Includes - Foreseen Use, Work Stations, Putting Into Service, Operating,

Operator Instructions

Read these instructions carefully before installing, operating,

servicing or repairing this tool. Keep these instructions in a safe

Tel No

(01494) 883300

Test Method

Tested in accordance with Pneurop

test code PN8NTC1 and ISO Standard 3744

Vibration Level

Test Method

Tested in accordance with ISO

Less than 2.5

Important

Dismantling, Assembly and Safety Rules

Manufacturer/Supplier Product Type

Universal Air Tool Company Limited

Unit 8

Lane End Industrial Park

High Wycombe

Bucks

accessible place.

RPM

10mm Belt Sander

16,000

Cycles Per Min

N/A

Model No/Nos Serial No (if any)

UT5764

HP14 3BY

Fax No

(01494) 883237

Product Nett Weight

1.72

0.78 3/8 10 30 10

Recommended Working

Recommended Minimum

Maximum

Use - Safety Glasses

Use - Safety Gloves

Use - Safety Boots

Use - Breathing Masks

Use - Ear Protectors

lbs

Kg

Air Pressure

Personal Safety Equipment

Recommended Use Of

Balancer Or Support

No

bar

6.3

n/a

7.0

bar

bar

90

n/a

100

Yes

Yes

Recommended Hose Bore

Noise Level

PSI

PSI

PSI

standard 8662/1

Size - Minimum

Ins M/M Ft M

Sound Pressure Level 85.0 dB(A)

Sound Power Level 96.0 dB(A)

Recommended Max.

Hose Length

Metres / Sec²

Foreseen Use of the Tool

The tool is designed for the purpose of cleaning or sanding of materials

using a continuous abrasive belt. Belts are available in various grades to

suit fine finishing or fast material removal.

Do not use the tool for any other purpose than that for which it was

designed. Do not modify this tool for any other use or for its use as a belt

sander without first consulting the manufacturer or the manufacturer’s

authorised distributor.

Work Stations

The tool should only be used as a hand held hand operated tool. It is

always recommended that the tool is used when standing on a solid

floor. It can be used in other positions but before any such use the

operator must be in a secure position having a firm grip and footing and

be aware of the safety rules to be obeyed when using the sander.

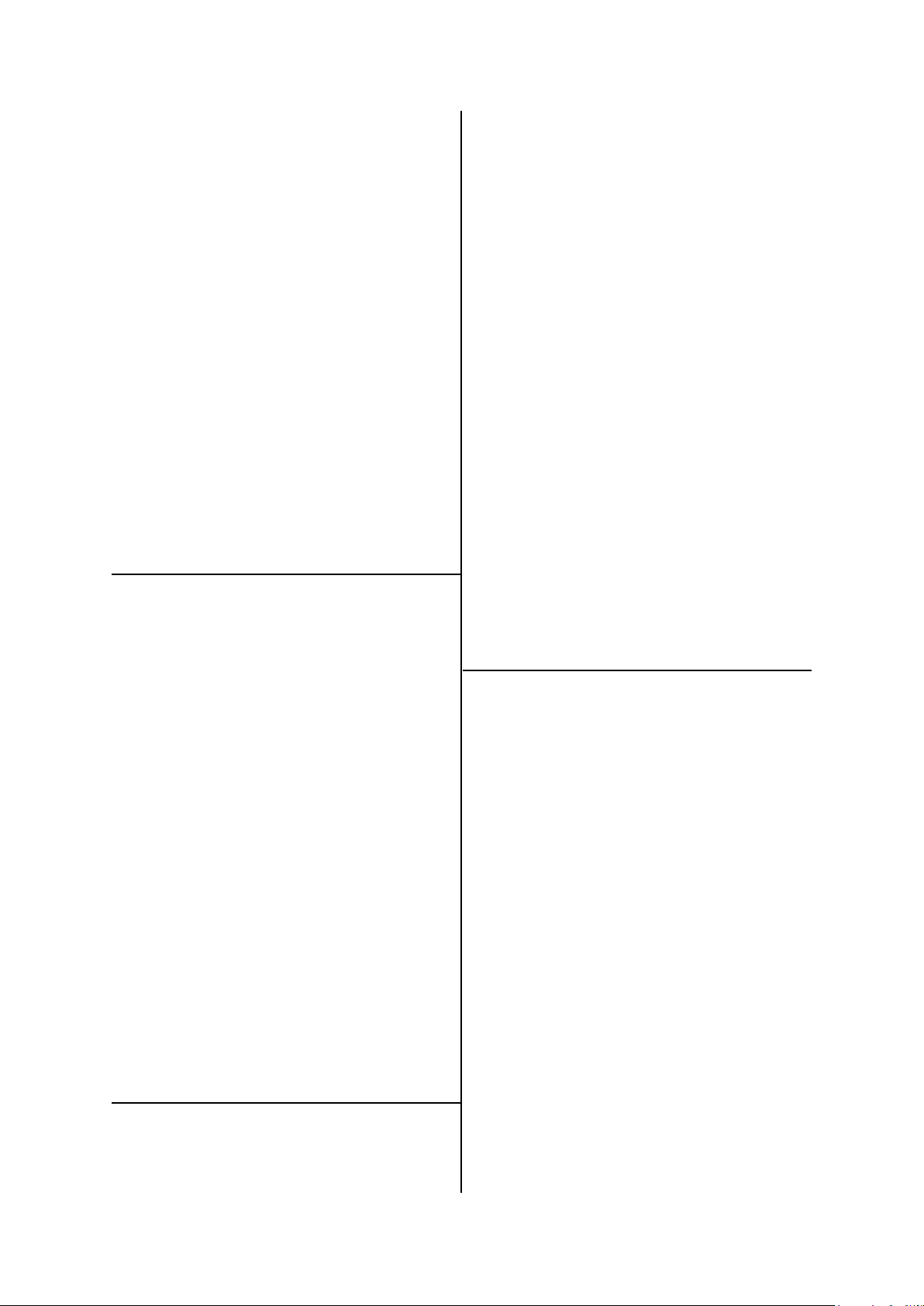

Putting Into Service

Air Supply

Use a clean lubricated air supply that

will give a measured air pressure at

the tool of 90 p.s.i./6.3 bar when the

tool is running with the trigger/lever

fully depressed. Use recommended

hose size and length. It is recommended that the tool is connected to

the air supply as shown in figure 1. Do

not connect the tool to the air line system without incorporating an easy to

reach and operate air shut off valve. The air supply should be lubricated.

It is strongly recommended that an air filter, regulator, lubricator (FRL) is

used as shown in Figure 1 as this will supply clean, lubricated air at the

correct pressure to the tool. Details of such equipment can be obtained

from your supplier. If such equipment is not used then the tool should be

lubricated by shutting off the air supply to the tool, depressurising the

line by pressing the trigger on the tool. Disconnect the air line and pour

into the air inlet a teaspoonful (5ml) of a suitable pneumatic motor lubricating oil preferably incorporating a rust inhibitor. Reconnect tool to air

supply and run tool slowly for a few seconds to allow air to circulate the

oil. If tool is used frequently lubricate on daily basis and if tool starts to

slow or lose power.

It is recommended that the air pressure at the tool whilst the tool is

running is 90 p.s.i./6.3 bar. The tool can run at lower and higher

pressures with the maximum permitted working air pressure of 100

p.s.i./7 bar.

Page No 1

Operating

Select a suitable abrasive belt of the required grade to achieve a fine

sanded finish or high metal removal. The belt size for this tool is 10 mm

wide x 330 circumference (continuous belt) and is available in various

grades, the lowest is grade 40 grit which is coarse for high material

removal and grits are available as 40, 50, 60, 80, 100 and 120. The

coarseness of the grit decreases as the grade number increases, hence

40 is coarse and 120 very fine.

To fit a belt, press down the tension bar and push the idle pulley towards

the tool until the tension bar clicks into place which releases the tension

and holds the tension off the belt. Fit the belt ensuring that it sits centrally

on the drive pulley and the idle pulley. Release the tension bar to tighten

the belt. Start the tool slowly and use the adjusting screw (8) to align the

belt centrally.

Apply the sander lightly to the work and allow the belt to cut. Take great

care when sanding around sharp edges and corners to avoid snagging

and belt damage or breakage. It is always recommended to use safety

glasses and a breathing mask. The sanding of certain materials may

create a hazardous dust which may require special breathing

equipment. Check before using the tool.

Even if the tool has a low noise level, the actual sanding process may

create a noise such that hearing protectors should be worn.

If there are sharp edges on the material being sanded then safety gloves

are recommended.

Do not continue to use belts that are clogged or worn as this will make

the sanding process inefficient and the need to apply unnecessarily high

loads to the tool.

Only use belts of the dimensions specified. To use an incorrect belt will

either cause it to break or fly off. Both occurrences could be dangerous.

Dismantling & Assembly Instructions

Disconnect tool from air supply.

Press on the end of idle pulley (2) until it clicks into place and remove the

tension from the grinding belt (1). Remove screw (13) and take off shoe

(12). Unscrew idle pulley shaft and idle pulley (2) being very careful not

to lose the very small washer (3). Remove screw (8). Tap out one off pin

(10) and remove bracket (5) and spring (9). Unscrew socket head

screw (7) from bracket (10). Tap out pin (43) and remove tension bar

(40) and spring (41) and lever pin (42). Lever pin (42) can be tapped out

of tension bar (40) if a replacement is required. It is then possible to pull

out tension bar (6). Tap out a second pin (10) from tension bar (6).

Remove spring (11) from tension bar (6). Remove cap screw (15) and

rubber flap may be removed from guard (14). Tap out lever pin (30) and

remove throttle lever (29). Unscrew valve body (31) with valve stem

(35). Remove O-ring (33) from valve body (31) and O-rings (34) and

(36) from valve stem (35). Take out spring (37). Unscrew air inlet (39)

and take off deflector (38). Take off guard assembly (14) from housing

(18). Do not remove the brass bushing from guard assembly (14). It is

then required to remove end cap (23). This component is screwed and

glued in place. It is advised to apply local heat to the end cap (23) and

the part of housing (18) into which it locates to ease removal. Locate a

pin in the hole in the side of drive pulley (17) and grip it and with a socket

unscrew nut (16). Pull off drive pulley (17). Remove key (22). Tap the

end of rotor (28) to drive the motor assembly out of housing (18).

Remove front end plate (20) and bearing (19) and spacer (21) from

rotor (28). Take off cylinder (26) and remove 4 off rotor blades (27).

Support rear end plate (25) and tap non threaded end of rotor to drive it

through the rear end plate (25). Tap out bearing (19) from front end

plate (20) and bearing (24) from rear end plate (25).

Reassembly

Clean all parts and examine for wear and damage. Replace any parts

with parts obtained from the manufacturer or an approved

representative. Reassemble in the reverse order, fit belt and adjust.

3) Use personal safety equipment.

4) Use only compressed air at the recommended conditions.

5) If the tool appears to malfunction remove from use immediately and

arrange for service and repair.

6) If the tool is used with a balancer or other support device ensure that

it is fixed securely.

7) Always keep hands away from the working attachment fitted to the

tool.

8) The tool is not electrically insulated. Never use the tool if there is any

chance of it coming into contact with live electricity.

9) Always when using the tool adopt a firm footing and/or position and

grip the tool firmly to be able to counteract any forces or reaction forces

that may be generated whilst using the tool.

10) Use only correct spare parts. Do not improvise or make temporary

repairs.

11) Do not lock, tape, wire, etc. the on/off valve in the run position. The

trigger/lever etc. must always be free to return to the ‘off’ position

when it is released.

12) Always shut off the air supply to the tool, and depress the

trigger/lever etc. to exhaust air from the feed hose before fitting,

adjusting or removing the working attachment.

13) Check hose and fittings regularly for wear. Replace if necessary. Do

not carry the tool by its hose and ensure the hand is remote from the

on/off control when carrying the tool with the air supply connected.

14) Take care against entanglement of moving parts of the tool with

clothing, ties, hair, cleaning rags, etc. This will cause the body to be

drawn towards the tool and can be very dangerous.

15) It is expected that users will adopt safe working practices and

observe all relevant legal requirements when installing, using or

maintaining the tool.

16) Do not install the tool unless an easily accessible and easily operable

on/off valve is incorporated in the air supply.

17) Take care that the tool exhaust air does not cause a problem or

blows on another person.

18) Never lay a tool down unless the working attachment has stopped

moving.

Safety Rules For A Sander

1) Read all the instructions before using this tool. All operators must be

fully trained in its use and aware of these safety rules.

2) Do not exceed the maximum working air pressure.

Page No 2

Loading...

Loading...