Page 1

Tel No

(01494) 883300

(01494) 883237

Air Hydraulic Blind Riveter

Includes - Foreseen Use, Work Stations, Putting Into Service, Operating,

Operator Instructions Important

Read these instructions carefully before installing, operating,

servicing or repairing this tool. Keep these instructions in a safe

Vibration Level

Test Method

Tested in accordance with ISO

Less than 2.5

Test Method

Tested in accordance with Pneurop

test code PN8NTC1 and ISO Standard 3744

Dismantling, Assembly and Safety Rules

accessible place.

Manufacturer/Supplier Product Type

Universal Air Tool Company Limited

Unit 8

Lane End Industrial Park

High Wycombe

Bucks

HP14 3BY

(Vacuum System)

Model No/Nos Serial No

UT180R (1/4”)

UT190R (3/16”)

Fax No

Product Nett Weight Recommended Use Of

Kg lbs

UT180R

UT190R

2.00 4.40

1.80 3.96

Air Pressure

Recommended Working

Recommended Minimum

Maximum

Balancer Or Support

No

bar

6.3

bar

n/a

7.0

bar

n/a

100

90

PSI

PSI

PSI

Recommended Hose Bore

Size - Minimum

Ins M/M Ft M

3/8 10 30 10

Noise Level

Personal Safety Equipment

Use - Safety Glasses

Use - Safety Gloves

Use - Safety Boots

Use - Breathing Masks

Use - Ear Protectors

Yes

standards 8662 Part 1

RPM

Cycles Per Min

Recommended Max.

Hose Length

Sound Pressure Level 70.5 dB(A)

Sound Power Level 82.4 dB(A)

Metres / Sec²

Foreseen Use of the Tool

This tool is designed to place blind rivets, also known as pop rivets in

pre-formed holes in sheet metal. The rivets are set in the sheet by a

pulling force exerted by the tool under the action of a hydro-pneumatic

cylinder. Upon placing the rivet correctly in the sheet, the stem of the

blind rivet will break off when the rivet is placed. Do not use the tool for

any other purpose than that for which it was designed unless first

consulting the manufacturer or the manufacturer’s authorised

representative.

Do not modify the tool for any other purpose or its use as a blind rivet

installation tool without first consulting the manufacturer or the

manufacturer’s representative.

Work Stations

The tool should only be used as a handheld, hand operated tool. It is

always recommended that the tool is used when standing on a solid

floor. It can be

used in other

positions but

before any such

use, the operator

must be in a

secure position

having a firm grip

and footing and

be aware of a

reaction force on

the hand as

result of the tool

doing work.

Putting Into Service

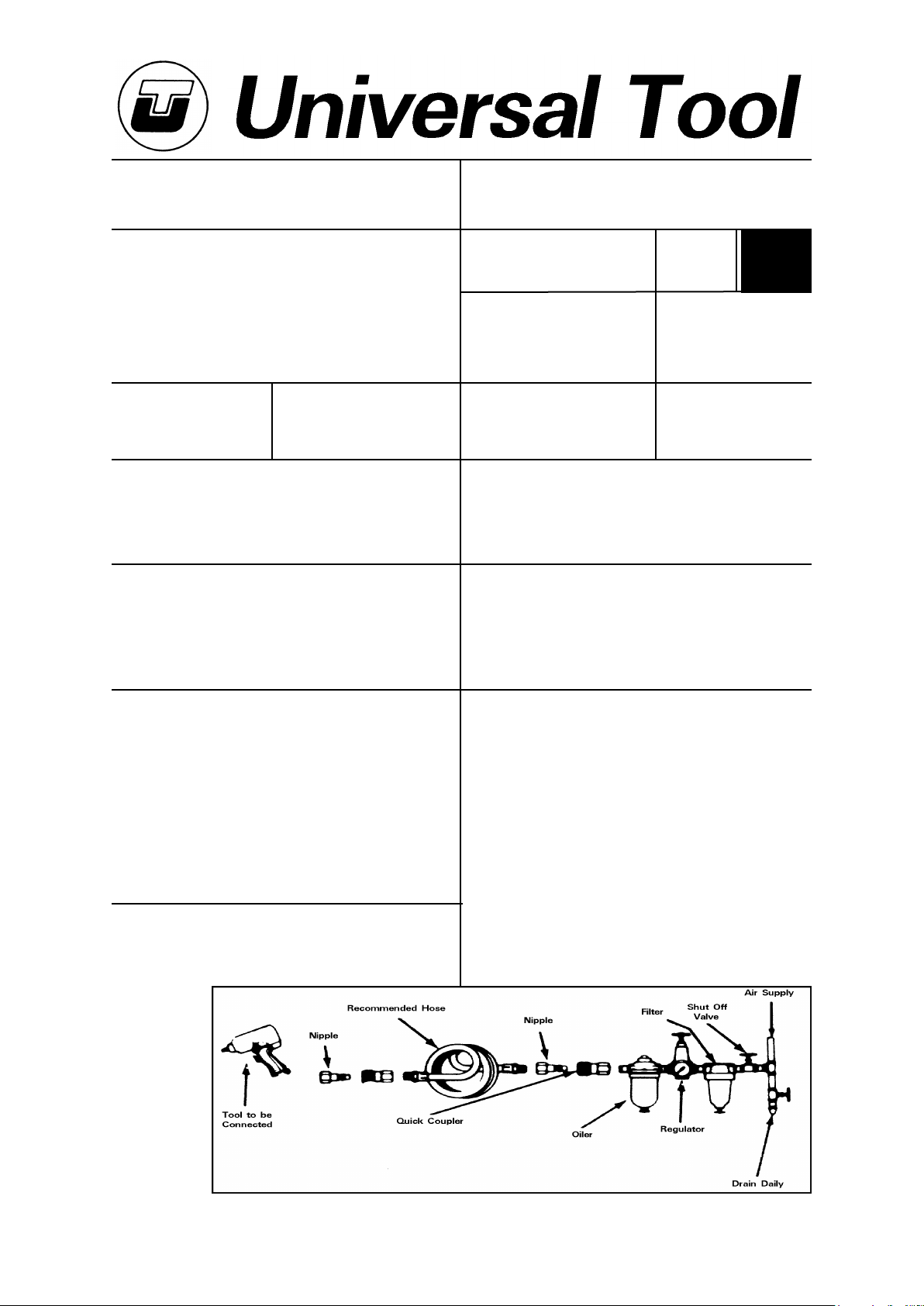

Air Supply

Use a clean lubricated air supply that will give a measured air pressure

at the tool of 90 p.s.i./6.3 bar when the tool is running with the trigger

fully depressed. Use recommended hose size and length. It is

recommended that the tool is connected to the air supply as shown in

figure 1. Do not connect the tool to the air line system without

incorporating an easy to reach and operate air shut off valve. The air

supply should be lubricated. It is strongly recommended that an air filter,

regulator, lubricator (FRL) is used as shown in Figure 1 as this will supply

clean, lubricated air at the correct pressure to the tool. Details of such

equipment can be obtained from your supplier. If such equipment is not

used then the tool should be lubricated by shutting off the air supply to

the tool, depressurising the line by pressing the trigger on the tool.

Disconnect the air line and pour into the intake bushing a teaspoonful

(5ml) of a suitable pneumatic motor lubricating oil preferably

incorporating a rust inhibitor. Reconnect tool to air supply and run tool

Page No 1

Page 2

slowly for a few seconds to allow air to circulate the oil. If tool is used

frequently lubricate on daily basis and if tool starts to slow or lose power.

It is recommended that the air pressure at the tool whilst the tool is

running is 90 p.s.i./6.3 bar. The tool can run at lower and higher

pressures with the maximum permitted working air pressure of 100

p.s.i./7.0 bar.

Operating

Connect the tool to a clean supply of compressed air set at the right

pressure. Ensure that the tool is equipped with the correct nose

equipment to fit the rivet being placed. It is necessary to match the nose

equipment to the diameter size of the rivet being placed.

To place rivets with the tool, insert the rivet body into the prepared hole

in the application, apply the tool so that the stem of the rivet enters the

nose of the tool, press the tool and rivet firmly against the application,

pull the trigger and the rivet will place. If the stem of the rivet fails to break

off, it may be necessary to increase the supplied air pressure up to the

maximum pressure allowed for the tool of 100 p.s.i. (7.0 bar).

Ensure that the broken off stem is clear of the nose end of the tool

before proceeding to place the next rivet.

Dismantling and Assembly Instructions

Disconnect tool from air supply.

Using spanners (62) provided, unscrew frame head (38) and

nosepiece (37) from (37-2) according to size fitted. Using 17mm and

19mm spanners unscrew jaw housing (39) by gripping jaw case end

(42). Pull out jaw pusher (41) from inside jaw case end (42) and pull out

jaw pusher spring (43). Grip case lock nut (46) and unscrew jaw case

end (42) and remove case washer ring (45) and case lock nut (46) from

end of oil piston (54). Unscrew parts (61), (60) and (59), then unscrew

frame cap (58) and note that when doing this it will release the load off

the compressed spring (56) so be prepared for this reaction. Using a

3mm pin knock out spring pin (34) and then using a 12mm spanner

unscrew trigger head (32) and remove parts (31), (30), (9) and (28).

Unscrew muffler (20) and remove retainer ring (27). Push a skewer into

the recess of the muffler and push out parts (21), (22), (23), (24), (25)

and (26). Turn the tool upside down and place it into a vice. Using

14mm and 10mm spanners undo parts (1) and (3-6), and remove

parts (3-5) and (2). Using a rubber mallet tap part (3) round the base,

and pull it off. Pull out the whole piston assembly parts (5), (6), (7), (7-1),

(8), (10), (10-1), (11-1) and, (14) using the special tool. Loosen (15)

and take down (29-6) and (14-1). If replacing these 2 parts please order

together. Empty out the hydraulic oil first then take out part (54). Then

empty out the hydraulic oil again.

Reassembly

Reassemble the tool in the reverse order.

Priming

Place the tool in a vertical position and unscrew oil tank plug (50) and

remove (49) oil seal washer. Fill with oil, use SAE10 using the provided

applicator, until the oil level reaches the bottom of the hole. Replace

parts (49) and (50).

9) Always when using the tool adopt a firm footing and/or position and

grip the tool firmly to be able to counteract any forces or reaction forces

that may be generated whilst using the tool.

10) Use only correct spare parts. Do not improvise or make temporary

repairs.

11) Do not lock, tape, wire, etc. the on/off valve in the run position. The

trigger/lever etc. must always be free to return to the 'off' position when

it is released.

12) Always shut off the air supply to the tool, and depress the

trigger/lever etc. to exhaust air from the feed hose before fitting,

adjusting or removing the working attachment.

13) Check hose and fittings regularly for wear. Replace if necessary. Do

not carry the tool by its hose and ensure the hand is remote from the

on/off control when carrying the tool with the air supply connected.

14) Take care against entanglement of moving parts of the tool with

clothing, ties, hair, cleaning rags, etc. This will cause the body to be

drawn towards the tool and can be very dangerous.

15) It is expected that users will adopt safe working practices and

observe all relevant legal requirements when installing, using or

maintaining the tool.

16) Do not install the tool unless an easily accessible and easily operable

on/off valve is incorporated in the air supply.

17) Take care that the tool exhaust air does not cause a problem or

blows on another person.

18) Never lay a tool down unless the working attachment has stopped

moving.

19) The tool should not be operated without the safety cap fixed to the

rear end of the tool.

20) Do not operate the tool if the frame head is not fitted.

21) Care must be taken to ensure that broken stems from the installed

rivets do not cause a hazard.

22) Excessive contact with hydraulic oil should be avoided. Wash

hands after any such contact.

Safety Rules For A Riveter

1) Read all the instructions before using this tool. All operators must be

fully trained in its use and aware of these safety rules.

2) Do not exceed the maximum working air pressure.

3) Use personal safety equipment.

4) Use only compressed air at the recommended conditions.

5) If the tool appears to malfunction remove from use immediately and

arrange for service and repair.

6) If the tool is used with a balancer or other support device ensure that

it is fixed securely.

7) Always keep hands away from the working attachment fitted to the

tool.

8) The tool is not electrically insulated. Never use the tool if there is any

chance of it coming into contact with live electricity.

Page No 2

Page 3

UT180R

UT190R

1/4” Air Hydraulic Blind Riveter

3/16” Air Hydraulic Blind Riveter

Ref No UT180R UT190R Description

1 1800001 1800001 Safety Valve Assembly

2 1800002 1800002 Rubber Bottom

3 1800003 1800003 Air Cylinder Body

3-5 1800305 1800305 Washer (2)

3-6 1800306 1800306 Nut (2)

4 1800004 1800004 Liner

5 1800005 1900005 Nut

6 1800006 1800006 Washer

6-1 1800601 1800601 Washer

7 1800007 1800007 Air Piston

7-1 1800701 1800701 Crashworthy Washer

8 1800008 1800008 O-Ring

9 1800009 1800009 O-Ring (2)

10 1800010 1800010 O-Ring

10-1 1801001 1801001 O-Ring (2)

11 1800011 1800011 O-Ring Depressor

11-1 1801101 1801101 O-Ring Depressor (2)

13 1800013 1800013 Tube

14 1800014 1800014 Rod

14-1 1801401 1801401 Rod (2)

15 1800015 1800015 Stem Nut

17 1800017 1800017 Backup-Up Ring (2)

18 1800018 1900018 O-Ring (4)

19 1800019 1800019 Stem

20 1800020 1800020 Muffler

21 1800021 1800021 Pad

22 1800022 1800022 O-Ring (4)

23 1800023 1800023 Cage (4)

24 1800024 1800024 Spring

25 1800025 1800025 Valve

26 1800026 1800026 Valve Cap

27 1800027 1800027 Reatining Ring

28 1800028 1800028 Valve Piston

29 1800029 1800029 Handle Body

29-6 1802906 1802906 Nut Stand

29-8 1802908 1802908 Handle Sheath

30 1800030 1800030 O-Ring

Ref No UT180R UT190R Description

31 1800031 1800031 Trigger Insert

32 1800032 1800032 Trigger Head

33 1800033 1800033 Trigger

34 1800034 1800034 Spring Pin

35 1800035 1800035 O-Ring

36 1800036 1800036 O-Ring

37 1800037 1900037 Nosepiece (3/16")

37-1 1803701 1903701 Nosepiece (5/32")

37-2 1803702 1903702 Nosepiece (1/8")

37-3 1903703 Nosepiece (3/32")

38 1800038 1900038 Frame Head

39 1800039 1900039 Jaw Case Front Tart

40 1800040 1900040 Jaw (3)

41 1800041 1900041 Jaw Pusher

42 1800042 1900042 Jaw Pusher Coupler

43 1800043 1900043 Spring

44 1800044 1900044 Piston Shaft

45 1800045 1800045 Case Washer

46 1800046 1800046 Case Lock Nut

49 1800049 1800049 Oil Seal Washer

50 1800050 1800050 Hexagon Socket Screw

51 1800051 1800051 Hook

52 1900052 Spring

53 1800053 1900053 Oil Cylinder Body

54 1800054 1900054 Piston Rod II

55 1800055 1900055 Bu-Ring

56 1800056 1900056 O-Ring (2)

57 1800057 1900057 O-Ring

58 1800058 1900058 Frame Cap Nut

59 1800059 1800059 Spent Mandrel Bottle

60 1800060 1800060 O-Ring

61 1800061 1800061 Mandrel Bottle Adaptor

61-1 1806101 1806101 Silencer

62 1800062 1900062 Spanner

63 1800063 1900063 Spanner Cage

64 1800064 1800064 Oil Can

65 1800065 1800065 Shutoff Valve

Mar 2006 Ver 1.00

Page No 3

Page 4

Accessories

Declaration of Conformity

Universal Air Tool Company Limited

Unit 8, Lane End Industrial Park, High Wycombe, Bucks, HP14 3BY, England

declare under our sole responsibility that the product

Models UT180R/UT190R Air/Hydraulic Riveters, Serial Number

to which this declaration relates is in conformity with the following standard(s) or other normative document(s)

EN792 (Draft), EN292 Parts 1 & 2, ISO 8662 Part 1, Pneurop PN8NTC1

following the provisions of

89/392/EEC as amended by 91/368/EEC & 93/44/EEC Directives

Lane End D.H.Moppett (Man. Director)

Place and date of issue Name and signature or equivalent marking of authorized person

Notes

Distributor

This document may not be copied wholly or in part by anyone without the consent of the Directors of Universal Air Tool Company Limited

Designed & Written in the U.K.

©Copyright of Universal Air Tool Company Limited, established in the United Kingdom, 1994

Page No 4

Loading...

Loading...