper body

connecting it onto the static lap belt - tongue snap button, (Fig 10). Adjust the shoulder adjuster

position to comfortably suit the user, (Fig 11).

5. The lap belt anchor points should be positioned to achieve belt angles of 30° or more to the

horizontal and preferably between 45° and 75° in order to fit low across the pelvis, reducing the

possibility of the belt loading the abdomen, (Fig 5). The pelvic restraint is designed to bear upon

the bony structure of the body and should be worn low across the front of the pelvis with any

junctions between the pelvic and shoulder restraints located near the wearer’s

.

Removing the occupant restraint

1. Disconnect the shoulder belt snap clip

from the lap belt snap button and the

lap belt tongue section from the lap

belt buckle section.

2. Remove each ATF fitting from the rail

by raising the yellow plunger and sliding

the fitting backward until the ATF feet

align with the cut outs in the rail, lift the

fitting out of the rail.

3. The wheelchair tie-down must now be

removed.

16

Wheelchair & Occupant Restraints Occupant Restraints

Page 17

A

Figure 10

Figure 9

Figure 9

Figure 8

A

B

Figure 2

A

Figure 5

Figure 5

Fi g ur e 11

17

Wheelchair & Occupant Restraints Occupant Restraints

EN

Fit and use

Page 18

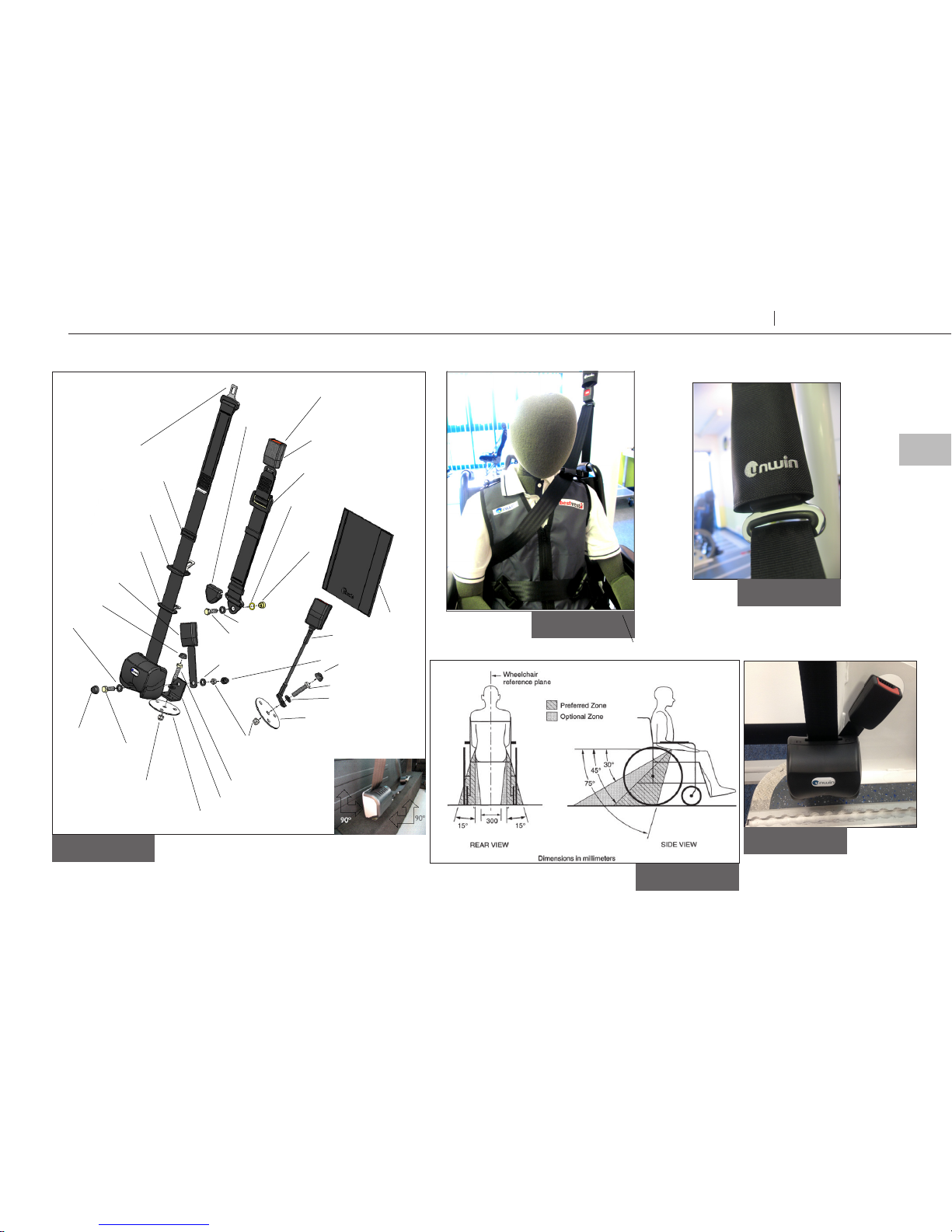

Fitting and using the 3 point WAV retractable occupant restraint

Fit and use

Bolted

1. The occupant restraint should be installed in accordance with previous safety information

section using the supplied hardware (Fig 12). Note: if fitting hardware, other than that provided

in this kit, is to be used then the fixing bolts should be of an equivalent cross section and an

equivalent grade namely B.S. Grade ’S’ (ISO 8.8)

2. The componentry is assembled (Fig 12) with the upper 3rd point and lower reel anchorage

points bolted to an approved anchorage position on the vehicle body.

Note: the upper 3rd point may be reversed as required, by unclipping the buckle from the

drop link tongue, reversing, and clipping back together. The inertia reel should be mounted at

an angle of 90/90° as viewed in 2 planes to the road level (see inset photo opposite). The reel

and its bracketry is bolted through the vehicle and reinforced on the underside, if required,

with the 100mm diameter load spreader plate and nyloc nut. All bolts should be tightened to a

torque of 40Nm. Note: All vehicle anchorage points may require reinforcement as necessary to

meet any required minimum strength recommendations for the vehicle.

3. Once installed check the free running of webbing into, and out of, the inertia reel and check the

‘lock up’ facility of the reel by engaging a short tug at various intervals along the extension and

retraction of the webbing in and out of the reel.

4. Adjust the drop link position at or above the shoulder height to comfortably suit the user, and

draw the running tongue across the occupant, through the fur thest arm of the wheelchair and

connect into the stalk to form a diagonal belt, Fig. 11.

5. Disconnect the fixed tongue from its buckle attached to the inertia reel, pass it through the

near arm of the wheelchair and connect back into the buckle forming the complete lap and

diagonal. (See Fig 11 & 13) The lap belt anchor points should be positioned to achieve belt angles

of 30° or more to the horizontal and preferably between 45° and 75° in order to fit low across

the pelvis reducing the possibility of the belt loading the abdomen, (Fig 5).

6. The pelvic restraint is designed to bear

upon the bony structure of the body and

should be worn low across the front of the

pelvis with any junctions between the pelvic

and shoulder restraints located near the

wearers hips.

7. Place the wrap around the drop link and

secure the Velcro to tidy the loose webbing

end. (Fig 14).

Removing occupant restraint

1. Unfasten the tongue from the stalks,

remove the occupant restraint and let the

webbing retract back into the housing.

2. The wheelchair tie-down should now be

removed as indicated on page 18 or 20.

Occupant restraints should not be held away

from the body by wheelchair components or

parts, such as armrests or wheels, and should

not be worn twisted in any way.

Occupant restraints should be adjusted as

firmly as possible and consistent with user

comfort. Upper torso restraints should fit

over the shoulder or shoulders.

18

Wheelchair & Occupant Restraints Occupant Restraints

Page 19

A

Figure 5

Fi g ur e 11

Figure 12

Figure 14

Fi gure 13

Figure 9

Plastic 3 bar slide

Running tongue

Drop link tongue

Flat washer

Bolt cap

7/16" unf x 1.5 bolt

7/16" unf nyloc nut

100 mm spreader plate

angle bracket

Flat washer

7/16" unf nyloc nut

Plastic nut cover

Bolt cap

Pillar loop

cover

Fixed tongue

7/16" unf x 1.5 bolt

Flat washer

Weavy washer

15m m

stepped

Drop link adjuster

Drop link buckle

3rd point anchorage

Drop link

Cover

Retractable occupant restraint

Flat washer

7/16" unf x 1.5 bolt

7/16" unf x 1.5 bolt

100 mm spreader plate

Buckle tang

Stalk

19

Wheelchair & Occupant Restraints Occupant Restraints

EN

Fit and use

Page 20

Equipment storage and maintenance

After care

• Store the restraints safely o the floor to avoid damage and ensure that it cannot

become a projectile in an accident. This can be achieved by using wall mounted

storage bag such as SLR111.

• Regularly inspect the Unwin restraints for damage, wear or malfunction. If any

problems are identified replace immediately.

• All webbings and components can be cleaned as necessary, but care should be

taken to prevent contamination of the webbings with polishes, oils and chemicals.

• To clean the straps use warm soapy water and a clean soft cloth. Rinse with clear

water and allow to air dry. To disinfect, use a mild spray disinfectant and do not

use products containing bleach. Important: when cleaning or disinfecting, do not

immerse buckles in the disinfectant or water.

• If the vehicle is involved in an accident when any restraints are deployed, remove

them from service and replace immediately. If in doubt please contact Unwin.

20

Wheelchair & Occupant Restraints Occupant Restraints

Page 21

Warranty

Unwin products are extensively tested using Unwin anchorage systems, and our full

warranty normally only applies to Unwin equipment when used with Unwin branded

anchorages or as instructed. Unwin have also participated in test programs with other

manufacturers anchorage products and will support warranty on the Unwin products

when used in conjunction with such jointly tested systems. For further details on

specific applications please contact the Sales Oce. In other situations, using Unwin

products, for which Unwin has not participated in a joint test program, a limited

Unwin warranty will apply.

21

Wheelchair & Occupant Restraints Occupant Restraints

EN

After care

Page 22

Declaration of conformity

Conforms to following directives

standards and regulations /

214/2014/EU Paragraphs 2.3.1 and 2.3.2

ISO 10542:2012

RESNA WC-4 2012 Section 18

R.107.06

2007/46/EC

Unwin, Martock August 2017

Chris Hellier

MD

Manufacturer /

Unwin

Unwin House

The Horseshoe Coat Road

Martock, Somerset, UK

Phone: +44 1935 827 740

E-mail: sales@unwinsafety.com

www.unwinsafety.com

Declares that the product /

Occupant Restraints:

DI, DK, STK, WK

Page 23

Accredited by URS as testing laboratory in accordance with ISO/IEC 17025:2005

Quality system certified in accordance with ISO 9001:2008

Illustrations, descriptions and specifications in the user manual are based on current product information.

Unwin reserves the right to make alterations without previous notice.

© 2017 Unwin

Page 24

UI2301A

facebook.com/UnwinSafety

twitter.com/UnwinSafety

linkedin.com/company/unwin

www.unwinsafety.com

UNWIN

Unwin House

The Horseshoe Coat Road

Martock, Somerset, UK

Phone: +44 1935 827740

E-mail: sales@unwinsafety.com

Loading...

Loading...