Page 1

Model 4-710d

Four-Channel Tone-Blending

Mic Preamplifier

Universal Audio Part Number 65-00051

Revision A

Universal Audio, Inc.

Customer Service & Tech Support: +1-877-MY-UAUDIO

Business, Sales & Marketing: +1-866-UAD-1176

www.uaudio.com

Page 2

ii

Notices

This manual provides general information, preparation for use, installation and operating instructions

for the Universal Audio Model 4-710d.

Disclaimer

The information contained in this manual is subject to change without notice. Universal Audio, Inc.

makes no warranties of any kind with regard to this manual, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. Universal Audio, Inc. shall not be

liable for errors contained herein or direct, indirect, special, incidental, or consequential damages in

connection with the furnishing, performance, or use of this material.

Copyright

© 2011 Universal Audio, Inc. All rights reserved.

This manual and any associated software, artwork, product designs, and design concepts are subject

to copyright protection. No part of this document may be reproduced, in any form, without prior written

permission of Universal Audio, Inc.

Trademarks

4-710d, 710, Twin-Finity, 4110, 8110, SOLO/110, SOLO/610, 2-610, LA-610, LA-2A, 2-LA2, LA-3A,

6176, 1176LN, 2-1176, 2192, DCS Remote Preamp, UAD and the Universal Audio, Inc. logo are

trademarks of Universal Audio, Inc. Other company and product names mentioned herein are

trademarks of their respective companies

FCC Compliance

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) the device must accept any

interference received, including interference that may cause undesired operation.

Contents of This Box

This package should contain:

• (1) Universal Audio 4-710d unit

• (1) Set of 4 rack mounting screws with washers

• (1) User Manual

• (1) Tip In Sheet

• (1) IEC power cable

• (1) Warranty Registration Card

• (1) UA full line catalog

Page 3

Notices

iii

Important Safety Information

Before using this unit, be sure to carefully read the applicable items of these operating instructions and the

safety suggestions. Afterwards, keep them handy for future reference. Take special care to follow the warnings

indicated on the unit, as well as in the operating instructions.

1. Water and Moisture - Do not use the unit near any source of water or in excessively moist environments.

2. Object and Liquid Entry - Care should be taken so that objects do not fall, and liquids are not spilled, into

the enclosure through openings.

3. Ventilation - When installing the unit in a rack or any other location, be sure there is adequate ventilation.

Improper ventilation will cause overheating, and can damage the unit.

4. Heat - The unit should be situated away from heat sources, or other equipment that produce heat.

5. Power Sources - The unit should be connected to a power supply only of the type described in the

operating instructions, or as marked on the unit.

6. Power Cord Protection - AC power supply cords should be routed so that they are not likely to be walked

on or pinched by items placed upon or against them. Pay particular attention to cords at plugs,

convenience receptacles, and the point where they exit from the unit. Never take hold of the plug or cord

if your hand is wet. Always grasp the plug body when connecting or disconnecting it.

7. Grounding of the Plug - This unit is equipped with a 3-wire grounding type plug, a plug having a third

(grounding) pin. This plug will only fit into a grounding-type power outlet. This is a safety feature. If you

are unable to insert the plug into the outlet, contact your electrician to replace your obsolete outlet. Do

not defeat the purpose of the grounding-type plug.

8. Cleaning - Follow these general rules when cleaning the outside of your 4-710d:

a. Turn the power Off and unplug the unit

b. Gently wipe with a clean lint-free cloth

c. If necessary, moisten the cloth using lukewarm or distilled water, making sure not to oversaturate it

as liquid could drip inside the case and cause damage to your 4-710d

d. Use a dry lint-free cloth to remove any remaining moisture

e. Do not use aerosol sprays, solvents, or abrasives

9. Nonuse Periods - The AC power supply cord of the unit should be unplugged from the AC outlet when left

unused for a long period of time.

10. Damage Requiring Service - The unit should be serviced by a qualified service personnel when:

a. The AC power supply cord or the plug has been damaged; or

b. Objects have fallen or liquid has been spilled into the unit; or

c. The unit has been exposed to rain; or

d. The unit does not operate normally or exhibits a marked change in performance; or

e. The unit has been dropped, or the enclosure damaged.

11. Servicing - The user should not attempt to service the unit beyond that described in the operating

instructions. All other servicing should be referred to qualified service personnel.

Page 4

Table Of Contents

iv

Notices ................................................................................................................................................... ii!

Introduction ............................................................................................................................................ 5!

A Letter from Bill Putnam Jr. ............................................................................................................................. 5!

Overview ........................................................................................................................................................... 6!

Features ............................................................................................................................................................ 6!

The Two Page, Two Minute Guide to Getting Started ............................................................................... 7!

Front Panel Descriptions ......................................................................................................................... 9!

Analog Controls ................................................................................................................................................ 9!

Digital Controls ............................................................................................................................................... 12!

Rear Panel Descriptions ....................................................................................................................... 14!

Digital Connectors .......................................................................................................................................... 14!

Analog Connectors .......................................................................................................................................... 15!

Interconnection Diagrams .................................................................................................................... 17!

Analog-Only Setup .......................................................................................................................................... 17!

Basic Digital Setup ......................................................................................................................................... 18!

Advanced Digital Setup .................................................................................................................................. 19!

Model 4-710d Overview ........................................................................................................................ 20!

Digital Clocking Primer ......................................................................................................................... 23!

Insider’s Secrets ................................................................................................................................... 25!

History of the Model 4-710d ................................................................................................................. 27!

Glossary of Terms ................................................................................................................................. 29!

Maintenance ......................................................................................................................................... 34!

Calibration ...................................................................................................................................................... 34!

Fuse ................................................................................................................................................................ 34!

Voltage Select ................................................................................................................................................. 34!

Service ............................................................................................................................................................ 34!

AES/EBU DB-25 Connector Pinouts ................................................................................................................. 34!

Session Recall Sheet ............................................................................................................................ 35!

Block Diagram ...................................................................................................................................... 36!

Specifications ....................................................................................................................................... 37!

Analog Section, Channels 1–4 ........................................................................................................................ 37!

Analog-To-Digital Converter Section ............................................................................................................... 39!

Digital Output Section .................................................................................................................................... 40!

Connector Types .............................................................................................................................................. 40!

Mechanical and Power .................................................................................................................................... 40!

Index ..................................................................................................................................................... 41!

Additional Resources ............................................................................................................................ 43!

Universal Audio Website ................................................................................................................................. 43!

Product Registration ....................................................................................................................................... 43!

Warranty ......................................................................................................................................................... 43!

Service & Support ........................................................................................................................................... 43!

Page 5

5

Introduction

A Letter from Bill Putnam Jr.

Thank you for purchasing the Model 4-710d Four-Channel Tone Blending Mic Preamplifer — Universal

Audio's new analog+digital hybrid product. The 4-710d combines four channels of our Model 710

Twin-Finity™ preamplifier with eight channels of pristine analog-to-digital conversion and adds a

complement of modern convenience features, all in a 2U, all-metal chassis at an amazing price.

Our all-original 710 Twin-Finity preamp with Tone Blending has proved to be wildly popular among

engineers, producers, and artists seeking a broad palette of sounds from clean to warm in a single,

affordable unit. The innovative preamp design of the Model 710 combines both the classic retro

warmth of UA tube design and the transient bite of solid-state. The 710 was created specifically to

add the tonal versatility and sonic inspiration missing from generic audio interface preamps. The key

to its sonic flexibility lies in its innovative circuit design, featuring a solid-state transimpedance input

amp simultaneously driving separate, phase-aligned tube and solid-state gain stages, which are then

summed to a single output. The mix between the single-ended class-A triode tube stage and solidstate transimpedance stage is controlled via a unique “Blend” knob. Blending is continually variable

between 100% tube and 100% solid-state offering a practically infinite range of unique preamp tones

and the ability to easily dial in your own signature sound.

With the 4-710d, we've added even more value to the 710 mic preamps. Each channel includes an

1176-style compressor; this dynamics circuit sounds incredible and provides yet another dimension of

available sounds. For flexible signal routing and external processing, the 4-710d also includes

send/return jacks in each preamp that can be individually switched via the front panel.

The 4-710d facilitates easy integration of analog signals into your digital world with its built-in high

quality 8-channel A/D converter. Selectable sample rates from 44.1 to 192 kHz, digital output via ADAT

optical or AES/EBU via industry-standard DB-25 connector, and flexible low-jitter clocking options

make it easier than ever to get mic, line, or instrument signals directly into your DAW with a minimum

of hardware and fuss. The A/D converters include LED metering, and an 8-channel soft limiter helps

prevent digital overs.

Most of us at Universal Audio are musicians and/or recording engineers. We love the recording process,

and we really get inspired when tracks are beautifully recorded. Our design goal for the

4-710d was to build a hybrid mic preamp and A/D converter that we would be delighted to use

ourselves—one that would induce that “a-ha” feeling you get when hearing music recorded in its

most natural, inspired form.

Developing the Model 4-710d – as well as Universal Audio’s entire line of quality audio products

designed to meet the needs of the modern recording studio while retaining the character of classic

vintage equipment – has been a very special experience for me and for all who have been involved.

While, on the surface, the rebuilding of UA has been a business endeavor, it's really been so much

more than that: in equal parts a sentimental and technical adventure.

We thank you, and we thank my father, Bill Putnam.

Sincerely,

Bill Putnam Jr.

Page 6

Introduction

6

Overview

The Universal Audio 4-710d is a four-channel microphone/line preamplifier with tube and solid-state

tone blending, offering four additional line inputs, dynamics control, and eight channels of pristine

analog-to-digital conversion. The 4-710d combines UA’s classic design approach with several modern

innovations, creating a unique studio device suited to a wide range of applications.

At the core of the 4-710d are four channels of tone-blending “Twin-Finity” mic preamps with truebypass 1176-style compression. Each of the four mic preamp channels allows for continuously

variable phase-aligned tone between 100% tube and 100% solid-state. Send and return jacks are

available for external processing or signal access.

The eight analog inputs are digitized via high-quality 24-bit A/D converters at selectable sample rates

up to 192 kHz. Digital output is available via dual ADAT “lightpipe” or AES/EBU DB-25 connectors,

facilitating integration with most popular audio interfaces.

Features

Preamplifiers

• Four TEC Award-winning 710 Twin-Finity™ microphone/line preamps, each featuring:

• Dual-path 285-volt Class-A tube and transimpedance solid-state preamps

• Phase-aligned tone-blending of tube and solid state circuits, creamy to crunchy

• Newly designed 1176-style compression circuit per preamp channel

• JFET Direct Input with 2.2MΩ ultra Hi-Z impedance w/auto input override

• Large backlit VU meters for flexible metering of input drive, gain level, and gain reduction

• Balanced send/return inserts (half-normalled)

• 48V phantom power

• 75 Hz low cut filter

• Polarity switch

• Monolithic balanced output stage

Analog-to-Digital Conversion

• Eight channels of high quality 24-bit A/D conversion:

• Selectable sample rates up to 192 kHz

• Digital output via dual ADAT optical and AES/EBU DB-25 connectors

• 8-channel soft limiter (switchable for all channels)

• Ultra-low jitter clock subsystem

• LED metering array with clip/hold indicators

• 75Ω BNC work clock I/O

• Digital outputs anti-pop protection on power-up

Other

• Universal voltage internal power supply

• Heavy-duty metal construction, two-space rack unit

• One year warranty including parts and labor

Page 7

7

The Two Page, Two Minute Guide to Getting Started

No one likes to read owner’s manuals. We know that.

We also know that you know what you’re doing—why else would you have bought our product?

So we’re going to try to make this as easy on you as possible. Hence this two-page spread, which we

estimate will take you approximately two minutes to read. It will tell you everything you need to know to

get your Universal Audio 4-710d up and running, without bogging you down with details.

Of course, even the most expert of us has to crack a manual every once in awhile. As the saying goes,

“as a last resort, read the instructions.” You’ll find those details you’re craving—a full description of

all front and rear panel controls, interconnection diagrams, insider’s secrets, history, theory,

maintenance information, block diagrams, specifications, even a glossary of terms—in the pages that

follow.

Getting Started With Your 4-710d:

Step 1: Place the 4-710d where you intend to use it. Chassis mounting hardware is provided, allowing

the 4-710d to be used in a standard 19" rack (taking just two spaces), and so we recommend that the

4-710d be securely mounted in a rack if possible.

Step 2: Mute your monitors and then, using a balanced cable with XLR connectors, connect the 4710d’s rear panel line output(s) to the appropriate input(s) on your patch bay, mixer, or DAW.

Step 3: Set the front panel +48V (phantom power), 15dB PAD, and LOW CUT switches to their down

(OFF) position.

Step 4: Set the front panel POLARITY switch to its down (IN ø) position.

Step 5: Connect the desired input source to one of the 4-710d’s rear panel balanced XLR mic and/or

line inputs ( page 15). Alternatively, an electric guitar or bass can be connected to a front panel

unbalanced 1/4" Hi-Z input ( page 9); however, note that the 4-710d’s jack sensing circuitry

automatically disconnects the channel’s rear-panel mic and line inputs when a cable is inserted into

that channel’s Hi-Z input. ( See page 17 for interconnection diagrams)

Step 6: If you are using a microphone or line-level input, set the channel’s front panel Input Select

switch to Mic or Line.

Step 7: Set the channel’s Meter switch to DRIVE (its down position).

Step 8: Set the channel’s Gain control to “0” and the Level control to approximately “5”.

Step 9: Set the channel’s Blend knob to its twelve o’clock position. This ensures an equal blend of

both of the 4-710d preamplifiers (solid-state and vacuum tube).

Manual conventions:

! Means that this is an especially useful tip

Means that this is an especially important bit of information

And when we need to direct you to a page or section elsewhere in the manual, we’ll use the universal signs

for rewind () or fast forward ().

Page 8

Getting Started

8

Step 10: Make sure the Power switch is off (down position) and then connect the supplied IEC power

cable to the rear panel AC power connector.

Step 11: Power on the 4-710d. The front-panel meters will light up.

Step 12: If a microphone requiring 48 volts of phantom power is connected to the 4-710d, turn on the

channel’s +48V switch.

Step 13: Unmute your monitors and slowly raise the channel’s Gain control. You should now be

hearing signal, with that channel’s meter becoming active.

Step 14: While viewing the meter, set the channel’s Gain control until optimum input signal strength

is achieved. Change the channel’s Meter switch to OUTPUT (its up position) and set the Level control

until optimum output signal strength is achieved.

Step 15: Experiment with differing degrees of Gain to hear the various amounts of coloration the 4710d can impart to your signal. (CAUTION: Very high Gain settings will result in significant amounts of

distortion). For the cleanest, most uncolored signal from the 4-710d, set the Gain knob to its lowest

usable setting, change the Meter to OUTPUT, and then adjust the Level control as necessary. If you

hear distortion when using a connected microphone even at the lowest Gain level, employ the -15 dB

pad to reduce the input level. If you hear low frequency rumble, employ the Low Cut filter switch.

Step 16: Finally, experiment with the Blend control to hear the different sonic signatures imparted by

the two discrete preamplifiers contained within the 4-710d. At the fully counterclockwise (TRANS)

position, only signal from the solid-state preamplifier is heard. At the fully clockwise (TUBE) position,

only the signal from the tube preamplifier is heard. Most uniquely, it is the in-between settings that

allow you to access the “twin-finity” of sounds offered by the 4-710d and create a custom blend that

best complements your signal source.

Because the Model 4-710d utilizes a tube, it needs several minutes to achieve a stable

operating temperature. During warm-up, audio quality may vary slightly.

For more detailed information, refer to the “Front Panel” and “Rear Panel” sections on

pages 9 and 14 of this manual.

Page 9

9

Front Panel Descriptions

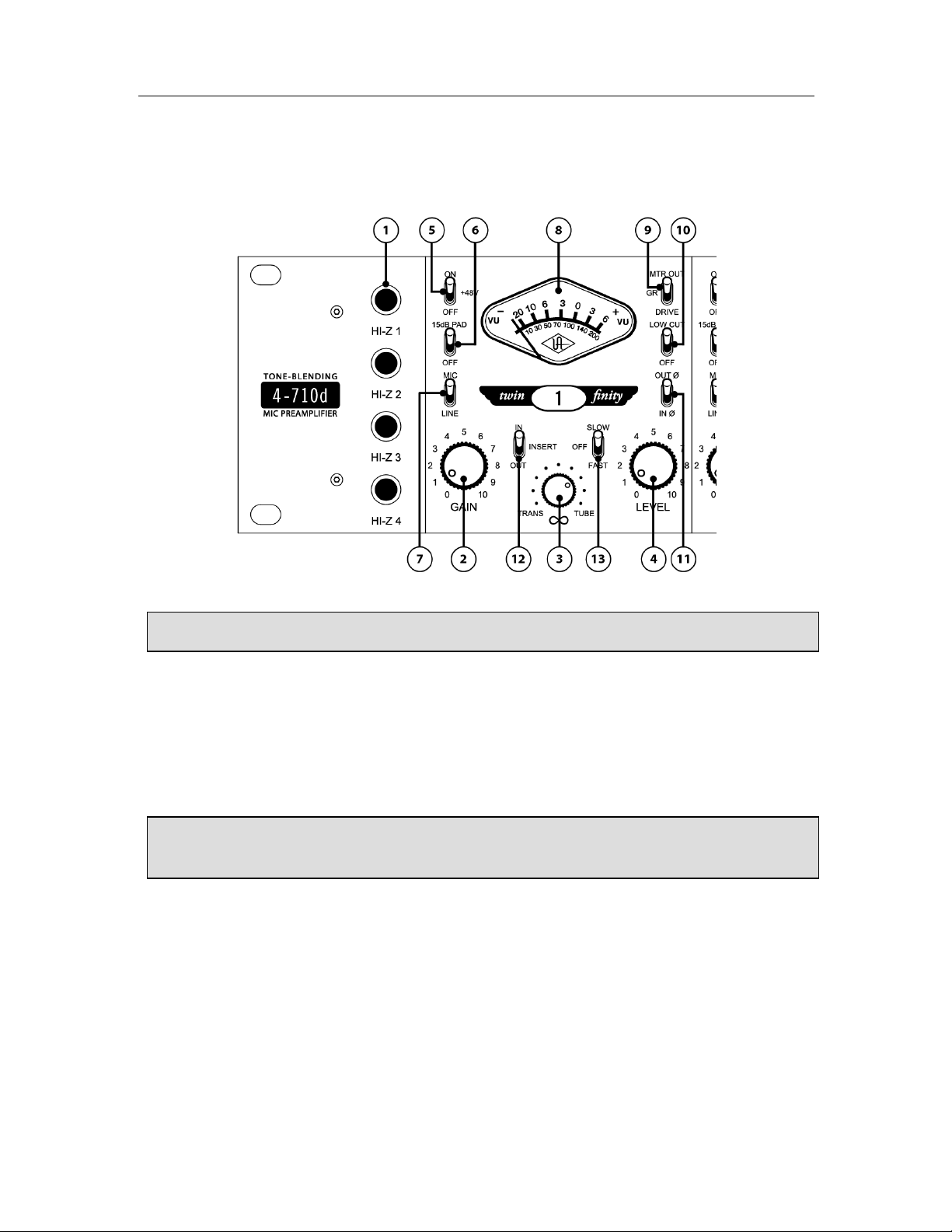

Analog Controls

(1) Hi-Z Inputs - Connect a high impedance signal from an instrument such as electric guitar or bass

to these standard unbalanced 1/4" phone jack connectors. The 4-710d’s jack detection circuitry

automatically switches from the selected rear panel MIC or LINE input to the channel’s front panel Hi–

Z input whenever a plug is inserted into this jack. The Hi-Z input impedance is 2.2MΩ for all four

inputs. These JFET direct inputs provide maximum fidelity with no high-end loss.

(2) Gain - Adjusts the gain of the channel’s input stage. Turning this knob clockwise raises the

amount of gain applied to the input signal. This control also determines the level sent to the

compressor if the compression circuit ( #13 on page 11) is engaged.

(3) Blend (“∞”) - This unique control sets the relative contribution from the solid-state and vacuum

tube preamplifier circuits. When in the fully counterclockwise (TRANS) position, only signal from the

solid-state preamplifier is heard. When in the fully clockwise (TUBE) position, only the signal from the

tube preamplifier is heard. At the twelve o’clock position, signal from both the solid-state and tube

preamplifiers is heard at equal amounts.

Making a connection to the 4-710d’s front panel Hi-Z input jack automatically disconnects

any signal arriving at the rear panel mic and line input.

The controls for channels 1-4 are identical, so each control is only described once.

Page 10

Front Panel

10

(4) Level - This is the channel’s master volume control. It determines the amplitude of the signal sent

to the rear panel LINE OUTPUT ( #8 on page 16) and INSERT SEND ( #11 on page 16) jacks. This

control also sets the level sent to the A/D converter inputs.

(5) +48V - Most modern condenser microphones require +48 volts of phantom power to operate. When

in the up position, 48 volts of phantom power are available at the channel’s rear panel MIC INPUT.

(See page 21 for more information about phantom power)

(6) -15 dB PAD - When enabled (placed in the up position), the channel’s MIC INPUT signal will be

reduced by 15 dB (this switch has no effect on LINE INPUT or Hi-Z signal). Use the PAD to reduce the

incoming signal in cases where undesired distortion is present at low gain levels (for instance, where

especially sensitive microphones are used on loud instruments or if the A/D converter is clipping).

(7) Input Select - Determines whether the channel’s MIC (up position) or LINE (down position) input is

active. If the channel’s Hi-Z input is in use, this switch has no effect.

( See “Analog Connectors” on page 15 for more info on the rear panel inputs)

(8) Meter - This standard VU meter can display the channel’s overall output level, tube drive level, or

amount of compressor gain reduction. The function that is displayed depends upon the setting of the

Meter Function switch (#9 on page 11).

Keep phantom power off (switch down) when it is not required.

To avoid loud transients, always make sure phantom power is off when connecting or

disconnecting microphones.

Always check the power requirements of your microphone with the manufacturer before

applying phantom power.

The numeric values for the Gain and Level knobs are relative scale markings and do not

represent specific dB values.

! You can come up with many useful tonal variations by experimenting with different Gain

and Level settings.

Page 11

Front Panel

11

(9) Meter Function - This three-position switch determines what the channel’s VU meter displays. In

the up (OUTPUT) position, it shows the final output level in dB. "0" on the VU meter corresponds to +4

dBu at the analog outputs and -16 dBFS at the A/D converter inputs. In the down (DRIVE) position, it

shows the input level to the tube stage after the front panel Gain control, but before the Blend and

Level controls, thus giving an accurate gauge of how hard the tube and solid-state preamplifiers are

being driven. In the center (GR) position, the meter displays the amount of gain reduction occurring in

the channel’s compressor if the COMP switch (#13 below) is engaged for the channel. If the

channel’s compressor is off, the meter will not deflect from zero when set to GR.

When the switch is in DRIVE mode, the meter is calibrated so that 0 VU is equal to 1.2% THD on a 1kHz

sine wave. When OUTPUT is selected, a meter reading of 0 VU corresponds to a level of +4 dBu at the

rear panel LINE OUTPUT jack.

( See “Drive Metering” on page 25 for additional analog metering info)

(10) Low Cut - When enabled (placed in the up position), the channel’s input signal passes through a

75 Hz low cut filter. This is normally used to eliminate rumble and other unwanted low frequencies

from an incoming signal.

( See page 21 for more information about low cut filtering)

(11) Polarity (“ø”) - Determines the polarity of the channel’s LINE OUTPUT ( #8 on page 16) and

the polarity of the signal at the A/D converter inputs. When off (in the down, IN ø position), pin 2 of the

LINE OUTPUT is hot (positive). When the switch is enabled (in the up, OUT ø position), the output signal

is placed out of phase and pin 3 of its LINE OUTPUT is hot (positive). Normally the switch should be off

and only enabled when it is desirable to reverse the polarity, i.e., in cases where more than one

microphone is utilized in recording a source signal.

( See page 21 for more information about polarity inversion)

(12) Insert – When enabled (placed in the up position), the input signal is routed through the channel’s insert jacks on the rear panel ( “Insert Loop” on page 16) for external processing. When

disengaged (in the down position), the signal at the return jack is ignored. The insert switch allows you

to leave external processors conveniently connected when you don’t want to currently use them on the

channel.

(13) Comp – This three-position switch controls the channel’s 1176-style analog compressor. The

compressor has a compression ratio of 4:1 and the threshold is 10 dBu.

When in the up (FAST) position, the compressor attack time is 0.3 ms and the release time is 100 ms.

When in the down (SLOW) position, the attack time is 2.0 ms and the release time is 1100 ms.

If the METER FUNCTION switch (#9 above) is set to GR, the amount of compressor gain reduction is

displayed in the METER.

! The Send jack is active even when Insert is disengaged, so you can route the channel’s

signal to a monitor mix, tuner, etc.

Page 12

Front Panel

12

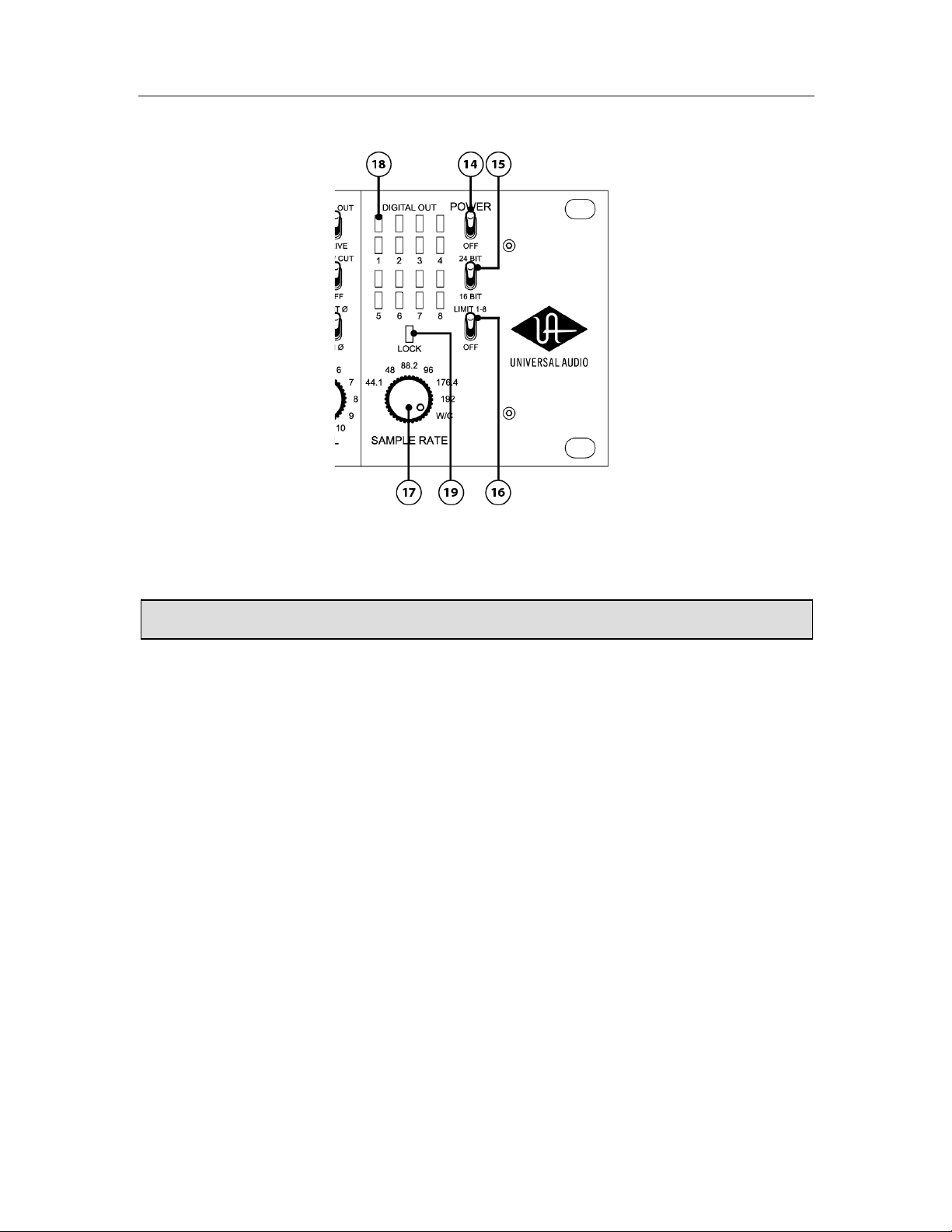

Digital Controls

(14) Power - Turns the 4-710d power on or off. When powered on, the front panel meters light up.

(15) Bit Depth – This switch determines the bit depth, or resolution, of the digital output signal for all

eight A/D channels. In the up position, the digital output word length is 24 bits; in the down position,

the digital output word length is 16 bits.

The actual A/D conversion of the 4-710d is always performed at a 24-bit word length. When the switch

is set to 16-bit mode, the 24-bit signal is triangular dithered to 16 bits.

(16) Limit 1-8 – This switch activates the built-in analog limiter for all eight inputs prior to A/D

conversion. The limiter is global for all eight inputs; it cannot be individually enabled per channel

(unlike the mic pre compressors on channels 1-4).

The limiter threshold is 17dBu (= -3dBFS) and the ratio is effectively infinite. The attack time is 0.075

ms and the release time is 100 ms. Although the limiter will help prevent “digital overs” (A/D clipping)

during conversion, it is not a “brick wall” limiter. It is still possible to clip the A/D input, especially

with very hot signal levels and/or signals with fast transient peaks.

(17) Sample Rate - This knob defines the internal sample rate of the A/D converter or selects external

clocking. The following sample rates are supported (kHz): 44.1, 48, 88.2, 96, 176.4, and 192.

When Sample Rate is set to W/C (external word clock) the 4-710d is a word clock slave and the

incoming clock rate at the rear panel’s BNC Word Clock In connector ( #2 on page 14) is used to

determine the sample rate for A/D conversion.

( For more details, please see the “Digital Clocking Primer” section on page 23)

The 4-710d should be powered off when it is not being used for extended periods of time.

Page 13

Front Panel

13

(18) Digital Out Level - These LEDs indicate the signal level of the A/D converters. Each of the eight

A/D channels has its own two-segment level indicator.

The lower LED illuminates green when the incoming signal is between -37 dBFS and -6 dBFS. This LED

displays the signal level continuously (it does not have peak/hold functionality).

The upper LED is a two-state indicator. When the incoming signal is between -6 dBFS and -1 dBFS, the

LED is yellow; the LED is red when the signal exceeds -1 dBFS. This LED has a peak/hold

implementation; signal peaks are “held” for 90 ms.

(19) Lock - When the 4-710d is locked (synchronized) to a clock source, the LOCK indicator glows

green. The indicator glows red when the clock is not locked. The clock is always locked when the

Sample Rate knob (#17 on page 12) is set to an internal sample rate. For the clock to be locked

when the clock source is external, a valid clock signal must be present at the rear panel word clock

input (see note above).

In order for the 4-710d to detect and lock to a valid external word clock, the frequency of

the incoming word clock must be within ±3% of any of the supported sample rates (44.1,

48, 88.2, 96, 176.4, or 192 kHz). If the frequency of the incoming work clock is not within

±3% of a supported sample rate, the LOCK indicator will glow red, the WORD CLOCK OUT

will be driven at 48 kHz, and the digital outputs will be driven at 48 kHz and muted.

The clock must be locked for proper A/D conversion.

If the clock won’t lock when the Sample Rate knob is set to W/C (external word clock),

verify that the external device is connected to the word clock BNC input and is transmitting

a valid clock signal.

The 4-710d cannot lock to an external device that is set to slave to the 4-710d!

Page 14

14

Rear Panel Descriptions

Digital Connectors

(1) AES/EBU Out – All eight channels of the 4-710d’s A/D converters are output in AES/EBU digital

format on this standard DB-25 connector. The 4-710d AES/EBU output supports “Single Wire” mode at

all available 4-710d sample rates. The AES/EBU output does not support “Dual Wire” mode at sample

rates above 96 kHz.

( The DB-25 connector pin-out assignments are detailed in Maintenance on page 34)

(2) Word Clock In – The 4-710d’s internal clock can be synchronized (slaved) to an external master

clock. This is accomplished by setting Sample Rate knob ( page 12) to “W/C,” connecting the

external word clock’s BNC connector to the Word Clock “In” port, and setting the external device to

transmit word clock.

The frequency of the incoming word clock must be within ±3% of any of the supported sample rates. If

not, the LOCK indicator will glow red, the word clock OUT will be driven at 48 kHz, and the digital

outputs will be driven at 48 kHz and muted.

External clocking is required when connecting the 4-710d to another digital device, such as a computer audio interface, whose digital clock is set to internal (making that device the “master” clock). All

digital devices in a system should be “slaved” to the master clock, otherwise clicks and/or pops could

be encountered when recording or monitoring the digital audio stream from the 4-710d.

( For more details, please see the “Digital Clocking Primer” section on page 23)

Digidesign’s 192 I/O supports AES/EBU at sample rates above 96 kHz only in Dual Wire

mode. Therefore the 4-710d is incompatible with the 192 I/O when connected via AES/EBU

at sample rates of 176.4 kHz and higher.

The 4-710d can be synchronized to an external “1x” clock signal only. Superclock,

overclocking, and subclocking are not supported.

Page 15

Rear Panel

15

(3) Word Clock Out – This BNC connector transmits a standard (1x) word clock. For all settings except

W/C, the 4-710d is the clock master and the clock rate sent by this port is specified by the Sample

Rate knob (#17 page 12). The 4-710d will drive the Word Clock to all devices on the chain.

When the Sample Rate is set to W/C (external word clock), the 4-710d is a word clock slave. If the

incoming external word clock is within ±3% of a supported sample rate (44.1 kHz, 48 kHz, 88.2 kHz,

96 kHz, 176.4 kHz, 192 kHz), Word Clock Out will mirror Word Clock In with a slight phase delay (about

40ns). If the incoming external word clock is not within ±3% of a supported sample rate, Word Clock

Out will default to 48kHz, and the digital outputs will be muted.

Word Clock Out does not truly mirror Word Clock In, so Word Clock Out should not be used to daisy

chain the Word Clock if the 4-710d is in the middle of the Word Clock chain. The correct method to

connect the 4-710d in the middle of a Word Clock chain is to use a T-connector at the 4-710d Word

Clock input, and leave the 4-710d Word Clock Out unconnected.

( For more details, please see the “Digital Clocking Primer” section on page 23)

(4) 75Ω Termination – This pushbutton switch provides internal word clock termination when

required. Termination is active when the switch is engaged (depressed).

Word clock termination should only be used at the receiving end of a word clock cable, or, if the cable

is daisy-chained across several units, termination should only be used on the last unit in the chain.

For example, if the 4-710d is the last “slave” unit at the end of a clock chain (when the

4-710d’s word clock “Out” port is not used), termination should be active. If the word clock is passed

through the 4-710d to another unit (when the 4-710d’s Word Clock Out port is connected, passing the

word clock through to another device), termination should be disabled.

(5) ADAT Optical Outputs 1 & 2 – Up to eight channels of the 4-710d’s A/D converters are output in

ADAT optical format using these two connectors. The particular 4-710d channels that are output at

each port depend upon the current sample rate setting. At sample rates of 44.1kHz and 48kHz, all

eight channels are output on both ADAT ports (mirrored). At higher sample rates, industry standard

S/MUX™ multiplexing is used to maintain high-resolution transfers. At rates of 88.2kHz and 96kHz,

channels 1-4 are output on ADAT port 1, while channels 5-8 are output on port 2. At 176.4kHz and

192kHz, channels 1 and 2 are output on port 1, while channels 3 and 4 are output on port 2 (channels

5-8 cannot be output via ADAT optical at the highest rates). These correlating values are shown in the

following table:

Analog Connectors

(6) AC Power Input – Connect a standard, detachable IEC power cable (supplied) here.

(7) Line Inputs 5 through 8 – These four line inputs feed directly into channels 5–8 of the 4-710d’s

A/D converters. Any ¼” phone plug (balanced TRS or unbalanced TS) carrying a line-level signal can

be connected here for output via the AES/EBU or ADAT digital outputs. These inputs are fed into the

limiter when the limiter (#16 on page 12) is enabled.

Sample Rate

Knob Setting:

ADAT Port 1

Output channels:

ADAT Port 2

Output channels:

44.1, 48

1-8

1-8 (mirrored)

88.2, 96

1-4

5-8

176.4, 192

1-2

3-4

Page 16

Rear Panel

16

Two 4-710d units can combined using these inputs to obtain eight mic pre channels on one 8-channel

digital stream. Simply connect the channel 1–4 line outputs of the first unit to the line inputs 5–8 of

the second unit; the digital outputs of the second unit will now contain the combined mic pres of both

units!

Note: There are no analog outputs for line inputs 5–8.

(8) Line Output - A balanced XLR connector that carries the line-level output signal of the 4-710d

channel. Note that Pin 2 is positive when the front panel Polarity switch ( #11 on page 11) is off (IN

ø). Pin 3 is positive when the front panel Polarity switch is engaged (OUT ø).

(9) Line Input - Connect any line-level input signal (coming from a device such as a mixer, DAW, tape

machine, or signal processor) into this balanced XLR connector. Pin 2 is wired positive (hot).

Any ¼” phone plug line-level output can also be connected to the Insert Return jack ( #12 below),

and if the Insert switch for the channel ( #12 on page 11) is engaged, that signal will be used for

the channel input instead of the XLR line input.

(10) Mic Input - Connect a microphone to this standard XLR connector. Pin 2 is wired positive (hot).

+48V phantom power is available via the front panel switch.

Insert Loop - An external audio processor (for example, EQ or compressor) can be inserted into the

analog path of channels 1-4 using the Insert Loop for additional processing of the channel’s signal

using the Send and Return jacks (#11 and #12 below). The Insert Loop can be enabled or disabled

using the Insert switch for the channel on the front panel ( #12 on page 11).

(11) Insert Send – Connect this jack to the audio input of the external processor. The signal at this

jack is post-preamp, so all level and sonic changes made with the associated channel’s front panel

controls will be reflected here. The jack is “half-normalled” which means you can extract the channel’s

signal from here even if you don’t use the associated Insert Return. This is handy for routing the signal

to a monitor mix, tuner, etc.

The signal at the Insert Send jack is identical to the signal at the XLR Line Output jack. Both channel

outputs can be used simultaneously without any signal loading issues.

(12) Insert Return– Connect this jack to the audio output of the external processor. The signal at this

jack is only audible if the associated channel’s Insert switch on the front panel ( #12 on page 11) is

engaged.

The Insert Return jack can be used as a ¼” line input for the channel in lieu of the XLR input. The

Insert Return is used as the input when the channel’s Insert switch ( #12 on page 11) is engaged.

Since the connectors for channels 1–4 are identical, each is only described once below.

All Insert connections accept standard ¼” male phone plugs. Balanced TRS and

unbalanced TS connectors can be used.

Page 17

17

Interconnection Diagrams

Analog-Only Setup

This diagram illustrates a typical system using the 4-710d in an analog-only configuration, such as

when using it as the front end to a public address system or analog recording device. In this setup, the

digital features of the 4-710d are not used.

The example shows a microphone connected to channel 1, a keyboard connected to the insert return of

channel 2 (to use the ¼” line input instead the XLR line input), and a guitar connected to channel 3

using the Hi-Z input. A signal processor (e.g., reverb) is connected via the insert loop of channel 1 for

the mic. The insert send of channel 3 (but not the return) is used as a guitar direct output for

connection to a tuner. The line outputs are connected to an analog mixer where the input signals are

combined before being sent to powered PA speakers.

Key points for this example:

• Mic/Line switch for channel 1 is set to “Mic”

• Insert switches for channels 1 and 2 are set to “In”

• Line outputs are connected to an analog mixer for monitoring

Page 18

Interconnections

18

Basic Digital Setup

This diagram illustrates a typical system using the 4-710d as the front end of a digital recording

setup. A variety of input sources are used, with the 4-710d performing A/D conversion on the inputs. In

this setup, the converted input signals are sent to the computer digitally via the ADAT lightpipe, and

the software monitoring features of the DAW are used to monitor the 4-710d inputs.

The example shows microphones connected to channels 1 and 2, guitar and electric bass connected to

the H-Z inputs of channels 3 and 4, and a stereo keyboard connected to line inputs 5 and 6. A guitar

effects processor is connected via the insert loop of channel 3. The insert send of channel 4 (but not

the return) is used as a bass direct output for connection to a tuner. The ADAT output from the 4-710d

is connected to the ADAT input of the computer’s audio interface for monitoring and recording.

Key points for this example:

• Mic/Line switch for channels 1 and 2 are set to “Mic”

• Insert switch for channel 3 is set to “In”

• ADAT output is connected to computer audio interface

• Internal clock is used (Sample Rate knob is NOT set to “W/C”)

• Computer is set to synchronize (“slave”) to ADAT external clock

• Computer DAW is used for software monitoring

Page 19

Interconnections

19

Advanced Digital Setup

This diagram illustrates a typical system using the 4-710d as the front end of a more complicated

digital recording setup. A variety of input sources are used, with the 4-710d performing A/D conversion

on the inputs while slaved to an external word clock. In this setup, the converted input signals are sent

to the computer digitally via the AES/EBU output, and the software monitoring features of the DAW are

used to monitor the 4-710d inputs.

(See the “Digital Clocking Primer” on page 23 for detailed info about synchronization)

The inputs and inserts are connected as in the previous example. The AES/EBU output from the 4-710d

is connected to the AES/EBU DB-25 input of the computer’s audio interface, and the word clock output

is connected from the audio interface to the 4-710d word clock input. The software monitoring features

of the DAW are used to monitor the 4-710d inputs.

Key points for this example:

• Mic/Line switch for channels 1 and 2 are set to “Mic”

• Insert switch for channel 3 is set to “In”

• AES/EBU output is connected to computer audio interface

• Word clock out from audio interface is connected to 4-710d word clock input

• Sample Rate knob is set to “W/C” (external clock synchronization is used)

• Computer DAW is used for software monitoring

Page 20

20

Model 4-710d Overview

The Universal Audio 4-710d, with its four mic preamps derived from our TEC award-winning UA Model

710 Twin-Finity Mic/Line/Hi-Z Preamplifier, combines our highly revered analog tube and solid state

preamplification technology... but with a twist. Its unique phase-aligned Blend controls allow the user

to literally dial in the desired sound, from precise ultra-clean solid-state tones to fat tube presence

and overdriven crunch, or anywhere in between. Additionally, each of the four mic preamp channels

has an 1176-style analog compressor that can be individually enabled for each channel.

Other features include JFET Direct Inject inputs (which allows for the direct connection of an electric

guitar or bass, or any instrument with a magnetic or acoustic transducer pickup); monolithic balanced

output stages; +69 dB of gain; +48V power and a -15 dB pad for the mic inputs; polarity inverts and

75 Hz low cut filters; output and “Drive” (input) VU metering; a universal auto-sensing internal power

supply that allows for operation at any voltage between 100 and 240VAC; and a 2U, rack-mountable

design for studio or stage.

4-710d Vacuum Tube Preamp

The 4-710d high voltage (285 VDC) Class-A tube preamp section is based upon both classic guitar

amplifier design and classic tube mic preamp design. The circuit utilizes a 12AX7 tube for warmth and

roundness and is the second gain stage, located downstream from the Gain control pot. This allows

the circuitry to be overdriven by the first stage into anything from mild harmonic distortion to all-out

grunge; however, the transition to tube saturation is extremely gentle. The result is the gradual onset

of harmonic overdrive—no hard clipping here. As an example, the transition from 1% THD to 4% THD

occurs over a 14 dB range. Because of its multiple gain stages, with a Gain control pot between them

(as well as a Drive Meter that displays the signal level entering the second stage), a wide variety of

tonal possibilities can be dialed in, from gentle warmth to extreme grit.

4-710d Solid-State Preamp

The 4-710d solid-state preamp circuitry utilizes Universal Audio’s transimpedance design for precision

sound and ultra-low distortion, delivering the highest possible quality of signal from input to output.

The term “transimpedance” refers to transistor configurations that employ current feedback to provide

gain and distortion immunity without the loss of sonic detail or musicality. Designed for applications

requiring the ultimate in transparent amplification with little or no coloration, its razor flat and

immensely wide frequency response yields highly accurate results and minimizes artifacts on the way

to the recording medium.

Noise and distortion are kept to near-theoretical minimums so critical signals may be generously

amplified without degrading the quality or character of the sound source. Zero-coloration preamps

such as these are especially useful for capturing the sound source with its original qualities and

character so that later processing may occur with maximum flexibility. There are no transformers or

tubes in the preamp signal path, and the 1176-style compressor/limiter (located after the

preamplifier) can be switched out as desired to eliminate permanent audio coloration. For many users,

the useful characteristics of these devices are preferred at the mix stage—and are commonly

implemented using DSP processors and plug-ins with excellent (and reversible) results, such as those

found on Universal Audio’s UAD plug-in platform.

About “Class A”

Most electronic devices can be designed in such a way as to minimize a particularly unpleasant form

of distortion called crossover distortion. However, the active components in “Class A” electronic

devices such as the 4-710d draw current and work throughout the full signal cycle, thus eliminating

crossover distortion altogether.

Page 21

Model 4-710d Overview

21

Phantom Power

Most modern condenser microphones require +48 volts of DC (Direct Current) power to operate. When

delivered over a standard microphone cable (as opposed to coming from a dedicated power supply),

this is known as “phantom” power. The 4-710d provides such power when the Phantom switch (

page 11) is engaged (placed in the +48V, up position), applying 48 volts to pins 2 and 3 of the rear

panel output connector.

While, in theory, this should result in no harm to the connected microphone even if it does not require

phantom power, problems can occur if the shield (pin 1) is broken or when using inexpensive

microphones that use the shield as their ground. The application of phantom power can even damage

those older ribbon microphones that have their output transformers wired with a grounded center-tap.

What’s more, the application of phantom power can often result in a loud pop (transient). For these

reasons, we strongly recommend that the Phantom switch be left in its off (down) position when

connecting and disconnecting microphones. Only turn the Phantom switch on if you are certain that

the connected microphone requires 48 volts of phantom power. If in doubt, consult the

manufacturer’s owner’s manual for that microphone.

Polarity Inversion

The occasional need for polarity inversion (changing the 4-710d front panel switch from IN ø to OUT ø)

is best demonstrated by a common example: recording an open-backed guitar amplifier with two

microphones, where one mic is placed close to the front of the amp's speaker and the other near the

back of the amp. The waveform display of the first mic will show an upward peak when the speaker

pushes outward, placing positive sound pressure on the mic. However, the waveform display of the

second mic (the one behind the amp) will show a downward (negative) valley when the speaker pushes

forward, because from the back of the amp the speaker moves away from the mic, thus creating

negative sound pressure. If these two signals are mixed, the positive waveform from the front mic

combines with the negative waveform from the back mic to result in cancellation of much of the amp's

sound and a "thinning effect" that is sonically disappointing. However, if the phase of one of the mic

signals is inverted, the two signals will combine instead of cancelling, and the result will be much

fuller and sonically pleasing.

Other double-mic applications often requiring phase inversion include piano soundboards, drum heads

(one mic on top of the drum and the other below it), and acoustic guitar miking, where one mic is

placed close to the soundhole and another further away or behind the guitar.

Low Cut Filtering

A common method for optimizing mixes is to apply low-cut filtering whenever possible. Excessive low

frequencies from microphones and instruments tend to build up in the mix, creating sonic “mud” that

masks musical detail, overloads or fatigues the listener’s ears, and sucks energy from power amps

and speakers. It isn’t uncommon to notice meters showing noticeably lower levels after low-cut

filtering is applied—a sure sign that such filtering was necessary. In addition, after low-frequency

mud is filtered, there is often more room in the mix to bring up important musical elements such as

vocals and lead instruments, resulting in a win-win situation (less mud = more music).

Typically, a low cut filter can be used to remove: vocal "B","P" and other popping sounds; moving-air

noise from close-miked vocals, drums, guitars and outdoor weather; instrument body noise from

handling guitars, basses, pianos, saxophones, etc; mic-stand vibrations; studio or stage floor

vibrations; air-conditioning; electrical hum; and unwanted proximity-effect bass boost.

Page 22

Model 4-710d Overview

22

A/D Conversion

The 4-710d conveniently provides eight channels of high-quality analog to digital (A/D) conversion

with digital output via AES/EBU DB-25 and ADAT optical connectors. No matter what task you give it,

the 4-710d can dramatically improve the quality of your audio environment. The 4-710d provides up to

eight channels of sterling sound quality for tracking, monitoring and mastering, with full support for

today’s higher sample rates of 88.2, 96, 176.4, and 192kHz. These capabilities make the 4-710d an

excellent front end for any digital audio workstation. The 4-710d delivers superb audio fidelity thanks

to its pristine Class-A analog signal path.

AES/EBU Digital Output

All eight channels of the 4-710d’s A/D converters are output in AES/EBU digital format on an industrystandard DB-25 connector. The 4-710d AES/EBU output supports “Single Wire” mode at all available

4-710d sample rates (the AES/EBU output does not support “Dual Wire” mode at sample rates above

96 kHz).

ADAT Optical Digital Output

The 4-710d provides two standard ADAT optical digital output ports. At sample rates of 44.1kHz and

48kHz, all eight channels are output on both ADAT ports. At higher sample rates, industry standard

S/MUX™ multiplexing is used to maintain high-resolution transfers.

Word Clock I/O

Word clock input and output is provided for synchronizing (slaving) with external hardware devices.

Connections are via standard 75-ohm BNC connectors. Switchable 75-ohm termination is available.

Digital Metering

Digital output level metering for A/D conversion is provided by eight 2–segment LED displays. Each

channel has its own output indicator.

(Digital meter behavior is described in #18 on page 13)

Page 23

23

Digital Clocking Primer

Digital clocking is a complicated issue, with a number of important aspects that are often not very

well understood.

First and foremost, a digital clock is used to maintain synchronization between different digital

devices. There are two primary purposes for clock synchronization:

1. Digital Conversion. Analog-to-digital (A/D) conversion and digital-to-analog (D/A) conversion need

extremely accurate clocking in order to correctly process the digital data. A low-quality clock can

degrade the signal in many ways, including loss of transparency, clarity, imaging and transient

response, as well as increased noise and distortion.

2. Digital Transmission. All digital devices need accurate clocking in order to properly transfer digital

data between interconnected devices. A low-quality clock can cause data reception errors, which

add distortion and noise, and if the clock isn’t synchronized correctly, samples may be dropped or

repeated, resulting in audible clicks or dropouts.

Clock quality is defined two ways: First, the sample rate must match the signal. This is referred to as

“sample rate synchronization.” Second, the clock signal must be stable over both short- and long-term

clocking intervals. “Jitter” refers to short-term clock accuracy, and “stability” or “drift” refers to longterm clock accuracy. These terms are discussed in more detail below.

Sample rate synchronization is required for proper digital transmission, and is relatively easy to

maintain. Basically, there must be one and only one “clock master” for all interconnected digital

devices. This is done by setting one device to “master” mode (where it synchronizes to its internal

clock and transmits that clock signal) and setting every other device to “slave” mode (where it

receives and synchronizes to external clock), with the appropriate clock signal routed between the

master and slave devices. Keep in mind that any device, whether it’s the clock master or a slave, can

send or receive data once everything is synchronized correctly.

When doing digital conversion, it’s best to have the converter serve as the clock master. For example, if

you’re recording, clock everything off the A/D converter. Likewise, if you’re mixing, clock everything off

the D/A converter. If you’re running multiple converters, use the device with the best quality clock as

master.

For all-digital transfers, e.g., a digital transfer from one DAW or storage device to another, clock

synchronization is maintained by simply setting up the proper master-slave relationship between

devices. Digital transfers can be affected by clock jitter, but not in the same way clock jitter affects

analog conversion. This is a widely misunderstood concept we’ll discuss in detail below.

Clock jitter is short-term variations in the edges of a clock signal, as opposed to clock drift, which is

long-term variations in the clock rate. A clock could be very stable over the long term, but still have

jitter, and vice versa. Timing variations are caused by noise and/or interference. If the

noise/interference is a high-frequency signal, the result is jitter, and if the noise/interference is a lowfrequency signal, the result is drift. As an analogy, a car with an out of balance wheel may drive

straight, but you’ll get lots of vibration (jitter); conversely, a car with a loose steering wheel might

have a smooth ride, but it will drift all over the road.

Clock drift affects long-term synchronization, like sound to picture, and can introduce slight pitch

variations in the audio. Usually however, the drift is so slow that these pitch variations are only tiny

fractions of a cent, and thus unnoticeable.

Page 24

Digital Clocking Primer

24

Clock jitter affects digital transmission and digital conversion differently, as follows:

• Clock jitter in digital transmission can be caused by a bad source clock, inferior cabling or

improper cable termination, and/or signal-induced noise (called “pattern-jitter” or “symbol-jitter.”)

Digital signal formats like AES/EBU, S/PDIF, and ADAT all embed a clock in the digital signal so the

receiving device can synchronize to the transmitted data bits correctly. The clock used for data

recovery is extracted from the signal using a clock synchronization circuit called a phase-lockedloop (PLL). This data-recovery PLL must be designed to respond very quickly to attenuate highfrequency jitter and avoid bit errors during reception. This clock from the data-recovery PLL cannot

be used to generate the clocks used for digital conversion without further clock conditioning! This

is a very common design flaw in most low- and mid-range digital converters.

• Clock jitter in digital conversion is what most people refer to when they discuss jitter. It’s easily

observed in a digital signal by looking at its spectrum in the frequency domain. A jittery signal will

have “side-lobes” around each frequency and/or spurious tones at random, inharmonic

frequencies. Usually, the jitter will be worse with higher signal frequencies. You can test your

converters by sampling a high-quality 10kHz sine wave, and viewing it in the frequency domain

(available with any good wave editing software package).

All modern over-sampling digital converters require a clock (called “m-clock”) that is many times

(typically several MHz) higher than the sample clock. M-clock is easy to generate when the converter is

the clock master, but quite difficult to generate correctly when the converter needs to sync to an

external clock.

External clock typically comes from a dedicated word clock input, or is extracted from the incoming

digital AES/EBU, S/PDIF or ADAT signal. Word clock cannot be used by the converters until it is

multiplied up to the m-clock rate. This requires a PLL or other frequency multiplier circuit which will

either be cheap and jittery, or expensive and clean, depending on who makes the converter. As we said

earlier, the clock recovered from the digital inputs is unsuitable for use as the converter’s m-clock, but

because it’s conveniently at the same frequency, many designers don’t bother cleaning up this signal.

Since the clock recovery, clock multiplier, and clock conditioning circuitry define the jitter for analog

conversion, no external clock source can clean up the jitter introduced by these circuits, regardless of

how perfect the external source clock is. The best they can do is avoid making it any worse, but this is

hardly worth the cost: It’s much better (and less expensive) to get a good converter than it is to try and

fix a bad one with an expensive master clock. The only reason to spend money on a high-quality master

clock is to ensure that multiple devices are synchronized correctly. This is essential for working with

audio for film/video, or when synchronizing multiple high-quality converters. A poor master clock can

also affect imaging and clarity in a multi-track environment.

The 4-710d provides high-quality analog to digital conversion for recording and/or playback. With its

pristine audio path, high-quality clocking, and simple front panel controls, it makes a great master or

slave audio interface for every digital studio, and thus provides a very cost effective way to improve

overall sound quality.

In order for the 4-710d to detect and lock to a valid external word clock, the frequency of

the incoming word clock must be within ±3% of any of the supported sample rates (44.1,

48, 88.2, 96, 176.4, or 192 kHz). If the frequency of the incoming work clock is not within

±3% of a supported sample rate, the LOCK indicator will glow red, the WORD CLOCK OUT

will be driven at 48 kHz, and the digital outputs will be driven at 48 kHz and muted.

Page 25

25

Insider’s Secrets

The Best of Both Worlds

There’s a reason why tube preamplifiers have long been favored by audio engineers (especially in this

age of digital recording): they impart a warmth and richness that makes most sounds larger than life.

However, there is no denying that tube preamps also tend to color the incoming signal somewhat,

albeit in a way which most listeners find pleasant and desirable.

On the other hand, the recording of voice and acoustic instruments sometimes requires precise signal

handling with meticulous attention to detail, definition and accuracy. Applications such as classical or

jazz recording demand faithful transfer of performances exactly as they happen, without coloration,

processing, noise or distortion, and that is where solid-state preamplifiers shine. Plus, by capturing

the sound as it is, you can leave sound sculpting and “coloration” decisions until later, during the

mixing stage.

So the question is, which kind of preamp to use? Up until now, the only solution has been to have an

arsenal of both kinds at your disposal, but with the 4-710d, that’s no longer necessary, since it

provides both designs in one box, as well as a unique Blend control that allows the user to dial in the

precise contribution of each preamp to the overall sound. As a good starting point, we recommend that

you set the Blend control to the desired degree of tube coloration, then back it off slightly (towards the

TRANS position) to dial in the precise amount of “snap” and detail you want in your sound.

Drive Metering

Because it shares lineage with vintage guitar amplifier designs, the 4-710d’s tube preamplifier can

contribute precise amounts of even-order harmonic distortion (the kind the ear enjoys listening to) to

your signal, ranging from pleasant amounts of rasp to all-out grunge. The Drive meter function can be

a great tool in helping to decide how high to raise the Gain control because it indicates how much tube

saturation is going to be present in the output signal. It does this by monitoring the signal that is

driving the tube. If what you want is crystal clear tube tone, then the meter will be bouncing around

near the low end of its range. If what you are after is a ton of tube dirt, then drive the meter into the

red; there is nothing wrong with either extreme. Once you use the Drive function a few times, you will

develop a feel for it, and should be able to dial in the desired tube character quickly and easily.

When in Drive mode, the 4-710d meter is calibrated so that 0VU is equal to 1.2% THD on a 1KHz sine

wave. However, measured distortion levels can be misleading because they are so source and style

dependent. 2% THD on a sine wave is a fair amount of distortion and will be apparent to even the nonmusically inclined. On a vocal track, however, that same 2% THD sounds like some really nice tube

warmth. On an overdriven guitar, 2% is barely even audible. The most important thing to remember

when using the Drive function is that there is no “wrong” meter reading, only wrong tones for a

particular track. So use the meter as guide, not as a pass/fail test. Do what feels and sounds right,

and don’t be afraid to push it.

Vocals, Vocals, Vocals

Just as certain microphones work best with certain vocalists, so too do certain mic preamps. The

presence of not just one, but two completely discrete preamps in the 4-710d mean that it will work

wonders with just about any microphone... and with just about any vocalist.

The crisp precision of a condenser microphone, for example, can be matched perfectly by the uncolored

accuracy of the 4-710d’s transimpedance solid-state preamp... or you can instead opt to use the tube

side to “warm up” the tone. Better yet, use the Blend control to dial in exactly the right amount of both

preamps to match both the microphone’s frequency characteristics and the timbral quality of the

vocalist. And if you’re using the already warm sound of a tube microphone for vocals, try

Page 26

Insider’s Secrets

26

complementing it with the 4-710d’s solid-state preamp (or use the Blend control to dial in a

combination of the two that favors the contribution of the TRANS side).

Electric Guitar and Bass

There’s something very special about the mix of tube preamplification and electric guitar and bass,

which is why tube amps are so prevalent in that world. Cranking up the 4-710d's Gain control will

impart anything from a slight bark to total grunge. Set the Blend control all the way to TRANS for that

overloaded console effect, or all the way to TUBE to emulate the grittiness and bite of an overdriven

guitar amp... or anywhere in-between for a custom guitar sound perfectly crafted to the context of the

song.

Electric bass players may want to set the Blend control so that the solid-state amp is slightly favored

(try a 10 o’clock position to start), allowing you to take advantage of the precision of the

transimpedance preamp stage, combined with just a touch of tube warmth. For acoustic bass, try

dialing in just a touch more tube preamp.

Acoustic Guitar

The 4-710d is also a powerful tool for the recording of acoustic guitar. Try pairing it with a smalldiaphragm omnidirectional mic and then set the Blend to about the 2 o’clock position (thus slightly

favoring the tube preamp) for a sound that is both pristine and warm.

Horns and Reeds

The incredible detail provided by the 4-710d’s solid-state transimpedance preamp make it a perfect

match for horn and reed instruments. Dial in just a touch of the tube preamp (set the Blend control to

approximately 9 o’clock) to add a touch of tube warmth, and you’ve got a sound that will work in just

about any musical context.

Drums

The huge range of sonic possibilities offered by the 4-710d make it an invaluable companion for any

kind of drum miking. The excellent transient response of its solid-state transimpedance preamp serves

to enhance overhead and ambient mics picking up the crispness of cymbals, while the roundness of its

tube preamp adds fullness to snare and tom mics. Again, the best solution is usually a blend of the

two, depending upon the specific mics being used and the mic positioning. Be sure also to experiment

with the 4-710d polarity control whenever multiple mics are being used!

Improving the Sound of Your Microphone

Incredible but true: in some cases, the 4-710d can make an inexpensive microphone sound like an

expensive one. Even an inexpensive stage dynamic microphone can come to life when routed through

one or both 4-710d preamps, adding richness and airiness to the sound without adding undesirable

graininess or coloration.

Live Applications

Although the 4-710d was designed primarily for use in recording, it can also serve as a powerful

addition to a live sound rig, especially in FOH (Front Of House) applications. Because its tube preamp

section is based on vintage guitar amp design, it can even be used as an onstage preamp; just plug

your instrument directly into its Hi-Z input and then route the 4-710d output to a power amp and/or

FOH console input.

Page 27

27

History of the Model 4-710d

Like the microphone, preamplifiers come in all shapes, sizes and colors. And, like a microphone, the

preamp is one of many devices that may impart a sound to a recording... or may conversely attempt to

avoid coloration. In this way, mics and preamps can be compared to the various paints, brushes and

surfaces a visual artist may choose from, or to the various films, lenses and filters the photographer

uses in his process. In the same way that a photographer might choose a certain filter to reject a

certain type of light, a recording engineer may do the same with a mic to tailor out a certain frequency

range. The photographer may choose a particular film to convey a certain atmosphere, and a recordist

might choose a particular preamp for the very same reason. The critical decision is whether or not the

given device imparts the correct character (or lack thereof) for a given recording. The best thing about

choosing the right mic and preamp for the job is that when the session is going great and the music is

truly happening, the quality, character and nuanced detail of the engineer’s tools really begin to shine.

Because it is the component which transforms the very low-level signal from a microphone into a

useable signal—a critical transition of energy—the quality of the preamplifier plays a huge role in

shaping the final signal. And ultimately, a great mic preamp is all about great design.

Throughout the half-century or so of modern recording technology, a number of preamp designs have

been introduced, all with their own strengths and weaknesses. Early preamplifiers relied on vacuum

tubes to boost signal. One of the most popular preamps of the era was the one inside the 610 console

built by Bill Putnam Sr. in 1960 for his United Recording facility in Hollywood. As was the case with

most of Putnam’s innovations, the 610 was the pragmatic solution for a recurring problem in the

studios of the era: how to fix a console without interrupting a session. The traditional console of the

time was a one-piece control surface with all components connected via patch cords. If a problem

occurred, the session came to a halt while the console was dismantled. Putnam’s answer was to build

a mic-pre with gain control, echo send and adjustable EQ on a single modular chassis, using a printed

circuit board. Though modular consoles are commonplace today, the 610 was quite a breakthrough at

the time.

While the 610 was designed for practical reasons, it was its sound that made it popular with the

recording artists who frequented Putnam’s studios in the 1960s. The unique character of its microphone preamplifier in particular made it a favorite of legendary engineers like Bruce Botnick, Bones

Howe, Lee Hershberg, and Bruce Swedien, who has described the character of the preamp as “clear

and open” and “very musical.” The 610 console was used in hundreds of studio sessions for internationally renowned artists such as Frank Sinatra, Ray Charles, Sarah Vaughan, the Mamas and Papas,

the Fifth Dimension, Herb Alpert, and Sergio Mendes. The Beach Boys’ milestone Pet Sounds album

was also recorded using a 610.

But by the mid 1960’s, tiny solid-state components called transistors, followed by advanced technological innovations such as FETs (Field Effect Transistors), op amps (operational amplifiers), and ICs

(Integrated Circuits), had become ubiquitous and inexpensive to manufacture. These all did the job of

vacuum tubes, but with greater efficiency and reliability, less heat, much smaller size, and much

longer lifetimes. For these reasons, audio circuit designers such as Bill Putnam began creating preamplifiers using transistors instead of tubes. One of the first of these was the Universal Audio 1108.

This was an exquisitely designed, widely used single-stage modular preamp made for modular recording consoles. It featured input and output transformers, with connections for modular equalizers

such as the UA 508 EQ. This amp design became the basis for the enormously popular 1176 limiter,

which utilized the same output transformer. Interestingly, the 1108 has probably been used on many

more classic recordings than the 610, due to its broad popularity.

Page 28

History of the Model 4-710d

28

Throughout the years, solid-state preamplifiers have evolved into ever more sophisticated designs

(such as the Precision mic preamp utilized in the Universal Audio SOLO/110 and multichannel

4110/8110, and the transimpedance design first unveiled in the Universal Audio DCS Remote Preamp).

Until fairly recently, solid-state models were the norm in recording studios, but somewhere around the

explosion of digital recording, tube preamps suddenly became fashionable again, serving for some as

the antidote to so-called “cold” DAWs. Despite the fact that technology has vastly improved the quality

of even the least expensive converters and that higher sample rates and bit rates are commonly being

used, many still find something unforgiving about the medium. But there is more than one way to skin

the digital cat, and nowadays engineers reach for those tools that inject the correct character back

into what some call an overly critical medium.

The key is knowing which tools to reach for... and, in the case of preamplifiers, whether to opt for the

“warmth” of tubes or the precision of solid-state. The Universal Audio 4-710d allows the recordist to

literally enjoy the best of both worlds. Not only does it combine two preamplifiers per channel—one

vacuum tube and one solid-state—in a single box, its unique Blend control allows the engineer to dial

in precisely the desired amount of tone from each. The 4-710d is truly a cutting-edge product for its

time.

In 2000, Bill Putnam Sr. was awarded a Technical Grammy for his multiple contributions to the recording industry. Highly regarded as a recording engineer, studio designer/operator and inventor, Putnam

was considered a favorite of musical icons Frank Sinatra, Nat King Cole, Ray Charles, Duke Ellington,

Ella Fitzgerald and many, many more. The studios he designed and operated were known for their

sound and his innovations were a reflection of his desire to continually push the envelope. Universal

Recording in Chicago, as well as Ocean Way and Cello Studios (now EASTWEST) in Los Angeles all

preserve elements of his room designs.