Page 1

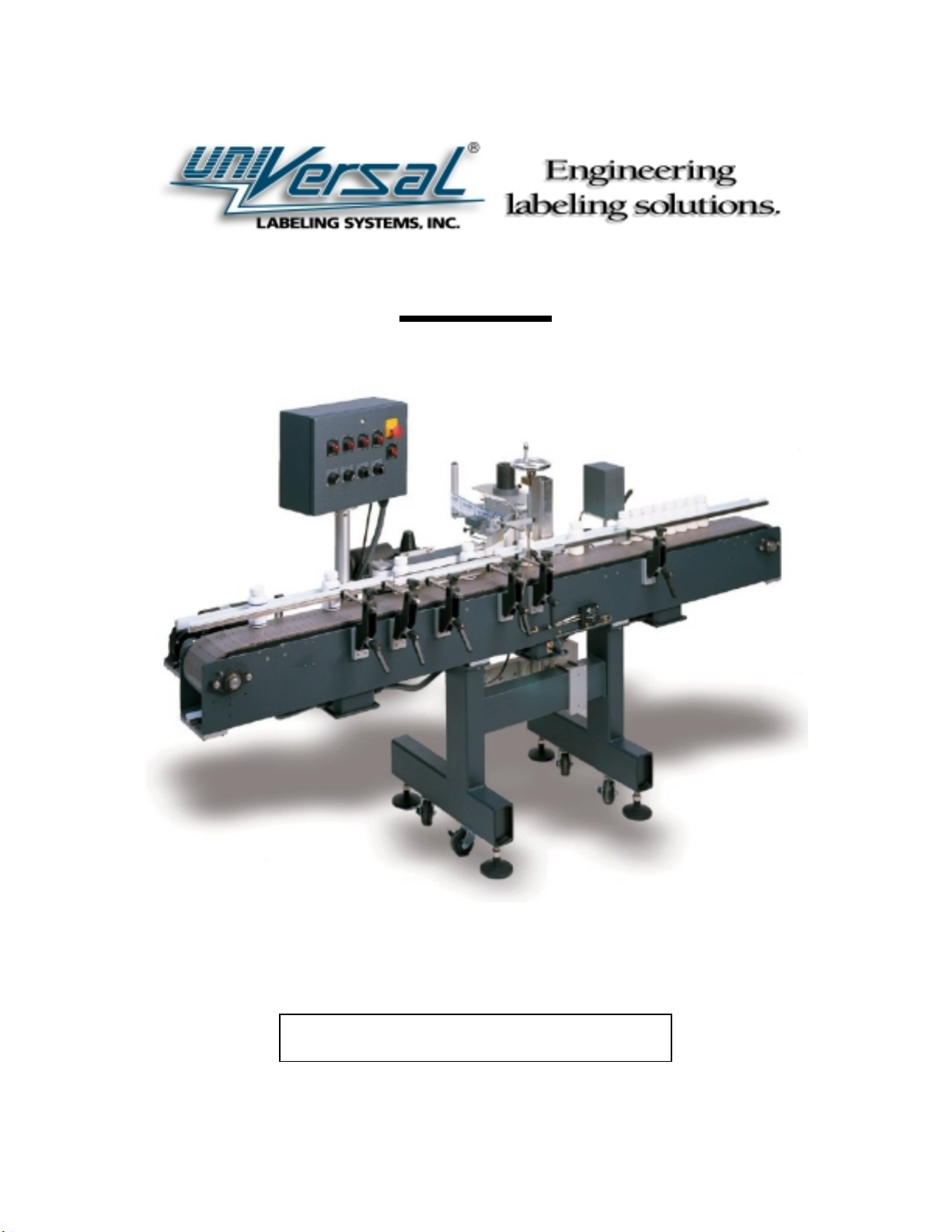

R-320

Operator’s Manual

Serial #

Page 2

WARRANTY

UniVersal Labeling Systems, Inc. warranties all parts to be free from defects in

material and workmanship for a period of one year from the date of shipment

from our facility.

This guarantee is based upon equipment being used 8 hours per day, or 40

hours per week, or in any increment which does not total more than a single

shift operation, or 2,080 hours per year. Warranty will be reduced

proportionally.

This warranty does not cover part failure caused by lack of normal

maintenance, abuse or misuse of the equipment.

PERFORMANCE GUARANTEE

All equipment manufactured by UniVersal Labeling Systems, Inc. carries a 30day performance guarantee. If your machinery does not perform as described

in our quote to you, UniVersal must be notified within 30 days of your

dissatisfaction and we will make every attempt to correct it. If after a

reasonable period of time, the machine does not meet the specified

performance, we will take your machine back and reimburse you in full.

Page 3

Warranty

Assembly and Operation

Drawings

Layout, Main

Exploded View (conveyor)

Exploded view BASE Conveyor

Assembly, Applicator Crank

Micro Adjustor

Sensor Mounting Bracket SBK

Wipe Down WPD-500

R320 Elect. Control box

R320 Control Box Electrical Schematic

Product Spacer

Turning Unit BOM

Turning Unit

Mounting Assy CP-1000

Electrical Schematic L15

Page 4

MODEL R-320

ASSEMBLY AND OPERATING INSTRUCTIONS

Conveyor Height can be adjusted from your system’s specified height by adjusting the

leveling pads

RE-TIGHTEN LOCKING BOLT AND ANGULAR BRACE, BEFORE REMOVING SUPPORT

AT BOTH ENDS OF CONVEYOR. FAILURE TO RE-TIGHTEN THE LOCKING SCREW

ON SLIDING SLEEVE COULD RESULT IN THE CONVEYOR AND ATTACHMENTS

DROPPING, CAUSING SERIOUS DAMAGE TO THE SYSTEM.

SEE APPLIER INSTRUCTION MANUAL FOR PROPER OPERATION OF APPLIER HEAD

AND WEBBING.

TO ADJUST SYSTEM FOR INDIVIDUAL CONTAINERS, PROCEED AS FOLLOWS:

1. Selecting the container to be labeled, place on conveyor for reference and adjust vertical

height of turning unit so that belt is centered vertically on container.

2. Adjust vertical height of guide rails opposite the applier and turning unit to center on product

but never low enough that rail drags on conveyor top.

3. Adjust guide rail across conveyor so that container is encapsulated securely between

the turning belt and the sponge backing plate. Move container along belt of turning

unit to establish that the sponge backing is adjusted parallel to belt. This is important,

as container must be controlled by turning unit and sponge backing on guide rail.

4. With applier head turned off, turn on conveyor. Set speed control by knob on control box on

front of conveyor to maximum speed.

5. Turn on turning unit by on-off switch located on control box on top of unit. (NOTE:

This unit’s power cord is to be plugged into control box on front of conveyor). Adjust

speed of turning unit so that turning belt is moving at a slightly higher rate of surface

speed than conveyor.

6. Place container on conveyor on entrance end and allow to proceed through turning unit.

7. When it is considered that the container is being properly controlled and guide rail

adjustments are proper, select the appropriate label; place roll on applier and web

properly. Refer to applier instructions.

Page 5

MODEL R-320

ASSEMBLY AND OPERATING INSTRUCTIONS

8. Stop conveyor by turning speed control to “O”. Turn off turning unit. Plug power

cord of applier into control box on front of conveyor. (NOTE: Applier and turning

unit will not receive power with switch on control box on front of conveyor in OFF

position).

9. Raise or lower applier so that label is centered on container. Label web must always

run to lower edge of peeler bar on this system, with edge of peeler bar clearing top of

conveyor EDGE. DO NOT LOWER APPLIER TO THE POINT WHERE EDGE

OF PEELER BAR IS RESTING ON TOP OF CONVEYOR EDGE.

10. Adjust peeler bar so that back side clears turning belt by no more than 1/8”.

11. Turn on master switch on applier, then turn on motor switch; one label will advance.

12. Product sensing micro switch is secured to edge of guide rail with arm extending

through guide rail. Activating this switch by hand will cause applier to deliver a label.

NOTE: Position label at end of peeler bar and adjust star wheel on applier so that 1/8”

to 1/4” of label is extending beyond peeler bar edge when label is delivered and

applier stops delivering a label. Trigger applier head with product sensing several

times to allow web to track properly and to observe extension of label beyond peeler

bar.

YOU SHOULD NOW BE READY TO LABEL

Turn on conveyor by speed control knob and adjust to just below maximum speed. Turn on

turning unit. Speed control knob on applier should be set at approximately 65 on dial - - with

turning unit at approximately the same setting.

With all systems running - - Place container on conveyor and

NOTE:

1. Point at which product switch activates relative to position of container. The ideal

point of which the applier starts delivering the label is as the container contacts the

center line of the first pulley of the turning unit and is encapsulated between the

turning unit belt and the rubber of the guide rail. Adjust the product sensing switch

back or forward to achieve the best results. A little experimenting by the operator for

the optimum position is in order. Triggering the applier too early or too late can result

in mis-register or wrinkled labels.

2. Next in this procedure, observe that as the label is being dispensed and applied that the

speed of the applier is not causing the label to be pulled by being too slow. (Speed up

by speed control on applier), or is delivering the label too fast as to incur wrinkling of

label on the container (slow applier by same procedure).

Page 6

MODEL R-320

ASSEMBLY AND OPERATING INSTRUCTIONS

IT IS EXTREMELY IMPORTANT THAT SPEEDS OF LABEL DELIVERY AND PRODUCT

BE MATCHED FOR SATISFACTORY PLACEMENT AND WIPE DOWN OF LABEL.

If label is tending to walk up or down on container, label applier may be rotated to position peeler

bar in parallel with container, so that label is started on container accurately, by loosening large

hex nut on swiveling bracket that applier is secured to and located on sliding sleeve on post.

Rotate applier by turning knurled knob at swivel point. NOTE: In making this adjustment, be

sure that rotating the applier does not cause the peeler bar to be forced into contact with top of

conveyor. Raise applier to prevent this, then lower into position after adjustment is made. Retest by passing one container through the system and noting the label placement. If still off, readjust as above until the optimum position is found.

It has been noted many times that during a labeling run that label placement may vary slightly.

This is most often the result of non-uniformity in the containers.

1. Slight tapers from top to bottom in the containers not visible to the eye.

2. Bottoms and sides of the containers not square, again not detectable visually.

Variations in containers as small as .005 inch can result in visual mis-alignment when wrapping

labels completely around containers. Most often these discrepancies are attributed to the abetting

system and are pointed out in these instruction as GUIDE LINES in TROUBLE SHOOTING the

equipment.

Suggestions for improvements in the design of our equipment is solicited and appreciated.

Many thanks for reading these instructions in their entirety.

Page 7

SUGGESTED SPEED SETTING

As tested at the factory, the following are suggested setting of speeds and time delays:

DIAL SETTING

* Conveyor Speed _______________

* Turning Unit _______________

* Applier _______________

Product Spacer _______________

These settings will product approximately _______________

parts per minute production

If speed of any of the above “*” are changed for any reason, comparable changes in the other

settings should be made.

The above speed settings are provided only as guidelines for start-up and may need to be changed

because of variables in voltages, area to area, and other variables over which we have no control.

SETUP INSTRUCTIONS

Page 8

When machine is received, open carton carefully and remove machine by placing hands under

machine base for lifting. Place machine on flat surface for installation of label roll holder to

machine. (NOTE: Acorn nuts and hex nuts to be removed). Slide label reel over the two

threaded studs, secure with hex nuts, then install the two acorn nuts. Machine is not ready for

installation and can be secured to an appropriately fabricated bars, flatplate, etc., by the four (4)

bolts on the bottom of machine that are securing the bottom cover for shipment.

FOR THOSE MACHINES EQUIPPED WITH LOW LEVEL ALARM AND/OR WEB

BREAK ALARM:

NOTE: Low level alarm is mounted to label reel bar and needs only to be plugged into small 2

prong plug dangling from rear of machine. Swinging curved bar is to be moved downward for

loading of labels and rests on outside of roll when in operation, under slight spring pressure.

When position of curved bar reaches a position near core of label roll, an audible sound will emit

from small box mounted to top of machine. Light will also come on at same time. Both audible

alarm and light may be cut off by toggle switch on top of box.

NOTE: Web break alarm - - located between the pull roll and web rewind. Waste web must

pass under plastic finger. The finger is supported by waste web and in the event of web breakage,

finger will drop downward causing audible signal and light to come on top of box on top of

machine.

SEE WIRING DIAGRAM IN BACK OF MANUAL

Page 9

Page 10

R320 AUTOMATIC SYSTEM

WITH L15H APPLICATOR

RECOMMENDED SPARE PARTS

PART # PART DESCRIPTION

200109 MICRO SWITCH, LABEL SENSING

200198 POWER MODULE

420173 STARWHEEL SPRING

L-129-S STARWHEEL, LABEL SENSING

L-137-H DRIVE ROLLER (HD)

L-140-F-3 SLIP CLUTCH COLLAR (REPLACES L-140-F-2)

L-175-1 ASSY. SPROCKET W/FELT & BEARINGS

L-143 LOWER IDLER ROLL ASSY (KNURLED ALUMINUM)

L-176-1 DRIVE BELT (120 X L037)

200160 TRANSFORMER

300013 REPLACEMENT MOTOR BRUSH FOR L-15H

300023 REPLACEMENT MOTOR BRUSH FOR TURNING UNIT

600008 4” TURNING UNIT BELT

600007 2” TURNING UNIT BELT

TA-215 2”W.x15”L. FOAM PAD W/PLATE

TA-415 4”W.x15”L. FOAM PAD W/PLATE

500030 PLASTIC COMPRESSION CLIP FOR CONVEYOR RAILING

L-132 IDLER ASSY (FOR L-15H)

LP-100-S-1-X ASSY, INTERMEDIATE SPROCKET

410000 CHAIN FOR L-15H (19.25”)

L-128-C REWIND SPOOL CLAMP FOR L-15

L-105-RA ASSY, WEB GUIDE CLAMP (R.H.)

L-105-LA ASSY, WEB GUIDE CLAMP (L.H.)

600300 1” PEELER PLATE TAPE (50’ ROLL)

200046 FUSE FOR CONTROL BOX (10 AMP)

500085 3/8 RATCHET HANDLE

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

TA-2/4 2 & 4 INCH TURNING UNITS

Bill of Material

ID# PART# QTY DESCRIPTION

1 300022 1 MOTOR, (1/4 HP. 100 RPM.)

2 400016 4 BEARING, (SEALED 3/8” 99R6)

3 410000 1 CHAIN, (# 25 LINK 19.375”)

4 410001 1 LINK, (# 25 MASTER)

5 600007 1 BELT, (2" X 37-1/4” 2" TA)

** 600008 1 BELT, (4" X 37-1/4” 4" TA)

7 TA-2-202 1 FRAME, MAIN

8 TA-2-203 2 POST, MOUNTING

9 TA-2-205 2 BLOCK, BEARING

10 TA-2-205-A 1 PLATE, IDLER ROLLER MOUNTING

11 TA-2-205-B 1 PLATE, UPPER BEARING MOUNTING

15 TA-2-219-1 1 COVER, MOTOR SHAFT

16 TA-2-201 1 PLATE, MOTOR BASE

** TA-4-401 1 PLATE, MOTOR BASE

17 TA-2-217 1 PLATE, CONVEYOR BELT BACKING

** TA-4-403 1 PLATE, CONVEYOR BELT BACKING

18 TA-4-406-1 1 COVER, TA CHAIN GUARD (1 OF 2)

19 TA-4-406-1 1 COVER, TA CHAIN GUARD (2 OF 2)

20 TA-4-407 1 SUPPORT, CHAIN GUARD

21 TA-2-206-A 1 SHAFT, IDLER ROLLER

** TA-4-408A 1 SHAFT, IDLER ROLLER

22 TA-2-206-B 1 SHAFT, DRIVE ROLLER

** TA-4-408B 1 SHAFT, DRIVE ROLLER

23 TA-2-204-A 1 ROLLER, IDLER 2” WIDE

** TA-4-409A 1 ROLLER, IDLER

24 TA-2-204-B 1 ROLLER, DRIVE 2” WIDE

** TA-4-409B 1 ROLLER, DRIVE

25 TA-4-413-1 1 SPROCKET, MOTOR

26 TA-4-412 1 SPROCKET, DRIVE

27 TA-2-218 1 PLATE, 2" COVER

** TA-4-418 1 PLATE, 4” COVER

28 L-172-04 2 SPACER, .125

29 L-172-03 OR L-172-12 3 SPACER, (.062 OR .093 RESPECTIVELY)

30 FLOOR STOCK 4 ACORN NUT, 1/4-20

31 FLOOR STOCK 4 1/4-20 x 1" H.H.M.S.

32 FLOOR STOCK 2 8-32 x 3/4" S.H.C.S.

33 FLOOR STOCK 17 10-32 x 3/4" S.H.C.S.

34 FLOOR STOCK 3 10-32 x 1/2" S.H.C.S.

35 FLOOR STOCK 2 8-32 x 3/8" SOCKET SET SCREWS

36 FLOOR STOCK 4 1/4-20 x 5/8" F.H.M.S.

37 FLOOR STOCK 4 6-32 x 3/8" S.H.C.S.

38 FLOOR STOCK 2 1/4-20 x 1/4" SOCKET SET SCREWS

39 FLOOR STOCK 2 10-32 x 1/4" SOCKET SET SCREWS

40 FLOOR STOCK 2 8-32 x 1" S.H.C.S.

41 FLOOR STOCK 2 8-32 HEX NUT

42 FLOOR STOCK 1 1/4-20 x 1/2" SET SCREW

43 FLOOR STOCK 2 8-32 x 3/8" S.H.C.S.

FILE: G:\ACCESSORIES\TA\TA2&4.DOC Revised 10:56 AM March 9, 2000

Page 21

TA-2/4 2 & 4 INCH TURNING UNITS

Bill of Material

ID# PART# QTY DESCRIPTION

44 TA-2-215B 4 GUIDE, BACK PLATE

45 SS-112 2 KNOB, MICROMETE R ADJ.

46 TA-2-215A 2 PLATE, TURN-AROUND MOUNT

47 FLOOR STOCK 2 BOLT, 3/8 x 2-1/4 H.H.M.S

48 FLOOR STOCK 11 WASHER, #10 x .06 THK.

49 FLOOR STOCK 4 WASHER, 1/4” x .06 THK.

50 FLOOR STOCK 4 WASHER, #6

51 200026 1 CONNECTOR, 4 PIN MALE (CONVEYOR MODEL)

52 TB-1 1 ASSEMBLY, TA BOX (FIELD UPGRADE MODEL)

N/S 300023 2 BRUSHES, FOR MOTOR 300022

(**) = SPECIFICALLY FOR 4” TURNING UNIT (TA-4)

FILE: G:\ACCESSORIES\TA\TA2&4.DOC Revised 10:56 AM March 9, 2000

Page 22

Page 23

Loading...

Loading...