Universal Nolin 2000L Installation Manual

OWNER’S MANUAL

MIRACOOL® GLASS DOOR MERCHANDISER

2000L

IMPORTANT

PLEASE RETAIN FOR YOUR RECORDS

700A Buffington Rd.

Spartanburg, SC 29303

Mailing Address:

PO Box 6650

Spartanburg, SC 29304

Customer Service:

1-800-486-8296

Fax: 864-804-5611

CONTENTS

GENERAL......................................................... 2

UNIT INSPECTION ...........................................2

INSTALLATION ............................................. 2-5

LOCATE UNIT..............................................2

LEVEL .........................................................4

INSTALL SHELVES .....................................5

CONDENSATE DISPOSAL ..........................5

START-UP .....................................................6-7

PRELIMINARY CHECKS..............................6

INITIAL START-UP.......................................7

REFRIGERATION SYSTEM SERVICE ........8-11

COMPONENTS............................................ 8

SERVICE AND TROUBLESHOOTING ....8-11

MAINTENANCE .........................................12-13

LAMP REPLACEMENT ..............................12

CONDENSATE REMOVAL.........................12

CONDENSER/EVAPORATOR ...................12

CABINET EXTERIOR................................. 12

INTERIOR SURFACE.................................12

GENERAL

egaP

These instructions cover the installation, operation,

and maintenance of Universal Nolin MiraCool

series glass-door merchandiser units, size 2000L

®

UNIT INSPECTION

Examine all packages for damage to packaging

material. Damage to external packaging may have

resulted in unit damage. Check packages for all

accessories and components, including legs,

casters, and shelves. File a claim immediately

with the shipping company if shipment is

damaged or incomplete.

INSTALLATION

LOCATE UNIT

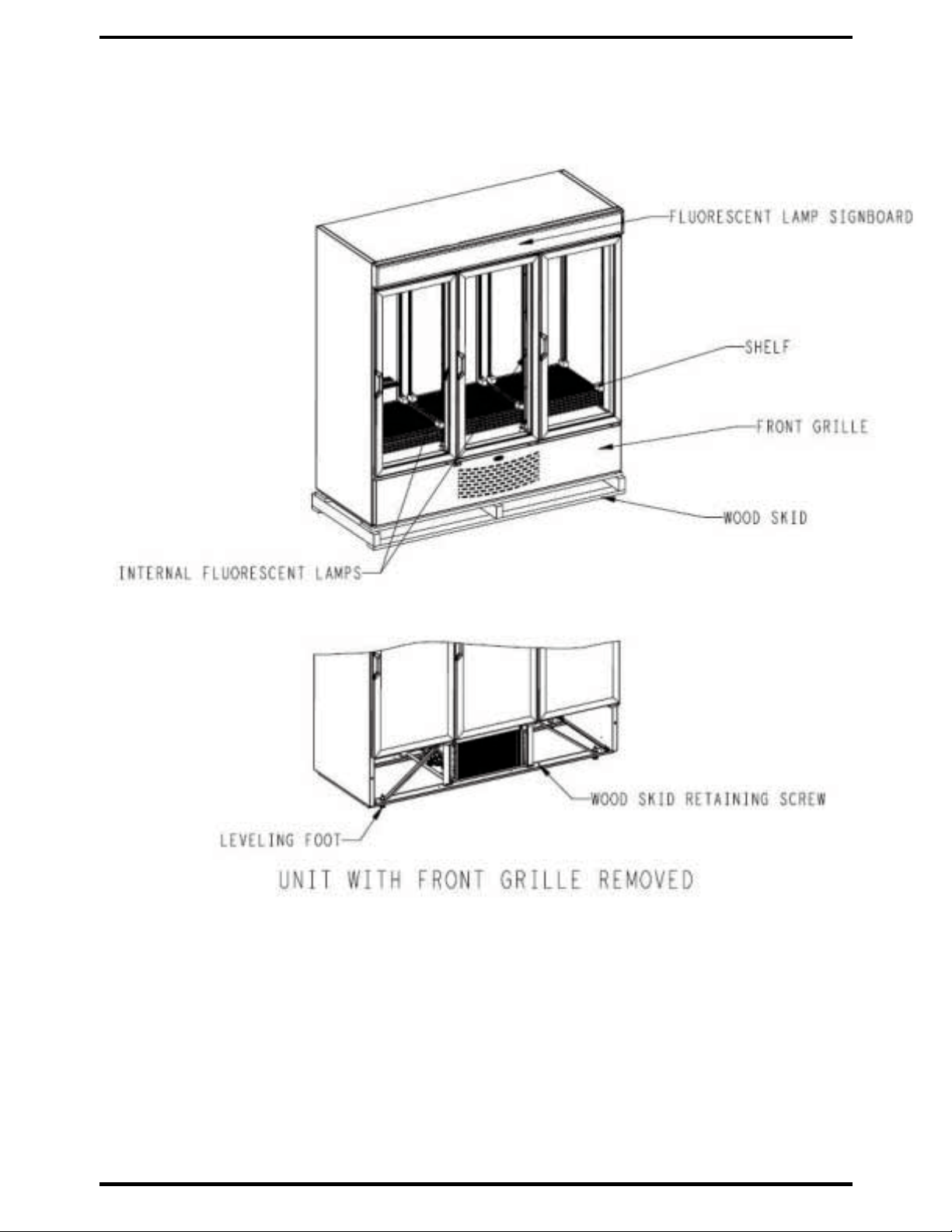

Refer to Figure 1 for unit components. Units are

designed for indoor placement only. Provide at

least 3 inches of space between unit cabinet and

any adjacent wall or fixtu

Remove skid base by removing the retaining

screws (8 hex head bolt screws). Refer to Figure

2 to remove the front grille and gain access to skid

retaining screws. If optional casters will be used,

unit must be located on flat, level surface. Refer to

Table 1 for a list of standard parts.

re.

TABLE 1 – STANDARD PARTS

PART FACTORY

INSTALLED

Note: Parts shown are for standard units. Quantity of shelves and clips may vary based on f actory-supplied options.

FIELD INSTALLED QUANTITY

51 X sevlehS

06 X spilC flehS

1 - - launaM noitcurtsnI

4 X teeF gnileveL

4 X spmaL

2

FIGURE 1 - MIRACOOL

®

BOTTLE COOLER UNIT COMPONENTS (MC2000H SHOWN)

3

LEVEL UNIT

To provide adequate condensate drainage and

proper door alignment and operation of unit, the

unit cabinet must be level. Leveling feet are

factory installed. Remove the front grille to gain

access to front and back feet.

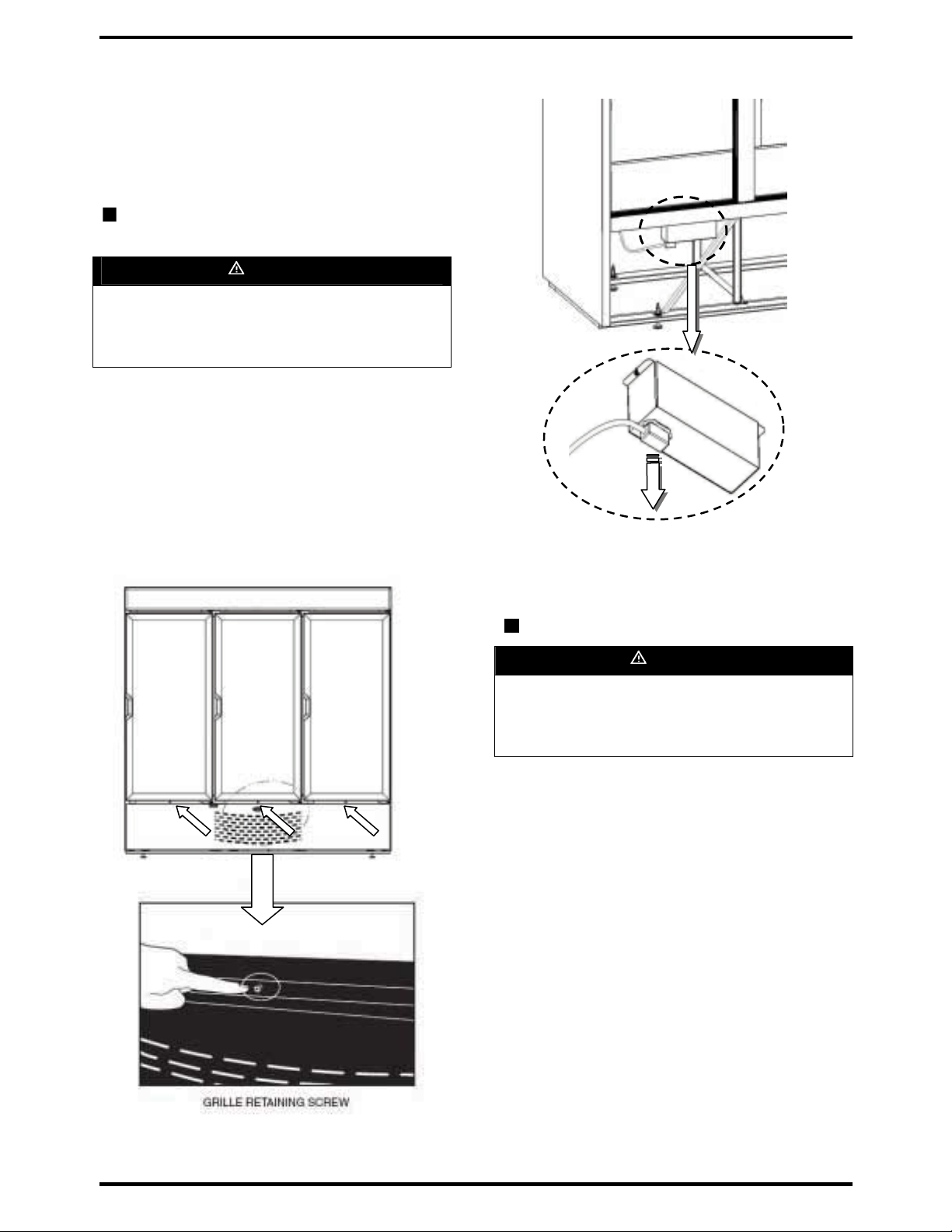

TO GAIN ACCESS TO LEVELING

FEET

DANGER

Before servicing unit, disconnect electrical

service. Failure to disconnect electrical service

could result in electrical shock and cause

personal injury or death.

1. After disconnecting the unit from the power

supply, remove the grille retaining screw

located in the upper-most part of the grille.

(See Figure 2)

2. Lift the grille up and away from the unit.

3. Unplug the power supply cord located at the

bottom of the cabinet. (See Figure 3)

FIGURE 3 – DISCONNECT SERVICE CORD

TO LEVEL UNIT

DANGER

Before servicing unit, disconnect electrical

service. Failure to disconnect electrical service

could result in electrical shock and cause

personal injury or death.

Swing Doors- The door is equipped with gravity

assisted cams and will not function properly

without proper leveling of cabinet. Adjust feet

using adjustable wrench so that unit sits

approximately level to floor and doors close

properly. For best door operation, adjust leveling

feet so that cabinet has a

front to back. Optional casters are available to

replace leveling feet.

Sliding Doors- The door will not function properly

without proper leveling of cabinet. Adjust feet

using adjustable wrench so that unit sits

approximately level to floor and doors close

properly.

1/16-in. rake or slant from

FIGURE 2 – REMOVE FRONT GRILLE

NOTE: If casters are not used, local codes may

require cabinet to be sealed around the perimeter

of the cabinet base. Consult local sanitation codes.

Use only sealant material approved for this use,

such as Dow Corning #732.

4

INSTALL SHELVES

Product shelves and a bag containing shelf

support clips are packed inside the unit. Refer to

Table 1 to verify quantity of shelves and shelf

supporting clips. Bottom shelf must be placed on

interior floor and should be inserted into the two

retainer clips provided at the rear corners or the

unit floor.

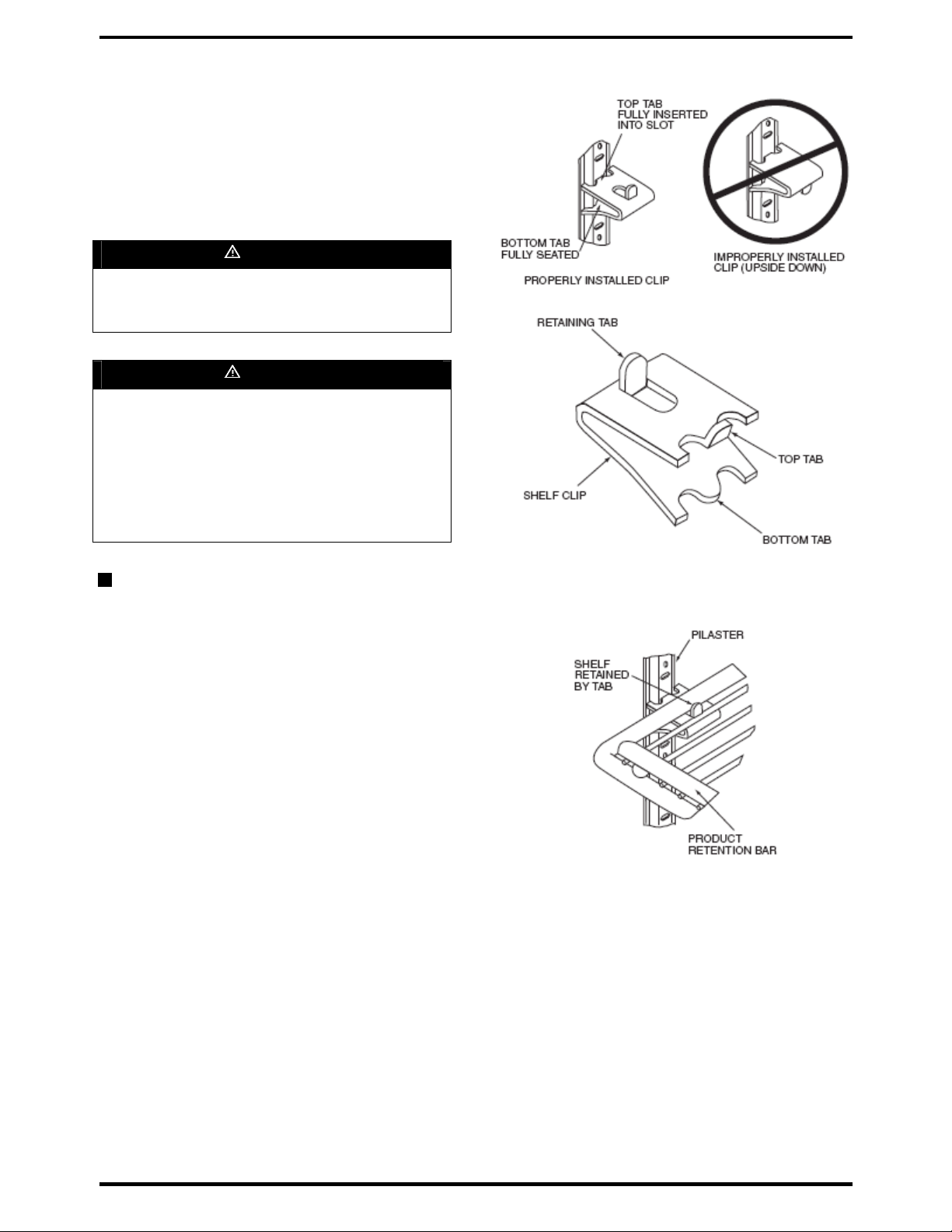

WARNING

Improper shelf clip installation may cause shelf

and/or product to fall which could result in

personal injury or damage to the unit.

WARNING

Do not overload the shelves. The unit is designed

to use all the shelves provided, installed in

equally spaced configuration. Failure to install

shelves correctly could result in personal injury or

damage to the unit. If fewer shelves or a different

installation configuration is desired, contact the

manufacturer to ensure that shelf overloading will

no occur.

TO INSTALL SHELVES

FIGURE 4 – SHELF CLIP INSTALLATION

1. Determine proper location for shelf clips.

Refer to the numbers on the pilaster to

ensure that all clips are properly located.

2. Insert top tab of the shelf clip into the

desired hole of the pilaster. The retaining

tab should be facing upward as shown in

Figure 4.

3. Rotate the clip downward and insert the

bottom tab into the appropriate hole on the

pilaster. If necessary, squeeze the clip

slightly during installation.

4. Install all remaining clip

above.

5. Install shelves onto clips so that the product

retention bar is facing upward. Be careful

not to dislodge clips during shelf installation.

6. Shelves must be placed so that the retaining

tab on the shelf captures the shelf as shown

in Figure 5.

7. Before loading the shelf, ensure that the

shelf is resting on each of 4 clips and that

the clip are installed as shown in Figures 4

and 5.

s as described

FIGURE 5 – PRO

PER INSTALLATION OF

SHELF ON CLIP

CONDENSATE DISPOSAL

The evaporator drain pan is located in the base of

the product. Airflow in compartment hastens

condensate evaporation so that external drain

plumbing is not required.

5

Loading...

Loading...