Part I. User’s Guide

1. Introduction............................................................................................. 2

1.1 System Feature................................................................................................................................3

1.1.1 Front View ............................................................................................................................3

1.1.2 Front Panel Controls and Indicators ........................................................................................3

1.1.3 Front I/O Ports......................................................................................................................4

1.1.4 Rear View .............................................................................................................................4

1.1.5 Inner View ............................................................................................................................5

1.2 System Specifications.......................................................................................................................6

1.3 Mainboard Layout ............................................................................................................................9

1.3.1 Block Diagram.......................................................................................................................9

1.3.2 Mainboard Layout................................................................................................................10

2. Important Safety ...................................................................................11

2.1 Intended Application Uses ..............................................................................................................11

2.2 Checking the Power Cord................................................................................................................11

2.3 Earth-Grounded Socket Outlets.......................................................................................................12

2.4 Before Removing the Access Covers................................................................................................12

2.5 Fans..............................................................................................................................................12

2.6 Electrostatic Discharge (ESD)..........................................................................................................12

2.7 Cooling and Airflow........................................................................................................................13

2.8 Battery ..........................................................................................................................................13

2.9 Network Connecting.......................................................................................................................13

3. System Installation................................................................................ 14

3.1 Preparing for Setup........................................................................................................................14

3.1.1 Unpacking...........................................................................................................................14

3.1.2 Packing List.........................................................................................................................15

3.1.3 Environmental Specifications................................................................................................16

3.2 Installing User Serviceable Component............................................................................................17

3.2.1 CPU....................................................................................................................................17

3.2.2 Memory ..............................................................................................................................18

3.2.3 Hard Disk Drives..................................................................................................................21

3.2.4 PCI Add-On Cards................................................................................................................22

4. BIOS and Jumper Setting ......................................................................23

4.1 BIOS .............................................................................................................................................23

4.1.1 Starting BIOS Setup Utility ...................................................................................................23

4.1.2 Updating BIOS Version.........................................................................................................24

4.1.3 Using Setup.........................................................................................................................25

4.1.4 Main Menu ..........................................................................................................................26

4.1.5 Advanced Menu...................................................................................................................26

4.1.6 PCI PnP Menu .....................................................................................................................36

4.1.7 Boot Menu ..........................................................................................................................38

4.1.8 Security Menu .....................................................................................................................39

4.1.9 Chipset Configuration Menu .................................................................................................41

4.1.10 Power Menu......................................................................................................................45

4.1.11 Exit Menu..........................................................................................................................46

4.2 Jumper Setting ..............................................................................................................................47

4.2.1 PCI-X Speed Setting(J22, J26)..............................................................................................48

4.2.2 VGA Enable / Disable(J18) ...................................................................................................49

4.2.3 Clear CMOS Header(JP1)......................................................................................................49

4.2.4 External SAS Port Enable/Disable(JP2)..................................................................................50

4.2.5 Jumper Setting on the SAS BP..............................................................................................50

5. Software & Utilities................................................................................ 51

5.1 NVRAID.........................................................................................................................................51

5.1.1 Basic Configuration Instruction.............................................................................................51

5.1.2 Setting up the BIOS.............................................................................................................52

5.1.3 Entering the RAID BIOS Setup Basic Configuration Instruction ...............................................53

NVIDIA RAID Utility Installation.......................................................................................................57

5.2 LSILogic SAS RAID(Optional)..........................................................................................................60

5.2.1 Introduction to Integrated RAID...........................................................................................60

5.2.2 Integrated Mirroring Overview..............................................................................................61

5.2.3 Creating Integrated Mirroring Volumes..................................................................................67

5.2.4 Integrated Striping Overview................................................................................................74

Part II. Technical Guide

1. Removing & Installing System Components..........................................82

1.1 Installing the CD-ROM Drive ...........................................................................................................82

1.2 Installing the Floppy Disk Drive.......................................................................................................84

1.3 Installing the Hard Disk Drive .........................................................................................................85

1.4 Removing the Power Supply Unit ....................................................................................................86

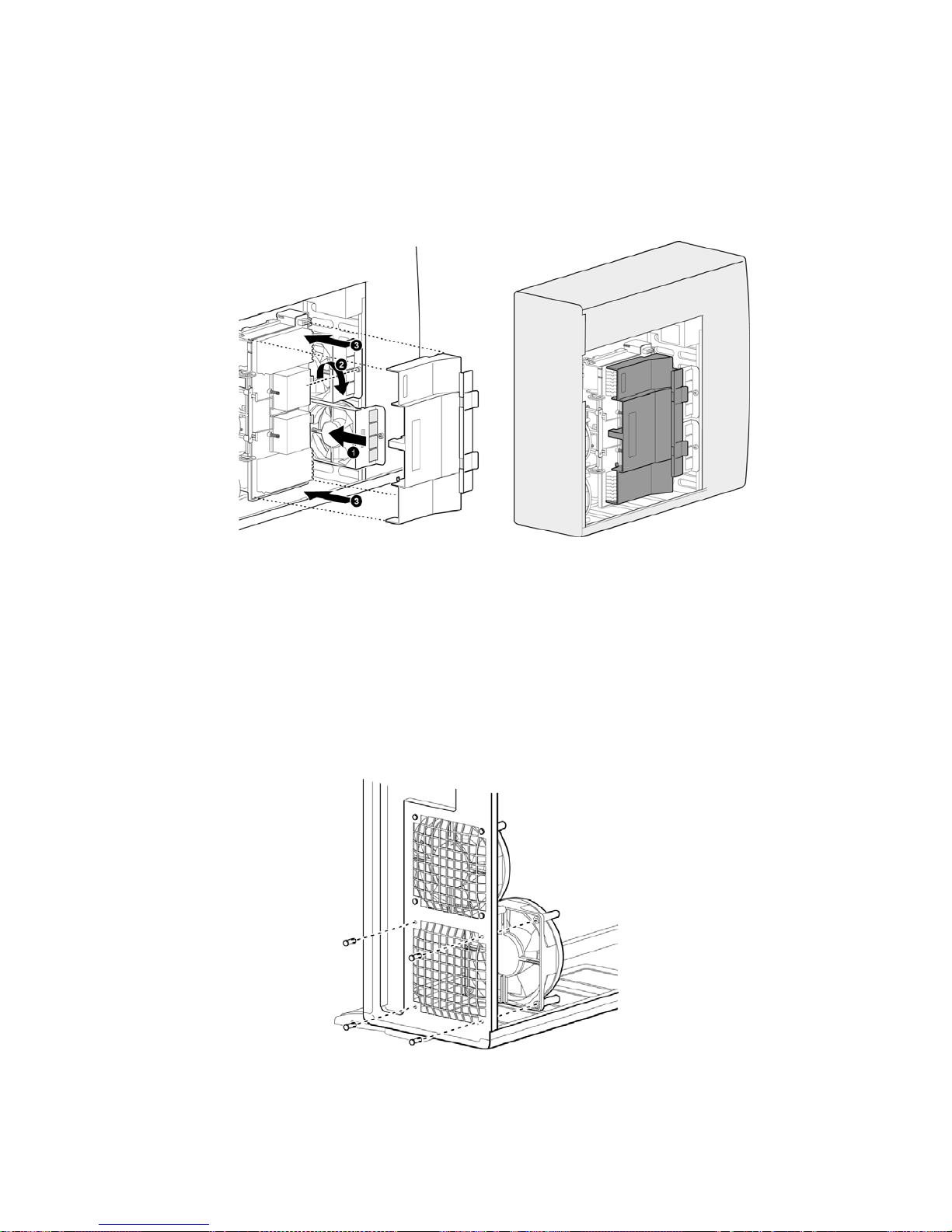

1.5 Replacing the Cooling Fan Unit........................................................................................................88

1.5.1 Center Fan Unit...................................................................................................................88

1.5.2 Rear Fan Unit......................................................................................................................89

1.6 Install CPU Board...........................................................................................................................90

1.7 Replacing the Interface Unit............................................................................................................91

1.7.1 Backplane Unit.....................................................................................................................91

1.8 Installing the Motherboard..............................................................................................................92

1.9 Installing the CPU Heatsink.............................................................................................................93

1.10 Installing the Front Bezel & Stand .................................................................................................94

Appendix....................................................................................................95

A. BIOS Post Code .................................................................................................................................95

1

Preface

The information in this User's Guide has been carefully reviewed and is believed to be accurate.

The vendor assumes no responsibility for any inaccuracies that may be contained in this document, makes no

commitment to update or to keep current the information in this Guide, or to notify any person or organization of

the updates.

NOTE: For any up-to-date version of this document, please see our web site at www.uniwide.com.

UNIWIDE Technologies, Inc. reserves the right to make changes to the product described in this manual at any

time and without notice. This product, including software, if any, and documentation may not, in whole or in part,

be copied, photocopied, reproduced, translated or reduced to any medium or machine without written consent.

Copyright Notice

The material in this document is the intellectual property of UNIWIDE Technologies, Inc.

We take every care in the preparation of this document, but no guarantee is given as to the correctness of its

contents. Our products are under continual improvement and we reserve the right to make changes without

notice.

Technical Support

If a problem arises with your system and no solution can be obtained from the user's manual, please contact your

place of purchase or local distributor. Alternatively, please try the following help resources for further guidance.

Visit the UNIWIDE website for FAQ, technical guide, BIOS updates, driver updates, and other information:

http://www.uniwide.com/

Contact our technical staff at: support@uniwide.com

Revision History

Revision Revision History Date

V1.2 Third release June 2007

Part I. User's Guide

2

1. Introduction

For the most demanding processing and graphics intensive applications, UniWorkstation platform will meet and

surpass expectations.

Often times, workstations are integrated using combination of desktop and server components, thus, excelling in

certain area of computing but lack in other. UniWorkstation is a tightly integrated, full-featured platform that can

excel in all aspects of performance requirements of a powerful workstation.

The key objective for UniWorkstation is to overcome the major areas that are often bottleneck. UniWorkstation

starts the latest AMD Opteron™ processor for Socket F(1207) supported, AMD Opteron™ main board. When

additional processing power is needed, 4-way can be scaled to 4-way configuration by plugging in a CPU &

Memory board. In addition, 16 DDR2 667MHz DIMM sockets are supported per CPU. This first-in-industry feature

increases the performance/value mix by reducing the cost of system memory by up to 100% over competition.

In line with extreme processing and data buffering capability, UniWorkstation has built-in SAS with RAID 0, 1, 1E,

maximizing on disk I/O with striping data across multiple disks. For those preferring SAS devices, SAS channel with

RAID option is available. Data transfer is optimized with on-board dual PCI-Express Gigabit Ethernet ports.

With 3 PCI Express slots, SLI is supported, aggregating dual GPU’s and delivering world-class graphics performance.

Last but not least, UniWorkstation employs cable-less and tool-less integration. This well thoughtout packaging

keeps all components ultra cool and easy to maintain, thus, optimizing on reliability and TCO.

Models Descriptions

UniWorkstation 5548

4-way, AMD Opteron™ for socket F (1207) based SAS/SATA Workstation,

nVidia 2200 + 2050 + AMD 8132 + LSI 1068 SAS chipset,

32 x DIMMs, 3 x 64/133 PCI-X, 3 x PCI-E ,

2 x Gigabit, 8 x Hot-swap SAS/SATA HDD

3

1.1 System Feature

1.1.1 Front View

a. 5.25” removable media drive bays

b. 3.5” FDD bay

c. Front panel controls and indicators

d. Front I/O ports

e. HDD activity/fail LEDs

1.1.2 Front Panel Controls and Indicators

a. LAN activity LED

b. System fault LED

c. Power ON/OFF switch & LED

d. Reset switch

Front Panel LEDs

LED Color State Description

Blue On System is turned on

System power

Off Off Power is off

LAN1/LAN2 activity Orange Blink Network is linked and accessed

Off Off Running/normal operation

System fault

Red On Critical or non-recoverable condition

4

1.1.3 Front I/O Ports

a. Headphone

b. MIC

c. USB 2.0 ports

d. IEEE 1394 port

1.1.4 Rear View

a. AC power inlet

b. AC power switch

c. PCI slots

d. MIC

e. Line OUT

f. Line IN

g. SPDIF(coaxial) OUT

h. SPDIF(coaxial) IN

i. System geographical ID switch

j. VGA ports

k. Serial port

l. PS/2 port(Keyboard & Mouse)

m. USB 2.0 ports

n. KVM over IP (Option)

o. IEEE 1394 port

p. GbE LAN port(IPMI)

q. GbE LAN port

r. External SAS port

s. Rear fan

5

LAN Port Function

The LAN port uses a CAT 6 LAN cable for connecting the motherboard to a local

area network by means of a network hub. The port has 2 indicator LEDs.

LED Color State Description

Green Blink LAN is linked and accessed

Link and Activity

Off Off LAN is not linked

Orange On Gigabit mode access

Green On 100M mode access

Speed

Off Off 10M mode access

1.1.5 Inner View

Link and Activity LED

Speed LED

a. Power supply

b. 5.25” ODD

c. 3.5” FDD

d. 3.5” HDD

e. Center fan

f. CPU duct

g. PCI-Express slots

h. PCI-X slots

i. Rear fan.

6

1.2 System Specifications

Processor

Four socket F(1207pin) AMD OpteronTM processors

Supports up to 4 Dual-Core AMD OpteronTM 8000 series processors

Integrated 128bit DDR-2 memory controller

Chipset

NVIDIA® nForceTM Professional 2200

NVIDIA® nForceTM Professional 2050

AMD-8132TM PCI-X 2.0 Tunnel

Winbond Super I/O chip

Analog Devices® hardware monitoring chip

Memory

128-bit dual channel memory bus

Eight DIMMs per CPU, up to 128GB memory capacity

Registered ECC DDR2 400/533/667 SDRAM DIMM

SATA Controller

Integrated nForceTM Professional 2200 and 2050

4 and 2 ports supporting RAID 0, 1, 10

SAS Controller

LSILogic LSI1068 8-ch SAS controller

4-CH shared with External SAS port

LSILogic Integrated RAID(0,1,1E) support

IDE Controller

Integrated nForceTM Professional 2200

One port for CD-ROM drive

7

Drive Bays

Supports eight hot-swap SATAII HDD – Default 4slot B/P

Supports eight hot-swap SAS HDD – Default 4slot B/P

Supports two 5.25” ODD and one 3.5” FDD (Optional)

Expansion Slots

Two x16 PCI-Express slot supporting full-length add-on card

One x4 PCI-Express slot supporting half-length add-on card

Two 64bit 133/100/66MHz PCI-X slot supporting half-length add-on card

One 64bit 133/100/66MHz PCI-X slot supporting full-length add-on card

Integrated I/O

Rear I/O

One VGA port

One serial port

One PS/2 keyboard & mouse port

Two USB 2.0 ports

Two RJ45 GbE ports

One IEEE-1394a(Firewire) port

One external SAS connector

Line-In/Line-Out/MIC/SPDIF IN/SPDIF OUT

Front Panel

LEDs: Power / GbE LAN1 / GbE LAN2 / System Fault

Switches: Reset / Power

Two USB 2.0 ports

One IEEE 1394 Port

Headphone / MIC Port

System Management

FAN connectors

For CPU / System - Two step speed control

Port 80h 7 segment display

BMC

Supports IPMI 2.0 specification

Auto fan speed control

Voltage and fan speed monitoring

8

LAN Controller

Two Broadcom® BCM5721 PCI-Express gigabit ethernet controllers

Support PXE function

Video Controller

XGI Volari Z9 / 16MB

BIOS

AMI BIOS

Support ACPI 2.0 with S0/S1/S3/S4 and S5

Support AMD PowerNow!

48-bit LBA support

Support USB K/B & Mouse

Serial Console Redirection

Support USB boot and PXE boot in boot sequence

Support serial over LAN function

Power Supply

1000W Power supply with PFC function

AC Input: 100-240V~, 50/60Hz, 10.0-5.0A

Form Factor

550(H) x 200(W) x 600(D)mm (21.65 x 7.87 x 23.62 inch)

Regulatory

CE(EMC) : EN55022(EMI), EN55024(EMS), EN61000-3-2(Harmonic), EN61000-3-3(Flicker)

CE(LVD) : EN60950-1

CB : IEC 60950-1

FCC : FCC 15 Subpart A

UL : UL 60950-1

MIC : KN22(EMI), KN24(EMS)

ROHS

WEEE

9

1.3 Mainboard Layout

1.3.1 Block Diagram

10

1.3.2 Mainboard Layout

① AMD® OpteronTM Socket 1207 - CPU0

② AMD® OpteronTM Socket 1207 - CPU1

③ AMD

®

OpteronTM Socket 1207 - CPU2

④ AMD

®

OpteronTM Socket 1207 - CPU3

⑤ Registered ECC DDR-II memory Slots

⑥ NVIDIA nForce

TM

Professional 2200

⑦ NVIDIA nForce

TM

Professional 2050

⑧ AMD

®

8132 PCI-X 2.0 Tunnel

⑨ HT Connector

⑩ PCI-X 64bit/133MHz Slots

⑪ PCI Express x16 Slot

⑫ PCI Express x4 Slot

⑬ Two Broadcom

®

PCI Express GbE Ports

⑭ LSILogic LSI1068X 8-ch SAS Controller

⑮ 32pin SAS Connector

○

16

External SAS Connector

○

17

Winbond 83627THF LPC Super I/O

○

18

XGI Volari Z9

○

19

10 Pin CPU Board Power Connector

(4Way Configuration)

11

2. Important Safety

Only a technically qualified person shall access, integrate, configure, and service this product.

To avoid personal injury or property damage, read, observe, and adhere to all of the following safety instructions

and information before you begin installing the product.

2.1 Intended Application Uses

This product was evaluated as information technology equipment (ITE), which may be installed in offices, schools,

computer rooms, and similar commercial type locations. The suitability of this product for other product categories

and environment (such as medial, industrial, alarm systems, and test equipment), other than an ITE application,

may require furthe r evaluation.

2.2 Checking the Power Cord

CAUTION

T o avoid electrical shock, check the power cord(s) that will be used with the product:

Do not attempt to modify or use the AC power cord(s) if they are not the exact type required.

If a power cord is not compatible with the AC wall outlet in your region, get one that meets the following criteria:

z The power cord must be properly rated for the AC voltage in your region.

z The power cord plug cap must have an electrical current rating that is at least 125% of the

electrical current rating of the product.

z The power cord plug cap that plugs into the wall socket-outlet must have a grounding type male

plug designed for use in your region.

z The power cord must have safety certifications for your region, and shall be marked with the

certification markings.

z The power cord plug cap that plugs into the AC receptacle on the power supply must be an IEC

320, sheet C13, type female connector.

z In Europe, the power cord must be less than 4.5 meters (14.76 feet) long, and it must be flexible

<HAR> (harmonized) or VDE certified cordage to comply with the chassis' safety certification

The power supply cord(s) is the main disconnect device to AC power.

The socket outlet(s) shall be near the equipment and shall be readily acce ssible for disconnect ion.

12

2.3 Earth-Grounded Socket Outlets

CAUTION

T o av oid electrical shock, the system power cor d(s) m ust be plu gged i nto so ck et -out let(s ) that is pro vi ded wi th a

suitable earth ground. The system will be provided with the following marking:

z Connect only to properly earth-grounded socket outlets.

2.4 Before Removing the Access Covers

CAUTION

T o a vo id pers onal inj ury or propert y damage, the fo llowing safe ty inst ructions apply when ev erac cessi ng ins ide th e

product:

z Turn off all peripheral devices connected to this product.

z Turn off the system by pressing the power button on the front of the product.

z Disconnect the AC power by unplugging all AC power cords from the system or wall outlet.

z Disconnect all cables and telecommunication lines that are connected to the system.

z Retain all screws or other fasteners when removing access cover(s). Upon completion of accessing

inside the product, refasten access cover with original screws or fasteners.

z Do not access inside power supply. There are no serviceable parts in the power supply.

z Return to manufacturer for servicing.

2.5 Fans

CAUTION

To avoid injury, do not contact moving fan blades.

2.6 Electrostatic Discharge (ESD)

CAUTION

Perform the procedures in this product guide only at an electrostatic discharge (ESD) workstation, because the server

components can be extremely sensitive to ESD. If no such station is available, you can reduce the risk of electrostatic

discharge ESD damage by doin g the f ol lowing.

z

Wear an antistatic wrist strap and attach it to a metal part of the server.

z Touch the metal on the server chassis before touching the server components.

z Keep part of your body in contact with the metal server chassis to dissipate the static charge while

handling the components.

13

z Avoid moving around unnecessarily.

z Hold the server components (especially boards) only by the edges.

z Place the server components on a grounded, static-free surface.

z Use a conductive foam pad if available but not the component wrapper.

z Do not slide the components over any surface.

2.7 Cooling and Airflow

CAUTION

For proper cooling and airflow, always install all acces s covers before turning on the system.

Operating the system for longer than five minutes without the covers in place can cause ov erheating and damage to system

components.

2.8 Battery

CAUTION

A risk of explosion if battery is replaced by an incorrect type.

Dispose of used batteries according to the instructions.

2.9 Network Connecting

CAUTION

This equipment is designed for indoor use only. All communication wirings connected to the system

are required to be limited to the internal of the building that this system resides in.

14

3. System Installation

3.1 Preparing for Setup

3.1.1 Unpacking

CAUTION

In setting the product out of the box, hold it in the midd le and not the cushion.

Depending on the weight of the product, two pe ople together should lift it.

① Heatsink box

② System top cushion

③ UniWorkstation 5548 system

④ Accessory box

⑤ System bottom cushion

⑥ Main box

15

3.1.2 Packing List

Unpack the package and check if all items listed below are present.

If any item contained in the package is damaged or missing, please contact your local dealer for replacement.

In addition, keep the box and packing materials for possible future use.

Accessory box

① Stand 4ea ② HDD guide 8ea (Default)

③ Screw 36ea

④ PS/2 Y-cable

⑤ Power code(Optional)

⑥ Manual and driver CD

UniWorkstation 5548

CPU Heatsink

16

3.1.3 Environmental Specifications

Place

In front of the system, minimum 25" of the space is needed for using and managing the system.

In rear of the system, minimum 30" of the space is needed for managing the system and airflow.

Power Supply

Before installing the system, check the power capacity of the place where the system is installed.

Grounding

The system should be grounded.

Temperature

The system should be installed where the airflow and temperature is proper.

If the system is installed in the r ack, the tem per atur e in r ac k should be less tha n 35 degr ee Cel sius.

In most case, the temperature of the rack is higher than that of its environment.

Airflow

Since the airflow of the system is front-to-rear, please do not cover of the system in any way that would obstruct

the airflow.

17

Gold Triangle

3.2 Installing User Serviceable Component

3.2.1 CPU

System mainboard accommodates Socket-F(1207 pin) AMD OpteronTM Processors at 2000 MT (Mega Transfer per

second). You must insert a CPU into CPU socket 0 (CPU0) first before installing one in CPU socket 1 (CPU1).

The correct CPU installation sequence is CPU0, CPU1, CPU2, CPU3.

CAUTION

If you are using 5548ES and 5548VA model, a minimum of four CPUs are required for proper operation.

Follow these instructions to install the CPU.

① The socket-locking lever must be raised (Pull out slightly, and then lift up).

② Locate the pin 1 of the CPU socket and pin 1 of the CPU. (Marked by a triangular hole in the Pin 1 corner)

Lower the locking lever and latching it into the fully locked position.

18

3.2.2 Memory

The system mainboard uses Dual Inline Memory Modules (DIMM). Two pair's banks are available;

each bank supports one CPU with Hyper Transport T echnolog y. The memory DIMMs accommodates Registered

ECC(400/533/667) SDRAM DIMM and Double Data Rate Memory (DDR2) memory modules in 128MB, 256MB,

512MB, 1GB, and 2GB, 4GB combinations. Total memory size for one CPU is up to 32GB.

CAUTION

The system mainboard has strict memory type and timing requirements.

Before you purchase DDR (Double Data Rate) memory for using in the system mainboard, you should contact your

local reseller for a recommend list of system memory tha t has b een validated on this system. It only supports

registered memory, not supports unbuffered type memory.

CAUTION

To take advantage of the 128-bit interface, you must install DIMMs in pairs of two. DIMM0 and DIMM1 are paired;

DIMM2 and DIMM3 are paired; DIMM4 and DIMM5 are paired; and slots DIMM6 and DIMM7 are paired. If you are

only installing two DIMMs into a Memory Bank, it is recommended that you install them in slots DIMM6 and DIMM7 to

get the full bandwidth.

NOTICE

For optimal dual-channel DDR operation, installing DIMMs in pa ir is highly recommended. For two DIMMs per CPU,

install them far from the CPU. For four or more DIMMs per CPU, install them same method to the CPU.

Memory Configuration Chart

(Note: X indicates a populated DIMM Slot, The chart below does not included all the configuration)

CPU 0 CPU 1 CPU 2 CPU 3

DIMM0

DIMM1

DIMM2

DIMM3

DIMM4

DIMM5

DIMM6

DIMM7

DIMM0

DIMM1

DIMM2

DIMM3

DIMM4

DIMM5

DIMM6

DIMM7

DIMM0

DIMM1

DIMM2

DIMM3

DIMM4

DIMM5

DIMM6

DIMM7

DIMM0

DIMM1

DIMM2

DIMM3

DIMM4

DIMM5

DIMM6

DIMM7

x x xx

x x x x x x x x

x x x x x x x x x x x x

x x x x x x x x x x x x x x x x

x x xx xx x x

x x x x x x x x x x x x x x x x

x x x x x x x x x x x x x x x x x x x x x x x x

128bit memory support

x x x x x x x x x x x xxxxxxxxxxxxxxx x x x x x x

19

Memory Installation Procedure

① Locate the DIMM modules.

② Make sure the DIMM’s pins are facing down, and check that the pin arrangement on the memory module

resembles the one pictured below.

CAUTION

Always populate H0 DIMM socket before installing memory modules in the H1 DIMM sockets.

③ Insert the module into the DIMM socket and press down evenly on both ends firmly until the DIMM module is

securely in place. (The tabs of the DIMM socket will close-up to hold the DIMM in place when the DIMM is

properly installed into the socket.)

20

21

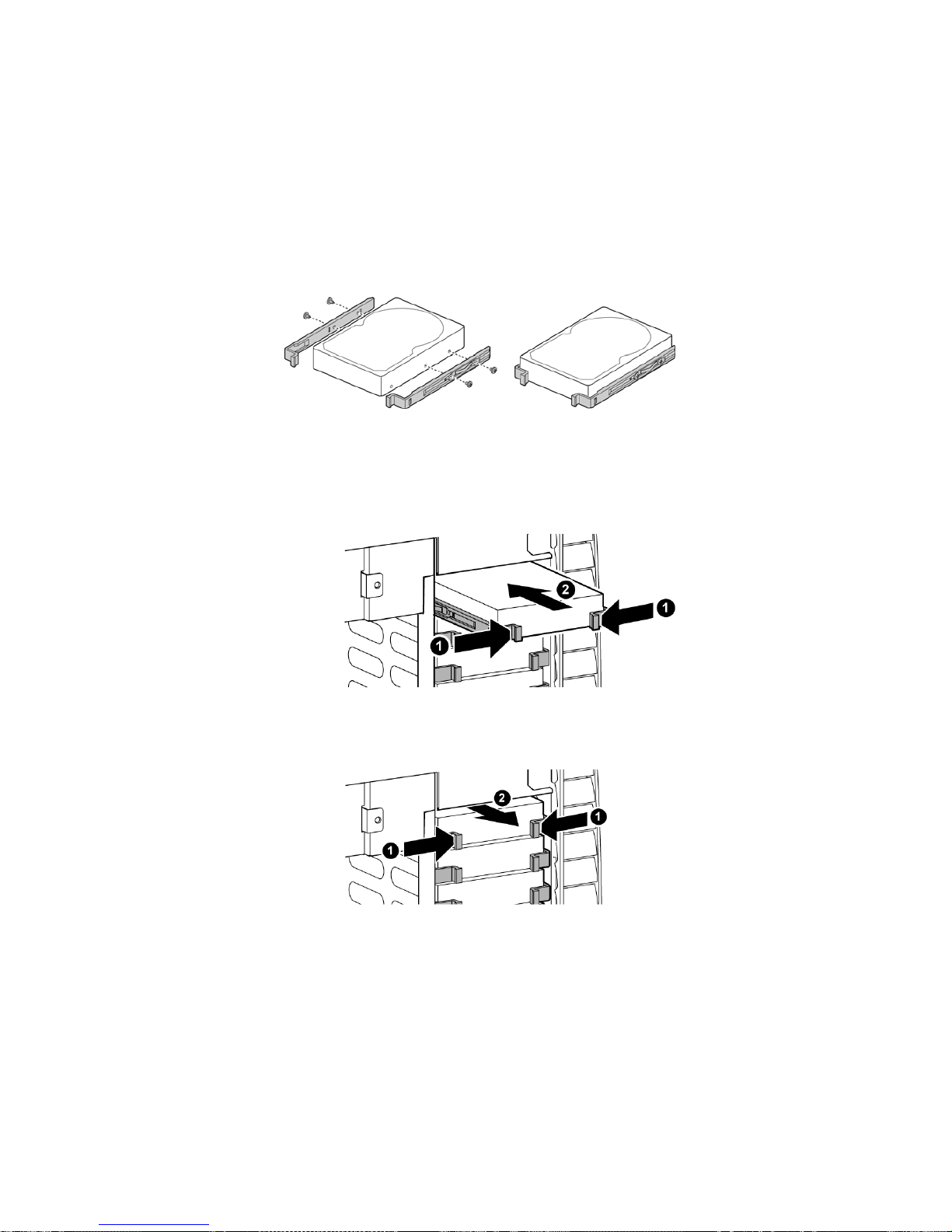

3.2.3 Hard Disk Drives

HDD ID Configuration

HDD Type Slot #7 Slot #6 Slot #5 Slot #4 Slot #3 Slot #2 Slot #1 Slot #0

SAS(SATA) ID8 ID 7 ID 6 ID 5 ID 4 ID 3 ID 2 ID 1

NOTICE

When you install hard disk drive into the system, we recomme nd using slot #0 first.

22

3.2.4 PCI Add-On Cards

WARNING

Please power off your power supply completely when adding or removing any expansion card or other system

components. Failure to do so may cause severe damage to both your motherboard and expansion card.

WARNING

Check compatibility of add-on card type when adding expansion card to slot.

PCI-X slot can't support exclusive 5V add-on card.

3.2.4.1 Expansion Card Installation Procedure

① Remove the screw for the expansion slot.

② Remove and save the expansion slot cover in case you later remove the add-in card.

③ Remove the add-in board from its protective wrapper. Be careful not to touch the components or gold edge

connectors. Place board on an antistatic surface.

④ Hold board by its top edge or upper corners. Firmly press it into an expansion slot on the server board.

⑤ Align the rounded notch in the retaining bracket of the expansion card with the threaded hole in the frame.

The bracket fits the space that was occupied by the slot cover.

⑥ Use the screw removed earlier. Insert it into the threaded hole, and tighten it firmly.

23

4. BIOS and Jumper Setting

4.1 BIOS

This chapter discusses the AMI BIOS Setup program built into the ROM BIOS. The Setup program allows users to

modify the basic system configurations according to their requirements. This special information is then stored in

battery-backed RAM so that it retains the Setup information when the power is turned off.

The AMI BIOS installed in your computer system's ROM (Read Only Memory) is a custom version of an industry

standard BIOS. The BIOS provides critical low-level support for standard devices such as disk drives and serial

ports. The AMI BIOS has been customized by adding important, but non-standard, features such as password

protection as well as special support for detailed fine-tuning of the chipset controlling the entire system.

The rest of this chapter is intended to guide you through the process of configuring your system using the Setup

utility.

4.1.1 Starting BIOS Setup Utility

The AMI BIOS is immediately activated when you power on the computer every time.

The BIOS reads the system information contained in the CMOS and begins the process of checking out the

system and configuring it. After completing the configuration stage, the BIOS will then continue to seek a

bootable disk with an operating system according to the BIOS settings (CD/DVD, Floppy, SCSI, etc), launch then

turn control over to the operating system. To access the BIOS Setup utility, press the DEL button during the first

stage of POST (Power On Self-Test) when the BIOS tag is displayed. This tag is the first display that the system

will show after power on and will have the BIOS version and other basic information about the system.

24

4.1.2 Updating BIOS Version

Creating a bootable floppy disk

a. DOS environment

i. Insert a 1.44 MB floppy disk into the drive.

ii. At the DOS prompt, type:format A : /S then press <Enter>.

b. Microsoft

®

Windows® environment(Microsoft® Windows® 95/98 only)

i. Insert a 1.44 MB floppy disk into the floppy disk drive.

ii. From your Windows desktop, click on Start, then select My Computer.

iii. Select the 3 1/2 Floppy Drive icon.

iv. Click File from the menu, and then select Format. A Format 3 1/2 Floppy Disk window appears.

v. If you are using Windows

TM

, select "Create an MS-DOS startup disk" from the format options field, then

click Start.

c. Download BIOS File and Utility

i. Download the latest BIOS file and AFUDOS/(BIOS flashing utility) to the bootable floppy disk. The latest

BIOS file and AFUDOS utility can be obtained through Uniwides website, located at

www.uniwide.com

under the Support menu; BIOS Download.

d. Using

"AFUDOS.EXE"

to update the BIOS

i. Update the BIOS using the AFUDOS.EXE utility in DOS environment.

ii. At the DOS prompt, type the command line: AFUDOS <”

filename.ROM

”>.

iii. Replace "filename"with the name of the latest (or original) BIOS file that you copied to the bootable

floppy disk.

iv. The screen displays the status of the update process

NOTICE

The BIOS information on the screen is for reference only.

What you see on your screen may not be exactly the same as shown.

CAUTION

DO NOT shutdown or reset the system while updating the BIOS! Doing so may cause system boot failure!

When the BIOS update process is complete, the utility returns to the DOS prompt. The AMI BIOS is immediately

activated when you power on the computer every time. The BIOS reads the system information contained in the

CMOS and begins the process of checking out the system and configuring it. After completing the configuration

stage, the BIOS will then continue to seek a bootable disk with an operating system according to the BIOS

settings (CD/DVD, Floppy, SCSI, etc), launch then turn control over to the operating system. To access the BIOS

Setup utility, press the DEL button during the first stage of POST (Power On Self-Test) when the BIOS tag is

displayed. This tag is the first display that the system will show after power on and will have the BIOS version

and other basic information about the system.

25

4.1.3 Using Setup

In general, you use the arrow keys to highli ght items, press <Enter> to select, pr ess <Esc> to quit. The following table

provides more details about how to navigate in the Setup program using the keyboard.

Key Function

Up Arrow( ) Key↑ Move to the previous item

Down Arrow( ) Key↓ Move to the next item

Left Arrow( ) Key→ Move to the previous item

Right Arrow( ) Key← Move to the next item

Esc key

In the Submenu: Exit the submenu.

In the BIOS main category: Quit Without saving chang e s.

Enter Key Select the item. A pop-up selection will disp lay on the screen to set the item value.

PgUp Key Previous page on Scrollable menus or jump to the first interactive item listed.

PgDn Key Next page on Scrollable menus or jump to the last interactive item listed

F1 Key

General Help on Setup navigation keys. Press <F1> key to pop up a small help

window that describes the appropriate keys to use and the possible selections for

the highlighted item. To exit the Help Window, press<ESC> key or <F1> key

again.

F2/F3 Key Change colors

F7 Key Discard changes

F8 Key Load failsafe defaults

F9 Key Load optimal defaults

F10 Key Save and Exit

Home Go to top of screen

End Go to bottom of screen

Esc Exit

NOTICE

The BIOS does NOT automatic ally save values that you have modi fied. If you do not save your values

before you exit the BIOS Setup Utility, all your changes will be lost.

If after making and saving system changes with the BIOS Setup Utility, you discover that your computer is

no longer able to boot, the AMI BIOS supports an override, which will reset your system to the Failsafe

defaults. If that fails, it is possible to manually clear the present CMOS information through the "Clea r

CMOS Header" on the motherboard (Refer to Jumper Settings for more information).

The best advice is to ONLY alter settings which you thoroughly understand. The default settings have

been carefully chosen by AMIBIOS to provide the maximum system performance and reliability.

Even a slight change to the chipset setup may cause potential and unpredictable failure to the system.

26

4.1.4 Main Menu

This is the first screen that is displayed when you enter the BIOS Setup Utility.

Each tab lined on the top of the screen represents each different menu. The following picture shows the main menu.

The main menu shows the BIOS version, date and ID; processor type, speed and count; system size. In

addition, system time and date is adjustable using + / - key or number keys.

NOTICE

You can check the BMC F/W version on the post and in the BIOS setup utility

4.1.5 Advanced Menu

You can make these modifications on the advanced menu.

27

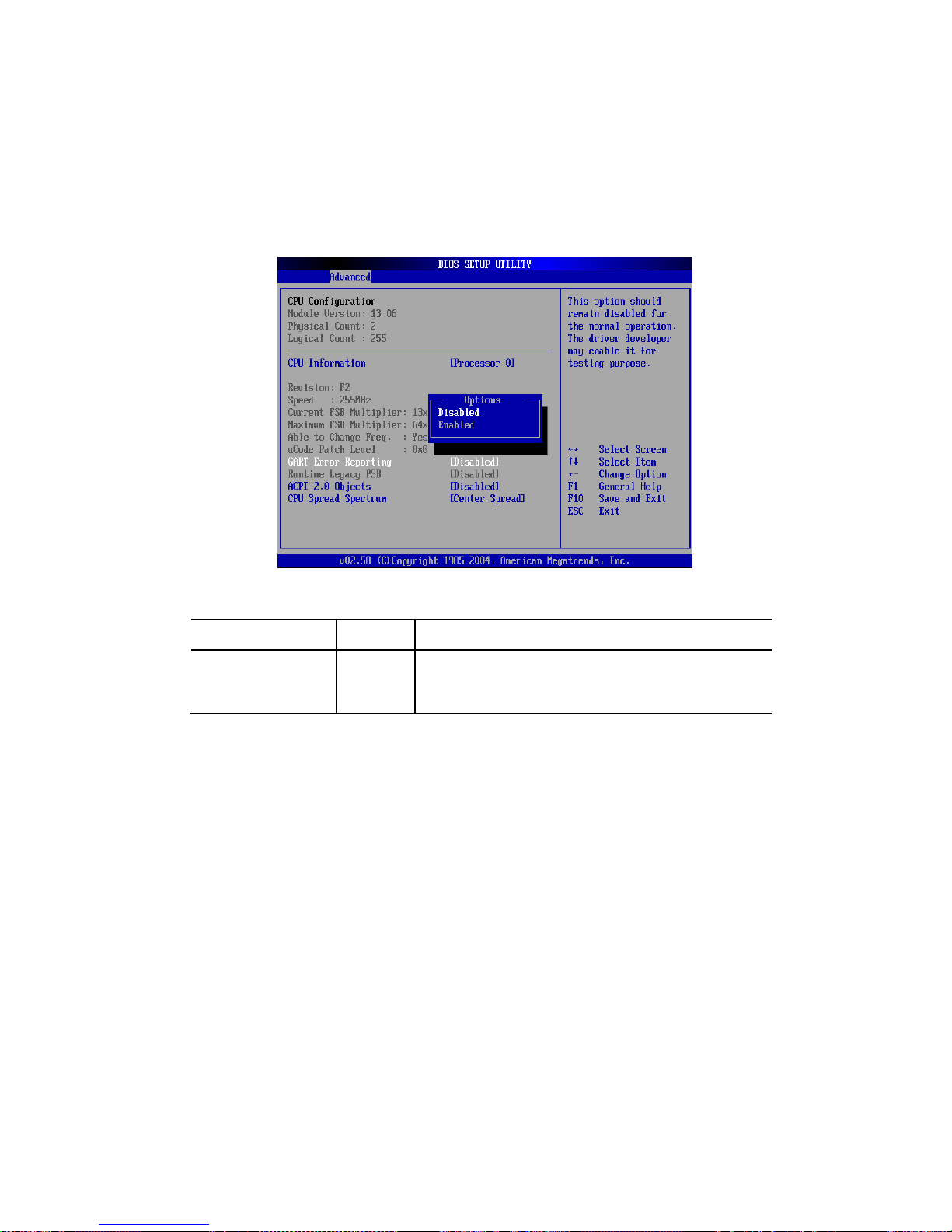

4.1.5.1 CPU Configuration Submenu

In CPU configuration, you can set up CPU frequency and enable/disable the Error Reporting. GART error

reporting should remain disabled for the normal operation.

Feature Options Description

GART Error Reporting

Disable

Enable

This option should remain disabled for the normal operation.

This driver developer may enable it for testing purpose.

28

4.1.5.2 IDE Configuration Submenu

You can make the selections on IDE Configuration menu.

Feature Options Description

OnBoard PCI

IDE Controller

Disable

Primary

Secondary

Both

Disable: disable the integrated IDE controller

Primary: enable only the Primary IDE controller

Secondary: enable only the Secondary IDE controller

Both: enable both IDE controllers

IDE Detect

Time out (sec)

0, 5, 10, 15,

20, 25, 30,35

Select the time out value for detecting ATA/ATAPI device

ATA (PI) 80Pin

Cable Detection

Host & Device

Host

Device

Select the mechanism for detecting 80 pin cable

Configuration

nVidia RAID ROM

Disabled

Enabled

Disable/enable nVidia ROM.

29

4.1.5.3 Floppy Configuration Submenu

Feature Options Description

Floppy

Configuration

Disabled

5 1/4” 360 KB

5 1/4” 1.2 MB

3 1/2” 720 KB

3 1/2” 1.44 MB

3 1/2” 2.88 MB

Select Floppy A or Floppy B and then selects

floppy-diskette type installed in your system.

30

4.1.5.4 Super IO Submenu

Feature Options Description

OnBoard Floppy

Controller

Disabled

Enabled

Allows BIOS to Enable or Disable Floppy Controller

Serial Port1

Address

Disabled

3F8/IRQ4

3E8/IRQ4

2E8/IRQ3

Allows BIOS to Select Serial Port1 Base Addresses.

Serial Port2

Address

Disabled

2F8/IRQ3

3E8/IRQ4

2E8/IRQ3

Allows BIOS to Select Serial Port1 Base Addresses.

31

4.1.5.5 ACPI Configuration Submenu

Feature Options Description

ACPI Configuration

ACPI Aware O/S

Yes/No

Enable: O/S supports ACPI

Disable: O/S doesn’t support ACPI

4.1.5.6 Hyper Transport Configuration Submenu

To set up the hyper transport speed and bandwidth, you can adjust over this menu.

The incorrect manipulation will impede the system running.

32

4.1.5.7 IPMI Configuration

To set up the BMC LAN Configuration, you can adjust over this menu.

4.1.5.8 MPS Configuration Submenu

33

4.1.5.9 PCI Express Configuration Submenu

Enable/Disable PCI Express L0 and L1 link power states.

4.1.5.10 Remote Access Configuration Submenu

34

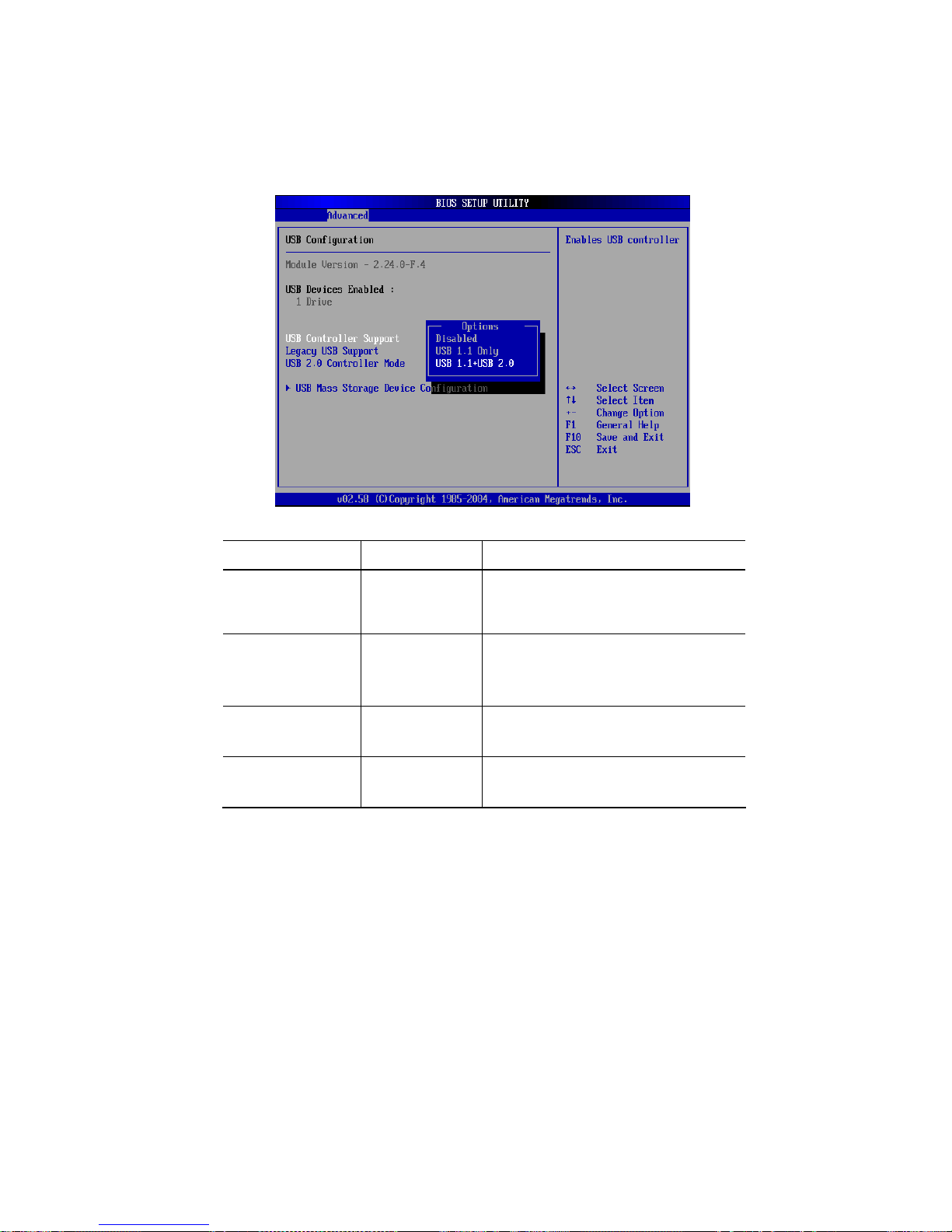

4.1.5.11 USB Configuration Submenu

Feature Options Description

USB Controller

Support

Disabled

USB 1.1 Only

USB 1.1+ USB 2.0

Enables USB controller

Legacy USB Support

Disabled/Enabled/

Auto

Enables support for legacy USB

Auto option disables legacy support if no

USB device connected

USB 2.0

Controller Mode

HiSpeed

FullSpeed

Configures the USB 2.0 controller in

HiSpeed(480Mbps) or FullSpeed(12Mbps).

USB Mass Storage

Device Configuration

Number of seconds POST waits for the USB

mass storage device after start unit command.

35

4.1.5.12 Onboard Device Configuration Submenu

Feature Options Description

SAS

Enabled

Disabled

On-board SAS controller Enabled/Disabled

IEEE 1394

Enabled

Disabled

On-board IEEE 1394 Enabled/Disabled

NIC0 PXE Setting

Enabled

Disabled

On-board NIC0 PXE Boot Enabled/Disabled

NIC1 PXE Setting

Enabled

Disabled

On-board NIC1 PXE Boot Enabled/Disabled

Audio CODEC Interface

Enabled

Disabled

On-board Audio CODEC Enabled/Disabled

36

4.1.6 PCI PnP Menu

PCI PnP Menu 1

PCI PnP Menu 2

37

Feature Options Description

Plug & Play O/S

Yes

No

Yes: lets the O/S configure PnP devices not

required for boot if your system has a Plug

and Play O/S

PCI Latency Timer

32, 64, 96, 128,

160, 192, 224, 248

Value in units of PCI clocks for PCI device latency

timer register

Allocate IRQ to PCI

VGA

Yes

No

Yes: Assign IRQ to PCI VGA card if card requests

IRQ

No: Doesn’t assign IRQ To PCI VGA card even if

card requests IRQ

Palette Snooping

Enabled

Disabled

Enabled: informs the PCI devices that an ISA

graphics device is installed in the system

so the card will function correctly

PCI IDE BusMaster

Enabled

Disabled

Enabled: BIOS uses PCI busmastering for

reading/writing to IDE drives

Offboard PCI/ISA IDE

card

Auto

PCI Slot1

PCI Slot2

PCI Slot3

PCI Slot4

PCI Slot5

PCI Slot6

Some PCI IDE cards may require this to be set to

the PCI slot number that is holding the card

IRQ3~IRQ15

Available

Reserved

Available: specified IRQ is available to be used by

PCI/PnP devices

Reserve: specified IRQ is reserved for use by

legacy ISA devices

DMA Channel 0, 1, 3,

5, 6, 7

Available

Reserved

Available: specified DMA is available to be used

by PCI/PnP devices

Reserve: specified DMA is reserve d for use by

legacy ISA devices

Reserved Memory Size

Disabled

16K

32K

64K

Size of memory block to reserve for legacy ISA

devices

38

4.1.7 Boot Menu

Feature Options Description

Quick Boot

Disabled

Enabled

Allow BIOS to skip tests while booting

Quiet Boot

Disabled

Enabled

Disabled: Display normal POST messages

Enabled: Display OEM logo

Bootup Num-Lock

Off

On

Select power on state for Num-Lock

PS/2 Mouse Support

Disabled

Enabled

Select support for PS/2 mouse

Wait for “ F1 “ if error

Disabled

Enabled

Wait for F1 key to be pressed if error occurs

Interrupt 19 Capture

Disabled

Enabled

Enabled: allows option ROMs to trap interrupt 19

Boot Endless Loop

Disabled

Enabled

39

4.1.8 Security Menu

Security Menu 1: Change Supervisor

Security Menu 2: Change User

40

Security Menu 3: Boot Sector

Feature Options Description

Change Supervisor Password Install or change the password

Change User Password Install or change the password

Boot Sector Virus Protection

Disabled

Enabled

Enable/Disable boot sector virus protection

41

4.1.9 Chipset Configuration Menu

4.1.9.1 NorthBridge Chipset Configuration Submenu

42

4.1.9.2 Memory Configuration Submenu

Feature Options Description

Memclock Mode Auto Limit

It can be set by the code using AUTO, or if you use

LIMIT, you can set one of the standards.

Bank Interleaving

Auto

Disabled

Interleaving allows memory accesses to be spread out

over BANKS on the same node, or across NODES,

decreasing access contention

Memory Hole

Remapping

Disabled

Enabled

Enable Software Memory Remapping Around Memory

Hole

43

4.1.9.3 ECC Configuration Submenu

Feature Options Description

Master

ECC Enable

Disabled

Enabled

Master ECC Enables support on all nodes for ECC

error detect and correction.

DRAM

ECC Enable

Disabled

Enabled

DRAM ECC allows hardware to report and correct

memory errors automatically maintaining system

integrity.

L2 Cache

BG Scrub

Disable

40ns

80ns

160ns

320ns

640ns

1.28us

2.56us

5.12us

10.2us

20.5us

41.0us

81.9us

163.8us

327.7us

655.4us

Allows the L2 date cache ram to be corrected

while idle.

Date Cache

BG Scrub

See above Allows the L1 date cache ram to be corrected

while idle.

44

4.1.9.4 IOMMU Mode Submenu

Feature Options Description

IOMMU Mode

AGP Present

Disabled

32MB

64MB

128MB

256MB

512MB

1GB

Set GART size in systems without AGP, or disable

altogether. Some OSes require valid GART for

proper operation. If AGP is present, select

appropriate option to ensure proper AGP operation.

45

4.1.10 Power Menu

The Power menu items allow you to change the power management settings.

Select an item then press Enter to display the configuration options.

Feature Options Description

Power Management/APM

Disabled

Enabled

Enable or disable APM

LAN & PME Resume

Disabled

Enabled

Enabled or disabled Internal 802.3 MAC to

generate P.M.E in SoftOFF.

RTC Resume

Disabled

Enabled

Disabled/Enabled RTC event to wake after a

power failure

Restore on AC/Power

Loss

Power Off

Power On

Last State

Power Off

Power On

Last State

46

4.1.11 Exit Menu

Feature Description

Save Changes and Exit

Exit system setup after saving the changes

F10 key can be used for this operation

Discard Changes and Exit

Exit system setup without saving the changes

ESC key can be used for this operation

Discard Changes

Discard changes done so far to any of the setup question

F7 key can be used for this operation

Load Optimal Defaults

Load optimal default values for all the setup questions

F9 key can be used for this operation

Load Failsafe Defaults

Load Failsafe default values for all the setup questions

F8 key can be used for this operation

47

4.2 Jumper Setting

This section covers the jumper setting. Refer to the following illustration for the location of the jumpers.

① PCI-X Speed CHB(J22)

② PCI-X Speed CHA(J26)

③ VGA Enable / Disable(J18)

④ Clear CMOS(JP1)

⑤ External SAS Enable / Disable(JP2)

48

4.2.1 PCI-X Speed Setting(J22, J26)

PCI-X speed can be selected by the switch. Please follow the below instruction.

133 100 66

1 OFF ON OFF

2 OFF OFF ON

1 Off: 2 Off - 133MHz 1 On: 2 Off - 100MHz 1 Off: 2 On - 66MHz

49

4.2.2 VGA Enable / Disable(J18)

This header lets you set your VGA port function. You can choose enable or disable this function or not. Onboard

VGA can be disabled by setting this jumper on.

4.2.3 Clear CMOS Header(JP1)

The onboard button cell battery powers the CMOS RAM. It contains all the BIOS setup information. Normally, it is

necessary to keep the jumper connected to pin1 and pin2 (Default) to retain the RTC data as shown below.

Follow these instructions to clear the CMOS RTC data:

① AC off.

② Short pin2 and pin3 with a jumper for a few seconds.

③ Replace the jumper on pin1 and pin2.

④ Turn on your computer by pressing the power-on button.

⑤ Enter BIOS Setup Utility when prompt by POST (DEL). Select either the <Load Optimal Defaults> or <Load

Failsafe Defaults> option under the "Exit" menu. Make changes to other features of the BIOS per user

requirements. “Save Changes and Exit” BIOS Utility.

ON OFF

Disable Enable(default)

1-2 2-3

Clear CMOS Normal(default)

50

4.2.4 External SAS Port Enable/Disable(JP2)

This header lets you set your External SAS port Enable/Disable function. You can choose enable or disable this

function or not.

4.2.5 Jumper Setting on the SAS BP

Jumper J8, J9 are used to determine which controller is used for the system hard drives.

Default setting is “1-2” for J8 and “1-3, 2-4” for J9 on-board SAS controller. If you want to use add-on another

SAS controller supporting SES(I2C) interface, you have to set the jumper to “2-3” for J8 and “3-5, 4-6” for J9.

ON OFF

Disable

Enable

Jumper SGPIO SES(I2C)

J8 1-2 2-3

1-3 3-5

J9

2-4 4-6

51

5. Software & Utilities

5.1 NVRAID

5.1.1 Basic Configuration Instruction

The following are the basic steps for configuring NVRAID

5.1.1.1 Non-Bootable RAID Array

① Choose the hard disks that are to be RAID enabled in the system BIOS.

② Specify the RAID level, either Mirroring (RAID 1), Striping (RAID 0), Striping and Mirroring (RAID 0+1), or

Spanning (JBOD) and create the desired RAID array.

③ Install the operating system on one hard disk then reboot the system.

④ Run the Windows nForce Setup application and install the RAID driver.

⑤ Initialize the NVRAID Array.

5.1.1.2 Bootable RAID Array

① Choose the hard disks that are to be RAID enabled in the system BIOS.

② Specify the RAID level, either Mirroring (RAID 1), Striping (RAID 0), Striping and Mirroring (RAID 0+1), or

Spanning (JBOD) and create the desired RAID array.

③ Boot from the Windows CD, then press F6 when the Windows Setup appears.

④ Install the floppy disk with the NVRAID driver for Windows when prompt. The drivers are available through

the UNIWIDE at www.uniwide.com under the Support Menu; Driver Download.

⑤ Initialize the NVRAID Array.

52

5.1.2 Setting up the BIOS

Enter the BIOS Setup Utility by power cycling your system and pressing the DEL button when prompt. Use the

arrow keys to navigate to the Advanced Menu and enter the IDE Configuration sub-menu by hitting the ENTER

key. Enter the sub-menu “Configuration nVidia RAID ROM. Enable “RAID Option ROM” for SATA and enable all

SATA drives for RAID as required..

① From the RAID Config window, "enable" the RAID Enable, the other items would be light, then you can enable

the disk that you want to use as RAID disks.

② Press F10 to save the configuration and exit.

53

5.1.3 Entering the RAID BIOS Setup Basic Configuration Instruction

① After rebooting your system, wait until you see the RAID software prompting you to press F10. The RAID

prompt appears as part of the system POST and boot process prior to loading the OS.

② Press <N>, and the NVIDIA RAID Utility-Defi ne a New Array window will appears(See the picture). The

default RAID Mode is set to Mirroring and Striping Block is set to Optimal.

5.1.3.1 Understanding the Define a New Array Window

Use the Define a New Array window to

z Select the RAID Mode

z Set up the Striping Block

z Specify which disks to use for the RAID Array

Depending on the platform used, the system can have one or more channels.

In a typical system there is usually one controller and multiple channels, and each channel has a slave and a

master.

The channel/controller/master/slave status of each hard disk is given in the Loc(location) columns of the Free

Disks and Array Disks lists.

1.0.M

M : Master

S : Slave

0 : Channel

Adapter - adapter 0 is used for PATA drives

1 and above is used for SATA drives.

54

In upper picture 1.0.M means the hard drive is attached to Adapter 1, Channel 0, and the drive is set to Master.

The following is a list of all possible combinations:

NOTICE

There is no such thing as Slave drive in Serial ATA. All drives are considered to be Master since there is a one to

one connection between the drive and the controller.

5.1.3.2 Using the Define a New Array Window

If necessary, press the tab key to move from field to field until the appropriate field is highlighted.

Selecting the RAID Mode

By default, this is set to mirroring. To change to a different RAID mode, press the down arrow key until the mode

that you want appears in the RAID mode box-either mirroring, striping, spanning, or stripe mirroring.

Selecting the Striping Block Size

Striping block size is given in kilobytes, and affects how data is arranged on the disk. It is recommended to leave

this value at the default Optimal, which is 32KB, but the values can be between 4 KB and 128 KB.

Assigning the Disks

The disks that you enabled from the RAID Config BIOS setup page appear in the Free Disks block. These are

the drives that are available for use as RAID array disks.

To designate a free disk to be used as a RAID array disk,

① Tab to the Free Disks section. The first disk in the list is selected

② Move it from the Free Disks block to the Array Disks block by pressing the right arrow key(→). The f irst disk

in the list is moved, and the next disk in the list is selected and ready to be moved.

③ Continue pressing the right-arrow key (→) until all the disks that you want to use as RAID array disks appear

in the Array Disks block.

1.0.M Adapter 1, Channel 0, Master

1.1.M Adapter 1, Channel 1, Master

1.2.M Adapter 1, Channel 2, Master

1.3.M Adapter 1, Channel 3, Master

2.1.M Adapter 2, Channel 1, Master

Serial ATA

2.2.M Adapter 2, Channel 2, Master

55

The picture below illustrates the Define a New Array window after two disks have been assigned as RAID1 array

disks.

NVIDIA RAID Utility – Array Disks

5.1.3.3 Completing the RAID BIOS Setup

① After assigning your RAID array disks, press F7. The Clear disk data prompt appears.

56

② Press Y to clear all drive data. The Array List screen appears, where you can review the RAID arrays that you

have set up.

③ Use the arrow keys to select the array that you want to set up, and then press Enter. The Array Detail

screen appears.

The Array Detail screen shows information about the array that you selected, such as Striping Block used, RAID

Mode, Striping Width, Disk Model Name, and disk capacity.

④ If you want to mark this disk as empty and wipe out all its contents then press C.

⑤ At the prompt, press Y to wipe out all the data, otherwise press N.

⑥ Press Enter again to go back to the previous window and then press F10 to exit the RAID setup.

57

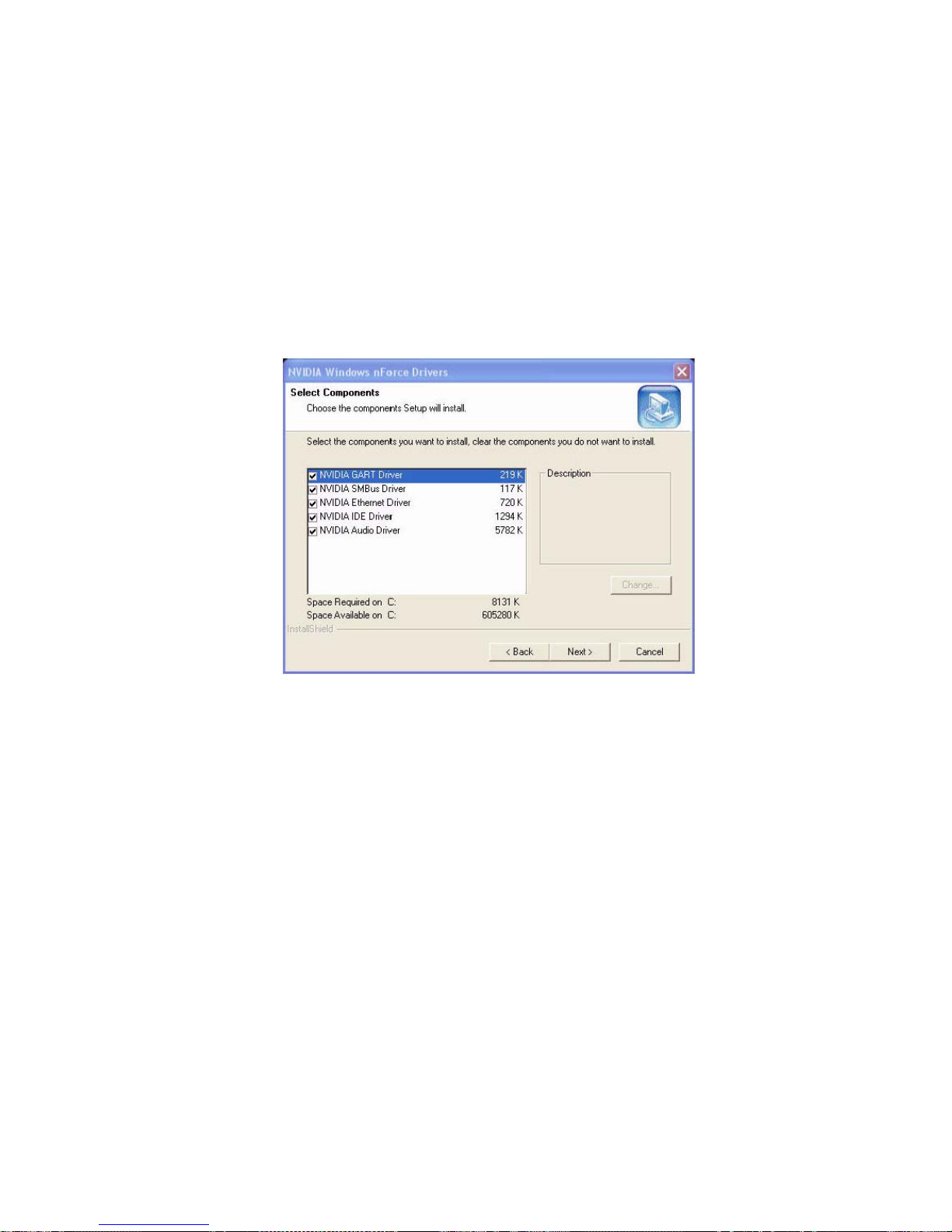

5.1.4 NVIDIA RAID Utility Installation

5.1.4.1 Installing the N V I D I A R A I D S o f tware Under Windows (For Non-Bootable RAID Array)

This section describes how to setup the application and install the RAID software which will upgrade the Windows

IDE driver and install the RAID driver.

① Start the nForce Setup program to open the NVIDIA Windows nForce Drivers page.

② Select the modules that you want to install. Select the relative options that you have configured.

③ Click Next and then follow the instructions.

④ After the installation is completed, be sure to reboot the system.

⑤ After the reboot. Initialize the newly created array.

58

5.1.4.2 Installing the RAID Driver (For Bootable RAID Array)

① After you complete the RAID BIOS setup, boot from the Windows CD, and the Windows Setup program

starts.

② Press F6 and wait for the Windows Setup screen to appear.

③ Specify the NVIDIA drivers:

a. Insert the floppy that has the RAID driver, press S, then press Enter. The Windows Setup screen

appears as below:

b. Select "NVIDIA RAID CLASS DIRVER" and then press Enter

c. Press S again at the Specify Devices screen, then press Enter.

d. Select " NVIDIA nForce Storage Controller" and then press Enter.

e. The following Windows Setup screen appears listing both drivers:

59

④ Press Enter to continue with operating system Installation, Be sure to copy the files from the floppy is

complete, then take out the floppy.

⑤ Following the instructions on how to install operating system, During the GUI portion of the installation you

might be prompted to click Yes to install the RAID driver. Click “Yes” as many times as needed in order to

finish the installation.

This will not be an issue with a signed driver.

NOTICE

Each time you add a new hard drive to a RAID array, the RAID driver will have to be installed under Windows once

for that hard drive. After that, the driver will not have to be in stalled.

60

5.2 LSILogic SAS RAID(Optional)

This chapter provides information of how to configure and use the components of the LSI Logic Integrated RAID

(IR) software with LSI SAS 1068/1068E controllers.

You may need to run the SAS BIOS setup utility when:

z You want to change the default SAS controller settings for customized features.

z You intend to manage any of the attached SAS devices.

5.2.1 Introduction to Integrated RAID

This section provides an overview of the LSI Logic Integrated RAID solution for LSI Logic SAS controllers, its

features, and its benefits. The LSI Logic Integrated RAID solution provides cost benefits for the server or

workstation market where the extra performance, storage capacity, and/or redundancy of a RAID configuration

are required.

z Integrated Mirroring (IM), which provides features of RAID 1 and RAID 1E (RAID 1

Enhanced). .RAID 1E is also called Integrated Mirroring Enhanced (IME).

z Integrated Striping (IS), which provides features of RAID 0.

By simplifying the IM and IS configuration options and by providing firmware support in its host adapters, LSI

Logic can offer the Integrated RAID solution at a lower cost than a hardware RAID implementation. FusionMPT™ firmware supports IM and IS volumes. You can configure IM and IS volumes together on the same LSI

Logic SAS controller.

Integrated RAID Benefits and Features

z Low cost RAID volume creation meets the needs of most internal RAID installations

z Easy to use - installation and configuration are not complex

z System can boot from an IM, IME, or IS volume

z No special OS- s pecific software required

z High reliability and data integrity

- Non-volatile write journaling

- Physical disks not visible to OS or to application software

z Low host CPU and PCI bus utilization

z Fusion-MPT architecture provides processing power

- Shared memory architecture minimizes external memory requests

- Functionality is contained in device hardware and firmware

61

5.2.2 Integrated Mirroring Overview

This section provides an overview of the LSI Logic Integrated Mirroring (IM) feature.

5.2.2.1 Introduction

As a result of the shift towards Network Attached Storage (NAS), ISPs need a cost effective, fault-tolerant solution

to protect the operating systems on small form factor, high-density, rack-mountable servers. The LSI Logic

Integrated Mirroring (IM) feature—which includes Integrated Mirroring Enhanced (IME)— provide data protection

for the system boot volume to safeguard critical information such as the operating system on servers and high

performance workstations. The Integrated Mirroring feature gives customers a robust, high-performance, faulttolerant solution to their storage needs, at a lower cost than a dedicated RAID controller.

The Integrated Mirroring feature supports simultaneous mirrored volumes with two disks (IM) or three to eight

disks (IME), to provide fault-toler ant protection for critical data. (If a hot spar e dis k is used, t he maximum volume size

is seven mirrored disks, plus the hot spare disk.) Up to two IM volumes are supported per SAS controller, with up

to ten drives total per controller.

If a disk in an Integrated Mirroring volume fails, the hot swap capability allows the volume to be easily restored

by simply swapping disks. The firmware then automatically re-mirrors the swapped disk. Additionally, each SAS

controller can have one global hot spare disk available to automatically replace a failed disk in the one or two IM

or IME volumes configured on the controller. The hot spare makes the Integrated Mirroring volume even more

fault-tolerant.

NOTICE

You can configure an Integrated Mirroring volume and an Integrated Striping volume on the same LSI Logic SAS

controller

The IM feature uses the s ame devi ce driv ers a s the st andard LSI Lo gic Fusion- MPT base d cont rollers, pr ovidi ng

seamless and transparent fault tolerance. This eliminates the need for complex backup software or expensive RAID

hardware. The IM feature operates independently from the operating system, in order to conserve system

resources. The BIOS based configuration utility makes it easy to configure IM and IME volumes.

The Integrated Mirroring feature is currently available as an optional component of the Fusion-MPT architecture

on LSI Logic controller products.

62

5.2.2.2 IM Features

LSI Logic Integrated Mirroring and Integrated Mirroring Enhanced support the following features:

z Configurations of one or two IM or IME volumes on the same LSI Logic SAS controller. Each volume can

consist of two mirrored disks (IM) or three to eight mirrored disks (IME).

z (Optional) One global hot spare disk per controller. If a global hot spare disk is defined, the upper limit

for an IME volume is seven mirrored disks.

z Mirrored volumes run in optimal mode or in degraded mode (if one mirrored disk fails).

z Hot swap capability.

z Presents a single virtual drive to the OS for each IM/IME volume.

z Supports both SAS and SATA disks, although the two types of disks cannot be combined on the same LSI

Logic SAS controller.

z Fusion-MPT architecture.

z Easy-to-use BIOS-based configuration utility (and DOS-based configuration utility for manufacturing use

only).

z Error notification: OS-specific event log updated by drivers and errors displayed inside the Fusion-MPT

BIOS.

z SES status LED support for Integrated Mirroring disks.

z Write journaling, which allows automatic synchronization of potentially inconsistent data after unexpected

power-down situations.

z Metadata used to store volume configuration on mirrored disks.

z Automatic background resynchronization while host I/Os continue.

z Background media verification ensures that data on the IM volume is accessible.

63

5.2.2.3 IM/IME Description

The LSI Logic Integrated Mirroring (IM) feature supports one or two mirrored volumes on each LSI Logic SAS

controller (or one mirrored volume and one Integrated Striping volume). Typically, one of these volumes is the boot

volume, as shown in Figure. This is accomplished through the firmware of the LSI Logic SAS controller that

supports the standard Fusion-MPT interfac e. The runtime mirro ring of the boot disk is tr anspar ent to the BIOS, drivers,

and operating system.

Host-based status software monitors the state of the mirrored disks and reports any error conditions.

In Figure, the system is configured with a second disk as a mirror of the first (primary) disk.

The advantage of Integrated Mirroring (RAID 1) is that there is always a mirrored copy of the data. The

disadvantage is that writes take longer because data must be written twice. On the other hand, performance is

actually improved during reads. Figure shows the logical view and physical view of an Integrated Mirroring

configuration with two disks in the mirrored volume.

64

An IME volume can be configured with up to eight mirrored disks, or seven mirrored disks and a global hot spare.

Figure shows the logical view and physical view of an Integrated Mirroring Enhanced (IME) volume with three

mirrored disks. Each mirrored stripe is written to a disk and mirrored to an adjacent disk. This type of

configuration is also called RAID 1E.

LSI Logic provides the BIOS-based configuration utility to enable the user to create IM and IME volumes during

initial setup and to reconfigure them in response to hardware failures or changes in the environment.

65

5.2.2.4 Integrated Mirroring Firmware

This section describes features of the LSI Logic Integrated Mirroring (IM) firmware, which supports up to two IM

volumes per LSI Logic SAS controller.

5.2.2.4.1 Host Interface

The IM host interface uses the Message Passing Interface, as described in the Fusion-MPT Message Passing

Interface Specification. Through the Fusion-MPT interface, the host OS has access to the IM volume as well as

the physical disks.

5.2.2.4.2 Resynchronization with Concurrent Host I/O Operation

The IM firmware allows Host I/Os to continue on the IM/IME volume while the volume is being re-synchronized in

the background. Resynchronization is attempted after a hot spare is activated due to a physical device failure, or

after a hot swap has occurred to a physical disk in the IM or IME volume.

5.2.2.4.3 Metadata Support

The firmware supports metadata, which describes the IM/IME logical drive configuration stored on each member

disk. When the firmware is initialized, each member disk is queried to read the stored metadata in order to verify

the configuration. The usable disk space for each member disk is adjusted down to leave room for this data.

5.2.2.4.4 Hot Swapping

The IM firmware supports hot swapping. The hot-swapped disk is automatically resynchronized in the background,

without any host or user intervention. The firmware detects hot swap removal and disk insertion.

Following a hot swap event, the firmware readies the new physical disk by spinning it up and verifying that it has

enough capacity for the mirrored volume. The IM firmware resynchronizes all hot-swapped disks that have been

removed, even if the same disk is re-inserted. In a two-disk mirrored volume, the IM firmware marks the hotswapped disk as the secondary disk and marks the other mirrored disk as the primary disk. The firmware

resynchronizes all data from the primary disk onto the new secondary disk.

5.2.2.4.5 SMART Support

The IM firmware enables Mode 6 SMART on the member disks in the mirrored volume. Mode 6 SMART requires

each physical disk to be polled at regular intervals. If a SMART ASC/ASCQ code is detected on a physical disk in

the volume, the firmware processes the SMART data, and the last received SMART ASC/ASCQ is stored in nonvolatile memory. The IM/IME volume does not support SMART directly, since it is just a logical representation of

the physical disks in the volume.

5.2.2.4.6 Hot Spare Disk

One disk can be configured as a global hot spare disk, which protects data on the one or two volumes configured

on the controller. If the IM firmware fails one of the mirrored disks, the firmware automatically replaces it with

the hot spare disk. The IM firmware then resynchronizes the mirrored data. The IM firmware is automatically

notified when the failed disk has been replaced, and the firmware then designates that disk as the new hot spare.

5.2.2.4.7 Media Verification

The IM firmware supports a background media verification feature that runs at regular intervals when the IM/IME

volume is in optimal mode. If the verification command fails for any reason, the other disk’s data for this segment

is read and written to the failing disk in an attempt to refresh the data. The current Media Verification Logical

Block Address is written to non-volatile memory occasionally to allow Media Verification to continue approximately

where it left off prior to a power-cycle.

66

5.2.2.4.8 Disk Write Caching

The IM firmware disables disk write caching by default. This is done to increase data integrity, so that the disk

write log stored in NVSRAM is always valid. If disk write caching were enabled (not recommended), the disk write

log could be invalid.

5.2.2.4.9 NVSRAM Usage

For the LSISAS1064/1064E and LSISAS1068/1068E controllers, the IM firmware requires at least a 32K NVSRAM

in order to perform write journaling. Write journaling is used to verify that the mirrored disks in the IM/IME

volume are synchronized with each other.

5.2.2.5 Fusion-MPT Support

The BIOS uses the LSI Logic Fusion-MPT interface to communicate to the SAS controller and firmware to enable

Integrated Mirroring. This includes reading the Fusion-MPT configuration to gain access to the parameters that

are used to define behavior between the SAS controller and the devices connected to it. The Fusion-MPT drivers

for all supported operating systems implement the Fusion-MPT interface to communicate with the controller and

firmware.

67

5.2.3 Creating Integrated Mirroring Volumes

This section describes how to create Integrated Mirroring (IM) and Integrated Mirroring Enhanced (IME) volumes

using the LSI Logic SAS BIOS Configuration Utility (SAS BIOS CU).

5.2.3.1 IM Configuration Overview

You can use the SAS BIOS CU to create one or two IM or IME volumes on each LSI Logic SAS controller, with an

optional global hot spare disk. All disks in an IM or IME volume must be connected to the same LSI Logic SAS

controller.

Although you can use disks of different size in IM and IME volumes, the smallest disk determines the “logical” size

of each disk in the volume. In other words, the excess space of the larger member disk is not used.

Refer to Section 2.2, “IM Features,” for more information about Integrated Mirroring volumes.

5.2.3.2 Creating IM and IME Volumes

The SAS BIOS CU is part of the Fusion-MPT BIOS. When the BIOS loads during boot and you see the message

about the LSI Logic Configuration Utility, press Ctrl-C to start the CU. After you do this, the message changes to:

Please wait, invoking SAS Configuration Utility...

After a brief pause, the main menu of the SAS BIOS CU appears. On some systems, however, the following

message appears next:

LSI Logic Configuration Utility will load following initialization!

In this case, the SAS BIOS CU will load after the system has completed its power-on self test.

You can configure one or two IM or IME volumes per Fusion-MPT controller. You can also combine IM, IME, and

Integrated Striping volumes on the same controller, up to a maximum of 10 physical disk drives.

68

The following guidelines also apply when creating an IM or IME volume:

z All physical disks in the volumes must be either SATA (with extended command set support) or SAS (with

SMART support). SAS and SATA disks cannot be combined in the same volume.

z Disks must have 512-byte blocks and must not have removable media.

z An IM volume must have two drives, plus an optional global hot spare. An IME volume. An IME volume

can have three to eight drives, or three to seven drives if you also create a global hot spare.

NOTICE

If a disk in an IM or IME volume fails, it is rebuilt on the global hot spare if one is available.

So adding a global hot spare greatly increases the level of data protection. (One global hot spare is allowed

for the one or two volumes configured on a controller.)

5.2.3.2.1 Creating a Second IM and IME Volume

Follow these steps to create an IM volume with the SAS BIOS CU:

① On the Adapter screen, use the arrow keys to select an LSI Logic SAS adapter.

② Press Enter to go to the Adapter Properties screen, shown in below Figure.

③ On the Adapter Properties screen, use the arrow keys to select RAID Properties on the screen and press Enter.

④ When you are prompted to select a volume type, select Create IM Volume. The Create New Array screen

shows a list of disks that can be added to a volume.

⑤ Move the cursor to the “RAID Disk” column and select a disk. To add the disk to the volume, change the “No”

to “Yes” by pressing the + key, . key, or space bar. When the first disk is added, the SAS BIOS CU prompts

you to either keep existing data or overwrite existing data.

⑥ Press M to keep the existing data on the first disk or press D to overwrite it. If you keep the existing data, this

is called a migration. The first disk will be mirrored onto the second disk, so the data you want to keep must

be on the first disk added to the volume. Any data on the second disk is overwritten. As disks are added the

Array Size field changes to reflect the size of the new volume.

69

⑦ (Optional) Add a global hot spare by moving the cursor to the hot spare column and pressing the + key, . key,

or space bar.

⑧ When the volume has been fully configured, press C and then select Save changes then exit this menu to

commit the changes. The SAS BIOS CU pauses while the array is being created.

5.2.3.2.2 Managing Hot Spares

Follow these steps to create an IME volume with the SAS BIOS CU:

① On the Adapter List screen, use the arrow keys to select an LSI Logic SAS adapter.

② Press Enter to go to the Adapter Properties screen, shown in Figure.

③ On the Adapter Properties screen, use the arrow keys to select RAID Properties on the screen and press Enter.

④ When you are prompted to select a volume type, select Create IME Volume. The Create New Array screen

shows a list of disks that can be added to a volume.

⑤ Move the cursor to the “RAID Disk” column and select a disk. To add the disk to the volume, change the “No”

to “Yes” by pressing the + key, . key, or space bar.

⑥ Repeat this step to select a total of three to eight disks for the volume (or three to seven disks if you will

create a global hot spare). All existing data on all the disks you select will be overwritten. As you add disks,

the Array Size field changes to reflect the size of the new volume.

⑦ (Optional) Add a global hot spare to the volume by moving the cursor to the hot spare column and pressing

the + key, . key, or space bar.

⑧ When the volume has been fully configured, press C and then select Save changes then exit this menu to