Page 1

Operator Instructions Important

t

Includes - Foreseen Use, Work Stations, Putting Into Service,

Operating, Dismantling, Assembly and Safety Rules

Manufacturer/Supplier Product Type

Universal Air Tool Company Limited

Unit 8

Lane End Industrial Park

High Wycombe

Bucks

HP14 3BY

Tel No Fax No

(01494) 883300 (01494) 883237

Read these instructions carefully before insta lling, operating,

servicing or repairing this tool. Keep these instructions in a safe

accessible place.

Straight Reversible

Screwdriver

Model No/Nos Serial No

UT8955

RPM

1600

Cycles Per Min

Product Nett Weight Recommended Use Of

2.42

1.1

Recommended Working

Recommended Minimum

Maximum

Perso n a l Sa fe t y E q ui pm en t

Use - Safety Glasses

Use - Safety Gloves

Use - Safety Boots

Use - Breathing Masks

Use - Ear Protectors

lbs

Balancer Or Support

Kg

Air Pressure

6.3

n/a

7.0

bar

bar

bar

No

90

n/a

100

Yes

Foreseen Use

These screwdrivers are designed for the tightening and

loosening of threaded fasteners within the range as specified by

the manufacturer. They should only be used in conjunction with

1/4" male hex shank screwdriver bits and fastener drivers.

Do not use the tool for any other purpose than that specified

without consulting the manufacturer or his authorised

representative.

Work Stations

The tool should only be used as a hand held, hand operated

tool. It is always recomme nded that th e tool is used wh en

standing on a solid floor. It can be used in other positions, but

before any such use the operator must be in a secure position

having a firm grip and footing. The operator must adopt a firm

grip sufficient to resist the torque reaction of the tool, i.e. the

tool will try to turn in the hand.

The operator must also be

aware t hat when lo osening

fasten ers, the tool can move

quite quick ly aw ay from the

fastener being undone. An al-

low anc e m us t b e m ade fo r

this rearwar d mo vement t o

avoid hand entrapment. The

operator must also make al-

lowance that if the tool does

turn in the hand, the hand is

not trapped against any rigid

object.

Recommended Hose Bore

Size - Minimum

3/8 10 30 10

Ins M/M Ft M

Noise Level

Sound Pressure Level 83.0 dB(A)

PSI

Test Method

PSI

est code PN8NTC1 and ISO Standard 3744

PSI

Vibration Level

Test Method

Tested in accordance with Pneurop

11.8

Tested in accordance with ISO

standards 8662 Parts1 & 7

Putting Into Service

Air Supply

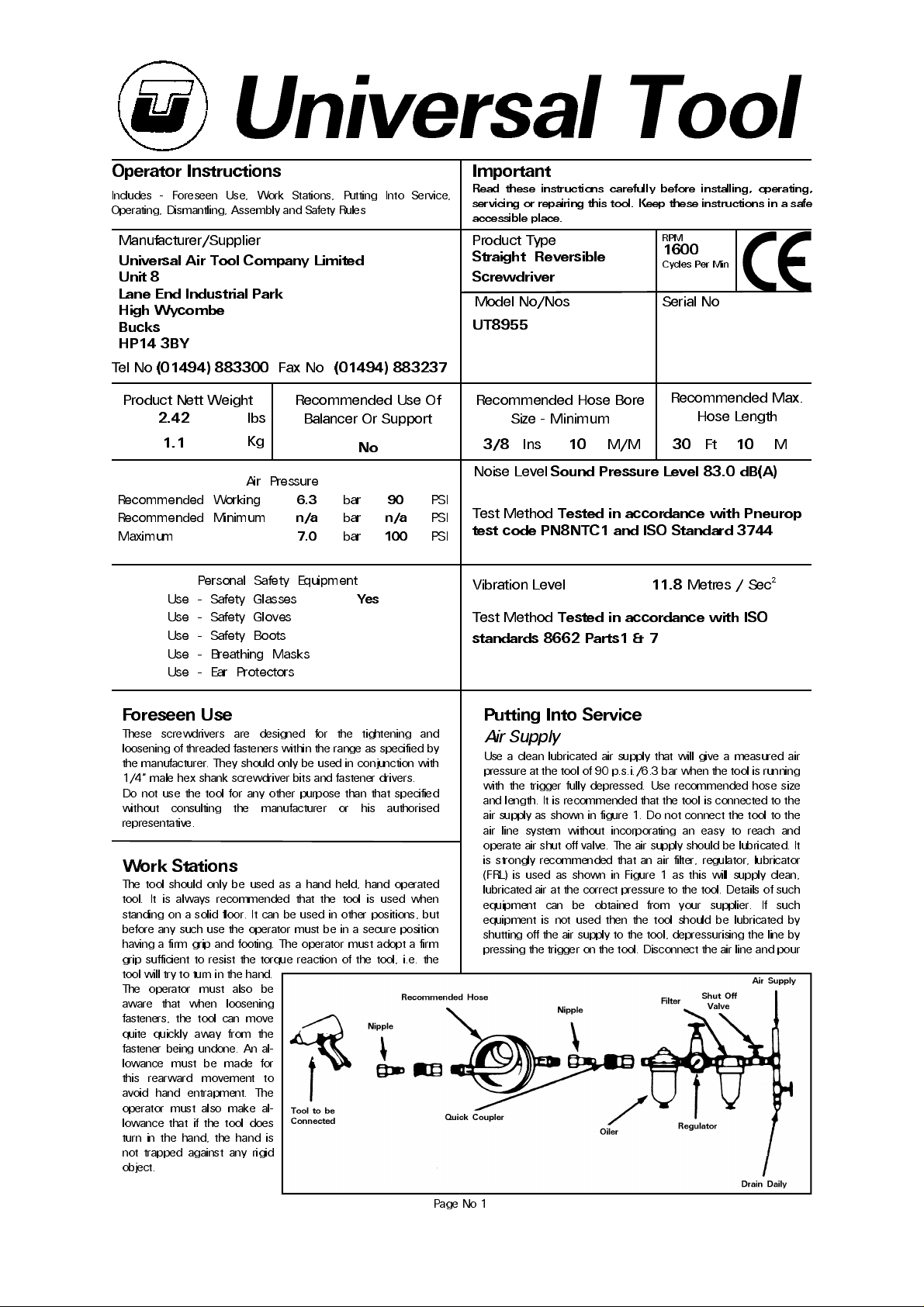

Use a clean lubricated air supply that will give a measured air

pressure at the tool of 90 p.s.i./6.3 bar when the tool is running

with the trigger fully depressed. Use recommended hose size

and length. It is recommended that the tool is connected to the

air supply as shown in figure 1. Do not connect the tool to the

air line sys tem withou t incorporating an easy to reach a nd

operate air shut off valve. The air supply should be lubricated. It

is strongly recommended that an air filter, regulator, lubricator

(FRL) is used as shown in Figure 1 as this will supply clean ,

lubricated air at the correct pressure to the tool. Details of such

equipment can be obtained from your supplier. If such

equipment is not used then the tool should be lubricated by

shutting off the air supply to the tool, depressurising the line by

pressing the trigger on the tool. Disconnect the air line and pour

Recommended Max.

Hose Length

Metres / Sec²

Page No 1

Page 2

into the intake bushing a teaspoonful (5ml) of a suitable

pneumatic motor lubricating oil preferably incorporating a rust

inhibitor. Reconnect tool to air supply and run tool slowly for a

few sec onds to allow air to circulate the oil. If tool is used

frequently lubricate on daily basis and if tool starts to slow or

lose power.

It is recommended that the air pressure at the tool whilst the

tool is running is 90 p.s.i./6.3 bar. The tool can run at lower and

higher pressures with the maximum permitted working air

pressure of 100 p.s.i./7.0 bar.

Operating

Select the correct screwdriver bit or fastener driver to suit the

screw or fastener to be tightened or loosened. Slide back the

sleeve (74) and insert appropriate drive bit.

This model has an adjustable clutch so that the torque applied

to the fastener can be adjusted to give the required tightness

within the torque range of the tool. To set the tool to give a

particular torque output, first remove the clutch housin g - left

hand thread and pull out the clutch assembly being careful not

to lose guide pin and spring (32) and (31). Hold the clutch carrier

or insert a 1/4 hex Allen key into work spindle (84) and with a

spanner rotate adjustment nut (77) until it just touches sleeve

bearing (76). T his is the clu tch set at its lowest ou tput lev el.

Reassemble the tool, try it on the joint to be fastened. If more

torque is required to place the fastener repeat the process but

rotate the adjustment nut (77) until there is a gap between it and

the sleeve bearing proceeding at approximately one turn of the

nut at a time until the correct tightness is achieved. If too high a

setting is reached rotate the adjustment nut back a part of a turn

at a time.

If the adjustm ent nut (77) is rotated too far along the clutch

spindle (84) it is possible that th e clutch will not slip and a

reaction torque against the hands will be felt. In this situation, if

the fastener is not sufficiently tightened or cannot be loosened

then the tool in adjustable clutch mode has insufficient capacity.

Select a more powerful tool. The person setting up the tool must

be aware of this torque reaction at high setting levels of the

clutch and that the tool will try to turn against the hand. All that

is required is a firm grip.

The tool, when the stall torque position has been reached, can

still be used to set or loosen fasteners, provided the operator is

aware of the need to resist the torque reaction of the tool.

Furth er adjustment of adjustin g nut (77) at th is point will not

increase the output of the tool. The only thing that will affect the

output is a change in the air supply pressure. The output can be

increased up to the use of the maximum allowed supply

pressure and decreased with a reduction in supply pressure until

the tool fails to operate.

It must also be understood that even if the clutch is set to slip it

may not do so if the supply air pressure falls below the pressure

at which the clutch was set. It is therefore strongly

recommended that a pressure control valve is used. Information

as to suitable equipment can be obtained from your supplier.

When using the tool keep the screwdriver bit pressed firmly into

the screw head to avoid cam out and screw head damage.

Dismantling & Assembly Instructions

Disconnect from air supply.

Grip the tool in a vice fitted with soft jaws on the flats at the rear

end of motor housing (1) and unscrew clutch housing (75) - left

hand thread and take out the clutch assembly being careful not

to lose guide pin (32) and guide pin spring (31). Grip the clutch

and with a sharp pointed needle tool prise out retaining ring (71)

and tak e off wash er (72), ball retain ing spring (73) and ball

retaine r (74) being careful not to lose bit retaining ball (83).

Again with a sharp pointed tool, remove a second retaining ring

(71) and pull off spacer (76). Unscrew adjusting nut (77) and pull

off spring seat (78), clutch spring (79) and thrust washer (80).

Remove from vice and tap the front end to remove 4 off balls

(81). Remove wiper (87) and then remove snap ring (85) and

separate clutch jaw (82) from work spindle (84). Remove a third

retaining ring (71) and pull off dog (86) from work spindle (22).

Unscrew lock ring (29) from motor housing (1). Grip the lock

ring and push out the internal assembly and separate bearing

(35), seal plat e (33), internal gear (18), 3 off idler gears (20)

complete with 3 off idler gear bushes (21) and work spindle

(22). Idler gear bushes may be pressed out of idler gears (20)

but do not remove 3 off idler gear pins (19) from work spindle

(22).

Grip the end of rotor (26) and pull out the complete motor

asse mbly. Remove pin (28), motor gask et (44) and take off

retainer ring (38). Grip the spacer (27) and with a non metallic

or soft metal (lead or aluminium) hammer tap the splined end of

the rotor (26) to drive it through bearing (34) and end plate (23).

Remove cylinder (24) and take out 5 off rotor blades (25) from

rotor (26). Support the rear end plate (23) and tap the rotor (26)

through the rear plate (23) and bearing (34).

Pull the sides of hanger (42) apart to remove it from its retaining

holes. Drive out roll pin (40) and remove leve r (2). Unscre w

bushing (10) complete with screen (11) and carefully prise out,

with a sharp needle pointed tool, deflector stop ring (8). Pull out

deflector (7) and prise out O-ring (9) from deflector (7). Remove

2 off screws (30) and pull off housing cap (12), muffler (41) and

housing gasket (13).

Unscrew valve screw (39) and remove O-ring (36), reverse valve

retainer (15), spring (16), plastic valve (4) and pin (3). Drive out

pin (45) to remove re verse valve bus h (6), reverse valv e (5),

spring (14) and push out valve bushing (17) if a replacement is

required.

Reassembly

Clean all components and examine for wear. Look in particular

for wear and cuts on O-rings, wear on rotor blades, gear and

clutch components.

Coat all parts with a pneumatic tool lubricating oil, one

preferably containing a ru st inhibitor and gre ase all bearin gs,

gears a nd clutch parts with a molybdenu m or lithium based

general purpose grease.

Before reassembling the motor, make sure that the faces of end

plates (23) that abut cylinder (24) are flat and free from burrs. If

necessary lap on a flat very fine grade of abrasive paper.

Reassemble in the reverse order.

When re fitting the comple te motor a sse m bly to the motor

housing (1) first make sure that the motor assembly is clamped

tightly together and that the rotor spins freely, slide the motor

assembly, with gasket into the motor housing (1) ensuring that

motor pin (28) locates in the motor assembly and in the hole in

the bottom of the main bore of motor housing (1) situated

between the two main ports.

Reset the clutch as required and/or set the correct air pressure.

Safety Rules For A Screwdriver

1) Read all the instructions before using this tool. All operators

must be fully trained in its use and aware of these safety rules.

2) Do not exceed the maximum working air pressure.

3) Use personal safety equipment.

4) Use only compressed air at the recommended conditions.

5) I f the too l appea rs to mal functio n remove f rom use

immediately and arrange for service and repair.

6) If the tool is used with a balancer or other support device

ensure that it is fixed securely.

7) Always keep hands away from the working attachment fitted

to the tool.

8) The tool is not electrically insulated. Never use the tool if there

is any chance of it coming into contact with live electricity.

9) Always when u sing the tool a dopt a firm footing and/or

position and grip the tool firmly to be able to counteract any

Page No 2

Page 3

UT8955

Straight Reversible Screwdriver

Ref No Part No Description

1 90019 1 Motor Housi ng

2 90019 2 Throttle Lev er

3 900193 Valve Pin

4 900668 Valve

5 90019 4 Rever se Val ve

6 90019 5 Rever se Val ve Bush

7 729702 Deflector

8 729703 Deflector Stop Ring

9 1012371 O-Ring

10 900196 Bushing

11 1005726 Screen

12 900197 Housing Cap

13 900198 Housing Gasket

14 900199 Reverse Spring

15 900200 Reverse Retainer

16 729063 Valve Spring

17 900201 Valve Bushing

18 732078 Internal Gear

19 900202 Idler Gear Pin (3)

20 732079 Idler Gear (3)

21 900203 Idler Gear Bush (3)

22 900204 Work Spindle

23 900102 End Plate (2)

24 900104 Liner

25 729709 Rotor Blade (5)

26 900103 Rotor

27 900101 Spacer

28 900105 Liner Pin

29 900205 Lock Ring

30 900206 Screw (2)

Nov 2004 Ver 1.2

Ref No Part No Description

31 900207 Guide Pin Spring

32 730272 Guide Pin

33 720231 Seal Plate

34 729012 Ball Bearing (2)

35 732081 Ball Bearing

36 729088 O-Ring

38 732069 Retainer Ring

39 900208 Valve Screw

40 729167 Roll Pin

41 900209 Muffler

42 900210 Hanger

44 900113 Motor Gasket

45 731930 Roll Pin

71 730257 Retainer Ring (3)

72 730258 Washer

73 730259 Ball Ret. Spring

74 730260 Ball Retainer

75 900355 Clutch Case

76 730262 Sleeve Bearing

77 730263 Adjust Nut

78 730264 Spring Seat

79 730265 Clutch Spring

80 730266 Thrust Washer

81 1005080 Steel Ball (1/4") (4)

82 730267 Clutch Jaw

83 1005164 Steel Ball (1/8")

84 730268 Work Spindle (B)

85 730269 Snap Ring

86 730270 Dog

87 730281 Wiper

Page No 3

Page 4

A

Declaration of Conformity

Universal Air Tool Company Limited

Unit 8, Lane End Industrial Park, High Wycombe, Bucks, HP14 3BY, England

declare under our sole responsibility that the product

Model UT8955, Straight Reversible Screwdriver, Serial Number

to which this declaration relates is in conformity with the following standard(s) or other normative document(s)

EN792 (Draft), EN292 Parts 1 & 2, ISO 8662 Parts 1 & 7, Pneurop PN8NTC1

following the provisions of

89/392/EEC as amended by 91/368/EEC & 93/44/EEC Directives

Lane End D.H.Moppett (Man. Director)

Place and date of issue Name and signature or equivalent marking of authorised person

forces or reaction forces that may be generated whilst using the

tool.

10) Use only correct spare parts. Do not improvise or make

temporary repairs.

11) Do not lock, tape, w ire, etc. the on/off va lve in the run

position. The trigger/lever etc. must always be free to return to

the 'off' position when it is released.

12) Always shut off the air supply to the tool, and depress the

trigger/lever etc. to exhaust air from the feed hose before fitting,

adjusting or removing the working attachment.

13) Check hose and fittings regularly for wear. Replace if

necessary. Do not carry the tool by its hose and ensure the hand

is remote from the on/off control when carrying the tool with

the air supply connected.

14) Take care against entanglement of moving parts of the tool

with clothing, ties, hair, cleaning rags, etc. This will cause the

body to be drawn towards the tool and can be very dangerous.

15) It is expected that users will adopt safe working practices

and observe all relevant legal requiremen ts whe n installing,

using or maintaining the tool.

16) Do not install the tool unless an easily accessible and easily

operable on/off valve is incorporated in the air supply.

17) Take care that the tool exhaust air does not cause a problem

or blows on another person.

18) Never lay a tool down unless the working attachment has

stopped moving.

19) Always en sure that the reverse button is in th e selected

position before starting the tool.

20) Do not use bits or sockets with excessive wear to the input

and output drives. Make sure the bit, socket, extension is firmly

fixed to the tool.

21) When loosening fasteners first ensure that there is sufficient

clearance behind the tool to avoid hand entrapment. The tool

will move a wa y from th e th rea ded join t a s the n ut/ bolt is

loosened and rides up the thread moving the tool with it.

Notes

Distributor

ccessories

This document may not be copied wholly or in part by anyone without the consent of the Directors of Universal Air Tool Company Limited

Designed & Written in the U.K.

©Copyright of Universal Air Tool Company Limited, established in the United Kingdom, 1994

Page No 4

Loading...

Loading...