Page 1

Operator Instructions

Includes - Foreseen Use, Work Stations, Putting Into Service,

Operating, Dismantling, Assembly and Safety Rules

Important

Read these instructions carefully before insta lling, operating,

servicing or repairing this tool. Keep these instructions in a safe

accessible place.

Manufacturer/Supplier Product Type

Universal Air Tool Company Limited

Unit 8

Lane End Industrial Park

High Wycombe

Bucks

3/4 Square Drive Pistol

Grip Impact Wrench

Model No/Nos Serial No

UT5315

HP14 3BY

Tel No Fax No

(01494) 883300 (01494) 883237

RPM

5000

Cycles Per Min

Product Nett Weight

9.90

4.50

lbs

Kg

Recommended Use Of

Balancer Or Support

No

Air Pressure

Recommended Working

Recommended Minimum

Maximum

6.3

n/a

7.0

bar

bar

bar

90

n/a

100

Perso n a l Sa fe t y E q ui pm en t

Use - Safety Glasses

Yes

Use - Safety Gloves

Use - Safety Boots

Use - Breathing Masks

Use - Ear Protectors

Yes

Foreseen Use Of Tool

The impact wrench is designed for the tightening and loosening

of threade d fas ten er s w ithin the ra nge as spe cifie d by the

manufacturer. It should only be used in conjunction with suitable

impact type 3/4" square female drive nut running sockets. Only

use sockets which are of the impact type.

It is allowed to use suitable extension bars, universal joints and

socket adaptors between the square output drive of the impact

wrench and the square female drive of the socket.

Do not use the tool for any other purpose than that specified

with out co nsul ti ng th e ma nufa ctur er or th e man uf act urer 's

authorised supplier. To do so may be dangerous.

Never u se an impact wre nch as a ha mmer to dislodge or

straighte n cross threaded fas teners. Never a ttempt to modify

the tool for other uses and never modify the tool for even its

recommended use as a nutrunner.

Work Stations

The tool should only be used as a handheld

hand operated tool. It is always recom-

mended that the tool is used when standing

on the solid floor. It can be in other positions

but before any such use, the operator must

be in a secure position having a firm grip

and footing and be aware that when loosen-

ing fasteners the tool can move quite quickly

away from the fastener being undone. An

allowanc e must alway s be made for this

rearward movement so as to avoid the pos-

sibility of hand/arm/body entrapment.

Recommended Hose Bore

Recommended Max.

Size - Minimum

3/8 10 30 10

Ins M/M Ft M

Noise Level

PSI

Test Method

PSI

test code PN8NTC1 and ISO Standard 3744

PSI

Vibration Level

Test Method

Sound Pressure Level 85.7 dB(A)

Sound Power Level 96.7 dB(A)

Tested in accordance with Pneurop

5.8

Tested in accordance with ISO

standards 8662 Parts 1 & 7

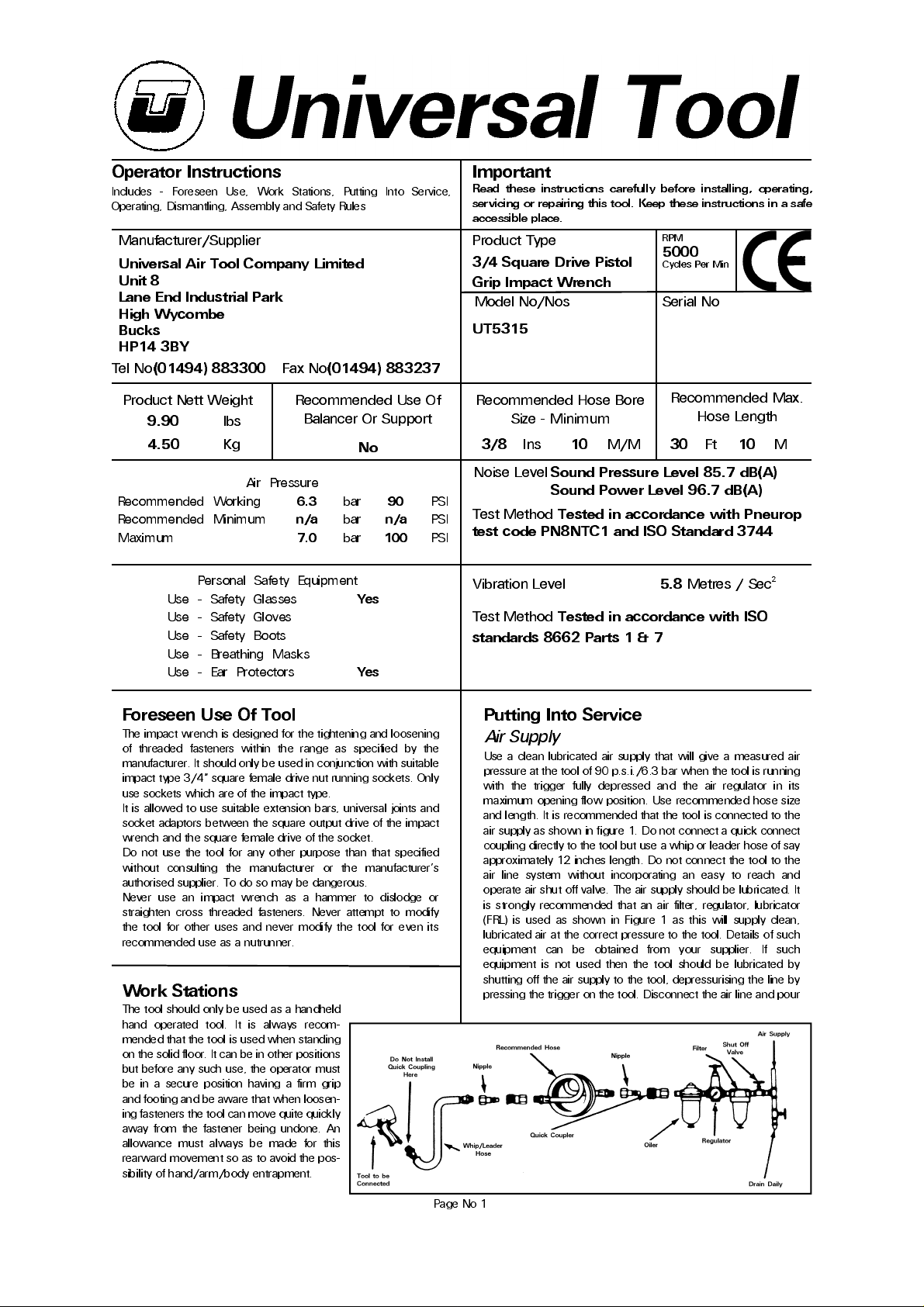

Putting Into Service

Air Supply

Use a clean lubricated air supply that will give a measured air

pressure at the tool of 90 p.s.i./6.3 bar when the tool is running

with the trigger fully depresse d and the air regu lator in its

maximum opening flow position. Use recommended hose size

and length. It is recommended that the tool is connected to the

air supply as shown in figure 1. Do not connect a quick connect

coupling directly to the tool but use a whip or leader hose of say

approximately 12 inches length. Do not connect the tool to the

air line sys tem withou t incorporating an easy to reach a nd

operate air shut off valve. The air supply should be lubricated. It

is strongly recommended that an air filter, regulator, lubricator

(FRL) is used as shown in Figure 1 as this will supply clean ,

lubricated air at the correct pressure to the tool. Details of such

equipment can be obtained from your supplier. If such

equipment is not used then the tool should be lubricated by

shutting off the air supply to the tool, depressurising the line by

pressing the trigger on the tool. Disconnect the air line and pour

Hose Length

Metres / Sec²

Page No 1

Page 2

into the intake bushing (21) a teaspoonful (5ml) of a suitable

pneumatic motor lubricating oil preferably incorporating a rust

inhibitor. Reconnect tool to air supply and run tool slowly for a

few sec onds to allow air to circulate the oil. If tool is used

frequently lubricate on daily basis and if tool starts to slow or

lose power. When lubricating, also ensure that screen (1) is

clean.

It is recommended that the air pressure at the tool whilst the

tool is running is 90 p.s.i./6.3 bar. The tool can run at lower and

higher pressures with the maximum permitted working air

pressure of 100 p.s.i./7.0 bar. For a lower air pressure the tool

will give a lower output for a given setting of the air regulator set

for 90 p si o perat io n and an i ncrea sed o utp ut fo r hig her

pressures. Hence it is possible that changes in supply pressure

can gi ve si tuat io ns wher e the fast ener i s und er o r o ver

tightened. For changes in pressure, the regulator position and

application should be reassessed.

It is recommended that joint tightness of the threaded fastener

assembly be checked with suitable measuring equipment.

Operating

The output of the impact wrench in prime working condition is

governed by mainly three factors

a) the input air pressure

b) the time the impact wrench is operated on the joint. Normal

time for joints of average tension requirement 3 to 5 seconds

c) the setting of the air regulator for a given joint a t a given

pressure operated for a given time.

The air regulator item (26) can be used to regulate the output of

the impact wrench if no other control means is available. It is

strongly recommended that an external pressure regulator

ideally as part of a filter/regulator/lubricator (FRL) is used to

control air inlet pressure so that the pressure can be set to help

control the ten sion requ ired to be applied to the th readed

fastener joint.

There is no consistent reliable torque adjustment on an impact

wrench of this type. However, the air regulator can be used to

adjust torque to the approximate tightness of a known threaded

joint. To set the tool to the desired torque, select a nut or screw

of known tightness of the same size, thread pitch and thread

condition as those on the job. Turn air regulator to low position,

apply wrench to nut and gradually increase power (turn regulator

to admit more air) until nut moves slightly in the direction it was

originally se t. The tool is now s et to duplicate tha t tightness,

note regulator setting for future use. When tightening nuts not

requiring critical torque values, run nut up flush and then tighten

an additional one-quarter to one-half turn (slight additional

turning is necessary if gaskets are being clamped). For additional

power needed on disassembly work, turn regulator to its fully

open position. This impact wre nch is rated a 3/4" bolt size.

Rating must be down graded for spring U bolts, tie bolts, long

cap sc rews, double depth nu ts, badly rusted con ditions and

spring fasteners as they absorb much of the impact power.

When possible, clamp or wedge the bolt to prevent spring back.

Soak rusted nuts in penetrating oil and break rust seal before

removing with impact wrench. If nut does not start to move in

three to five seconds use a larger size impact wrench. Do not

use impact wrench beyond rated capacity as this will drastically

reduce tool life.

NOTE: Actual torque on a fastener is directly related to joint

hardness, tool speed, condition of socket and the time the tool

is allowed to impact.

Use the simplest possible tool-to-socket hook up. Every

connection absorbs energy and reduces power.

Dismantling & Assembly Instructions

Disconnect from air supply.

Remove red boot (56) remove clamp screw (13) and drain the

oil in the front end into a suitable container. Grip motor housing

Page No 2

(1) in a vice and tap out spring pin (28). Pull out air regulator

(26) with o-ring (27). Take out screw (9) and remove deflector

(8). Unscrew retainer plug (31) take out stop pin (29) and

spring (30) and it will be possible to push out the reverse valve

(25) from the motor housing (1). Unscrew 4 off screws (4) with

washers (5) and tap the square drive end of the anvil shank

(51) and this will drive the motor and hammer assemblies out

of the rear end of the motor housing (1). Pull off the hammer

mechanism from the motor assembly. The hammer

mechanism maybe pulled apart separating the anvil shank (51)

spring (50) drive cam (48) 2 off anvil hammer bars (49) steel

ball (47) drive cam base (46) hammer cage (45) and anvil

washer (52). Note the notch in the spline of the anvil shank

(51) and the wide splined tooth drive cam (48) for correct

reassembly. Anvil collar (54) and o-ring (53) maybe prised off

the anvil shank (51) oil seal (7) maybe prised and the anvil

bushing (6) pressed out of the motor housing (1). Unscrew 3

off rotor screws (43) and washers (44) and take off end cap (2)

and gasket (3). It is then possible to pull the motor assembly

apart but first note the orientation of the cylinder (37) to the

front and rear end plates before pulling off the front and rear

plate assemblies from the rotor (38). Remove 6 off rotor blades

(39) from rotor (38). With a suitable punch tap out bearings

(32) and (41) remove oil seals (33) from rear plate (40) and

front plate (34). Prise out o-ring (35) from the grove in front

plate (34).

Reassembly

Clean all component parts and examine for wear and cracks

etc. before reassembling Look in particular to wear and cuts on

o-rings and oil seals, wear on rotor blades and wear and

cracks on hammer bars (49) and anvil (51) particular around

the square drive. Check carefully cage (45). Make sure that the

faces of the end plates (40) and (34) about cylinder (37) are flat

and free from burrs and surface marking. If necessary lap faces

on a flat, very fine grade of abrasive paper. Lightly coat all parts

with suitable pneumatic tool lubricating oil and reassemble in

the reverse order (See note below).

Note in particular

a) that the hammer bars (49) -2 off are located in the two

identical shaped grooves in the hammer cage (45).

b) that the cut away portion of the front flange of the cylinder

(37) abuts the two notches in the face of the front plate

(34).

On completing assembly ensure that all parts are locked tight

and the anv il rotates a nd the trigger, reve rse v alve a nd air

regulator mechanisms operate freely. Remove oil plug (13) and

pour in one ounce (28cc) of standard SAE20 grade oil. Do not

over fill as this will result in a reduction of power in the tool

performanc e. Pour approx 5ml of a good quality pneuma tic

lubricating oil (preferably one containing a rust inhibitor) into the

air intake with the trigger depressed. Connect tool to a suitable

air supply and reset for operation required. Refer to section on

operation instructions.

Safety Rules When Using an Impact

Wrench

1) Read all the instructions before using this tool. All operators

must be fully trained in its use and aware of these safety rules.

All service and repair must be carried out by trained personnel.

2) The socket used must be of the correct drive size and the

"impact" type. Never use sockets other than impact type.

3) Do not use sockets with excessive wear to the input and

output drives. Check that the square on any other type of drive

or the impact wrench is not cracked or excessively worn before

fitting or changing socket, extension, etc. Make sure that the

socket is firmly fixed to the tool.

4) Always ensure that a stable position or footing is adopted

before using the tool.

Page 3

UT5315 3/4" Square Drive Pistol Grip Impact Wrench

Ref No Part No Description

1 B8260 01 120 92 0 Motor Housi ng

2 B8260 34 120 92 0 End Cap

3 B8260 35 000 00 0 End Cap Ga ske t

4 B8261 02 001 00 0 Hex. So cke t Bolt (4)

5 B826143000000 Spring Washer (4)

6 B826017200100 Anvil Bushing

7 B8260 37 001 00 Oil Sea l

8 B826038200110 Muffle Steel Cover

9 B8111 06 001 00 0 Phili ps Pan Scr ew s (2)

11 B826045800000

12 B8260 69 800 00 0 Rear Pr otecti ng Ru bber

13 B8111 05 001 00 0 Clamp Sc rews

14 B826004740000 Trigger

15 B8321 04 000 00 0 Clamp Sc rews

16 B811129000000 Spring Pin

17 B8260 06 800 00 0 Throttle Bu shin g

18 B8260 07 200 10 0 Throttle Pi n

19 B826008000000 Steel Ball

20 B8110 09 280 00 0 Compre ssio n Spr in g

21 B811010200110 Hose Fitting

21-1 B811010201110 Hose Fitting

22 B8110 67 770 00 0 Dust Cove r

23 B826002120100 Valve Sleeve

24 B924118800000 O-Ring

25 B8260 03 200 10 0 Rever se Val ve

26 B8260 12 200 11 0 Air Re gul ator

27 B826117800000 O-Ring

28 B826128000000 Spring Pin

Nov 2004 Ver 1.00

Front Protecting

Rubber

Ref No Part No Description

29 B826125210100 Pin

30 B811068280000 Spring

31 B8111 08 001 00 0 Clamp Sc rew

32 B8260 28 000 00 0 Ball B ear in g

33 B8260 36 000 00 0 Oil Sea l (2)

34 B826027120100 Front End Plate

35 B826116800000 O-Ring

36 B826114000000

37 B826024310100 Cylinder

38 B818025220100 Rotor

39 B826026700000 Rotor Fan (6)

40 B8260 29 120 10 0 Rear End Plate

41 B8260 30 000 00 0 Ball B ear in g

43 B8261 01 000 00 0 Hex. So cke t Bolt (3)

44 B811144000000 Spring Washer (3)

45 B8260 19 220 10 1 Hammer C age

46 B826043220101 Drive Cam Base

47 B826061250000 Steel Ball

48 B826022220102 Drive Cam

49 B8260 21 220 10 0 Hammer B ar (2)

50 B826062280000 Spring

51 B826018230110 Anvil(141.5mm)

51-1 B826018223110 Anvil(257mm)

52 B826016210100 Anvil Washer

53 B826121800000 O-Ring

54 B826066280000 Anvil Collar

55 B8261 40 800 00 0 O-Ring (3)

56 B8260 75 802 00 Red Boot (Not Shown)

Page No 3

Thread Se cur e Re coi l

(3)

Page 4

Declaration of Conformity

Universal Air Tool Company Limited

Unit 8, Lane End Industrial Park, High Wycombe, Bucks, HP14 3BY, England

declare under our sole responsibility that the product

Model UT5315 3/4 Impact Wrench, Serial Number

to which this declaration relates is in conformity with the following standard(s) or other normative document(s)

EN792 (Draft), EN292 Parts 1 & 2, ISO 8662 Parts 1 & 7, Pneurop PN8NTC1

following the provisions of

89/392/EEC as amended by 91/368/EEC & 93/44/EEC Directives

Lane End D.H.Moppett (Man. Director)

Place and date of issue Name and signature or equivalent marking of authorised person

5) Ensure that the tool has been correctly set up on a test joint.

Incorrect set up could cause joint breakage with sudden and

unexpected movement of the tool.

6) Use only correct spare parts for repair.

7) Always ensure that the reverse valve is in the correct position

before operating the tool. Do not run the tool unless the socket

is first located on the joint.

8) Check hose and fittings regularly for wear. Use quick connect

couplings only as recommended. See "Putting into Service". Do

not carry the tool by the hose and ensure that the hand is away

from the on/off valve when carrying.

9) Do not attempt to hold or guide the socket by hand when the

tool is running.

10) Do not exceed maximum recommended air pressure.

11) Use safety equipment as recommended.

12) The tool is not electrically insulated. Do not use where there

is a possibility of coming into contact with live electricity.

13) Preferably shut off the air supply before changing sockets or

at least ensure that the hands are well clear of the operating

trigger.

14) Take care against entanglement of moving parts of the tool

with clothing, ties, hair, cleaning rags, etc.

15) When loosening fasteners first ensure that there is sufficient

clearance behind the tool to avoid hand entrapment. The tool

will move away from the threaded joint as the nut/bolt etc. is

loosened and rides up the thread moving the tool with it.

16) Only use extensions, adaptors and universal joints suitable

for use with impact wrenches.

17) If the tool appears to malfunction remove from use

immediately and arrange for service and repair.

Notes

Distributor

Accessories

This document may not be copied wholly or in part by anyone without the consent of the Directors of Universal Air Tool Company Limited

Designed & Written in the U.K.

©Copyright of Universal Air Tool Company Limited, established in the United Kingdom, 1994

Page No 4

Loading...

Loading...