Page 1

Read these instructions carefully before installing, operating,

servicing or repairing this tool. Keep these instructions in a safe

Includes - Foreseen Use, Work Stations, Putting Into Service,

Operator Instructions

Recommended Max.

Less than 2.5

Tested in accordance with Pneurop

Important

Operating, Dismantling, Assembly and Safety Rules

accessible place.

Manufacturer/Supplier Product Type

Universal Air Tool Company Limited

Unit 8

Lane End Industrial Park

High Wycombe

Bucks

HP14 3BY

Laminate Trimmer

Model No/Nos Serial No

UT1054

Tel No Fax No(01494) 883300 (01494) 883237

Product Nett Weight

2.0

0.9

lbs

Kg

Recommended Working

Recommended Minimum

Maximum

Personal Safety Equipment

Use - Safety Glasses Yes

Use - Safety Gloves Yes

Use - Safety Boots

Use - Breathing Masks Yes

Use - Ear Protectors Yes

Recommended Use Of

Balancer Or Support

Air Pressure

6.3

bar

n/a

bar

7.0

bar

No

90

n/a

100

Recommended Hose Bore

Size - Minimum

Ins M/M Ft M

3/8 10 30 10

Noise Level Sound Pressure Level 83.0 dB(A)

PSI

Test Method

PSI

test code PN8NTC1 and ISO Standard 3744

PSI

Vibration Level

Test Method Tested in accordance with ISO

standards 8662/1

RPM

22,000

Cycles Per Min

Hose Length

Metres / Sec²

Foreseen Use Of the Tool

This tool is primarily designed for use with 1/4" dia. shank

carbide burrs of hardened steel countersink cutters provided their

speed rating matches the speed of the tool.

This tool should not be fitted with cutting off wheels, bonded

abrasive mounted point grinding wheels, saw blades, drill bits,

etc. If there is any doubt about the correct use of this product

contact your supplier for advice.

Work Station

The tool should only be used as a hand held, hand operated tool.

It is always recommended that the tool is used when standing on

the solid floor. It can be used in other positions but before any

such use, the operator must be in a secure position having a firm

grip and footing and be aware of the extra safety precautions that

must be observed when using this tool.

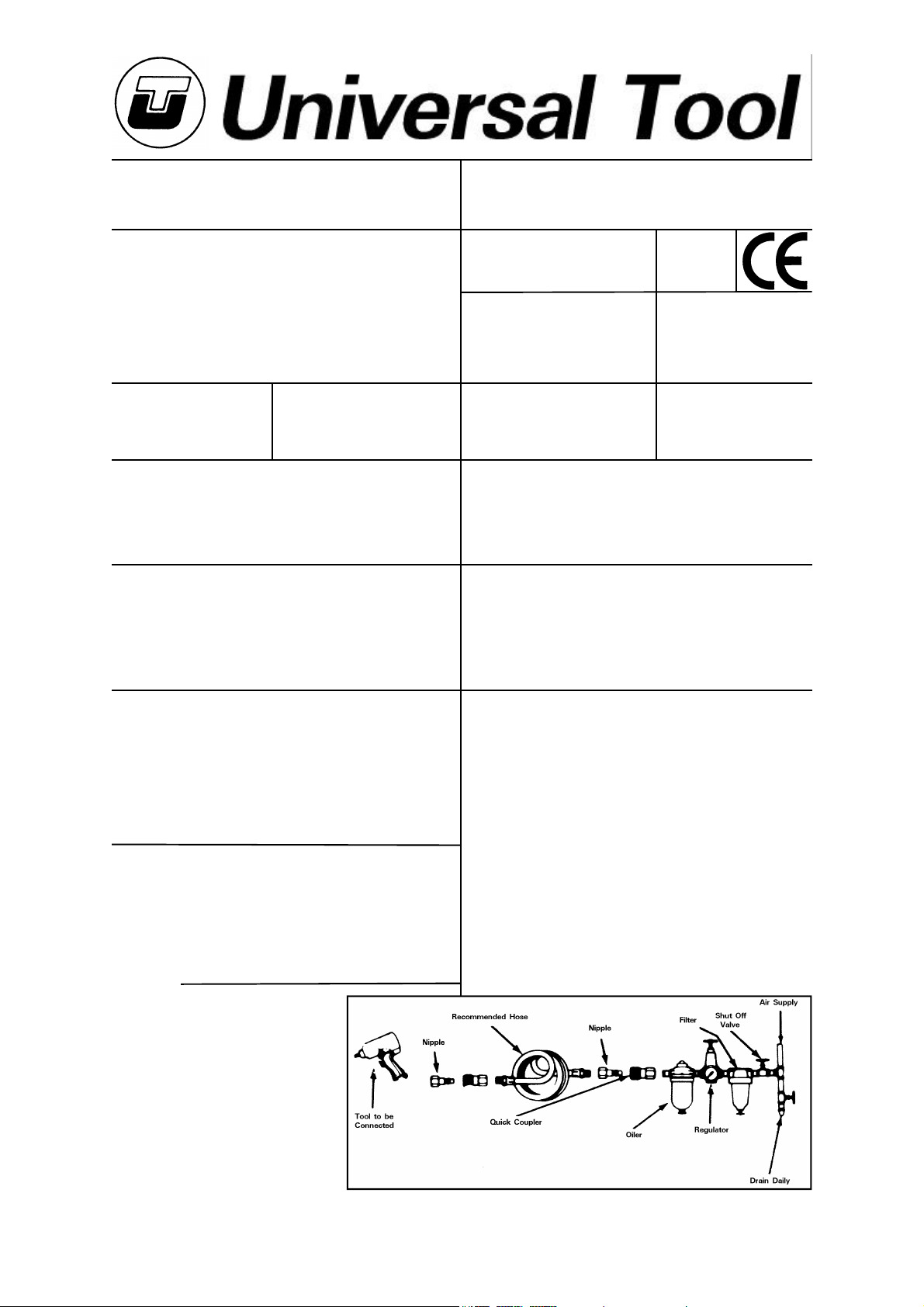

Putting Into Service

Air Supply

Use a clean lubricated air supply that will

give a measured air pressure at the tool of

90 psi/6.3 bar when the tool is running

with the lever/trigger fully depressed. Use

recommended hose size and length. It is

recommended that the tool is connected to

the air supply as shown in figure 1. Do not

connect the tool to the air line system

without incorporating an easy to reach and

operate air shut off valve. The air supply should be lubricated. It

is strongly recommended that an air filter, regulator, lubricator

(FRL) is used as shown in Figure 1 as this will supply clean,

lubricated air at the correct pressure to the tool. Details of such

equipment can be obtained from your supplier. If such

equipment is not used then the tool should be lubricated by

shutting off the air supply to the tool, depressurising the line by

pressing the lever/trigger on the tool. Disconnect the air line and

pour into the intake bushing a teaspoonful (5ml) of a suitable

pneumatic motor lubricating oil preferably incorporating a rust

inhibitor. Reconnect tool to air supply and run tool slowly for a

few seconds to allow air to circulate the oil. If tool is used

frequently lubricate on daily basis and if tool starts to slow or lose

power.

It is recommended that the air pressure at the tool whilst the tool

is running is 90 psi/6.3 bar. The tool can run at lower and higher

pressure with the maximum permitted working air pressure of

100 psi/7.0 bar.

Page No 1

Page 2

Operating

shank. Always match correctly the shank size to the collet size.

Select a suitable burr/cutter that has a free running speed higher

than the maximum running speed marked on the tool. Make

sure that the diameter of the shank exactly matches the diameter

of the collet mounted in the tool. The collet size available for this

tool is 1/4" dia (6.35 mm).

Never try to close a 1/4" diameter collet to secure a 6 mm

If uncertain, have parts measured by a competent person. Push

the shank as far as possible into the collet and tighten the collet

nut using the spanners provided on the collet nut and output

spindle. The shank of the mounted point may be pulled forward

from the maximum insertion length but always ensure a

minimum gripping length of 10 mm.

The cutting edge of the burr/cutter must be between the Shoe

Plate (44) and the Adjusting Bar (39). Set depth of cut by

screwing Adjusting Screw (35) to set roller height.

The cutter must be unchipped and in good condition especially

the shank. The fitting of the burr/cutter should be done by a

trained operator. When first starting the tool with a new cutter

the tool should not be near other persons and be held in a

protected area, i.e. under a bench and run for a few seconds.

This will protect personnel from possible effects of damage to the

cutter before it was fitted to the tool.

Always use eye protection and wear protective gloves if there are

sharp edges in the work area. The tool and the process can

create a noise level such that the use of ear protectors is advised.

If the process creates a dust then use a suitable breathing mask.

Check that the material being work will not cause harmful dust or

fumes. If this is so then special breathing masks may be

required. If the tool vibrates when first fitting burr/cutter or

during operation, remove from service immediately and correct

fault before continuing to use.

Do not apply excessive pressure as this will reduce the cutting

efficiency and apply light loads to allow the burr/cutter to cut.

Handle the tool with care. If the tool is dropped, carefully check

for damage, i.e. chipping and start for the first time as for fitting

a new cutter, i.e. under a bench.

Never exceed the maximum air pressure. If there is possibility

always use this tool with a pressure reducing valve fitted in the

supply line. Your supplier will advise of suitable equipment. This

tool is fitted with a speed regulator and the speed may be

reduced by rotating Air Regulator (4) with a suitable screwdriver.

When making speed checks always rotate the air regulator to the

position to give the highest maximum speed.

Dismantling & Assembly Instructions

Disconnect tool from air supply.

Using the spanners provided remove Collet (26) and Collet Nut

(27). Loosen Setscrew (31) and Capscrew (29). Slide out Motor

Housing (12) from Trimmer Housing (28).

Motor Assembly

Hold motor housing in soft jawed vice on flats provided. Using a

peg spanner remove Locking Nut (25) , Silencer (24) and motor

assembly complete with Spindle (23). Hold cylinder (19) tightly in

the hand and tap the rear end small diameter of the Rotor (16)

out of the Rear End Plate (14) and Bearing (13). Remove Cylinder

(19 and the 3 off Rotor Blades (15). Grip Rotor (16) tightly in soft

jawed vice and using a spanner on flats provided unscrew

Spindle (23). Tap or press out Rotor (16) , Bearing (22) and

Spacer (21) from Front End Plate (20). Using pliers remove Pins

(18) from Cylinder (19).

Using a wide blade screwdriver remove Throttle Valve Screw (1)

complete with O- Ring. Pull out Regulator (4) , O-ring (3) , Throttle

Valve Spring (5) , O-ring (6) and Throttle valve (7). Press out

Throttle Valve Bushing (8) if necessary. Press out Pin (10) and

remove Lever (9). Using a spanner remove Air Inlet (11).

Clean and examine parts for wear or damage and replace only

with genuine replacement parts. Ensure that the faces of End

Plates (14) and (20) are flat and free from burrs. Lap on a flat fine

grade or abrasive paper if necessary. Lightly lubricate all parts

with Shell Tellus R10 or equivalent. Lubricate bearings with a

molybdenum based grease. Ensure that Pins (18) locate in End

Plates (14) and (20).

Dismantling Trimmer Housing

Unscrew Nut (40) and remove Washers (11) and (42) and Shoe

(43). Using a Phillips screwdriver remove Screws (33) and

remove Shoe Plate (44). Screw out Adjust Screw (35) and

remove Adjust Bar (39). Press out Pins (34) and remove Adjust

Screw (35). Holding adjust Bar (39) in a vice, remove Screw (36)

, Washer (37) and Ball Bearing (38).

Reassemble in reverse order examining all parts for signs of wear

or damage replacing any parts necessary. Lubricate all parts as

necessary.

Assembly Complete Tool

Insert motor assembly into trimmer housing ensuring that the

motor is inserted fully into the housing. Line up Lever (9) with

Adjust Screw (35). Tighten Set Screw (31) and Cap Screw (29).

Safety Rules For A Laminate Trimmer

1) Read all the instructions before using this tool. All operators

must be fully trained in its use and aware of these safety rules.

2) Always select suitable abrasive to use with this tool - see

Operating Instructions.

3) Always shut off air supply to the tool and depress the lever to

exhaust air from the feed hose before fitting, adjusting or

removing the burr/cutter.

4) Always adopt a firm footing and/or position before using the

tool.

5) Use only correct spare parts.

6) Check hose and fittings regularly for wear. Do not carry the

tool by its hose.

7) Never tie down the lever.

8) Never exceed the maximum air pressure and check the free

running speed frequently. Have air regulator fully open when

making speed checks.

9) Use safety equipment as recommended.

10) Take care against entanglement of moving parts of the tool

with clothing, ties, hair, cleaning rags, etc.

11) Use only compressed air at the recommended pressure.

12) Do not attempt to fit any other attachment than those

recommended - see "Foreseen Use of Tool".

13) If the tool appears to malfunction, remove from use

immediately and arrange for service/repair.

Page No 2

Page 3

UT1054 Laminate Trimmer

Ref No Part No Description

1 729262 Throttle Valve Screw

2 729073 O-Ring

3 729088 O-Ring

4 729282 Regulator

5 729258 Throttle Valve Spring

6 1012370 O-Ring

7 729259 Throttle Valve

8 729261 Throttle Valve Bushing

9 900578 Throttle Lever

10 729167 Pin

11 729162 Air Inlet

12 900579 Motor Housing

13 1010183 Ball Bearing

14 900580 Rear End Plate

15 729709 Rotor Blade

16 900581 Rotor

17 729711 Rotor Spacer

18 729707 Pin (2)

19 729708 Liner (Cylinder)

20 900582 Front End Plate

21 729714 Motor Shim

22 729113 Ball Bearing

Ref No Part No Description

23 729715 Spindle

24 900583 Silencer

25 900584 Locking Nut

26 92233 Collet (1/4")

27 729719 Collet Nut

28 900585 Trimmer Housing

29 900339 Cap Screw

30 900586 Screw

31 900587 Set Screw (2)

32 900588 Clamp Screw

33 900589 Screw (4)

34 900590 Pin (2)

35 900591 Adjust Screw

36 900592 Screw

37 900593 Washer

38 900594 Ball Bearing

39 900595 Adjust Bar

40 900596 Nut

41 900066 Washer

42 900597 Washer

43 900598 Shoe

44 900599 Shoe Plate

Jan 2002 Ver 1.1

Page No 3

Page 4

Declaration of Conformity

This document may not be copied wholly or in part by anyone without the consent of the Directors of Universal Air Tool Company Limited

Universal Air Tool Company Limited

Unit 8, Lane End Industrial Park, High Wycombe, Bucks, HP14 3BY, England

declare under our sole responsibility that the product

Model UT1054 Laminate Trimmer 22,000 rpm, Serial Number

to which this declaration relates is in conformity with the following standard(s) or other normative document(s)

EN792 (Draft), EN292 Parts 1 & 2, ISO 8662 Parts 1 & 7, Pneurop PN8NTC1

following the provisions of

89/392/EEC as amended by 91/368/EEC & 93/44/EEC Directives

Lane End D.H.Moppett (Man. Director)

Place and date of issue Name and signature or equivalent marking of authorised person

Accessories

Notes

Distributor

© Copyright of Universal Air Tool Company Limited, established in the United Kingdom, 1994

Designed & Written in the U.K.

Page No 4

Loading...

Loading...