UNTRODE bq2002C Technical data

bq2002C

NiCd/NiMH Fast-Charge Management IC

Features

Fast charge of nickel cadmium

➤

or nickel-metal hydride batter

ies

Direct LED output displays

➤

chargestatus

Fast-charge termination by -∆V,

➤

maximum voltage, maximum

temperature, and maximum

time

Internal band-gap voltage ref

➤

erence

➤

Selectable pulse-trickle charge

rates

➤

Low-power mode

➤

8-pin 300-mil D I P or 150-mil

SOIC

Pin Connections

TM

LED

BAT

V

1

2

3

4

SS

8

7

6

5

CC

INH

V

TS

CC

General Description

The bq2002C Fast-Charge IC is a lowcost CMOS battery-charge controller

providing reliable charge termination

for both NiCd and NiMH battery appli

cations. Controlling a current-limited

or constant-current supply allows the

bq2002C to be the basis for a costeffective stand-alone or system-inte

grated charger. The bq2002C inte

grates fast charge with pulsed-trickle

control in a single IC for charging one

or more NiCd or NiMH batterycells.

Fast charge is initiated on application

of t he charging supply or battery

replacement. For safety, fast charge is

inhibited if the battery temperature

and voltage are outside configured

limits.

Pin Names

TM Timer mode select input

LED

BAT Battery voltage input

V

SS

Charging status output

System ground

Fast charge is terminated by any of

the following:

Peak voltage detection (PVD)

n

Negative delta voltage (-∆V)

n

Maximum voltage

n

Maximum temperature

n

Maximum time

n

-

After fast charge, the bq2002C pulsetrickles the battery per the preconfigured limits. Fast charge may be

inhibited using t h e INH pin. The

bq2002C may also be placed in lowstandby-power mode t o reduce

system power consumption.

TS Temperature sense input

V

CC

Supply voltage input

INH Charge inhibit input

CC Charge control output

8-Pin DIP or

Narrow SOIC

PN-200201.eps

SLUS136 - SEPTEMBER 1997

1

bq2002C

Pin Descriptions

TM

LED

BAT

V

SS

TS

V

CC

INH

T ime rmodeinput

A three-level input that controls the settings

for the fast charge safety timer, voltage ter

mination mode, pulse-trickle, and voltage

hold-off time.

Charging output status

Open-drain output that indicates the charging

status.

Battery input voltage

Thebattery voltage sense input. The input to

this pin is created by a high-impedance re

sistor divider network connected between

the positive and negative terminals of the

battery.

System ground

Temperaturesense input

Input for an external battery temperature

monitoring thermistor.

Supply voltage input

5.0V±20%power input.

Charge inhibit input

When high, INH suspends t he fast charge in

progress. When returned low, the IC resumes operation at th e point where initially

suspended.

CC

Charge control output

An open-drain output used to control the

charging current to the battery. CC switch

ing to high impedance (Z) enables charging

-

current to flow, and low to inhibit charging

current. CC is modulated to provide pulse

trickle.

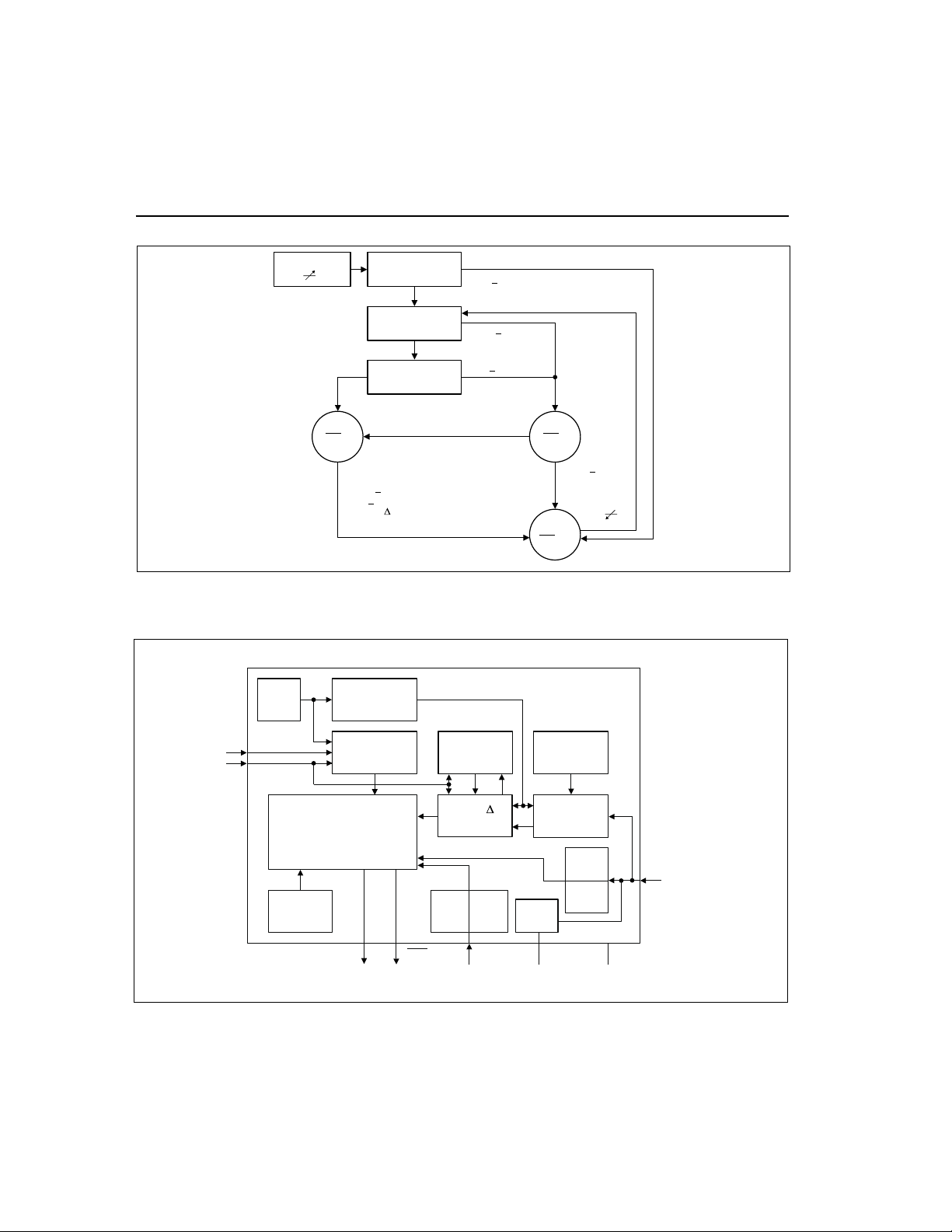

Functional Description

Figure 2 shows a state diagram a n d Figure 3 shows a

block diagram ofthe bq2002C.

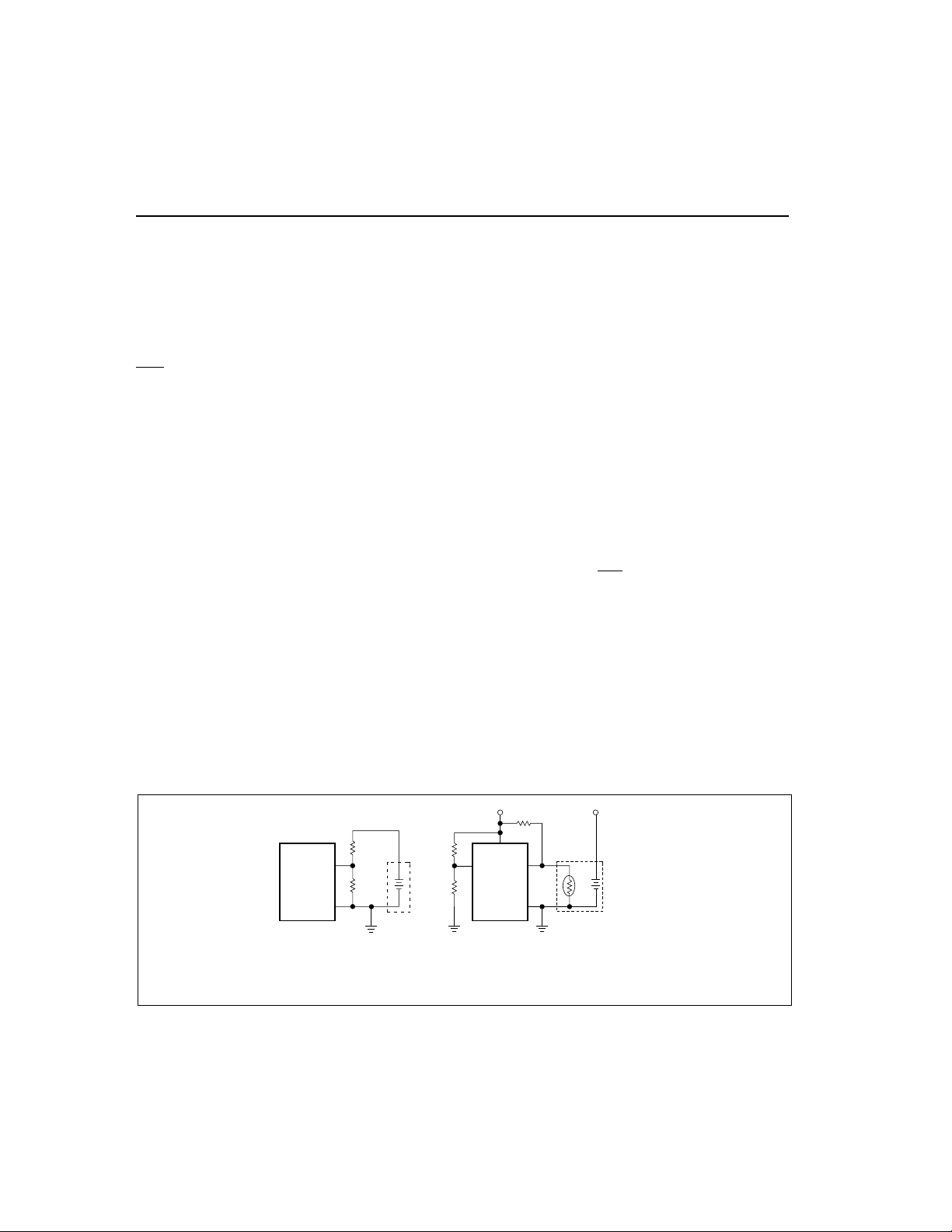

Battery Voltageand Temperature

Measurements

Battery voltage a n d temperature are monitored for

maximum allowable values. The voltage presented on

the battery sense input, BAT, should represent a

single-cell potential for the battery under charge. A

resistor-dividerratio of

RB1

= N - 1

RB2

is recommended to maintain the battery voltage within

the valid range, where N is the number of cells, RB1 is

the resistor connected to the positive battery terminal,

and RB2 is th e resistor connected to the n egative

battery terminal. SeeFigure 1.

Note:

This resistor-divider network input impedance to

end-to-end should be at least 200k

A ground-referenced negative temperature coefficient

thermistor placed near the battery may be used as a lowcost temperature-to-voltage transducer. The temperature

sense voltage input at TS is developed using a resistorthermistor network between V

Ω

and less than 1MΩ.

and VSS. SeeFigure 1.

CC

-

V

CC

RB1

BAT

bq2002C

BAT pin connection Thermistor connection

RB2

V

SS

NTC = negative temperature coefficient thermistor.

R3

R4

Mid-level

setting for TM

V

CC

TM

bq2002C

T

V

SS

PACK +

RT

S

N

T

C

Fg2002/C.eps

Figure 1. Voltage and Temperature Monitoring and TM Pin Configuration

2

bq2002C

OSC

V

CC

Chip on

4.0V

V

TS

V

BAT

0.84V < V

BAT

/2

> V

CC

Fast

LED =

Low

V

BAT

VTS < VCC/2 or

PVD or - V or

Maximum Time Out

Clock

Phase

Generator

Battery Voltage

too High?

< 2V

Battery Voltage

too Low?

Battery

Temperature?

> 2V or

V

V

V

BAT

BAT

TS

V

> V

2V

>

BAT

< 0.84V

V

BAT

< V

V

CC

TS

> 0.84V and

< 2V and

/2

CC

/2

Figure 2. State Diagram

Trickle

LED =

Flash

Trickle

LED = Z

Charge

Pending

V

BAT

V

> 2V

BAT

2V

2

SD

ps

.e

2C

00

TM

INH

Charge-Control

State Machine

Power-On

Reset

Timing

Control

Sample

History

PVD, - V

ALU

HTF

Check

CC

LED

Figure 3. Block Diagram

3

TCO

Check

TS

Power

Down

Voltage

Reference

A to D

Converter

LBAT

Check

MCV

Check

V

CC

V

SS

Bd2002CEG.eps

BAT

bq2002C

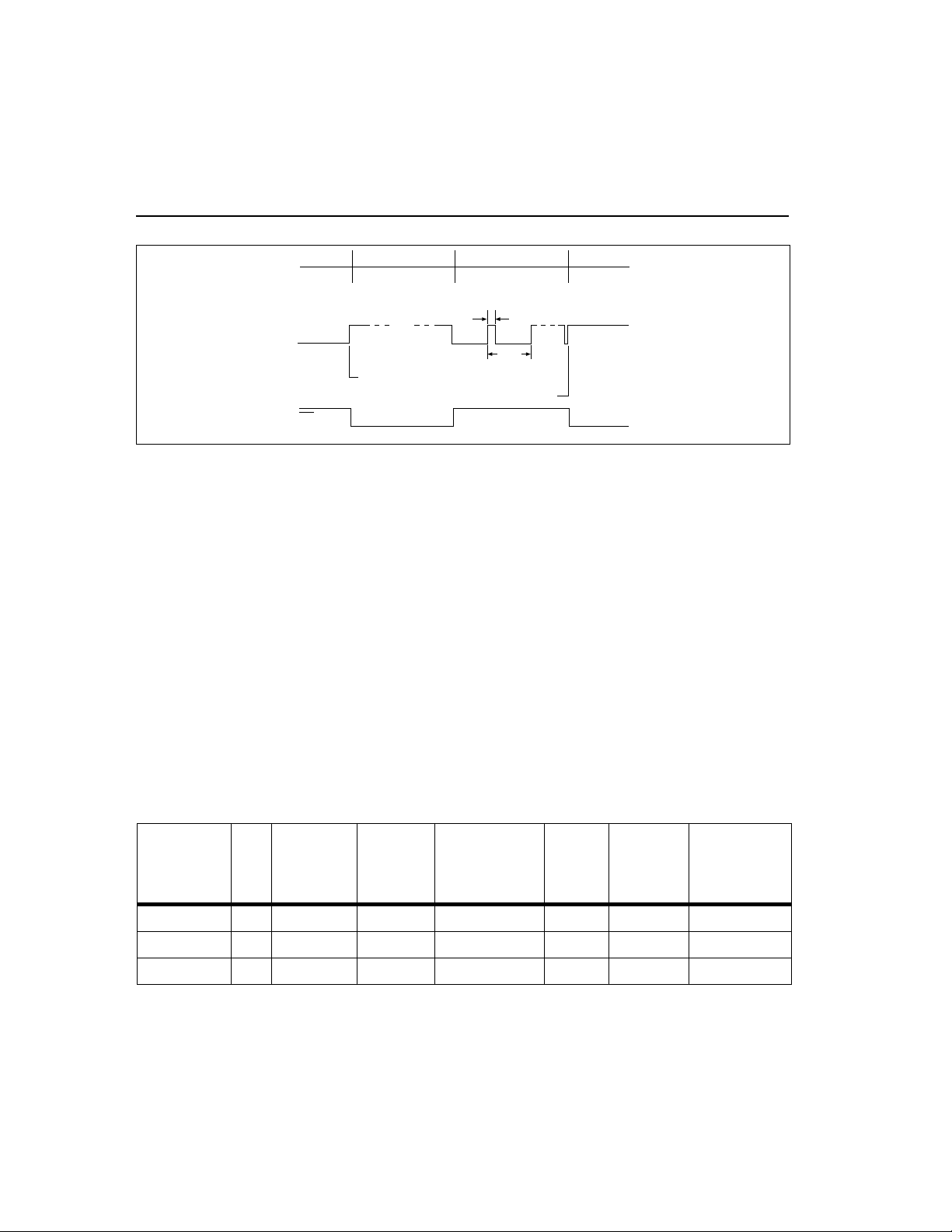

Fast ChargingVCC = 0 Fast Charging

CC Output

Charge initiated by application of power

Charge initiated by battery replacement

LED

Figure 4. Charge Cycle Phases

Starting A Charge Cycle

Either of twoevents starts a chargecycle (see Figure 4):

1.Application ofpower to V

2. Voltage at the BAT pin falling through the maximum

cell voltage V

MCV

where

V

If the battery is within t h e configured temperature and

voltage limits, the IC begins fast charge. The valid

battery voltage range is V

V

LBAT

The valid temperature range isV

V

HTF

If V

≤

V

LBAT

or VTS≤

BAT

or

CC

= 2V±5%.

MCV

LBAT<VBAT<VMCV,

= 0.175∗VCC±

TS>VHTF

= 0.6∗VCC±

V

HTF

5%.

, the IC enters the charge-

where

20%

where

Pulse-Trickle

1s

See

Table 1

TD2002C1.eps

pending state. In this state pulse trickle charge is

applied to the battery and the LED flashes until the

voltage an d temperature come into t he allowed fast

charge range or V

≥

V

, the IC enters the Charge Complete/Battery

MCV

Absent state. In this state the LED is off and trickle

rises above V

BAT

. Anytime V

MCV

BAT

charge is applied to th e battery until the next new

charge cycle begins.

Fast charge continues until termination by one or more of

the five possible termination conditions:

n

Peak voltage detection (PVD)

n

Negative delta voltage (-∆V)

n

Maximum voltage

n

Maximum temperature

n

Maximum time

Table 1. Fast-Charge Safety Time/Hold-Off Table

Typical

Corresponding

Fast-Charge

Rate TM Termination

Fast-

Charge

Time Limits

(minutes)

Typical PVD

and -∆V

Hold-Off

Time (seconds)

Pulse-

Trickle

Rate

C/2 Mid PVD 160 300 C/32 73 18.7

1C Low PVD 80 150 C/32 37 18.7

2C High -

Notes:

Typical conditions = 25°C, VCC= 5.0V

Mid = 0.5*V

Tolerance on all timing is ±12%.

V 40 75 C/32 18 9.4

∆

±0.5V

CC

4

Pulse-

Trickle

Pulse Width

(ms)

Maximum

Synchronized

Sampling

Period

(seconds)

Loading...

Loading...