Page 1

G PEELER

WE THANK YOU FOR YOUR PURCHASE OF OUR G PEELER.

GP1960100 ED7

Page 2

G PEELER

TABLE OF CONTENTS

DESCRIPTION PAGE

Table of Contents 1

Overall View of Peeler 2

Installation 3

Operating Instructions 3

Cleaning 3

Maintenance 4

Housing Assembly 5-7

Drive Assembly 8-9

Wiring Diagram 115V, 60HZ, 1PH 10

Wiring Diagram 220-230V, 50/60HZ, 1PH 11

Wiring Diagram 115V, 60HZ, 1PH Canadian Specification Only 12

Wiring Diagram 220-240V, 50HZ, 1PH British Specification Only 13

Warranty Back Cover

OPERATOR SAFETY

READ AND MAKE SURE THAT YOU UNDERSTAND INSTRUCTIONS AND

SAFETY WARNINGS BEFORE ATTEMPTING TO OPERATE THE PEELER.

NEVER PUT FINGERS OR HANDS IN PEELER WHILE THE PEELER IS

OPERATING OR SERIOUS INJURY COULD RESULT

PAGE 1

Page 3

G PEELER

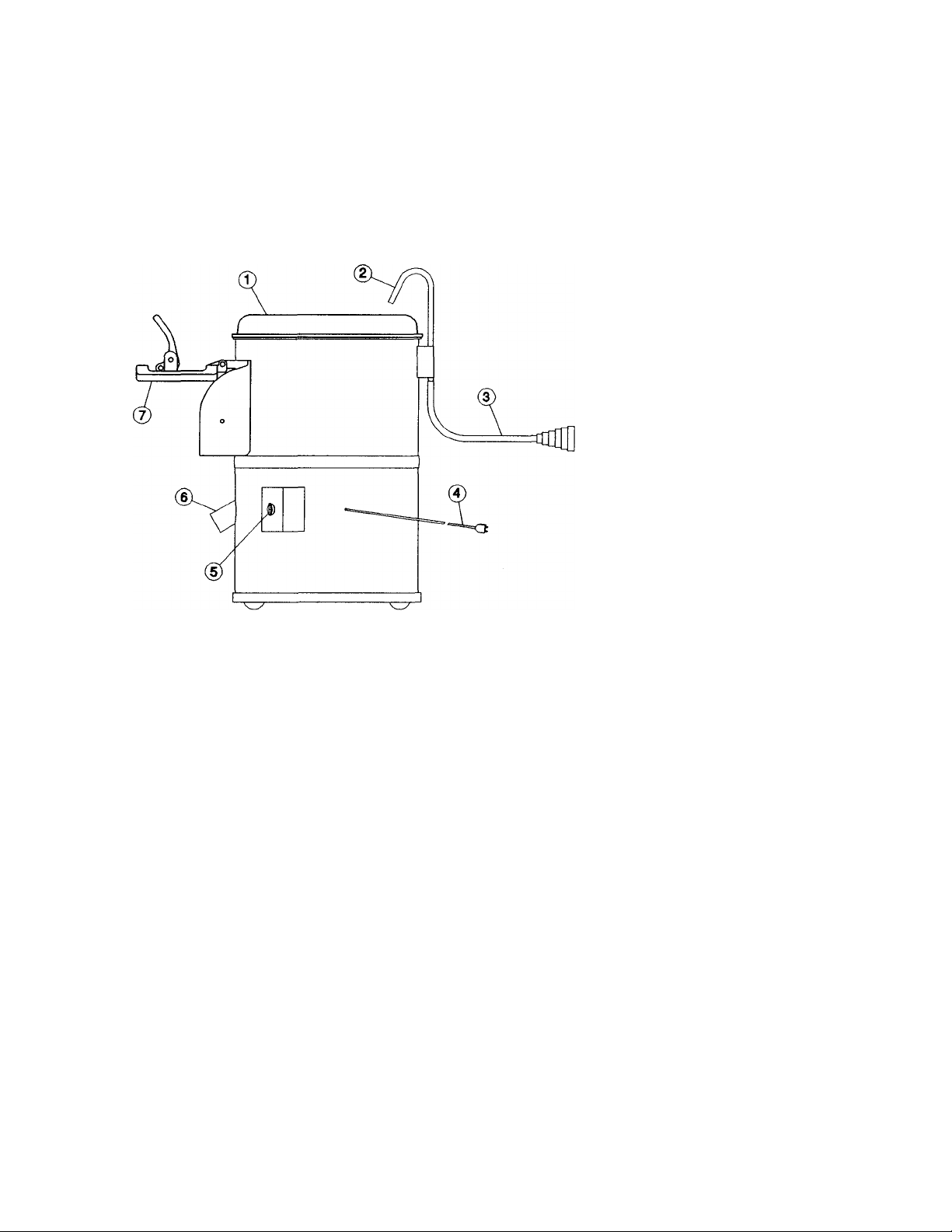

OVERALL VIEW OF PEELER

FIGURE 1

G PEELER

1 - COVER 5 - TIMER KNOB

2 - WATER INLET TUBE 6 - DRAIN OUTLET

3 - FLEXIBLE HOSE 7 - DISCHARGE DOOR

4 - ELECTRICAL CORD

PAGE 2

Page 4

G PEELER

After machine has been properly installed, adjust cold water faucet for a small flow of water

or discharge

three minute average peeling time may have to be increased or decreased accordingly. The

Wash inside of peeler and flush out thoroughly with flexible hose. Allow discharge door to

INSTALLATION

After peeler has been removed from carton, remove cover, shipping spacer, water inlet

hose and any literature packed in the peeler. Place peeler on sink drainboard or any

suitable location. Be sure that drain outlet [Fig. 1 (6)] is located so that water and peelings

will discharge into sink.

Pull up into position water inlet tube (Fig. 1 [2]). Turn tube in holder allowing for easy

removal of cover.

Slip small end of flexible hose (Fig 1 [3]) over water inlet tube. Attach large end into cold

water faucet; close and latch discharge door [Fig. 1 [7])

CAUTION: Before making electrical connections, check the specifications on the

to flush away peelings.

To start peeler: Turn timer knob (Fig. 1 [5]) beyond desired time, then turn back to three

minute mark. This is the average time required to peel a 20 Ib load.

Insert potatoes or other vegetables through opening in cover (Fig. 1 [1]).

Timer (fig 1 [5]) will automatically stop unit. Inspect vegetables. If you are satisfied with

peeling, unlatch discharge door. Have receptacle ready to receive vegetables directly into sink. To eject the vegetables, start machine (by turning timer), hold door partly

open. Rotation of peeling disc will eject load. Timer may be turned off and on without

damage.

Peeling time will vary with the size, shape and condition of potatoes or vegetables. The

estimated capacity of 20 Ibs. is based on US Grade 1 potatoes. Unusually large or long

potatoes may require a slight reduction in load to obtain satisfactory results.

CAUTION: DO NOT OVERLOAD. THERE SHOULD BE AT ALL TIMES ROOM IN THE

Noise emissions below 70 db(A).

nameplate to make sure that they agree with those on your electric service.

Plug electric cord (Fig. 1 [4]) into AC outlet.

OPERATING INSTRUCTIONS

PEELER FOR COMPLETE TUMBLING OF VEGETABLES FOR PROPER

PEELING.

CLEANING

WARNING: DISCONNECT ELECTRIC POWER BEFORE CLEANING. Proper cleaning is

essential for insuring the long life of your UNIVEX peeler.

As soon as peeling is complete and before peeled particles dry and stick, remove cover

(Fig. 2 [2]) and peeling disc (Fig. 3 [1]), wash thoroughly with cold water only.

remain unlatched, thus prolonging the life of the door seal.

PAGE 3

Page 5

G PEELER

MAINTENANCE

Reverse procedure to

WARNING: DISCONNECT THE ELECTRICAL POWER PRIOR TO PERFORMING

Maintenance is simple and has been kept to a minimum through modern engineering

design.

Lubricate two oil cups found at each end of motor (Fig. 3 [16]) with a few drops of light

motor oil SAE 10-20, or equivalent, twice a year or more often if peeler is subjected to

heavy use. Turn grease cap (Fig. 3 [10]) 1/4 turn weekly, when cap no longer turns,

remove cap and refill with grease.

To expose driving mechanism for lubrication or service, lay unit on side and remove

bottom cover (Fig. 2 [11]). On permanent installation, it will be necessary to first remove

peeler from base.

To replace "V" belts, (Fig. 3 [23]) release tension spring (Fig. 3 [17]) to loosen belts. Hold

motor in slack position and roll belts off the large pulley. (Fig. 3 [12])

install new belts. Do not use any metallic tools to force belts over pulleys. To do so will

greatly shorten belt life. Always install inner belt first.

ANY MAINTENANCE

PAGE 4

Page 6

G PEELER

HOUSING ASSEMBLY

FIGURE 2

ILLUS. NO. PART NO. DESCRIPTION QTY.

1 1120044 HOUSING 1

2 1120029 COVER 1

3 1120038 TUBE, WATER INLET 1

4 1200008 SCREW, PPHD 8-32 X 3/8 11

5 1120019 HOSE, WATER INLET 1

6 1120060 CORD, ELECTRICAL, 115V, With Plug 1

1120060-1 CORD, ELECTRICAL, 220/230V, Without Plug 1

7 1120048 STRAIN RELIEF, CORD 1

8 2200016 LABEL, TIMER 1

9 1120020 TIMER, 5 MIN., 1 POL, 115V 1

1120020A TIMER, 5 MIN., 2 POL, 220/230V 1

10 1012050 KNOB, TIMER 1

11 1120061 COVER, BOTTOM 1

12 1320093 FEET, RUBBER 3

13 1120036 HOSE, DRAIN 1

14 4400155 SCREW, HEX HD 1/4-20 X 1/2 2

15 1120040 PIN, DISCHARGE DOOR 1

16 1120028 HANDLE, DISCHARGE DOOR 1

17 4400154 SET SCREW, HEX 10-32 X 1/4 1

18 1120039 BAR, LATCH 1

19 1120041 STOP, DOOR 2

20 1120042 PIN, HINGE 1

21 1120027 DOOR, DISCHARGE 1

22 1120022 SEAL, DISCHARGE DOOR 2FT

23 1120026 HOUSING, DISCHARGE 1

24 1120023 GASKET, HOUSING CHUTE 1

PAGE 5

Page 7

G PEELER

HOUSING ASSEMBLY

FIGURE 2 (cont)

ILLUS. NO. PART NO. DESCRIPTION QTY

25 2200004 LABEL, GREASE (Not Shown) 1

26 4400113 LABEL, STOP UNPLUG (Not Shown) 1

27 4400270 LABEL, WARNING (Not Shown) 1

FOR CANADIAN SPECIFICATIONS ONLY

6 1120060-2 CORD 115V, CSA ONLY 1

30 4400238 CIRCUIT BREAKER 1

31 4400227 LABEL, RESET 1

32 4400226 LABEL, CSA (not shown) 1

FOR BRITISH SPECIFICATIONS ONLY

6 8800209 CORD 220-230, BRITISH ONLY 1

7 7100107 STRAIN RELIEF, CORD 1

30 7100097 CIRCUIT BREAKER 1

31 4400227 LABEL, RESET 1

32 4400423 LABEL, CE (NOT SHOWN) 1

33 4400335 LABEL, GROUND (NOT SHOWN) 1

PAGE 6

Page 8

G PEELER

HOUSING ASSEMBLY

FIGURE 2

PAGE 7

Page 9

G PEELER

DRIVE ASSEMBLY

FIGURE 3

ILLUS. NO. PART NO. DESCRIPTION QTY.

1 1120002 DISC, PEELING 1

2 1120114 DISC, DRIVE PEELING ASSY 1

3 1000517 BEARING, TRUST 1

4 4400179 SCREW, HEX HD 3/8-24 X 3/4 3

5 1200079 LOCKWASHER, 3/8, SS 3

6 1120003 GASKET, BEARING 1

7 1120214 BEARING, HOUSING 1

8 4400127 WASHER, 3/8 1

9 1120006 TUBE, GREASE INTAKE 1

10 1120007 CUP, GREASE 1

11 2200002 CONE, GREASE CUP 1

12 1120009 PULLEY, DRIVEN 1

13 4400174 SET SCREW 5/16-24 X 1/4 1

14 1200113 KEY, WOODRUFF #9 1

15 2200021 TAB, TENSION SPRING, 115V 1

16 6090012 MOTOR, 1/3HP, 100-120V/200-240V, 50/60HZ, 1PH 1

17 1120017 SPRING, BELT TENSION 1

18 1120224 STUD, PIVOT ROD 1

19 4400083 NUT, JAM 3/8-24 1

20 1120047 TAB, BELT TENSION 1

21 8900031 SET SCREW 10-32 X 1/2 1

22 1120011 PULLEY, DRIVE 1

23 1120025 BELT 2

24 1120225 ROD, MOTOR PIVOT 1

25 1200060 NUT, HEXHD 10-32 2

PAGE 8

Page 10

G PEELER

DRIVE ASSEMBLY

FIGURE 3

PAGE 9

Page 11

WIRING DIAGRAM G -PEELER

11SV.60HZ, 1PH

FIGURE 4

G PEELER

PAGE 10

Page 12

WIRING DIAGRAM G -PEELER

220-230V, 50/60HZ, 1PH

FIGURE 5

G PEELER

PAGE 11

Page 13

WIRING DIAGRAM G -PEELER

115V.60HZ, 1PH

FOR CANADIAN SPECIFICATIONS ONLY

FIGURE 6

G PEELER

PAGE 12

Page 14

WIRING DIAGRAM G -PEELER

230V, 50HZ, 1PH

FOR BRITISH SPECIFICATIONS ONLY

FIGURE 7

0 PEELER

PAGE 13

Loading...

Loading...