Unix CCTV PT 980 User Manual

User’s Manual

Speed Dome Camera

Anti-vandal

x

10

2 3

Safety Information

x10 Anti-vandal

Speed Dome Camera

User’s Manual

Ver. 3 . 1 / 2009.09

This symbol indicates that dangerous voltage

consisting a risk of electric shock is present within

this unit.

Warning Precaution

This exclamation point symbol is intended to alert the

user to the presence of important operating and

maintenance (servicing) instructions in the literature

accompanying the appliance.

TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE COVER (OR BACK) NO USER SERVICEABLE

PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

CAUTION

:

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT OPEN.

To prevent damage which may result in fire or electric shock hazard, do not expose this appliance to rain or moisture.

1. Be sure to use only the standard adapter that is specified in the specification sheet. Using any other adapter could

cause fire, electrical shock, or damage to the product.

2. Incorrectly connecting the power supply or replacing battery may cause explosion, fire, electric shock, or damage

to the product.

3. Do not connect multiple cameras to a single adapter. Exceeding the capacity may cause abnormal heat generation

or fire.

4. Securely plug the power cord into the power receptacle. Insecure connection may cause fire.

5. When installing the camera, fasten it securely and firmly. A falling camera may cause personal injury.

6. Do not place conductive objects (e.g. screw drivers, coins, metal things, etc.) or containers filled with water on top

of the camera. Doing so may cause personal injury due to fire, electric shock, or falling objects.

7. Do not install the unit in humid, dusty, or sooty locations. Doing so may cause fire or electric shock.

8. If any unusual smells or smoke come from the unit, stop using the product. In such case, immediately disconnect

the power source and contact the service center. Continued use in such a condition may cause fire or electric shock.

9. If this product fails to operate normally, contact the nearest service center. Never disassemble or modify this

product in any way.

10. When cleaning, do not spray water directly onto parts of the product. Doing so may cause fire or electric shock.

WARNING

WARNING

Precautions Contents

4 5

67Product & Accessories

Parts Name & Functions

4 Precation

1. Introduction

8

10

11

12

13

14

16

17

DIP Switch Setup

Installation Using Surface Mount Bracket

Installation Using Flush Mount Ring Bracket(Option)

Installation Using Ceiling Mount Bracket(Option)

Installation Using Wall Mount Bracket(Option)

Installation Using Wall Mount Bracket with Junction Box(Option)

Cabling the 5P Terminal Block

Cabling the 7P Terminal Block

2. Installation

18

19

20

21

22

24

25

26

28

30

31

32

34

36

37

38

40

Check Points before Operation

Main Functions

OSD Information

General Rules of Menu Operation

OSD Menu Contents

OSD -

ROOT MENU & SYSTEM INFORMATION

OSD -

DISPLAY SETUP

OSD -

MOTION SETUP

OSD -

FUNCTION SETUP>PRESET SETUP

OSD -

FUNCTION SETUP>SCAN SETUP

OSD -

FUNCTION SETUP>PATTERN SETUP

OSD -

FUNCTION SETUP>GROUP SETUP

OSD -

FUNCTION SETUP>SCHEDULE SETUP

OSD -

CAMRA SETUP>WB SETUP

OSD -

CAMRA SETUP>AE SETUP

OSD -

SYSTEM SETUP

OSD -

SYSTEM INITIALIZE

3. OSD Menu

41

42

44

Dimensions

Dimensions of Option Brackets

Specifications

4. Specification

Operating

Before using, make sure power supply and others are properly connected.

While operating, if any abnormal condition or malfunction is observed, stop using the camera immediately and then

contact your Special dealer.

Handling

Do not disassemble or tamper with parts inside the camera.

Do not drop or subject the camera to shock and vibration as this can damage camera.

Care must be taken when you clean the clear dome cover. Especially, scratch and dust will ruin your quality of camera.

Installation and Storage

Do not install the camera in areas of extreme temperature, which exceed the allowable range.

Avoid installing in humid or dusty places.

Avoid installing in places where radiation is present.

Avoid installing in places where there are strong magnetic elds and electric signals.

Avoid installing in places where the camera would be subject to strong vibrations.

Never expose the camera to rain and water.

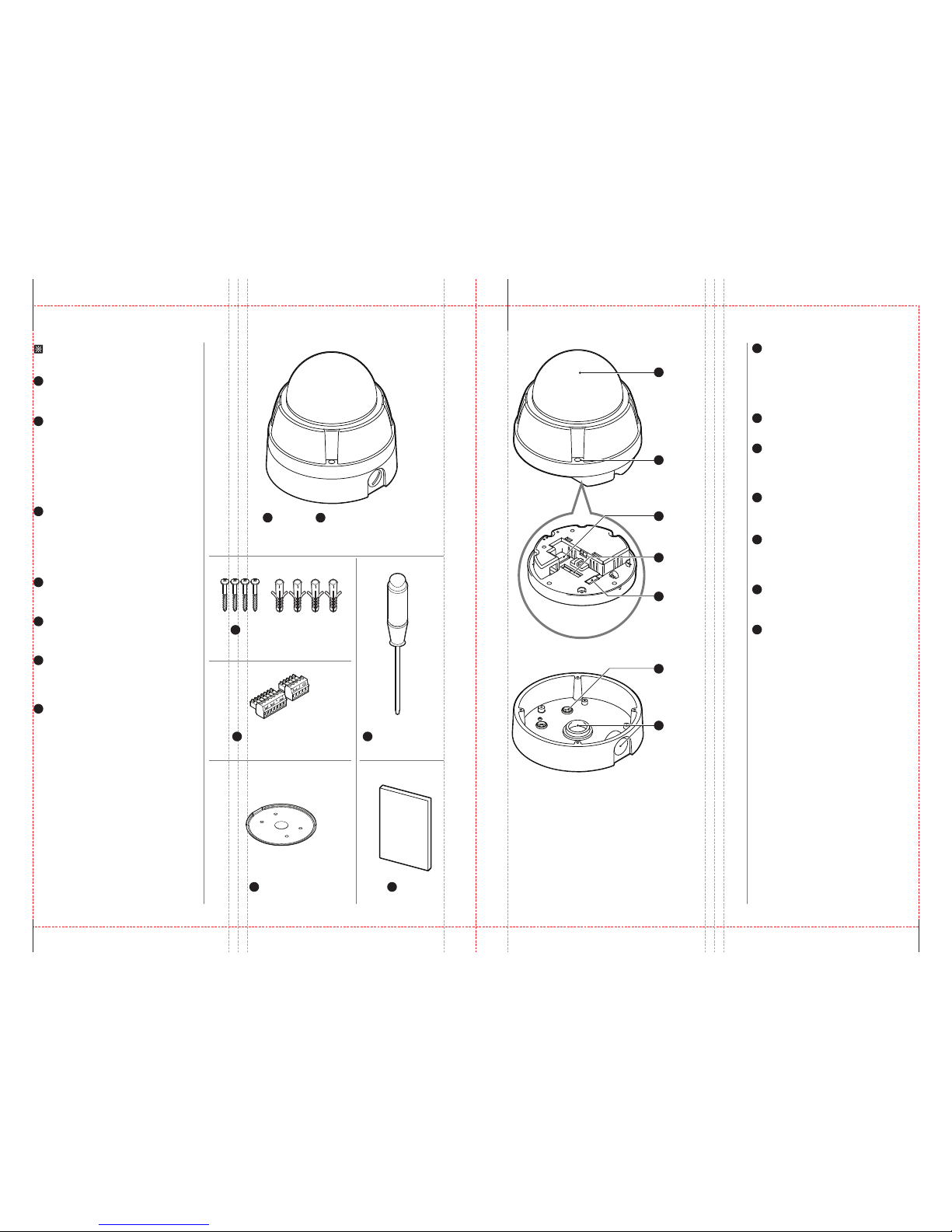

Product & Accessories Parts Name & Functions

1

6 7

Main Body

Main Body + Surface Mount Bracket

1

2

1

Terminal Block x2: 5P+7P

4

Rubber Gasket

6

Screw & Plastic Anchor-4pcs

3

Manual

7

User’s Manual

Surface Mount Bracket

2

Camera module, screws, terminal block slot and

DIP switches are included.

- It is used when installing the camera right on to

the ceiling.

- To install the camera with the surface mount

bracket, the bracket needs to be separated from

the main body, then needs to be re-assembled

the bracket and the main body according to the

order.

Terminal Block

4

Power, video, communication and alarm input

cables are connected through the terminal blocks.

Torx Screw Driver

5

It is used to screw/unscrew the fixed screws on

the main body.

Rubber Gasket

6

Manual

7

Please read the manual carefully before installing.

It is installed between the surface mount bracket

and wall/wall mount bracket to prevent the water

leakage.

Screw & Plastic Anchor

3

- Screws are used to fix the surface mount bracket

to the ceiling.

- Plastic anchors are used to tighten the screws to

the hole by inserting them into the holes in

advance.

Please check if all the camera and

accessories are included in the package.

Torx Screw Driver

5

Main Body

Dome Cover

1

Lockup Screw

2

Surface Mount Bracket

Bottom of Main Body

Dome Cover

1

- Protects the camera module from outside

environment.

- Do not detach protection vinyl from the dome

cover before finishing all installation processes

to protect dome cover from scratches or dust.

Lockup Screw

2

Fixes main body to the surface mount bracket.

7P Terminal Block Slot

3

- Power, keyboard controller/DVR video device are

connected to this terminal block.

- Refer page 17 for details.

DIP Switch

4

- Adjusts camera ID and protocols.

- Refer page 8, 9 for details.

5P Terminal Block Slot

5

- Alarm input and relay out cables are connected to

this terminal block.

- Refer page 16 for details.

Mounting Hole

6

This is used to attach the surface mount bracket

to the ceiling.

¾” Pipe Mounting Hole

7

- This is used to pass the cables to the cameras.

- When water protection is needed, connect the

¾” pipe through this hole, then pass the cables

through the pipe.

5P Terminal Block Slot

5

7P Terminal Block Slot

3

DIP Switch

4

Mounting Hole

6

¾” Pipe Mounting Hole

7

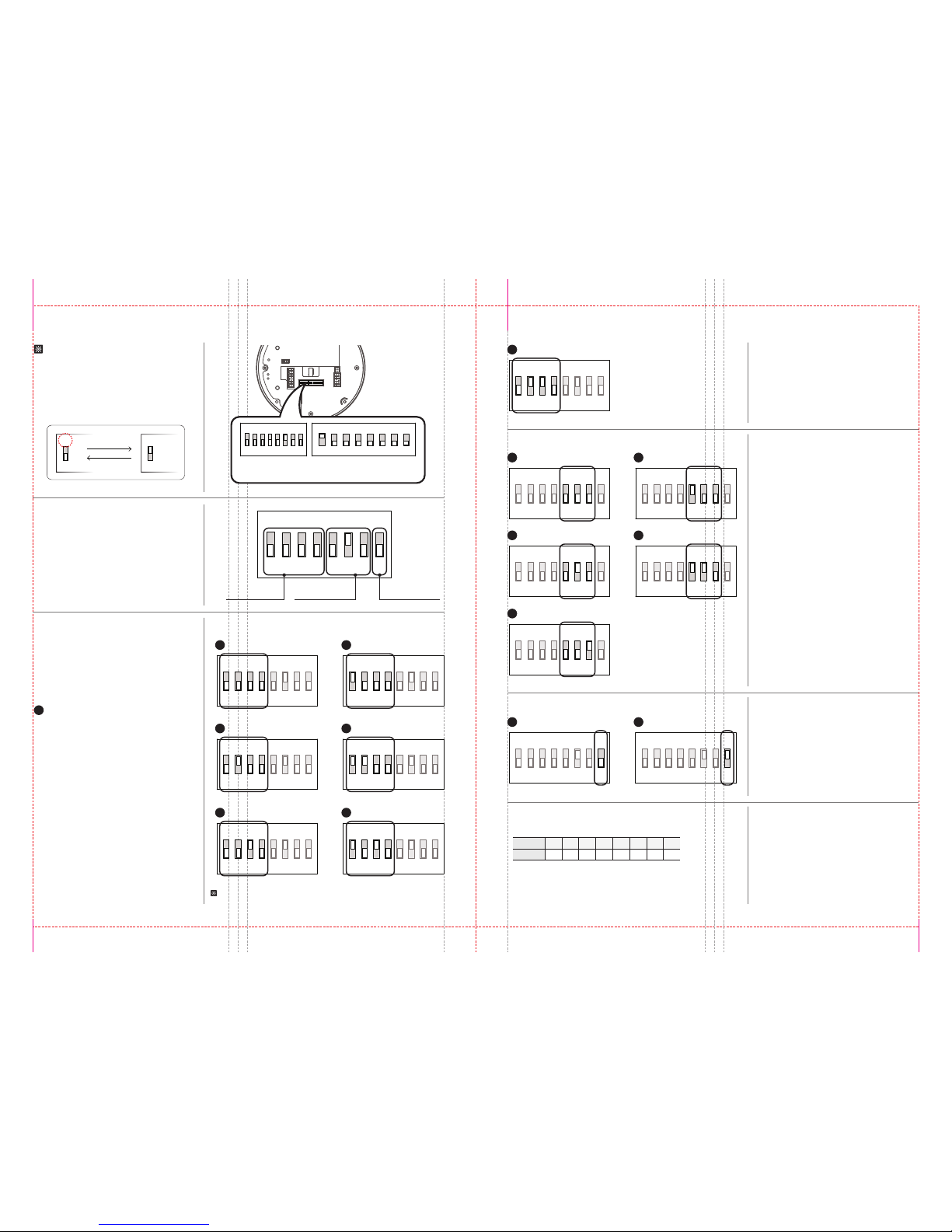

DIP Switch Setup DIP Switch Setup

2

8 9

Choose the appropriate baud rate protocol by setting the DIP switch

Choose the termination resistor on/off to notify the last camera.

ON

21 3 4 5 6 7 8

ON

21 3 4 5 6 7 8

ON

21 3 4 5 6 7 8

ON

21 3 4 5 6 7 8

2400 BPS

1

4800 BPS

2

9600 BPS

3

19200 BPS

4

ON

21 3 4 5 6 7 8

38400 BPS

5

ON

21 3 4 5 6 7 8

Normal

1

ON

21 3 4 5 6 7 8

Last Camera

2

Camera ID Setup

- ID number of camera is set using binary number. The example is shown below.

Pin 1 2 3 4 5 6 7 8

1 2 4 8 16 32 64 128ID Value

- Select the appropriate baud rate with DIP switch

combination.

- The factory default is 9600BPS.

3. Baud Rate Setup

- If you want to control a certain camera, you must

match the camera ID with ‘CAM ID, setting of DVR

or keyboard controller.

-

ID number of the camera is set using binary number.

-

The range of ID is 0~255.

Factory default of

camera ID is 1.

- Camera ID will be effective without rebooting

the camera.

5. DIP Switch for Camera ID Setup

- Pin 8 is use for on/off of RS-485 termination.

Normally, it must be off state.

-

Especially, when you have trouble with long daisy

chain style connection, turn on this termination

switch of the last camera.

4. RS-485 Termination Setup

Auto Protocol

1

Communication

Protocol Setup Pin Baud Rate Setup Pin

RS-485 Termination

Setup Pin

Auto Protocol

1

- If you set the protocol as auto protocol, camera will

automatically recognize the kind of protocol.

Pin On/Off

If the pin is located ‘ON’ side of the printed

label, it means on. In reverse, means off.

Pin On

Pin Off

Before installing the camera, you should

set the DIP switch to configure the camera

ID, communication protocol.

Choose the appropriate communication protocol by setting the DIP switch.

ON

21 3 4 5 6 7 8

ON

21 3 4 5 6 7 8

PELCO-D

2

ON

21 3 4 5 6 7 8

PELCO-P

3

ON

21 3 4 5 6 7 8

SAMSUNG

4

ON

21 3 4 5 6 7 8

Bottom of Main Body

ON

1

ON

1

If there is other combination of pins from above, it will be recognize as

auto protocol.

ON

21 3 4 5 6 7 8

ON

8J

21 3 4 5 6 7 8

DIP Switch for

Communication

DIP Switch for

Camera ID Setup

AD(American Dynamics)

7

ON

21 3 4 5 6 7 8

- It is consist of communication protocol, baud rate

and RS-485 termination setup pins.

- If you change the camera protocol by changing

the DIP switch, the change will be eective after

rebooting the camera.

1. DIP Switch for Communication

- If you want to control using DVR or keyboard

controller, their protocol must be identical to the

camera’s protocol. Otherwise, you cannot control

the camera.

- The factory default is auto protocol.

2. Communication Protocol Setup

2. Communication Protocol Setup

Panasonic

5

ON

21 3 4 5 6 7 8

GE(Kalatel)

6

ON

21 3 4 5 6 7 8

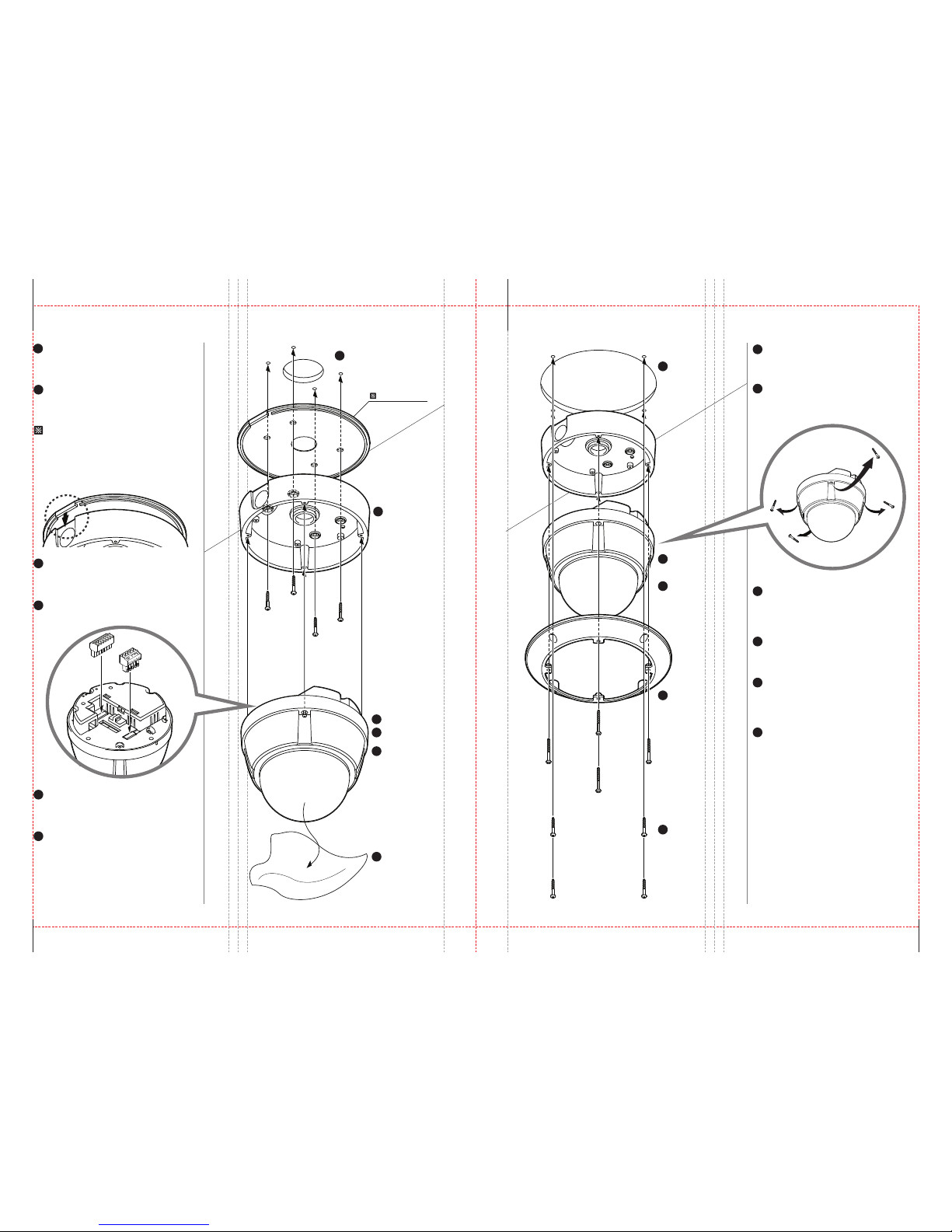

Installation Using Surface Mount Bracket Installation Using Flush Mount Ring Bracket (Option)

2

10 11

Drilling the Hole on the Ceiling

1

Fix the Main Body

5

Connect the

Terminal Blocks

4

Connect the Cables

3

Detach the

Protection Vinyl

6

Drilling the Hole on the Ceiling

To pass cables through the ceiling, drill a hole

(30mm diameter) on the ceiling panel.

Pass the cables to the ¾” pipe hole, and screw

the surface mount bracket to the ceiling.

Fix the Main Body

5

Screw the main body to the surface mount bracket

by screwing 4 lock-up screws.

Detach the Protection Vinyl

6

Detach the protection vinyl from the dome cover.

Detach the Protection Vinyl

6

Detach the protection vinyl from the dome cover.

Fix the Surface

Mount Bracket

2

1

Fix the Surface Mount Bracket

Rubber Gasket

2

Rubber Gasket

Connect the Terminal Blocks

4

Connect the terminal blocks to the main body.

Connect the Cables

3

- Connect wire cables to the terminal blocks.

- Refer page 16, 17 for details.

- Before installing the gasket, the hole in the center

is to be cut by knife when only necessary.

- When installing gasket, the protrusion of the

gasket should be matched with the groove joint

of the bottom of the surface mount bracket.

Fix the Main Body

5

Fix the Flush Mount

Ring Bracket to the

Main Body

3

Drilling the Hole on the Ceiling

1

To pass cables through the ceiling, drill a

hole(70mm diameter) on the ceiling.

Separate the Lock-up Screws from the

Main Body

2

Separate the 4 lock-up screws from the main body

in advance.

Fix the Flush Mount Ring Bracket to the

Main Body

3

Fix the flush mount ring bracket to the main body

using torx screws.

Fix the Main Body

5

Screw the main body with the surface mount

bracket to the ceiling using the screws on the

surface mount bracket.

Connect Wire the Cables and Terminal Blocks

4

Connect wire cables to the terminal blocks.

Refer page 16, 17 for details.

Separate the Lock-up

Screws from the Main

Body

2

Wire the Cables and

Terminal Blocks

4

Drilling the Hole

on the Ceiling

1

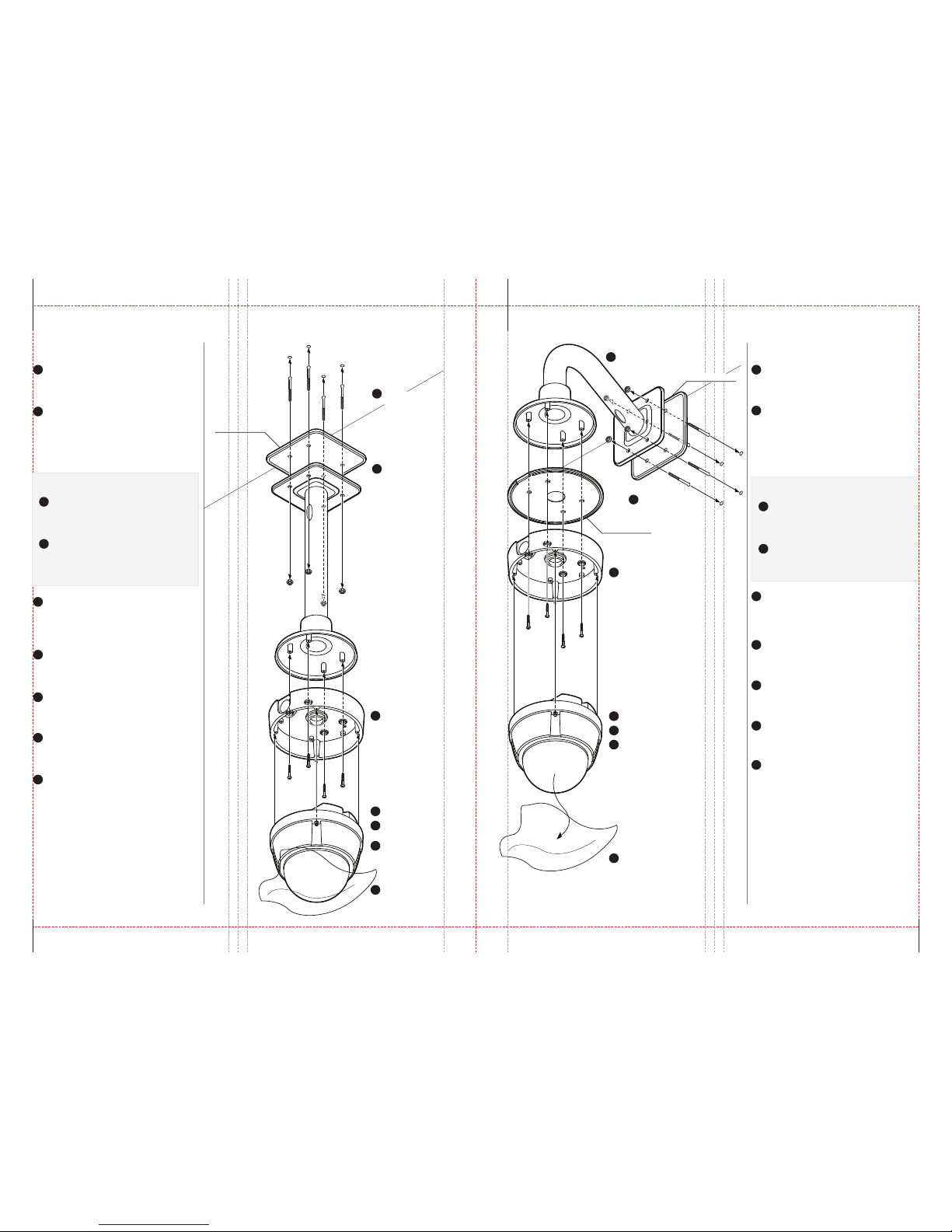

Installation Using Ceiling Mount Bracket (Option) Installation Using Wall Mount Bracket (Option)

2

12 13

Fix the Main Body

7

Connect the

Terminal Blocks

Wire Cables

4

Fix the Surface

Mount Bracket

Detach the

Protection Vinyl

Drill the Ceiling and Fix the Anchor Bolts

1

Fix the Ceiling Mount Bracket

2

On the ceiling, drill a hole (6mm diameter/ 50mm

depth), and fix the anchor bolts.

1. Drill a hole (20mm diameter) on the pipe of the

bracket to pass the cables.

2. On the fixed anchor bolts, attach the rubber

gasket and screw the ceiling mount bracket.

Fix the Wall Mount Bracket

1. Drill a hole (20mm diameter) on the pipe of the

bracket to pass the cables.

2. On the fixed anchor bolts, attach the rubber

gasket and fix the wall mount bracket with nuts

and screws.

Fix the Surface Mount Bracket

3

Pass the cables through the hole of the surface

mount bracket, screw the surface mount bracket

to the ceiling mount bracket.

Connect the Terminal Blocks

5

Connect terminal block to the main body.

Refer page 10.

Fix the Main Body

6

Screw the main body to the surface mount bracket.

(Screws are included in the main body.)

Detach the Protection Vinyl

7

Detach the protection vinyl from the dome cover.

Wire Cables

4

Wire the cables to the terminal block.

Refer page 16, 17.

Fix the Surface Mount Bracket

Pass the cables through the hole of the surface

mount bracket, screw the surface mount bracket

to the wall mount bracket.

Connect the Terminal Blocks

Connect terminal block to the main body.

Refer page 10.

Fix the Main Body

Screw the main body to the surface mount bracket.

(Screw are included in the main body.)

Detach the Protection Vinyl

Detach the protection vinyl from the dome cover.

Wire Cables

Wire the cables to the terminal block.

Refer page 16, 17.

Fix the Ceiling

Mount Bracket

Rubber Gasket

Rubber Gasket

Drill the Wall and

Fix the Anchor Bolts

1

2

3

3

6

5

Fix the Main Body

Connect the Terminal Blocks

Wire Cables

4

6

5

Drill the Ceiling and

Fix the Anchor Bolts

1

Fix the Surface Mount Bracket

Detach the Protection Vinyl

7

Fix the Wall Mount Bracket

1. Installing on the Concrete Ceiling 1. Installing on the Concrete Wall

Drill the Ceiling

1

Fix the Ceiling Mount Bracket

2

To pass cables to upside of ceiling, drill a hole

(30mm diameter) on the ceiling.

Pass the cables into the ceiling mount bracket,

and screw the ceiling mount bracket to the

ceiling.

2. Installing on the Wooden Ceiling

Drill the Wall

Fix the Wall Mount Bracket

Drill the Wall and Fix the Anchor Bolts

On the wall, drill a hole (6mm diameter/50mm

depth), and fix the anchor bolts.

1

2

3

5

6

7

4

1

2

To pass cables to the wall, make a hole about

30 mm on the wall.

Pass the cables into the wall mount bracket,

and screw the wall mount bracket to the wall.

2. Installing on the Wooden Wall

2

Rubber Gasket

Loading...

Loading...