Page 1

Operator Instructions Important

Includes - Foreseen Use, Work Stations, Putting Into Service, Operating,

Dismantling, Assembly and Safety Rules

Manufacturer/Supplier Product Type

Universal Air Tool Company Limited

Unit 8

Lane End Industrial Park

High Wycombe

Bucks

HP14 3BY

Tel No Fax No(01494) 883300 (01494) 883237

Read these instructions carefully before installing, operating,

servicing or repairing this tool. Keep these instructions in a safe

accessible place.

Right Angle Drills

Model No/Nos Serial No

UT8807B 3/8" Capacity

UT8807B-1/2

1/2" Capacity

RPM

800

Cycles Per Min

Product Nett Weight Recommended Use Of

2.64 (3/8) 2.97 (1/2)

1.20 (3/8) 1.35 (1/2)

lbs

Kg

Balancer Or Support

No

Air Pressure

Recommended Working 6.3 bar 90 PSI

Recommended Minimum n/a bar n/a PSI

Maximum 7.0 bar 100 PSI

Personal Safety Equipment

Use - Safety Glasses

Yes

Use - Safety Gloves

Use - Safety Boots

Use - Breathing Masks

Use - Ear Protectors

Foreseen Use Of Tool

This drill is designed for the purpose of drilling holes in all types of

materials, i.e. metals, wood, stone, plastics etc. using drilling bits

designed for this purpose. It may be used with other forms of cutting

tools, polishing devices or for sanding using coated abrasive products.

Before using any such products first check with the manufacturer their

suitability for use with this type of drill. Do not use bonded abrasive

products (i.e. grinding wheels) or saw blades or any device which has

a permitted safe working speed less than the free speed of the drill.

Do not use this drill for any other purpose than that specified without

consulting the manufacturer or the manufacturer's authorised supplier.

Work Stations

The tool should only be used as a handheld hand operated tool. It is

always recommended that the tool is used when standing on the solid

floor. It can be

used in other

positions but

before any such

use, the operator must be in a

secure position

having a firm

grip and footing

and be aware

that the drill can

develop a

torque reaction

see section

"Operating".

Recommended Hose Bore

Size - Minimum

Ins M/M Ft M

3/8 10 30 10

Recommended Max

Hose Length

Noise Level Sound Pressure Level 83.9 dB(A)

Test Method Tested in accordance with Pneurop

test code PN8NTC1 and ISO Standard 3744

Vibration Level

Less than 2.5

Metres / Sec²

Test Method Tested in accordance with ISO

standard 8662/1

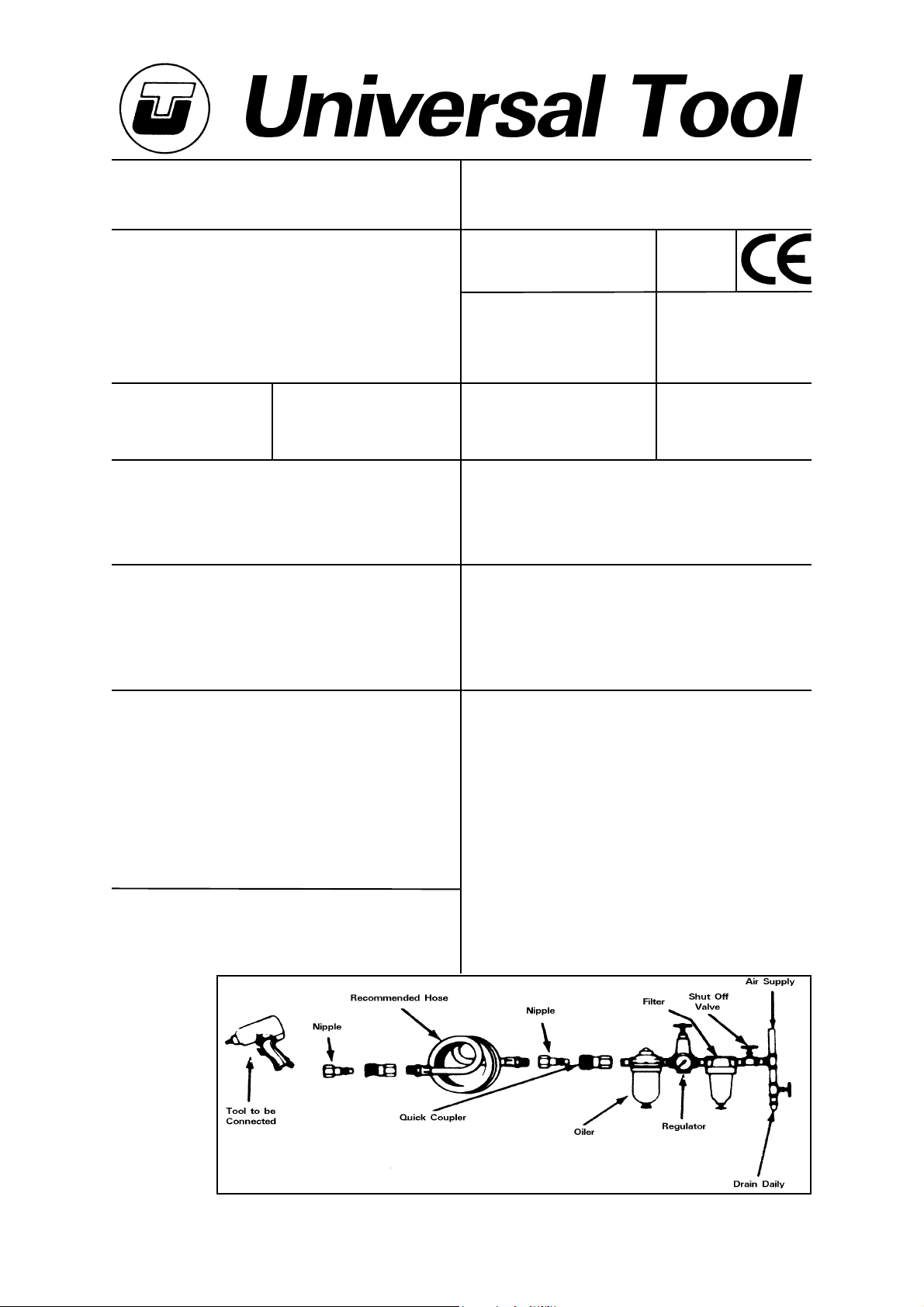

Putting Into Service

Air Supply

Use a clean lubricated air supply that will give a measured air pressure

at the tool of 90 p.s.i./6.3 bar when the tool is running with the trigger

fully depressed. Use recommended hose size and length. It is

recommended that the tool is connected to the air supply as shown

in figure 1. Do not connect the tool to the air line system without

incorporating an easy to reach and operate air shut off valve. The air

supply should be lubricated. It is strongly recommended that an air

filter, regulator, lubricator (FRL) is used as shown in Figure 1 as this will

supply clean, lubricated air at the correct pressure to the tool. Details

of such equipment can be obtained from your supplier. If such

equipment is not used then the tool should be lubricated by shutting

off the air supply to the tool, depressurising the line by pressing the

trigger on the tool. Disconnect the air line and pour into the intake

bushing a teaspoonful (5ml) of a suitable pneumatic motor lubricating

Page No 1

Page 2

oil preferably incorporating a rust inhibitor. Reconnect tool to air

supply and run tool slowly for a few seconds to allow air to circulate

the oil. If tool is used frequently lubricate on daily basis and if tool starts

to slow or lose power.

It is recommended that the air pressure at the tool whilst the tool is

running is 90 p.s.i./6.3 bar. The tool can run at lower and higher

pressures with the maximum permitted working air pressure of 100

p.s.i./7.0 bar.

Operating

Select suitable drill bit, insert the shank into the drill chuck as far as

possible and tighten chuck with key supplied making sure that the

shank of the device is securely clamped centrally between the three

chuck jaws. Remove chuck key.

When drilling holes of all sizes it is advised to use a pointed punch to

mark the centre at which the hole is to be drilled as this will provide

a starting point for the drill tip. This procedure will prevent the drill bit

from skidding, ensure that the hole is drilled where intended and help

to prevent drill breakage when using small drills. When drilling,

particularly with small diameter drills, always try to ensure that load

applied to the drill is such that the drill bit is always at right angles to

the hole being drilled. Do not force the drill but allow it to cut.

When drilling always adopt a firm posture to be able to counteract any

sudden movement of the drill due to torque reaction. Such torque

reaction can occur when the drill stalls due to a too heavy load being

applied or the material being too hard or tough. The torque reaction

can occur when the drill breaks through the material being drilled,

particularly on sheet metal. Always use eye protection and hand

protection is advised, particularly when drilling holes in metals where

the material being removed from the hole is in the form of long sharp

strips. Do not tie the drill chuck key to the drill as the attaching device

i.e. string or chain could become entangled with the rotating chuck

and bit etc.

If using an abrasive device, drilling stone or performing any operation

where dust is created, it is recommended to use a breathing mask.

Always ensure that the material to be drilled is firmly fixed to prevent

its movement.

It is also recommended that when drilling holes of large diameter to

first pre drill a hole of smaller diameter as this will reduce effort

required to drill the hole and minimise torque reaction.

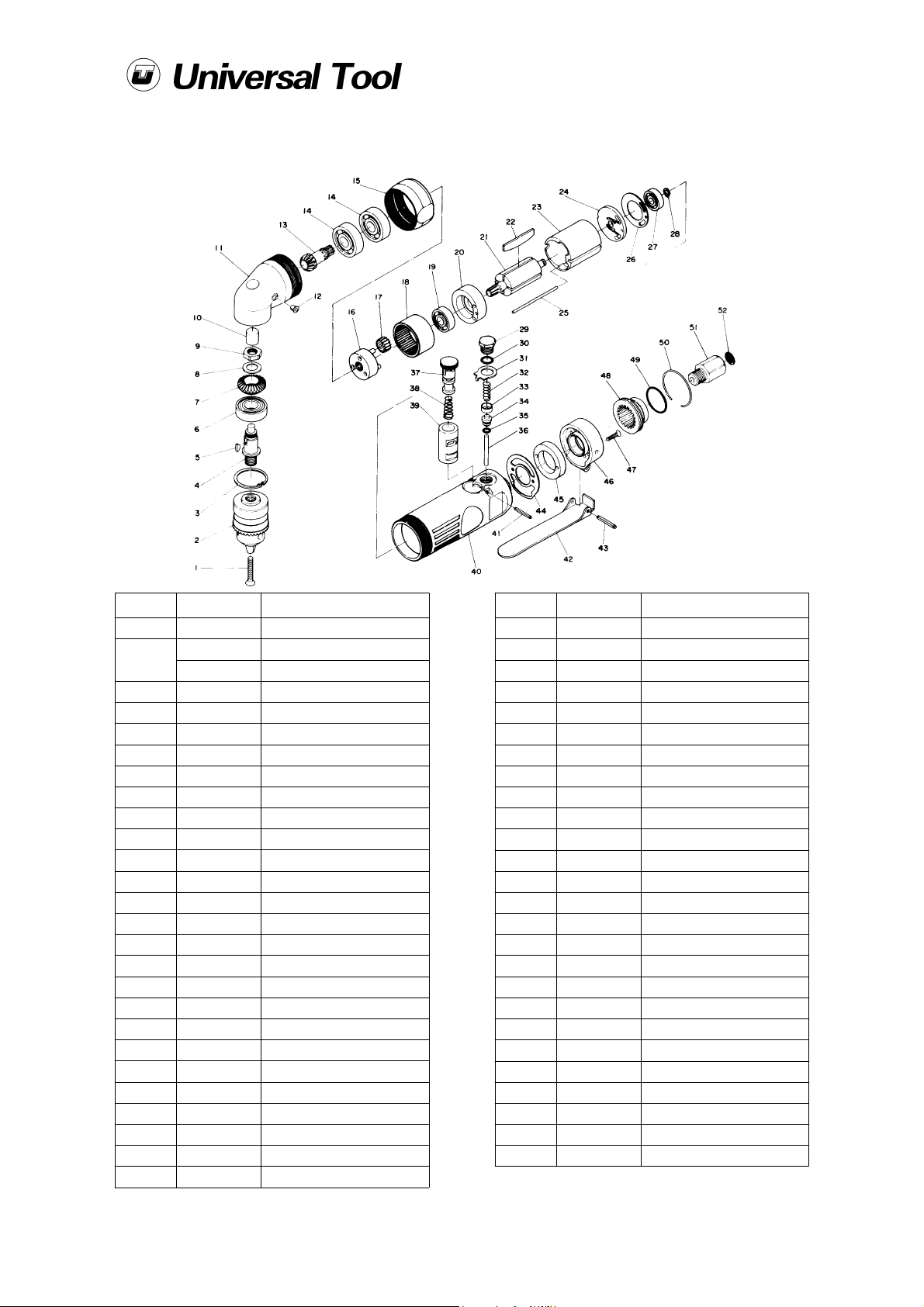

Dismantling & Assembly Instructions

Disconnect tool from air supply.

To remove the drive chuck (2) first open the chuck jaws with the key

provided and remove chuck screw(1) [left hand thread]. Place chuck

key securely into chuck and give the key a sharp tap so as to unscrew

a right hand thread. Grip motor housing (40) in a vice with soft jaws

on the flats at the rear end. Drive out pin (43) and take off throttle lever

(42). Unscrew inlet bushing (51) together with screen (52). With a

needle pointed tool, prise out deflector retainer (50), pull out deflector

(48) and remove O-Ring (49) from deflector (48). Unscrew 2 off

screws (47) and take off body cap (46), muffler (45) and gasket (44).

Unscrew valve screw (29) together with O-Ring (30) and reverse

retainer (31) and take out spring (32) and pull out valve pin (36), valve

(34), O-Ring retainer (33) and O-Ring (35).

Pull out reverse valve (37) and take out spring (38). Do not remove

either of the brass bushes in the motor housing (40) unless

replacements are required. If necessary reverse bush (39) can be

taken out of motor housing (40) by first removing pin (41). With circlip

pliers remove retaining ring (3) and pull out the output spindle

assembly. Unscrew nut (9), remove washer (8), bevel gear (7) and

key (5). Drive spindle (4) through bearing (6). Tap out needle bearing

(10) from angle head (11) but do not remove grease plug (12) unless

a replacement is required.

Slacken lock ring (15) and then unscrew angle head (11) [left hand

thread] from main assembly. Take out gear drive assembly and

dismantle by pressing pinion gear (13) through 2 off bearings (14).

Unscrew completely lock ring (15) and take out planet gear with pins

assembly (16), 3 off idler gears (17) and internal gear (18). Pull out the

motor assembly, complete with cylinder pin (25) from motor housing

(40).

Grip the front end plate (20) by hand and with a non metallic or soft

metal (lead or aluminium) hammer tap the splined end of the rotor

(21) to drive it through the front end plate (20) and bearing (19)

assembly. Tap out bearing (19) from front end plate (20). Remove

cylinder (23) and take out four off rotor blades (22) from rotor (21).

Take off retaining ring (28) from rotor (21) and support rear end plate

(24) in a piece of tube with a diameter as close as possible to the

maximum diameter of the rotor and tap the non splined end of the

rotor to drive it through the rear end plate (24) and bearing (27).

Take out motor gasket (26) from motor housing (40).

Reassembly

Clean all component parts and examine for wear before

reassembling. Use only manufacturer or distributor supplied parts.

Check in particular for wear on bevel gears, O-Rings and rotor blades.

Lightly coat all parts with a suitable pneumatic tool lubricating oil,

preferably one incorporating a rust inhibitor. Pack bearings and grease

gears and bevel gears with a lithium or molybdenum based general

purpose grease. Reassemble in the reverse order taking note of the

following:

1) When fitting gasket (26) make sure that it does not cover the ports

and is positioned correctly.

2) Make sure that the motor locating pin locates correctly in the holes

in the motor end plates and in the small hole between the two ports

at the bottom of the main bore of the motor housing.

3) Check the diameter of the pins in planet gear with pin assembly

(16). If the diameter of these pins falls below0.155" (3.93mm) replace

the assembly.

4) For the motor assembly, ensure that the motor end plates that abut

the cylinder are flat and free from burrs and sharp edges. If necessary

lap the faces on a very fine grade of abrasive paper laid on a flat

surface. Set the clearance between the rear end plate and the rotor

with the components pulled apart by hand to be between 0.0015"

(0.040mm) and 0.0025" (0.065mm).

Safety Rules When Using A Drill

1) Read all the instructions before using this tool. All operators must be

fully trained in its use and aware of these safety rules. All service and

repair must be carried out by trained personnel.

2) Always select a suitable cutting, abrasive device suitable for use

with this drill.

3) Always shut off the air supply to the drill and depress the trigger to

exhaust air from the feed hose before fitting, adjusting or removing the

device. Remove drill chuck.

4) Always adopt a firm footing and/or position and be aware of

torque reaction developed by the drill.

5) Use only correct spare parts.

6) Check hose and fittings regularly for wear. Do not carry the tool by

its hose and ensure that the hand is remote from the on/off valve

(trigger) when carrying the tool with air supply connected.

7) Do not exceed maximum recommended air pressure. Avoid low

air pressures as this will allow the drill to stall more easily and develop

torque reaction.

8) Use safety equipment as recommended.

9) The tool is not electrically insulated. Do not use where there is a

possibility of coming into contact with live electricity, gas pipes, water

pipes, etc. Check the area of operation before performing the

operation.

10) Take care against entanglement of moving parts of the tool with

clothing, ties, hair, cleaning rags, etc. This will cause the body to be

moved towards the work process and can be very dangerous.

11) Do not attempt to hold or guide the drill chuck when the tool is

running. Keep hands clear of the drilling process.

12) Use only compressed air at recommended conditions.

13) Do not attempt to fit attachments, i.e. for sawing, hedge cutting,

grinding, chain sawing, etc.

14) If the tool appears to malfunction remove from use immediately

Page No 2

Page 3

UT8807B

UT8807B-1/2

3/8" Capacity Angle Drill

1/2" Capacity Angle Drill

Ref No Part No Description

1 900418 Chuck Screw

2

3 722001 Retaining Ring

4 900419 Spindle

5 900420 Key

6 732229 Ball Bearing

7 900421 Bevel Gear

8 900422 Washer

9 900423 Nut

10 731956 Needle Bearing

11 900424 Angle Head

12 900390 Grease Plug

13 900425 Pinion Gear

14 732191 Ball Bearing (2)

15 900426 Lock Ring

16 732446 Planet Gear w/Pin

17 731038 Idler Gear (3)

18 900427 Internal Gear

19 729188 Ball Bearing

20 900428 Front Plate

21 900429 Rotor

22 729709 Rotor Blade (4)

23 900104 Cylinder

24 900102 Rear End Plate

25 900105 Cylinder Pin

26 900113 Motor Gasket

Apr 1999 Ver 1.2

H0019 Chuck 3/8" Capacity

H0020 Chuck 1/2" Capacity

Ref No Part No Description

27 729012 Ball Bearing

28 729180 Retaining Ring

29 900208 Valve Screw

30 729088 O-Ring

31 900200 Reverse Retainer

32 729063 Valve Spring

33 729043 O-Ring Retainer

34 731998 Valve

35 1008173 O-Ring

36 900193 Valve Pin

37 900194 Reverse Valve

38 900199 Reverse Spring

39 900195 Reverse Bush

40 900430 Motor Housing

41 731930 Roll Pin

42 900192 Throttle Lever

43 729167 Lever Pin

44 900198 Gasket

45 900209 Muffler

46 900197 Body Cap

47 900206 Screw (2)

48 729702 Deflector

49 1012371 O-Ring

50 729703 Deflector Retainer

51 900196 Inlet Bushing

52 1005726 Screen

Page No 3

Page 4

Declaration of Conformity

Universal Air Tool Company Limited

Unit 8, Lane End Industrial Park, High Wycombe, Bucks, HP14 3BY, England

declare under our sole responsibility that the product

Model UT8807B Right Angle Drills, Serial Number

to which this declaration relates is in conformity with the following standard(s) or other normative document(s)

EN792 (Draft), EN292 Parts 1 & 2, ISO 8662 Part 1, Pneurop PN8NTC1

following the provisions of

89/392/EEC as amended by 91/368/EEC & 93/44/EEC Directives

Lane End D.H.Moppett (Man Director)

Place and date of issue Name and signature or equivalent marking of authorised person

and arrange for service and repair.

15) If an additional side handle is fitted to the tool ensure that it is

correctly positioned and fixed securely.

16) If the drill is used with a balancer or other suspension device

ensure that it is fixed securely.

Accessories

Notes

Distributor

This document may not be copied wholly or in part by anyone without the consent of the Directors of Universal Air Tool Company Limited

Designed & Written in the U.K.

© Copyright of Universal Air Tool Company Limited, established in the United Kingdom, 1994

Page No 4

Loading...

Loading...