Page 1

Operator Instructions

Includes - Foreseen Use, Work Stations, Putting Into Service, Operating,

Dismantling, Assembly and Safety Rules

Important

Read these instructions carefully before installing, operating,

servicing or repairing this tool. Keep these instructions in a safe

accessible place.

Manufacturer/Supplier Product Type

Universal Air Tool Company Limited

Unit 8

Lane End Industrial Park

High Wycombe

Bucks

115 Degree Angle Die

Grinder (6mm Collet)

Model No/Nos Serial No

UT8777AC

HP14 3BY

Tel No Fax No(01494) 883300 (01494) 883237

RPM

18,000

Cycles Per Min

Product Nett Weight

0.99

0.45

lbs

Kg

Recommended Use Of

Balancer Or Support

No

Air Pressure

Recommended Working

Recommended Minimum

Maximum

Personal Safety Equipment

Use - Safety Glasses

Use - Safety Gloves

Use - Safety Boots

Use - Breathing Masks

Use - Ear Protectors

6.3

n/a

7.0

bar

bar

bar

Yes

Yes

Yes

Yes

90

n/a

100

Foreseen Use Of Tool

This die grinder is primarily designed for use with bonded abrasive

mounted point grinding wheels. It may also be used with steel rotary

files and carbide burrs provided their speed rating matches the speed of

the grinder.

This tool should not be fitted with cutting off wheels, saw blades, drill

bits, etc. If there is any doubt about the correct use of this product

contact your supplier for advice.

Also make sure that the shank size of the attachment to be driven

matches with the collet size fitted in the grinder and that the maximum

allowed running speed of the attachment exceeds that marked on the

grinder.

There are special rules governing the use of bonded abrasive mounted

point grinding wheels - for details see section "Operating".

Work Stations

The tool should only be used as a handheld hand operated tool. It is

always recommended that

the tool is used when standing on the solid floor. It can

be used in other positions

but before any such use, the

operator must be in a secure position having a firm

grip and footing and be

aware of the extra safety

precautions that must be

observed when using Grinding Machines.

Recommended Hose Bore

Recommended Max.

Size - Minimum

Ins M/M Ft M

3/8 10 30 10

Noise Level Sound Pressure Level 82 dB(A)

PSI

Test Method Tested in accordance with Pneurop

PSI

test code PN8NTC1 and ISO Standard 3744

PSI

Vibration Level

Less than 2.5 Metres / Sec²

Test Method Tested in accordance with ISO

standards 8662/1 and 8662/13

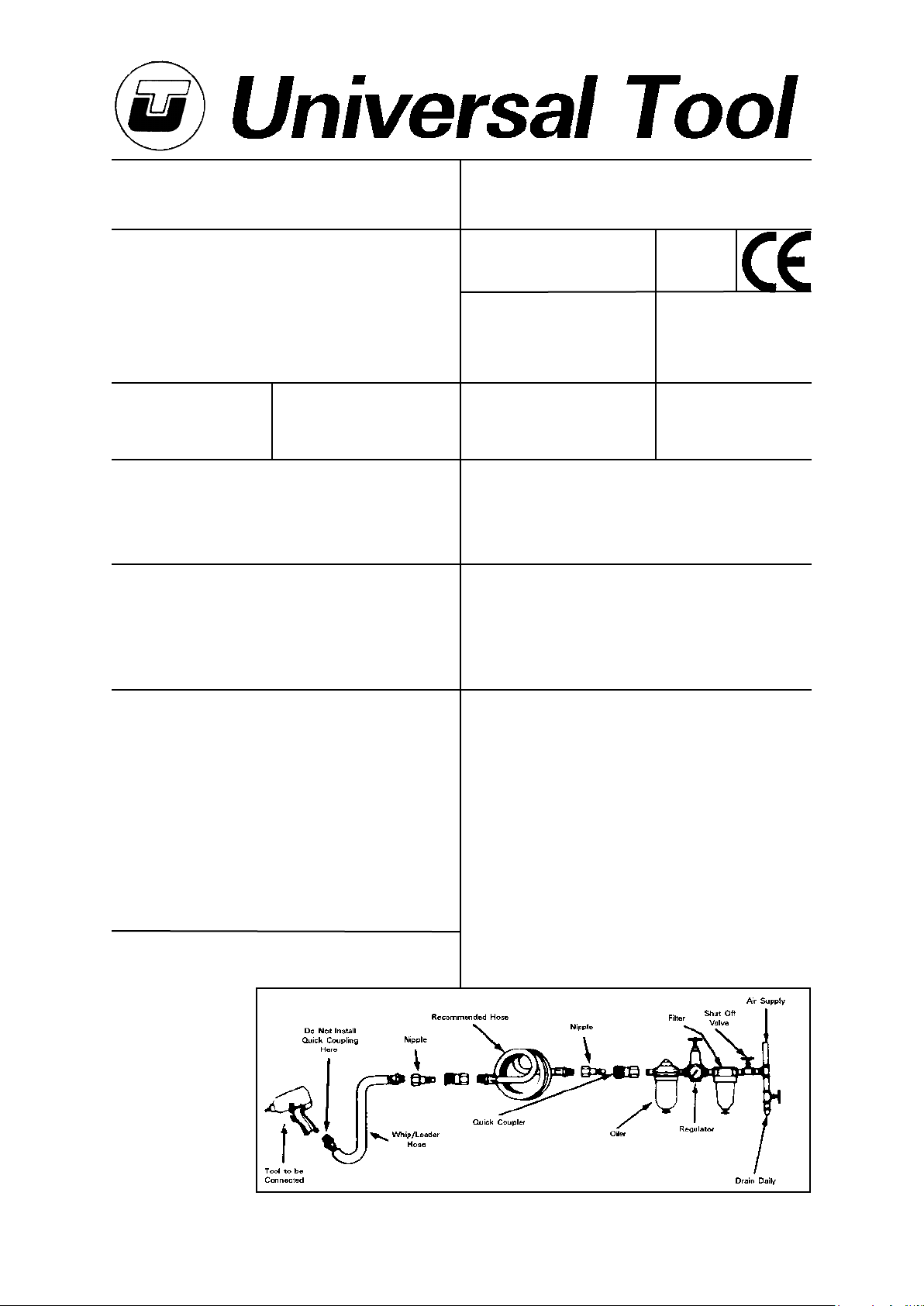

Putting Into Service

Air Supply

Use a clean lubricated air supply that will give a measured air pressure

at the tool of 90 p.s.i./6.3 bar when the tool is running with the

lever/trigger fully depressed. Use recommended hose size and length.

It is recommended that the tool is connected to the air supply as shown

in figure 1. Do not connect the tool to the air line system without

incorporating an easy to reach and operate air shut off valve. The air

supply should be lubricated. It is strongly recommended that an air filter,

regulator, lubricator (FRL) is used as shown in Figure 1 as this will supply

clean, lubricated air at the correct pressure to the tool. Details of such

equipment can be obtained from your supplier. If such equipment is not

used then the tool should be lubricated by shutting off the air supply to

the tool, depressurising the line by pressing the lever/trigger on the tool.

Disconnect the air line and pour into the intake bushing a teaspoonful

(5ml) of a suitable pneumatic motor lubricating oil preferably

incorporating a rust inhibitor. Reconnect tool to air supply and run tool

Hose Length

Page No 1

Page 2

slowly for a few seconds to allow air to circulate the oil. If tool is used

frequently lubricate on daily basis and if tool starts to slow or lose power.

It is recommended that the air pressure at the tool whilst the tool is

running is 90 p.s.i./6.3 bar. The tool can run at lower and higher

pressures with the maximum permitted working air pressure of 100

p.s.i./7.0 bar.

Operating

Select a suitable mounted point that has a free running speed higher

than the maximum running speed marked on the tool. Make sure that

the diameter of the shank exactly matches the diameter of the collet

mounted in the grinder. There are two standard sizes of collet available

for use with this grinder, i.e.

1) - 1/4" dia (0.250ins) (6.35mm)

2) - 6mm (0.236ins)

Never try to force a 1/4" diameter shank into a 6mm collet. Never try to

close a 1/4" diameter collet to secure a 6mm shank. Always match

correctly the shank size to the collet size. If uncertain, have parts

measured by a competent person.

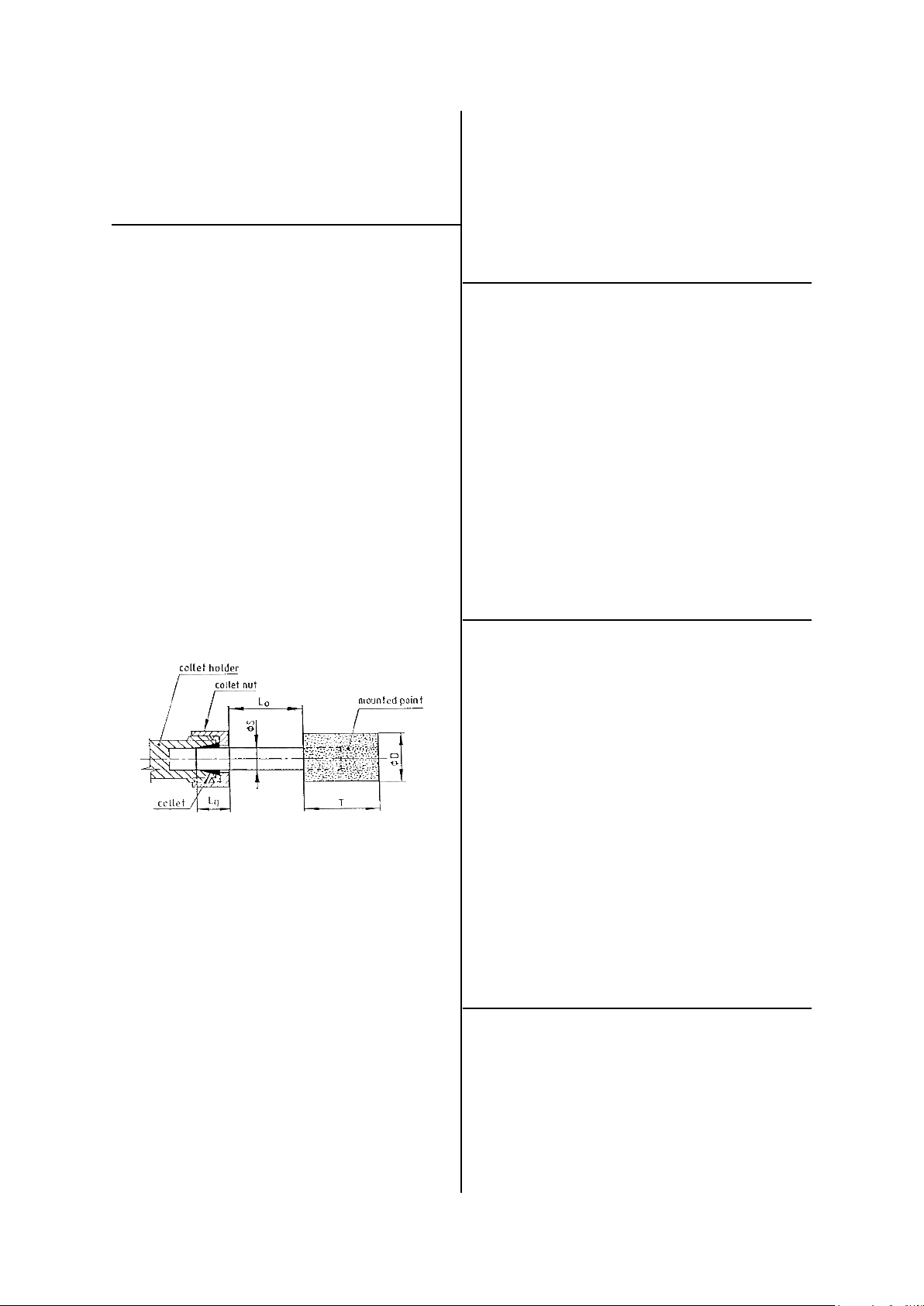

Push the shank as far as possible into the collet and tighten the collet nut

using the spanners provided on the collet nut and output spindle.

The shank of the mounted point may be pulled forward from the

maximum insertion length but always ensure a minimum gripping

length of not less than 10mm - See Figure 2.

Be aware that the allowed running speed of the mounted point is

lowered because of an increase in the length of the shank between the

end of the collet and the body of the mounted point. This distance is

shown in Diagram 2 as "LO" and is called the overhang. The

information with respect to mounted point size, permissible running

speed and reduction in running speed due to an increase in overhang is

available from the supplier of the mounted point.

If the increase in overhang for access reasons takes the permissible

running speed of the mounted point below the free running speed of

the grinder select a smaller diameter mounted point.

D = diameter of mounted point

T = length of mounted point

Lo = overhang

S = diameter of shank

Lg = gripping length

The fitting of the mounted point should be done by a trained operator.

When first starting the grinder with a new wheel fitted, the grinder

should not be near other persons and be held in a protected area, i.e.

under a bench and run for a few seconds. This will protect personnel

from possible effects of damage to the mounted point before it was

fitted to the grinder i.e. wheel breakage.

Always use eye protection and wear protective gloves if there are sharp

edges in the work area. The tool and the grinding process can create a

noise level such that the use of ear protectors is advised.

If the grinding process creates a dust then use a suitable breathing

mask.

Check that the material being worked will not cause harmful dust or

fumes. If this is so then special breathing masks may be required.

If the grinder vibrates when first fitting a mounted point or during

operation, remove from service immediately and correct fault before

continuing to use.

Do not apply excessive pressure as this will reduce the cutting

efficiency and can bend the shank of the mounted point causing

vibration and the possibility of breakage. Apply light loads to allow the

wheel to cut.

Handle the grinder with care. If the grinder is dropped, carefully check

the mounted point for damage, i.e. cracks, chipping and start for the

first time as for fitting a new wheel i.e. under a bench.

Never exceed the maximum air pressure. If there is this possibility

always use this grinder with a pressure reducing valve fitted in the

supply line. Your supplier will advise of suitable equipment.

Dismantling & Assembly Instructions

Disconnect tool from the air supply.

Using wrenches (26) & (27) grip collet nut (25) and spindle (2) and

unscrew collet nut (25) to remove any fitted grinding wheel and to take

out collet (24). Unscrew clamp nut (1) and pull out the complete motor

assembly from housing (12). Grip rear end plate (10) and tap the non

threaded end of rotor (6) to drive the rotor through rear end plate (10)

and bearing assembly. Remove cylinder (8) noting how the pin (9)

locates in rear end plate (10). Remove 4 off rotor blades (7) from rotor

(6). Grip rotor (6) and unscrew spindle (2). Pull off front end plate (4) and

bearing assembly. Remove collar (5) and tap out bearing (3) from end

plate (4) and bearing (11) from end plate (10). Unscrew air inlet (22)

and remove O-ring (17) and exhaust sleeve (16). Pull out throttle spring

(21) and throttle value (20). Drive out spring pin (15) and remove valve

stem (13) and trigger button (14).

Reassembly

Clean all items and examine for damage and wear. Replace any parts

with parts obtained from the manufacturer or an approved supplier.

Coat all parts with a pneumatic tool lubricating oil and assemble in the

reverse order.

Safety Rules When Using A Die Grinder

1) Read all the instructions before using this tool. All operators must be

fully trained in its use and aware of these safety rules.

2) Always select suitable abrasive to use with this tool - see Operating

Instructions.

3) Always shut off the air supply to the grinder and depress the lever to

exhaust air from the feed hose before fitting, adjusting or removing the

mounted point.

4) Always adopt a firm footing and/or position before using the grinder.

5) Use only correct spare parts.

6) Check hose and fittings regularly for wear. Do not carry the tool by its

hose.

7) Do not remove and never tie down the safety lever.

8) Never exceed the maximum air pressure and check the free running

speed frequently. Have air regulator fully open when making speed

checks.

9) Use safety equipment as recommended.

10) Take care against entanglement of moving parts of the tool with

clothing, ties, hair, cleaning rags, etc.

11) Use only compressed air at the recommended pressure.

12) Do not attempt to fit any other attachment than those

recommended - see "Foreseen Use of Tool".

13) If the tool appears to malfunction, remove from use immediately,

and arrange for service and repair.

Page No 2

Page 3

UT8777AC 115 Degree Angle Die Grinder

Ref No Part No Description

1 RL12601 Clamp Nut

2 RL80527 Chuck Spindle

3 RL80524 Ball Bearing

4 RL84625 Front End Plate

5 RL80523 Spindle Collar

6 RL84622 Rotor

7 RL80519J Rotor Blade (4)

8 RL84621 Cylinder

9 RL13035 Roll Pin

10 RL84619 Rear End Plate

11 RL84618 Ball Bearing

12 RL126512PV Housing

13 RL12613 Valve Stem

14 RL50314 Trigger Button

Dec 2008 Ver 1.0

Ref No Part No Description

15 RL12122 Pin

16 RL12616 Muffler

17 RL80515 O-Ring (9.5X1.85mm) (2)

18 RL12618 Bushing

19 RL12127 Throttle Seat

20 RL12128 Throttle Valve

21 RL12129 Throttle Spring

22 RL126221 Air Inlet

23 RL12623NC Comfort Grip

24 RL80528B Collet (6mm)

25 RL80529 Collet Nut

26 RL80530A Wrench 12mm

27 RL80530B Wrench 17mm

Page No 3

Page 4

Declaration of Conformity

Universal Air Tool Company Limited

Unit 8, Lane End Industrial Park, High Wycombe, Bucks, HP14 3BY, England

declare under our sole responsibility that the product

Model UT8777AC Die Grinder, Serial Number

to which this declaration relates is in conformity with the following standard(s) or other normative document(s)

EN792 (Draft), EN292 Parts 1 & 2, ISO 8662 Parts 1 & 13, Pneurop PN8NTC1

following the provisions of

89/392/EEC as amended by 91/368/EEC & 93/44/EEC Directives

Lane End D.H.Moppett (Man. Director)

Place and date of issue Name and signature or equivalent marking of authorised person

Accessories

Notes

Distributor

This document may not be copied wholly or in part by anyone without the consent of the Directors of Universal Air Tool Company Limited

Designed & Written in the U.K.

©Copyright of Universal Air Tool Company Limited, established in the United Kingdom, 1994

Page No 4

Loading...

Loading...