Page 1

Operator Instructions

Includes - Foreseen Use, Work Stations, Putting Into Service, Operating,

Dismantling, Assembly and Safety Rules

Important

Read these instructions carefully before installing, operating,

servicing or repairing this tool. Keep these instructions in a safe

accessible place.

Manufacturer/Supplier Product Type

Universal Air Tool Company Limited

Unit 8

Lane End Industrial Park

High Wycombe

Bucks

Spray Gun - Syphon Type

(1 litre cup) 1.8mm

Model No/Nos Serial No

UT57A

HP14 3BY

Tel No Fax No(01494) 883300 (01494) 883237

RPM

N/A

Cycles Per Min

N/A

Product Nett Weight

1.85

0.84 5/16 8 30 10

Recommended Working

Recommended Minimum

Maximum

Use - Safety Glasses

Use - Safety Gloves

Use - Safety Boots

Use - Breathing Masks

lbs

Kg

Air Pressure

Personal Safety Equipment

Recommended Use Of

Balancer Or Support

No

2.06

n/a

4.83

bar

bar

bar

30

n/a

70

Yes

Yes

Yes

Recommended Hose Bore

Size - Minimum

Ins M/M Ft M

Noise Level Sound Pressure Level TBA dB(A)

PSI

Test Method Tested in accordance with ISO

PSI

Standard 3744

PSI

Sound Power Level TBA dB(A)

Vibration Level

Test Method Vibration testing not required for a

spray gun

Recommended Max.

N/A

Metres / Sec²

Use - Ear Protectors

Foreseen Use of Tool

This product is designed for the purpose of applying liquids in the form

of paint, lacquers, etc. to a surface for the purpose of providing a

decorative or protective finish. It must not be used for or modified for

any other purpose unless first consulting the manufacturer or an

authorised representative.

Work Stations

The spray gun should only be used as a handheld hand-operated

device. It is always recommended that the spray gun is used when

standing on the solid floor. It can be used in other positions provided the

spray gun is kept near vertical and the operator has a firm grip and

footing. Any work station must take account that the liquid being

sprayed should not be breathed in and the liquid can be highly

flammable and spraying should never be undertaken near naked flames

or hot surfaces. Do not smoke. It should also take account that not all of

the liquid being sprayed will be applied to the object being sprayed and

account must be taken that this surplus, i.e. “over spray” will be

deposited in the surrounding area.

(see later). The gun is fitted with a quart (2 pints/1.13 litres) syphon cup

complete with paint strainer.

Use 1.8mm diameter nozzle for polymer paints, oil base paints, epoxy

paints for metals, acrylic lacquers, urethane.

Before spraying any material first read any instructions concerning its

safe use and if nothing is available check with the manufacturer about its

use and the need to use personal safety equipment.

Prepare the paint in accordance with the manufacturer’s

recommendations and place in syphon container. Do not overfill.

Connect the gun to a clean, moisture/oil free air supply at the right

pressure. Fit container to the gun and lock in position. Use the material

adjustment control screw (18) to adjust material flow and the fan

adjustment assembly (17) to adjust from round to fan spray pattern.

Make all adjustments before attempting to spray the work piece.

Note the spray gun can work at pressures of between 30 and 70 psi

and the air consumption is approximately for these pressures from 3 to

7 cfm.

For advice on spraying, using, cleaning, etc., the spray gun, see

attached sheets 4 to 7.

Hose Length

Operating

The Spray Gun is a handheld syphon type

compressed air atomising spray gun

suitable for use with most liquids for paint

spray finishing or the application of

surface coatings. It is a non bleeder type

with external mix nozzle air cap assembly

and full control for material application

and spray pattern between round and fan

Page No 1

Page 2

Dismantling & Assembly Instructions

Disconnect the spray gun from the air supply.

Remove the basic cup container by use of the cam lever on the top of

the lid and empty the contents of the cup into a safe, suitable container.

Such a container should be kept in an approved paint storage area.

Unscrew the lock nut on top of the cup lid assembly to remove the lid

assembly from the spray gun body.

Pull off the paint strainer from the body of the lid assembly centre tube

and unscrew the nut on the underside of the lid. It is then possible to

separate the lid, centre tube assembly, the locking cup arm and the

cam lever.

Take off the E ring (24) from the trigger stud (23) and re move the trigger

(21).

Unscrew nipples (6) & (19) from the spray gun body (5). Unscrew air

cap (1) and nozzle (2) then unscrew the nipple at the top rear of the

body (1) and remove the pattern adjustment assembly (7) complete.

Unscrew the fluid adjusting screw (18) and take out the needle (16)

packing holder (9) and O-ring (10) take off the fluid adjust guide set (15)

spring (14) air valve seat set (13 & 13-1) air valve seat set (12 & 12-1)

and gasket (11).

Plug (24) and packing (3) can now be removed from the air valve body.

Unscrew packing screw (8) and remove packing (9).

Reassembly

Clean all parts thoroughly to remove all traces of paint with suitable paint

removal liquids. Be careful when cleaning paint air cap (1), nozzle (2)

particularly from the small holes. Clean out holes using wooden

cocktail sticks or non metallic toothpick as any increase in hole

size, deformation or raising of burrs will change the spray pattern.

Carefully check packing (3) and (9) for paint contamination, splitting

and hardening and replace with other worn or damaged parts as

necessary. Replace parts with parts obtained from the manufacturer or

an authorised distributor.

Safety Rules when Using or Cleaning a

Spray Gun

Warning

Many fluids that will clean painted surfaces are very flammable and

the vapours should not be breathed. Always ensure that such

cleaning materials are correctly stored, used away from hot surfaces

and flames and cleaning takes place in well ventilated areas.

There are available special spray gun cleaning devices where the

spray gun may be partially or totally dismantled and the parts cleaned

within a container.

Smoking should be totally banned in areas where spray painting is

performed or cleaning takes place.

Use of spray guns should conform with all legislation relating to spray

painting.

Fire extinguishers should be readily available in the spray application

and cleaning areas.

All work stations must be provided with adequate ventilation to

remove any fumes resulting from the spray painting work and

cleaning process.

Paint flowing through hoses can create static electricity which if a

spark occurs could cause fire or an explosion. Such risks should be

eliminated by the use of “earthing” techniques.

Certain materials that can be used with spray guns may give off toxic

vapours that can be poisonous, irritants or create a general hazard to

health. The instruction supplied with any material should be carefully

read and understood before using the material. If such information is

not availabe - find out - never use if such information is not available.

Always follow the manufacturer’s instructions.

It is recommended that respiratory equipment is always used when

paint spraying and the type and efficiency of the equipment to match

the requirement of the material being used.

Use protective gloves when spraying and cleaning.

Use eye goggles when spraying and cleaning.

It is recommended that all operators connected with any aspect of

spray painting, including cleaning are fully trained by personnel

competent to train.

Certain solvents are in the category “Halogenated Hydrocarbon

Solvents” and these solvents can have a chemical reaction with

zinc plated, galvanized or aluminium parts and can cause an

explosion hazard particularly if the parts are under pressure. This

equipment as supplied is suitable for use with these materials but the

instructions supplied with the solvent must always be carried out.

Golden Rule - Before using any equipment with “Halogenated

hydrocarbons solvents” Check that it is acceptable to do so.

Misuse

Never ever point a spray gun in operating mode at any other

person. Make sure that the ejected spray from the nozzle never

comes in contact with any part of the body.

Never exceed the maximum allowed working pressure.

Before attempting to change materials or clean the spray gun

disconnect from the air supply and tip any unused material into

suitable containers, seal and store as required by legislation, i.e.

fireproof stores, etc.

Cleaning the Gun

It cannot be emphasized too strongly that the care, cleaning and

maintenance of the gun are of utmost importance. At the end of each

day or shift, the gun should be thoroughly cleaned. Never immerse

the complete gun in a cleaning solvent. This allows sludge and dirt to

collect in passages/holes within the gun which may eventually be

blown on to the surface being sprayed. Solvents also remove

lubricants from packings and cause the air valve and material needle

to stock.

The air cap/spreader should be removed and immersed in clean

cleaning fluid. If the holes have become clogged never never use

wire or other metallic devices to clean them. The small holes are

precision drilled to very close tolerances and any enlargement by the

abrasive action of metal will permanently affect and distort the spray

pattern when the only remedy is a replacement part.

Some additional advice is given in the following diagrams

(see page 7).

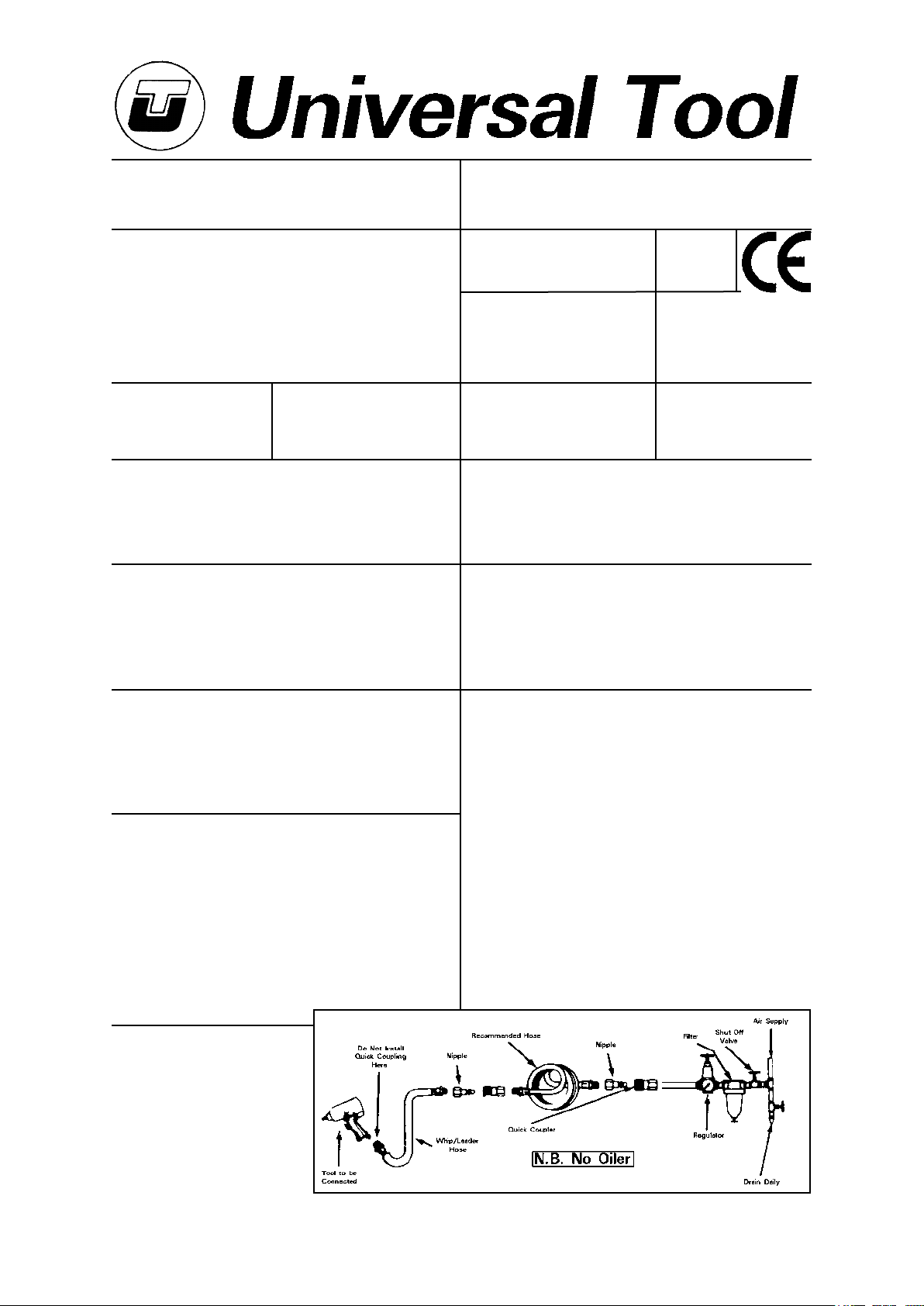

Hints on Paint Spraying

Having selected the type of system/gun to be used and the paint to

be sprayed, it is important to make sure that the compressor has

sufficient capacity to supply the gun on a continual basis. As most

compressors deliver air with oil/moisture content and sometimes

small particles of dirt, it is strongly recommended that an air

filter/moisture remover is incorporated in the air line between the

gun and the compressor. Most compressors produce the

compressed air at 100 psi and above so the incorporation of a

pressure reducing valve may be necessary as most spray guns are

designed to work at between 30 and 80 psi with the average being

50 psi. The importance of this equipment cannot be stressed

enough as oil and moisture in the airline combined with over

pressure, can almost certainly lead to very poor contaminated paint

finishes.

It is important to remember that a spray gun is a highly efficient

compact and delicate piece of equipment. The care with which it is

used will pay dividends in the form of superior finishes and reduction

in rejects to the operator who familiarises himself/herself with its

possibilities and limitations. It is the daily routine cleaning that keeps

the equipment at peak efficiency, not the occasional attention of the

operator who only remembers when the desired finish is not

achieved.

Handling the Spray Gun

To use a spray gun efficiently, there are a number of very

important general principles and fundamental motions of

Page No 2

Page 3

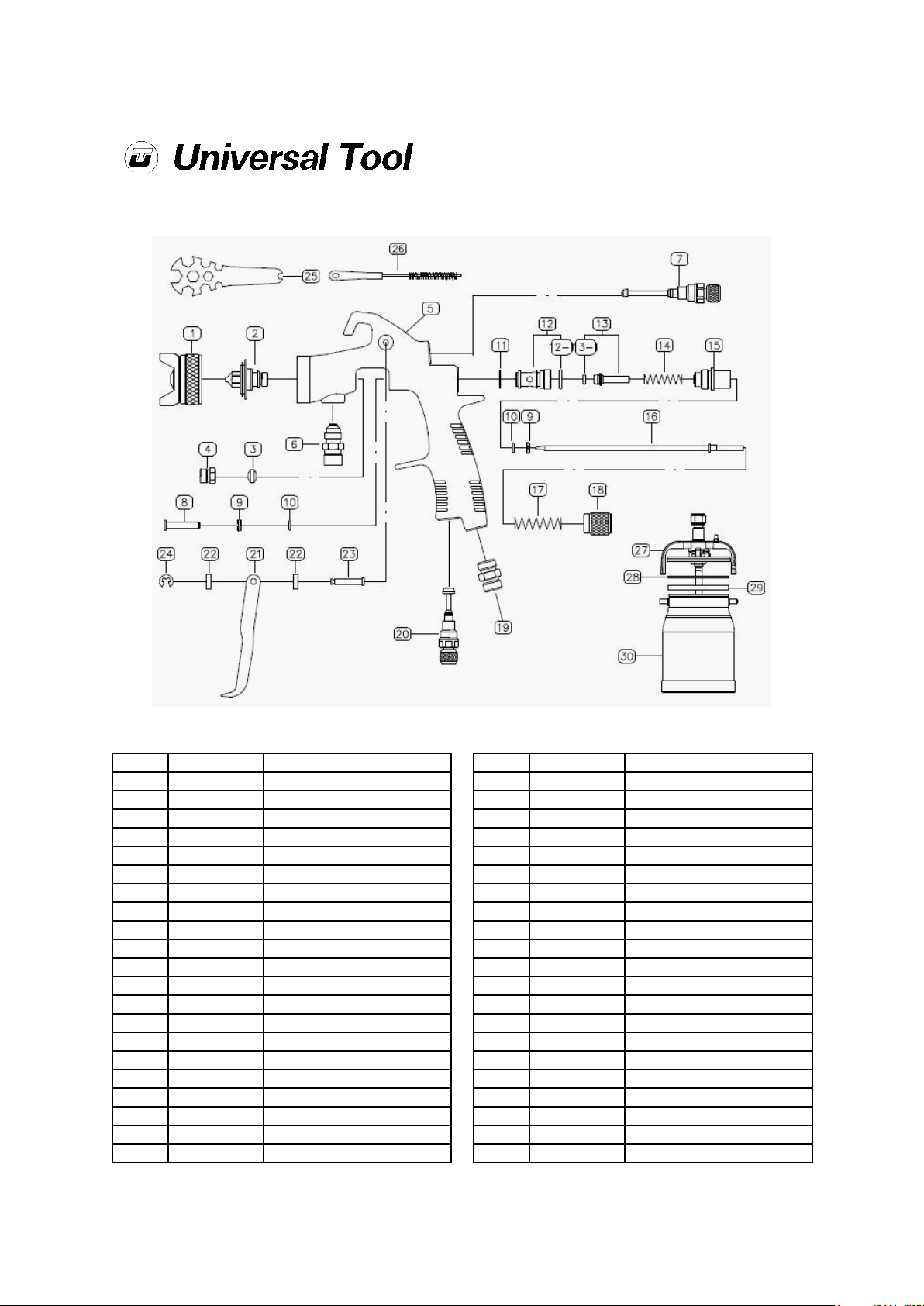

UT57A Spray Gun - Syphon Type

Ref No Part No Description

1 9920000201 Air Cap

2 9930000101 Fluid Nozzle 1.3

2 9930000102 Fluid Nozzle 1.4

2 9930000103 Fluid Nozzle 1.5

2 9930000106 Fluid Nozzle 1.8

2 9930000107 Fluid Nozzle 2.0

2 9930000109 Fluid Nozzle 2.5

3 9000000100 Needle Packing Set

4 9000000200 Needle Packing Seat

5 9910000200 Body Set

6 9000000300 Fluid Nipple

7 9000000401 Pattern Adj.Set

8 9000000500 Air Valve Shaft

9 9000000600 Packing Holder

10 9000000700 O-Ring

11 9000000800 Gasket

12 9000000900 Air Valve Seat Set

12-1 9000000910 O-Ring

13 9000001000 Air Valve Seat Set

13-1 9000000700 O-Ring

14 9000001100 Air Valve Spring

May 2008 Ver 1.10

Ref No Part No Description

15 9000001200 Fluid Adj.Guide Set

16 9940000101 Fluid Needle 1.3

16 9940000102 Fluid Needle 1.4

16 9940000103 Fluid Needle 1.5

16 9940000106 Fluid Needle 1.8

16 9940000107 Fluid Needle 2.0

16 9940000109 Fluid Needle 2.5

17 9000001300 Needle Spring

18 9000001401 Fluid Adj.Knob

19 9000001500 Air Inlet Nipple

20 9000001601 Air Adj.Set

21 9000001700 Trigger

22 9000001800 Gasket

23 9000001900 Trigger Stud

24 9000002000 E-Ring

25 9710001400 Spanner

26 9720002100 Brush

27 9830000310 Complete Lid Ass’y

28 9830000330 Gasket

29 9830000340 Gasket

30 9830001920 Cannister

Page No 3

Page 4

which the operator of the gun should study closely,

practise and follow.

Firstly, the gun at all times should be held in a comfortable

position and at a distance of about 7 to 9 inches from the

surface to be coated and, most importantly, at right

angles to the surface. The working strokes should be

made in straight uniform passes backwards and forwards

across the surface in such a manner that the spray pattern

overlaps the previous by about 50%.

Secondly, the speed of the stroke must be constant to

maintain uniform thickness of coat and each stroke

should be made with a relaxed arm and flexible wrist so

that the gun is kept at right angles to the surface

throughout the whole operation.

Thirdly, trigger control should always be by a smooth

even pressure of the finger and never pulled abruptly or

released with a jerk. A little time spent in practising fine

pressure control of the trigger as distinct from using the

material needle adjusting screw, is amply rewarded

when complex shaped articles are to be coated. Correct

triggering of the spray gun is an essential part of the stroke

technique. To prevent paint build up at the beginning and

end of each stroke, the movement of the gun should

commence before the trigger is pulled and the trigger

released again before movement ceases.

Common Errors in Handling

1) Holding the Gun at the Wrong Distance

When the gun is held too close to the surface, the paint is

concentrated into a smaller area and unless very rapid

strokes are made, the surface will be overloaded

inevitably resulting in “sags” and “runs”. When held too far

from the surface, a coarse dry coating that has an

“orange peel” effect results.

2) Varying the Speed of the Stroke

A smooth uniform finish depends largely upon the even

stroke of an operator in relation to the volume of paint flow

and this should be regulated to conform to the operator’s

natural speed of movement.

3) Tilting the Gun

If the gun is tilted out of the vertical position this will result

in an uneven coat. It may also affect the paint supply if the

level of paint in a gravity or syphon cup is low.

4) Swinging or Arcing the Gun

This is perhaps the most common fault in handling a spray

gun and is caused by keeping the arm and wrist rigid

resulting in the gun swinging in an arc from the shoulder,

consequently not pointing at the surface at right angles

throughout the whole stroke, resulting in uneven paint

deposit.

5) Incorrect Overlapping

If the spraying strokes are too far apart and do not overlap

by about 50%, a streaky finish will result whilst too much

overlap can easily overload the surface. The perfect finish

will be only obtained if the many factors involved in spray

painting receive the necessary care and attention. It can

be taken for granted with the high degree of perfection in

the design and manufacture of spray guns that failure to

achieve a good finish is more likely to be attributed to poor

operator technique than equipment fault.

6) It should also be noted that a spray gun may have a

choice of nozzle and air cap combinations called

“settings”. Each setting will control the air consumption

and type and amount of paint that can be applied in a

given time. The incorrect choice of setting to paint type

can give poor results. Seek advice from the manufacturer.

Terms to Describe a Poor Paint Finish

1) Orange Peel

This is a finishing effect so called because it resembles the

texture and appearance of orange

peel.

Common causes - unsuitable paint thinners

- atomising pressure too high or low

- material viscosity too high

- material not thoroughly mixed

- material too cold

- conditions in the finishing room (i.e.

draughts, temperature, humidity)

- poorly prepared surface or

contaminated surface

- holding gun too close or far from

surface

- applying too thin a coat

2) Runs and Sags

Common causes - too much material applied

- material being too thin

- tilting gun at an angle causing spray

pattern to strike surface unevenly

3) Streaky Finish

Common causes - tilting the gun

- split spray pattern

- incorrect overlapping of spray strokes

- spraying with heavy top or bottom

spray pattern

4) Mist or Fog

Common causes - over atomisation due to too high an

atomising air pressure

- improper use of the gun arcing or

swinging too far from surface, not

releasing trigger at the end of the

spray stroke

5) Starving

Common cause - insufficient air or material feeding the

gun

Page No 4

Page 5

Faults & Remedies

Air leaking from Spray Gun

Cause Remedy

- Dirt on air valve seating - Remove and clean

- Worn or damaged seating - Replace

- Broken air valve spring - Replace

- Air Valve Sticking - Lubricate gland and loosen gland nut

- Bent air valve stem - Replace air valve

Material (Paint) leaking from Spray Gun

Cause Remedy

- Material nozzle or needle worn or damaged - Replace

- Foreign body in material nozzle - Remove nozzle and clean

- Broken material needle spring - Replace

- Wrong size of needle - Replace

- Material needle sticking - Remove gland, lubricate and adjust gland nut

- Material nozzle loose - Tighten

- Dirt or lumps in paint - Strain

Jerky or spitting spray

Cause Remedy

- Loose material nozzle and/or air cap - Tighten

- Insufficient material (paint) in container - Replenish

- Dry gland packing or gland nut loose - Lubricate and/or tighten gland nut

- Loose or cracked centre tube in syphon cup

or lid assembly

- Obstructed fluid passageways - Clean

- Damaged material needle tip or worn and

damaged nozzle seating

- Replace

- Replace

Jerky or Spitting Spray

Cause Remedy

- Material too viscous to syphon - Thin

- Blocked vent in lid/plastic tube - Clean

- Poor seal in lid - Replace

- Loose, dirty or damaged container lid and

coupling

Poor quality spray patterns

Cause and remedy - See separate page

- Tighten, clean or replace

Page No 5

Page 6

Spray Gun Paint Patterns

Faults and Remedies

Faulty Spray Patterns

Top Heavy Spray

Cause

a) Wing holes partially obstructed

b) Damaged or obstruction of material

nozzle tip

c) Air cap or material nozzle not seating

correctly due to dirt or damage

Bottom Heavy Spray

Cause

a) Wing holes partially obstructed

b) Damage or obstruction to bottom of

material nozzle tip

c) Air cap or material nozzle not seating

correctly due to dirt or damage

Remedy

Turn the air cap through 180°. If defective pattern is reversed, fault is

due to air cap

Remove and clean air cap

If defective pattern does not reverse then fault is with the material nozzle

Remove nozzle and clean

Do not use metal objects to clear holes

Cause

a) Air hole in either wing of air cap restricted

or blocked allowing full pressure of air on

the other side to force the spray pattern in

direction of restricted or blocked side

b) Material nozzle tip damaged or having

particles of dirt or dried paint on one side

Correct Spray Patterns

The spray pattern is

variable from round to fan

Cause

a) Too high an

atomising

air pressure

b) Attempting

to obtain a

too wide fan

spray with

thin material

Cause

A fan spray pattern that is heavy in the

middle or a pattern that has an

anatomised “salt & pepper” effect

indicates too low an atomising

pressure

Remedy

Increase air pressure from your air

supply. Correct air pressures are

discussed elsewhere in this booklet

Remedy

Reducing air pressure will cure

cause (a)

To correct cause (b) open

material control to fully open

position. At same time reduce

width of spray pattern

If material is being pressure fed,

increase pressure on container

to give increased material flow

with all patterns in

between

Spitting

Air in material

passages

Remedy

As above

Do not use metal objects to clear holes

Cause

Dried material around nozzle tip

restricts the passage of atomising air

at one point through the centre

opening of air cap and results in this

pattern being obtained. Can also be

caused by a loose fitting air cap

Cause

a) Dirt in material nozzle or a loosely fitted

nozzle/air cap

b) Dried out gland packing around

material needle valve

c) Loose fitting nut or fractured feed tube

in container

d) Insufficient material in container

e) Obstructed fluid passageways

Page No 6

Remedy

If dried material is causing

the trouble, remove air cap

and wipe off material tip,

using a rag wetted with

thinners

Tighten air cap

Remedy

a) Clean and refit tightly

b) Lubricate and tighten (if

necessary replace

gland packing)

c) Tighten or replace

d) Replenish material

e) Clean

Page 7

Advice on Cleaning Spray Guns

When used with a cup, thinner or

suitable solvent should be syphoned

through the gun by inserting tube in

open container of that liquid. Move

trigger constantly to flush passageway

and clean tip of needle.

Ensure Adequate Ventilation.

When the gun is used with a pressure

fed container or gravity bucket, remove

the hose, turn the gun upside down and

pour thinners into the fluid opening whilst

moving the trigger constantly. This will

flush all passageways.

It is extremely poor practice to place an

entire gun in thinners. When this is done

the solvent dissolves the oil in the gland

packing and causes the gun to split.

It is good practice to place the nozzle

and fluid connection in thinners. Vessel

used should be shallow enough to

prevent thinner from reaching the

pickings.

Page No 7

Page 8

Declaration of Conformity

Universal Air Tool Company Limited

Unit 8, Lane End Industrial Park, High Wycombe, Bucks, HP14 3BY, England

declare under our sole responsibility that the product

Model UT57A Spray Gun, Serial Number

to which this declaration relates is in conformity with the following standard(s) or other normative document(s)

EN792 (Draft), EN292 Parts 1 & 2, ISO 8662/1

following the provisions of

89/392/EEC as amended by 91/368/EEC & 93/44/EEC Directives

Lane End D.H.Moppett (Man. Director)

Place and date of issue Name and signature or equivalent marking of authorised person

Accessories

Notes

Distributor

This document may not be copied wholly or in part by anyone without the consent of the Directors of Universal Air Tool Company Limited

Designed & Written in the U.K.

©Copyright of Universal Air Tool Company Limited, established in the United Kingdom, 1994

Page No 8

Loading...

Loading...