USER

MANUAL

APPLICABLE TO

SLASH OL/SLASH PLUS/SLASH PLUS UDP

SLASH PRO OL/SLASH PRO/SLASH PRO UDP

SLASH J UDP/SLASH DJ2

UNIZ DESKTOP 3D PRINTER

DISCLAIMER

lease read and understand the contents of this user manual carefully. Failure to read

P

in order to operate the device smoothly, efficiently and safely.

The conditions or methods used for assembling, handling, storage, use or disposal of the

device are beyond the control of UNIZ Technology LLC. For this and other reasons, UNIZ does

not assume responsibility and expressly disclaim liability for loss, injuries, damage, or expense

arising out of or in any way connected with the assembly, handling, storage, use or disposal of

the product.

The information in this document was obtained from sources which we believe are reliable.

However, the information is provided without any warranty, express or implied, regarding its

correctness.

the manual may lead to personal injury, inferior results or damage to the SLASH. All

users who operate the Slash are expected to understand the contents of the manual

CONTENTS

A

B

C

WELCOME

DESIGN RULES

D

SLASH SERIES 3D PRINTER DESIGN RULE

SETTING UP YOUR PRINTER

UNBOXING

PRODUCT DESCRIPTION

SLASH PRINTER TYPES

ACTION BUTTON COLOR GUIDE

PRINTER ACTIVATE AND UPGRADE

UNIZ SOFTWARE USER

MANUAL

···········································02

·····················01

························04

····························06

·············07

·········18

TROUBLE SHOOTING

E

TROUBLE SHOOTING

ROHS AUTHENTICATION

F

ROHS AUTHENTICATION

APPENDIX

G

SOFTWARE INTERFACE

START YOUR FIRST PRINTING JOB

ADDITIONAL TOOLS

··························17

··········19

·······························32

TECHNICAL SPECIFICATIONS

·······································33

·····························34

························42

··················43

WELCOME

A

SLASH SERIES 3D PRINTER

his user manual is designed to help you start your SLASH series 3D printer

T

great quality prints.

You might be familiar with other types of 3D printers. Regardless, it is still essential

that you read this manual carefully in order to make the most out of your SLASH

printer.

experience. Learn everything about using your SLASH 3D printer by following

the instructions in this user manual and experience how easy it is to produce

01

Federal

Communications

Commission

Conformite

Europeenne

SETTING UP YOUR

B

UNBOXING

The SLASH comes in reusable, durable packaging that has been specially designed to protect your

SLASH in transport. To properly unpack your SLASH, please follow the steps described below.

START UNBOXING

Start unpacking by correctly orienting the cardboard box, then slide the foam packaging out of the

box by pulling the cardboard handle beneath the printer while holding the box.

PRINTER

UNBOXING

OPEN IT UP

On the foam packaging, you will find the Quick Start Guide and accessories.

REMOVE THE FOAM PACKAGING

In the foam part on top of your SLASH, you will find all accessories of your SLASH. Take these out

and put them aside. Open up the package by removing the foam wrap at the middle. Now you can

take out the SLASH and place it on your desk. Make sure you hold the SLASH by the aluminium

casing while carrying it.

REMOVING PROTECTION

There is some packaging material around the machine. You may remove it.Then, your SLASH is

ready for use!

02

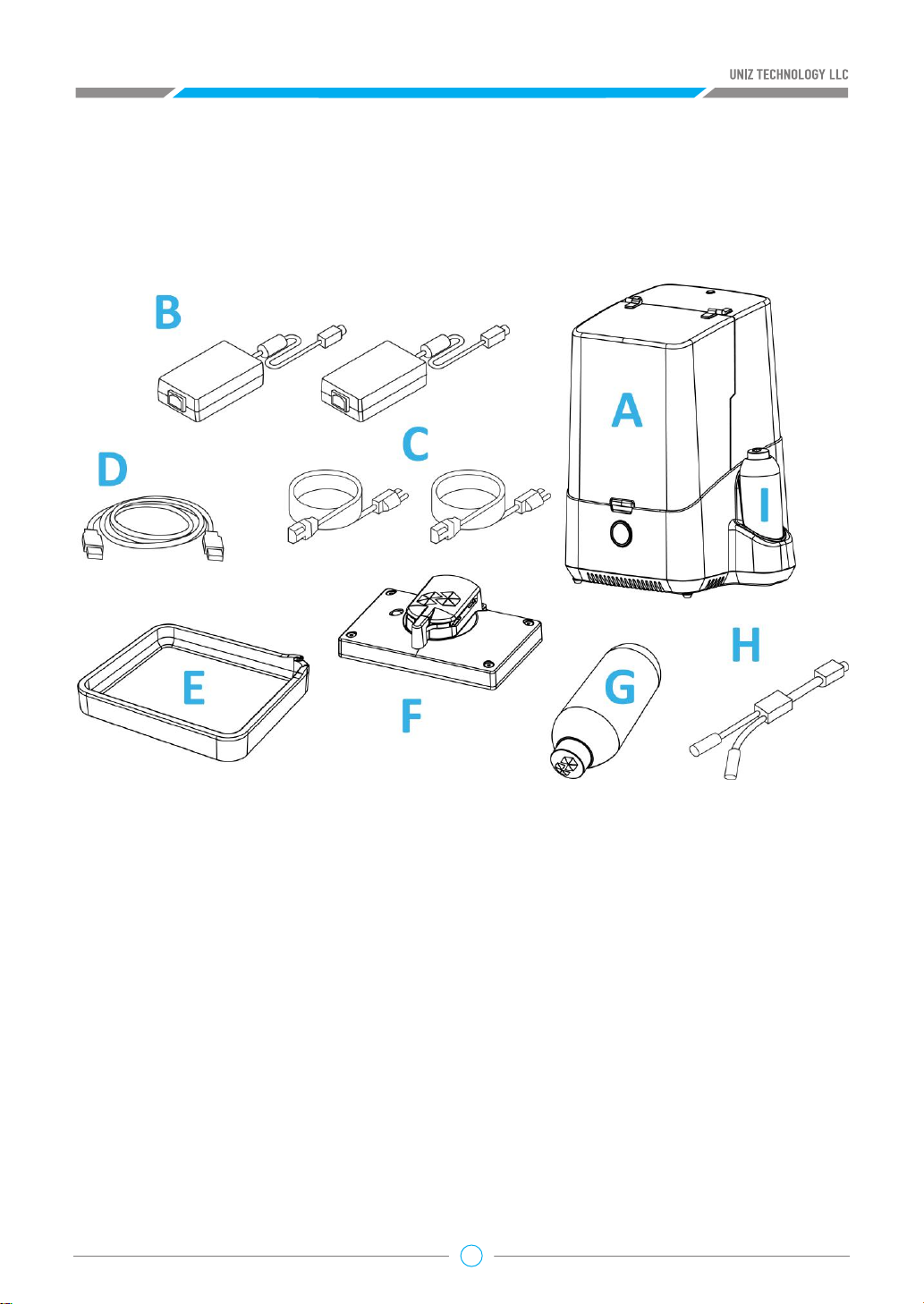

PACKING LIST

Supplied with your package is the UNIZ desktop 3D printer and several other accessories. This is

everything you need to start printing. Check if all accessories are included before continuing.

UNIZ Desktop 3D Printer

A .

Power Adapter x 2

B .

Power Cable x 2

C .

USB Cable

D .

Resin Tank

E .

Building Platform

F .

Resin Bottle

G .

Power Combiner

H .

Cleaning Bottle

I .

03

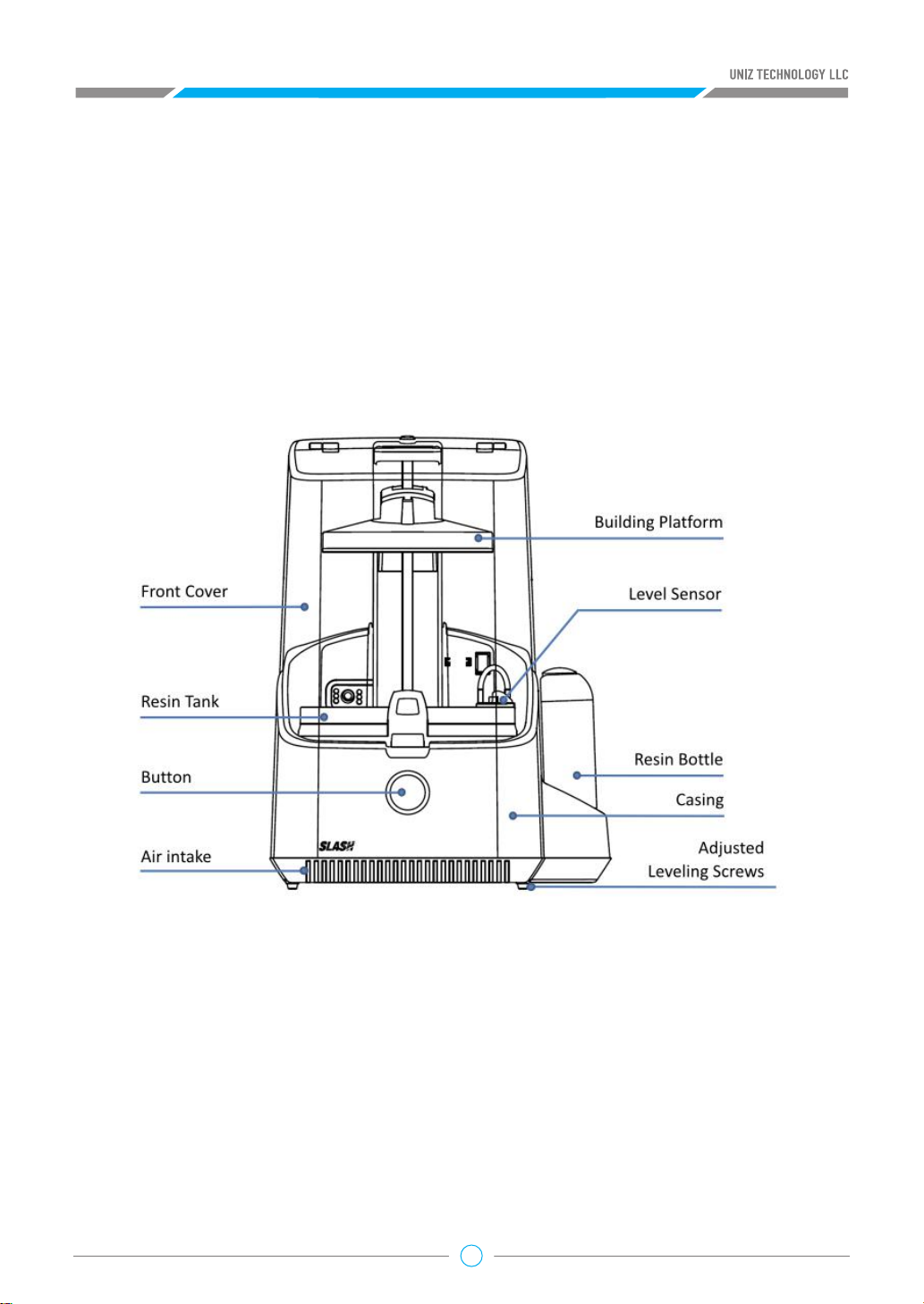

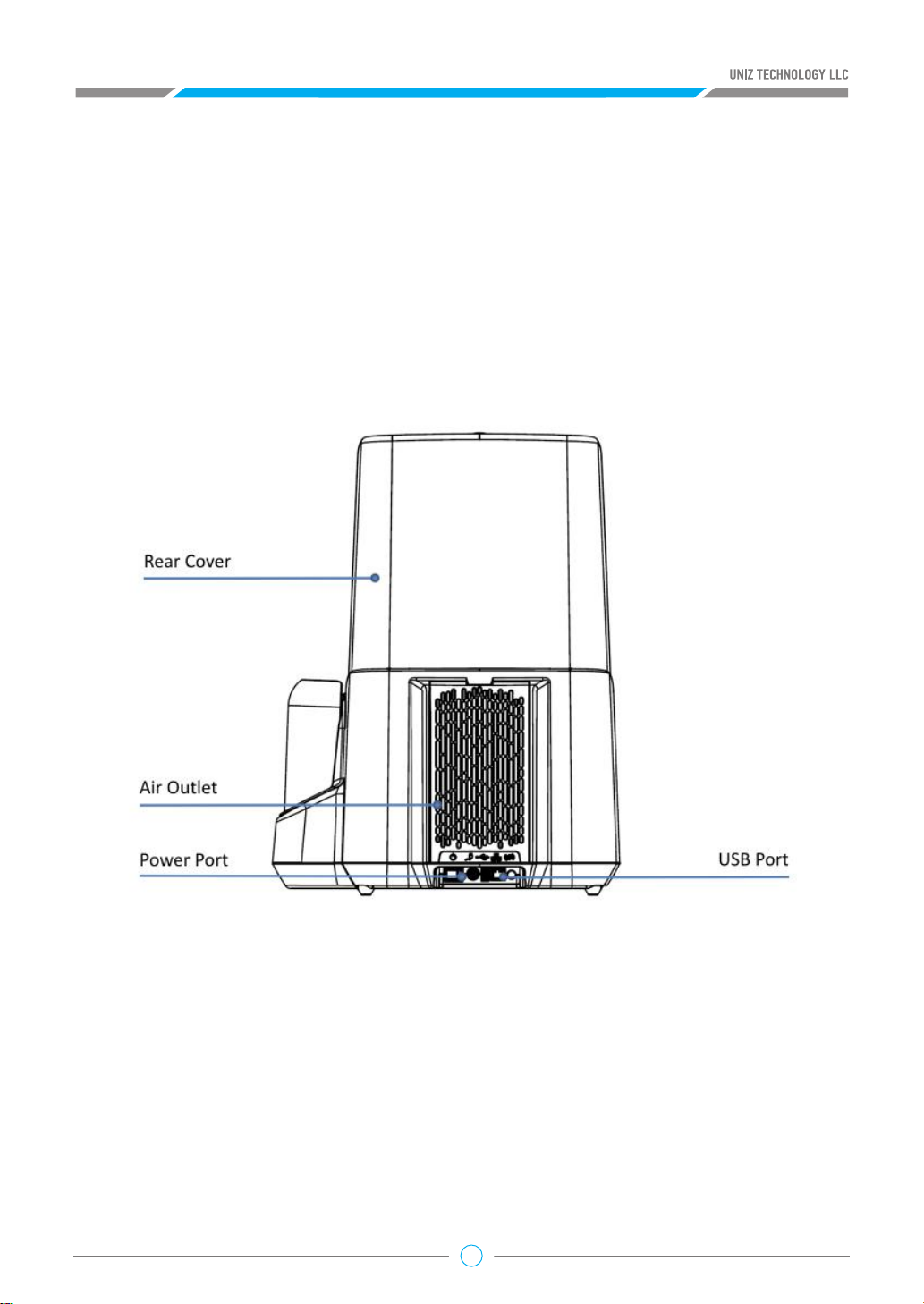

PRODUCT DESCRIPTION

04

05

SLASH PRINTER TYPES

You can identify the printer’s type by checking the label

underneath the printer and on the box.

06

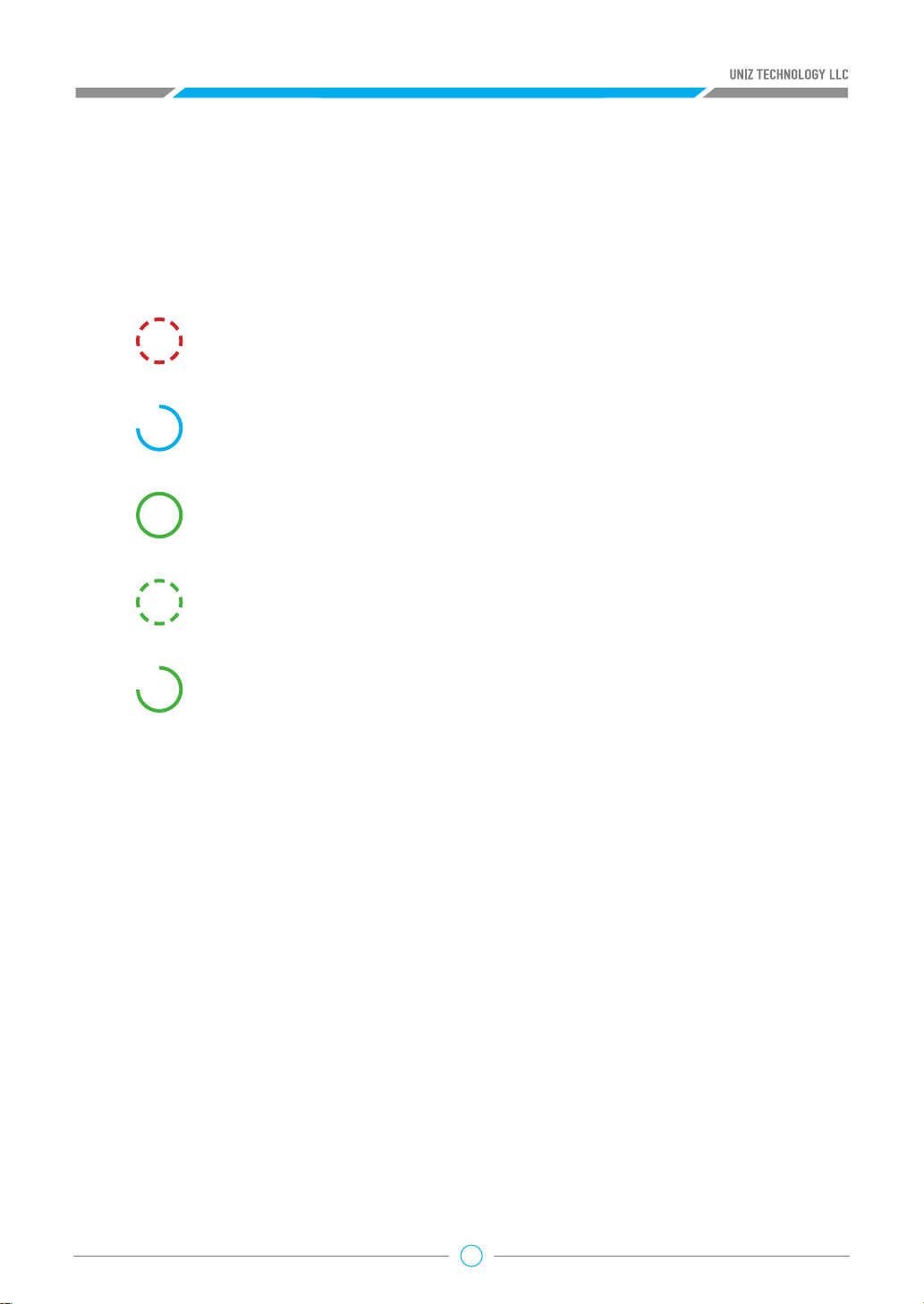

ACTION BUTTON COLOR GUIDE

Breathing red

Printer busy (starting up/paused/z axis moving)

Progressing blue

Data transfer in progress

Green

STANDBY-The printer is connected and waits for a command.

Breathing green

Data transferred, waiting for touch confirmation.

Progressing green

Printing in progress-The lights indicate completed progress.

07

PRINTER ACTIVATE AND UPGRADE

1. Printer Network

Check if the printer is connected to the Internet and set up for the printer connection.

Note:

The Printer's Wi-Fi feature supports 2.4GHz band only, it does not support 5 GHz connections.

Method 1: UNIZ Desktop

1. Plug into a power supply and switch on the printer.

2. Connect the printer and PC via USB and start the software.

3. Select the printer in the list to open the printer control interface.

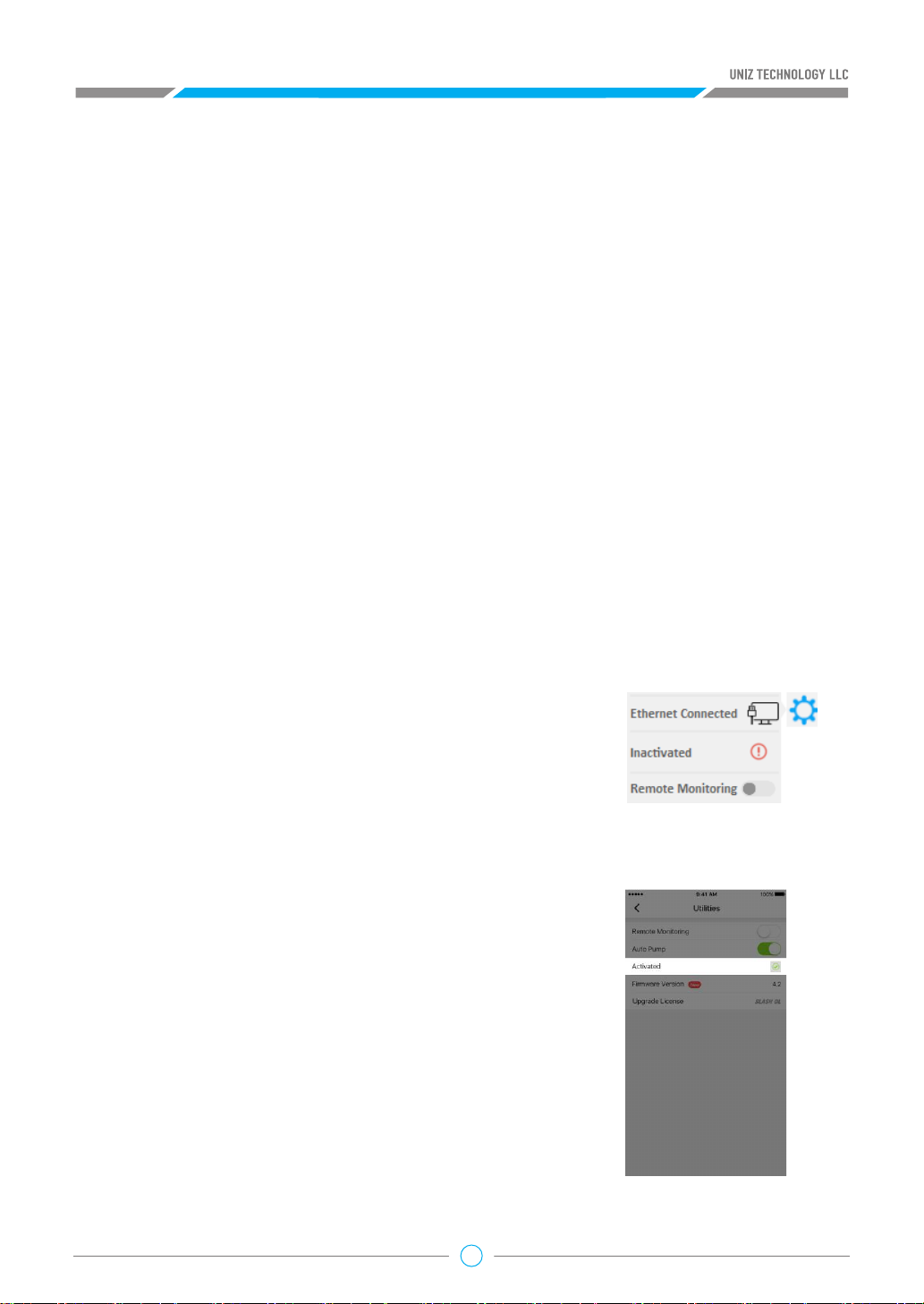

4. View network status

Press the “Printer Settings” button open the submenu. The first item is

the Network which shows the connection status.

configued.

configured

●

Wi-Fi Disconnected means the current Wi-Fi is not connected and needs to be

●

Wi-Fi Name means the current Wi-Fi is connected.

●

Ethernet Disconnected means the current Ethernet is not connected and needs to be

●

Ethernet Connected means the current Ethernet is connected.

08

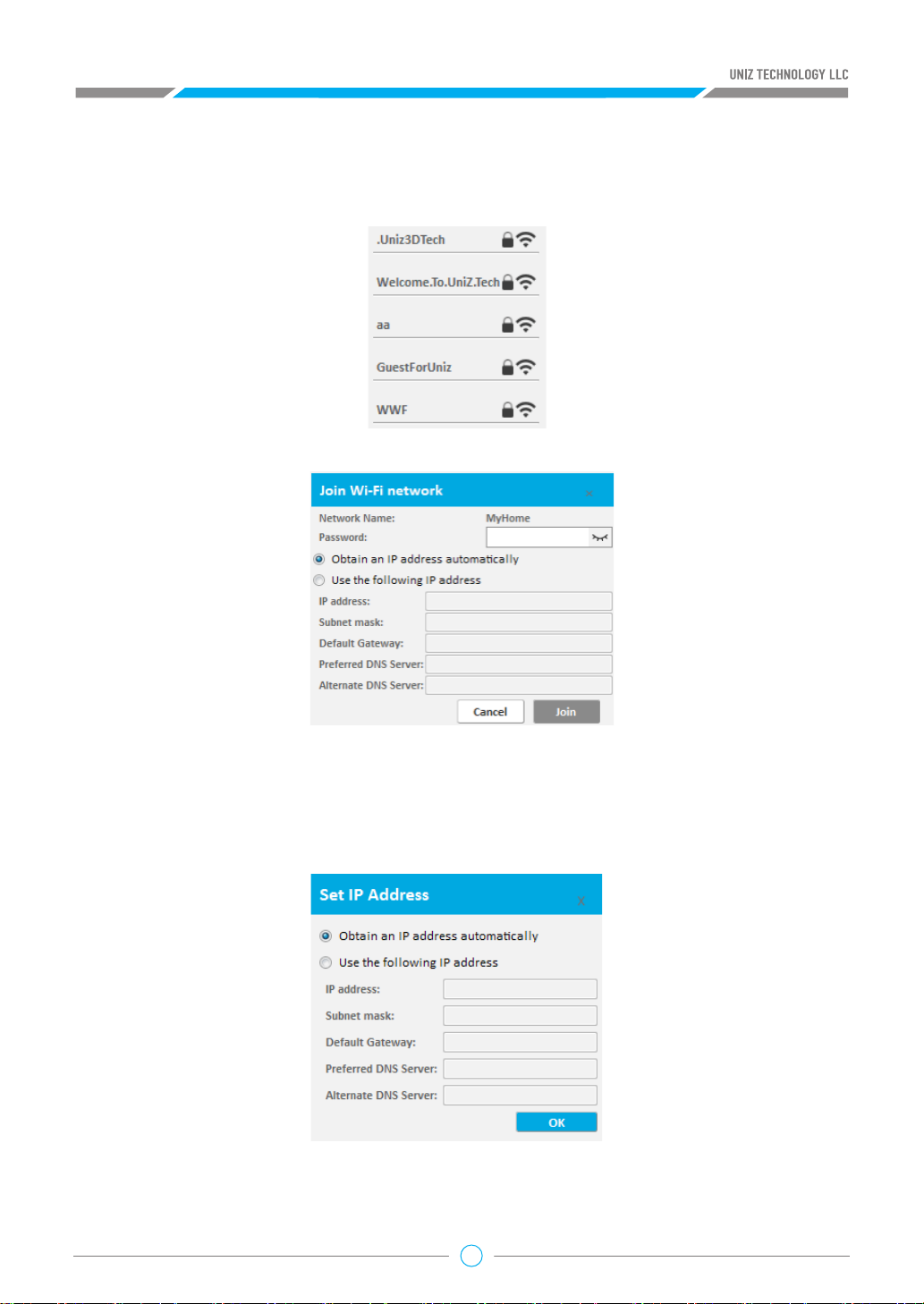

5. Set up the network

This function only supports setting via USB connection.

●

Click the first item. The Wi-Fi list will pop up in the left if it is Wi-Fi connection;

Click the Wi-Fi name on Wi-Fi list configure the IP address settings.

In the box you can enter password and obtain IP address automatically or set fixed IP

address manually.

●

Click the first item. The IP address settings should pop up if you are connected via Ethernet.

(software should be 1.2.0 or higher version and firmware should be 4.1 or higher version).

In the box you can obtain IP address automatically or set fixed IP address manually.

09

Method webpage·

1. Plug into a power supply and switch on the printer.

2. Connect to the printer's Wi-Fi hotspot.

a. Find the SSID and Password on the side label.

b. Access the Wi-Fi Setting of your mobile device, and connect to

UNIZ3D##:##:##:##:##:## as shown in the SSID.

3. Check and Set Network.

a. Find IP address on the side label.

b. Open the browser on PC or mobile device and enter the IP address; open the printer page

and select the "Network" option.

10

c. Click Check Network to check if the printer is connected to your network.

d. If the printer is not connected to the Internet, please choose your home Wi-Fi hotspot, type in

the password and click the Connect button.

e. After the printer is connected to your home Wi-Fi hotspot and Internet, disconnect your PC or

mobile device from the printer Wi-Fi and reconnect to home or office network.

Tips:

After setting up the connection, please make sure that PC or mobile device and printer are

connected to the same LAN to ensure that PC or mobile phone can control the printer through

the network.

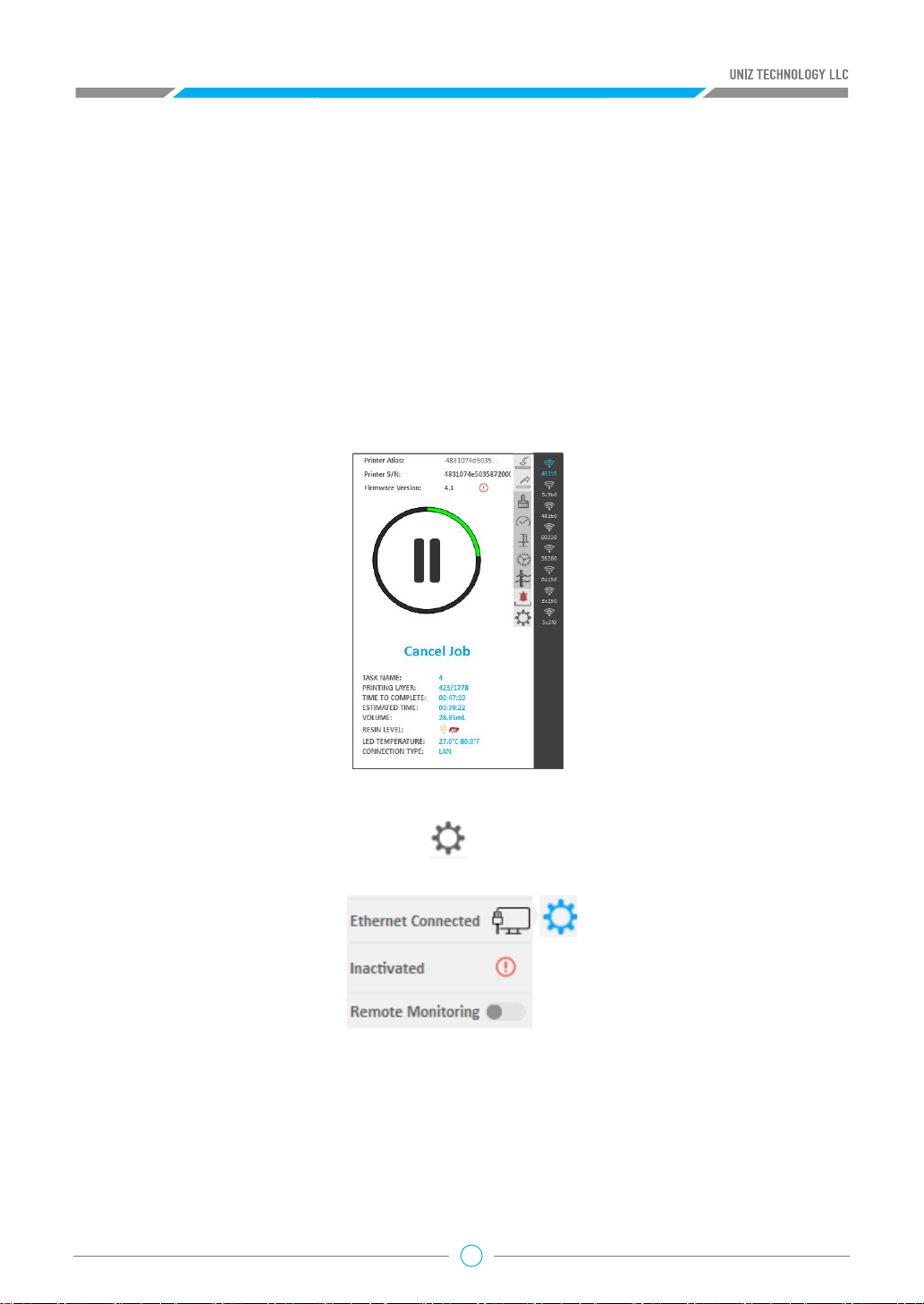

2. Activate the printer

Before activation, make sure that the printer is powered on and connected to the network. Slash OL

or SLASH PRO OL models must be activated before printing. After successful activation, the printer

will automatically launch a seven-day trial period in which the SLASH OL/PRO OL will become and

function as a SLASH PLUS UDP/SLASH PRO UDP.

Method 1: UNIZ Desktop

a. Start the UNIZ Desktop and select the printer in the list to open the printer control interface

b. Click the “Printer Settings” button to open the submenu. The second option shows the activation

status

c. Click the item to execute the activation function.

If the printer is inactivated, clicking this item will activate the

printer and the system will bind the printer to the currently

logged-in user.

Method 2: UNIZ App

Printer activation is supported by UNIZ App of 1.2.0 or higher.

a. Click the "Printer" button in the main menu of App, find the

printer that needs to be activated in the list of printers, and

open the printer control panel.

b. Click the "Utilities" button on the control interface to enter

the setting interface. The third item is the activation function,

showing the activation status ("Inactivated "or" Activated ").

c. Click “Inactivated”/ “Activated” to activate/reactivate the

printer with the current login account.

11

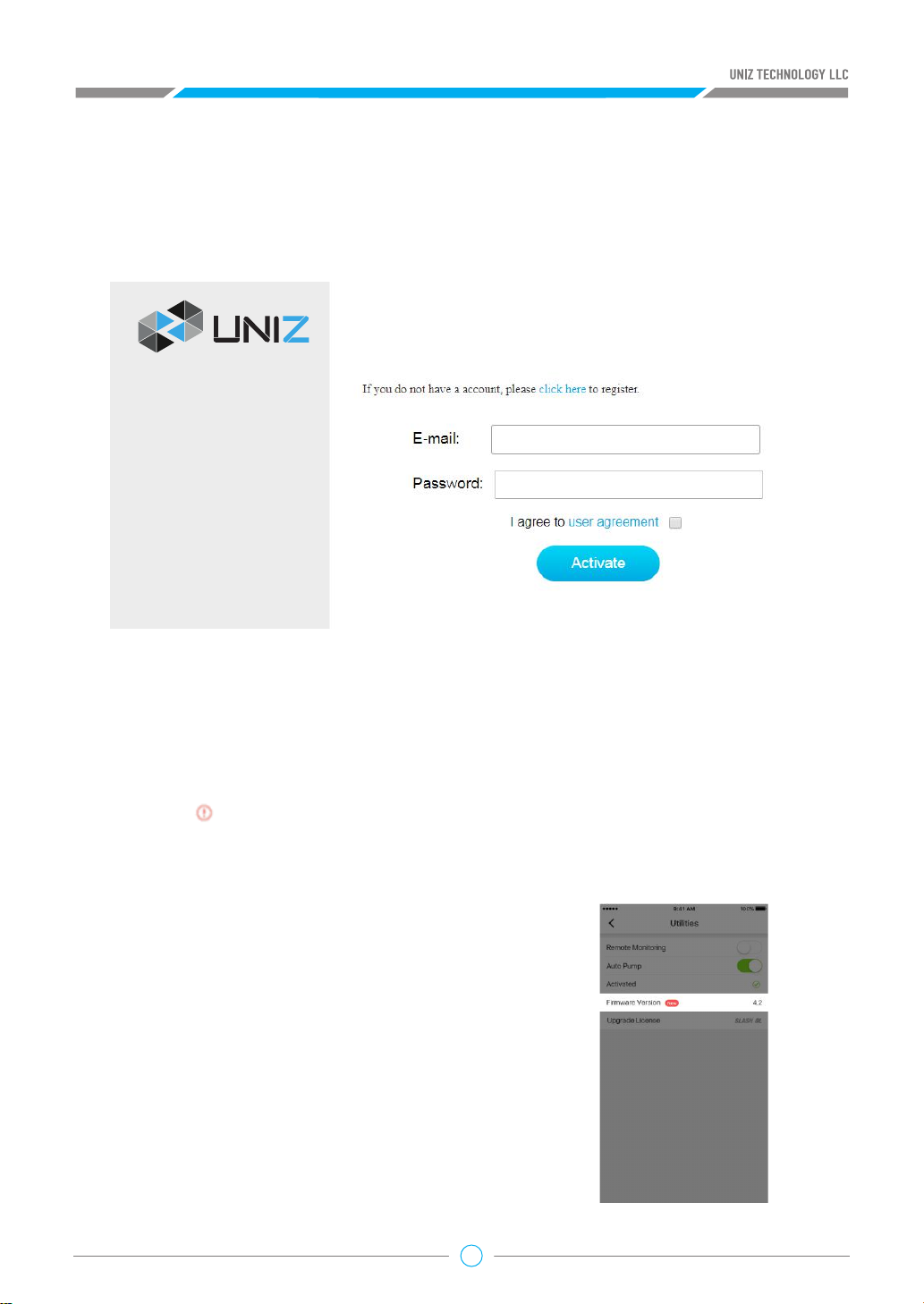

Method 3: Activate from the webpage

a. Connect the PC or mobile device to the printer’s Wi-Fi and open the printer page in the

browser.

b. Select the Activation tab in the printer page and input UNIZ account and password, then click

the Activate to complete the activation.

Network

Activation

Upgrade

3. Updating the Firmwaret

Before upgrading the firmware, make sure that the printer is powered on and is connected to the

internet.

Method 1: Upgrade from the UNIZ Desktop

a. Launch the software and select the printer to open the printer control interfacet.

b. An icon will show next to the firmware version when there is a new version available.

available. Click the icon to start upgrading. Restart the printer when the upgrade is finished.

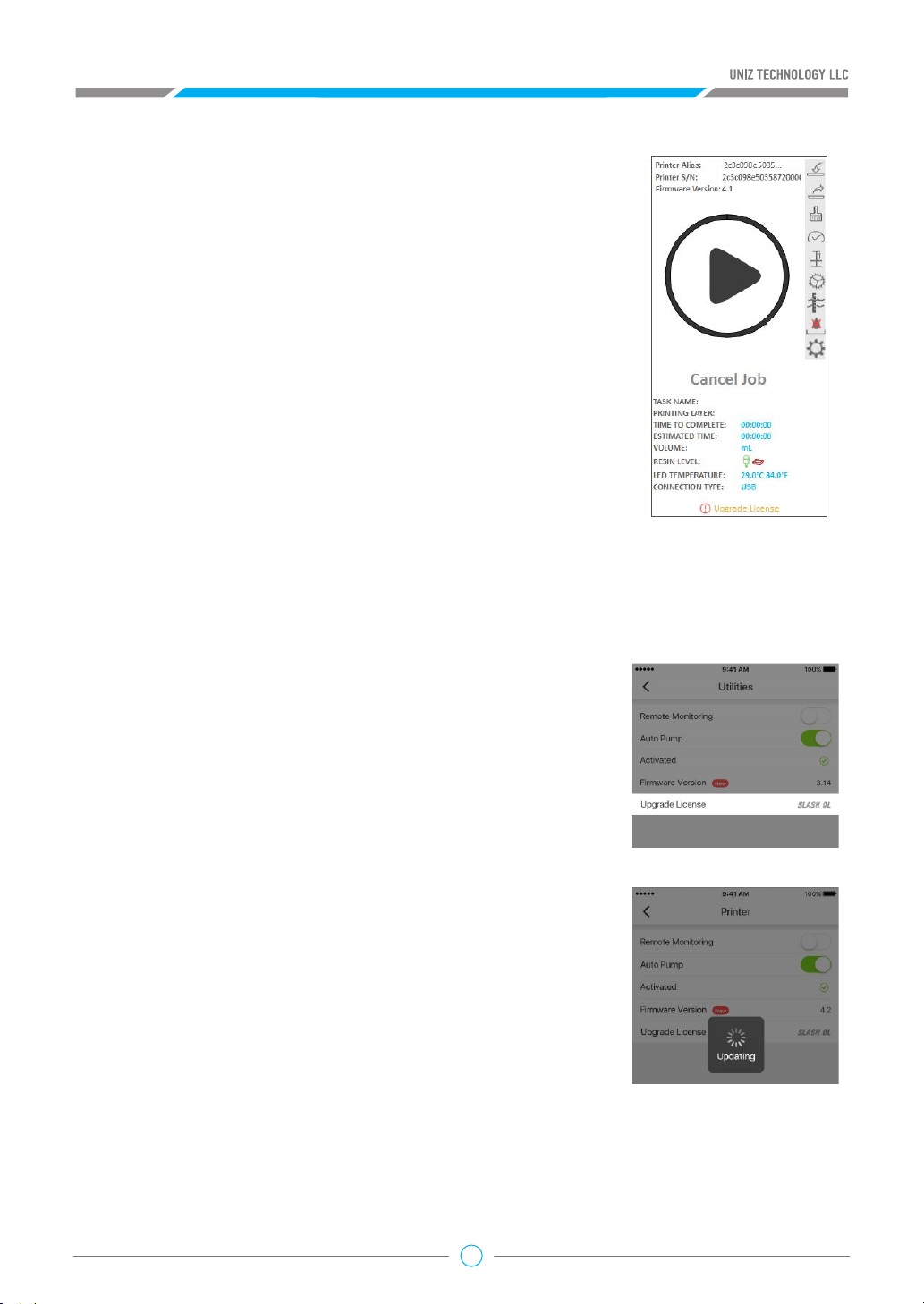

Method 2: Upgrade from the UNIZ App

(1) Check the firmware version of the current printer

Click "Printer" in the main menu of App, find the printer

that needs to be updated in the list of printers, open

the printer control panel, click the "Utilities" button,

and you can see the current firmware version in the

window.

(2) Updating the firmware

An icon “New” will show next to the firmware version

when there is new version firmware available. Click the

icon to start upgrading. Restart the printer when the

upgrade is finished.

12

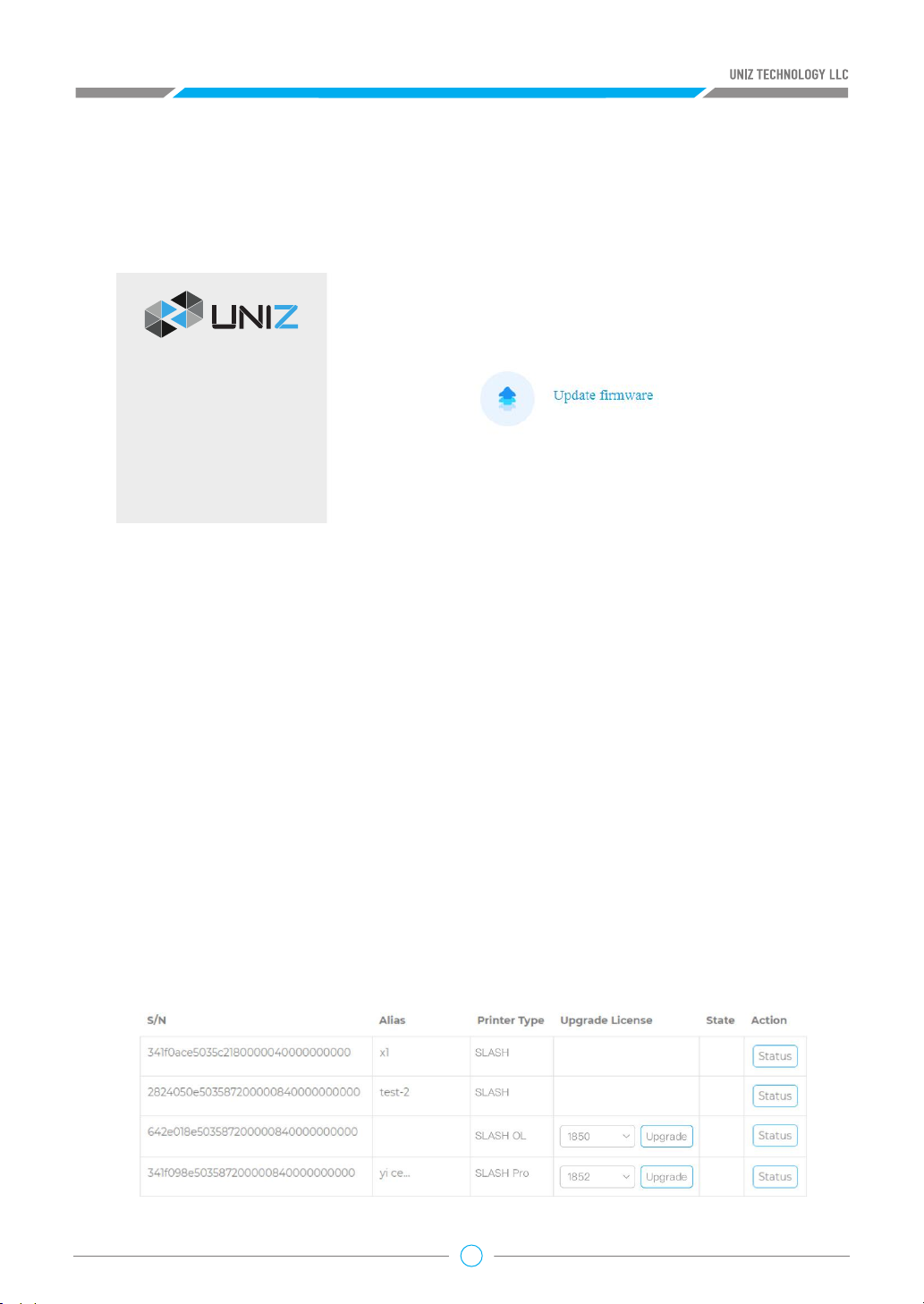

Method 4: Upgrade from the webpage

a. Connect the PC or mobile device to the printer Wi-Fi and open the printer page in the browser.

b. Select the Upgrade tab in the printer page and click Upgrade firmware to start the printer

firmware updated. Restart the printer after the upgrade is complete.

Network

Activation

Upgrade

4. Upgrading the Printer License

Before Upgrading the license, make sure that the printer is powered on and is connected to the

network.t

Software Requirements:

UNIZ APP 1.2 or higher

UNIZ Desktop 1.2 or higher

Printer Firmware 4.0 or higher

SLASH OL and SLASH PRO OL support license upgrades. The printer type will change as follows:

SLASH OL -> SLASH PLUS UDP

SLASH PRO -> SLASH PRO UDP

(1) You can purchase license upgrades from the online store by visiting official website https://

www.uniz.com.

(2) Click My Printer in the left menu of the Dashboard from the website to show the activated

printers under the current username and choose the one that needs to be upgraded. Select the

purchased license in the Upgrade License list and click Upgrade to complete the process.

13

Tips:

The printer will be shown only when activated with the current account.

(3)License upgrades can be executed in the UNIZ App or

the UNIZ Desktop printer control interface.

●UNIZ Desktop

a. From the ‘connected printers menu’ in the top right,

select the printer in the list of printers, and open the

printer control interface.

b. Click the "Upgrade License" button below

If the user has not purchased the license or if the printer

and the license have not been bound, the system will

display a notification that directs to the purchasing

webpage.

If the printer and the license have been bound, the system

will start the upgrading process.

Please restart the printer manually after the upgrade is

complete. The printer model should change upon the next

power up.

●UNIZ App

a. Click the "Printer" button in the main menu the app,

select the corresponding printer in the list of printers, open

the printer details control panel, click the "Utilities" button,

and the “Upgrade License” option can be seen in the

window.

b. Click the “Upgrade License” option

If the user has not purchased the license or if the printer

and the license have not been bound, the system will link to

the corresponding license purchasing webpage or remind

the user to go Dashboard for binding;

If the printer and the license have been bound, the system

will start the upgrading.

Please restart the printer manually after upgrade is

complete and the printer model will shift into the

upgraded model.

14

5. Trial and Trial Expiration

SLASH OL and SLASH PRO OL models automatically get a seven-day free trial with SLASH PLUS UDP

or SLASH PRO UDP models after successful activation.

In trial

During the trial period, check whether the printer is connected to the Internet and whether the

resin bottle information is normal before printing.

During the trial period, the trial status will be shown under the firmware version in the printer

control panel (ln use/Expired).

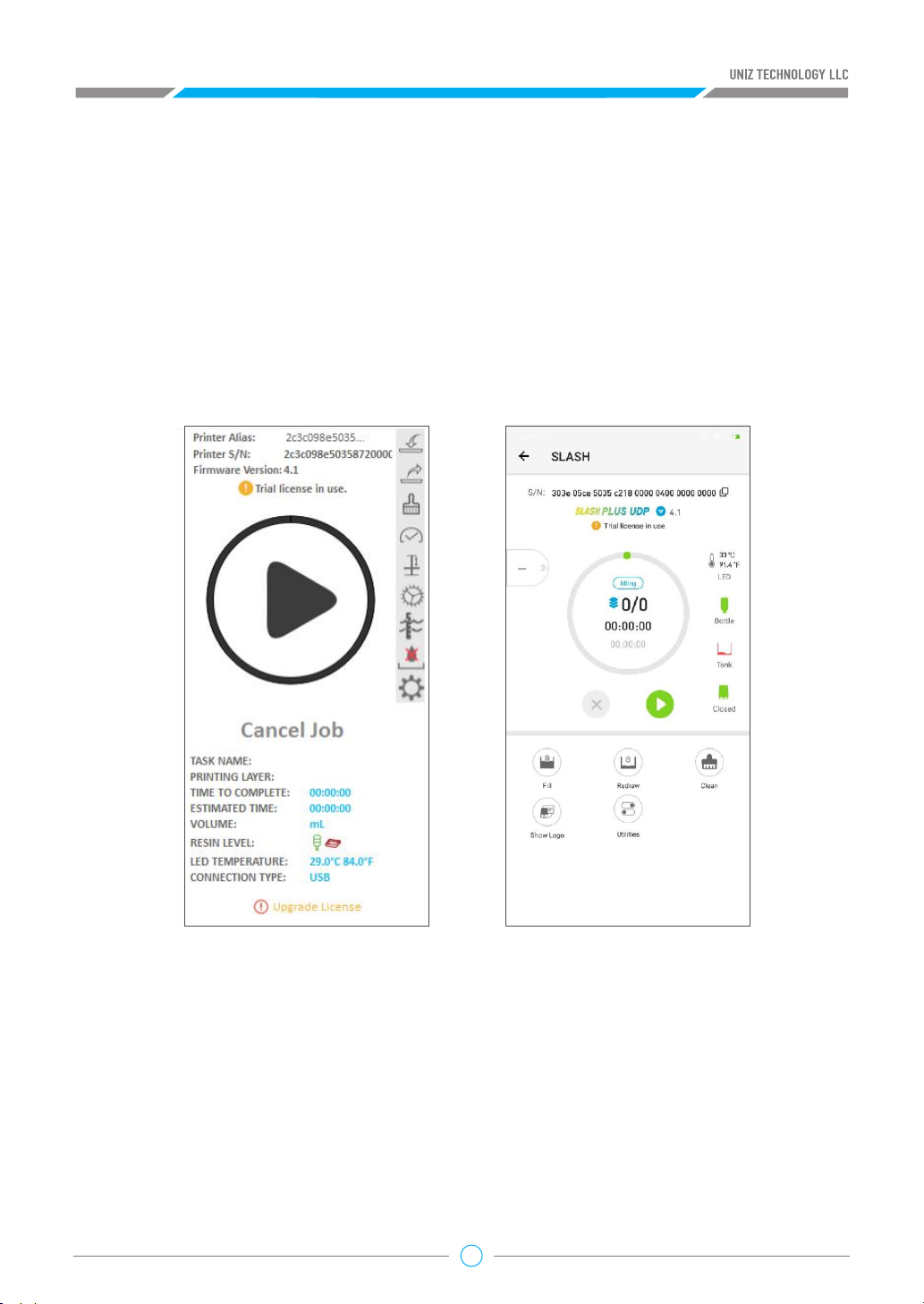

On the left is the Desktop printer control interface, and on the right is the App printer control

interface.

15

Trial Expiration

(1) If the trial period has expired, the system will pop up the dialog box as shown below after

opening software control panel or clicking “Starting Print”.

(2) Click “OK” and the printer will perform the printer reset operation. After the reset operation is

completed, the system will prompt as below

.

(3) After the next restart, the printer will be restored to its original model.

16

UNIZ SOFTWARE USER

C

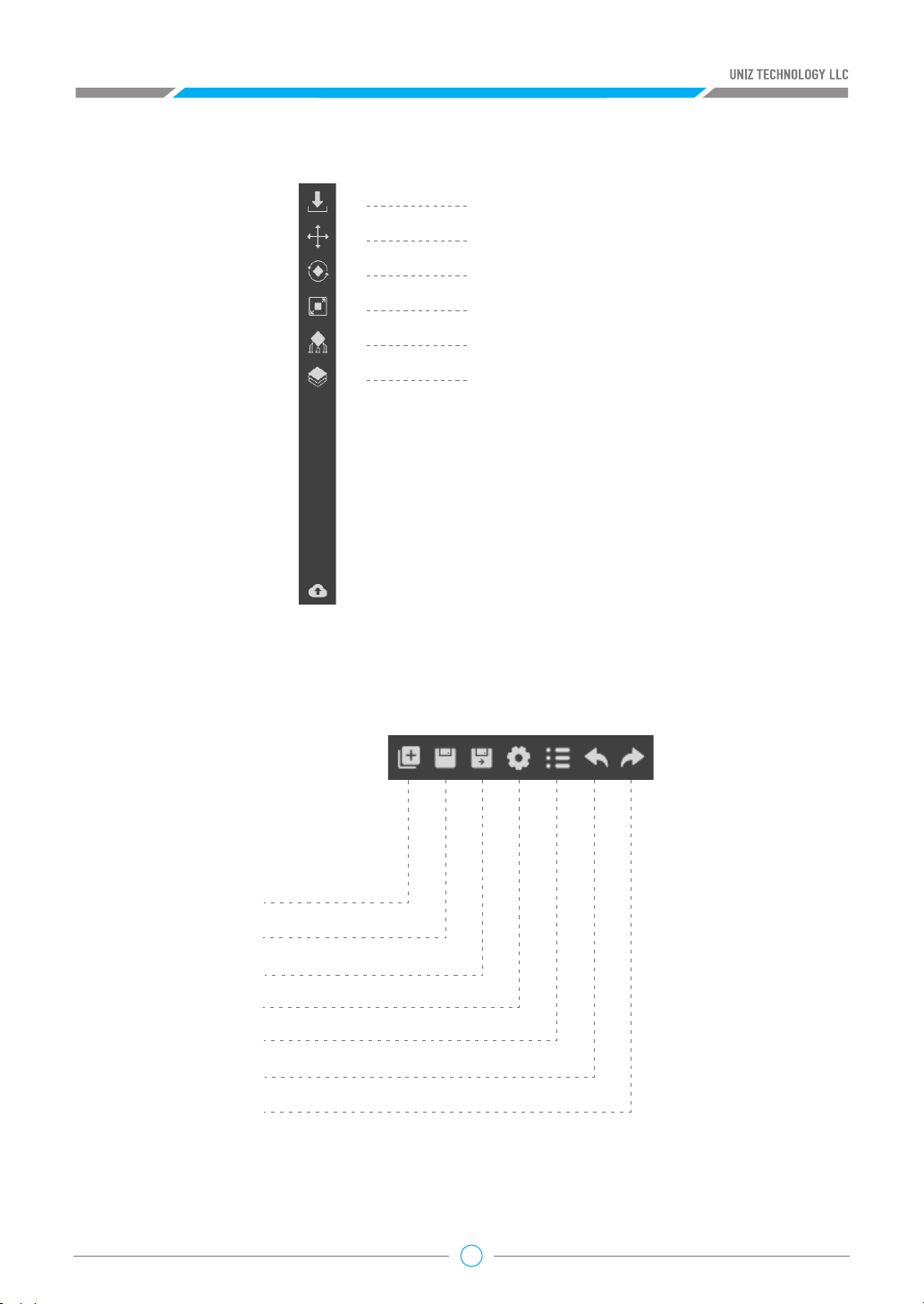

1. Software Interface

Open UNIZ Desktop and click Control button to show the 3D model viewer.

MANUAL

1.1 Viewer

17

1.2 Main Tools

Load 3D Models

Move Selected Model

Rotate Selected Model

Scale Selected Model

Generate Supports

Slice

1.3 Additional Tools

New Scence

Save Scence

Save Scence as

Advanced Setting

Model List

Undo Operation

Redo Operation

18

1.4 Printer Control

Uniz provides printer control function based on USB and network connection. This function also

supports multiple printers’ control. Printer connected via USB will be marked with the icon in

the right printing tool bar.

Click the Search button in the tool bar to search all the printers (only selected printer type) in

the same network of the computer which will be marked with the icon.

Printer connected via both USB and network will be marked with the icon and USB

communication will be prior.

1.5 Status Bar

The status bar appears along the lower edge of the window and shows software progress, such as

loading, generating supports, and slicing

Loading: 58%

2. Start Your First Printing Job

2.1 Load 3D Models

To load one or more 3D models, you may either drag-and-drop onto the 3D viewer, click Load File

Button from the Main Tools, or double click on the file directly (if UNIZ Desktop+ is set as default

software to open such file format). Supported file formats: STL, OBJ, AMF, 3MF and UNIZ.

Tips: UNIZ file does not support multiple loads in parallel.

2.2 Select Object(s)

Click the left mouse button on an object to activate it for further operations. Click and drag the

pointer across objects to select multiple objects. The activated objects will turn blue once selected.

19

2.3 Change View

Viewing your model from preferred angle will benefit model positioning. To rotate the view, right

click and drag around the activated object. To pan, hold the shift key and click-drag with right

mouse or hold down the scroll wheel and move mouse around. To zoom in or out, use the scroll

wheel.

2.4 Change Position

Pressing the “Position” Button will open following sub menu.

• Once the Position tab is open, hold the left mouse

button on the object and move the mouse to move

the object freely in the X-Y plane. If the “Shift” key is

held down, the object will be moved up and down

along the Z-axis instead.

• The activated object can also be moved by inputting X/

Y/Z values in the field, press “Enter “to apply changes.

• Bring the active part in contact with platform.

• Use the “Centered” button to center active part on

platform.

• Use the “Duplicate” button to duplicate the active

part.

Tips:

Make sure the models are distributed evenly on build platform. Un-balanced forces on the

build platform may result in inferior precision or cracking of the printed parts. Once supports

are attached to a model, its Z-position cannot be modified.

2.5 Change Orientation

Press the “Rotation” Button on the main tools will open following sub menu.

• Once the Rotation tab is open, hold the left mouse

button on the object and move the mouse to freely

rotate the object.

• Rotate any model more precisely in one of the three

main axes by dragging one of the circular rings on the

manipulator.

• The activated object can also be rotated by inputting X/

Y/Z values in the field. Press “Enter” to apply changes.

UNIZ's orientation tools are relative not absolute, so

the X, Y, and Z rotation angles reset to 0 degrees after

applying a rotation.

• Press “To Align Bottom Plane” button to align the

selected plane to the bottom of build platform.

• Click the “Reset” Button to restore the activated object to the original status.

20

Tips:

Large Flat surfaces or Long Straight lines with supports may be printed at an oblique angle

of at least 10° to the build platform to increase the success rate. The forces during peeling

may distort thin layers of a flat surface or a line mounted on the support structures if printed

horizontally. If a planar surface or thin line is oriented at an oblique angle, there is only little

overhang for each new layer. Furthermore, thin-walled parts occupy significant less area in a

slice when printed at an oblique angle.

2.6 Change Size

Press the “Size” Button on the main tools will open following sub menu.

• Once the Size tab is open, the activated object can be

scaled freely by holding the left mouse button on the

object and moving the mouse.

• The activated object can also be scaled by inputting X/

Y/Z values in the field. Press ‘Enter’ to apply changes.

The object will scale uniformly in Uniform Scaling

mode. In Non-uniform Scaling mode the object will

scale independently for each axis without affecting the

other axes.

• If you prefer to scale to a fixed ratio put a value into the

scale box.

• Click the ‘Reset’ Button to restore the activated object

to the original size.

• Units: toggle between millimeters and inches.

Tips:

Changing an object’s size will break previously generated supports and you will need to redo

these.

21

2.7 Generate Supports

Some models need additional support structures to print successfully, especially those with

overhangs. Press the “Supports” Button on the main tools to open the Supports sub menu.

Once the Supports tab is open, supports can be added to the active object by pressing the

“Generate” button. Support parameters can be adjusted using spacing, Support Diameter, Head

Length, and Point Size sliders.

• Spacing defines the closest distance between two

adjacent supports.

• Support Diameter defines the diameter of the support

pillar.

• Head Length defines the length between the straight

support pillar and angled pillar to the object (point).

• Point Size defines the diameter of the support where it

touches the object.

• Internal Supports, checking this box will generate

supports inside the model to shore up overhangs.

Without internal supports, the overhangs may fail

during print.

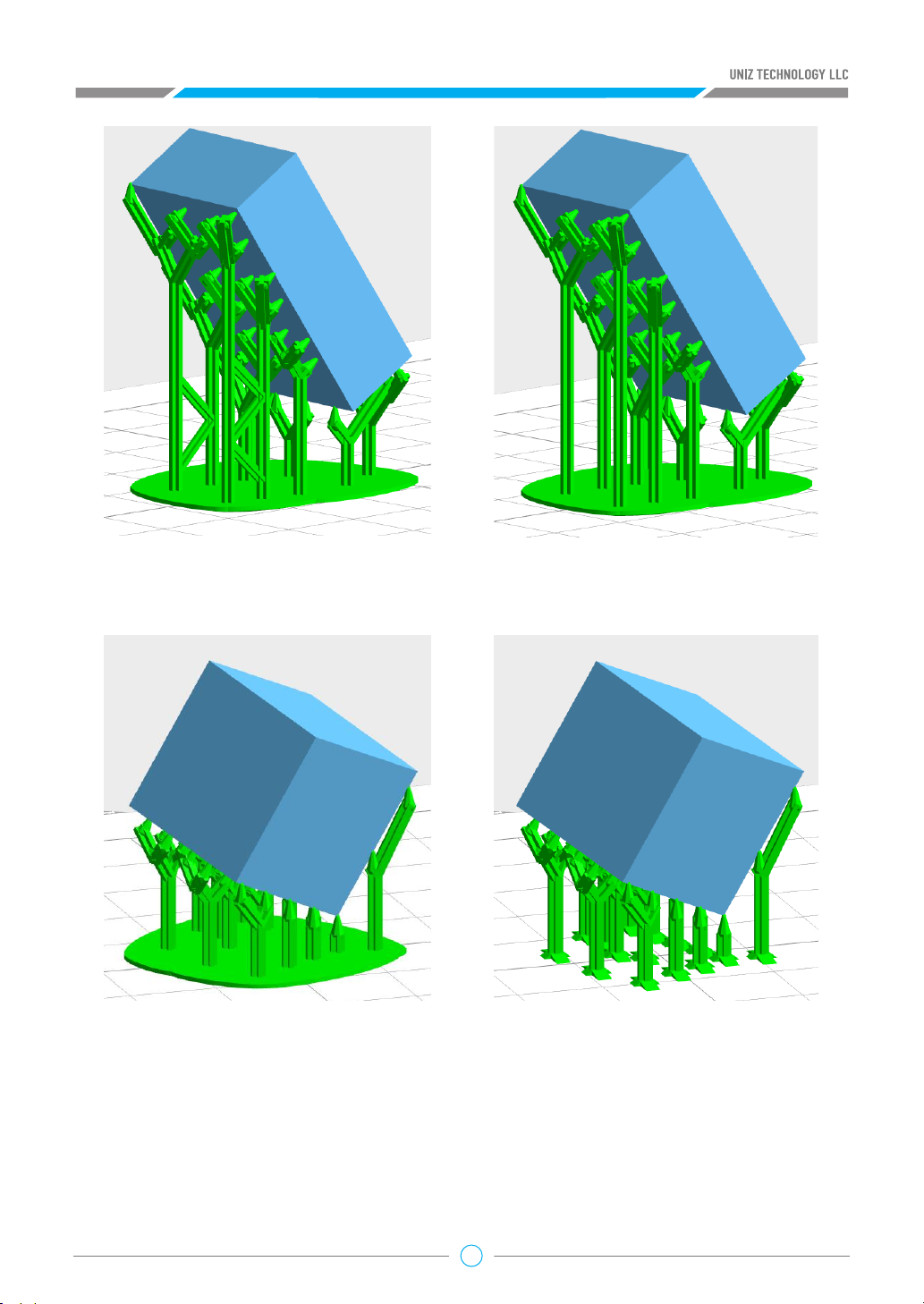

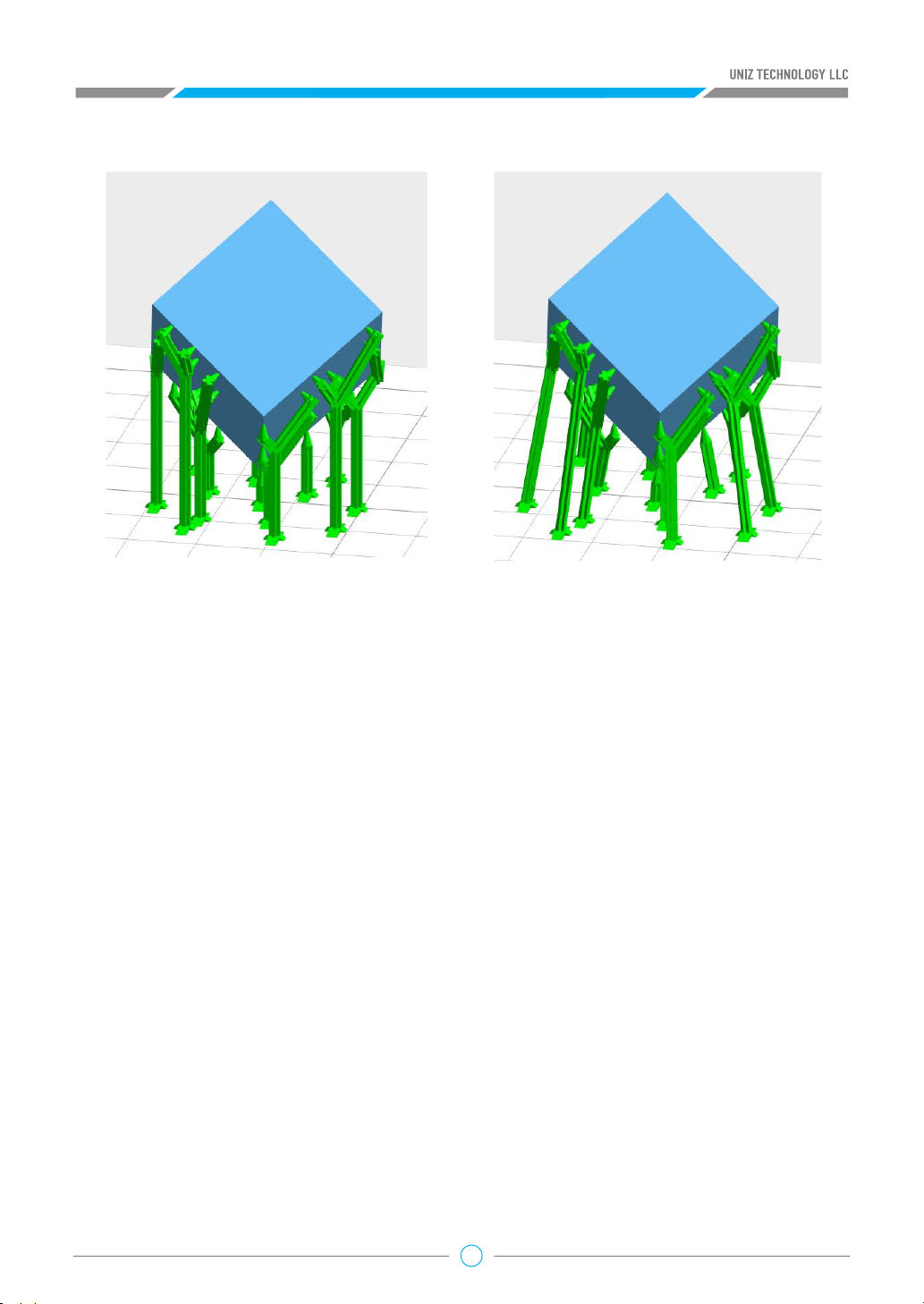

• Connection, Long supports are unstable in structure. Click the connection check box to add

connection parts between long supports for increasing supports stability when generating

supports. The left picture below shows supports with connection and the right one shows

supports without connection. This box is checked by default. Foundation, Click the check box

to add Foundations when generating supports. The left picture below shows supports with

foundation and the right one shows supports without foundation

22

• This box is checked by default. The system will recalculate the foundation when the user

finishes and quit the function of editing supports manually.

• Support Angle, Supports will be generated when the angle between the model part surface

and the horizontal direction is smaller than the support angle, otherwise they will not be

generated. The bigger the support angle is, the wider the scope of generating support. Set this

value to prevent generating supports at steep places and to eliminate unnecessary supports.

You can manually set the angle ranging from 45°to 75°, and the default angle is 60°

• Tilt Angle, To ensure discontinuous exposure in part area under the UDP mode, supports need

to be tilted. Users can manually set the tilt angle ranging from 0°to 20°, and the default angle

is 0°.

23

The left picture below is vertical supports and the right is with tilted supports.

• “Lift”: lift the activated object from the build platform upwards by 5mm.

• “Down”: push the activated object down to the build platform.

• “Generate”: generate the support structure using the current settings for all selected models.

• “Edit”: allow the user to manually add, modify, or delete support structures.

• Entry/Exit Manual Edit

Press the “Edit” button, the system enters manual edit support mode. Even if the object is not

selected, you can edit supports manually. Click the “Edit” button again, the system will return to

automatic support mode.

Add Support

Trace the mouse cursor over the model, when your cursor appears as a green line, clicking on the

surface of the model will add a support. If the cursor appears as a red line, it means a support is

not needed.

Modify Support

Click on the surface of the support and, it will be highlighted to indicate that it has been selected.

Once selected, you can drag and drop the support to a target location. If the support turns red

while moving, the position of the support is not ideal and therefore it is not recommended.

You can also change the Support Radius, Header Length, or Point Size sliders to modify support

properties.

Delete Support

Once a support is selected simply press the “DELETE” key to remove it.

24

Tips:

The “Lift”, “Down”, “Generate” buttons are only enabled when a model is being selected.

2.8 Slice

Press the “Slice” Button on the main tool bar and it will open two sub menus, one on the left and

one on the right. The left menu is to start Slice and Show Slices, and the right drag bar and menu is

for customization of slice profile.

a. Slice Parameters

Slice parameters allow users to customize the slice parameters of each segment of a model.

After version 1.2.0 and the upper Desktop sets a separate slider at the third layer by default and

users cannot move this slider in the bar. The Exposure Time of the first three layers will be set

directly in the slice parameter interface rather than in the advanced settings.

Since 1.3.0 version, “Slice Parameters” has been adding “Preference”

and “LED Power”, accordingly “LED Power” will be removed from

“Advanced Settings”. Uniz Desktop will no longer memorize “Exposure

Time”, therefore “Restore” function be abolished. Users can

memorize favorite printing parameters by “Preference”.

25

• “Resin Type” provides different default values for different resin type.

• "Preference": Each resin can define multiple preference to memorize frequently-used printing

parameter, including: Layer Thickness, Exposure Time, Cool Down Time, Pixel Shrink, LED Power,

Motor Speed, Rise Height, Infill, UDP Mode. Right click on button, popup “Preference Editor”

dialog. In “Preference Editor”, click “Add” to create a new preference and click “Remove” to

delete the selected preference. Note: Preference values are obtained directly from the slice

parameters interface and there are not editable; Only the self-defined preference is deletable.

• “Thickness” is the layer thickness, which is related to Z resolution.

• “Exposure Time” is the exposure time of a layer in a particular segment segment, and it may

vary due to a different layer thickness setting or different resin types, i.e. zWax resin takes about

2x exposure time per layer compare to zABS.

• “Cool Down Time” is the time to cool down the exposed layer to protect the polymer film from

overheating. To prolong the lifetime of the resin tank film, it is recommended to keep the film

temperature under 50 degrees Celsius. Overheating the film can cause it to warp, delaminate

and break.

Tips: Avoid exposing the same spot or area over and over; try to orient the model’s walls or pillars in

oblique angle so the exposure area changes on subsequent layers.

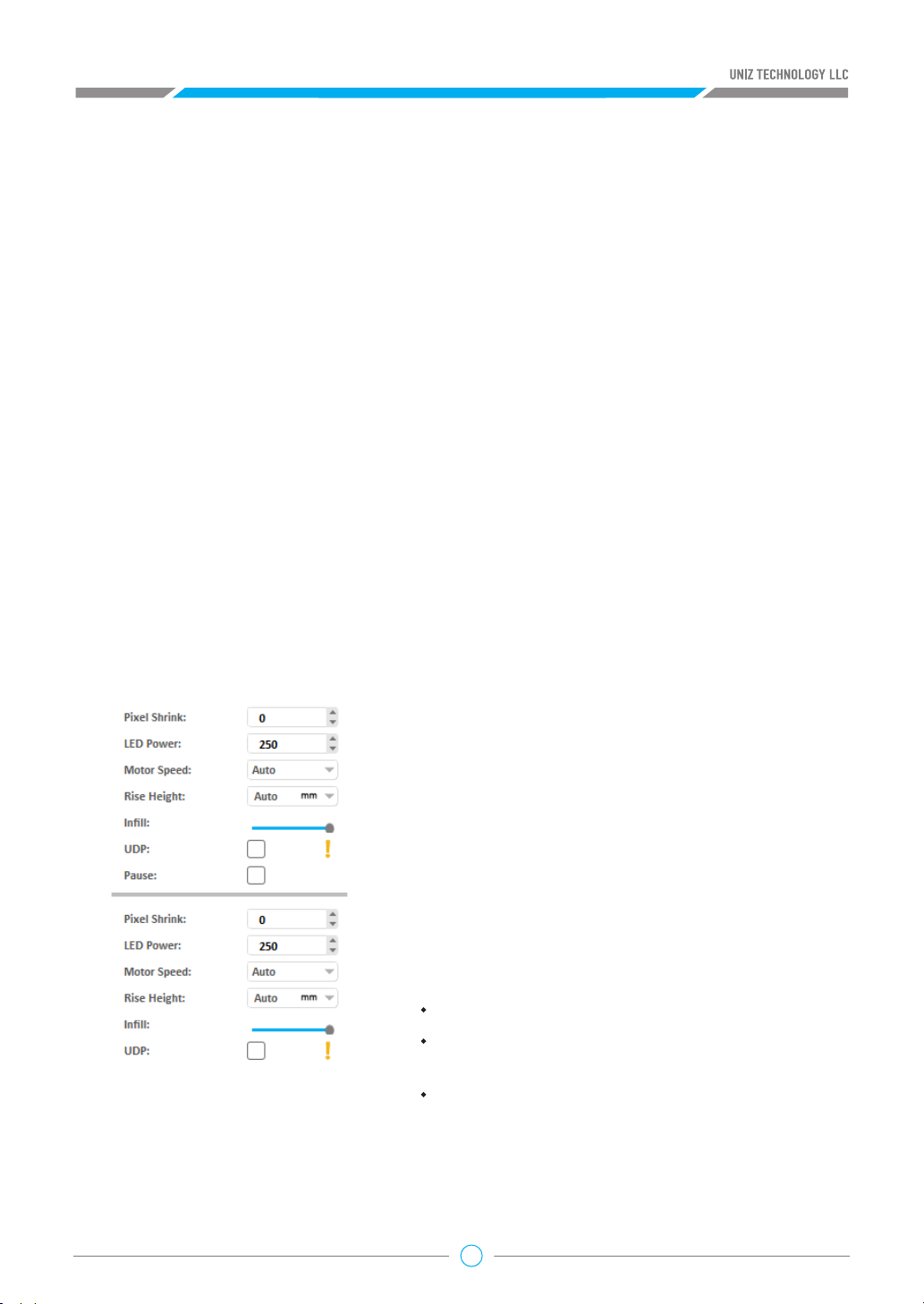

Pressing the “Advanced” Button will open following sub menu.

• “Pixel Shrink”: Shrink or expand the slice polygons.

If value is zero do nothing; If positive shrink slice, if

negative, then expand. The unit is pixels.

• “LED Power” sets the power to the UV LEDS and will

have an impact on curing of the resin Power of LED

module. 150-250 is suggested.

• “Motor Speed” defines the speed of electric motor that

controls the peel motion of the platform.

• “Rise Height” defines the travel height of the peel

motion.

• “Infill”: drag the slider horizontally to modify the infill

ratio ranging from 0% to 100%. The model will be

:

hollowed but not filled when the ratio is 0%;

hollowed and filled by the ratio when the ratio is

among 10% to 90%;

filled but not hollowed when the ratio is 100%;

View the Advanced Settings for the hollowing wall thickness and infill type.

• “UDP” option will be added into the slice parameters when users choose the printers with UDP

function. Users need to check this box when printing UDP model. The Cool Down Time, the

26

Motor Speed and the Rise Height will apply the default value set by the software and they

cannot be modified by the users from the interface.

• “Pause” sets a pre-set pause at the layer of choice during printing, and the pause can be

resumed after pressing the Resume button in the printing control tab.

b. Customize Your Own Z Resolution

By Dividing the model the model into multiple segments and defining different slice parameters, Z

resolution customization can be used to balance print speed and surface quality.

Click the block on the slider bar to start customizing print parameters. The white line shows the

division layer of the two adjacent segments. The upper menu sets the properties of the segment

above the division, and the lower menu sets the properties of the lower segment. You may drag

the slider block to change the division location or double click on blank space on the slider bar to

add another division layer. Press the Delete key when dragging the slider block to erase the division

layer. The last division layer cannot be deleted.

Double click the selected slider and you get a text box. Type layer in the text box and then press

ENTER key to finish and close the editing.

Click the “+” Key to move the slider up one layer incrementally until it reaches the next slider or

the top layer of the model.

Click the “-” Key to move the slider down one layer incrementally until it reaches the next slider.

Notice:

The slider at the bottom (that marks the third layer) does not support operations by the +/button.

Click the “PageUp” Key to select the separate slider above.

Click the “PageDown” Key to select the separate slider below

c. Slice Tools

Click the “Slice” Button to slice all models on the build platform with the defined parameters. The

estimated print information will show in the status bar.

Estimated Time 00:12:40 Volume 17.20ml Layers 57

Click “Show Slices” Button to check any individual layer of the sliced model.

27

You can input a specific layer number in the top right to quickly move to that layer

Drag the right slider vertically to view each layer.

Click the Up/Down arrow to view the previous/next layer incrementally.

If Print When Finished is checked, the sliced data will be sent to the selected printer in the right

bar automatically. The printer still needs confirmation to print via the main button located at the

front of the printer.

Tips:

“Print When Finished” will only be enabled when a printer is connected, the corresponding

Printer Control Panel is open, and the printer is in ready status.

2.9 PRINT

Printer connected via USB will be marked with the icon in the right printing tool bar.

Click the button in the tool bar to search all the printers in the same network . These will be

marked with the icon.

a. Print Tools

Press the printer icon / to open the Printer Control Panel / .The Printer Control

Panel is used to control the printer for printing and regular maintenance. Press the icon the icon to

close the Panel.

Start Job: Click “Start” Button , the system will send the

current slice data to printer and start printing.

Pause Job: Click “Pause “ to suspend a printing job.

Resume Job: Click “Resume” to resume a paused printing job.

Cancel Job: Click “Cancel Job” to cancel the current printing job.

Renaming a Printer: Double clicking the printer name or s/n to

input a new alias and press enter to finish renaming.

Upgrade firmware: An icon “ ” will show next to the firmware

version when there is new version firmware available. Double click

the icon to start upgrading. Restart the printer when the upgrade is

finished.

Fill Resin: Click “Fill” to start pumping resin from the bottle into

the tank. Click again to stop.

Redraw Resin: Click “Redraw” to start redrawing resin from the tank back into the bottle. Click

again to stop.

Full Screen Clean: Click “Clean” to expose the entire screen in order to fully cure and clean the

resin at the bottom of the tank. Debris from previous jobs may damage the LCD screen in the next

job. The Clean function will form an entire resin film entrapping the debris from previous jobs.

28

Once the resin film is removed, the resin tank is clean and ready for the next print job.

TIPS: It is recommended to check the bottom of resin tank before every print job. When there is

debris either floating in the resin or sticking to the bottom of vat, it can damage the LCD.

NOTE: DO NOT remove the resin tank during cleaning exposure. After exposure, however,

you may lift the resin tank to remove the cured resin film.

Show Logo: Show Logo is used to verify if the LCD screen is functional. Before using this function,

remove the build platform and resin tank, then click “Show Logo” Button to show the UNIZ logo on

the LCD screen to test communication and LCD screen.

Reset Z-Axis Zero Position: Reset Z-axis Zero Position is used to re calibrate the vertical motor.

Please remove the resin tank and wipe clean the build platform before using this function. On

the popup box, click “Yes” Button, then push the build platform down manually to touch the LCD

screen. Then click “Yes” again, and the build platform will rise back up.

This function is used if there are issues relating to the initial distance between the build platform

and the screen. This may help with failed prints or adhesion issues.

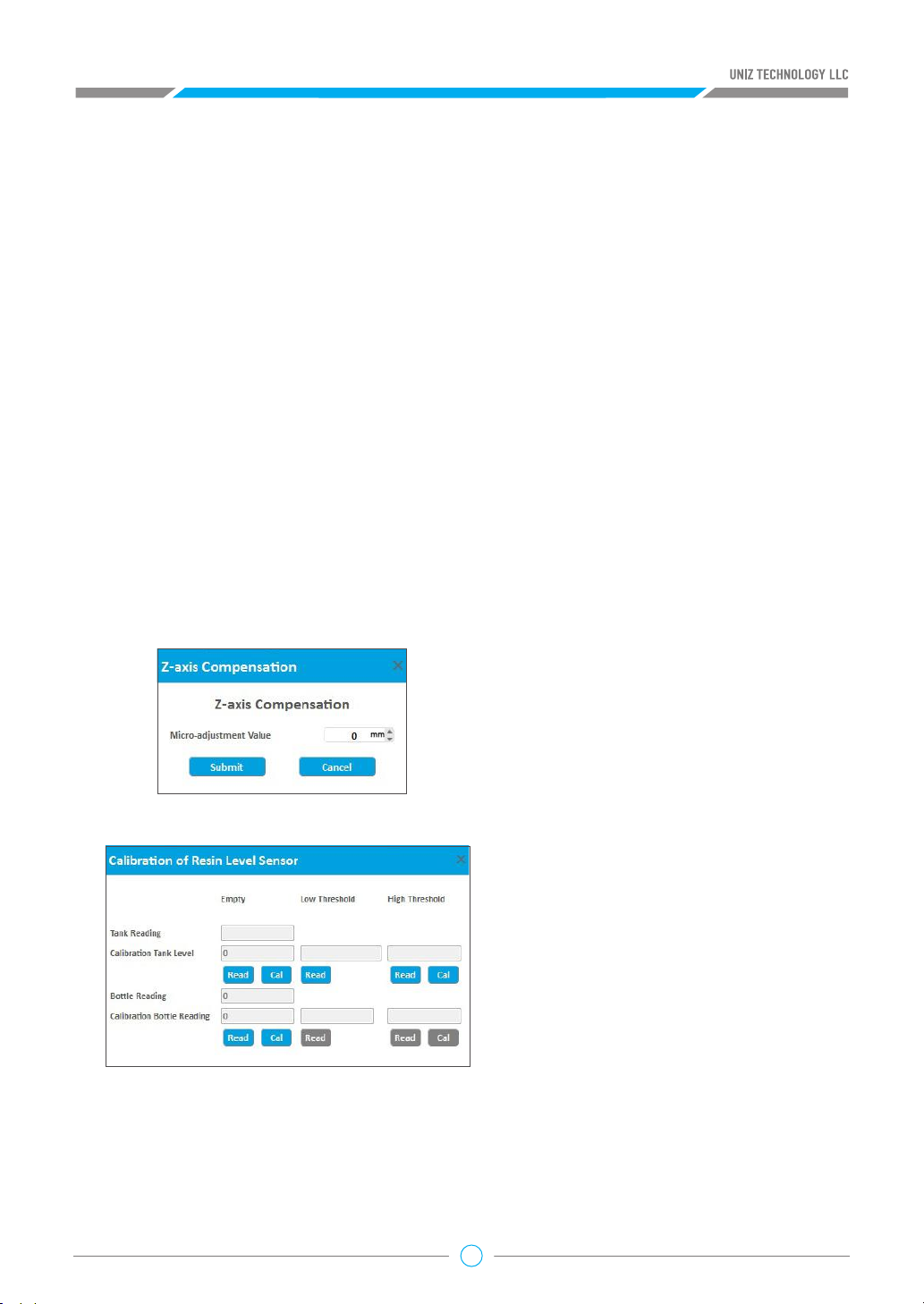

Z-axis Compensation: Enter a value to set a compensation value for the z-axis. This will shorten

the z-axis height from the mechanical calibrated value.

Resin Tank Level Cal

This function is used only when the

printed model is smaller than the

theoretical value along the Z axis

direction. The adjustment value is equal

to the theoretical value minus the actual

value.

Calibration of Resin Level Sensor: Click

“Calibration of Resin Level Sensor”

button to open the dialogue box.

1. Install an empty resin tank and, attach resin sensor to the tank;

2. Calibrate Tank Empty Level: Clicking “Read” and “Cal” button until “Tank Reading” is

29

within ±50.

3. Calibrate Tank Low Threshold: Replace the empty Tank with a Tank filled with 2-3mm resin (or

fill the empty Tank with 2-3mm resin), click “Read” button.

4. Calibrate Tank High Threshold: Replace the Tank with a Tank filled with 7-8mm resin (or fill the

Tank with 7-8mm resin), click “Read “button, and finish the Tank Level Calibration by clicking

“Cal” button.

Calibration of Bottle Resin Level

1. Install an Empty Resin Bottle, and install Resin Level Sensor to the Resin Tank

2. Calibrate Bottle Empty Level: Clicking “Read” and “Cal” button until “Bottle Reading” is within

±50.

3. High/Low threshold is not available in this version.

Auto Pump

1. Click “Auto Pump” Button to turn on / off automatic pumping. If resin level is

too low in the tank and “Auto Pump” is on, the printer will pump resin from the bottle into the

tank automatically.

Printer Settings

Press the “Printer settings” button to popup the submenu including three functions: Network,

Activation,Remote Control, Retime Air Pump and Retime Resin Pump Tube.

1. Network

This shows the printer connection network

status and provides network settings. It supports

automatic and manual IP configuration.

This function only supports setting via USB

connection.

TIP: The Printer's Wi-Fi feature supports 2.4GHz

band only, it does not support 5 GHz connections.

2. Activation

This shows the activation status of the printer. Click to start activating.

3. Remote Control

This shows the remote control status. Users can manually turn on/off the remote control function.

When this function is started for the first time, the system needs to register the printer to the IoT

which may take some time.

4. Air Pump

Display running-time and recommended lifespan of Air Pump. Click right button , it will restart

timer.

30

5. Resin Pump Tube

Display running-time and recommended lifespan of Resin Pump Tube. Click right button , it will

restart timer.

Upgrade License

An icon at the bottom of the printer control panel means this type of printer

can be upgraded. Click the icon to start upgrading the license.

b. Print Process

Send Data to Printer: Click “Start” Button to send the sliced model to the selected printer.

Complete File Transfer: Once you click Start, UNIZ Desktop’s progress bar and the printer’s front

LED circle button will indicate the file transfer progress by lighting in blue.

Confirm Print Job: Make sure that your printer is ready to print and then touch the printer’s front

circular button to confirm print job.

WARNING: Before final confirmation, please make sure the build platform, resin tank, and resin

bottle are installed. Make sure the build platform and resin tank are clear of debris. Make sure the

resin level sensor is properly installed.

After confirmation, you may disconnect your computer from the printer.

Do not disconnect the printer and the software or turn off the UNIZ software during the data

transmission.

2.10 Upload Slice (Optional)

If you want to share your print to the UNIZ Cloud, press the “Upload” Button on the main tools to

open following sub menu.

After your upload completed, you can see the

review progress in Uploaded Models item in

Library. Once the model is approved, the slice

will be displayed on the UniZ store.

31

3. Additional Tools

New Scene: The current scene will be discarded, and a new scene will be created.

Save Scene: Save the current scene in UNIZ file format which includes 3D model data, support

structures, operation history (translation, orientation, scaling), and slice profile. You can load any

saved scene and resume editing at a later time.

Save Scene as: Save current scene to another .UNIZ file.

Advanced Settings:

• “Wall Thickness of Hollowing” sets the

shell thickness of parts hollowed with the

advanced settings in the slice menu.

• “Fill Style” sets the fill style of parts

hollowed with the advanced settings in

the slice menu.

• “Generate Reports”: Tick the left checkbox

to create reports automatically whenyou

start a printing. Click the right button to

modify saving path of reports.

Model List:

Model List provides a modeless dialog for viewing, finding, selecting, hiding, duplicating and

deleting models in 3d scene.

Undo Operation: Undo previous operation.

Redo Operation: Redo a previously undone operation.

32

DESIGN RULES

D

Models Printed in UDP mode must conform to certain design rules in order to print

successfully and prevent damage to the printer. Read more about the design rules at the

link below.

Download link: https://www.uniz.com/support/design_specification

33

E

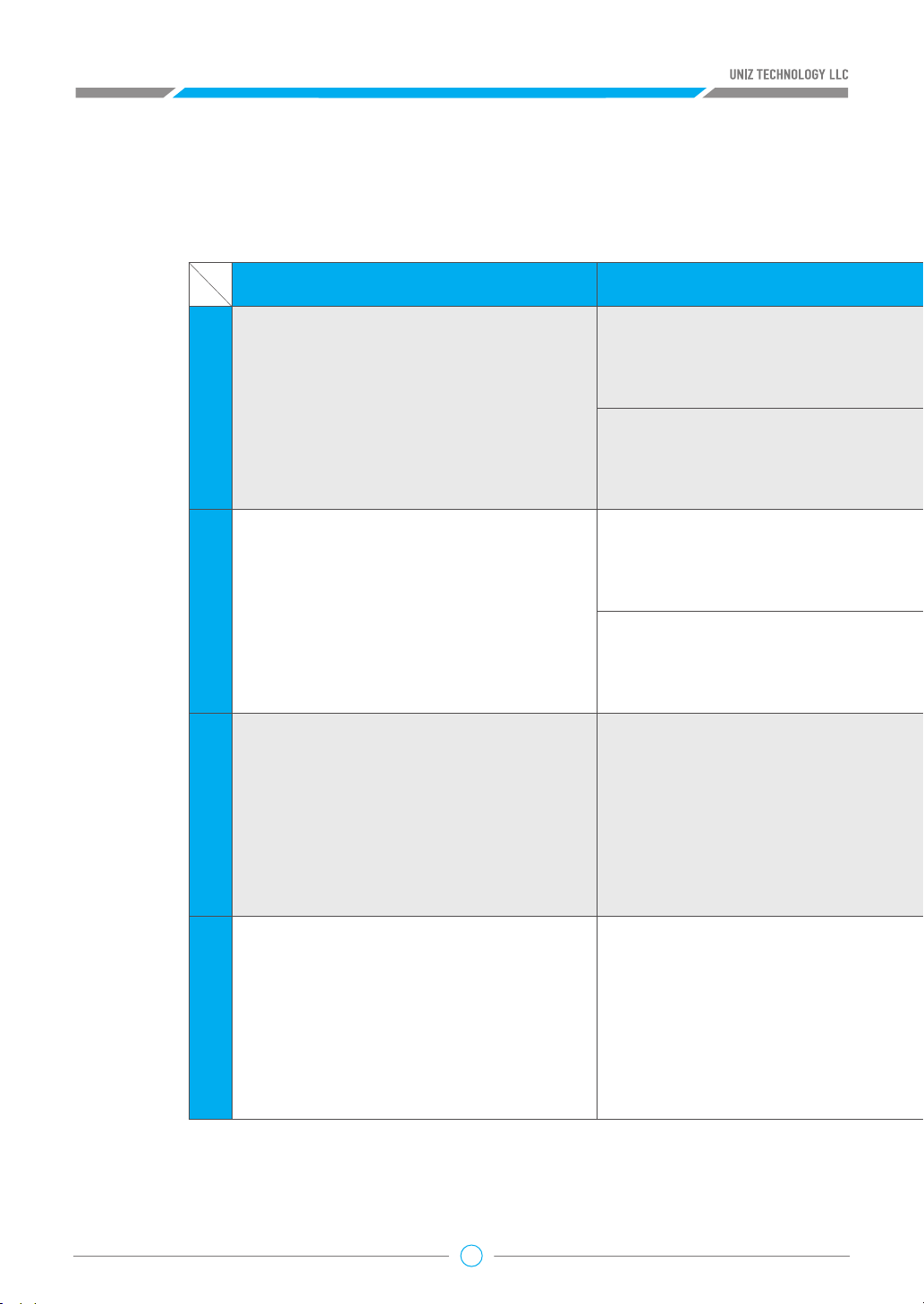

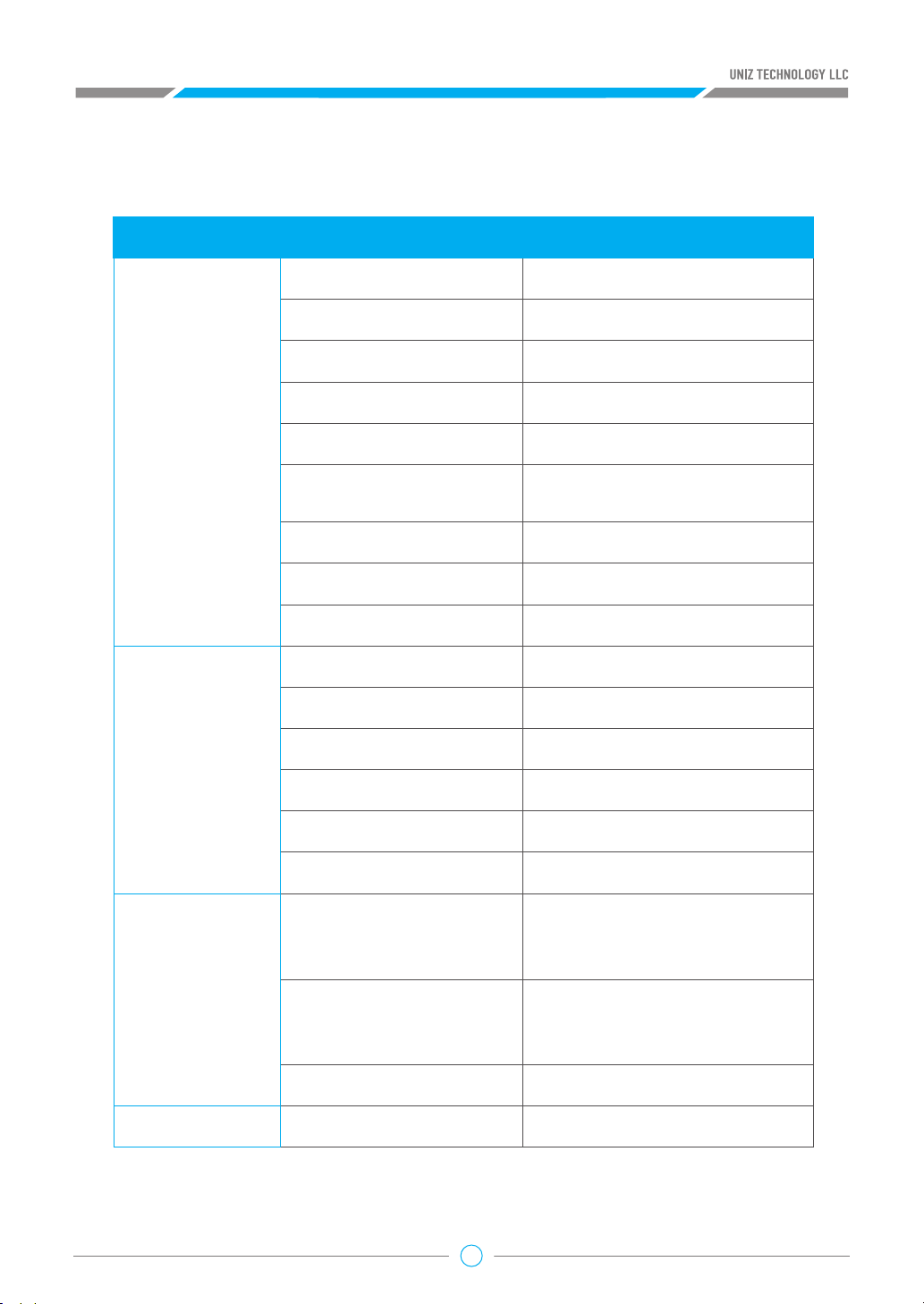

Problems Reason Soluons

1

2

3

4

The first layer is not scking correctly

Printed model / layered fault

A stripe of part fail to print

Abnormal LCD performance under

the show logo funcon: no displaying, flickering or different displaying

on le/right side

The calibraon for plaorm inial point is not in

correct posion

Build plaorm surface is too smooth, printed

model falls into the resin tank

The sucon force between the resin tank film and

models is too strong

A row of lights are damaged on the LED light

board

The LCD cable is not inserted properly; damaged

LCD cable

The screen is damaged

Insufficient adhesion between printed layers

TROUBLE SHOOTING

Model with layering

A strip of part fail to print

issues

34

Follow z-axis calibraon procedure and calibrate

again.

Use provided sandpaper to roughen the surface

of the build plaorm and clean up.

Follow the guidance to re-insert or install the

LCD cable.

Follow the guidance to replace the LCD panel.

Return to the factory for repair.

1. Replace with a new resin tank;

2. Remove the resin tank, clean the LCD panel and the boom

of the resin tank film; wipe them with alcohol and then with a

dry paper towel. (Note: touch ONLY the glass part of the screen,

the area covered with black tape should not be touched);

3. Increase cool down me.

Use provided sandpaper to roughen the surface of the build

plaorm and clean up.

Use provided sandpaper to roughen the surface of

the build plaorm and clean up.

35

Black spot or black bar appears on the screen

The tension of the resin tank film is not strong

Problems Reason

Problems with supports structures

Solid resin residue on the boom of the build

plaorm causes damage to the resin tank film

Wrinkles on the resin tank film

The model boom is not pressed to the XY plane

5

6

7

Stripy or grainy defects on the

printed model

Edge warp defects on the printed

model

There are wavy lines on the XY plane

enough

ghtly

8

Liquid or solid resin residue appear

on the screen surface

36

Soluons

LCD panel may be over heated. Let it cool or follow

the guidance to replace the LCD panel.

Return to the factory for repair.

Follow the guidance to manually add the supports

Check the first layer slice for any error

Replace with a new resin tank and increase the

cooling me properly for the next print

Replace with a new resin tank and clean the

residual resin on the screen

37

Problems Reason

Resin bole not inserted into the right place

The top vent hole of the resin bole has not

Light-blocking tape is damaged

The boom of the build plaorm and the LCD

There is leak from the liquid cooling system

9

10

11

12

The resin leaks from the right boom

of the printer

Excessive printed part appears. Light

leaks outside the screen display area

Printed model has ripples or wavy

lines on the side face

Oily liquid exuded from the seams

area in front of the label at the print-

er boom, and the level of the liquid

in the coolant tank has significantly

reduced

been pierced

Shaky Z axis

13

Considerable size differences exceeding 1mm among the first several

layers or between the le and the

right of the printer

38

panel are not parallel

Soluons

Clean up the residual resin according to the

guidance and replace with a new resin bole,

make sure the bole is inserted all the way in

Pierce either top hole of the resin bole with the

provided awl

Replace with new tape, cut and cover any exposed

area

Adjust the ghtness of the lead screw nut and the

build plaorm holder according to the guide

Replace with new LCD cooling module or return to

the factory for repair.

Adjust the build plaorm parallelism according to

the tutorial video

39

14

Z-axis limit switch is dysfunconal.

Light-blocking tape is damaged

The fan cable has stuck or the bolt is over

There is poor contact in the circuit

board cable or program error

Problems Reason

The build plaorm could not descend

aer it rises to the highest, with

abnormal sound during the starng

or finishing process of prinng.

15

16

17

18

Automac pumping failed.

Abnormal display appear on the front

light of the printer

Touch problems occur with the front

light of the printer

Abnormal sound can be heard from

the rear cooling fan

The circuit board has broken

ghtened

40

Soluons

Check if the micro switch cable is broken;

return to the factory for repair if it is well

connected

Replace with new tape, cut and cover any

exposed area

Reinsert the cable and restart

Replace with a new circuit board according to

the guidance

Remove the rear fan filter cover and check if

there is any cable interference; adjust the

ghtness of the bolt accordingly

41

F

ROHS AUTHENTICATION

Hazardous Substance

Pb Hg Cd Cr(VI) PBB (PBDE)

Mainboard

Motor

Column

Power

Fans

Cooling

Board

Resin

Tank

LCD

Board

LED

Board

42

APPENDIX

G

TECHNICAL SPECIFICATIONS

SLASH OL

LCD Stereolithography

192 × 120 × 200mm

7.5" × 4.7" × 7.9"

150μm

±70μm

10, 25, 50, 75, 100, 150, 200, 300μm

10, 25, 50, 100, 150, 200, 300μm

Profile customizable

Profile customizable

Polymer film natural peel

Up to 100x more durable than PDMS

UDP ready**

Uniz smart support technology

Up to 600 mm/hr (UDP mode)

Up to 200 mm/hr (Normal mode)

Automac level control

350 × 400 × 530 mm [W×H×D]

14" × 16" × 21", 14KG/30LB

Prinng

Prinng Technology

Build Volume

XY Resoluon

Highest accuracy**

Layer Thickness(Z resoluon)

Separaon Mechanism

Support

Prinng Speed

Resin Level Control

Dimension/Weight

Operang Temperature

Power Requirement

Hardware

Opcal System

Mechanical

Connecvity

System Requirement

Desktop

Soware

Mobile Apps

*Highest accuracy only achievable at integer multiples of smallest pixel sizes.

**Not applicable to all geometries, UDP specific design rules apply.

Advanced Features

Compable Format

Compable Systems

43

Suggested 18–28° C Suggested 64–82° F

100-240VAC, 6A 50/60Hz

5500 Lux blue LED array

liquid cooling system

Cast Aluminum & CNC, Injecon Molding

USB, Wifi, Ethernet

Windows 7 and up (64-bit only)

Mac OS X 10.7 and up (64-bit only)

16GB RAM, OpenGL 2.1

Discrete Graphics

Mul-printer management

Built-in advanced model repair

Ultra large file support (1GB+)

STL, OBJ, AMF, 3MF, UNIZ

iPhone, iPad, Android Phone and Tablet

SLASH PLUS

Prinng

Hardware

Prinng Technology

Build Volume

XY Resoluon

Highest accuracy**

Layer Thickness(Z resoluon)

Separaon Mechanism

Support

Prinng Speed

Resin Level Control

Dimension/Weight

Operang Temperature

Power Requirement

Opcal System

LCD Stereolithography

192 × 120 × 200mm

7.5" × 4.7" × 7.9"

75μm

±20μm

10, 25, 50, 100, 150, 200, 300μm

10, 25, 50, 75, 100, 150, 200, 300μm

Profile customizable

Profile customizable

Polymer film natural peel

Up to 100x more durable than PDMS

Uniz smart support technology

Up to 200 mm/hr

Automac level control

350 × 400 × 530 mm [W×H×D]

14" × 16" × 21", 14KG/30LB

Suggested 18–28° C Suggested 64–82° F

100-240VAC, 6A 50/60Hz

5500 Lux blue LED array

liquid cooling system

Mechanical

Connecvity

System Requirement

Desktop

Soware

Advanced Features

Compable Format

Mobile Apps

*Highest accuracy only achievable at integer multiples of smallest pixel sizes.

Compable Systems

44

Cast Aluminum & CNC, Injecon Molding

USB, Wifi, Ethernet

Windows 7 and up (64-bit only)

Mac OS X 10.7 and up (64-bit only)

16GB RAM, OpenGL 2.1

Discrete Graphics

Mul-printer management

Built-in advanced model repair

Ultra large file support (1GB+)

STL, OBJ, AMF, 3MF, UNIZ

iPhone, iPad, Android Phone and Tablet

Prinng

Hardware

Desktop

Soware

Mobile Apps

Operang Temperature

Power Requirement

Opcal System

Dimension/Weight

Prinng Technology

XY Resoluon

Build Volume

Separaon Mechanism

Support

Highest accuracy**

Prinng Speed

Resin Level Control

Mechanical

Layer Thickness(Z resoluon)

Connecvity

System Requirement

Advanced Features

Compable Format

Compable Systems

Suggested 18–28° C Suggested 64–82° F

100-240VAC, 6A 50/60Hz

5500 Lux blue LED array

liquid cooling system

Uniz smart support technology

350 × 400 × 530 mm [W×H×D]

14" × 16" × 21", 14KG/30LB

LCD Stereolithography

75μm

192 × 120 × 200mm

7.5" × 4.7" × 7.9"

Polymer film natural peel

Up to 100x more durable than PDMS

UDP ready**

±20μm

Up to 600 mm/hr (UDP mode)

Up to 200 mm/hr (Normal mode)

Automac level control

10, 25, 50, 100, 150, 200, 300μm

Profile customizable

Cast Aluminum & CNC, Injecon Molding

USB, Wifi, Ethernet

Windows 7 and up (64-bit only)

Mac OS X 10.7 and up (64-bit only)

16GB RAM, OpenGL 2.1

Discrete Graphics

Mul-printer management

Built-in advanced model repair

Ultra large file support (1GB+)

STL, OBJ, AMF, 3MF, UNIZ

iPhone, iPad, Android Phone and Tablet

SLASH PLUS UDP

10, 25, 50, 75, 100, 150, 200, 300μm

Profile customizable

*Highest accuracy only achievable at integer multiples of smallest pixel sizes.

**Not applicable to all geometries, UDP specific design rules apply.

45

Prinng

Hardware

Desktop

Soware

Mobile Apps

Operang Temperature

Power Requirement

Opcal System

Dimension/Weight

Prinng Technology

XY Resoluon

Build Volume

Separaon Mechanism

Support

Highest accuracy**

Prinng Speed

Resin Level Control

Mechanical

Layer Thickness(Z resoluon)

Connecvity

System Requirement

Advanced Features

Compable Format

Compable Systems

Suggested 18–28° C Suggested 64–82° F

100-240VAC, 6A 50/60Hz

5500 Lux blue LED array

liquid cooling system

Uniz smart support technology

350 × 400 × 730 mm [W×H×D]

14" × 16" × 29", 14KG/30LB

LCD Stereolithography

150μm

192 × 120 × 400mm

7.5" × 4.7" × 7.9"

Polymer film natural pee

Up to 100x more durable than PDMS

UDP ready**

±70μm

Up to 600 mm/hr (UDP mode)

Up to 200 mm/hr (Normal mode)

Automac level control

10, 25, 50, 100, 150, 200, 300μm

Profile customizable

Cast Aluminum & CNC, Injecon Molding

USB, Wifi, Ethernet

Windows 7 and up (64-bit only)

Mac OS X 10.7 and up (64-bit only)

16GB RAM, OpenGL 2.1

Discrete Graphics

Mul-printer management

Built-in advanced model repair

Ultra large file support (1GB+)

STL, OBJ, AMF, 3MF, UNIZ

iPhone, iPad, Android Phone and Tablet

SLASH PRO OL

10, 25, 50, 75, 100, 150, 200, 300μm

Profile customizable

*Highest accuracy only achievable at integer multiples of smallest pixel sizes.

**Not applicable to all geometries, UDP specific design rules apply.

46

SLASH PRO

Prinng

Hardware

Prinng Technology

Build Volume

XY Resoluon

Highest accuracy**

Layer Thickness(Z resoluon)

Separaon Mechanism

Support

Prinng Speed

Resin Level Control

Dimension/Weight

Operang Temperature

Power Requirement

Opcal System

LCD Stereolithography

192 × 120 × 400mm

7.5" × 4.7" × 15.8"

75μm

±20μm

10, 25, 50, 75, 100, 150, 200, 300μm

10, 25, 50, 100, 150, 200, 300μm

Profile customizable

Profile customizable

Polymer film natural peel

Up to 100x more durable than PDMS

Uniz smart support technology

Up to 200 mm/hr

Automac level control

350 × 400 × 730 mm [W×H×D]

14" × 16" × 29", 18KG/40LB

Suggested 18–28° C Suggested 64–82° F

100-240VAC, 6A 50/60Hz

5500 Lux blue LED array

liquid cooling system

Mechanical

Connecvity

System Requirement

Desktop

Soware

Advanced Features

Compable Format

Mobile Apps

*Highest accuracy only achievable at integer multiples of smallest pixel sizes.

Compable Systems

47

Cast Aluminum & CNC, Injecon Molding

USB, Wifi, Ethernet

Windows 7 and up (64-bit only)

Mac OS X 10.7 and up (64-bit only)

16GB RAM, OpenGL 2.1

Discrete Graphics

Mul-printer management

Built-in advanced model repair

Ultra large file support (1GB+)

STL, OBJ, AMF, 3MF, UNIZ

iPhone, iPad, Android Phone and Tablet

Prinng

Hardware

Desktop

Soware

Mobile Apps

Operang Temperature

Power Requirement

Opcal System

Dimension/Weight

Prinng Technology

XY Resoluon

Build Volume

Separaon Mechanism

Support

Highest accuracy**

Prinng Speed

Resin Level Control

Mechanical

Layer Thickness(Z resoluon)

Connecvity

System Requirement

Advanced Features

Compable Format

Compable Systems

Suggested 18–28° C Suggested 64–82° F

100-240VAC, 6A 50/60Hz

5500 Lux blue LED array

liquid cooling system

Uniz smart support technology

350 × 400 × 730 mm [W×H×D]

14" × 16" × 29", 18KG/40LB

LCD Stereolithography

75μm

192 × 120 × 400mm

7.5" × 4.7" × 15.8"

Polymer film natural peel

Up to 100x more durable than PDMS

UDP ready**

±20μm

Up to 600 mm/hr (UDP mode)

Up to 200 mm/hr (Normal mode)

Automac level control

10, 25, 50, 100, 150, 200, 300μm

Profile customizable

Cast Aluminum & CNC, Injecon Molding

USB, Wifi, Ethernet

Windows 7 and up (64-bit only)

Mac OS X 10.7 and up (64-bit only)

16GB RAM, OpenGL 2.1

Discrete Graphics

Mul-printer management

Built-in advanced model repair

Ultra large file support (1GB+)

STL, OBJ, AMF, 3MF, UNIZ

iPhone, iPad, Android Phone and Tablet

SLASH PRO UDP

10, 25, 50, 75, 100, 150, 200, 300μm

Profile customizable

*Highest accuracy only achievable at integer multiples of smallest pixel sizes.

**Not applicable to all geometries, UDP specific design rules apply.

48

Prinng

Hardware

Desktop

Soware

Mobile Apps

Operang Temperature

Power Requirement

Opcal System

Dimension/Weight

Prinng Technology

XY Resoluon

Build Volume

Separaon Mechanism

Support

Highest accuracy**

Prinng Speed

Resin Level Control

Mechanical

Layer Thickness(Z resoluon)

Connecvity

System Requirement

Advanced Features

Compable Format

Compable Systems

* Equipped with two LCD modules, outpung the same slices.

* * Highest accuracy only achievable at integer mulples of smallest pixel sizes

Suggested 18–28° C Suggested 64–82° F

100-240VAC, 6A 50/60Hz

5500 Lux blue LED array

liquid cooling system

Uniz smart support technology

350 × 400 × 530 mm [W×H×D]

14" × 16" × 21", 14KG/30LB

LCD Stereolithography

47μm

Duo LCD*, 120 × 68 × 200mm

4.76" × 2.67" × 7.9"

Polymer film natural peel

Up to 100x more durable than PDMS

±10μm

Up to 200 mm/hr

Automac level control

10, 25, 50, 75, 100, 150, 200, 300μm

Profile customizable

Cast Aluminum & CNC, Injecon Molding

USB, Wifi, Ethernet

Windows 7 and up (64-bit only)

Mac OS X 10.7 and up (64-bit only)

16GB RAM, OpenGL 2.1

Discrete Graphics

Mul-printer management

Built-in advanced model repair

Ultra large file support (1GB+)

STL, OBJ, AMF, 3MF, UNIZ

iPhone, iPad, Android Phone and Tablet

SLASH DJ2

10, 25, 50, 75, 100, 150, 200, 300μm

Profile customizable

49

Prinng

Hardware

Desktop

Soware

Mobile Apps

Operang Temperature

Power Requirement

Opcal System

Dimension/Weight

Prinng Technology

XY Resoluon

Build Volume

Separaon Mechanism

Support

Highest accuracy**

Prinng Speed

Resin Level Control

Mechanical

Layer Thickness(Z resoluon)

Connecvity

System Requirement

Advanced Features

Compable Format

Compable Systems

Suggested 18–28° C Suggested 64–82° F

100-240VAC, 6A 50/60Hz

5500 Lux blue LED array

liquid cooling system

Uniz smart support technology

350 × 400 × 530 mm [W×H×D]

14" × 16" × 21", 14KG/30LB

LCD Stereolithography

47μm

120 × 68 × 200mm

4.76" × 2.67" × 7.9"

Polymer film natural peel

Up to 100x more durable than PDMS

±10μm

Up to 600 mm/hr (UDP mode)

Up to 200 mm/hr (Normal mode)

Automac level control

10, 25, 50, 100, 150, 200, 300μm

Profile customizable

Cast Aluminum & CNC, Injecon Molding

USB, Wifi, Ethernet

Windows 7 and up (64-bit only)

Mac OS X 10.7 and up (64-bit only)

16GB RAM, OpenGL 2.1

Discrete Graphics

Mul-printer management

Built-in advanced model repair

Ultra large file support (1GB+)

STL, OBJ, AMF, 3MF, UNIZ

iPhone, iPad, Android Phone and Tablet

SLASH J UDP

10, 25, 50, 75, 100, 150, 200, 300μm

Profile customizable

* Highest accuracy only achievable at integer multiples of smallest pixel sizes

50

Loading...

Loading...