Page 1

A

Operator Instructions Important

Includes - Foreseen Use, Work Stations, Putting Into Service,

Operating, Dismantling, Assembly and Safety Rules

Manufact urer/Supplier Product Type

Universal Air Tool Company Limited

Unit 8

Lane End Industrial Park

High Wycombe

Bucks

HP14 3BY

Tel No Fax No

(01494) (01494) 883237

Read these instructions carefully before insta lling, operating,

servicing or repairing this tool. Keep these instructions in a

safe accessible place.

Pistol Rev. Screwdriver

djustable Clutch

Model No/Nos Serial No

UT5964A

RPM

1,800

Cycles Per

Product Net t Weight Recommended Us e Of

2.2

1.00

Recommended Working

Recommended Minimum

Maximum

Perso n a l Sa fe t y E q ui pm en t

Use - Safety Glasses

Use - Safety Gloves

Use - Safety Boots

Use - Breathing Masks

Use - Ear Protectors

lbs

Balancer Or Su pport

Kg

Air Pressure

6.3

n/a

7.0

bar

bar

bar

No

Yes

90

n/a

100

PSI

PSI

PSI

Foreseen Use

This screwdriver is des igned for th e tightening an d loosening

of threade d fas ten er s w ithin the ra nge as spe cifie d by the

manufacturer. It should only be used in conjunction with

1/4" male hex shank screwdriver bits and fastener drivers.

Do not use the tool for any other purpose than that specified

without consulting the manufacturer or his authorised

representative.

Work Stations

The tool should only be used as a hand held, hand operated

tool. It is always recomme nded that th e tool is used wh en

standing on a s olid floor. It can be used in othe r positions,

but before any such use the operator must be in a secure

position hav ing a firm grip a nd footing. T he opera tor m ust

adopt a firm grip sufficient to resist the torque rea ction of

the tool, i.e. th e t ool will try

to turn in the hand. The

operator must also be aware

that when loosening fasteners,

the tool can move quite

quickly away from the fastener

being undone. An allowance

must be made for this rear-

ward movement to avoid hand

entrapment. The operator must

also make all owanc e that i f

the tool does turn in the hand,

the hand is not trapped

against a ny rigid object.

Recommended Hos e Bore

Size - Minimum

3/8 10 30 10

Ins M/M Ft M

Noise

Sound Pressure Level 84.3 dB(A)

Recommended Ma x.

Hose Length

Sound Power Level 89.7 dB(A)

Test Met hod

Tested in accordance with

Pneurop test code PN8NTC1 and ISO

Vibration

Test Met hod

Less than 2.5

Metres / Sec²

Tested in accordance with ISO

standards 8662 Parts 1 & 7

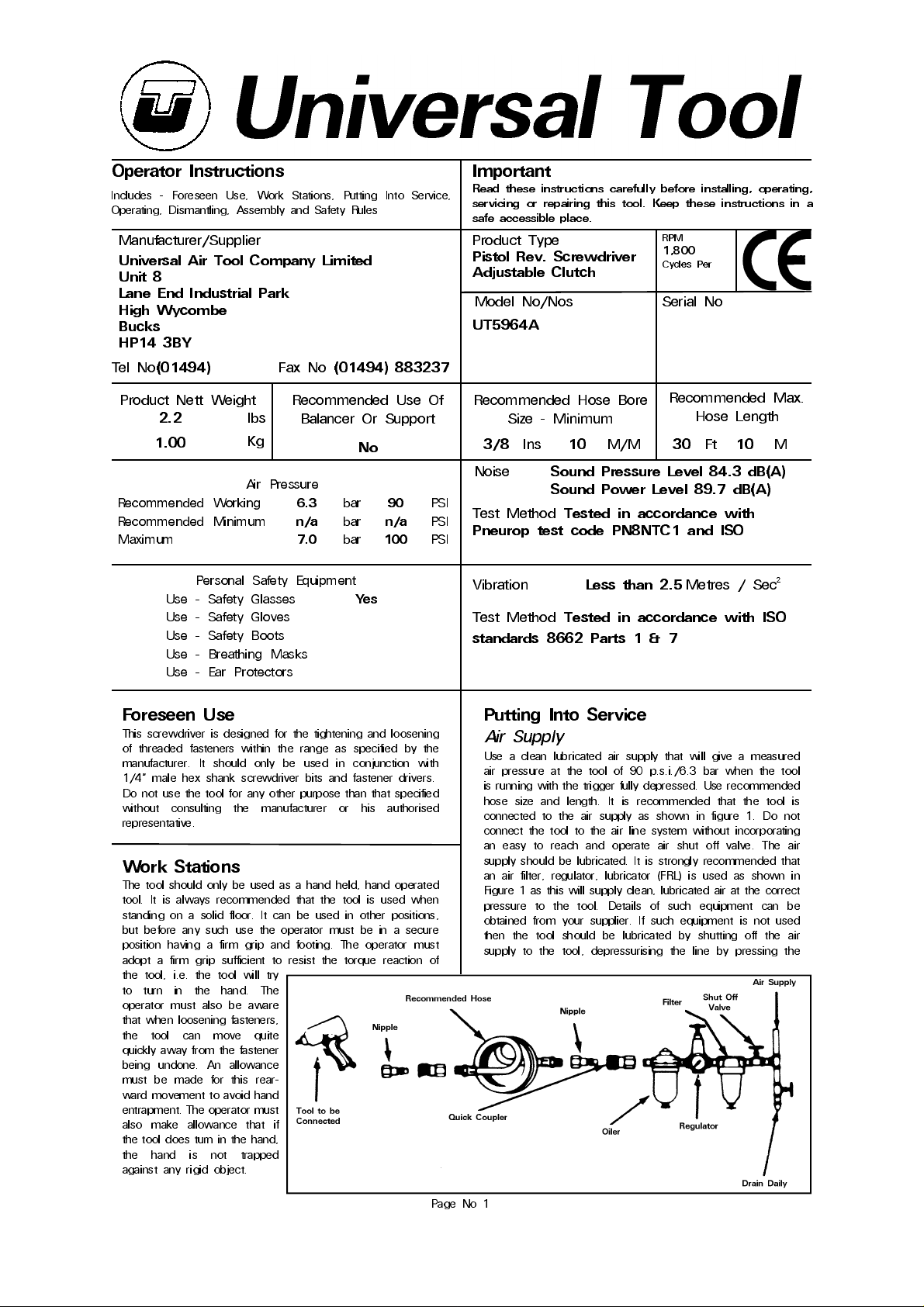

Putting Into Service

Air Supply

Use a c lean lubricat ed air supply that w ill give a measu red

air pressu re at the tool of 90 p.s.i./6.3 bar when the tool

is running with the trigger fully depressed. Use recommended

hose size and length. It is recommended that the tool is

conne cted to the a ir supply as s hown in figure 1. Do not

connect the tool to the air line system without incorporating

an easy to reach and operate air shut off valve. The air

supply sh ould be lubricated. It is stron gly rec ommende d that

an air filter, regulator, lubrica tor (FRL) is us ed as sh own in

Figure 1 as this will supply clean, lubricated air at the correct

pres sure t o th e too l. Deta ils of s uch eq uipm ent ca n be

obtained from your su pplier. If such equipme nt is not used

then the tool should be lubricated by shutting off the air

supply to the tool, depres su risin g the line by pre ss ing the

Page No 1

Page 2

trigger on the tool. Disconnect the air line and pour into the

intake bus h ing a tea s poonful (5ml) of a su itable pneu ma tic

motor lubricating oil preferably inc orporating a rust inhibitor.

Reconnect tool to air supply and run tool slowly for a few

second s t o al lo w ai r to ci rcul at e th e o il . I f to o l i s u sed

frequen tly lubricate on daily bas is and if tool starts to slow

or lose power.

It is recommende d that the air pressu re at the tool whilst

the tool is running is 90 p.s.i./6.3 bar. The tool can run at

lower and higher pressures with the maximum permitted

working air press ure of 100 p.s.i./7.0 bar.

Operating

Select the correct screwdriver bit or fastener driver to suit the

screw or fastener to be tightened or loosened. Slide back the

sleev e (44) and inser t appropriate drive bit. Th is model has

an external adjustable clutch so that the torque applied to the

fastener can be adjusted easily to give the required tightness

within the torque range of the tool. To set the tool to give a

particular torque output, turn the adjust ring (49) If the fastener

is not sufficiently tightened or cannot be loosened then the

tool in adjustable clutch mode has insufficient capacity. Select

a more power ful tool. The person setting up the tool must

be aware of this torque reaction at high setting levels of the

clutch and that th e tool will try to turn against the hand. All

that is required is a firm grip. The tool, when the stall torque

position has been reached, can still be used to set or loosen

fasteners, provided the operator is aware of the need to resist

the torque reaction of the tool. The only thing that will affect

the output is a change in the air supply pressure. The output

can be inc re as ed u p to the use of th e m ax imu m a llowed

supply pressure and decreased with a reduction in supply

pressure until the tool fails to operate. It must also be

understood that even if the clutch is set to slip it may not do

so if the supply air pressure falls below the pressure at which

the clutch was set. It is therefore strongly recommended that

a pressure control valve is used. Information as to suitable

equipmen t can be obtained from your su pplier. When using

the tool keep the screwdriver bit pressed firmly into the screw

head to avoid cam out and screw head damage.

Dismantling & Assembly Instruction

Disconne ct tool from a ir supply.

Grip the tool by hand then unscrew an d remove clutch

housing (7) from clam p nut (41) – left hand thread.

Remove adjust cover (47) from clutch housing (7). Pull out

the clutch assembly grip the clutch assembly and with a

sharp pointed ne edle tool prise out retaining ring (31) and

remove wa sher (46), spring (45), and ball retainer (44)

being care ful not lose screwdriver bit reta ining ball (35).

Again with the sharp pointed tool, remove secon d retaining

ring (31) and pull off spacer (43). Unscre w adjust nut (47)

and pull off washer (46), clutch spring (39) and washer

(38). Tap front end to remove 4 off balls (37). Remove

retaining ring (33) and separate clutch (36). Remove a third

retaining ring (31) and pull off drive clutch (30). Unscrew

clamp nut (41) and push out the internal assembly and

ball bearing(29), internal gear (32), 3 off planet gears (25)

and work spindle (28). Do not remove the 3 off pins from

work spindle (27). Drive out pin (6), uns crew set scre w

(23) and pull off trigger (24) and remove spring (22). Grip

valve stem (21) and pull out the complete valv e assembly.

Separate reverse leve r (20), reverse retaine r (19), o-ring

(18), reverse bushing (17) and o-ring (16). Unscrew air

inlet (2) and scre w (3) and remove exha ust diffuser (4) and

damping mate rial (5). Grip end of rotor (13) and pull out

the complet e motor assembly. Remove 2 pins (11), motor

gasket (9) Grip spacer (15) and with a non metallic or soft

Page No 2

metal (lead of aluminium) hammer tap the splined end of

the rotor (13) to drive it through bearing (8). Remove

cylinder (12) and tak e out 5 off rotor blades (14) fr om the

rotor (12). Support end plate (10) and tap the rotor (13)

through the end plate (10) and bearing (8).

Reassembly

Clean all co mpon ent par ts and ex amine to wear b efor e

reassembling. Look in particular for wear and cuts on o-rings,

wear on rotor blades, gear, and clutch components. Coat

all parts with pneumatic tool lubricating oil and grease all

bearings, gears, and clutch parts with a molybdenum or

lithium bas ed gen er al purpose grea s e. Be fore re asse mbling

the motor make sure that the faces of end plates (10) that

abut cylinder (12) are flat and free from burrs. If necessary,

lap on a flat ve ry fine grade of abras ive paper. Reassem ble

in the reverse order. When refitting the complete motor

assembly to housing (7) first make sure that the assembly

is clampe d tightly togethe r and the rotor spins fre ely, slide

the assembly with gasket into the housing (7) ensuring that

motor pin (11) locates in the motor assembly and in the

hole in the bottom of the ma in bore of hous ing (7) suited

between the two main ports. Reset the clutch as required

and/ or set th e correct air pressu re – see Operatin g.

Safety Rules For A Screwdriver

1) Read all the instructions before using this tool. All operators

must be fully tra ined in its use and aware of these sa fety

rules.

2) Do not exceed the maximum working air pressure.

3) Use personal safety equipment.

4) Use only compressed air at the recommended conditions.

5) I f the too l appea rs to mal functio n remove f rom use

immediately and arrange for service and repair.

6) If the tool is used with a balancer or other support device

ensure that it is fixed securely.

7) Always ke ep ha nds awa y from th e work ing attac hm en t

fitted to the tool.

8) The tool is not electrically insulated. Never use the tool

if there is any chance of it coming into contact with live

electricity.

9) Always when u sing the tool a dopt a firm footing and/or

position and grip the tool firmly to be able to counteract

any force s or reaction forces th at may be genera ted whilst

using the tool.

10) Use only correct spare parts . Do not improvise or make

temporary repairs.

11) Do not lock, tape, wire, etc. the on/off valve in the run

position. The trigger/lever etc. must always be free to return

to the 'off' position when it is rele ased.

12) Always shu t off the air supply to the tool, and depress

the trigger/lever etc. to exhaust air from the feed hose before

fitting, adjusting or removing the working attachment.

13) Check hose and fittings regularly for wear. Replace if

nece ssary. Do not carry the tool by its hose an d ensu re the

hand is rem ote from t he on/ off cont rol whe n carryin g the

tool with the air supply c onnected.

14) Take care against entanglement of moving parts of the

tool with clothing, ties, hair, cleaning rags, etc. This will

caus e the body to be drawn towards the tool and ca n be

very dan gerous.

15) It is expected that users will adopt safe working practices

and observ e all r ele va nt lega l requ irem ents wh e n in st alling,

using or maintain ing the t ool.

16) Do not install the tool unless an easily accessible and

easily operable on/ off valve is incorporate d in the air supply.

17) Take ca re tha t th e t ool exh au st air does n ot ca us e a

problem or blows on another pers on.

18) Never la y a tool down u nle ss th e working att ac hm en t

has stopped movin g.

Page 3

UT5964A

1,800RPM Pistol Grip Reversible Screwdriver - Adj. Clutch

Ref No Part No Description

1 82253-12 Rubber Grip

2 70103 Air Inlet

3 40309 Screw (2)

4 70110 Exhaust Diffuser

5 82250 Damping Material

6 82202 Pin

7 822101 Motor Housing

8 030113 Ball Bearing (2)

9 80211 Motor Gasket

10 80214 End Plat e (2)

11 80217 Spring Pin (2)

12 80218 Cylinder

13 80215 Rotor

14 80216 Rotor Blad e s (5)

15 80219 Spacer

16 82247 O-Ring

17 82206 Reverse Retainer

18 82209 O-Ring

19 82212 Reverse Retainer

20 82210 Reverse Lever

21 82205A Valve Stem Set

22 82208 Valve Spring

23 82246 Set Screw

24 82204 Trigger

25 80223 Planet Gear (3)

26 80225 Bushing (3)

Nov 2004 Ver 1.00

Ref No Part No Descriptio n

27 30124 Pin (3)

28 80226 Work Spindle

29 080227 Ball Bearing

30 80229 Drive Clutch

31 80230 Retainin g Ri ng (3)

32 80222 Internal Gear

33 80231 Snap Ring

34 80232 Cam Spindle

35 40145 Steel Ball (9)

36 80234 Clutch

37 80235 Steel Ball (4)

38 80236 Thrust Washer

39 812E37 Spring

40 812E36 Thrust Washer

41 812E28 Clamp Nut

42 812E38 Guide

43 80240 Spacer

44 80242 Ball Retainer

45 80243 Spring

46 80244 Washer

47 812E21 Adjust Nut

48 812E12 O-Ring

49 812E20 Adjust Ring

50 812E41 Head Cap

51 812E39 Indicator

Page No 3

Page 4

Declaration of Conformity

Universal Air Tool Company Limited

Unit 8, Lane End Industrial Park, High Wycombe, Bucks, HP14 3BY, England

declare under our sole re sponsibility tha t the produc t

Model UT5964A Pistol Reversible Screwdriver, Serial Number

to which this declaration relates is in conformity with the following standard(s) or other normative document(s)

EN792 (Draft), EN292 Parts 1 & 2, ISO 8662 Parts 1 & 7, Pneurop PN8NTC1

following the provisions of

89/392/EEC as amended by 91/368/EEC & 93/44/EEC Directives

Lane End D.H.Moppett (Man. Director)

Place and date of issue Name and signature or equival ent marking of authorised

19) Always en sure that the r everse button is in th e selected

position before startin g the tool.

20) Do not use bits or sockets with excessive wear to the

input and output drives. Make sure the bit, socket, extension

is firmly fixed to the tool.

21) When lo osenin g fasten ers fir st ensure that the re is

sufficient clearance behind the tool to avoid hand entrapment.

The to ol w i l l mo v e aw ay f r o m t h e t hreaded joint as the

nut/bolt is loosened and rides up the thread moving the

tool with it.

Accessories

Notes

Distributor

This document may not be copied wholly or in part by anyone without the consent of the Directors of Universal Air Tool

Designed & Written in the U.K.

©Copyright of Universa l Air Tool Company Limite d, established in the Un ited Kingdom, 1994

Page No 4

Loading...

Loading...