Page 1

Pu tt ing You in Con trol of Tod ay 's Tech n ology

ViewSonic Tweety RF Remote

Product Specification

Work Order: 50-954

November 05, 2001

Rev. 2.9A

URCs: 4012B00

Author: Jason Etter

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 1 of 63

Page 2

Page 3

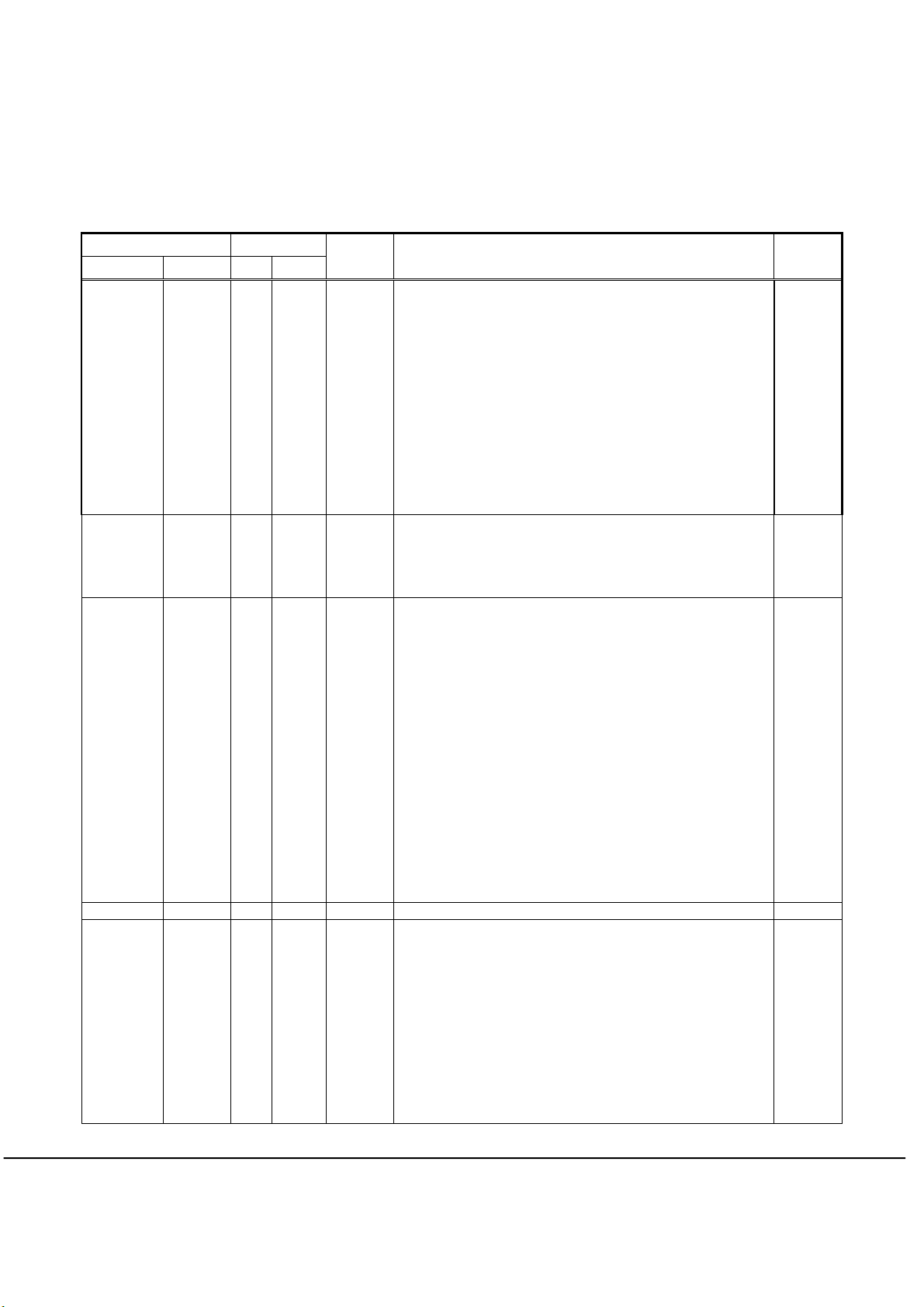

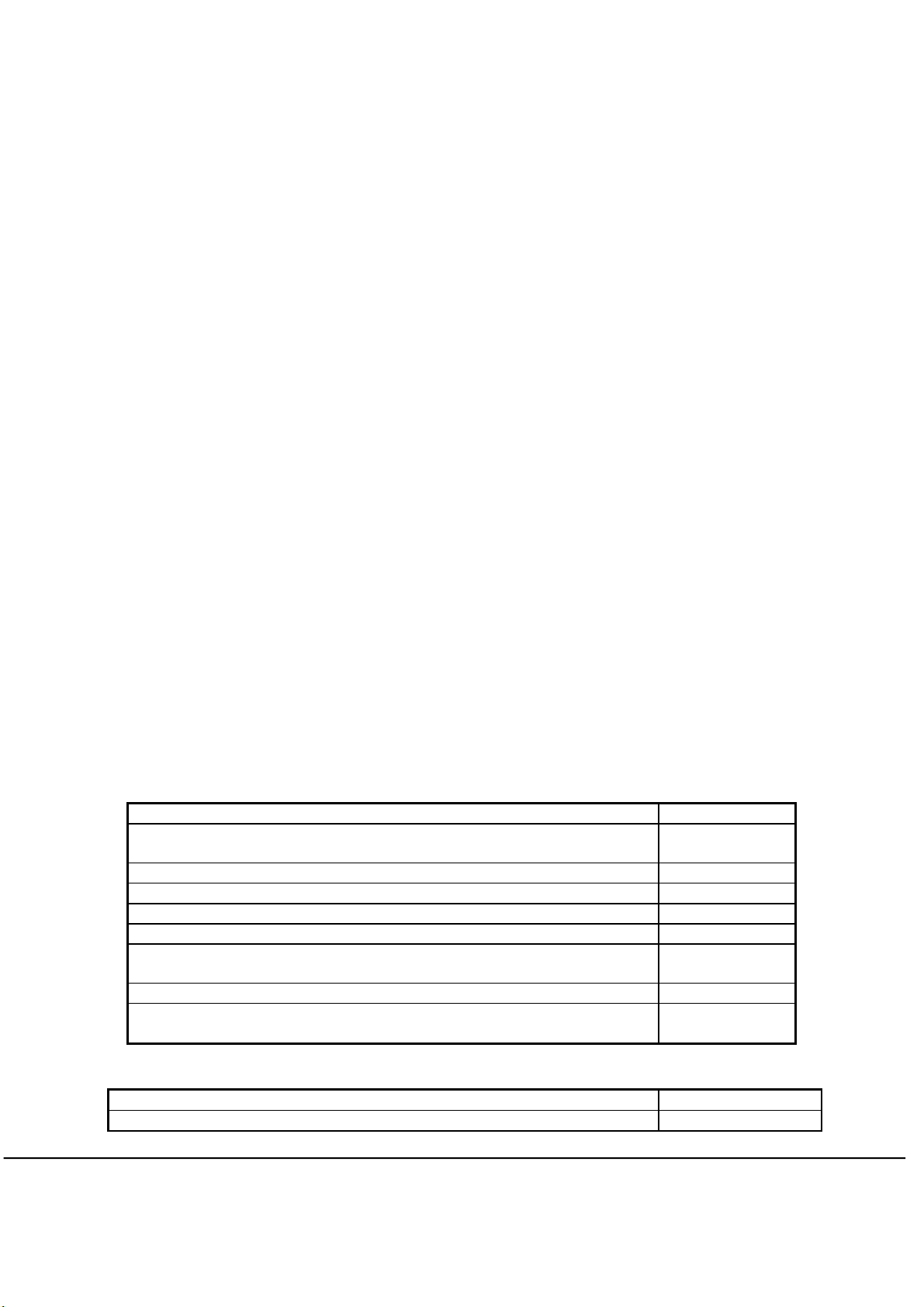

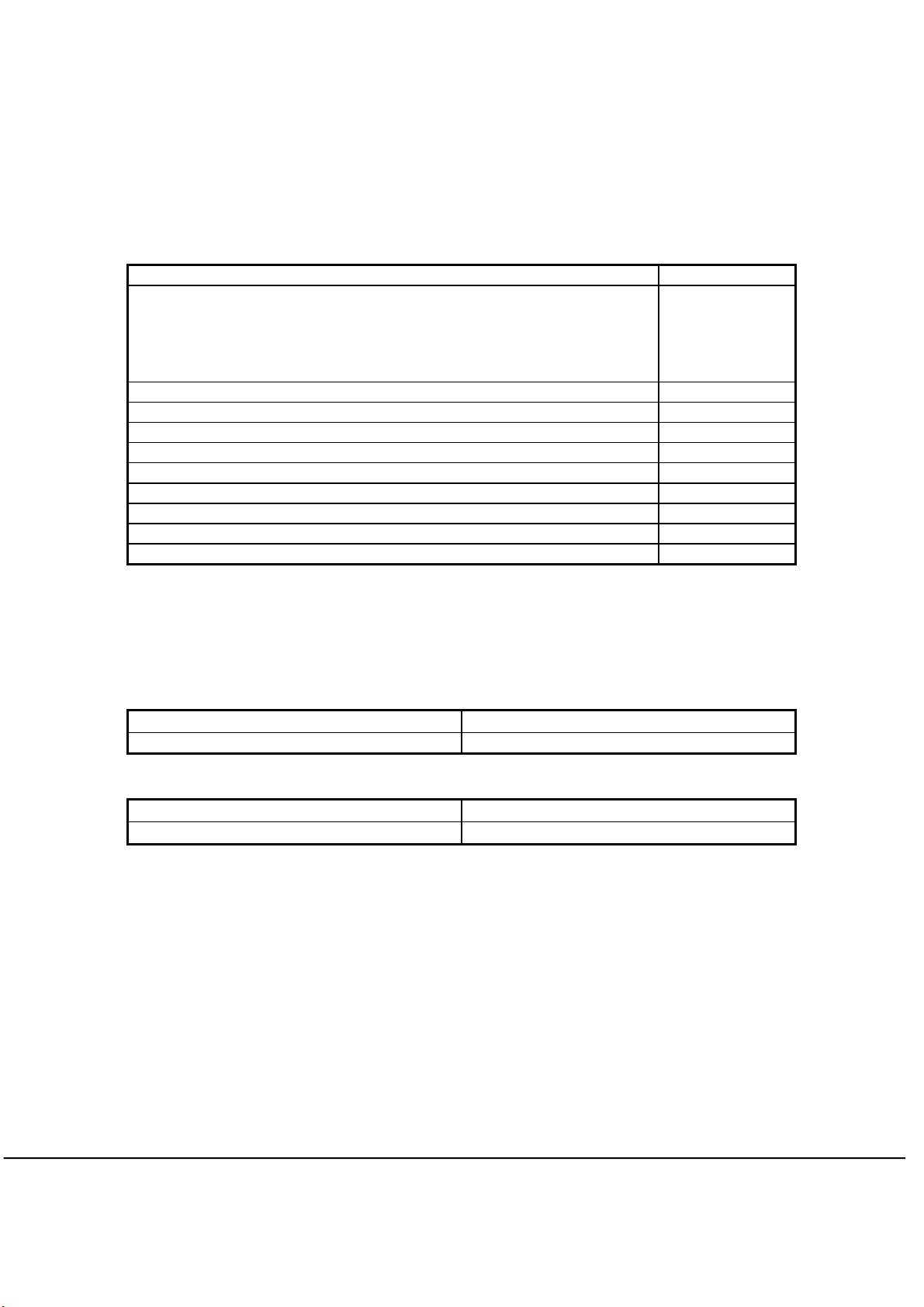

Revision History

Product Revision History

Specification Software

Rev Date Ver Date

A 12/6/00 Initial Draft JE

B 12/20/00 1.1 Added Network Description JE

3.2.4 Added Make and Break data for MUTE

3.3.2 Revised ID Setup

3.3.3 Revised RF Channel Change

4 Added table on RF Transmission

5 Added Hardware Interface Table

6.1.2 Revised RF Channel Frequency table and added frequency control

6 Revised UEI key Data Packet information

6.1.6 Added Serial Input Timing Diagram

7.4 Added Battery life information and table

C 01/12/01 1.0 Changed Part Number reflect SOP package JE

6.2 Changed Varapoint Data to reflect the Data in section 6.0

D 02/05/01 ALL

E 02/13/01 1.1

Rev1.0 Kicked-off Specification JE

Rev 1.1 1.1

Sect.

3.3.2,

3.2.4,

3.2.5

3.1.1

3.1.2

3.1.3

3.2.4

3.3.1

3.3.2

3.3.3

3.3.5

6

7.4

8.6

3.2.1/2

3.2.4

3.3

3.3.1

3.3.3

3.3.5

3.3.9

4

6

7.4

10.1

Update Description By

information.

Per new NMB Specification and Bill Browns Comments

Programming Instructions per Anthony’s request

Added these sections per Anthony’s request.

Updated IC package and part number, added comment on polydome keys.

Updated IC Package Type

Referenced spec section for Mfg. Reset, SETUP, and Stuck Key

Time-out, removed visible LED for SW only to No visible LED

Changed from double sided PCB to single sided PCB and added

comment on Gold Flash required for Varapoint

Revised Key chart to match actual key labels.

Revised Stuck Key Time-out and added diagram for STUCK KEY

data packet to be sent out to HOST and added diagram for IDLE

MODE (SLEEP) data packet to be sent out to HOST

Revised ID Setup

Revised RF SETUP procedure

Added Factory Test mode for RF Channel Test

Added comment on packet data to be sent two times for all key

presses to end of this section.

Revised Battery Life Section per Bill Brown

Added Color and Printing specification

Revised IC from DIE package to QFP

Changed Target Device from TV to Viewsonic

Updated Key Table

Updated Definitions in regards to LED blinking methodology

Updated Stuck Key, sleep and Keep alive information and appendix

Updated RF Channel Change section

Updated Factory Test

Updated Low Battery section for the 6volt design

Changed data rate from max. 19.2 bps to fixed 9600 bps

Updated Data Packet and Pointing device information

Added statement on the each key press is calculates @ 1 second

Changed Low non operating range from –20 C to -10C

JE

JE

JE

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 3 of 63

Page 4

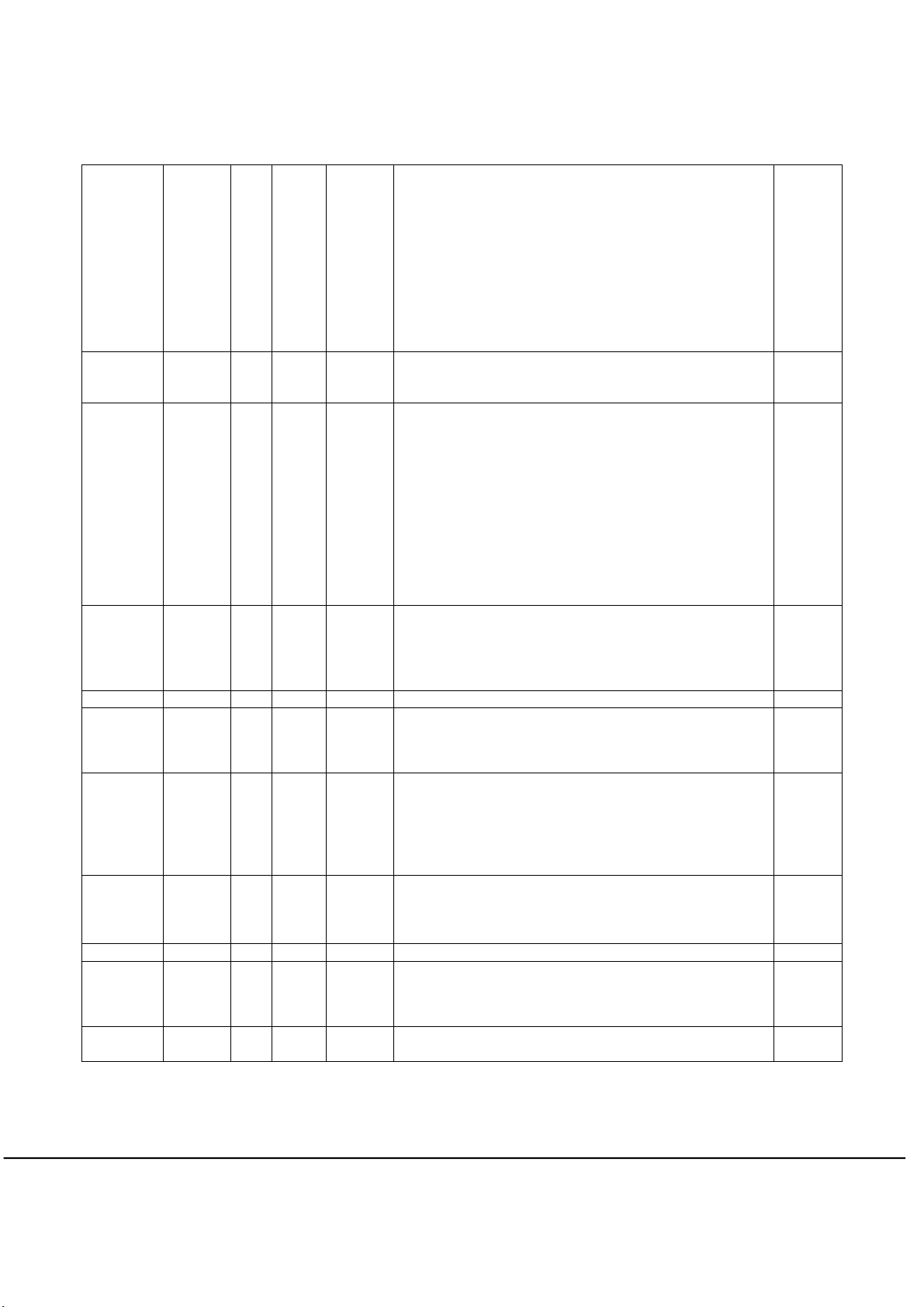

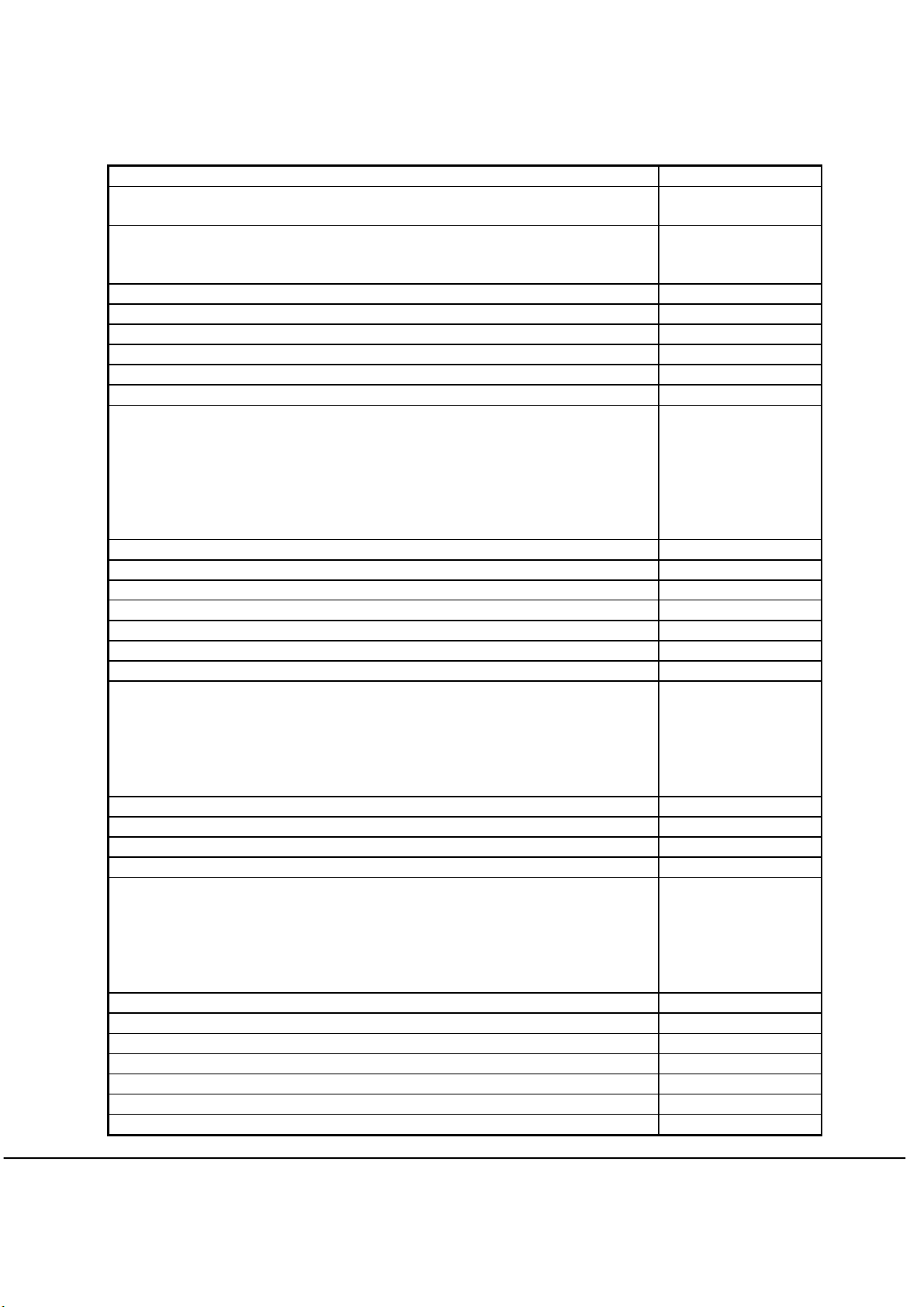

Rev 2.0 3.1.1

3.3

3.1.3

3.1.4

3.1.5

3.4

1.1, 4,

6.1.1

4.1

Rev 2.1 5.1.1

5.1.2

5.1.3

2.2 2.1.1

3.1.5

3.1.6

10.2

2.3 3.4 &

3.4.7.1

3.4.6.1

5.1.2

2.4 5.1.2 Revised RF Channel Data to match the transmission table JE

2.5 7.6

11

3.2.4,

3.4.6.2

2.6 3.4

3.4.3

3.4.5

4.12

2.7 3.2.4,

3.4.6.2,

7.6

11

2.8 11 Updated Rendering with new Vara-touch pointer JE

2.9 3.2.4,

3.4.6.2

3.4

2.91 1.1

4.9

Changed IC package to QFP (from DIE)

Changed MUTE to RESYN in “Conventions and Notations”

Changed PCB material from FR4 to Paper Phenolic

Item 14- Added URC number

Item 3- No FCC testing by UEI

Revised “Remote UEI Key and Pointing Device Data Packet”

Changed RF Operating Band range to 2446.7 – 2464.3MHz

4

Table 2, Rqmt No. 4.10 – Changed to “Simplex”

Added Manchester Data Coding table

Revised RF Channel and Operating Bands

Revised RF Channels and Frequencies

Added Pulse Width Timing section

Added comment that NMB receiver Spec 0.9 takes precedence

Modified item 3 to state FCC certification will be done by Optoma

with UEI for support only.

Item 1 (Batteries Included) has been changed from No to Yes-Bulk

Item 2 (Batter Cover) Rating Label required has been changed from

No to yes installed in specified area.

Item 10 Device Label in addition to packaging changed from Yes

to Installed on Unit

Changed FCC requirement to read as follows “Optoma will certify

the complete unit with remote and keyboard.

With documentation and possible engineering support to Optoma

from UEI.

Added provision to allow for using the varapoint mouse and the left

and Right select keys simultaneously

Add notes on power state for entering Factory Test modes and E2

Revised RF Channels and Frequencies

Updated Color Specification Chart

Imported revised rendering dated 8/15/01 Style A rev 3.0

Updated Key charts for Smart and Enter Key

Added Definition for Mouse Right and Left while used in conjunction

with the mouse

Updated Device Number Setup definition

Updated E2 Initializtion Definition

Changed power source from 2.2VDC to 2.2VDC

Updated key-tables to reflect silk-screening changes

Updated Rendering imported with silk-screening changes

Added Break Data ‘F6’ for the Sync Key

Added Break Data ‘F6’ for the Sync Key

Revised Comment in Re-Sync Section in regards to no Break-Code

being sent after the Re-Sync key was released.

Corrected Frequency

Output power is –18dbm

Lee

JE

JE

JE

JE

JE

JE

JE

RM

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 4 of 63

Page 5

Approvals:

Jerry Bardin

VP, Engineering (UEI)

Steve Gates

Sr.Director of Production Engineering

Development (UEI)

Ken Sweeney

Director of OEM Sales-West (UEI)

Huyen Phan

Manager, SQA (UEI)

Jay Conway

Director, Library Technology (UEI)

Anthony Phan,

Manager, Software

Jason Etter

Sales Applications Engineering (UEI)

Date: Jakob Kishon

Viewsonic

Date: Dave Schafer

D2M

Date: Mike Zapka

ViewSonic

Date: Rich Acosta

NMB RF Receiver Group

Date: John Gou

Manager/NMB RF Receiver

Group

Date:

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 5 of 63

Page 6

Table of Contents

Product Revision History ...........................................................................................................................................................................3

1 Purpose and Scope .....................................................................................................................................................................8

1.1 Description.................................................................................................................................. 8

1.2 Project Type ................................................................................................................................8

2 Applicable Documents ..............................................................................................................................................................8

2.1 Project Documentation ........................................................................................................... 8

2.1.1 Customer Specification ............................................................................................... 9

2.1.2 Other Product Documentation ................................................................................. 9

2.2 UEI Standard Documentation

2.2.1 UEI Standard Glossary.................................................................................................. 9

2.2.2 UEI Standard Hardware General Information .................................................... 9

2.2.3 UEI Standard Operational Features Descriptions ............................................ 9

2.2.4 UEI Standard Testing Procedures............................................................................ 9

3 Functional Requirements ....................................................................................................................................................... 9

3.1 Product Summary..................................................................................................................... 9

3.1.1 General Information ...................................................................................................... 9

3.1.2 Software Information.................................................................................................... 9

3.1.3 Hardware Information .................................................................................................11

3.1.4 Mechanical Information .............................................................................................12

3.1.5 Quality/ Testing Information

3.1.6 Miscellaneous Information ........................................................................................13

3.2 Product Library.........................................................................................................................13

3.2.1 Target Device Mode Mapping ...................................................................................13

3.2.2 Defaults..............................................................................................................................13

3.2.3 Library Upgrade Support ............................................................................................13

3.2.4 Key Table .............................................................................................................................14

3.3 Operational Features......................................................................................................................15

3.4 Remote UEI Key and Pointing Device Data Packet......................................................................16

3.4.1 Definitions ............................................................................................................................20

3.4.2 Time Event / Data Packet Transmission Diagram............................................................23

Some notations used in the Time Event / Data Packet Diagram .....................................................27

Notation 27

Function Description...........................................................................................................................27

Make ........................................................................................................................................................................................................... 27

3.4.3 Device Number Setup..........................................................................................................28

3.4.4 RF Channel Change ............................................................................................................29

3.4.5 E2 Initialization....................................................................................................................31

3.4.6 Factory Test Mode(s)...........................................................................................................32

3.4.7 Key Test (Also used in Factory Test for Key): ..................................................................33

3.4.8 Low Battery Indicator .........................................................................................................38

4 RF Transmission General Specification ....................................................................................................................................... 39

4.1 Data Coding...................................................................................................................................40

5 Hardware Interface.........................................................................................................................................................................41

5.1 Transmitter Outline /Interface .......................................................................................................41

5.1 Product Performance Requirements ..............................................................................................43

5.1.1 RF CHANNEL and OPERATING BANDS ......................................................................43

5.1.2 RF Channels and Frequencies ............................................................................................43

5.1.3 RF Channel Operation Range ............................................................................................44

5.1.4 RF Modulation Scheme and Modulation Level ................................................................44

5.1.5 Maximum Bit Rate ..............................................................................................................44

5.1.6 RF Power Management.......................................................................................................44

• T2 = Frequency Stable Time. Typically, it should be T2 > 20ms ............................................44

5.1.7 Transmitter Data Input Level ............................................................................................44

The transmitter data input level should be fixed as the supply voltage drops when using battery.

It is required that the Input level will be Vp-p = 100mv (+/- 10%).................................................44

.............................................................................................. 9

...................................................................................12

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 6 of 63

Page 7

5.1.8 Communication Link...........................................................................................................44

6 Electrical Requirements .................................................................................................................................................................46

6.1 Power.............................................................................................................................................46

6.2 Visible LEDs .................................................................................................................................46

NA .............................................................................................................................................................46

6.3 Transmission IC.............................................................................................................................46

6.4 Battery Life....................................................................................................................................46

6.5 Range.............................................................................................................................................46

7 Mechanical Requirements.............................................................................................................................................................. 47

7.1.1 HRC Assembly.....................................................................................................................47

7.1.2 Assembly LED’s...................................................................................................................47

7.2 Enclosure.......................................................................................................................................47

7.2.1 Enclosure and Battery Cover Shape ..................................................................................47

7.2.2 Material ................................................................................................................................47

7.2.3 Texture..................................................................................................................................48

7.2.4 Color .....................................................................................................................................48

7.3 Keypad with Polydome .................................................................................................................48

7.3.1 Material ................................................................................................................................48

7.3.2 Tactile Feel ...........................................................................................................................48

7.3.3 Force Vs. Travel...................................................................................................................49

7.3.4 Life ........................................................................................................................................50

7.3.5 Keypad Pull-out Force ........................................................................................................50

7.3.6 Key stick and key stuck.......................................................................................................50

7.4 PCB Material .................................................................................................................................50

7.5 Battery Compartment ....................................................................................................................50

7.6 Printing ..........................................................................................................................................50

7.7 Labeling.........................................................................................................................................52

7.7.1 Date Code .............................................................................................................................52

7.7.2 Part Number Label..............................................................................................................52

7.7.3 Country of Origin ................................................................................................................52

8 QUALITY ........................................................................................................................................................................................ 53

8.1 Appearance....................................................................................................................................53

8.2 Cosmetic........................................................................................................................................53

8.2.1 Evaluation Criteria..............................................................................................................53

8.2.2 Definition of Flaw and Defect .............................................................................................54

8.2.3 Definition of Classes ............................................................................................................54

8.2.4 Cosmetic Evaluation............................................................................................................55

8.3 Durability Testing..........................................................................................................................56

8.3.1 Structure and Strength........................................................................................................56

8.3.2 Printing.................................................................................................................................56

8.3.3 Battery Contact....................................................................................................................57

8.3.4 Painting wear test (if necessary) .........................................................................................57

8.3.5 Rubber coating wear test (if necessary) .............................................................................57

8.3.6 Epoxy key test ......................................................................................................................57

9 ENVIRONMENTAL & SHOCK REQUIREMENTS ................................................................................................................59

9.1 Temperature...................................................................................................................................59

9.2 Humidity Test................................................................................................................................59

9.3 Low Temperature Test...................................................................................................................59

9.4 High Temperature Test..................................................................................................................59

9.5 Thermal Shock...............................................................................................................................60

9.6 Drop Test .......................................................................................................................................60

9.7 Solvent Resistance.........................................................................................................................61

9.8 Liquid Spill....................................................................................................................................61

10 Standard Compliances...............................................................................................................................................................62

10.1 ESD Protection ..............................................................................................................................62

10.2 FCC ...............................................................................................................................................62

11 Rendering.................................................................................................................................................................................... 63

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 7 of 63

Page 8

Purpose and Scope

1.1 Description

The Viewsonic-Tweety remote will be a dedicated 2.4 gHz RF remote with 10 channel capability.

This will be a 6V product and will use 4 AAA batteries. It will use a Samsung 16K

(S3P/C80F9XFE-QZR5) (QFP) Micro-controller.

Network Description:

The RF modules support up to 10 channels in the ISM band of 2446.7MHz to 2464.3MHz,

providing a form of frequency division multiple access (FDMA). This enables the simple

implementation of systems requiring multiple devices to be operating continuously and

concurrently.

Note: This document contains all functional specifications and testing/quality requirements

that UEI will perform. By signing off on this document, the customer agrees that these

product/project parameters are final. Any further revisions will be accompanied by

Engineering Change Request and appropriate authorizations.

Features

Samsung 16K(QFP)

•

E2 (128 byte) –To save RF Channel Data and Device ID

•

34 keys

•

6V product (4 AAA)

•

Varapoint

•

W-Link 2.4 gHz RF transmitter

•

Slide Door

•

Poly Dome Keys

•

1.2 Project Type

OEM-West

2 Applicable Documents

Appendix A: NMB/UEI Remote Devices and Receiver Module Rev. 0.1

Appendix B: NMB RF-Receiver (UART) and HOST (Image Processor)

2.1 Project Documentation

The following documents of exact issue and date form part of this specification:

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 8 of 63

Page 9

2.1.1 Customer Specification

NMB RF-Receiver and Host Image Processor rev 0.9

(This spec takes precedence a changes to the receiver software must also be made to

the remote and keyboard)

2.1.2 Other Product Documentation

N/A

2.2 UEI Standard Documentation

UEI SPEC 0020, UEI SPEC HE003, UEI SPEC 0002

2.2.1 UEI Standard Glossary

N/A

2.2.2 UEI Standard Hardware General Information

Refer to Section 3.1.3

2.2.3 UEI Standard Operational Features Descriptions

2.2.4 UEI Standard Testing Procedures

Refer to Section 6.0, Section 7.0 and Section 9.0.

3 Functional Requirements

3.1 Product Summary

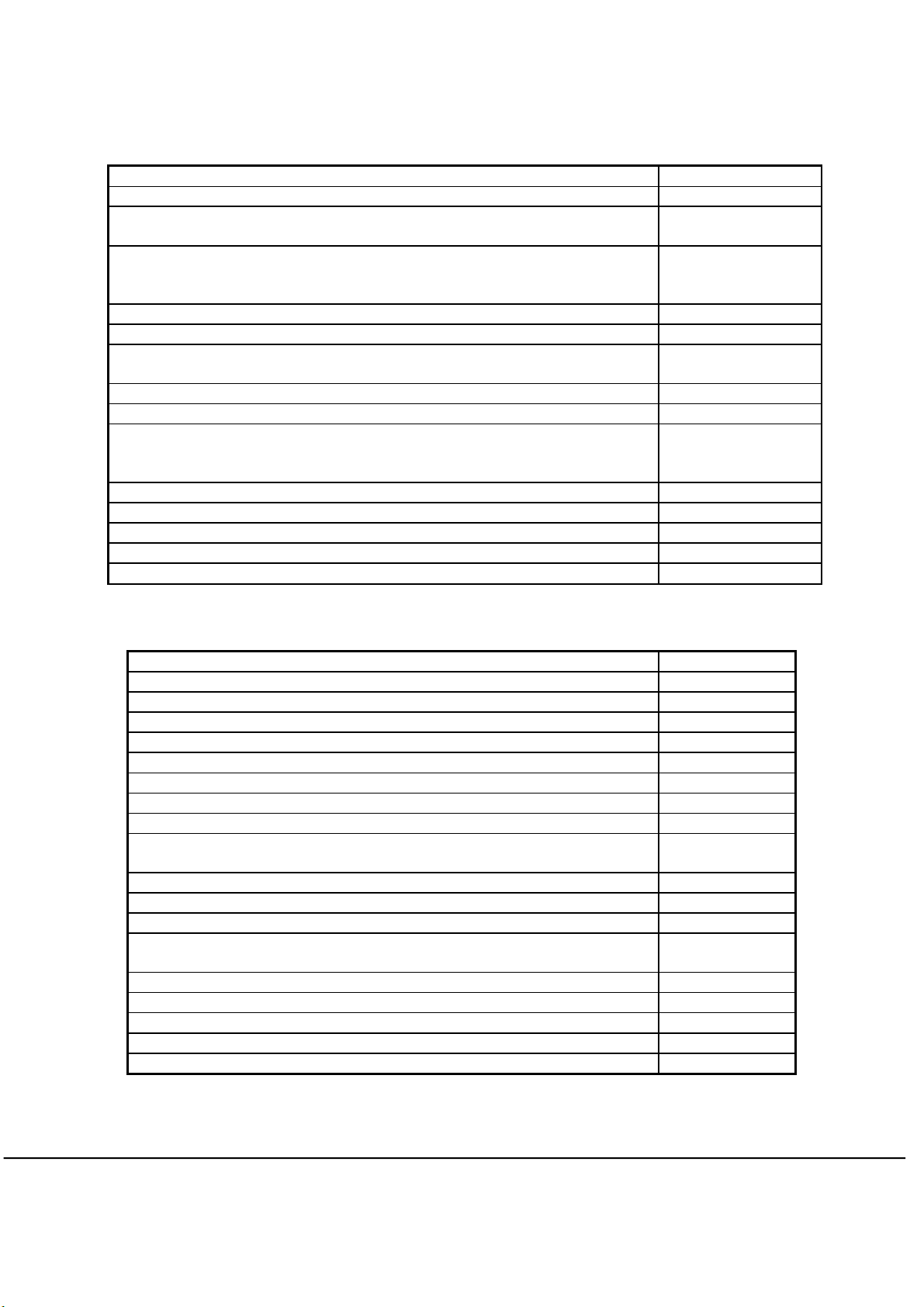

3.1.1 General Information

Functional Keychart Included Yes

IC Type and size and package type Samsung (16K)

(QFP)

Keypad Parameters Specified Yes

Mode Indicator LEDs No

Multiple Devices (Jumpers) No

OTPs Used for initial Production Yes

Product Development Type:

OFA, OEM, Private Label, Cable, Chip Only

Request Load Included NA

Upgradeable Product (E2) NA

3.1.2 Software Information

Channel Scan No

Channel +/- Simulation w/Lock Option No

OEM-West

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 9 of 63

Page 10

Channel Lock No

Device Mode Keys

DEDICATED

Dual Functional via Shift Key

a) One Time Use

b) Shift Lock w/Time-Out

No

No

E2 Auto-Sizing No

E2 Device Mode Lock No

E2 Upgradeable via Modem (997) No

E2 Upgradeable via 6 pin interface No

Factory Test Mode Yes

Favorite Channel Scan (996) No

Functional Keys – Additional

a) brightness Control

b) Color Control

c) Menu

d) Shifted Functions With/without time-outs

e) Teletext – Simple

f) Teletext – Fastext

No

No

No

No

No

No

Functional Keys – Standard Yes

Hidden Keys No

High Frequency Capable No

ID Code Verification No

ID Default Selection No

ID Lock/Unlock for Specific Mode No

ID – Number of Digits NA

ID Offset

a) Constant number offset to all Ids

b) Offset by Hardware setting (Jumper,....)

c) Custom renumbering to some or all Ids

None

None

None

Illuminated Key Pad No

Keymover (994) – Full with Synthesizer No

Liquid Crystal Display (LCD) No

Low Voltage Detection – Software Yes

Macros

a) Hard Coded

b) Premium Channel

c) User Defined

1) Single

2) Multi-level Rotating

No

No

No

No

Mode Reassignment (992) No

Modem No

Network Downloading No

Power On Mode Key No

Power Toggle No

Power Up w/Default Device Mode and Codes No

Power Up w/ No Defaults No

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 10 of 63

Page 11

Punch Through to Last Device (by Key Group) No

Record Safety No

Remote Finder with Lock Option No

Reset to Defaults

a) Operational Reset (980)

b) Manufacturing Reset (981) Section 3.3.4

Set Up Section 3.3.2 Custom

Simultaneous Double Key Press - Standard Action No

Simultaneous Double Key Press - Alternative Action No

Sleep Feature via UEI w/Lock Option No

Step and Set (991) No

Stuck key Time-Out Custom

Keypress = 60 sec.

Pointer = 120 sec.

Synthesizer No

Visible LED - for user feedback No

Visible LED - for mode indication No

Volume Lock No

No

No

Custom

3.1.3 Hardware Information

1. Crystal IR Carrier Operation No

2. Keyboard Layout and # of keys 34

3. LCD (Segmented, Pixel), Backlight (LED, EL) None

4. IR LEDs (1,2) (W,WW,WN) [Wide, Narrow] NA

5. Lighted Keypad (LED, EL), Color No

6. Low Voltage Detection (Software Controlled) Yes

7. Mode Indicator LEDs No

8. Modem No

9. PCB Material (Paper phenolic, FR4), Other Paper Phenolic

10. PCB Type (Single Sided, Double Sided, Silver thru holes, etc.)

11. Gold Flash

12. Plush Port No

13. Plush Port Opening No

14. RAM Retention NA

15. RF Operation Yes

16. RF Finder No

17. Visible LEDs for user feedback (2, 3, 5 mm) (Red, Green) No

18. 3 or 6 Volt Operation (AAA,AA) –4AAA 6V (4 AAA)

19. 6 pin E2 Interface No

20. Other (describe) N/A

Single Sided

Yes-Varapoint

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 11 of 63

Page 12

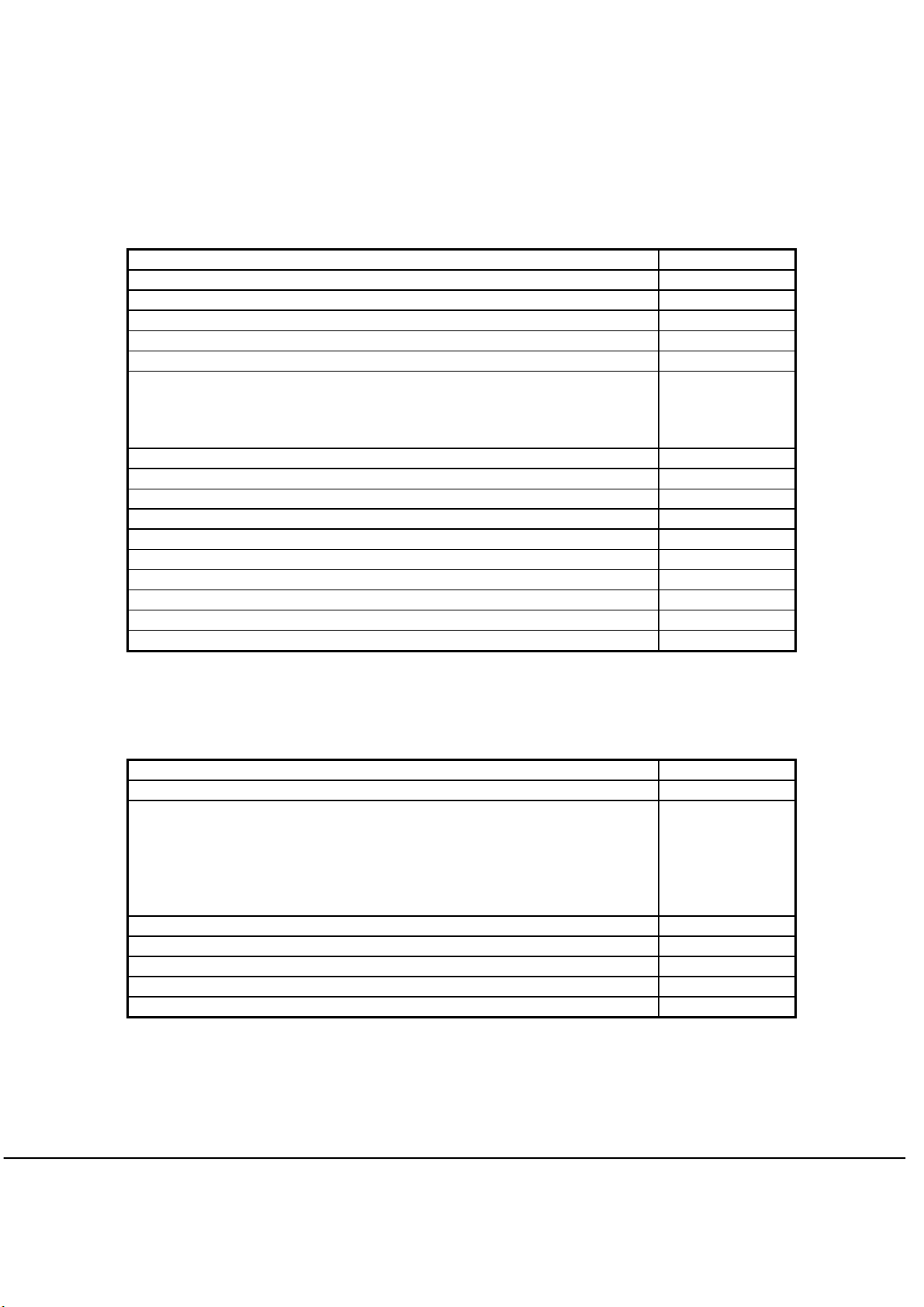

3.1.4 Mechanical Information

1. Battery Compartment Yes

2. Colors & Labels Section 8.2.4

3. Force versus Travel (Keypad with Polydome) Section 8.3.3

4. IR Lens No

5. Key Clearance Section

6. Keypad Definition Yes

7. List of Consigned Parts Microcontroller

EEprom

RF Transmitter

Varapoint

8. Material Section

9. Overlay No

10. Packaging Requirements in BOM Bulk

11. Plastic Case design or rendering included Yes

12. Prototype/Model Yes

13. Sliding Door Yes

14. Unique Parts No

15. URC with B00# 4012B00

16. Weight TBD

17. Other (describe) Viewsonic Jewel

3.1.5 Quality/ Testing Information

1. Environmental Testing Yes

2. ESD Protection Yes

3. FCC or UL Certification Requirements No- Optoma to

apply for

certification UEI

will supply

support.

4. Production Line Testing Procedures Yes

5. Quality Assurance Provisions UEI Standard

6. Reliability Testing Yes

7. SIO Test Verification No

8. Other (describe) N/A

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 12 of 63

Page 13

3.1.6 Miscellaneous Information

1. Batteries (Included) Yes-Bulk

2. Battery Cover

a) Rating label silk screened on outside of battery door

3. Customer Service Support Required No

4. Date Code Label Yes

5. Labeling Yes

6. Packaging Yes-Bulk

7. Units per Box – shipping 100

8. Users Manual Development (Type: staples/folded map) NA

9. User Manual Type Responsibility Customer

10. Device Label- inside addition to package Installed on unit

11. Country of Origin Location: Molded, Label, Silkscreened On Rating Label

Yes, label to be

installed in

specified area

3.2 Product Library

This will be a dedicated remote.

3.2.1 Target Device Mode Mapping

Mode Load/ Device Assignment

Viewsonic Dedicated

3.2.2 Defaults

Mode/Feature Default State

Viewsonic RF Channel 1

3.2.3 Library Upgrade Support

N/A

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 13 of 63

Page 14

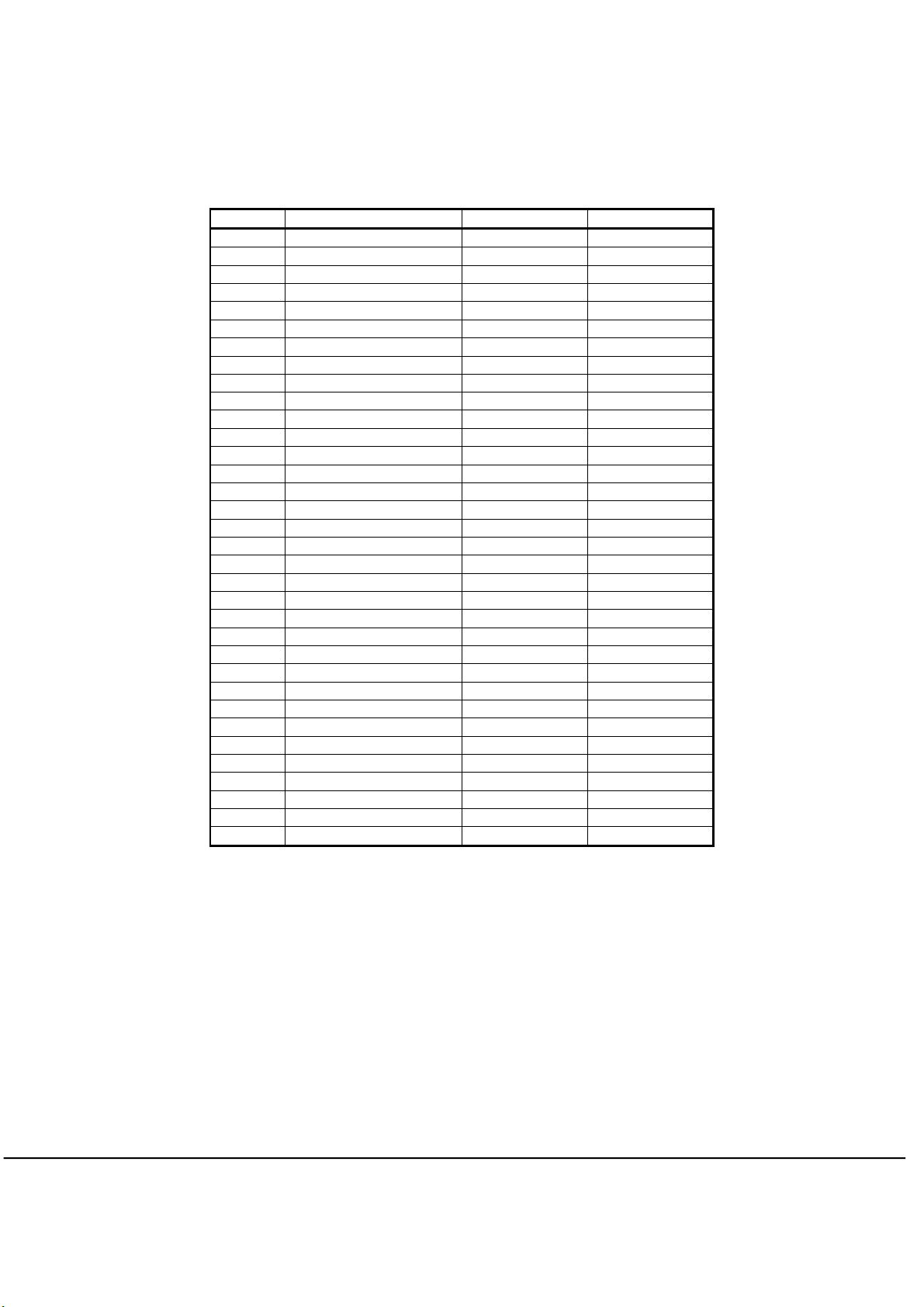

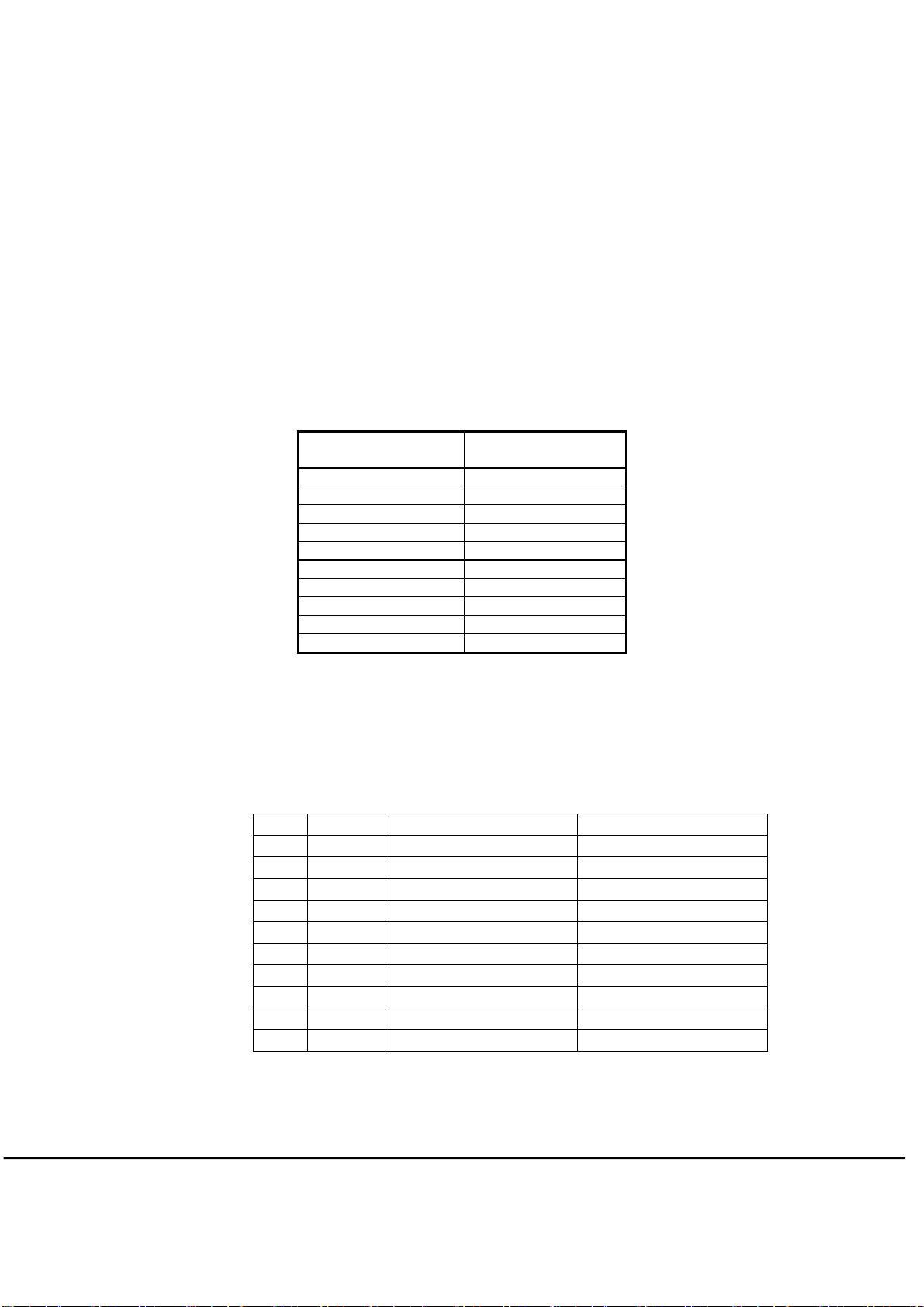

3.2.4 Key Table

Key # Key Label Make Code Break Code

1 POWER 75 F5

2 VL+ 74 F4

3 VL- 73 F3

4 MUTE 6B EB

5 CH+ 6F EF

6 CH- 70 F0

7 PREVIOUS 6D ED

8 MENU/EXIT 6E EE

9 PIP 6C EC

10 ENTER * *

11 SMART * *

12 REVERSE 57 D7

13 PLAY 58 D8

14 FFD 59 D9

15 RECORD 5A DA

16 STOP 5B DB

17 PAUSE 5C DC

18 INSTANT REPLAY 5D DD

19 JUMP COMM 5E DE

20 JUMP PRESENT 5F DF

21 EPG 60 E0

22 +100 61 E1

23 MULTIVIEW 62 E2

24 1 13 93

25 2 14 94

26 3 15 95

27 4 16 96

28 5 17 97

29 6 18 98

30 7 19 99

31 8 1A 9A

32 9 1B 9B

33 0 1C 9C

34 RE-SYNC 76 F6

* SET and Reset in Pointing Device Data Packet

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 14 of 63

Page 15

3.3 Operational Features

Conventions and Notations

The operation of the remote control and the programming sequence use the following

shorthand notations.

The relational operator <<>> around a key is an instruction to press and hold the key for 3

seconds.

For example:

<<RESYNC + CH+ >>

Press RESYNC and hold for 3 seconds

The relational operator <> around a key is an instruction to press the key and then release.

For example:

<RESYNC>

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 15 of 63

Page 16

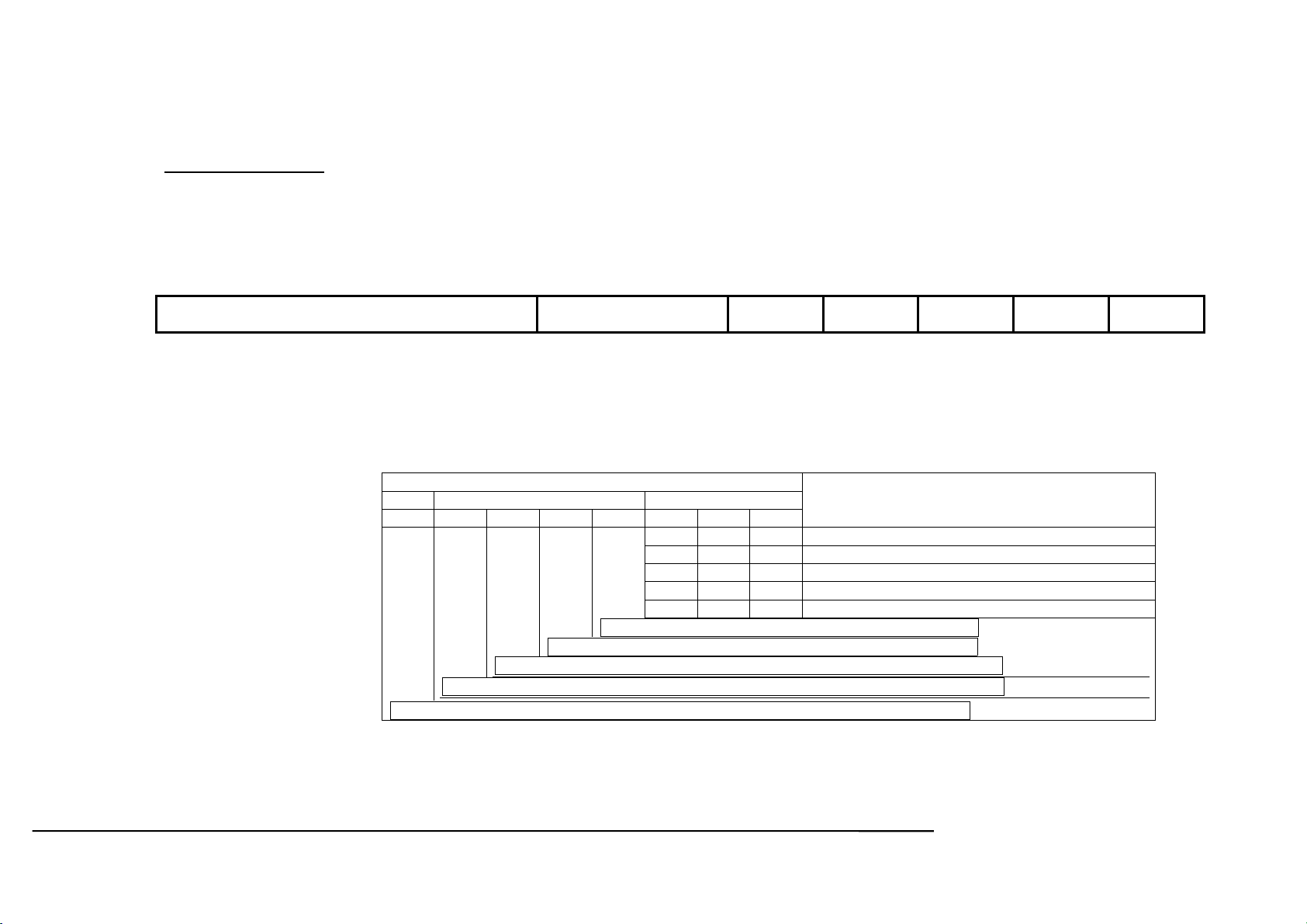

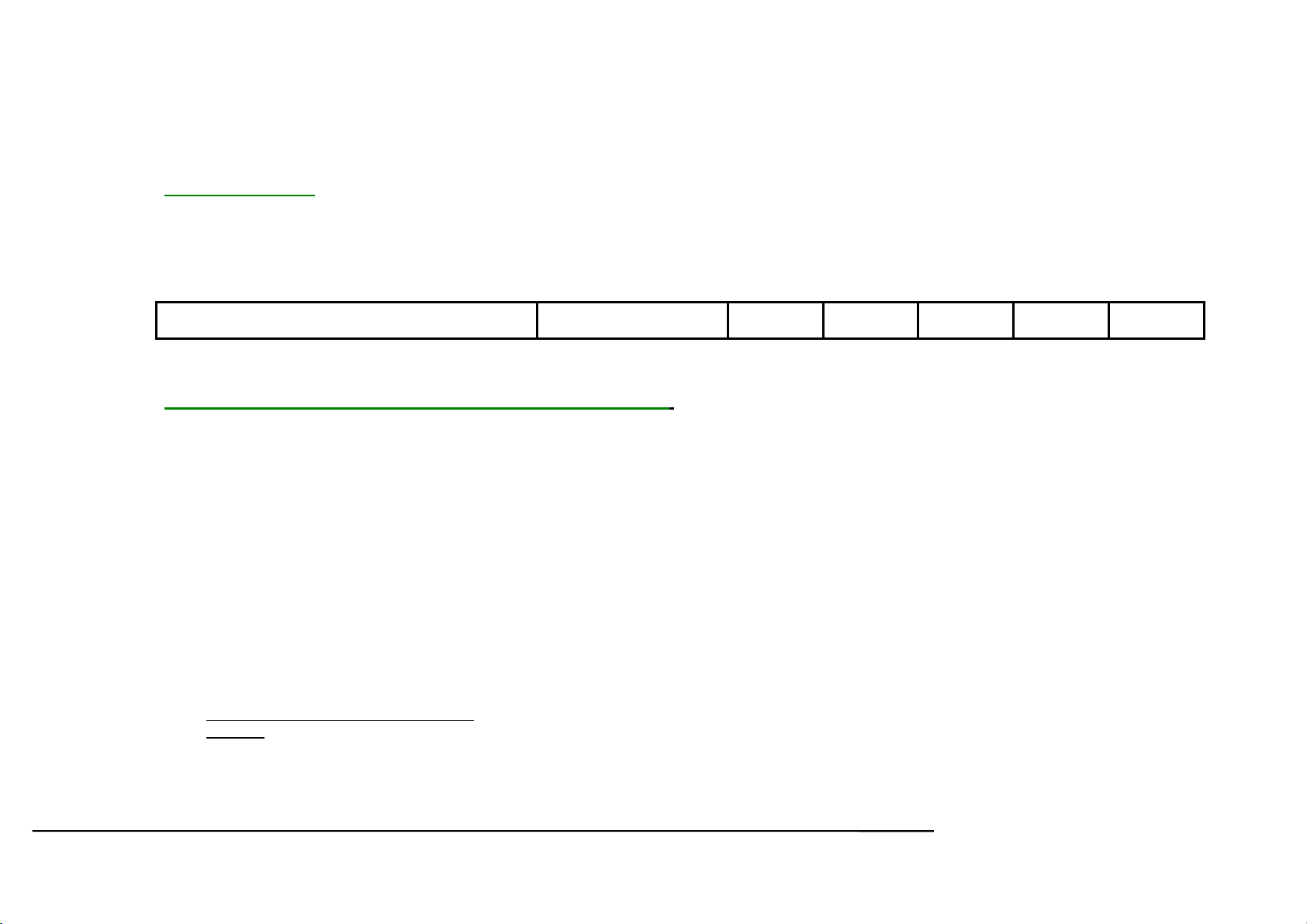

3.4 Remote UEI Key and Pointing Device Data Packet

Data Packet Definition

Byte10 Byte09 Byte08 Byte07 Byte06 Byte05 Byte04 Byte03 Byte02 Byte01 Byte0

(MSB)

0x0F

Sync Bytes: Four data bytes of 0x0F each are used to stabilize the demodulation of the Receiver side after a period of no

signal input.

Preamble: Two data bytes of 0x55 each are used for decoder bit sync.

Device Number: Device number from 0 to 99 (decimal)

Device Address / Status:

X-Coordinate: Keyboard Data (0), X-Data for Pointing Device.

Y-Coordinate / Scan Code:

:

0x0F

Sync Bytes

0x0F

0x0F

0x55

Preamble

0x55

0-0x63

(0-99

decimal)

Device

Number

(LSB)

Dev Addr /

Status

X Coord

Y Coord /

ScanCode

32 bits 16 bits 8 bits 8 bits 8 bits 8 bits 8 bits

Device Address / Status

Batt Pointing Device Status Device Address

Described Function

b7 b6 b5 b4 b3 b2 b1 b0

0 0 0 RF Receiver

0 0 1 NMB Keyboard Keypad

0 1 0 UEI Remote Control Keypad

0 1 1 NMB Keyboard Pointing Device

1 0 0 UEI Remote Control Pointing Device

Pointing Device Left Button Status (0=Up, 1=Down)

Pointing Device Right Button Status (0=Up, 1=Down)

X-Coordinate sign bit (0=Positive, 1=Negative)

Y-Coordinate sign bit (0=Positive, 1=Negative)

Battery power level Status (0=Ok, 1=Low)

Keyboard Data: Scan Code (Make/Break) [See Table 3: Scan Code Table], Y-Data for Pointing Device.

CheckSum

Viewsonic Tweety RF Remote

Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 16 of 63

Page 17

CheckSum: The sum of Device Number + Device Address / Status + X-Coordinate + Y-Coordinate/Scan Code.

(Add all the indicated bytes without carry’s).

LEFT/RIGHT MOUSE key Operation

1. When the

This bit will be set as long as the <Left> key is held down, and it will be reset (or cleared) when the <Left> key is released.

1.1. While the <Left> key is held down:

a) If the Pointing Device is not active, the transmitted data packet will have Left key status bit in the Device Address / Status Byte

set and the X-Coordinate Byte and Y-Coordinate / Scan Code Byte contained all zeros.

b) If the Pointing Device is

and the X-Coordinate Byte and Y-Coordinate / Scan Code Byte contained the X and Y positional values of the Pointer movement.

1.2. While the <Left> key is pressed and held down, if another key (other than <Right> key) is now pressed, the pointing device Left key

status bit in the Device Address / Status Byte will be reset.

a) If the Pointing Device is not active, no data packet will be transmitted. Both keys must be released for the remote to return to its

normal operation

b) If the Pointing Device is active prior to the key presses as described in 1.2 above, the transmitted data packet will have Left key

status bit in the Device Address / Status Byte reset and the X-Coordinate Byte and Y-Coordinate / Scan Code Byte contained the

X and Y positional values of the Pointer movement.

2. When the <Right> key is pressed, its corresponding pointing device right key status (Bit 4) in the Device Address / Status Byte will be set.

This bit will be set as long as the <Right> key is held down, and it will be reset (or cleared) when the <Right> key is released.

2.1. While the

a) If the Pointing Device is not active, the transmitted data packet will have Right key status bit in the Device Address / Status Byte

set and the X-Coordinate Byte and Y-Coordinate / Scan Code Byte contained all zeros.

b) If the Pointing Device is active, the transmitted data packet will have Right key status bit in the Device Address / Status Byte set

and the X-Coordinate Byte and Y-Coordinate / Scan Code Byte contained the X and Y positional values of the Pointer movement.

2.2. While the

status bit in the Device Address / Status Byte will be reset.

key is pressed, its corresponding pointing device left key status (Bit 3) in the Device Address / Status Byte will be set.

<Left>

, the transmitted data packet will have Left key status bit in the Device Address / Status Byte

active

<Right>

<Right>

key is held down:

key is pressed and held down, if another key (other than

key) is now pressed, the pointing device Right key

<Left>

set

Viewsonic Tweety RF Remote

Universal Electronics Inc. Confidential Page 17 of 63

Rev 2.9A November 05, 2001

Page 18

a) If the Pointing Device is not active, no data packet will be transmitted. Both keys must be released for the remote to return to its

normal operation

b) If the Pointing Device is

active

prior to the key presses as described in 2.2 above, the transmitted data packet will have Right key

status bit in the Device Address / Status Byte reset and the X-Coordinate Byte and Y-Coordinate / Scan Code Byte contained the

X and Y positional values of the Pointer movement.

3. When

<Left>

and

<Right>

) keys are both being held down (with one key is pressed before the other), the corresponding pointing device

left key status (Bit 3) and right key status (Bit 4) in the Device Address / Status Byte will both be set. These bits will be set as long as

the <Left> and <Right> keys are held down. If any one of these two keys is released first, its corresponding status bit will be reset while

the corresponding status bit of remaining key remains set. Both bits will be reset (or cleared) when both keys are released. During this

time, if the Pointing Device is not active, the X-Coordinate Byte and Y-Coordinate / Scan Code Byte will be all zeros in the transmitted data

packet.

: It is up to the Host application software to make use of the case where both left and right key status bits in the Device Address /

Note

Status Byte are set. This condition would indicate that both <Left> and <Right> keys are currently being pressed and held down.

4. When the Pointing Device is active and one (or both) of <Left> (or <Right>) key is pressed, the X-Coordinate Byte and Y-Coordinate /

Scan Code Byte will be updated with the X and Y value of their corresponding positional movements. The transmitted data packet will

have the corresponding Left (or Right) key status bit in the Device Address / Status Byte set or reset accordingly.

Note

:

If both keys <Left> and <Right> are pressed at the same time, this would be considered as invalid (simultaneously key press). There will be

no data packet sent out in this case.

Viewsonic Tweety RF Remote

Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 18 of 63

Page 19

Re-Sync Data Packet

Byte10 Byte09 Byte08 Byte07 Byte06 Byte05 Byte04 Byte03 Byte02 Byte01 Byte0

0x00

Dev Addr /

Status

X Coord

0x76

Y Coord /

ScanCode

(LSB)

0xYY

CheckSum

(MSB)

0x0F

0x0F

Sync Bytes

0x0F

0x0F

0x55

Preamble

0x55

0-0x63

(0-99

decimal)

Device

Number

32 bits 16 bits 8 bits 8 bits 8 bits 8 bits 8 bits

How does the Re-Sync operates and When the “Re-Sync” code is sent:

Activating the <Re-Sync> key allows the user to send the “signature data” and to synchronize the RF Transmitter and Receiver RF-channel.

To activate the Re-Sync function:

Press <Re-Sync> key first.

While <Re-Sync> key is held down, press a digit key <d> where d is any digit keys from 1, 2, 3, …, 8, 9, 0 representing RF-channel 1,

2, 3, …, 8, 9, 10 respectively.

The process can pictorially be represented as below:

{{ <Re-Sync> + <d> }} <d>

is <Digit> Key for Digit 1, 2, 3, …, 9, 0

Press/Release <d> key, while <Re-Sync> key is held down. The system first sets up “d” RF-channel for RF Transmitter (digit number

corresponding to channel 1 through 10), it then sends out the “Re-Sync” Make code data packet, minimum of 10 or more, as long as key still held

down.

If the <Re-Sync> and <d> keys are both

released

If another <Digit> key is

pressed/released while the <Re-Sync>

key is still held down

The “Sleep” code data packet will be sent when no key activities are detected after 5 seconds (Refer to

Sleep Code transmission section for details).

The system will setup another RF-channel, corresponding to that digit key, for the Transmitter, it then

sends out another “Re-Sync” Make code data packet in that RF channel setting.

This process will be repeating as above in response to different <Digit> key is pressed/released while

<Re-Sync> key is still held down.

This Re-Sync signature data transmission process will be repeated as described above each time another <Digit> key is pressed/released until

both Transmitter and Receiver units match its selected RF-channel. This channel frequency will then be used to transmit the data packet.

Viewsonic Tweety RF Remote

Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 19 of 63

Page 20

3.4.1 Definitions

Stuck Key Time-out

After any key is pressed continuously for 60 seconds, the remote will stop sending data packets and turn off RF transmission to conserve battery life.

Transmission can begin again, after all keys are released and key is pressed.

Stuck-Key Data Packet

Byte10 Byte09 Byte08 Byte07 Byte06 Byte05 Byte04 Byte03 Byte02 Byte01 Byte0

(MSB)

0x0F

How and When the Stuck-Key code is sent:

The Stuck-Key Code Data Packet will be sent:

After two data packets of the Make Code of the detected key press, <K1> say, have been sent out. If this (same) key, <K1>, is still being held down for more

than 60 seconds, then two data packets of Stuck-Key code will be sent with 10 ms delay time interval between data packets. A Make Code data packet of the

same key sent every 70 ms time interval during this 60 seconds stuck key condition.

For the pointing device, after sending out the X-Coord and Y-Coord continuously up to 2 minutes which is the time to be considered as stuck key timeout for

pointing device. Two data packets of Stuck Code will be sent.

Two data packets of Sleep Code will be sent following the Stuck Code data packet. The RF Transmitter will then be turned OFF.

Sleep Mode

This is the idle state of the micro-controller when it draws the least amount of current. Upon entering the idle mode, the remote will transmit a unique byte

(FD) to notify the receiver that it is entering into the sleep mode.

0x0F

Sync Bytes

0x0F

0x0F

0x55

Preamble

0x55

0-0x63

(0-99

decimal)

Device

Number

0x00

Dev Addr /

Status

X Coord

0xFC

Y Coord /

ScanCode

32 bits 16 bits 8 bits 8 bits 8 bits 8 bits 8 bits

(LSB)

0xYY

CheckSum

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential

Page 20 of 63

Page 21

Sleep Data Packet

Byte10 Byte09 Byte08 Byte07 Byte06 Byte05 Byte04 Byte03 Byte02 Byte01 Byte0

0x00

Dev Addr /

Status

X Coord

0xFD

Y Coord /

ScanCode

(LSB)

0xYY

CheckSum

(MSB)

0x0F

0x0F

Sync Bytes

0x0F

0x0F

0x55

Preamble

0x55

0-0x63

(0-99

decimal)

Device

Number

32 bits 16 bits 8 bits 8 bits 8 bits 8 bits 8 bits

How and When the Sleep code is sent:

The Sleep Code Data Packet will be sent:

After depressed key, <K1> say, is released and two Data-Packets of K1 Break Code sent, the RF Transmitter will be turned OFF. If no other key press activities are

detected after 5 seconds, the RF Transmitter will then be turned ON to send two data packets of Sleep code , the RF Transmitter will again be turned OFF and the

remote software goes into its actual Sleep mode.

3.4.1.1 Repeated Make code Data Packet

Byte10 Byte09 Byte08 Byte07 Byte06 Byte05 Byte04 Byte03 Byte02 Byte01 Byte0

0x00

Dev Addr /

Status

X Coord

Y Coord /

ScanCode

(LSB)

0xYY

CheckSum

(MSB)

0x0F

0x0F

0x0F

0x0F

Sync Bytes

32 bits 16 bits 8 bits 8 bits 8 bits 8 bits 8 bits

How and When the repeated Make Code is sent:

The repeated Make Code Data Packet will be sent:

After a depressed key, <K1> say, is detected, two data packets of its Make code will be sent with 10 ms delay between data packets. The

Make code packet of the same key will be sent out for every 70 ms time interval as long as this <K1> is still being held down and the overall

time since its first key press detection does not exceed 60 seconds.

0x55

Preamble

0x55

0-0x63

(0-99

decimal)

Device

Number

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential

Page 21 of 63

Page 22

Note:

If another key, <K2> say, is pressed while <K1> is still held down, the Make code data packet of the same K1 key will be sent out as defined

above. Until <K1> is released, two data packets of <K1> Break code will be sent with 10 ms delay between data packet. Since <K2> is now still

held down, two data packets of <K2> Make code will be sent with 10 ms delay between data packets.

Packet gap between the last Break Code of K1 sent and the first Make Code of K2 sent is 10 ms..

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential

Page 22 of 63

Page 23

Timing Events versus Data Packet transmission for various operational situations:

3.4.2 Time Event / Data Packet Transmission Diagram

Te_2

Te_1

Make

~10ms~

Make

Te_1a

Notes:

Time values are approximate and NOT to scale

Refer to APPENDIX for notation descriptions used in this Diagram and Table below.

Time Event / Data Packet Transmission

Time Event

Te_1

Key Press & Time Event Data Packet Transmission & Time Event Remark

<K1> is pressed and detected

Te_2 <K1> key is still being

depressed

Te_4

Te_4a

Te_4b

70 ms after Te_2, <K1> is still

being held from the time event

Te_1 when the <K1> depress

is first detected..

Another 70 ms elapsed after

Te_4 and <K1> is still being

held down

<K1> is still being held down

70 ms after Te_4a.

--------------------------- // ------------------------ // ------------------ 60 seconds ---------------- // ------------------------ // -----------------

- ~ 70ms -- //

Te_2a

~10ms~

Te_3

Break

Make

Te_4

- // ---- 70ms --- // -----

Break

Te_3a, Te_1a

Te_3b, Te_6a

Te_3c, Te_6a

Make

Te_4a

- // ---- 70ms -- // ----

Make

Te_4b

First Make-Code-Data-Packet (<K1> Scan Code) will be sent. It follows by

about 10 ms delay.

Second Make-Code-Data-Packet (of same <K1> Scan Code as above) will

be sent.

Make code data packets of K1 are now transmitted.

Another Make code Data Packets are sent

Case where a key press, <K1> say, is

detected. Make-Code-Data-Packets are

sent with 10 ms delay between the data

packets.

This is the case where:

From the time event Te_1 and for

every 70 ms elapsed time interval, and

60 seconds stuck-key timeout has not

been reached, Make code Data-Packet

of the same key will be sent out as long

as key <K!> is still being held down.

Another Data Packet of Keep-Alive code is sent. See remark column.

StkKy

Te_5

Te_5a

Sleep

Te_6

Te_6a

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential

Page 23 of 63

Page 24

Time Event / Data Packet Transmission Diagram (continued)

Te_2

Te_1

Make

~10ms~

Make

Te_1a

Notes:

Time values are approximate and NOT to scale

Refer to APPENDIX for notation descriptions used in this Diagram and Table below.

--------------------------- // ------------------------ // ------------------ 60 seconds ---------------- // ------------------------ // -----------------

- ~ 70ms -- //

Te_2a

~10ms~

Te_3

Break

Make

Te_4

- // ---- 70ms --- // -----

Break

Te_3a, Te_1a

Te_3b, Te_6a

Te_3c, Te_6a

Make

Te_4a

- // ---- 70ms -- // ----

Make

Te_4b

StkKy

Te_5

Te_5a

Sleep

Te_6

Te_6a

Time Event / Data Packet Transmission (continued)

Time Event

Te_3

Te_3a, Te_1a

Te_3b, Te_6a

Te_3c,

Te_5a

Te_6a

Key Press & Time Event Data Packet Transmission & Time Event Remark

70 ms after Te_2a:

<K1> key is now released.

70 ms after Te_2a:

<K1> is released but another

key is pressed, <K2> say

within 5 seconds.

70 ms after Te_2a:

<K1> is released but NO other

key press detected after 5

seconds elapsed.

70 ms after Te_2a:

While <K1> is still being held

down, another key, <K2> say,

Two Break-Code-Data-Packets (of <K1> Scan Code) will be sent, separated

by about 10 ms time interval between them.

Two Break-Code-Data-Packets (of <K1> Scan Code) sent with 10 ms

separation. The RF Transmitter will then be turned OFF. When another key,

<K2>, is pressed within 5 seconds, the RF Transmitter will be turned ON to

send two Make-Code-Data-Packets of K2 (10 ms between packets) as shown

at Te_1a

Two Break-Code-Data-Packets (of <K1> Scan Code) will be sent with 10

ms time delay in between when <K1> is released. Since no other key press

is detected beyond 5 seconds, a Sleep-Code-Data-Packet will be sent, the RF

transmitter will then be turned OFF to conserve the power.

Make code data packet of K1 sent as defined before. If <K1> released, Break code

data packets of K1 sent

, 10 ms later, Make code data packet of K2 sent. If

<K2> is still down, Make code data packet of K2 sent, etc.. , until <K2>

released, then Break code data packet of K2 sent.

70 ms from the last Make-Code-DataPacket sent and <K1> released.

Case where <K1> released, and <K2>

pressed within 5 seconds after <K1>

released.

Case where <K1> released and no

other key press is to be followed after

more than 5 seconds.

Case of Sequence BreakCode/Stuck/Sleep to indicate the

situation.

is pressed

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential

Page 24 of 63

Page 25

Key Type Data Packet Transmission, a Summary:

All keys including the pointing device buttons are Make/Break type. When a key or button is pressed, the remote will transmit the data packet as shown in the

protocol on previous pages.

For reliable data transmission, keystroke and control push buttons data packets are transmitted twice wirelessly from the Remote Control RF Transmitter. The

transmission is one time for Keep-Alive code and a minimum of 10 times for Re-Sync code.

MAKE

10ms

MAKE BREAK

10ms

BREAK

Followings are some scenarios of key press:

Case of a normal Key pressed/released:

Key Pressed Make Code sent.

Key Released Break Code sent, RF Transmitter turned OFF.

If no key press is detected after 5 seconds, RF Transmitter is turned ON and Sleep Code is sent. After that the RF

Transmitter is again turned OFF and the unit goes to SLEEP mode.

If a key press is detected within 5 seconds, that key data transmission will be serviced as described above.

If a key pressed then stuck for a long time, then Make Code of the same depressed key will be sent for every 70 ms time

interval within 1 minute from the time the original Make code sent. When 1 minute duration is expired, a Stuck code will be

sent, followed by Sleep code and the RF Transmitter is then turned OFF. Note that the software would only be able to go

to STOP (or SLEEP) mode when a stuck key is released.

Case of Make code kept resend

(use <K1> and <K2> as an example):

<K1> pressed Make Code of K1 sent.

<K2> is then pressed while <K1> is still down and both keys are now down within 1 minute. The Make code of K1 will be

sent for every 70 ms time interval as described above, until one of the following conditions occurs:

<K1> is released first while <K2> is still held down. Break code of K1 will be sent and Make code of K2 will be

sent after 70 ms.

<K2> is released first while <K1> is still held down. Nothing changes except the same Make code of K1 will be

sent for every 70 ms time interval. Until <K1> is released and its Break code is sent.

Viewsonic Tweety RF Remote

Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 25 of 63

Page 26

Case of Re-Sync data packet sent:

{{<Re-Sync>+<Digit>}} A <Digit> key is pressed while <Re-Sync> key is held down:

A minimum of 10 data packets of Re-Sync code (0x76) will be sent with 10 ms delay separated each data packet. Or the

Re-Sync data packets will be kept sending out as long as the keys are held down.

Viewsonic Tweety RF Remote

Universal Electronics Inc. Confidential Page 26 of 63

Rev 2.9A November 05, 2001

Page 27

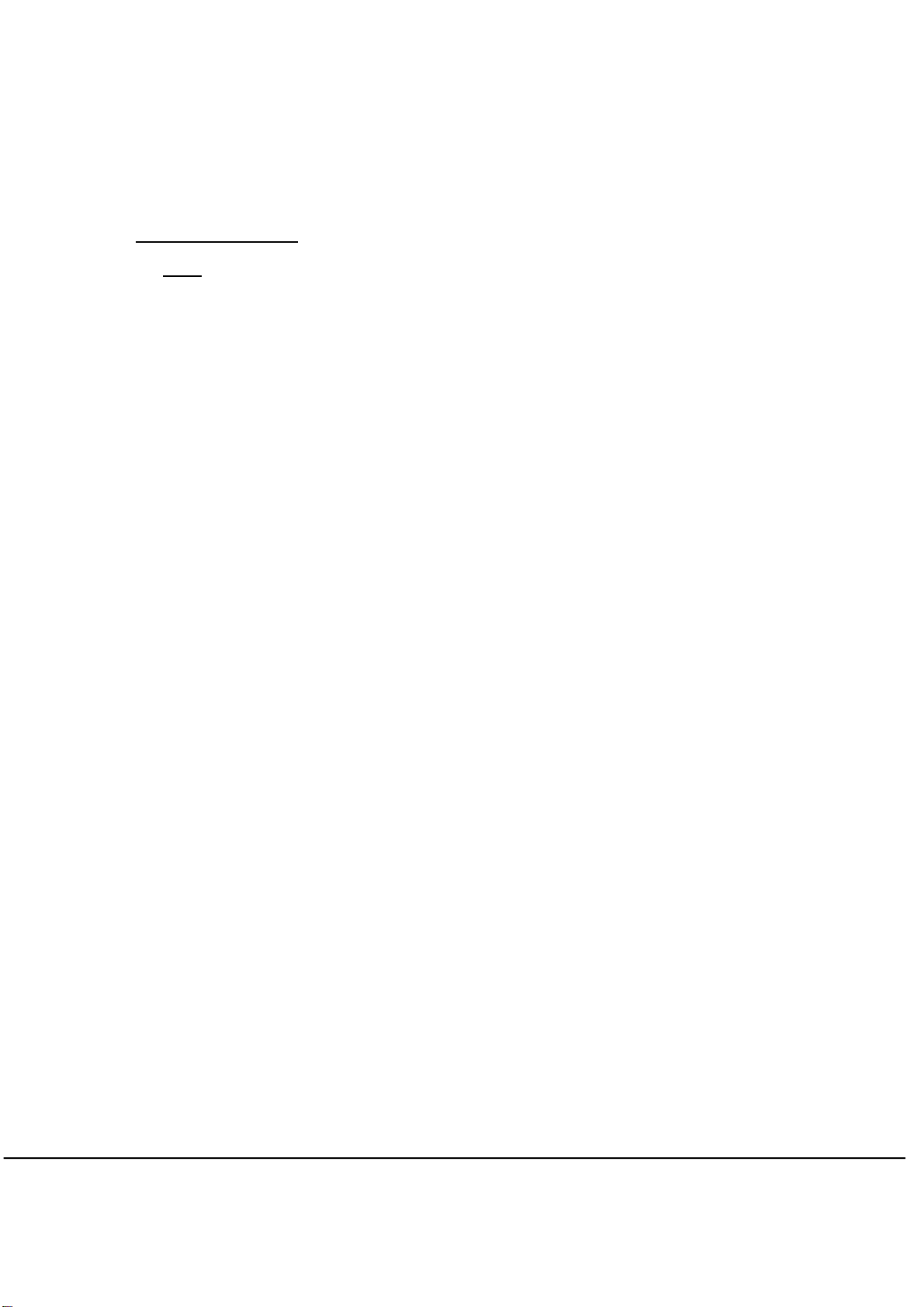

APPENDIX

Some notations used in the Time Event / Data Packet Diagram

Notation Function Description

for Scan Code of Keyboard Keypad or Remote Keypad, or X-

for Scan Code of Keyboard Keypad or Remote Keypad, or X-

_ij, where i = 1, 2, 3, etc …

in the sequence of key press events

in the sequence of key press event after <K1>

Make

Break

ReSyn

StkKy

Sleep

Te_ij

<K1>

<K2>

Make Code

Coordinate, or Y-Coordinate of the Pointing Device

Break Code

Coordinate, or Y-Coordinate of the Pointing Device

Make Code for Re-Sync

Make Code for Stuck-Key

Make Code for Sleep

Time Event

and j = nothing (empty) or a, b, c, etc …

First Key press

Second Key press

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 27 of 63

Page 28

3.4.3 Device Number Setup

Note:

To prevent possible interference from multiple users environment, each remote will be set to a specific User Device Number (User DN#, between 00 to

99). If the User DN# has not been setup, the OSD will prompt the user to program a device number setup.

To program, press <Re-Sync> key first then press <CH+> key, hold down both keys for about 3 seconds, then released:

<<Re-Sync> + <CH+>>

1. The software is now expecting the user to enter two digit numbers representing the device number by press/release <Digit> <Digit> keys. (In

the software test module, this process completes with 2 LED blinks indication).

2. If <AnyKey> key, other than <Digit> keys, is pressed after the above sequence, the software will abort the Device Number Setup mode. (In

the software test module, this error condition will be indicated by a long LED blink).

3. Within 10 seconds (timeout value) after the above sequence entry, if NO key is pressed (or the timeout expired between <Digit> key press),

the software will exit the Device Number Setup mode and the remote will retain the current settings. The software will then return to its normal

operation without having the device number updated. During this 10 seconds time, if the Pointer device is activated, the software will exit the

Device Number Setup mode and will service the pointer movement of the remote.

Each Remote has a Device ID and a Device Number (00-99). The Device ID shows the category of the Remote. The Host will validate the

received data packet from the Remote, by checking the Device Number, to see if it has been registered for that Device ID or not.

After the channel synchronization, the Device ID and Device Number of each Remote will be registered in the Host.

Note

: For both Keyboard and Remote Control, the Keypad and Pointing Device have the same Device Number. During synchronization, only Device ID

of the Keypad and the Device Number of the Pointing Device will be sent. The Host should also register the Device Number for the Pointing Device of

the corresponding device.

Viewsonic Tweety RF Remote

Universal Electronics Inc. Confidential Page 28 of 63

Rev 2.9A November 05, 2001

Page 29

3.4.4 RF Channel Change

Re-Sync Data Packet

Byte10 Byte09 Byte08 Byte07 Byte06 Byte05 Byte04 Byte03 Byte02 Byte01 Byte0

(MSB)

0x0F

How does the Re-Sync operates and When the “Re-Sync” code is sent:

Activating the <Re-Sync> key allows the user to send the “signature data” and to synchronize the RF Transmitter and Receiver RF-channel.

To activate the Re-Sync function:

Press <Re-Sync> key first.

While <Re-Sync> key is held down, press a digit key <d> where d is any digit keys from 1, 2, 3, …, 8, 9, 0 representing RF-channel 1, 2, 3, …,

8, 9, 10 respectively.

The process can pictorially be represented as below:

Press/Release <d> key, while <Re-Sync> key is held down. The system first sets up “d” RF-channel for RF Transmitter (digit number

corresponding to channel 1 through 10), it then sends out the “Re-Sync” Make code data packet, minimum of 10 or more, as long as key still held

down.

If the <Re-Sync> and <d> keys are both

released

0x0F

Sync Bytes

0x0F

0x0F

0x55

Preamble

0x55

0-0x63

(0-99

decimal)

Device

Number

32 bits 16 bits 8 bits 8 bits 8 bits 8 bits 8 bits

{{ <Re-Sync> + <d> }} <d> is <Digit> Key for Digit 1, 2, 3, …, 9, 0

No Break Code data packet for “Re-Sync” will be sent. The “Sleep” code data packet will be sent

when no key activities are detected after 5 seconds (Refer to Sleep Code transmission section for

details).

0x00

Dev Addr /

Status

X Coord

0x76

Y Coord /

ScanCode

(LSB)

0xYY

CheckSum

Viewsonic Tweety RF Remote

Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 29 of 63

Page 30

If another <Digit> key is

pressed/released while the <Re-Sync>

key is still held down

This Re-Sync signature data transmission process will be repeated as described above each time another <Digit> key is pressed/released until

both Transmitter and Receiver units match its selected RF-channel. This channel frequency will then be used to transmit the data packet.

The system will setup another RF-channel, corresponding to that digit key, for the Transmitter, it then

sends out another “Re-Sync” Make code data packet in that RF channel setting.

This process will be repeating as above in response to different <Digit> key is pressed/released while

<Re-Sync> key is still held down.

Viewsonic Tweety RF Remote

Universal Electronics Inc. Confidential Page 30 of 63

Rev 2.9A November 05, 2001

Page 31

3.4.5 E2 Initialization

EEPROM Initialization:

Note:

The EEPROM device must have been previously initialized for the remote to be able to

get into the Factory RF Channel Test Mode.

Press <Re-Sync> key first then press <CH-> key, hold down both keys for about 3 seconds, then

released. The software will enter the E2 Initialization mode WHEN the <Enter> key is pressed

and released after the above described sequence.

<<Re-Sync> + <CH->>

1. If

<Enter>

the EEPROM. (In the software test module, this process completes with 4 LED blinks

indication)

2. If <AnyKey> key, other than <Enter> key, is pressed after the above sequence, the

software will abort the EEPROM Initialization mode. (In the software test module, this

error condition will be indicated by a long LED blink).

Within 10 seconds (timeout value) after the above sequence entry, if NO key is pressed, the

software will exit the EEPROM Initialization mode and the EEPROM device will not be initialized.

The software will then return to its normal operation. But during this 10 seconds time, if the

Pointer device is activated, the software will exit the EEPROM Initialization mode and will service

the pointer movement of the remote.

key is pressed/released after the above sequence, the software will initialize

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 31 of 63

Page 32

3.4.6 Factory Test Mode(s)1

To enter this RF Channel test mode, press and hold a combination keys <<1>+<3>> for at least 3

seconds then released, within 6 seconds after the battery/power is applied to the unit:

<<1> + <3>>

2

The software will start with setting up RF-channel 1 and send through the Transmitter the entire

packet for the first channel continuously for the first 300 ms, with a 10-20ms gap between each

channel. The process is automatically with the next RF-channel setup until all 10 RF-channels

have been cycled through per Table1 below:

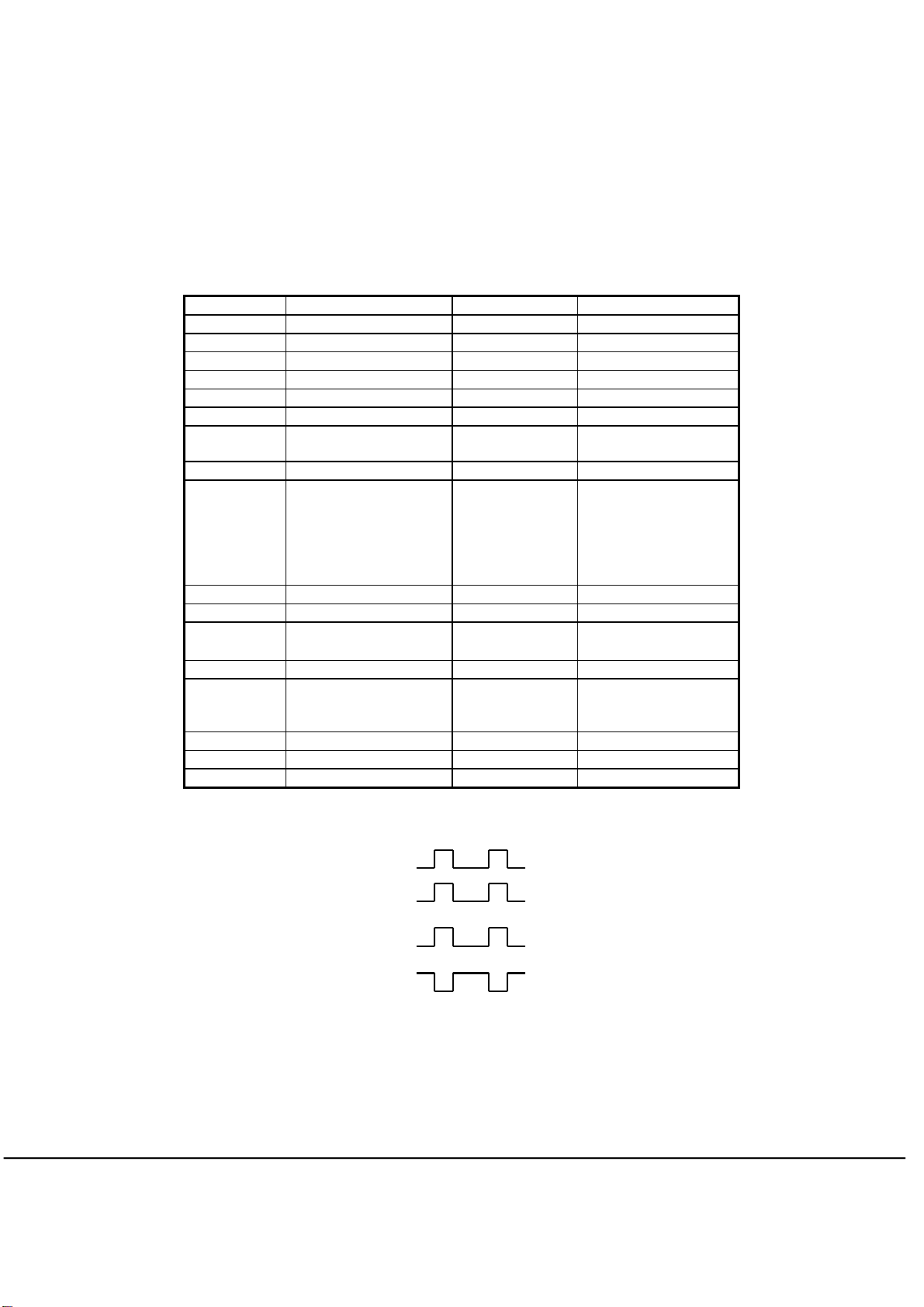

3.4.6.1 Table1: Factory Test Mode for RF Channel Test

Test Channel Time (ms) Packet Sent

1

2

3

4

5

6

7

8

9

End test

0 - 300 0F 0F 0F 0F 55 55 FF FF 01 01 00

300 - 400

Nothing sent while changing RF Ch. 1

400 - 700 0F 0F 0F 0F 55 55 FF FF 02 02 02

700 - 800

Nothing sent while changing RF Ch. 2

800 - 1100 0F 0F 0F 0F 55 55 FF FF 03 03 04

1100 - 1200

Nothing sent while changing RF Ch. 3

1200 - 1500 0F 0F 0F 0F 55 55 FF FF 04 04 06

1500 - 1600

Nothing sent while changing RF Ch. 4

1600 -1900 0F 0F 0F 0F 55 55 FF FF 05 05 08

1900 - 2000

Nothing sent while changing RF Ch. 5

2000 - 2300 0F 0F 0F 0F 55 55 FF FF 06 06 0A

2300 -2400

2400 - 2700 0F 0F 0F 0F 55 55 FF FF

2700 - 2800

Nothing sent while changing RF Ch. 6

07 07

Nothing sent while changing RF Ch. 7

2800 - 3100 0F 0F 0F 0F 55 55 FF FF 08 08 0E

3100 - 3200

Nothing sent while changing RF Ch. 8

3200 - 3500 0F 0F 0F 0F 55 55 FF FF 09 09 10

3500 - 3600

3600 - 3900 0F 0F 0F 0F 55 55 FF FF

3900

Nothing sent while changing RF Ch. 9

00 00

Nothing sent while changing RF Ch. 10

0C

FE 0

1

FACTORY TEST MODE can be entered upon cold power up and/or warm power up

2

IF E2 is not initialized, the remote will not enter the FACTORY TEST MODE.

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 32 of 63

Page 33

Key Test (Also used in Factory Test for Key):

An integrated hardware/firmware/software test unit will be designed for the Key Test. This Key

Test Unit can be used during this project software development as well as for factory test in an

actual production manufacturing. No special combination key sequence is required to get into this

Key Test mode.

The integrated Key Test unit is functionally represented as below:

RF

Receiver

TxD

RxD

+5V

GND

Firmware

Unit

Input

:

Manchester

code from

RF Receiver

output

Output

:

RS-232

------------------------------------------→

←

------------------------------------------

---------------------------------------------

---------------------------------------------

RS-232 interface (9600 baud)

Software

Unit

Input:

RS-232

Output:

Display on

Computer

Monitor

Computer

Screen

Monitor

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 33 of 63

Page 34

3.4.6.1 Firmware Unit:

This so-called “unit” is

actually a firmware portion

data packet after striping off all the Sync bytes and Preamble bytes. It then output these 5 bytes

through the RS-232 protocol format.

Byte4 Byte3 Byte2 Byte1 Byte0

Device Number DevAddr/Status X-coordinate

(8 bits) (8 bits) (8 bits) (8 bits) (8 bits)

Byte0

CheckSum

The result of the addition (without carry) of Byte1 through Byte4

(Device Number + Device Address / Status + X-coordinate + Y-coordinate /

Scan Code)

Byte1

Y-coordinate / Scan Code

Y-data for Remote Control Pointing Device, or

Make/Break Scan Code of the pressed/released key on the Remote Control

Keypad. See Table2 for details.

Byte2

X-coordinate

X-data for Remote Control Pointing Device.

Always 0 for Remote Control Keypad

Byte3

Device Address / Status

Please refer to details on next page

Byte4

Device Number

Device Number is chosen from 0 to 99 by system Host interface. The Host

will validate the received data packet by checking the Device Number if it is

registered for that device.

that processes to keep 5 bytes of the 11-byte

Y-coordinate /

Scan Code

CheckSum

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 34 of 63

Page 35

Byte3 details:

Device Address / Status

b7 b6 b5 b4 b3 b2 b1 b0

Details Byte3 Description

0 1 0 UEI Remote Control Keypad

1 0 0 UEI Remote Control Pointing Device

Pointing Device Left Button Status (0=Up, 1=Down)

Pointing Device Right Button Status (0=Up, 1=Down)

0 Positive

1 Negative

0 Positive

1 Negative

0 OK, good

Sign Bit of X-coordinate

Sign Bit of Y-coordinate

Battery power level status

1 Low

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 35 of 63

Page 36

3.4.6.2 Software Unit:

This so-called “unit”

is actually a software portion

receives a data packet of 5 bytes, as described above, through the RS-232 communication

protocol, it will display the output on the computer screen monitor. The display output information

will depend on the data input information received from the RS-232 inputs.

The display output will be designed as such:

• All 34 keys (Table2, columns 1 & 2) are to be programmed to be graphically displayed as key

buttons (with proper key label if possible). A color-coded scheme are to be designed to

visually represent the key status condition depending on (b2b1b0=010 in the Device Address

/ Status byte).

Color-coded Key press status

Gray

Red

Green

Indicates a key that had never been pressed and/or released, or

the key is malfunctioned that the remote could not detect when

pressed.

Indicates when the key is pressed and the software receives its

Make Code corresponding to that key.

Indicates when the key is released and the software receives its

Break Code corresponding to that key.

•

Two allocated display locations on the screen monitor are to be programmed to show the

value of X-coordinate and Y-coordinate of the Pointing Device. These values are data

received in Byte2 and Byte1 when the pointing device on the remote control is activated

(b2b1b0=100 in the Device Address / Status byte).

• An allocated display location on the screen monitor is to be programmed to show the status

of the battery level condition. This status is to be decoded from bit b7 of Byte 3 (Device

Address / Status byte) in the received data packet.

•

An allocated display location on the screen monitor is to be programmed to show the Device

Number. This value is to be extracted from Byte4 in the received data packet.

(in the integrated Key Test Unit). After it

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 36 of 63

Page 37

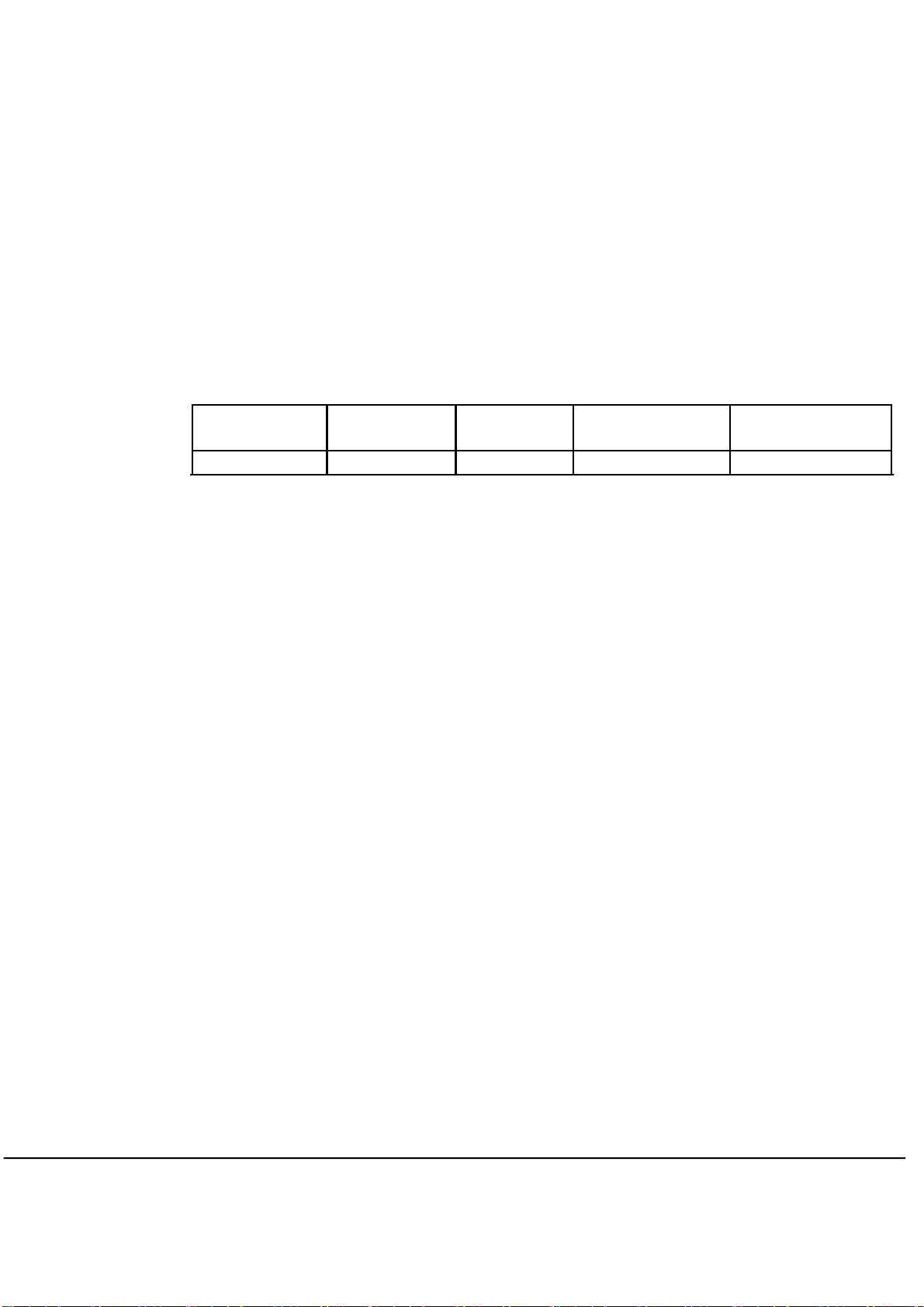

Table2: Key Test (Also used for Factory Key Test)

: Make Code and Break Code are in Hexadecimal.

Note

Key # Key Label Make Code Break Code

1 POWER 75 F5

2 VL+ 74 F4

3 VL- 73 F3

4 MUTE 6B EB

5 CH+ 6F EF

6 CH- 70 F0

7 PREVIOUS 6D ED

8 MENU/EXIT 6E EE

9 PIP 6C EC

10 ENTER * *

11 SMART * *

12 REVERSE 57 D7

13 PLAY 58 D8

14 FFD 59 D9

15 RECORD 5A DA

16 STOP 5B DB

17 PAUSE 5C DC

18 INSTANT REPLAY 5D DD

19 JUMP COMM 5E DE

20 JUMP PRESENT 5F DF

21 EPG 60 E0

22 +100 61 E1

23 MULTIVIEW 62 E2

24 1 13 93

25 2 14 94

26 3 15 95

27 4 16 96

28 5 17 97

29 6 18 98

30 7 19 99

31 8 1A 9A

32 9 1B 9B

33 0 1C 9C

34 RE-SYNC 76 F6

* Set and Reset in Pointing Device Data Packet

Other allocated display locations on the screen monitor:

ID Number : xx

Battery Good / Battery Low

X-data of Pointing Device Y-data of Pointing Device

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 37 of 63

Page 38

3.4.7 Low Battery Indicator

When the batteries in the unit reach approximately 3.4 Volts the remote will send a specific frame

of data to indicate the remote batteries are low. The user will be prompted via an onscreen

display to change the batteries.

When the unit's batteries reaches 2.9 Volts +/- 200 mV the remote will not respond to key presses.

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 38 of 63

Page 39

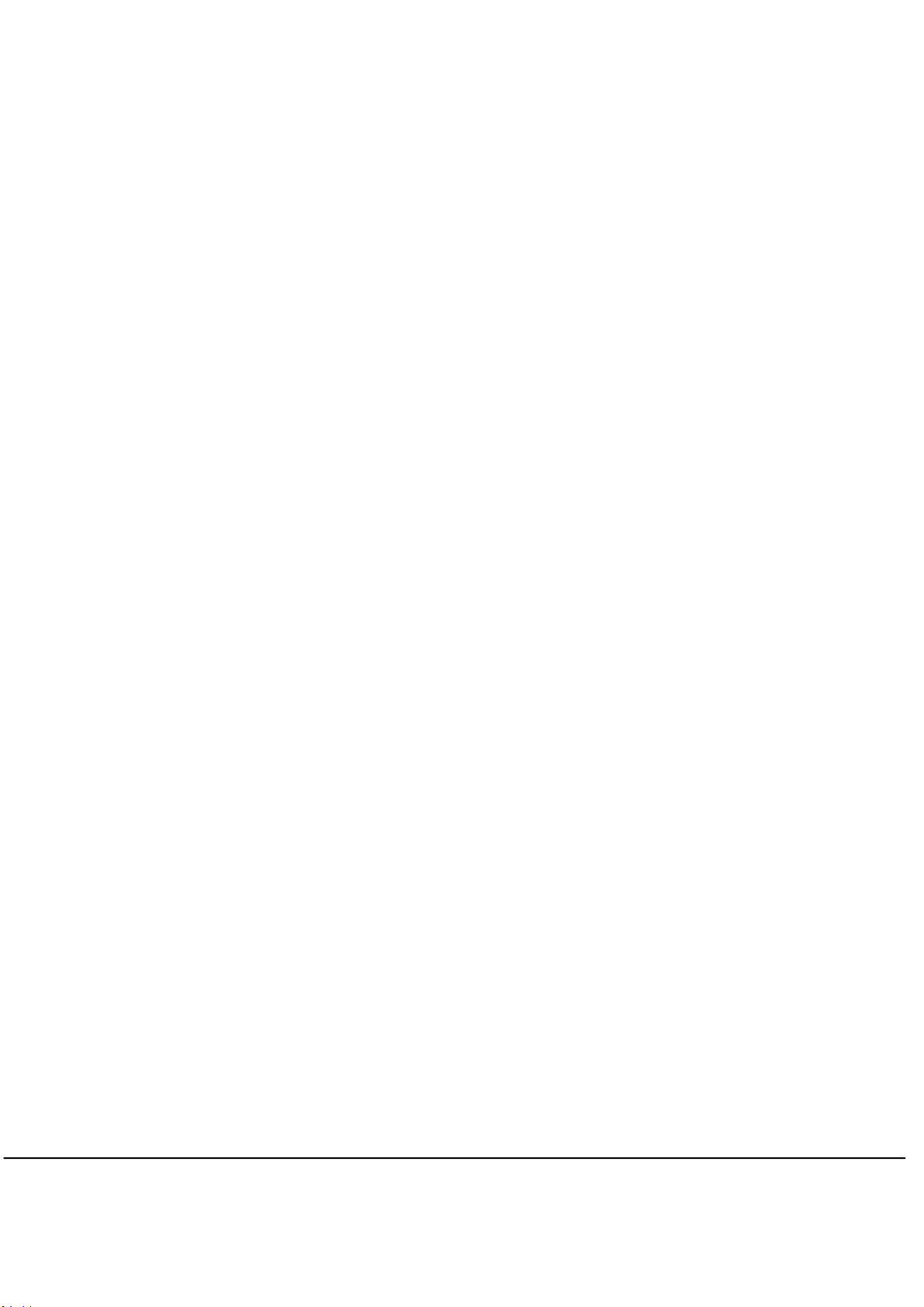

4 RF Transmission General Specification

The performance requirements are contained in the table below

Table 2. General Specification

Rqmt No. Parameter Description Tx Module

4.1 Number of channels 10 channels

4.2 Channel spacing 1,2,3 & 1.6 MHz

4.3 Receive frequency band N/A

4.4 Demodulation N/A

4.5 Receiver sensitivity Minimum N/A

4.6 Data rate Fixed 9600 bps

4.7 Transmit frequency

band

4.8 Modulation FSK

4.9 Radiated power

FCC Requirements

4.10 Simplex type Transmit only

4.11 RF frequency tolerance ± 10 ppm

4.12 Temperature range Operating

4.13 Power source Nominal 2.5 VDC

4.14 Power consumption Maximum

4.15 Dimensions 28mm x 22mm x 8mm

4.16 Weight To be determined

4.17 Other requirements PLL lock on time 50 ms

Note

* : The output data of channel 1-5 and channel 6-10 are different.

Channel 1~5 : Tx input data

Rx output data

Channel 6~10: Tx input data

Rx output data

2446.7 to 2464.3 MHz

Maximum

Fundamental

Spurious

emissions

Storage

operational

supply current

-18 dBm

50 millivolts/meter @ 3

meters

500 microvolts/meter

@ 3 meters

0 to 50 °C

-10 to 60 °C

15 mA

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 39 of 63

Page 40

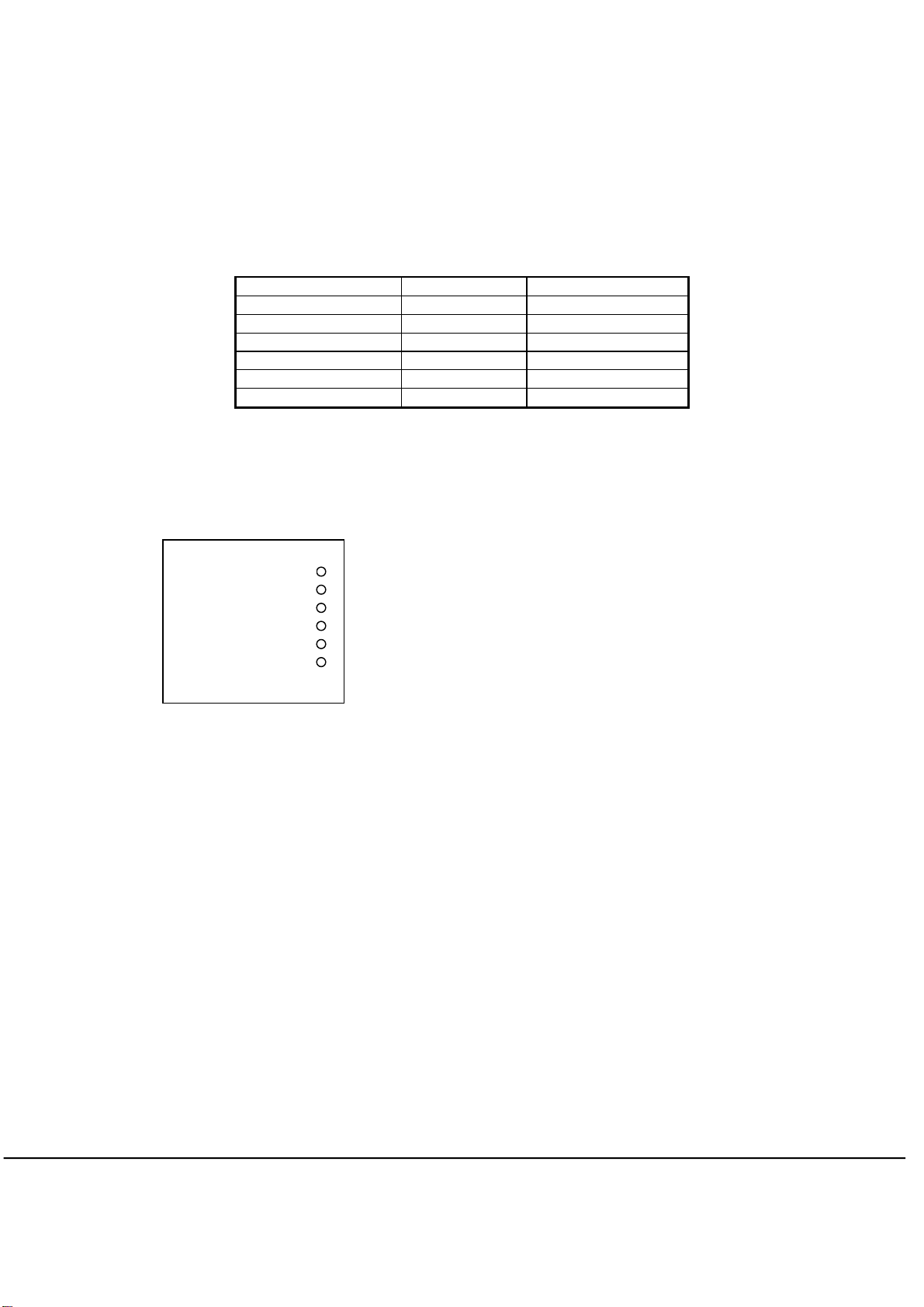

4.1 Data Coding

Data coding is necessary for the wireless communication, which is to eliminate the DC offset of the

demodulation caused by the series 1’s or 0’s. Following describes Manchester Coding implementation:

1 0 0 0 1 1 0 1 1 1 1 1 0

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 40 of 63

Page 41

5 Hardware Interface

1

The interface to the module shall be as described in the table below.

Table 1. Hardware Interface

Parameter Pin Number Tx Module

Input voltage - Vcc 1 2.2 volts

Ground 2 Ground

Data 3 Data input

Synthesizer enable 4 TTL input

Synthesizer SDA 5 TTL input

Synthesizer SCK 6 TTL input

5.1 Transmitter Outline /Interface

Dimension 28* 22*8 mm or smaller if 04/02 components are used

1. Vcc (2.2 V)

2. GND

3. Data in (Vp-p = 0.1V)

4. LE (TTL)

5. SDA (TTL)

6. SCK (TTL)

( Top View )

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 41 of 63

Page 42

Page 43

5.1 Product Performance Requirements

5.1.1 RF CHANNEL and OPERATING BANDS

2400 to 2483.5 MHz

5.1.2 RF Channels and Frequencies

Channel Tx module transmit

1

2

3

4

5

6

7

8

9

0

Frequency Control

Serial data is processed using the SDA, SCK, LE pins. Serial data controls the RF module. Binary

serial data is entered through the SDA pin. One bit of data is shifted into the shift register on the

rising edge of the clock (SCK). When the load enable (LE) pin is high, stored data is latched. After

the both 19-bit register being latched, the frequency will be locked.

Transmitter

CH Freq. 19-bit Register 19-bit Register

2446.7 MHz

1

2448.7 MHz

2

2449.7 MHz

3

2451.7 MHz

4

2454.7 MHz

5

2456.3 MHz

6*

2457.3 MHz

7*

2459.3 MHz

8*

2462.3 MHz

9*

2464.3 MHz

0*

*Channels 6,7,8,9, and 0 will be inverted when transmitted.

0010000000001010001 0010111111000100110

0010000000001010001 0010111111001001110

0010000000001010001 0010111111001100010

0010000000001010001 0010111111010001010

0010000000001010001 0010111111011000110

0010000000001010001 0010111111101100110

0010000000001010001 0010111111101111010

0010000000001010001 0010111111110100010

0010000000001010001 0010111111111011110

0010000000001010001 0011000000010000110

frequency

2446.7 MHz

2448.7 MHz

2449.7 MHz

2451.7 MHz

2454.7 MHz

2456.3 MHz

2457.3 MHz

2459.3 MHz

2462.3 MHz

2464.3 MHz

Viewsonic Tweety RF Remote Rev 2.9A November 05, 2001

Universal Electronics Inc. Confidential Page 43 of 65

Page 44

5.1.3 Pulse Width Timing for RF Transmitter

Long Low: 108.0us (+/- 5%)

Long High: 102.0us (+/- 5%)

Short Low: 53.0us (+/- 5%)

Short High: 50.0us (+/- 5%)

5.1.4 RF Channel Operation Range

The remote shall communicate at a minimum distance of 5m in a direct line of site

5.1.5 RF Modulation Scheme and Modulation Level

Modulation Scheme

Frequency Shift Keying (FSK

Modulation Level

± 70 kHz (Nominal)

5.1.6 Maximum Bit Rate

9600 baud (bps)

5.1.7 RF Power Management

RF Power On

Allocate Frequency X

Tx Data Input X X

T1 T2

• T1 = Power On Stable Time. Typically, it should be T1 > 5ms

• T2 = Frequency Stable Time. Typically, it should be T2 > 20ms

5.1.8 Transmitter Data Input Level

The transmitter data input level should be fixed as the supply voltage drops when using battery. It

is required that the Input level will be Vp-p = 100mv (+/- 10%).

5.1.9 Communication Link