Page 1

1000M MANUAL

Signature Series Slicer

OPERATORS MANUAL

Persons under age 18 are not permitted to operate or have accessibility

to operate this equipment per

U.S. Dept. Of Labor Employment Standards Administration Fact Sheet

No. ESA91-3.

1000M ED 2

Page 2

TO INSURE BOTH SAFE AND TROUBLE-FREE PERFORMANCE

2

WE STRESS THAT ALL PERSONNEL THAT WILL BE INVOLVED WITH

YOUR NEW UNIVEX SLICER MUST READ AND UNDERSTAND

THESE INSTRUCTIONS BEFORE

UNIT.

ATTEMPTING TO OPERATE THIS

..............................

WE APPRECIATE YOUR COOPERATION AND YOUR

BUSINESS. SHOULD THERE BE A QUESTION OR IF WE

CAN BE OF FURTHER ASSISTANCE, PLEASE CALL US,

800-258-6358.

Page 3

TABLE OF CONTENTS

3

DESCRIPTION PAGE

Table of Contents .................................................................................................. 3

List of Illustrations ................................................................................................. 3

Introduction .......................................................................................................... 5

Installation Instructions ......................................................................................... 5

Safety Warnings ................................................................................................... 5-6

Operating Instructions ........................................................................................... 6

Sharpening Instructions ......................................................................................... 7

Operator's Care of Slicer - Cleaning Instructions ....................................................

Lubrication Instructions ..........................................................................................

9

10

Warranty Information .............................................................................................11

LIST OF ILLUSTRATIONS

ILLUSTRATIONS PAGE

Figure 1 Overall View of Meat Slicer .................................................................4

Figure 3 Sharpener Assembly..……………………………………………………….....7

Figure 4 Sharpener Positioning..………………………………………………………...

8

Figure 2 Lubrication Assembly ..........................................................................9

Page 4

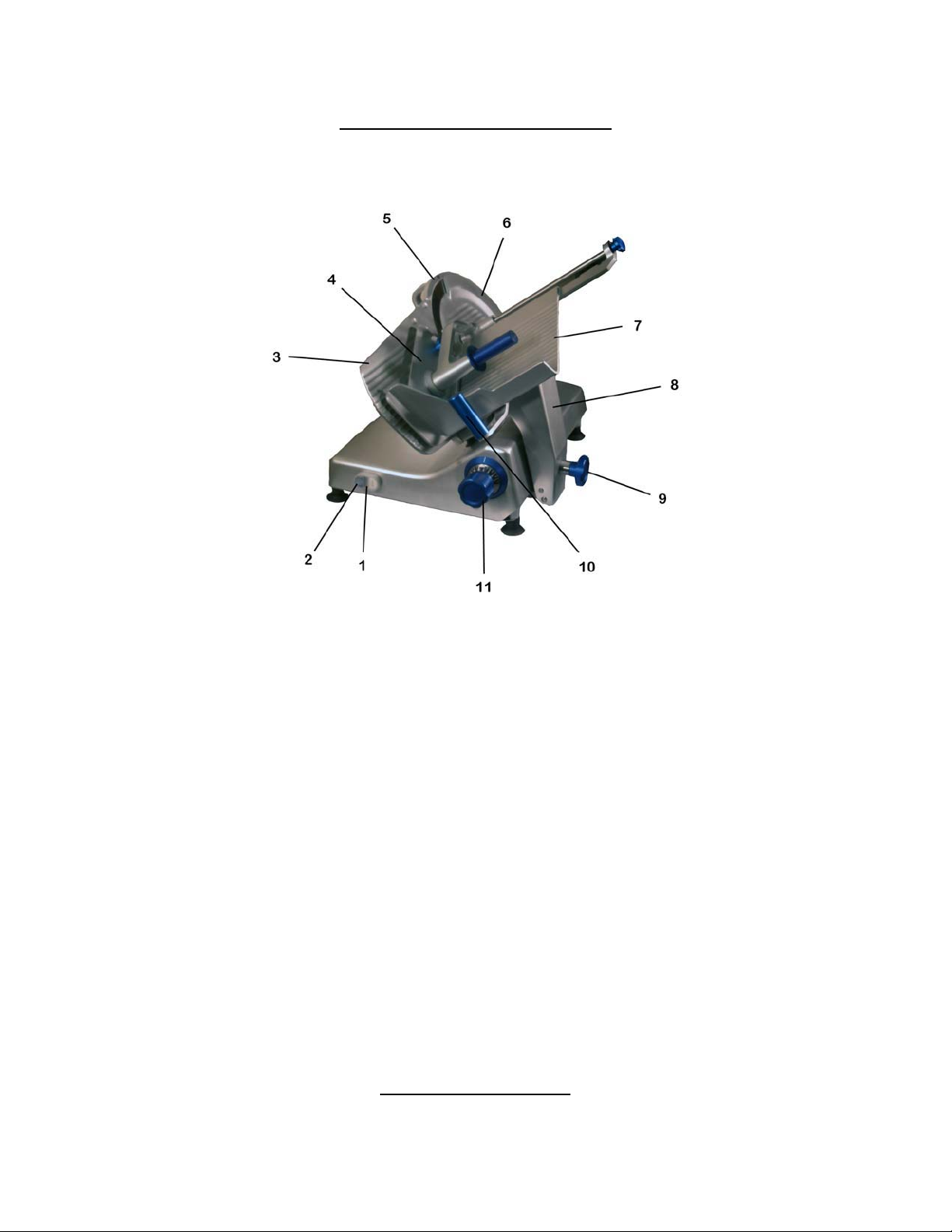

OVERALL VIEW OF MEAT SLICER

4

Figure 1

1 INDICATOR LIGHT 7 CARRIAGE

2 ON-OFF SWITCH 8 CARRIAGE ARM

3 FENCE 9 CARRIAGE ARM KNOB

4 LAST SLICE DEVICE 10 CARRIAGE HANDLE

5 PROTECTIVE GUARD 11 GRADUATED KNOB

6 KNIFE GUARD 12 SERIAL NAME PLATE (ON REAR)

OPER

OPERATOR'S MANUAL

Page 5

INTRODUCTION

5

This manual contains instructions for the Installation, Operation, Care, and Sharpening

of the

1000M Meat Slicing Machine. It is recommended that alloperators familiarize

themselves with this manual prior to operating the Slicer.

INSTALLATION INSTRUCTIONS

INSPECTION

All UNIVEX slicers are inspected and tested at the factory; however, they should be

inspected carefully by the person making the installation for loose, damaged or broken

parts. Detached parts and fixtures should be checked against packing list to determine

all are present. Any damages, imperfections or shortages should be reported to the

dealer or UNIVEX and shipping carrier.

Warning:

After slicer has been inspected, wash slicer completely with warm water and

mild soap. For SAFETY, follow the cleaning instructions on Page 9.

INSTALLATION

The most efficient installation of your slicer will depend upon the layout of your

kitchen. Locate your slicer where it will save steps for the operator and be sure to

provide sufficient clearance around it for ease of maintenance and cleaning, as well as

for efficient and safe use.

Slicer should be operated on a sturdy bench or table with the height determined to suit

the operator. It is most important that the forearm of the operator be at the proper level

for ease and safety of operation, as well as for maximum production. This height is

considered optimum when the carriage handle (Figure 1 [10]) of the slicer is at

approximately the height of the operator's elbow when standing.

IMPORTANT

Warning/Caution: Before making electrical connections, CHECK the

specifications on the nameplate to make sure that they agree with those

on your electrical service. A grounding type three-terminal plug is

provided for safety. If you do not have a mating receptacle, have a

qualified electrician provide one with grounding provisions in accordance

with local safety codes.

IMPORTANT SAFETY WARNINGS

It is a violation of United States Department of Labor regulations to permit operation of the slicer

by any person under the age of 18 years.

Warning:

The slicer knife is extremely sharp! Never touch the knife, always keep

hands and fingers clear of the knife. Never run slicer without the guard and all

other parts in place and securely fastened. Take extra care to avoid accidents

by keeping the knife guard and sharpening assembly cover ON at all times.

When the machine is not in use, the slice adjustment knob should be turned fully

back to the closed position (beyond "0") so that the knife edge is not exposed.

Page 6

Observe the cleaning instruction on Page 9 for best results and for safety. Also

6

remember to always turn off the slicer and disconnect the electrical supply cord

before cleaning.

When slicing, always work the carriage using only the carriage arm handle

(Figure 1 [10]). Do not hold or push the carriage from any other place.

OPERATION INSTRUCTIONS

The UNIVEX slicer is designed to meet the cook's demand for an efficient, sturdy slicer.

The

UNIVEX slicer will give unfailing performance over a period of years, when operated

and maintained according to instructions contained herein.

START/STOP SWITCH

The slicer is started by pushing the ON/OFF switch (Figure 1 [2]). A indicator light

(Figure 1 [1]) is provided to indicate when the slicer is turned on.

SLICE ADJUSTMENT

Warning: Dial-type knob adjustment (Figure 1 [11]) allows for slice thickness ranging

from paper thin up to .9". Dial graduations allow you to precisely set up specific

slice thickness for various needs. When not in use, always return knob back to

its fully closed position (beyond "0") so that the knife edge is not exposed.

POSITIVE HOLD CARRIAGE

Caution: A last slice gravity feed grip (Figure 1 [4]) is provided which can be locked out

of the way when not required. Do not use this last slice device to work the

carriage back and forth. Use only the carriage arm handle (Figure 1 [10]).

Always make sure the carriage is positively secured to the slicer by checking to

see that the carriage arm knob (Figure 1 [9]) is fully tightened.

PROTECTIVE GUARD

Warning: The protective guard (Figure 1 [5]) covers the knife edge completely except at

the forward edge where slicing will be performed. This forward edge is covered

by the edge of the fence, but only when the slice adjustment is completely

closed.

The knife guard (Figure 1 [6]) can be removed for cleaning by unscrewing the

knife guard knob (Figure 3 [35]). For safety, keep the knife guard on at all times

except when cleaning. Never operate the slicer with the knife guard removed.

SHARPENING INSTRUCTIONS

This slicer is equipped with a knife having a concave or hollowed surface for superior

slicing quality. Of course, any knife, however superior, must be sharpened regularly and

properly in order to produce not only the highest quality slices, but also to allow it to

maintain its productivity. The knife sharpener (Figur

e 3) on this machine is a fence

mounted design. Since the sharpener is not exposed during the slicing of product, the

stones remain free of food contamination and in the best possible condition for

sharpening.

Page 7

Warning: The following sharpening procedure will provide high quality sharpening

7

results and should also be followed for safety considerations:

1. Warning:

Keep away from the knife edge.

2. The knife cutting area should be clean and free from food, especially grease.

Grease will ruin the ability of a grinding stone to sharpen an edge. The stone

simply will not cut. If cleaning is necessary, follow the procedure outlined on

Page 8. Remember to unplug the electrical supply cord.

3. Pull the carriage all the way back towards the front of the slicer. Lift the last

slice device (Figure1 [4]) all the way up and rotate into the stored position.

Loosen sharpener mounting knob (Figur

gure 3) and place it on the top of the fence with the body of the sharpener

(Fi

on the right side of the fence and the mounting knob (Fi

e 3 [1]). Lift sharpener assembly

gure 4) on the left

side of the fence.

4. Completely open the slice adjustment so that the knife edge is

at the maximum slice thickness. Warning:

5. Slide the carriage towards the blade until the plasti

(Figure

4) drops into the notch on the top of the fence. The plastic bead

should now be resting flush with the top edge of the fence (

be moved slightly so that it is not touching the sharpener body

knob (Figure

3 [1]) until sharpener is secure to the fence. Do not tighten too

Keep away from the knife edge.

c bead of the sharpener

the carriage should

). Tighten the

much.

6. Turn slicer ON.

Rotate the sharpener dial downward (Figure 3 [5]) on the

right side of the sharpener assembly to position “1” and hold. This will start the

grinding stone rotating. Run until the beveled cutting surface on the back side

of the blade cleans up. This can take from 15 to 30 seconds depending on

how dull the blade was allowed to become. return sharpener wheel to center

position.

7. Turn slicer OFF

and check for the formation of a very slight burr on the top

side of knife opposite the bevel which indicates complete grinding of the bevel.

This slight burr can be detected either visually or by picking with a small piece

of stiff paper.

8. Turn slicer ON. Rotate sharpener

dial upward (Figure 3 [2]) to position “2” on

the sharpener assembly (this will engage the honing stone) and hold for 1 to

2 seconds. Turn OFF the slicer. Blade should now be completely sharpened and

honed.

Caution:

It is important for best slicing results not to hone the knife too long or

the keen edge will be destroyed due to the formation of an undesirable

second bevel on the opposite side. This condition tends to be the

primary cause of unsatisfactory slicing results.

9. Turn slicer OFF. Loosen sharpener mounting knob (Figure 10 [28]). Slide

sharpener towards front of machine and lift of the fence. Close fence fully.

10. Clean slicer and knife according to the cleaning procedure on Page 8 in order

to thoroughly remove grinding debris.

Page 8

8

1 LOCKING KNOB ASSEMBLY

2 HONING POSITION

3 SHARPENER OPERATION

SELECTION DIAL

4 SHARPENER NEUTRAL

POSITION

5 SHARPENING POSITION

FIGURE 3

POSITION THE SHARPENER

ASSEMBLY SO THAT THE LOCKING

KNOB ASSEMBLY IS BEHIND THE

FENCE.

SLIDE THE CARRIAGE FORWARD

UNTIL THE PLASTIC BEAD SLIPS

INTO THE NOTCH ON THE FENCE.

TIGHTEN THE KNOB TO SECURE

THE SHARPENER TO THE FENCE.

FIGURE 4

Page 9

OPERATORS CARE OF SLICER

9

CLEANING

Warning: 1. Never touch the knife edge. Always keep your hands, fingers and arms

clear of knife.

Warning:

Caution:

Warning

Warning:

2. Turn off slicer and DISCONNECT ELECTRICAL CORD before cleaning.

3. Turn slice adjustment knob (Figure 1 [11]) to the fully closed position

(beyond "0") so that the knife edge is not exposed. While holding the

adjustment knob all the way closed loosen the carriage arm knob. The

carriage may now be tilted away from the fence to the cleaning position.

Note that with the carriage tilted the fence becomes locked in the

cleaning position which covers the forward portion of the knife.

4. Remove last slice device (Figure 5 [3]), which may be washed in a sink,

by loosening knobs (Figure 5 [4]). Use only warm water and mild soap.

Rinse carriage assembly with warm water and dry thoroughly using a

clean soft cloth. Never wash the slicer or any of its parts in a

dishwashing machine or the clear protective finish will be damaged.

5. Wash body of slicer using warm water and mild soap using a clean soft

cloth. Under no circumstances should the slicer be hose rinsed.

6. Remove knife guard (Figure 1 [6]) by loosening knife guard knob (Figure

3 [35]) Then carefully lift and remove guard by the handle(Figure 3 [18]).

7. Rotate the meat deflector (Fig. 3 [7]) by swinging away from the back of the

blade.

8. CAREFULLY wash the front and rear of the knife with a cloth using warm

water and mild soap. CAREFULLY wash between the knife edge and

protective guard (Figure 1 [5]) using a soft cloth inserted between knife

edge and guard on both front and rear of knife using extreme caution to

never touch the knife edge. Rinse with warm water applied with a cloth.

Dry thoroughly with a clean soft cloth.

Caution:

9. Following cleaning, a commercial non-toxic sanitizer may be wiped on

the clean surfaces with a soft clean cloth or sprayed as recommended

on the container labeling. It is important that the sanitizer be compatible

with anodized aluminum or the clear protective finish on the slicer will

be damaged. Surface should be wetted completely, but not to the point

of running or puddling.

Warning:

10. Replace the knife guard. Never leave the slicer without its knife guard

installed!

11. Return the meat deflector to it’s original position. Lower carriage to operating

position and tighten carriage arm knob.

Page 10

LUBRICATION & FUNCTION CHECK

10

Warning: Turn off slicer and DISCONNECT ELECTRICAL CORD before lubricating.

Close fence all the way.

General lubrication should be performed in accordance with the lubrication instructions

below. During this lubrication sequence, be sure to check for free operation and

movement of related parts as well as for excessive wear and looseness of various parts.

Be sure to check all handles and knobs for tightness.

LUBRICATION INSTRUCTIONS

A = Clean and apply mineral B = Apply Petro-Gel (4400408) often as

oil weekly.

required to maintain light film.

Page 11

The UNIVEX 100M Slicer carries a

one-year, onagainst any defects

workmanship. The one-year

on the date of purchase by the end

remains in full effect provided the unit is

properly in accordance with our i

Any work to be performed under this

must be performed between the hours

8:00 a.m. and 5:00 p.m. local time, Monday

through Friday. UNIVEX will not cover

overtime

the

UNIVEX

at 800-258-6358

before arranging repair

the unit to

Damages incurred in transit or incurred because

of installation error, accident, alteration or

misuse are not covered. Transit damages should

be reported to the carrier immediately.

UNIVEX will not be liable for any

consequential,

special damages.

site parts and labor warranty

charges of any kind. Please call

Warranty Service Department

.

UNIVEX.

compensatory, incidental or

Warranty

in materials or

period begins

user and

used

nstructions.

warranty

of

to report warranty claims

or attempting to return

Loading...

Loading...