Page 1

—

I

—

-

/

/

/

/

t

.a:+

4

r

r

—

—

a

-‘

K

4-

-j

-

/

Page 2

INDEX

Features

Needle

Inserting

Winding

Threading

Placing

Upper

Setting

Sewing

Adjusting

Feeding

Thin

or

Darning

Preparing

Removing

and

and

Thread

the

Needle

the

Bobbin

the

Bobbin

Threading

the

Stitch

in

Reverse

the

Tensions

of

Fabric

Light

Weight

and

Monogramming

to

Sew

the

Work

Parts

Bobbin

Case

Chart

Case

in

Length

Fabrics

Shuttle

7-8

10

10

2

3

4

4

5

5

6

7

7

8

9

9

Straight

Zigzag

Sewing

Satin

Stitch

Blind

Stitch

Sewing

Making

Narrow

Embroidering

Cording

Quilting

Seam

Care

Cleaning

Accessories

Check

on

Buttonholes

Hemmer

&

Guide

Guage

and

and

Up

Stitching

Hem

Buttons

with

Zipper

Maintenance

for

or

Cloth

Oiling

Smooth

Foot

a

the

Hoop

Guide

of

Your

Shuttle

Sewing

Machine

11

11-12

12

13

14

15

16-17

17

18

19

19

20

21

22

23

Page 3

2

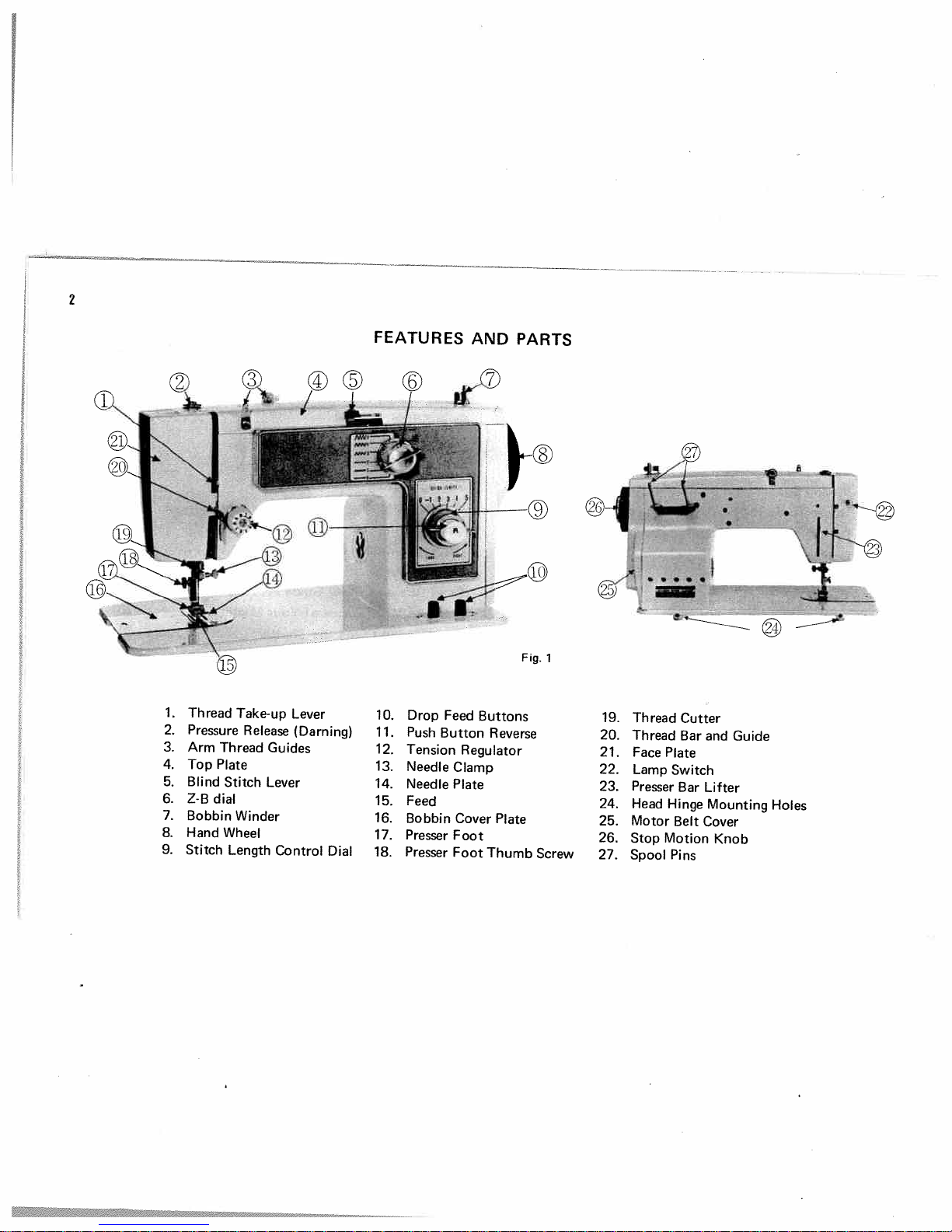

1.

2.

3.

4.

5.

6.

7.

8.

9,

Thread

Pressure

Arm

Top

Plate

Blind

Z-Bdial

Bobbin

Hand

Stitch

Takeup

Release

Thread

Stitch

Winder

Wheel

Length

Lever

Guides

Lever

Control

(Darning>

Dial

FEATURES

I

10.

11,

12.

13.

14.

15.

16.

17.

18.

Drop

Push

Tension

Needle

Needle

Feed

Bobbin

Presser

Presser

Feed

Button

Regulator

Clamp

Plate

Cover

Foot

Foot

AND

Buttons

Reverse

Thumb

Plate

PARTS

Fig.

1

Screw

19.

20.

21.

22.

23.

24.

25.

26.

27.

Thread

Thread

Face

Lamp

Presser

Head

Motor

Stop

Spool

Cutter

Bar

Plate

Switch

Bar

Hinge

Belt

Motion

Pins

and

Guide

Lifter

Mounting

Cover

Knob

Holes

Page 4

3

Extremely

tarpaulin,

canvas,

Heavy

fabric,

denim,

Medium

fabric,

suiting,

Medium

percale,

chintz,

wool,

Sheer

dimity,

handkerchief

plastic

Very

batiste,

ninon,

duck,

upholstery

ticking,

leatherette

heavy

velveteen,

felt,

broadcloth,

gingham,

taffeta,

shantung,

voile,

crepe,

.

.

film,

sheer

lace,

net,

Fabric

heavy

sacking,

etc.

drapery

terry,

sheer

etc.

lawn,

linen,

etc.

chiffon,

organdy,

marquisett,

etc.

linen,

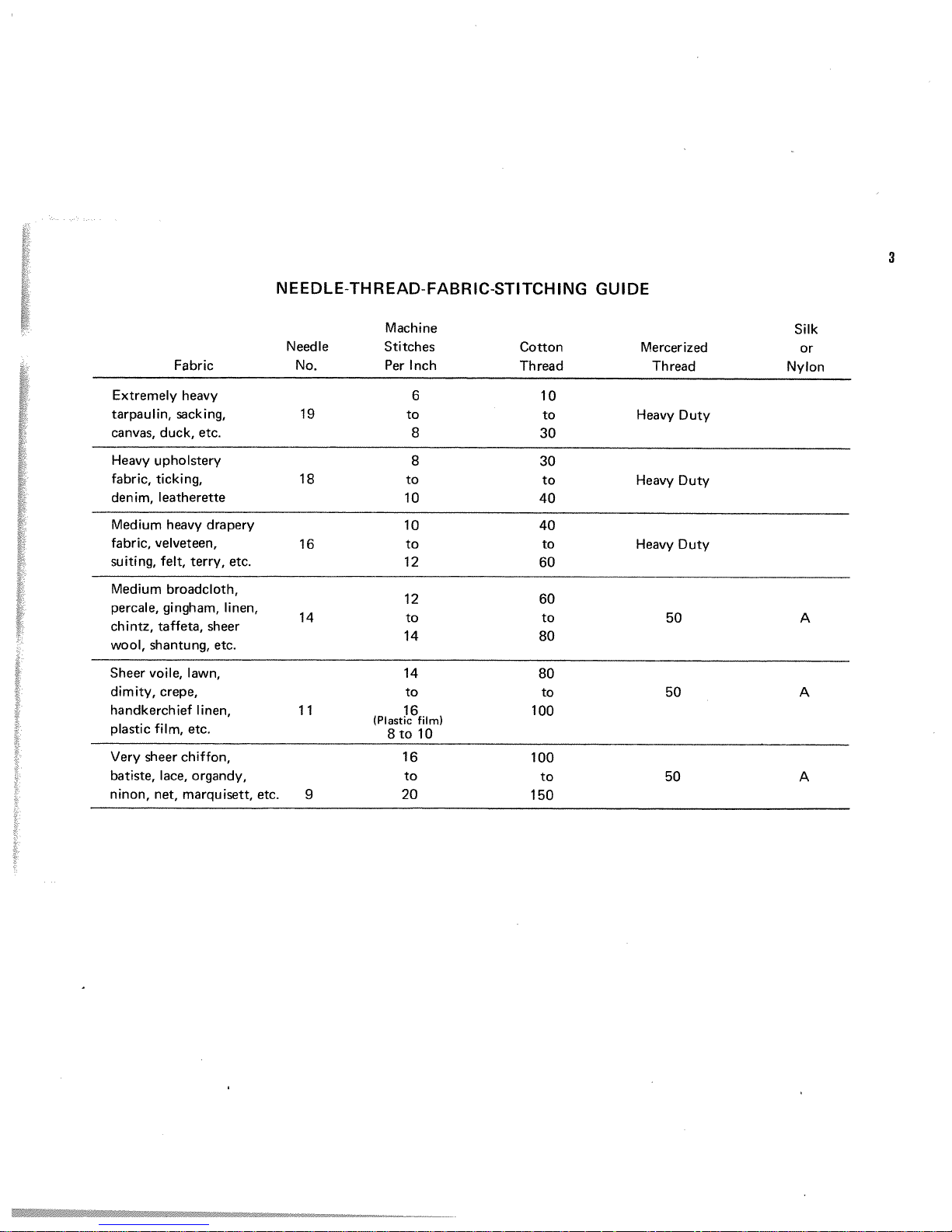

NEEDLE

Needle

etc.

No.

19

18

16

14

11

9

THREAD

Machine

Stitches

Per

(Plastic

to

8

16

20

FABRIC

Inch

6

to

8

8

to

10

10

to

12

12

to

14

14

to

16

film)

10

to

STITCHING

Cotton

Thread

10

to

30

30

to

40

40

to

60

60

to

80

80

to

100

100

to

150

GUIDE

Mercerized

Thread

Heavy

Duty

Heavy

Duty

Heavy

Duty

50

50

50

Silk

or

Nylon

A

A

A

Page 5

4

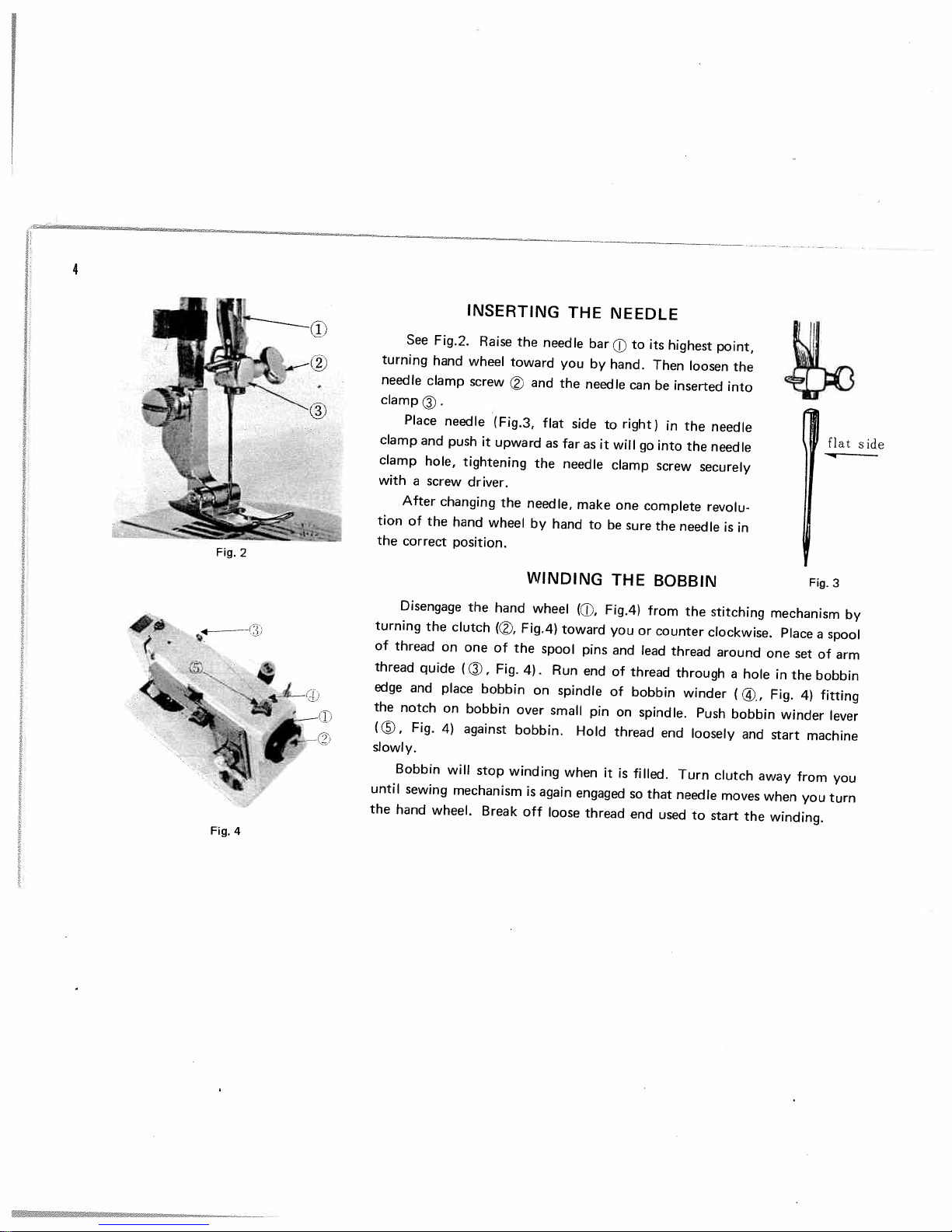

INSERTING

See

Fig.2.

Raise

the

turning

needle

clamp

clamp

clamp

with

tion

the

44

I

.‘

turning

of

thread

edge

1

the

(,

slowly.

until

the

Fig.

4

hand

clamp

©.

Place

and

hole,

screw

a

After

of

the

correct

Disengage

the

thread

guide

and

notch

Fig.

Bobbin

sewing

hand

wheel.

wheel

screw

needle

push

it

tightening

driver.

changing

hand

position.

the

clutch

on

one

(©.

place

bobbin

on

bobbin

against

4)

will

stop

mechanism

Break

toward

(Fig.3,

upward

the

wheel

hand

((,

of

the

Fig.

bobbin.

winding

over

THE

needle

you

and

the

flat

sidetoright)

as

far

the

needle

needle,

by

hand

WINDING

wheel

Fig.4)

toward

spool

Run

4).

on

spindle

small

when

is

again

off

loose

NEEDLE

bar

(1’

by

hand.

needle

as

will

it

clamp

make

to

be

THE

Fig.4)

(ID.

you

pins

and

end

of

of

pin

Hold

it

engaged

thread

to

can

one

sure

thread

bobbin

on

thread

is

filled.

so

end

its

highest

Then

be

in

go

into

screw

complete

the

BOBBIN

from

or

counter

lead

thread

spindle.

end

that

used

loosen

inserted

the

the

securely

needle

the

through

winder

Push

loosely

Turn

needle

to

point,

the

into

needle

needle

revolu

is

in

stitching

clockwise.

around

hole

a

(®..

bobbin

and

clutch

moves

start

the

i.JJ

mechanism

Place

one

set

in

the

Fig.

winder

start

away

from

when

winding.

flat

Fig.3

a

spool

of

bobbin

fitting

4)

lever

machine

you

turn

side

by

arm

you

Page 6

5

the

in

the

of

the

spring

Step

thread

as

1

edge

bobbin

shown

(illustrated

of

the

on

top

case

in

Fig.

8

bobbin

leads

as

shown

Fig.

Fig.

in

7.

5

Fig.

from

case

in

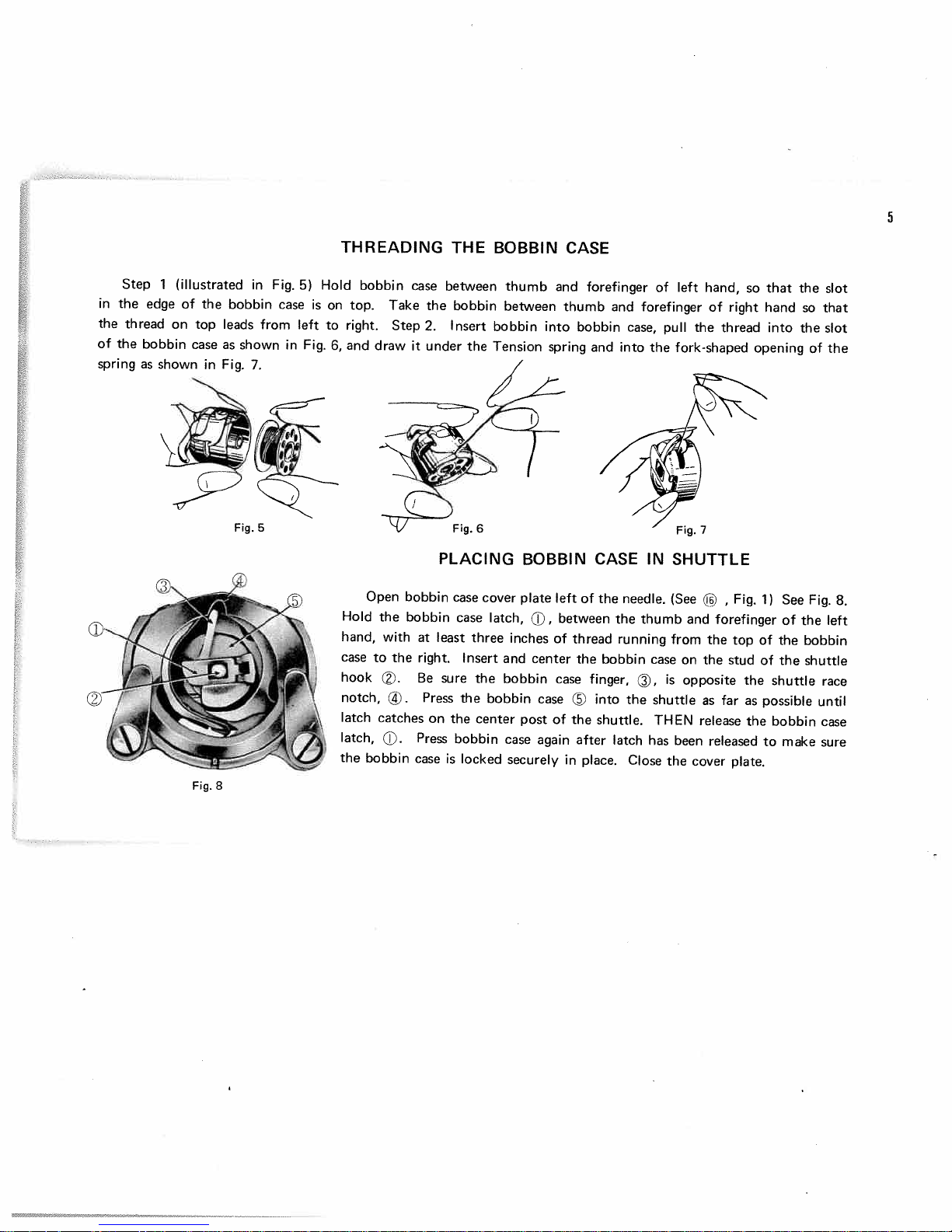

THREADING

Hold

5)

on

is

left

to

Fig.

6,

case

latch

latch,

the

bobbin

top.

right.

and

Hold

hand,

hook

notch,

Take

Step

draw

Open

the

with

the

to

.

®.

catches

.

bobbin

case

the

2.

under

it

bobbin

bobbin

at

right.

Be

Press

on

Press

case

THE

between

bobbin

Insert

Tension

the

Fig.

6

PLACING

case

cover

case

latch,

least

three

Insert

sure

the

the

bobbin

center

the

bobbin

is

locked

BOBBIN

thumb

between

bobbin

CASE

and

thumb

into

spring

BOBBIN

plate

left

between

(J,

of

inches

and

bobbin

post

case

securelyinplace.

center

case

of

again

thread

case

©

the

forefinger

bobbin

and

CASE

the

of

the

bobbin

finger,

into

shuttle.

after

and

case,

into

needle.

the

running

®,

the

latch

Close

of

left

forefinger

pull

the

fork-shaped

Fig.

IN

SHUTTLE

(See

thumb

from

case

on

is

shuttle

THEN

has

been

the

hand,

of

the

7

and

forefinger

the

the

opposite

as

release

released

cover

right

thread

,

Fig.

top

stud

the

far

plate.

that

so

hand

into

opening

1)

of

of

as

possible

the

to

See

of

the

the

shuttle

bobbin

make

the

so

the

of

Fig.

the

bobbin

shuttle

until

slot

that

slot

the

8.

left

race

case

sure

Page 7

B

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

you

(Fig.

out

draw

inches

Turn

their

to

Place

lead

down

into

under

into

Up

left.

Down

again.

Into

Through

into

three

through

Hold

until

will

9)

straight.

toward

long.

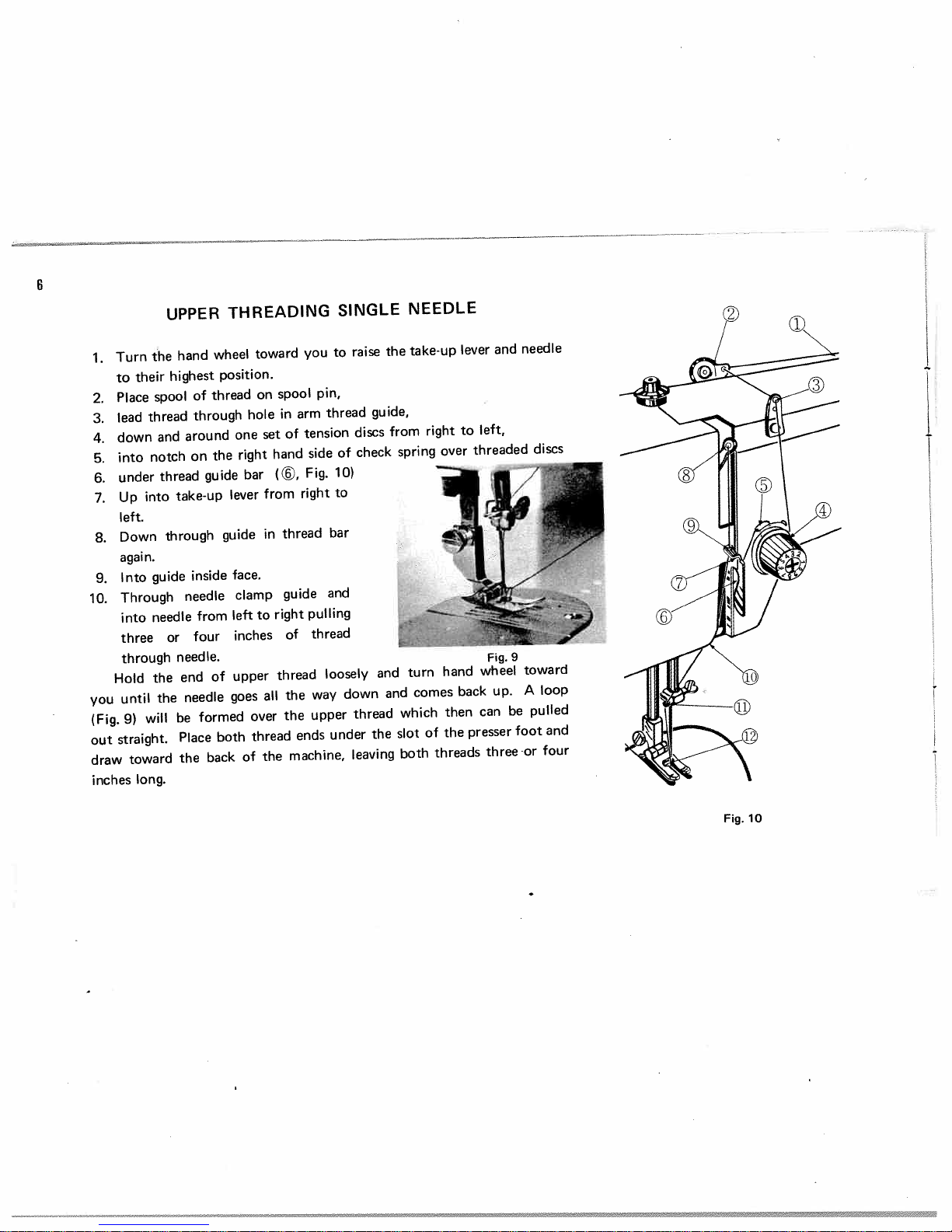

UPPER

the

highest

spool

thread

and

notch

thread

through

guide

needle

or

the

the

hand

of

through

around

on

guide

take-up

inside

needle

from

four

needle.

end

needle

formed

be

Place

the

THREADING

toward

wheel

position.

on

thread

hole

set

one

right

the

bar

from

lever

in

guide

face.

clamp

to

left

inches

upper

of

all

goes

over

thread

both

the

of

back

spool

in

of

hand

(©,

thread

guide

right

of

thread

the

the

machine,

you

pin,

arm

tension

side

Fig.

right

pulling

thread

way

upper

ends

SINGLE

raise

to

thread

discs

of

check

10)

to

bar

and

loosely

down

thread

under

leaving

the

guide,

from

and

and

the

NEEDLE

take-up

right

spring

turn

comes

which

of

slot

threads

both

over

I

hand

then

the

lever

left,

to

threaded

wheel

back

can

presser

and

Fig.9

up.

be

foot

three-or

needle

discs

toward

loop

A

pulled

four

and

Fig.

10

Page 8

7

length

The

is

5

the

Figures

Number

you

Fig.1)as

adjust

released

is

turn

the

to

Before

properly.

screw

the

(Fig.

and

Turn

When

,

(0

Always

tension

thread,

turn

tension.

threaded

small

counterclockwise

the

of

longest,

control

indicator

on

stitches

of

to

wish

asitwill

far

ADJUSTING

the

when

(Fig.

dial

The

left.

adjusting

12)

to

stitch

but

dial

sew

upper

it

11)

higher

When

on

loosen.

is

the

the

to

inch

par

backward

go.

tension

raised.

is

to

lower

necessary

side

regulated

control

right

STITCH

The

THE

with

To

right,

the

the

number

tension

to

the

of

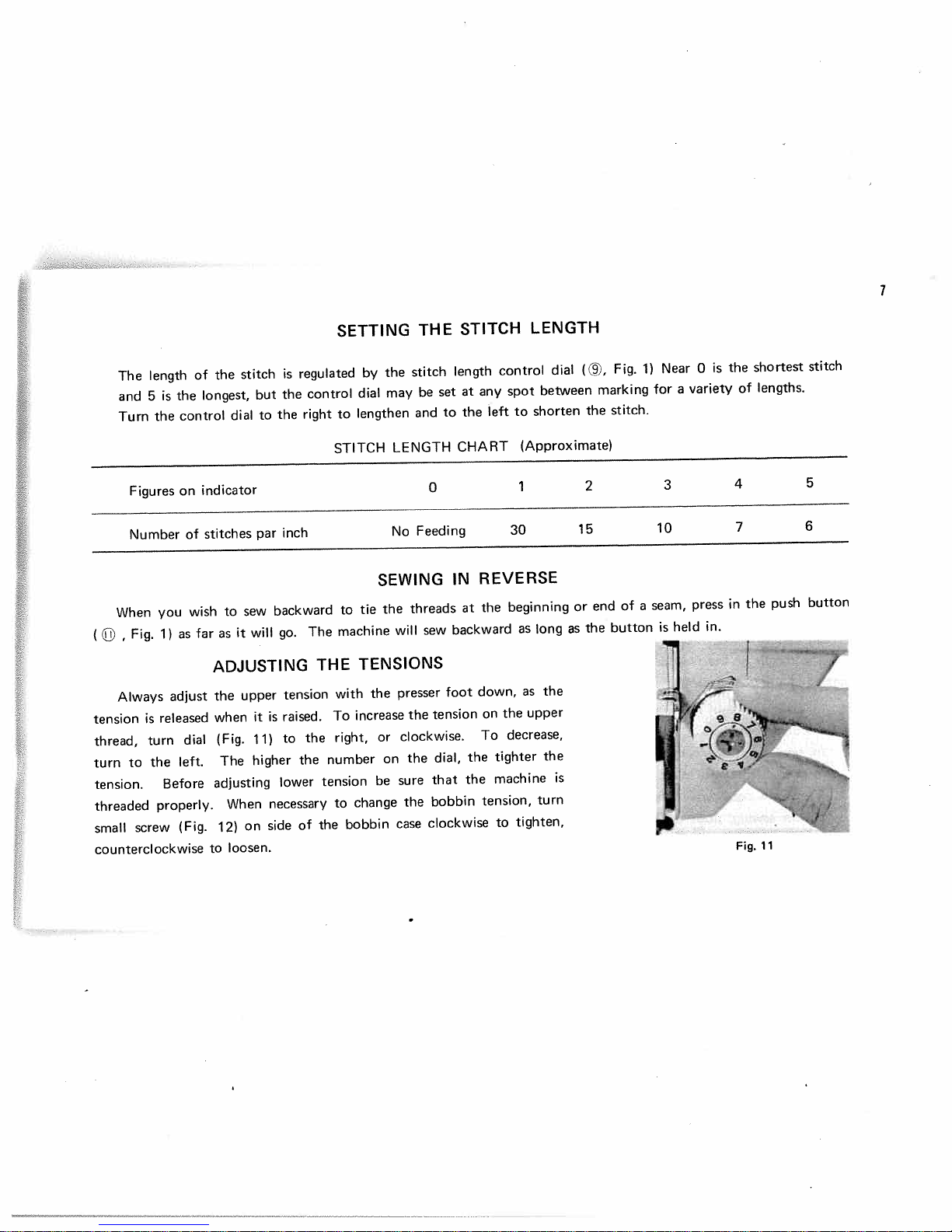

SETTING

the

by

dial

may

lengthen

to

LENGTH

No

SEWING

the

tie

to

machine

TENSIONS

the

increase

or

on

be

change

bobbin

THE

stitch

be

and

0

Feeding

threads

will

sew

presser

tension

the

clockwise.

dial,

the

that

sure

bobbin

the

clockwise

case

STITCH

length

at

set

the

to

CHART

IN

at

backward

foot

the

the

LENGTH

control

any

spot

shorten

to

left

(Approximate)

1

30

REVERSE

beginning

the

as

as

down,

upper

the

on

decrease,

To

tighter

machine

tension,

tighten,

to

dial

between

long

the

the

is

turn

as

(),

15

or

marking

the

2

end

the

Fig.

stitch.

of

button

1)

a

Near

for

3

10

seam,

is

a

held

is

0

variety

press

in.

the

in

of

4

7

the

Fig.

shortest

lengths.

push

11

stitch

5

6

button

Page 9

When

the

upper

and

lower

tensions

perfect

a

fabric

in

,oosen

pulled

fabric

forms

(Fig.

12

Fig.

;

‘%

-4

Fig.

/////

•y

1

Q/

:\\‘

\\‘‘

Fig.

When

(Fig.

When

loops

15).

‘

14

up

stitch

(Fig.

the

over

14).

the

over

willbeformed

13).

upper

tension

the

upper

upper

tension

the

lower

c\\

“

thread

thread

c’

‘

with

is

too

tight,

which

is

too

lying

‘\

Fig.

15

both

loose,

are

is

flat

properly

threads

the

lying

the

under

interlocking

lower

flat

upper

balanced,

thread

on

thread

fabric

the

is

the

The

setting

1.

In

the

In

2.

marked

When

3.

button

go.

heightofthe

of

push

the

button

sewing

on

marked

on

sewing

“UP”

itisnecessary

sewing,

buttons.

thin

thick

down

push

feed

dog

materials,

“DOWN”

materials,

farasit

as

turn

to

the

may

such

down

the

button

such

will

regulated

be

silk,

as

as

as

go.

work

marked

FEEDING

according

creape

farasthe

overcoats,

freely

as

“DOWN”asfar

OF

chine

de

while

line.

push

embroidering

in

FABRIC

to

the

etc.,

the

button

as

thickness

push

and

will

it

material

of

the

being

Fig.

sewn,

16

by

proper

Page 10

When

thin

on

about

Release

Fig.

halfway

In

darning,

release

the

on

the

way

plate.

down.

cap

lighter

silk

halfway

and

17)

spot.

DARNING

order

mending

the

snap

down,

To

SEWING

WEIGHT

pressure

or

filmy

down,

all

the

then

move

to

and

cap

(,

lock,

which

return

(Fig.

18)

way

press

(a),

feed

THIN

material,

AND

the

certain

Fig.

Fig.

drops

to

LIGHT

OR

FABRICS

sew

the

to

pressure

the

Fig.

18)

is

by

cap

required

pressing

(©,

MONOGRAMMING

in

freely

fabric

of

Press

feed

press

free-hand

by

“DOWN”

well

“UP”

kinds

completely

18)

17)

the

normal,

satisfactorily

cap

snap

down

any

direction

embroidery,

pressing

below

button,

should

lock,

again

button

the

be

((I),

to

for

down

all

needle

push

PUIsz

Fig,

9

17

Fig. 18

Page 11

lii

Have

Do

may

and

highest

the

hand

The

ing

and

the

and

slightly

needle.

try

not

deflect

NEVER

Place

lower

Turn

point

needle

wheel

speed

amount

the

sure

Be

needle

presser

20,

take-up

to

the

run

material

the

hand

the

at

to

of

to

bar

foot

pass

and

holding

Leave

PREPARING

lever

the

help

needle

machine

and

You

its

start

the

of

foot.

wheel

are

highest

the

machine

pressure

presser

REMOVING

the

stop

located

are

draw

and

the

thread

ends

the

highest

at

feeding

and

without

threads

toward

now

point,

machine.

machine

threads

in

of

cause

in

ready

regulated

is

exerted

at

fabric

the

over

both

thread

TO

point

by

to

it

material

position

you

to

is

it

You

on

THE

when

highest

the

the

hands,

under

SEW

before

pulling

break.

until

begin

not

merely

by

the

WORK

the

back

thread

the

starting

the

under

under

the

sewing.

necessary

press

increasing

control.

thread

position.

to

and

cutter.

as

so

presser

material

presser

presser

the

needle

to

the

take-up

left,

the

to

not

foot.

By

touch

or

Now

Pull

sew.

to

as

foot.

foot

at

is

having

control.

decreas

Fig.

down

bend

this

its

the

lever

raise

19

the

Fig.

20

Page 12

11

straight

For

the

straight

Changing

hinged

cover

narrow

and

foottotheir

1.

Set

Set

Select

Push

Use

Move

Select

the

the

the

zigzag

1.

2.

3.

4.

2.

3.

NOTE:

stitch

the

replace

highest

blind

Z-B

desired

button

the

blind

desired

1.

2.

sewing

needle

Foot

and

foot

the

points.

stitch

dial©to

stitch

®

presser

stitch

stitch

When

finished

In

zigzag

the

on

on

plate

and

tighten

zigzag

lever

“0”

length

and

ZIGZAG

foot

lever

length

you

work

sewing,

surface

fine

which

Plate.

needle

Dto

position.

on

reverse

and

cDto

on

sew

will

of

fabric

To

screw

“M”

dial

stitching

needle

dial

thin

not

loosen

the

STRAIGHT

very

or

are

included

change

securely.

with

plate

position.

®.

canbeperformed.

SEWING

plate.

position.

“M”

©.

fabric,

pucker.

the

cloth.

soft

presser

apply

upper

in

To

that

a

material,

your

foot,loosen

change

straight

for

and

select

thin

tension

STITCHING

want

may

you

accessory box.

thumb

needle

plate,remove

sewing,

desired

sheetofpaper

slightly,

and

screw

while

zigzag

to

see

to

Both

the

use

the

have

remove

and

raising

width

reverse side

that

the

straight

narrow needle

zigzag

screws

and

the

needle

dial

on

of

lower

stitch

slide

the

thread

presser

slots.

foot.

the

bar

Fig.

fabric.

does

foot

Replace with

bobbin

and

the

21

Then

not appear

and

case

presser

the

Page 13

12

How

3.

ZB

versatile

dial

and

your

stitch

machine

length

is

control

will

dial.

become

apparent

with

practice,

as

just

changing

the

Satin

Use

The

is

obtained

action.

The

Patterns

V\ANWA/WM/\/\

Stitch

zigzag

satin

width

presser

stitch

may

by

foot

which

setting

set

be

is

anywhere

really

the

just

stitch

a

length

from

very

ZIGZAG

short

as

just

past

Stitch

Long

zigzag

near

STITCH

Length

Long

Short

Long

Short

and

(Repeat)

stitch,

as

0

to

0

Short

possible

the

Fig.

and

widest,

22

PATTERNS

Gradually

and

I

basis

the

without

5.

for

stopping

Any

return

Any

most

Z.

B

point

from

move

to

point

from

embroidery,

the

feeding

Dial

from

0.

1

to

0

(Repeat)

1

to

5.

to

5,

5.

Fig.

23

Page 14

A

-vct,

m

I

C-)

I

-4

-4

C,,

z

I

—

CD

8

C).

-

o.

CD

ri

-

3•

CD

0

CD

CD

‘

—

-‘

CD3

N

(C

-.,

—(0,

0

ci)

Q.

ci)

<

‘.4

C)

0

r

—

CD

C.)

(0

CD

£

-4

3

1!

‘

.

‘-4

CD

D

CD

‘4

40V

—

D

8

1

ci)

in

ci)

CD

OCD

in

C—

<3

ci)

0

-4

0

-‘

ci)-CD

-.

U,

-4,

-

CD3

ci)

CD

;

-.

3•

CD

3

8

ci)

0

CD

U,

C-

(p

A

A

AA

A

A

-4

0

CD

CD

(‘3

CD

CD

CD

VVV

-4

CD

C’)

V

.

3

CD

CD

3

CC

CD

ci)

3

CD

ci)

C)

CD

-

n

CD

4

ci)

CD

‘-4

-4

-‘

-4,

0

0

CD

in

in

-‘

CD

V

c

CD

-4,

in

—

ci)

CD

-‘

3

.,,

o

0

ci)

D

‘-4

—

CD

C

4,

3

-

-4

CD

0

(C

.CD

-

CD

3

0

8

ci,

-4

0

-C

Page 15

14

10.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Remove

Push

Set

Set

Place

Turn

Turn

if

necessary.

When

stopping

To

“0,”

a

rounded

button

thread

Apply

If

a

for

the

to

permit

to

the

the

the

lock

and

four

drop

blind

Z-B

the

the

the

needle

with

the

to

under

the

hole

two

fabric

presser

feed

stitch

dial

button

Z-B

dial

hand

goes

the

zigzag

make

toothpick

fabric

button,

above

button

hole

stitching

with

foot

button

to

wheel

a

few

method

button.

and

lever

“0”

so

until

into

needle

stitch

stitches

in

the

forming

the

the

replace

marked

to

position.

that

its

the

needle

slowly

the

center

in

the

and

over

the

regular

to

is

to

be

Now

remaining

same

with

“DOWN”

“M”

position.

left

goes

by

hand

of

left

prevent

in

the

button

way.

a

shank.

sew

on

sewn,

lift

two

procedure

SEWING

button

hole

through

each

hole.

same

Fasten.

buttons,

follow

presser

holes.

all

the

comes

to

be

hole,

ravelling,,

hole.

between

Remove

with

the

foot

Hooks,

as

for

ON

sewing

way

directly

the

sure

run

If

you

the

the

same

slightly

sewing

BUTTONS

foot.

down.

right

the

needle

the

return

wish

two

toothpick

four

procedure

snaps,

two

under

hand

machine

the

you

holes,

holes,

and

etc.,

hole

the

hole

clears

Z-8

may

and

hooks,

move

needle,

of

both

at

medium

dial

place

and

wind

as

above

fabric

are

sewn

buttons.

the

sew

etc.

to

then

button.

holes

speed,

gently

in

the

making

lower

button.

five

the

or

presser

Correct

six

foot.

width

stitches,

Fig.

25

Page 16

A

buttonhole

1.

Replace

Move

2.

Set the

3.

4.

Set the

Stitch

5.

With

6.

showing lower

7.

Take

Remove

8.

tion

9.

Stitch

10.

Remove

showing

11.

Stitch

12.

Slit

cutterorseam

If

you

paper

NOTE:

MAKING

can

be

regular

the

Z-B

stitch

the

needle

4or5

needle

showing

the

bar

the

the

buttonhole

plantomake

which

When

the

on

presser

blind

stitch

dial

length

length

out

bar

stitchesinfabric.

from

right

length

needle from fabric,

tack

sameaslower

ripper.

canbetorn

the

pitch

both

madeinany

foot

lever

AU

to

position

control

of

the buttonhole.

of

fabric,

tack of

fabric,

side

of

of

the buttonhole.

of

buttonhole

bar

between

Be

buttonholes

away

left

side

by

means of

will

side

BUTTONHOLES

length

within

buttonhole

with

“M”

to

turn the

buttonhole

buttonhole

careful

pitchisdifferent

be

position.

for

forward

dial

at

number

Z-B

turn

and

the

LI

turn

tack.

the

after

the

Z-B

the

two

rows

nottocut the stitching

on

sheer

stitching

stitch

the

same.

the

foot.

stitching

between

%

dial

to

dial

Z-B

dialtothe

of

stitching

or soft

under

from

length

range

the

right,

the

to

material,

the

the

control

of

limited width.

of

buttonhole.

“0”

and

to

right

left,

to

with

or

place

fabric.

right

side

dial,

the

to the

the

the

the

so

“1”

illustration

illustra

illustration

buttonhole

bar

tacks.

tarlatan

pitch,

that

pitches

adjust

15

Fig.

26

4

or

2

Ifl

Buttonhole

Fig

27

Page 17

18

With

with

Set

the

number

For

be

sewn

rolled

the

material

can

continue

bar

and

beginning

and

sew

by

adjusting,

tion.

the

hemmer.

When

proceed

Insert

the

slot

the

narrow

Z-B

“3”

general

easily.

sew

in

Be

hemming

to

edge

on

needle

hemmer

dial

for

zigzag

hemming,

diagonally,

Then

to

being

2

of

the

order

and

careful

(Fig.

make

of

lace

the

right

NARROW

at

its

foot.

at

“0”

stitched

and

insert

the

point

rolled

or

3

stitches

hem

between

that

the

the

sewing

not

to

28)

and

sewing

a

hem

or

trimming

side

of

highest

Set

position

cut

prepare

it

in

edge

feed

in

the

the

HEMMER

position,

the

blind

for

hem.

the

the

into

the

just

beneath

the

scroll.

slowly

your

of

result

too

much

on

lace

same

(be

sure

hemmer.

stitch

straight

Set

right

material

scroll

and

right

material

will

be

or

are

required

manner

the

replace

stitch

corner

of

the

Then

carefully,

thumb

can

as

too

right

regular

lever

stitched

length

of

so

hemmer.

needle,

be

given

little

as

side

to

“M”

to

the

that

lower

holding

and

scrolled

in

the

material

in

one

explained

is

down)

presser

position.

hem

or

suit.

material

it

can

Pull

so

that

the

presser

forefinger

nicely

illustra

operation,

above.

into

—

foot

at

to

be

Out

it

the

r

into

Fig.

29

Page 18

Make

leading

scroll

the

for

as

of

top

lace

the

plain

the

edge

Should

sure

lace

hemmer

of

hemming,

fabric.

in

one

you

that

edge

Then

stitching.

Fig.

encounter

the

with

30

needle

into

with

put

pierces

the

the

the

the

(Fig.

skipped

it

hemmer’s

hand.

left

side

right

and

lace

29)

EMBROIDERING

stitches,

to

close

slot

To

apply

up.

fabric

embroidering

pressing

button

the

after

prefer

rather

carefully

the

edge

the

the

with

lace

the

Insert

combined

easy

It

is

down

marked

embroidery

Stretch

removing

and

high

and

fabric

just

hand

right

the

in

from

lace

the

into

WITH

follow

to

monogramming.

or

snap

the

“DOWN”

spring

fabric

the

the

the

lower

while

speed

sure

be

stretched

not

is

above

“French

hemmer

on

in

presser

presser

to

the

while

the

HOOP

A

a

lock

down

the

an

moving

keep

turned

guiding

Manner,”

with

left,

and

stamped

Release

the

on

all

needle

embroidery

foot.

lifter.

bar

the

fingers

enough

tight

edge

the

the

hem

the

design

pressure

way.

the

clamp.

hoop,

the

Set

hoop

out

of

material

insert

right

the

The

slowly

of

or

the

the

side

can

to

or

pressure

release.

Then

(See

and

stitch

operate

the

darning

a

hem.

being

fabric

down,

made

be

work

hang

Fig.

place

width

with

needle.

from

Push

30)

the

both

Begin

hemmed

be

to

and

to

free

the

upper

the

under

at

machine

hands.

spring

to

hemmed

put

enclose

hand

the

drop

the

the

is

stitch,

into

it

the

when

foot

feed

end

needle

size

Work

needed.

on

by

you

at

17

of

a

Page 19

18

This

covered

insert

Loosen

right

or

CORDING.

Loosen

cord.

needle

cord

baste

To

adjustable

and

cord,

attachment

thumb

of

left

centered

is

in

covered

sew

foot

on

cording,

screw

needle.

Fold

thumb

place

so

edge

in

(Fig.

needle

of

is

and

to

bias

screw

needle

cord

base

THE

used

to

slide

strip

and

31,32).

to

stitches

fabric.

ADJUSTABLE

make

to

in

zippers.

sew

to

fabric

set

closer

either

over

foot

Machine

reset

foot

of

hole.

material,

and

so

to

CORDING

Fig.

Loosen

needle

of

Stitching

more

Adjust

convenient,

closing.

is

AND

31

thumb

hole.

should

Guide

be

to

sew

ZIPPER

SEWING

and

screw

metal

close

to

from

of

either

FOOT

IN

slide

zipper

zipper

Fig.

ZIPPER

foot

so

along

allow

to

right

or

32

needle

edge

left

of

easy

side,

enters

foot

opening

which

(Fig.

center

33)

and

ever

Page 20

19

guide

This

placing

by

the

Use

foot

lightly

the

needle,

the

of

to

line,

top

presser

press

stitching

When

of

rows

accompanying

Adjust

the

clamp

on

bar

seam

seam

making

for

pronged

the

successive

attached

is

may

it

gauge

stitching

screw

width

QUILTING

holder

(Fig.

screw

fabric.

rows

so

serve

also

SEAM

as

along

threaded

in

desired.

parallel

between

34).

letting

By

will

that

as

GAUGE

guide

a

edges

hole

GUIDE

rows

be

the

seam

a

for

of

in

of

the

Adjust

the

an

curved

width

OR

straight

fabric.

bed

stitching

presser

the

guide

equal

part

guide.

CLOTH

Fasten

machine

of

foot

curved

ride

distance

is

seams

is

attached

and

the

on

the

to

GUIDE

and

gauge

(Fig.

bar

apart.

the

to

first

right

even

with

35).

Fig.

34

Fig.

35

Page 21

20

CARE

MAINTENANCE

AND

YOUR

OF

MACHINE

TO

HOW

Your

operating

sewing

of

Before

points

toward

Avoid

To

back

unit

point

To

rarely

Fig.

in

OIL

machine

smoothly.

you

oiling

indicated

until

you

over-oiling.

parts

oil

on

indicated

moving

oil

require

38.

YOUR

should

do.

the

by

the

under

hinges

its

in

oiling,

MACHINE

How

upper

arrows

take-up

Only

the

Fig.

37.

parts

open

be

often

a

and

inside

plate

oiled

part

in

lever

drop

bed

apply

occasionally

depends

of

Fig.

36

at

is

needed

is

the

of

a

face

the

oil

and

the

turn

its

machine,

drop

plate,

at

the

on

sewing

hand

lowest

each

at

of

spots

to

amount

unit

point.

at

oil

which

indicated

keep

wheel

point.

tip

at

the

each

only

it

36

Fig.

37

Fig.

Page 22

Fig.

21

SHUTTLE

The

This

Cleaning

Turn

position.

Remove

Turn

remove

Clean

by

Apply

When

Turn

position.

Place

into

Replace

into

clamps,

ped

Put

4.

Put

5.

into

THE

stitch

loose

with

will

and

remove

To

the

bobbin

the

the

the

removing

drop

a

the

replace

to

the

shuttle

position.

notch,

securely

bobbin

the

notch

forming

threads

interfere

removal

hand

head

Tilt

shuttle

two

shuttle

shuttle

all

of

cleaning

hand

shuttle

and

(B),

into

bobbin

(E)

shuttle

the

wheel

case

race

race,

threads,

oil

shuttle

the

wheel

hook,

race

lock

making

into

bobbin

case

of

mechanism

and

the

with

the

of

until

on

back

Fig.

(A>

race

cover

the

lint,

finger

with

has

until

(D),

cover,

into

certain

position.

into

cover.

race

lint.

efficient

will

lint

assembly,

needle

the

hinges.

its

39.

cover

(C)

shuttle,

etc.

tip

been

assembly:

the

against

(C),

position

the

case.

shuttle

the

occasionally

operation

safeguard

proceed

reaches

clamps

shuttle

and

shuttle

and

outer

to

completed,

needle

reaches

shuttle

fitting

with

clamps

race,

as

(B)

hook.

edge

driver

pin

shuttle

have

becomes

the

follows:

its

outward

race

of

proceed

its

and

lower

at

race

been

fitting

the

of

perfor

highest

and

(D)

cover

shuttle.

highest

adjust

edge

cover

snap

tongue

as

OILING

CLEANING

39

AND

clogged

machine.

mance.

1.

2.

3.

4.

5.

follows

1.

2.

3.

Page 23

22

Ripper

1.

Small

2.

Large

3.

Plastic

4.

Bobbins

5.

Felts

6.

Package

7.

Quilting

8.

Cloth

9.

Needle

10.

11.

Straight

Embroidery

12.

Button

13.

Buttonhole

14.

Narrow

15.

Zipper

16.

“THOSE

PURCHASED

BE

DEALER’S

ACCESSOR

(Buttonhole

Driver

Driver

Oiler

(3)

for

Spool

Needle

of

Guide

Guide

plate

Stitch

Sewing

Hemmer

Foot

PARTS

ARE

AT

STORE”

I

ES

(Sealed

pin

and

Thumb

Straight

for

Presser

Spring

Foot

(Plastic)

Foot

Foot

STANDARD

ANY

Cutter)

and

Filled)

(2)

Screw

Stitch

Foot

SEWING

CAN

AND

MACHINE

©

Iii

I\\

©

00

©

Page 24

Although

they

Upper

Be

Check

Use

Do

Lower

Check

Be

Needle

Do

Be

Skipped

Do

Insert

Use

Be

Stitches

Make

Machine

Clean

If

for

can

be

Thread

sure

on

correct

not

have

Thread

correct

sure

lower

Breaks

not

tug

sure

presser

Stitches

not

use

needle

correct

sure

pressure

Loop

sure

Binds

thread,

condition

a

while,

your

remedied

Breaks

needle

correct

needle

upper

Breaks

or

a

blunt

correctly.

needle

tensions

dust

continues,

and

sewing

is

inserted

way

method

tension

pull

foot

on

and

wipe

with

size

tension

on

is

or

size

foot

are

dry.

machine

minor

properly.

to

thread

for

thread.

of

threading

is

not

the

fabric

firmly

bent

for

thread.

is

sufficient

properly

lint

from

it

may

Then

CHECK

is

adjustments.

machine.

too

tight.

too

tight.

while

attached

needle.

balanced

hook,

be

lubricate

designed

bobbin

sewing

to

when

shuttle

that

the

UP

for

case.

bar.

sewing

and

machine

again

FOR

maximum

this

as

heavy

that

machine

and

with

will

race.

is

fine

SMOOTH

efficiency,

bend

and

fabrics.

is

threaded

gummy

with

sewing

SEWING

should

eventually

oil.

machine

any

correctly.

Apply

oil.

of

break

kerosene

the

the

following

needle.

oil

to

difficulties

holes,

run

23

occur

rapidly

Page 25

0

1’

1

I

I,

‘1

Loading...

Loading...