Page 1

INSTRUCTION

MANUAL

G PEELER

tø

A

2'

«

F

Persons under age 18 are not permitted to operate or

have accessibility to operate this equipment per

U.S. Dept. of Labor Employment Standards

Administration Fact Sheet No. ESA91-3.

unuvex

GP/0904

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

ED12

Page 2

G PEELER

TO INSURE BOTH SAFE AND

TROUBLE-FREE PERFORMANCE WE STRESS

THAT ALL PERSONNEL THAT WILL BE

INVOLVED WITH YOUR NEW UNIVEX G PEELER

MUST READ AND UNDERSTAND THESE

INSTRUCTIONS BEFORE, ATTEMPTING TO

OPERATE THIS UNIT.

WE APPRECIATE YOUR COOPERATION AND

YOUR BUSINESS. SHOULD THERE BE A

QUESTION OR IF WE CAN BE OF FURTHER

ASSISTANCE, PLEASE CALL US,

1-603-893-6191.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 3

TABLE OF CONTENTS

G PEELER

DESCRIPTION

Table of Contents

Overall View of Peeler

Installation

Operating Instructions

Cleaning

Maintenance

Housing Assembly

Disk Drive Assembly

Motor Drive Assembly

Wiring Diagram 115V, 60HZ, 1PH

Wiring Diagram 220-230v, 50160HZ, 1PH

Wiring Diagram 115V, 60HZ, 1PH Canadian Specification Only

Wiring Diagram 220-240 V, 50HZ, 1PH British Specification Only

Warranty

PAGE

2

3

3

3

4

5

8

9

10

il

12

13

Back Cover

7

OPERATOR SAFETY

IT IS A VIOLATION OF UNITED STATES DEPARTMENT

REGULATIONS TO PERMIT OPERATION OF THE G-PEELER

PERSON UNDER THE AGE OF 18 YEARS.

READ AND MAKE SURE THAT YOU UNDERSTAND

SAFETY WARNINGS BEFORE ATTEMPTING TO OPERATE

NEVER PUT FINGERS OR HANDS IN PEELER WHILE

OPERATING OR SERIOUS INJURY COULD RESULT.

Page 1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OF LABOR

BY ANY

INSTRUCTIONS AND

THE PEELER.

THE PEELER IS

Page 4

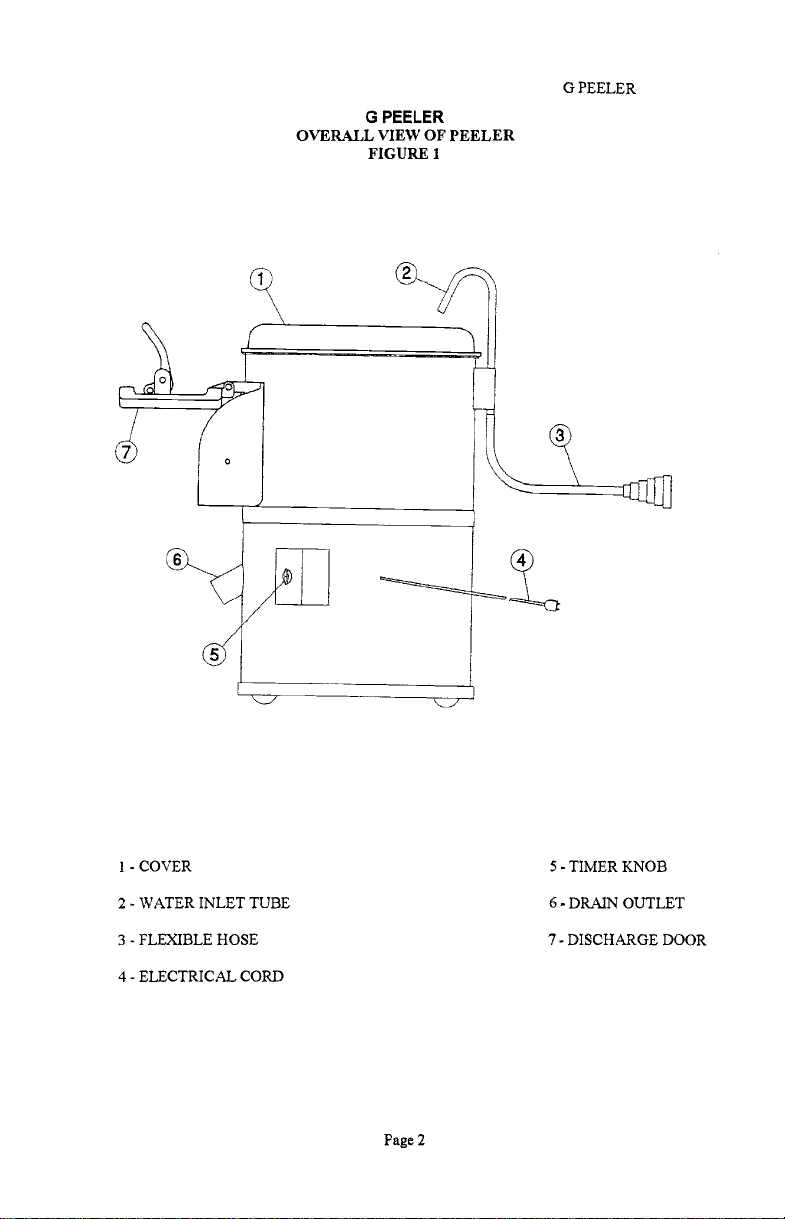

OVERALL VIEW OF PEELER

G PEELER

FIGURE 1

G PEELER

COVER 5- TIMER KNOB

WATER INLET TUBE

FLEXIBLE HOSE

6- DRAIN OUTLET

7- DISCHARGE DOOR

ELECTRICAL CORD

Page 2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 5

G PEELER

JNSTALLATION

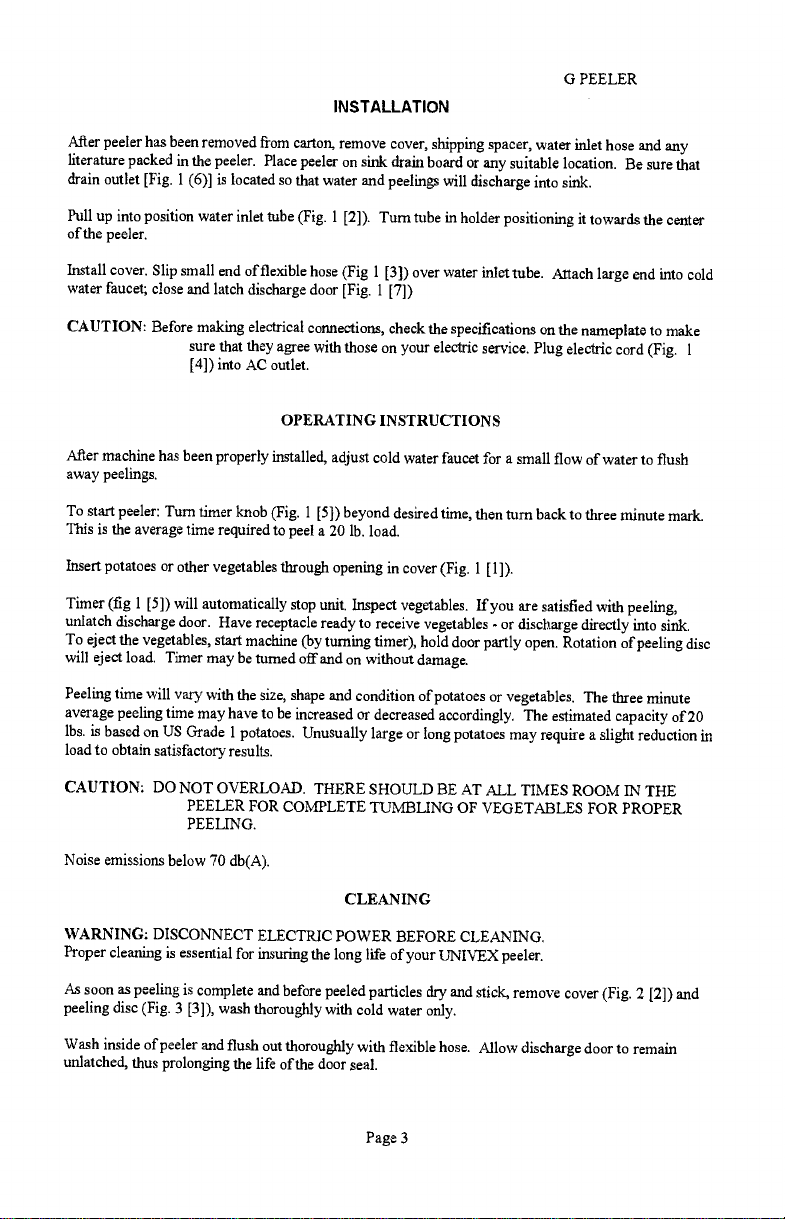

After peeler has been removed from carton, remove cover, shipping spacer, water inlet hose and any

literature packed in the peeler. Place peeler on sink drain board or any suitable location. Be

drain outlet [Fig. 1(6)1 is located so that water and peelings will discharge into sink.

sure that

Pull up into position water inlet tube (Fig. 1 [2]). Turn tube in holder positioning it towards the center

of the peeler.

Install cover. Slip small end of flexible hose (Fig 1 [3]) over water inlet tube. Attach large end into cold

water faucet; close and latch discharge door [Fig. 1 [7])

CAUTION: Before making electrical connections, check the specifications on the nameplate to make

sure that they agree with those on your electric service. Plug electric cord (Fig.

[4]) into AC outlet.

1

OPERATING INSTRUCTIONS

After machine has been properly installed, adjust cold water faucet for a small flow of water to flush

away peelings.

To start peeler: Turn timer knob (Fig. 1 [5]) beyond desired time, then turn back to three minute mark.

This is the average time required to peel a 20 lb. load.

Insert potatoes or other vegetables through opening in cover (Fig. 1 [1]).

Timer (fig 1 [5]) will automatically stop unit. Inspect vegetables. If you are satisfied with peeling,

unlatch discharge door. Have receptacle ready to receive vegetables - or discharge directly into sink.

To eject the vegetables, start machine (by turning timer), hold door partly open. Rotation of peeling disc

will eject load. Timer may be turned off and on without damage.

Peeling time will vary with the sìze, shape and condition of potatoes or vegetables. The three minute

average peeling time may have to be increased or decreased accordingly. The estimated capacity of 20

lbs. is based on US Grade i potatoes. Unusually large or long potatoes may require a slight reduction in

load to obtain satisfactory results.

CAUTION: DO NOT OVERLOAD. THERE SHOULD BE AT ALL TIMES ROOM IN THE

PEELER FOR COMPLETE TUMBLING OF VEGETABLES FOR PROPER

PEELING.

Noise emissions below 70 db(A).

CLEANING

WARNING: DISCONNECT ELECTRIC POWER BEFORE CLEANING.

Proper cleaning is essential for insuring the long life of your UNIVEX peeler.

As soon as peeling is complete and before peeled particles dry and stick, remove cover (Fig. 2 [2]) and

peeling disc (Fig. 3 [3]), wash thoroughly with cold water only.

Wash inside of peeler and flush out thoroughly with flexible hose. Allow discharge door to remain

unlatched, thus prolonging the life of the door seal.

Page 3

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 6

MAINTENANCE

G PEELER

WARNING: DISCONNECT THE ELECTRICAL POWER PRIOR TO PERFORMING ANY

MAINTENANCE

Maintenance is simple and has been kept to a minimum through modem engineering design.

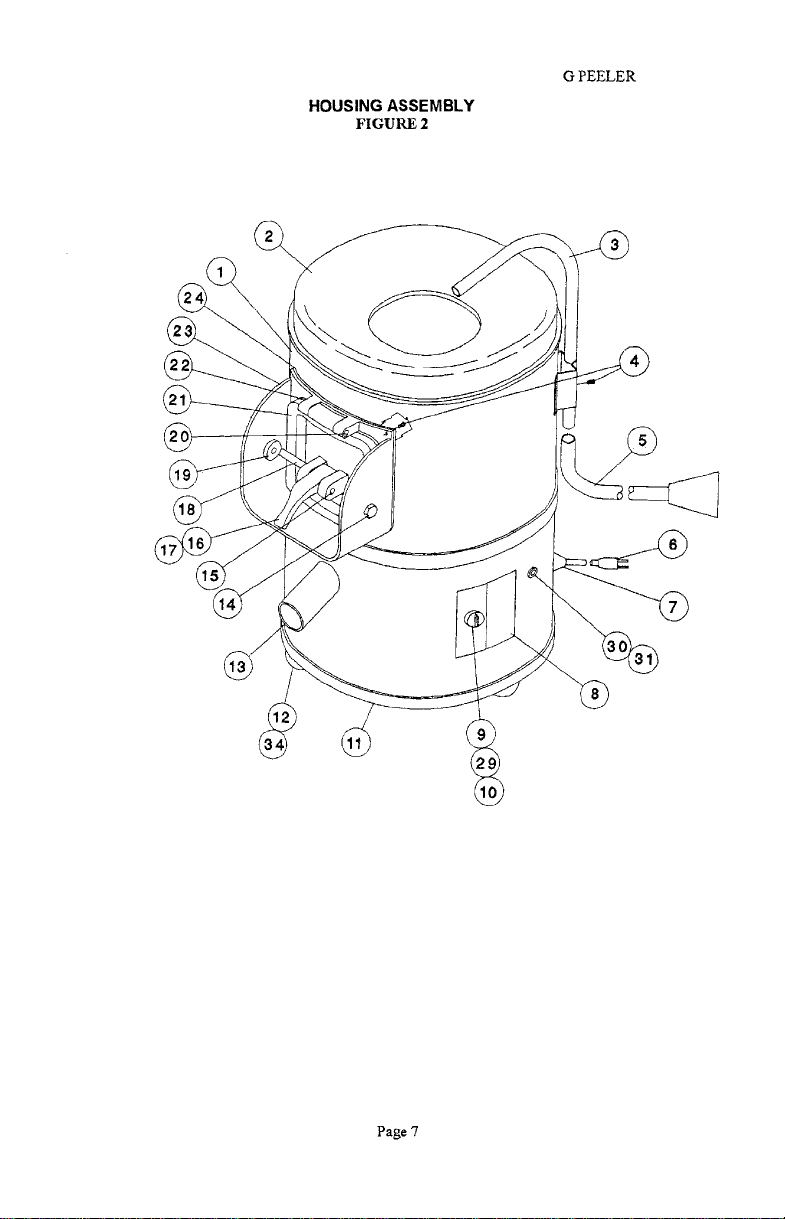

To expose driving mechanism for service, lay unit on side and remove bottom cover (Fig. 2 [1 1]).

To replace belt, (Fig. 4 [3]) release tension spring (Fig. 4 [8]) to loosen belt. Hold motor in slack

position and roll belt off the large pulley. (Fig. 4 [5]) Reverse procedure to install new belt. Do not use

any metallic tools to force belt over pulleys. To do so will greatly shorten belt life.

Page 4

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 7

HOUSING ASSEMBLY

FIGURE 2

G PEELER

ILLUS. NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

PART NO.

1120304

1120029

1120038

1200008

1120019

1120060

1120060.1

1120048

1120064

1120062

1120063

7100028

1120061

2300125

1120036

4400155

1120040

1120028

DESCRIPTION

HOUSING

COVER

TUBE, WATER INLET

SCREW, PPHD 8-32 X 3/8

HOSE, WATER INLET

CORD, ELECTRICAL, 115V, With Plug

CORD, ELECTRICAL, 220/230 V, Without Plug

STRAIN RELIEF, CORD

LABEL, TIMER

TIMER, 5 MIN., 1 POL, 115V

TIMER, 5 MIN., 2 POL, 220/230V

KNOB, TIMER

COVER, BOTTOM

FEET, RUBBER

HOSE, DRAIN

SCREW, HEX HD 1/4.20 X 1/2

PIN, DISCHARGE DOOR

HANDLE, DISCHARGE DOOR

QTY.

1

1

1

11

1

1

1

1

1

1

1

1

1

3

1

2

1

17

18

19

20

21

22

23

24

4400154

1120039

1120041

1120042

1120027

1120022

1120026

1120023

SET SCREW, HEX 10-32 X 1/4

BAR, LATCH

STOP, DOOR

PIN, HINGE

DOOR, DISCHARGE

SEAL, DISCHARGE DOOR

HOUSING, DISCHARGE

GASKET, HOUSING CHUTE

1

1

2

1

1

2FT

1

1

Page 5

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 8

HOUSING ASSEMBLY

FIGURE 2 (cont)

G PEELER

ILLUS. NO.

25

26

27

28

29 4400079

34

FOR CANADIAN SPECIFICATIONS ONLY

6

30

31

32

FOR BRITISH SPECIFICATIONS ONLY

6

7

30

PART NO.

DESCRIPTION

RESERVED

RESERVED

4400270

LABEL, WARNING (Not Shown)

RESERVED

SCREW M4-0.7 X 6MM LO (Not Shown)

1200465

1120060-2

4400238

SCREW, SS RD BD SLOTTED 1/4-20 X 5/8

CORD 115V, CSA ONLY

CIRCUIT BREAKER

4400227 LABEL, RESET

4400226

8800209

7100107

7100097

LABEL, CSA (not shown)

CORD 220-230, BRITISH ONLY

STRAIN RELIEF, CORD

CIRCUIT BREAKER

QTY

2

3

31

32

33

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

4400227

4400423

4400335

LABEL, RESET

LABEL, CE (NOT SHOWN)

LABEL, GROUND (NOT SHOWN)

Page 6

Page 9

HOUSING ASSEMBLY

FIGURE 2

G PEELER

Page 7

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 10

ILLUS. NO.

1

2

3

4

5

6

7

8

9

10

ii

12

13

PART NO.

1120310

1120307

1120002

4400230

6509012

1030035

1200117

1030019

1120311

1120318

1200077

1200206

1120305

G PEELER

DISK DRIVE ASSEMBLY

FIGURE 3

DESCRIPTION

HOUSING, BEARING

DISC, DRIVE PEELING ASSY

DISC, DRIVE PEELING

KEYSQ3/16X1 1/2

SEAL, OIL

BEARING, BALL 5204ZZ

RETAINING RING, INT.

BEARING, BALL 6204LL

GASKET, BEARING HOUSING

RING, REINFORCEMENT

LOCKWASHER 5/16

SCREW, HEX HD SS 5/16.18 X 5/8

HOUSING, DIVIDER (PART OF ITEM 10F FIG. 2)

QTY.

1

1

1

1

1

3

1

1

1

4

4

2

Page 8

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 11

MOTOR DRIVE ASSEMBLY

FIGURE 4

G PEELER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1200412

1120302

1120303

1200119

1120302

1200036

1120047

1120017

2200021

1120316

4400083

6090012

1120225

1200060

SET SCREW 1/4-20 X 1/4

PULLEY, DRIVE

BELT, POLY-V

RETAINING RING, EXT.

PULLEY, DRIVEN

SET SCREW 5/16-24 X 3/8

TAB. BELT TENSION

SPRING, BELT TENSION

TAB, TENSION SPRING, 115V

BOLT, MPTOR MOUNT

NUTJAM3/8-24

MOTOR 1/3HP, 100-120V/200-240V, 50/60HZ, 1PH

ROD, MOTOR PIVOT

NUT, HEX HD 10-32

2

1

1

2

2

1

1

1

1

1

2

Page 9

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 12

WIRING DIAGRAM G-PEELER

115V, 60HZ, 1PH

FIGURE 5

GREEN

WHITE

BLACK

TIMER

G PEELER

POWER N

WHITE

BLACK

MOTOR

Page 10

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 13

WIRING DIAGRAM G-PEELER

220-230V, 50160HZ, 1PH

FIGURE 6

TIMER

GREEN

WHITE

BLACK

G PEELER

POWER IN

WHITE

BLACK

MOTOR

Page 11

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 14

WIRING DIAGRAM G-PEELER

FOR CANADIAN SPECIFICATIONS ONLY

i

r

115V, 60HZ, IPH

FIGURE 7

GREEN

WHITE

BLACK

TIMER

CIRCUIT BREAKER

G PEELER

POWER IN

J

L

WHITE

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

BLACK

MOTOR

Page 12

Page 15

WIRING DIAGRAM G-PEELER

230V, 50HZ, 1PH

FOR BRITISH SPECIFICATIONS ONLY

FIGURE 8

OREEN

WHITE

i

CROUIT BREAKER

G PEELER

ROWER IN

Page 13

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Loading...

Loading...