Page 1

L60

Label Applier

Operator’s Manual

Serial #

Page 2

Operator’s Manual

Version: D 12/18/2001

The information contained in this manual is the sole property of Universal Labeling

Systems, Inc. No parts of this manual may be reproduced or transmitted in any form

or purpose other than the purchaser’s personal use without prior consent of

Universal Labeling Systems, Inc.

Universal Labeling Systems, Inc.

3501 8th Ave South, Saint Petersburg, FL 33711

Phone (727) 327-2123 Fax (727) 323-4403

Page 2

Page 3

Table of Contents

SECTION 1 OVERVIEW .................................................................................................4

INTRODUCTION......................................................................................................4

UN-PACKING INSTRUCTIONS ..............................................................................5

PRODUCT WARRANTY .........................................................................................6

SPECIFICATIONS ...................................................................................................7

SECTION 2 SETUP AND OPERATION .........................................................................8

ASSEMBLING THE L60..........................................................................................8

FUNCTION OF UNWIND ASSEMBLY....................................................................9

WASTE REMOVAL ...............................................................................................10

MOUNTING THE L-60 ...........................................................................................11

THEORY OF OPERATION....................................................................................12

LOWER “HALL EFFECT” SENSOR (OPTIONAL) ..............................................13

“SMART HEAD” (OPTIONAL) .............................................................................14

EXPLANATION OF LABEL TRANSFER..............................................................15

WEBBING THE L60 ..............................................................................................17

RUNNING THE L60 ...............................................................................................19

LABEL SENSING STAR WHEEL .........................................................................20

DATA LOGIC SENSOR (OPTIONAL) ..................................................................21

LION SENSOR (OPTIONAL) ................................................................................22

SECTION 3 MAINTENANCE........................................................................................23

STARWHEEL MAINTENANCE.............................................................................23

GENERAL MAINTENANCE..................................................................................24

SECTION 4 TROUBLESHOOTING ..............................................................................25

TROUBLESHOOTING (continued)......................................................................26

TROUBLESHOOTING (continued)......................................................................27

TROUBLESHOOTING (Registration) .................................................................28

SECTION 5 TECHNICAL..............................................................................................29

VACUUM HEAD FUNDAMENTALS .....................................................................29

TECHNICAL SUPPORT .....................................................................................................30

DRAWINGS AND BILL OF MATERIALS...........................................................................31

MAIN ASSEMBLY .................................................................................................31

FRONT SIDE PANEL ASSEMBLY .......................................................................31

REAR SIDE PANEL ASSEMBLY .........................................................................31

BELT TENSIONER ASSEMBLY...........................................................................31

TAMP ASSEMBLY ................................................................................................31

BLOW ASSEMBLY ...............................................................................................31

GAUGE ASSEMBLY .............................................................................................31

FRONT PANEL ASSEMBLY.................................................................................31

FRONT PANEL (PLC) ASSEMBLY......................................................................31

GUIDE ASSEMBLY...............................................................................................31

VALVE ASSEMBLY ..............................................................................................31

UNWIND ASSEMBLY ...........................................................................................31

WEBBING DIAGRAM............................................................................................31

TAMP PNEUMATIC DIAGRAM ............................................................................31

BLOW PNEUMATIC DIAGRAM ...........................................................................31

LION EYE OPTICAL LABEL SENSOR ASSEMBLY ...........................................31

DATA LOGIC OPTICAL LABEL SENSOR ASSEMBLY .....................................31

RECOMMENDED SPARE PARTS .......................................................................31

POWER MODULE SETUP SHEET.......................................................................31

ELECTRICAL DIAGRAM ......................................................................................31

ELECTRICAL DIAGRAM (PLC) ...........................................................................31

Page 3

Page 4

SECTION 1 OVERVIEW

INTRODUCTION

Featuring solid-state circuitry and an AC Synchronous Motor, the L60 is a high performance,

low maintenance label applicator. The L60 applicator is designed to apply a pressure

sensitive label to a product through the action of an air-cylinder-mounted, or blow-on,

vacuum head. The labeling process can be automatic when interfaced with a conveyor, or

semi-automatic with a table-based product fixture. When triggered, the L60 Tamp vacuum

head extends to meet the product. When the air cylinder returns the vacuum head to the

home position, another label is indexed onto the head and is waiting to be applied to the

next product. The L60 BLOW vacuum head blows the label onto the product, and another

label is indexed and ready for the next product.

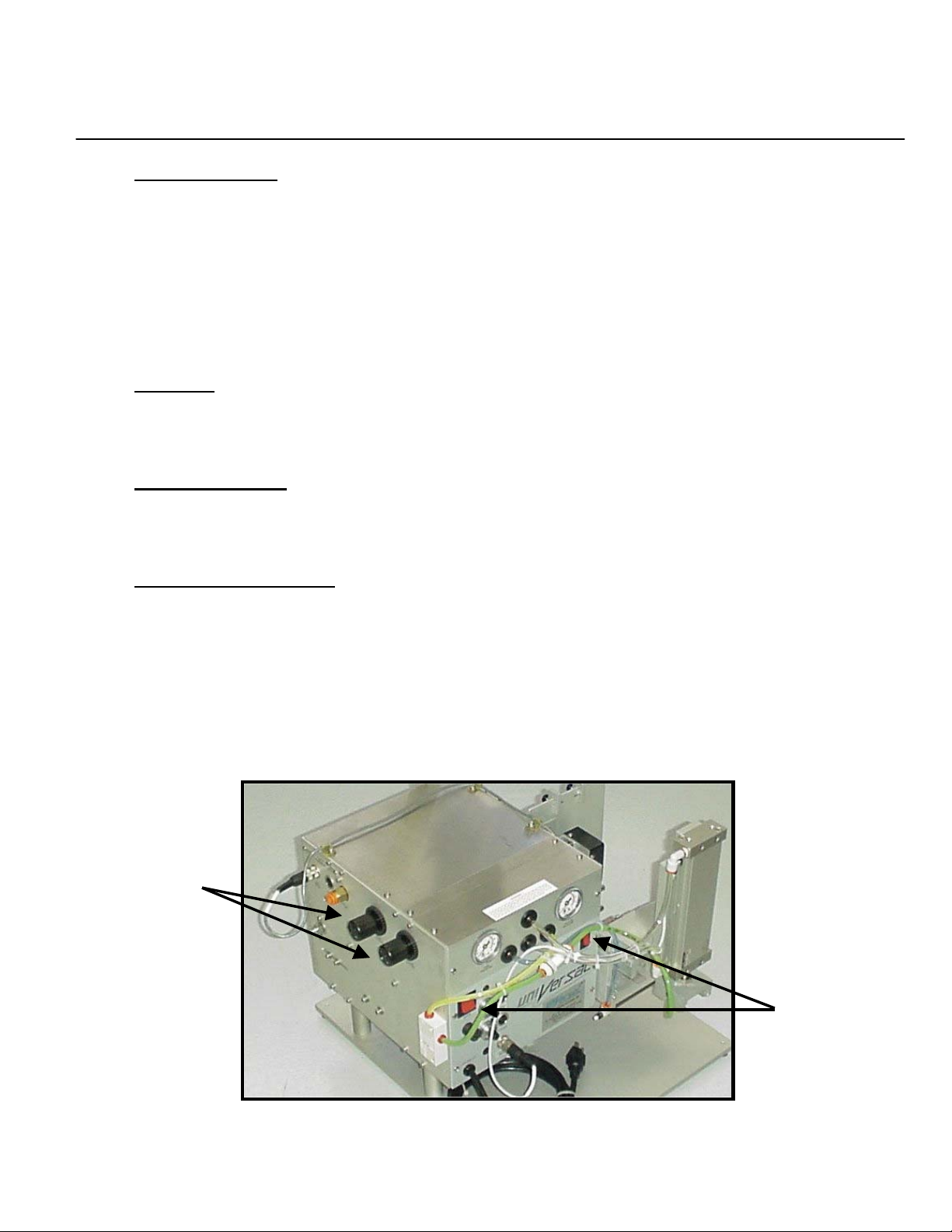

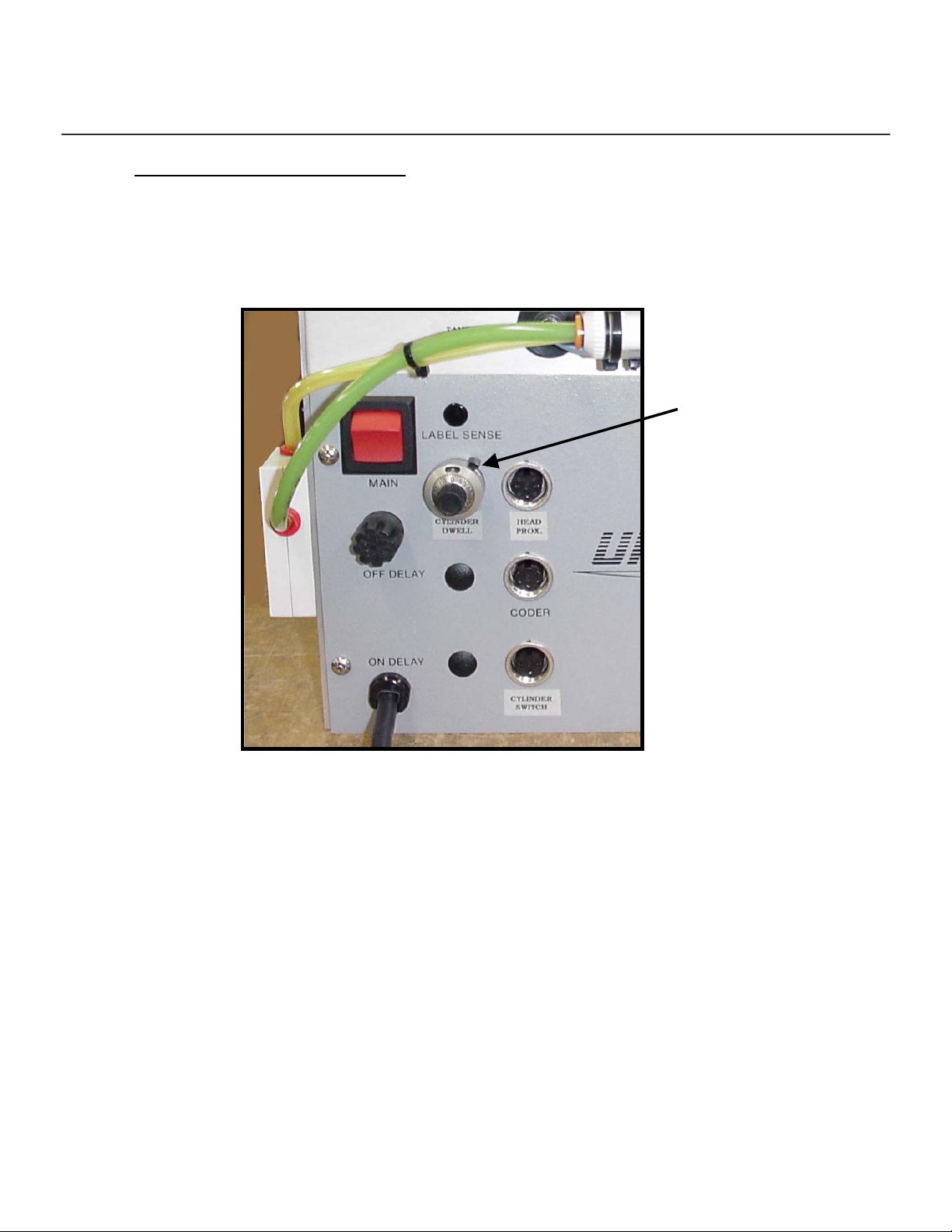

Switches:

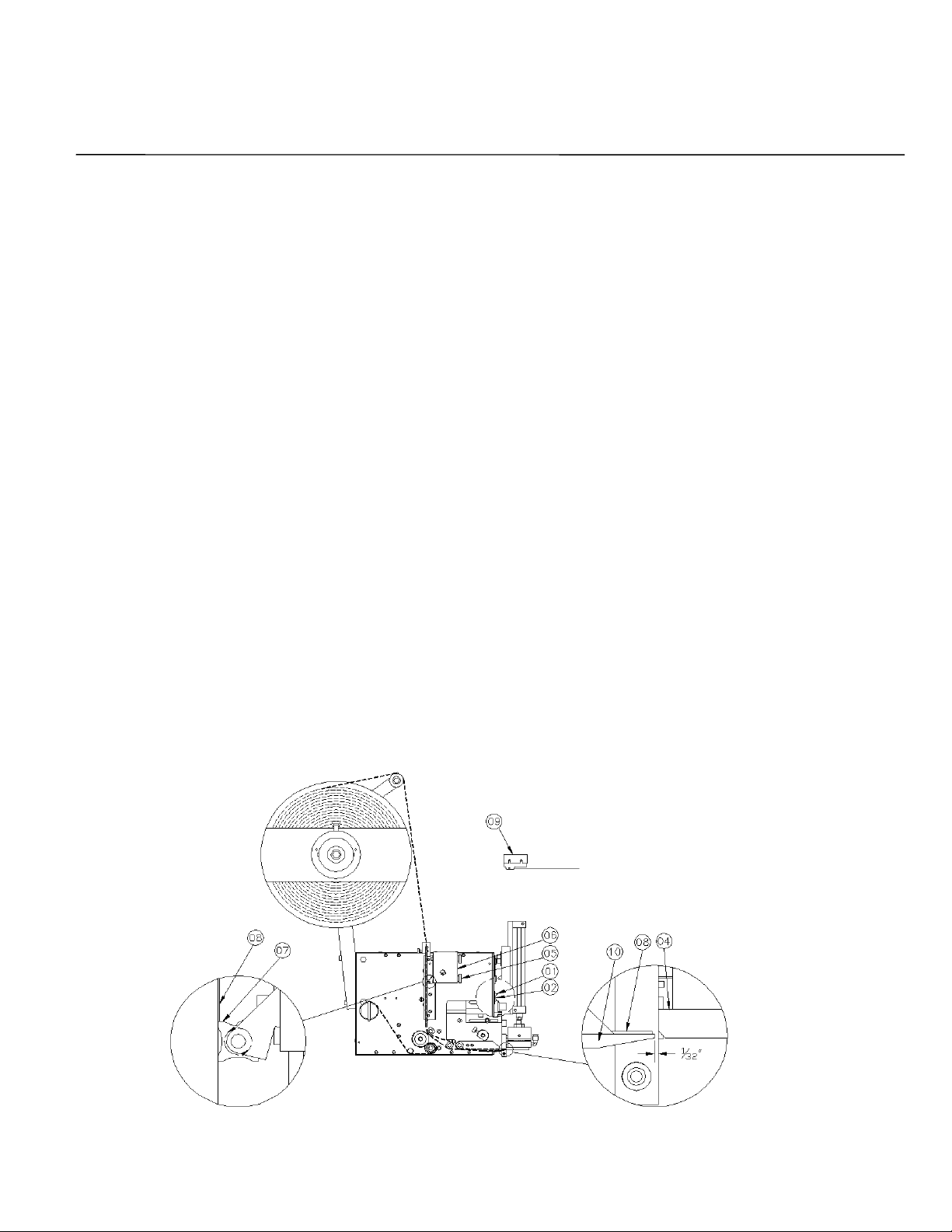

There are two switches on the front panel of the applicator. The Main switch turns the

power on or off, and if a Hot Stamp Coder is used, will allow it to heat up. The Motor switch

controls the motor that turns the drive roller and waste rewind. Fig 1

Product Detection:

The product can be detected on the leading or trailing edge. To change from leading to

trailing edge, set switch 4 of the power module to the ON position. (See lower left of

Drawing L15-D-02)

Recommended Settings:

There are many different label compositions, so there is no one set of machine settings (air

pressure, etc.), which will work on all types of labels. The following recommended air

regulator settings will give the operator a place to start.

Set the air cylinder pressure to about 15 psi. The vacuum pump input pressure will vary

according to label density and size, which you can start at 5-10 psi. Turning the regulator

knobs on the side of the machine can regulate air pressures. Fig 1

Air

regulators

Fig 1

Switches

Page 4

Page 5

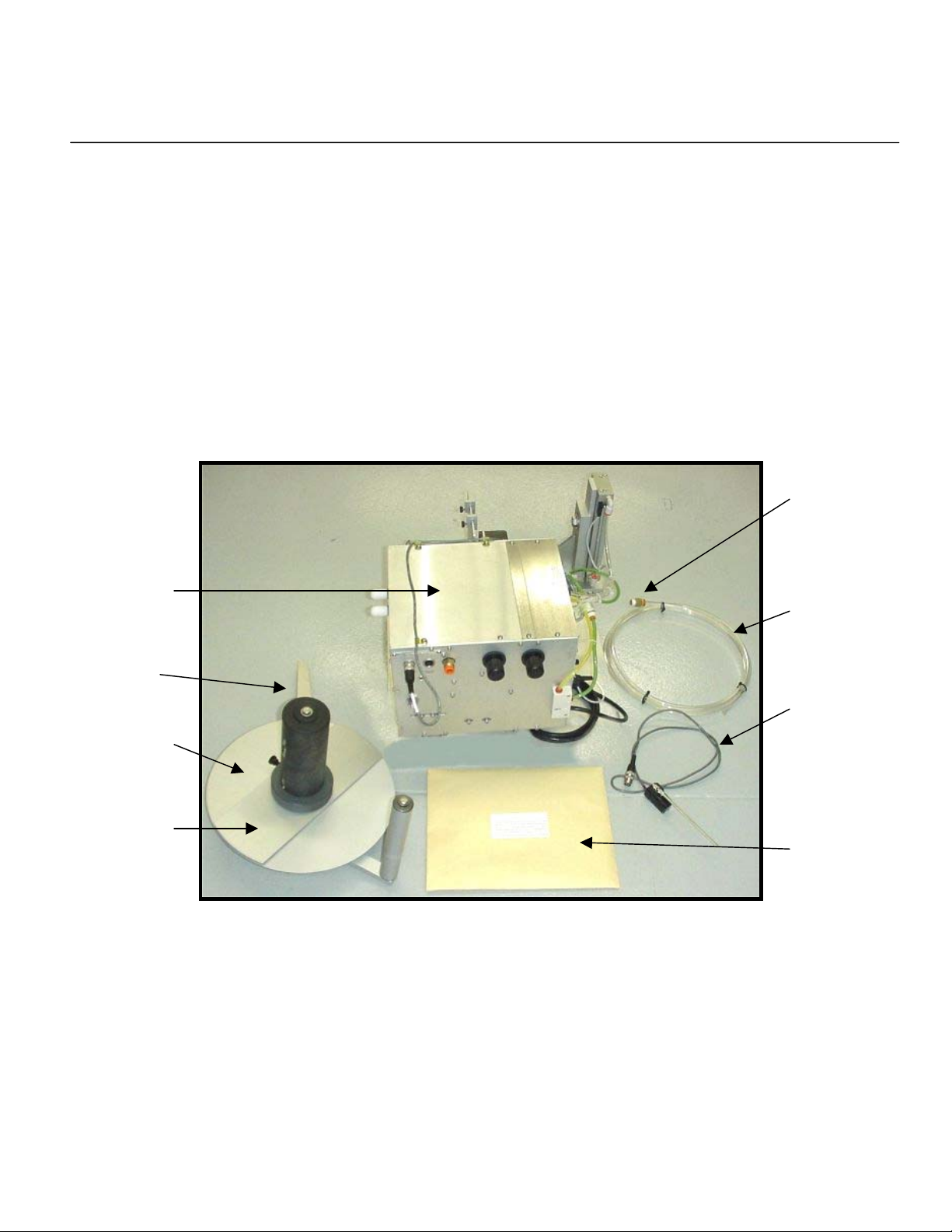

UN-PACKING INSTRUCTIONS

When the machine is received, the shipping carton will contain the following items.

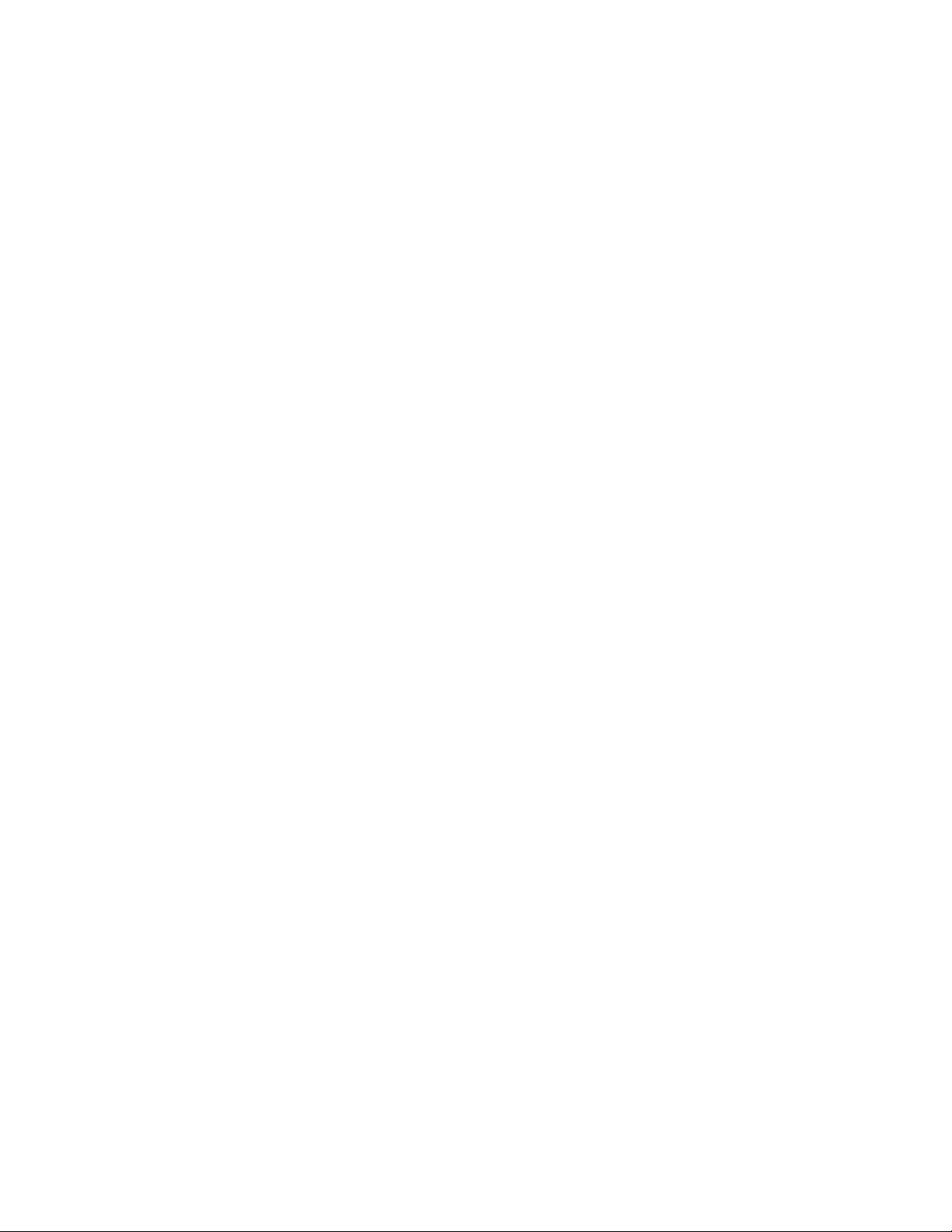

Fig 2

1. L-60 Body.

2. Unwind assembly.

3. Unwind assembly-backing plate.

4. Unwind assembly label roll retainer.

5. Air Fitting Part #100373 ¼ NPT x 3/8.

6. 10’ of 3/8” hose.

7. Product switch in a padded envelope.

8. This manual in manila envelope.

Extended peeler bar assembly (OPTIONAL). See notes below. **

5

1

2

3

4

Fig 2

**When the machine is ordered with an extended peeler bar assembly, it will be

packed disassembled from the machine body.

Remove the machine body by placing your hands under the bottom for lifting. Refer

to the packing list, and check all packing materials to insure all of the machine parts

and accessories are accounted for.

6

7

8

Page 5

Page 6

PRODUCT WARRANTY

Universal Labeling Systems, Inc. warranties all parts to be free from defects in

material and workmanship for a period of one year from the date of shipment from

our facility.

This guarantee is based upon equipment being used 8 hours per day, or 40 hours

per week, or in any increment which does not total more than a single shift

operation, or 2,080 hours per year. Warranty will be reduced proportionally.

This warranty does not cover parts failure caused by lack of normal maintenance,

abuse or misuse of the equipment.

PERFORMANCE GUARANTEE

All equipment manufactured by Universal Labeling Systems, Inc. carries a 30-day

performance guarantee. If your machinery does not perform as described in our

quote to you within 30 days of shipping, Universal Labeling Systems, Inc. will make

every attempt to correct it. If after a reasonable period of time, the machinery does

not meet the specified performance, we will take your machine back and reimburse

you in full.

Page 6

Page 7

SPECIFICATIONS

Electrical Power: 115VAC, 3 Amps, 60Hz

Compressed Air: Clean, Dry, 40PSI, 5CFM

Lubrication: The L60 label Applicator requires no lubrication

Label Apply speed: Depends on label size

Label Size: 4-3/8” wide on 3” Core -12” Diameter roll

Optional Wide label kit: 6-3/8” wide on 3” Core -12” Diameter roll

Standard Size: 19” Wide x 21” Deep x 24.75” Tall

Weight: 62 lbs (23.44 Kg)

L60 w/ Base Plate 68 lbs (25.71 Kg)

Page 7

Page 8

SECTION 2 SETUP AND OPERATION

ASSEMBLING THE L60

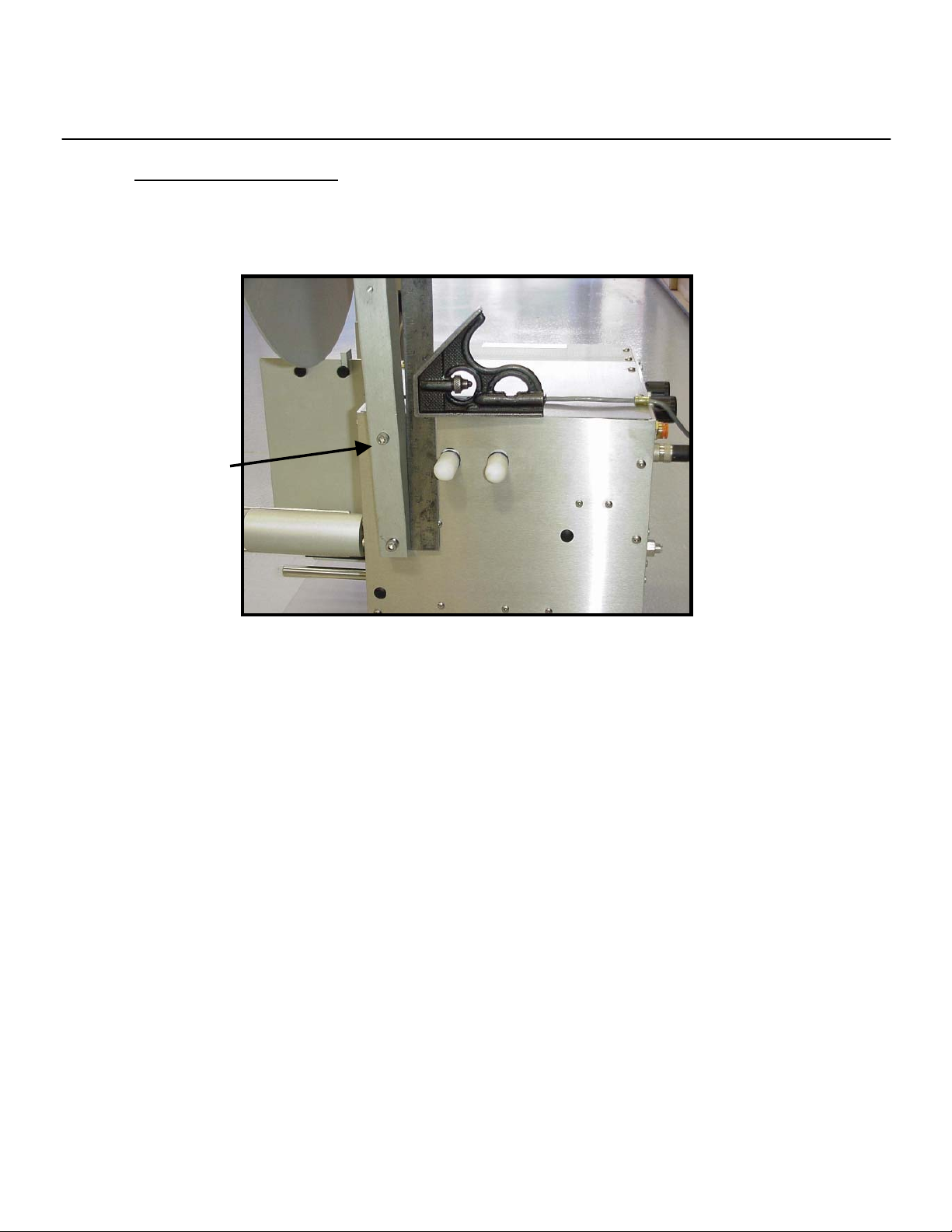

Using a square, mount the Unwind Assembly to the back of the L60 using the 2

screws provided. The top screw is a ¼-20x1-1/2” socket head cap screw, the

bottom screw is ¼-20x1-1/4”.

Please

note:

Screws.

Top one is

longer.

Fig 3

Maximum reliability is assured when the Compressed Air supplied to the L60 is

Clean & Dry. Over time, moisture will take its toll on the Solenoid Valves and Air

cylinder. Also it is not recommended to add Oil to the Compressed Air line supplied

to the L60. The air valves and air cylinder will eventually fail and oil will end up on

the label from the Air Assist tube which helps feed the label on to the vacuum head.

This will cause the label to not adhere properly to the product.

Run 40 psi @5CFM minimum compressed air to the L60 and procure necessary

fittings to make the connection to the air inlet located on the side opposite the label

drive and rewind. DO NOT CONNECT THE AIR TO THE UNIT AT THIS TIME.

Page 8

Page 9

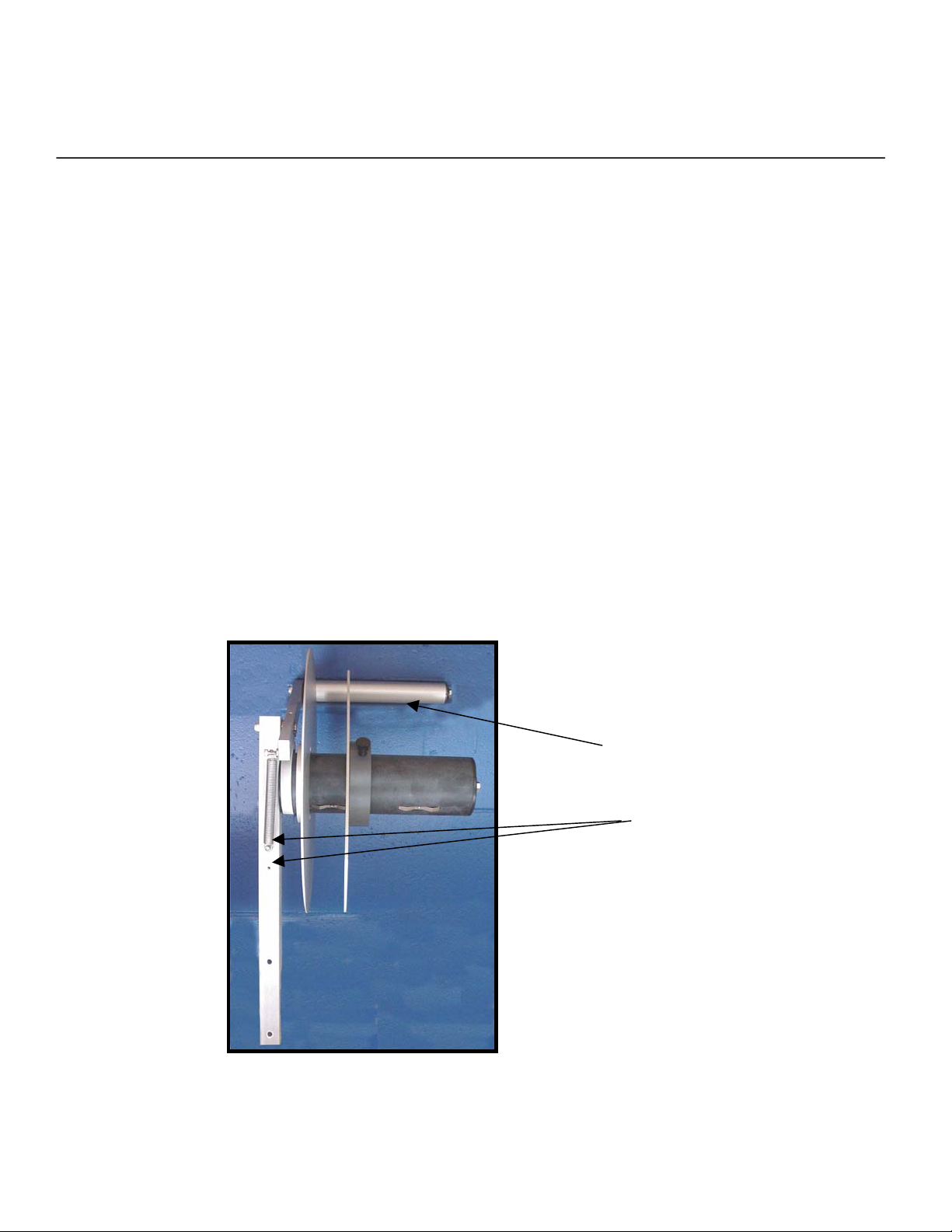

FUNCTION OF UNWIND ASSEMBLY

The unwind is simple, but important to the operation of the L-60 machine. When the

motor starts, the web and labels are pulled through the machine by the drive roller.

The label stock pulls on the brake arm, releasing the brake, and allows the roll of

labels to unwind. When the motor stops, the brake arm returns to the rest position.

This movement tightens the brake band around the 3" diameter main unwind hub

and the roll of labels stops unwinding.

The L-60 has a fixed speed, AC drive motor that transmits power to the drive roller.

The AC drive is directly influenced by the load it is trying to pull. In this case, the load

is the tension of the brake arm spring and the weight of the roll of labels. The brake

arm spring shown below in Fig # 4, should be fastened to the unwind assembly

mounting bar in the tapped hole which provides the least amount of tension at the

brake arm. (The hole closest to the hub.)

If the L-60 is dispensing a long label (10" for example), you may have to increase

the tension on the brake arm spring (Move spring attachment point to lower hole See Fig # 4) to keep the brake arm from bottoming out.

The length and speed figures mentioned above are only examples. Your observation

of the unwind operation will be the best indication of when a tension change may be

needed.

Fig 4

Dancer Arm

Spring located in top

hole. Move to bottom

hole for larger labels.

Page 9

Page 10

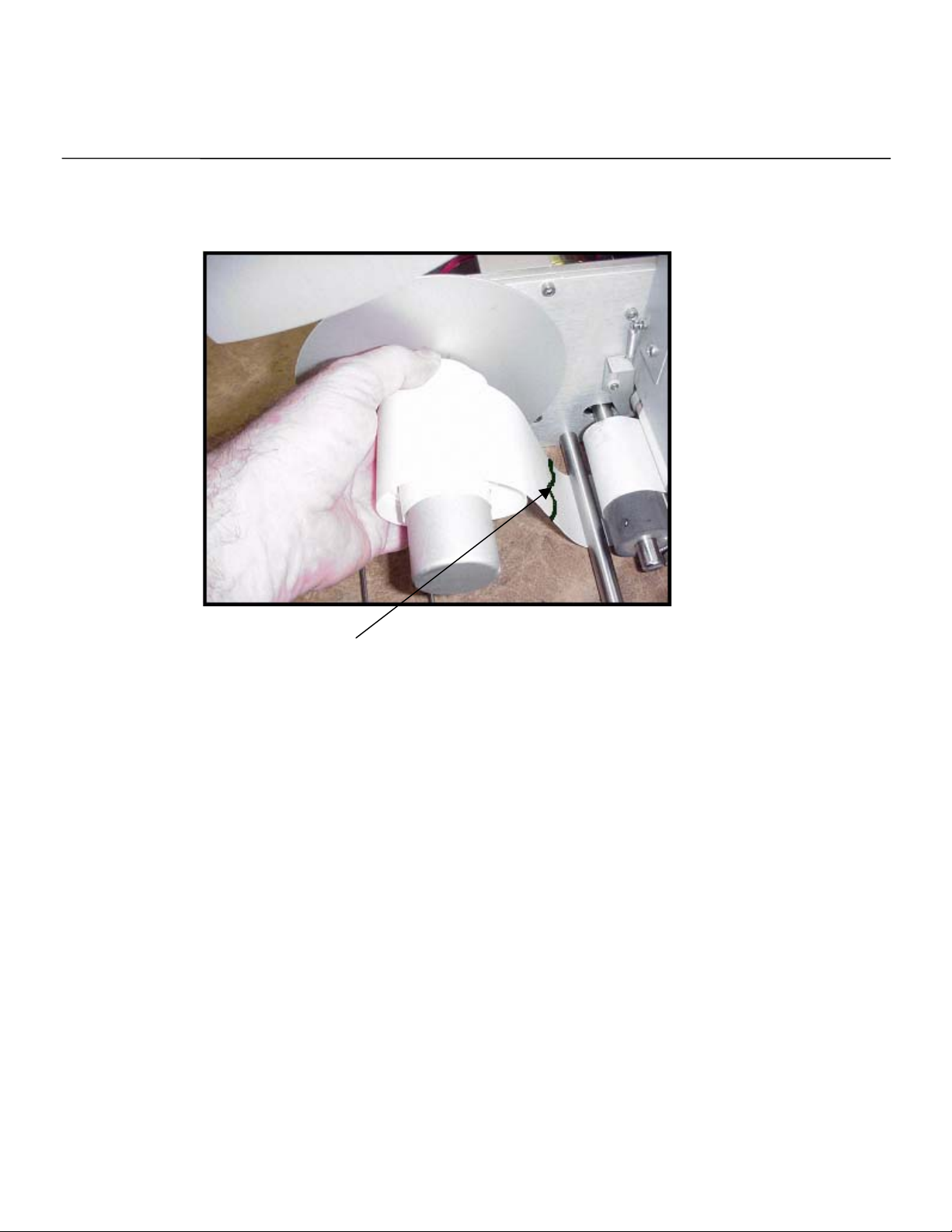

WASTE REMOVAL

1. To remove waste web, turn off the machine, and remove the rewind spool

clamp.

Fig 5

2. Tear the web first.

3. While holding the rewind backing plate, turn the whole waste web in the

opposite direction and pull.

Page 10

Page 11

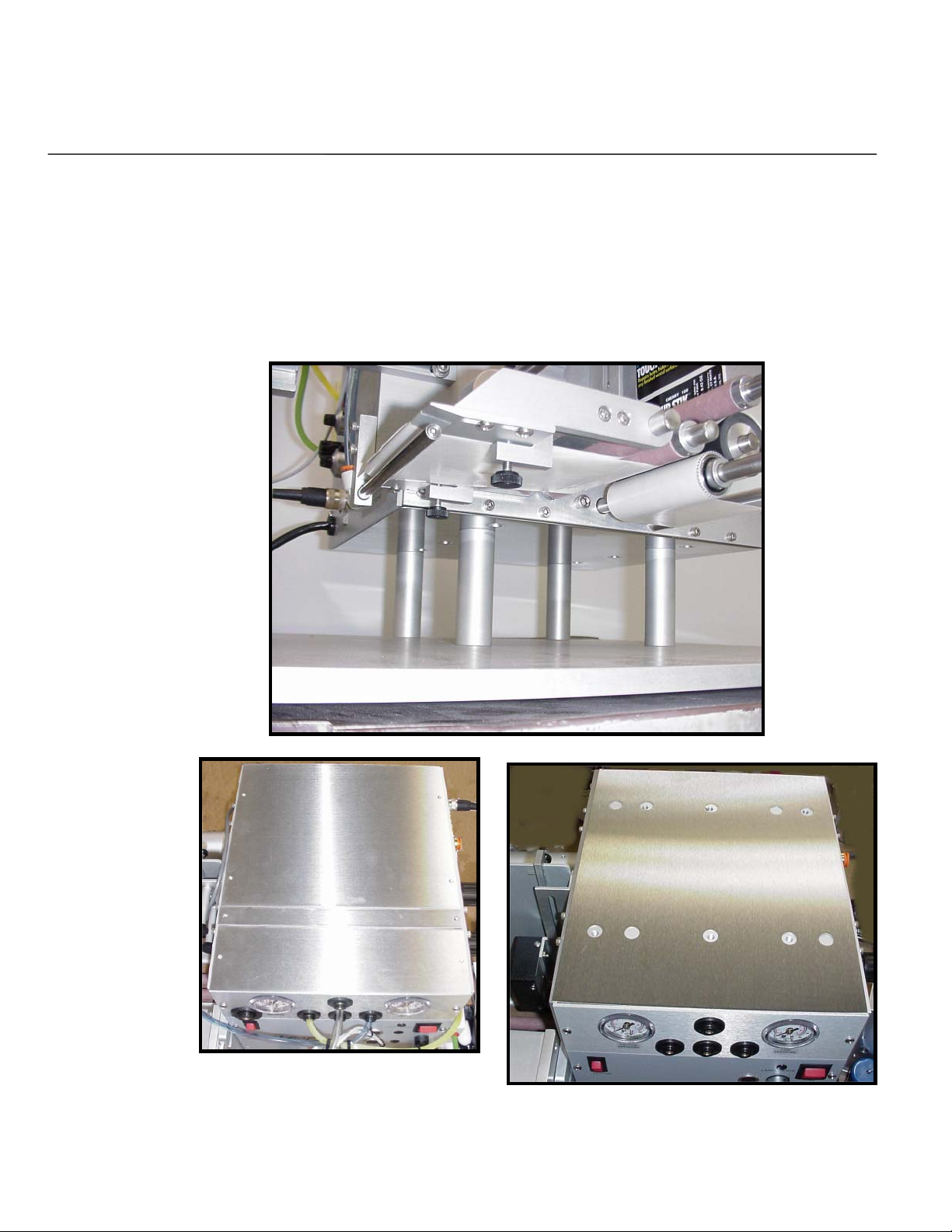

MOUNTING THE L-60

The L-60 can be mounted from the bottom or the top. The most common method is

bottom mount (see Fig 6). Fig 6 shows the L-60 mounted to the optional base plate

with standoffs. Fig 7 shows the top of an L-60 ordered with standard mounting and

can accept a coder. Fig 8 shows an L-60 Ordered for top mount.

Six holes have been provided in the two lower tie bars. Any combination may be

used. The hole pattern most used is 6-1/2" square, which is where the 4 legs are

shown in Fig. 6. All the holes are tapped 1/4-20.

Fig 7

Fig 6

Fig 8

Page 11

Page 12

THEORY OF OPERATION

TAMP CYLINDER RETURN OPTIONS

Dwell Timer (Standard on all L60 Tamp Applicators)

“Dwell Time” is the time duration of the signal that opens the valve, which activates

the air cylinder. This time duration can be adjusted with the three- turn dial located

on the front panel of the machine. Turn the dial clockwise and the duration to

Dwell timer

Fig 9

increase the dwell time signal. After the label apply signal is given, the air cylinder

extends and the time duration terminates, the air cylinder then retracts and returns

the vacuum head to the home position.

Setting the Dwell time:

1. Turn the dial counter-clockwise to “0”.

2. Activate foot switch or product sensor. You will notice that the air cylinder will not

extend.

3. Turn the dial to “10”. The air cylinder should extend a short distance and return.

4. Turn the dial until the vacuum head touches the product. The dwell time is now

set. The distance of the machine from the product and air pressure will affect

this setting.

Page 12

Page 13

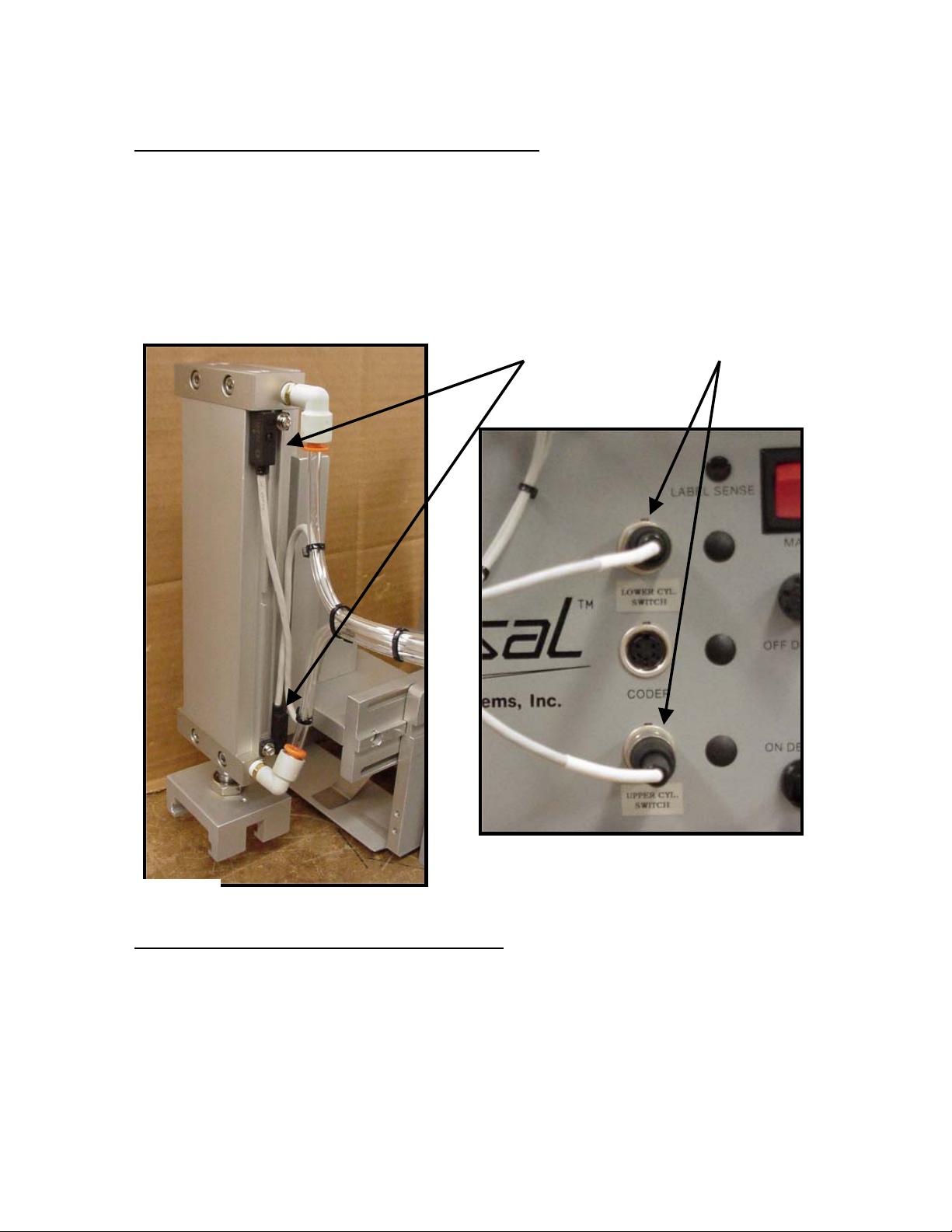

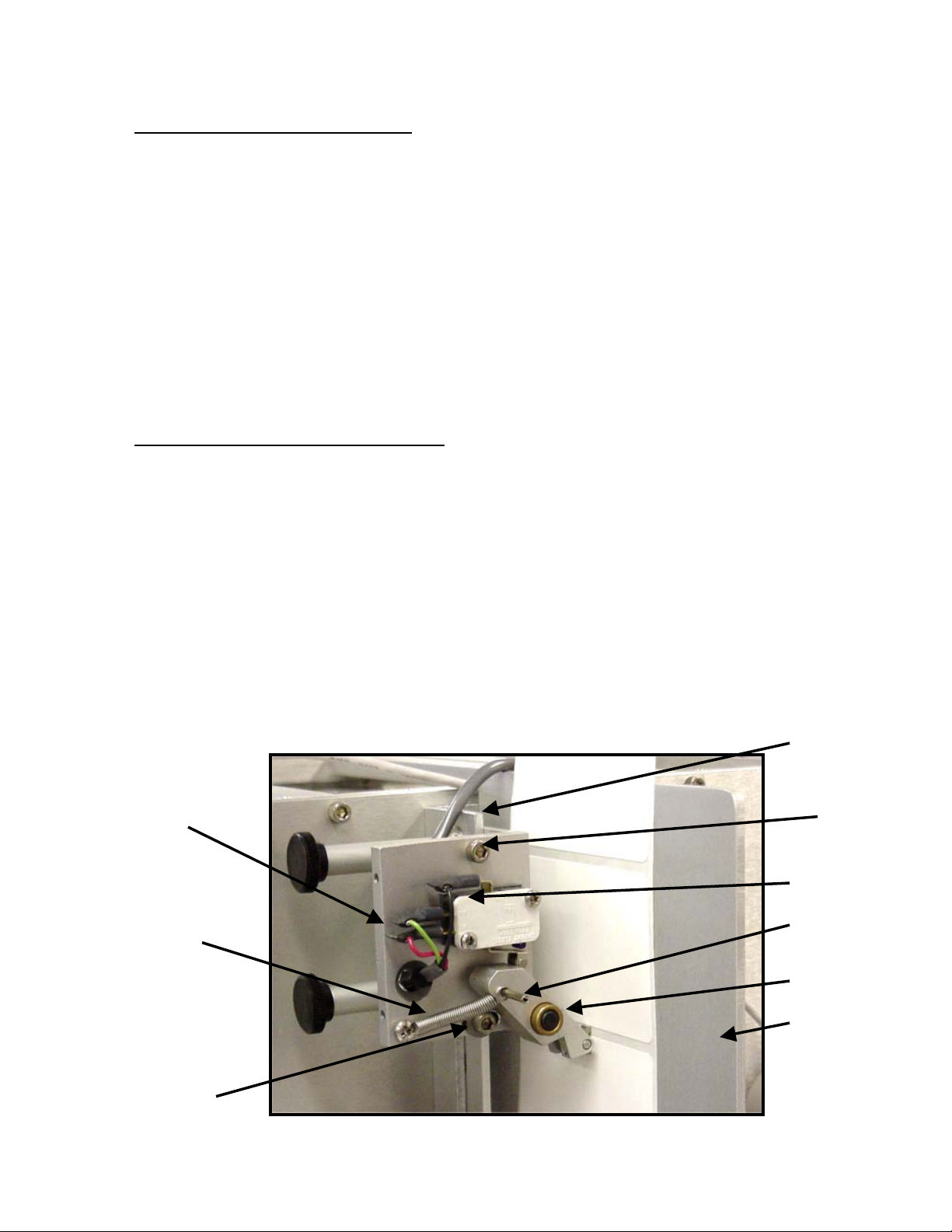

LOWER “HALL EFFECT” SENSOR (OPTIONAL)

Some L60 tamp label applicators are equipped with two sensors that are attached to

the air cylinder. One is located at the top of the cylinder and the other is located

below it. The upper sensor sends a signal to the machine so another label will be

dispensed onto the vacuum head. The lower sensor can be adjusted to control or

limit the stroke of the air cylinder that returns the vacuum head to the home position.

The lower sensor is the only one that may require adjustment.

Hall effect

sensors.

Hall effect

connections.

Fig 11

Fig 10

Adjusting the Lower “Hall Effect” Sensor:

1. With Main switch “On” and Motor switch “Off”.

2. Disconnect air supply or turn tamp regulator “Off”.

3. Bring Tamp Head down to new product height.

4. Loosen Phillips screw on Hall Effect Sensor.

5. Slide sensor to top of cylinder, then down until the indicator light on the sensor

lights up.

6. Tighten the Phillips screw on the sensor.

Page 13

Page 14

“SMART HEAD” (OPTIONAL)

The Smart Head is used if there is a variation in height of the product or the location

of the product on the conveyor cannot be controlled. Simply put, the air cylinder is

going to travel it makes contact with the product. A “smart head“ vacuum head is

constructed so that the pad that holds the label compresses when the label is

applied. When a sensor detects a specific amount of compression, it sends a signal

to the machine telling the air cylinder to return the vacuum head to the home

position.

Sensor

Fig 12

Fig 13

“Smart head”

connection plug

Page 14

Page 15

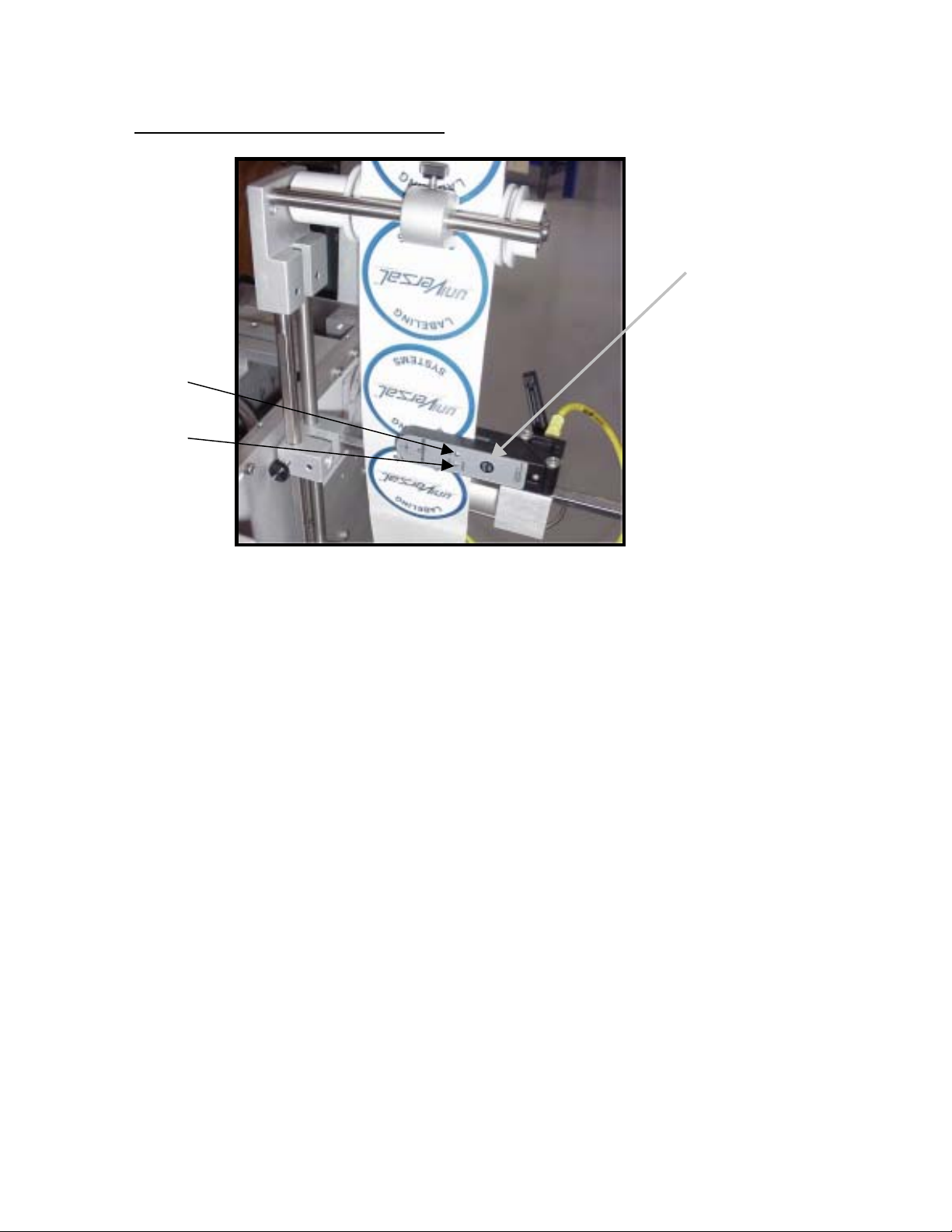

EXPLANATION OF LABEL TRANSFER

As the label is being peeled, it should first contact the center of the bevel on the

Vacuum Head. This will deflect the label slightly downward. The air from the Air

Assist Tube will keep the label up against the face of the Vacuum Head.

NOTE: The label is deflected downward so that after it is transferred to the head, it

will be resting in a position below the peeler plate edge. This is done so the label

will not contact the peeler plate edge, as it is being tamped or blown onto the

product.

Label

deflecting

off center

of bevel

Fig 14

With the product sensor plugged into the proper receptacle, you can cycle the

applicator by breaking the beam (photo eye) or tripping the foot switch or micro

switch in the fixture. The foot or micro switch in the fixture are used when the L60 is

operated as a semi-automatic labeling device, while a photoelectric switch is used

when the L60 is mounted in line for automatic label application. When activated, the

motor will be turned on and the air will rush through the Air Assist Tube assisting the

label transfer. The amount of air rushing through the tube is most critical to a

smooth transfer and ultimately the accuracy of the Label Applicator. All the

applicators are tested at the factory and the Air Assist Tube airflow is set at that time.

However, different label stocks react differently during the transfer process,

therefore, the following procedure should be employed if the proper label transfer

cannot be achieved.

Page 15

Page 16

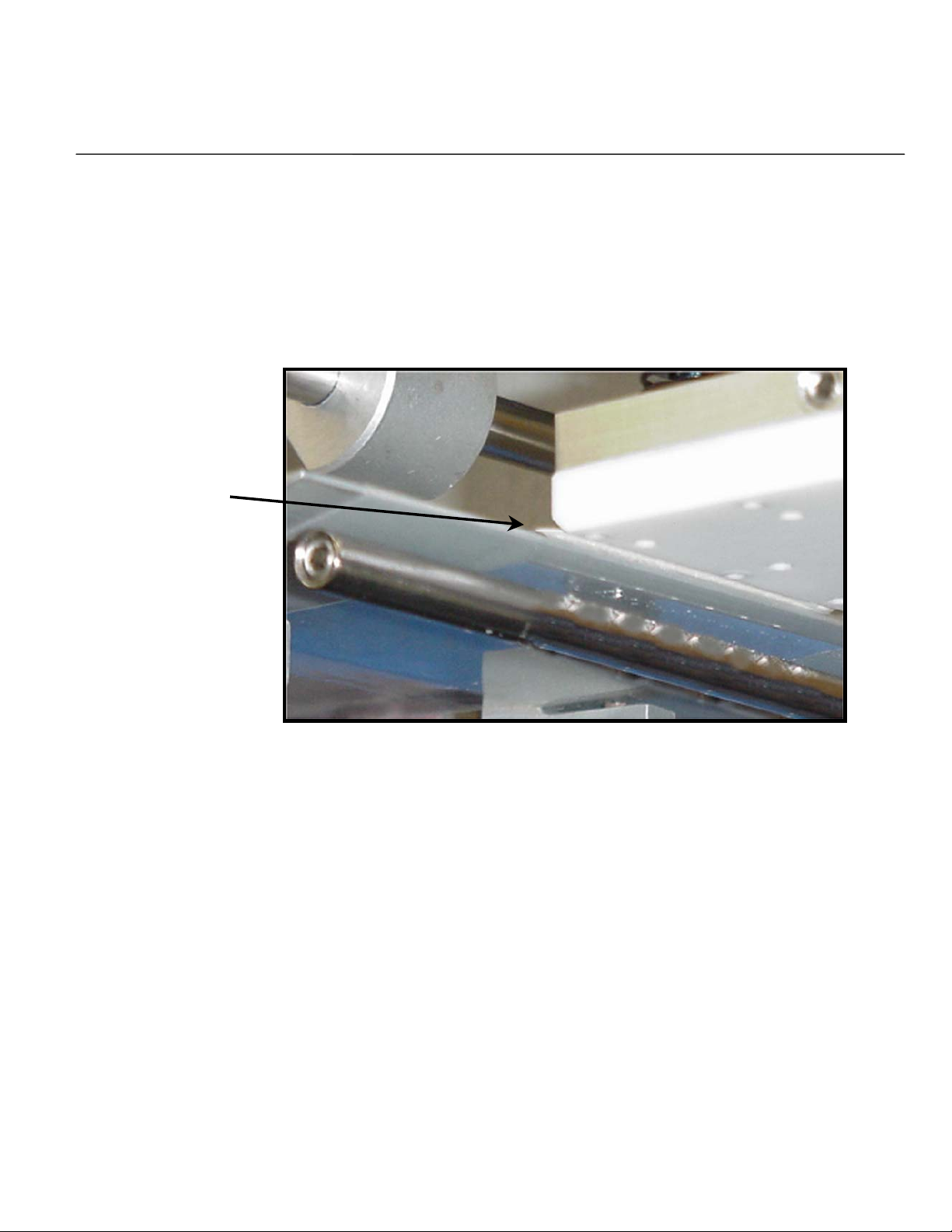

Air

Assist

tube

Air Assist Tube

The Air Assist (Drawing L60-I-30D #26) is a tube with a series of holes through

which air rushes assisting the transfer of the label to the Vacuum Tamp or Blow

Head. The air will rush through the tube only when the motor is running and the

label is being peeled and transferred.

Fig 15

It is our experience that as the roll of labels becomes smaller in diameter, some

labels tend to curl after they are peeled from the backing web. The Air Assist tube

blows the label up as it is being peeled, assisting the label onto the Vacuum Head. It

is regulated by a needle valve

Assist Tube on the front of the machine. This air is supplied by the main incoming

line and is subject to house line pressure. Experience will tell you how much air is

needed to assist the label onto the vacuum head.

Adjusting the Air Assist Tube air pressure

1. Close the needle valve at the end of the Air Assist Tube by turning it clockwise.

2. Cycle the applicator by triggering the Product Switch Assembly.

NOTE: The label will peel, but not transfer to the head.

3. Open the needle valve by turning it counter clockwise ½ turn.

4. Repeat steps 2-3 until the label transfers onto the head with little or no deviation

from a straight-line motion.

(Drawing L60-I-30D #28) attached to the Air

Page 16

Page 17

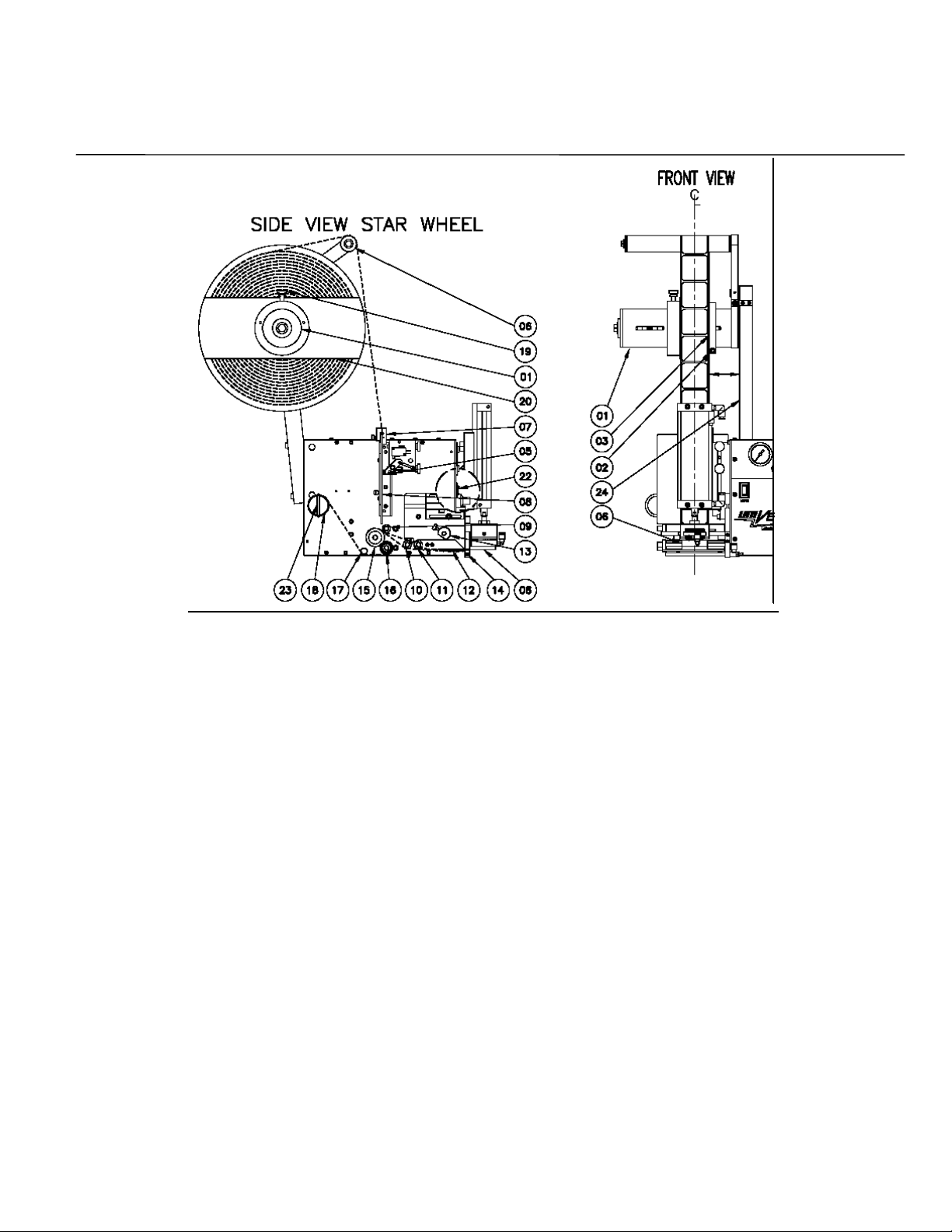

WEBBING THE L60

Fig 16

1. Turn off the Main Power switch (22) on the Front Panel

2. Loosen the black thumbscrew (19).

3. Slide off the removable label retainer (20).

4. Place a roll of labels on the Unwind Hub (01).

5. Loosen the Socket Head Cap Screw (02) on the Clamp of the Unwind

Backing Disc (03) and position the roll of labels so the labels track centered

on the Vacuum Head (06) when peeled off (See FRONT VIEW). (NOTE: For

round or oval labels, it is important that the Star Wheel (05) be on the

centerline of the label).

6. NOTE: If the unit is equipped with photoelectric label sensing or a clear label

sensor, the position of the sensor relative to the label is not critical in most

cases. The clear label sensor detects the difference in thickness from the

label to the backing material. Metalized graphics or alphanumeric characters

will cause this sensor to false trigger. Locate the sensor away from the path

of metalized material. (See SIDE VIEW PHOTO SENSOR)

7. Replace the removable label retainer (20) and tighten thumbscrew (19).

8. Pull the web over the Brake Arm (06) and down between the Web Guides

(07) on the Label Guide Support Plate (08). (NOTE: If equipped with

photoelectric sensor, slide web between white idler roller and web drag (21).

9. Adjust the Web Guides (07), so the web is held with minimum side play but

still moves freely.

Page 17

Page 18

10. Pull the web under the Star Wheel and down between the first Idler Roll (09)

and the Label Guide Support Plate (08), then forward over Idler Roll (10) and

under Idler Roll (11).

11. NOTE: There are 2 Web guides located here also. Adjust them as above in

Step 8.

12. Next, pull the web between the Peeler Plate (12) and the Web Drag (13).

13. Pull the web until approximately 18” extends from the peeler plate, Remove

any labels that are on this part of the web.

14. Bring the web back between the Peeler Plate (12) and Air Assist Tube (14),

under Idler Roll (10) then up around the Drive Roller (15).

15. Push the Drive Roller (15) away from the Nip Roller (16).

16. Slide the web between the Nip Roller (16) and Drive Roller (15), under the

Web Stand-Off Stud (17) then up to the Rewind Spool (18).

17. Secure the web around the Rewind Spool using Web Retention Clip (23) and

turn the Rewind Spool until the web is held firmly. This may require pulling

even more web, which will peel off some labels. Catch these labels so they

don’t stick on something.

18. Grasp the Rewind Spool and turn it counterclockwise for Right Hand, or

clockwise for Left Hand to take up slack in the web.

19. Loosen the thumbscrew on the Web Drag Assembly (13) and apply moderate

pressure by lifting up on the thumbscrew, forcing the thin Web Drag Plate

down on the labels. This will keep the label from buckling as it is fed onto the

vacuum head.

Page 18

Page 19

RUNNING THE L60

1. Turn the main switch ON (01).

2. Turn motor switch ON (02).

3. Connect air supply. CAUTION: This may bring the Tamp Head up abruptly.

Keep fingers clear.

4. Cycle the machine several times (trigger the Product Switch (09)) and

observe the label web tracking. Web tracking should settle to a consistent

line. Once you have determined a consistent line has been achieved, set the

web guides on each side of the web.

NOTE: To ensure the label feeds properly onto the Vacuum Head (04), the Head

(04) must be as close as possible to the edge of the peeler bar (10), without hitting

it.

1. Loosen the two Thumbscrews (05) that hold the Star Wheel Assembly (06).

2. Slide the assembly up until the Star Wheel completely turns over and is down

on a flat side.

3. Next, slide the Star Wheel Assembly (06) up or down until the point of the Star

Wheel (07) catches the lead edge of a label (08).

4. Tighten the Thumbscrews (05).

5. Trigger the Product Switch (09) to dispense a label.

6. It may be necessary to repeat steps 5 several times.

7. It may also be necessary to adjust the air assist blow tube pressure (See Air

Assist Tube on page 9)

NOTE: The position of the label relative to the peeling edge can also be adjusted via

the three-turn dial on the front panel marked “OFF DELAY” if your machine is

equipped with this feature. Release the lock (black tab) and turn clockwise for more

delay.

Fig 17

Page 19

Page 20

LABEL SENSING STAR WHEEL

The star wheel causes the applicator to stop dispensing a label. When the star

wheel is down on a flat side, it will slide over the label until the lead edge of the next

label contacts the point of the wheel causing the wheel to turn over. As it turns up

on a point and back down, the star wheel arm activates a small micro-switch

breaking the circuit, thus stopping the advance of the label web. If the star wheel

arm fails to activate the switch as it turns over the applier will dispense labels

continuously.

NOTE: If the unit is equipped with photoelectric label sensing or a clear label

sensor, the position of the sensors relative to the label is not critical in most cases.

The clear label sensor detects the difference in thickness from the label to the

backing material. Metalized graphics or alphanumeric characters will cause this

sensor to false trigger. Locate the sensor away from the path of metalized material.

Star Wheel Adjustment Procedures

Loosen the two screws (2 and 7), which hold the mounting plate (9) to the mounting

bracket (1). The screw hole (7) is slotted allowing the plate to move toward or away

from the label guide support plate (6). With the star wheel (5) laying flat against the

label web, move the mounting plate (9) in toward the label web as far as it will go.

Then slowly bring it back until the micro-switch (3) activates. (A small “click” will be

heard when this occurs). Tighten the screws (2 and 7) to hold the plate in this

position. To be sure that tightening the screws did not change the position of the

plate, check by raising the star wheel off the label web. A “click” should be heard

when the star wheel is raised and also when it is lowered. A further check should be

made by pulling the label web under the star wheel until it starts to turn up on a

point. A “click” should be heard at this point and also as the star wheel drops back

down onto a flat side. Be sure that the spring (8) is attached to the star wheel arm

(4) as this assures a firm contact of the star wheel to the label.

1

9

2

3

4

8

5

6

7

Fig 18

Page 20

Page 21

DATA LOGIC SENSOR (OPTIONAL)

OUT Light

READY Light

Fig 19

1. Remove one label from the liner to a get a bigger liner area.

2. Move the liner underneath the sensor cross hairs. Push and hold “Auto SET”

button until the green “READY” light turns off. Let go of the button.

3. The “READY” light will begin to flash.

4. Now move the label underneath the cross hairs. Push and hold ”AUTO SET”

button until green “Ready” light turns off. Let go of the button.

5. The “READY” light will now be on solid. The set procedure is now complete. If

you make a mistake or something went wrong, you can repeat the procedure.

6. If the sensor is set up correctly, the “OUT” light should come on in the label gap.

To make sure that it does, move the label around under the cross hairs to see if it

false detects called “hot spots” anywhere on the label.

7. If the sensor detects “hot spots” on the label, repeat steps 1-5 again. This time

when you put the label underneath the sensor put the specific “hot spot” under

the cross hairs.

8. Turning the power on or off does not affect sensitivity. Once the sensor is

programmed the values are burned into the chip inside the sensor.

Auto SET button

Page 21

Page 22

LION SENSOR (OPTIONAL)

Setup Procedure:

1. Remove labels and web from inside the sensor.

2. Center the “Gain Adjust” by turning it four turns Counter-clockwise.

3. Then, turn the “Gain Adjust” back 2 turns clockwise.

4. Set the “Zero Adjust” to a point where the ZERO light starts to come on.

5. While moving labels on the web through the sensor.

Set the “Gain Adjust” to a point where the “Edge” light starts to flash.

6. Keep Turing the “Gain Adjust” ½ turn clockwise.

7. The sensor is now ready to use.

Fig 20

Fig 20A

Gain Adjust

Zero Adjust

Page 22

Page 23

SECTION 3 MAINTENANCE

STARWHEEL MAINTENANCE

After continued use, the starwheel label sensor may become fouled with glue and

the points could become dull enough so that it might fail to catch the leading edge of

a label, thus allowing more than one label to be dispensed. It should be cleaned and

sharpened as follows:

Remove the 3 screws that hold the plastic black cover. Remove the starwheel pivot

assembly and clean the starwheel with mineral spirits, lighter fluid, etc., until the

wheel turns freely. If the points are dull, sharpen by placing the assembly flat on a

piece of crocus cloth or other very fine emery clothes or paper. (See illustration

below). Gently hone the points by moving the assembly in one direction until all the

points are sharp, i.e.. If you do 10 strokes on one side, do 10 strokes on the other

three sides. This will keep the starwheel concentric. Lightly oil the wheel, making

sure it turns freely before reinstalling.

Fig 21 Fig 22

Remove 3 Pan head

screws

Hone direction

Fig 23

Page 23

Remove spring and slide

Star wheel assembly off.

Hold Index finger on top

of star to keep it steady.

Page 24

GENERAL MAINTENANCE

The Drive Roll (Drawing L60-I-00D #06) should be kept clean to avoid slippage.

This can affect the label transfer onto the Vacuum Head. Clean with lacquer thinner,

alcohol or similar cleaner to remove glue build-up.

Fig 24

The Rewind Assembly should be set just tight enough to rewind the waste web.

Adjusting the tension of the Rewind Assembly is accomplished by:

1. Loosening the nut that secures the Slip Clutch Spring Retainer (See Fig 25

below)

2. With a flat head screwdriver, turn the Slip Clutch Spring Retainer clockwise for

more tension, or counter clockwise for less tension.

Nut

Fig 25

Page 24

Page 25

SECTION 4 TROUBLESHOOTING

Symptom:

Label hesitates on delivery.

Solution:

1. Drive Roll dirty. Clean with mineral spirits.

2. Idler Rollers binding. Clean and adjust if necessary.

3. Pulleys loose on shaft. Tighten carefully. Do not strip threads or Allen

wrench receptacle.

4. Drive Belt loose. Tighten Belt Tensioner Assembly.

Symptom:

Label does not always peel from backing web.

Solution:

Try increasing the Web drag tension device.

Symptom:

Label hangs up on peeler bar edge when tamping or blowing onto product.

Solution:

1. Try reducing or increasing the vacuum.

2. Check the air assist pressure.

3. Check the distance from the Vacuum head and peeler edge making sure

4. Check Air supply.

5. Check Solenoid valves.

6. Make sure the Air regulators are turned on.

7. Adjust Vacuum Head. (See page 29)

they are not too close.

Page 25

Page 26

TROUBLESHOOTING (continued)

Should malfunctions occur, the following procedure should determine where the

problem is:

1. Remove label web from the machine.

2. Turn the switches “ON”.

3. Trip the product-sensing switch. The drive roll should start turning.

4. Slide the label web down under the star wheel, or (through the photo electric or

clear label sensor) until the star wheel turns up on a point and back down. The drive

roll should stop turning. If the L60 is equipped with photoelectric label sensing or a

clear label sensor, pass the label through the opening until the motor stops.

Drive Roll does not START, check the following:

1. Is the product-sensing switch plugged in side panel?

2. Is the product sensing switch malfunctioning? Check for make and break of

switch; listen for relay operation of electric eye.

3. Is the power module plugged into its receptacle securely? The power module is

found on the back of the front panel, inside the machine, and can be seen by

removing the top cover.

Drive Roll fails to STOP when star wheel turns over:

1. Remove three screws and pull off star wheel cover (See page 13). Lift up and let

down star wheel by hand; if drive roller still turns, remove spring from pin on star

wheel arm and pull Star Wheel Pivot Arm Assembly off. Activate the switch by hand.

If drive roll still turns, check for make and break with ohmmeter, and replace if

necessary.

2. Check quick disconnect connections for proper contact.

3. If Drive Roll stops when the switch is operated by hand, replace the star wheel

and adjust the star wheel assembly by loosening the two screws that hold the

backing plate and move it to a position where the star wheel will open the switch

when it turns on a point. (See page 12 for star wheel adjustment procedures).

If these adjustments fail to correct the problem, reset the power module. This can

be accomplished by removing front panel. Make sure that you ground yourself

before touching the circuit board. Static electricity can damage the board. Place

fingers on each side of circuit board. (DO NOT TOUCH ELECTRICAL

COMPONENTS ON BOARD.) Move board side to side and push down to be sure

board is seated in contacts on bottom.

Page 26

Page 27

TROUBLESHOOTING (continued)

1. Is machine receiving power from power source? Check the outlet with a

voltmeter.

2. Are all electrical connections in place and tight?

3. Does motor and drive train turn freely? (Turn machine off and turn drive roll by

hand.)

4. Is machine webbed correctly? (Check webbing diagram)

5. Are drive roll and star wheel clean and operating properly?

6. Is any wiring frayed, chafed, or broken?

7. Is Belt Tensioner Assembly at correct tension? (Taunt)

8. Are adjusting screws and studs tight?

9. Are pulleys tight on shafts? Tighten set screws carefully avoid stripping threads.

And /or Allen wrench receptacle.

Page 27

Page 28

TROUBLESHOOTING (Registration)

Normally, at average speeds, the Applicator will hold registration to within plus or

minus 1/32nd inch.

Variations of more than those limits are normally caused by:

Problem 1:

Label web binding.

Solution:

Check Web Guides (Drawing L60-I-60D #09 & #10) and Unwind Assembly

(Drawing UWA-13R-I-00), for proper clearance. Is peeler tape worn? (Drawing

L60-I-30D #29)

Problem 2:

Drive Roll glazed (Drawing L60-I-00D #06) and slippery or covered with labels or

glue.

Solution:

Clean with mineral spirits, lacquer thinner, alcohol, or other solvent.

Problem 3:

Drive Roll not parallel to Lower Idler Roller (Drawing L60-I-00D #06 & L60-I-10D

#05).

Solution:

Turn motor switch “off” and remove label web from Drive Roll and Idler Roller. Push

the Drive Roll away from the idler Roller and place two narrow strips of paper

between the Drive Roll and Idler Roller at each end of the drive roll. Release the

Drive Roll. The two strips, now trapped between the rolls, should have the same

“drag” when the strips are pulled in opposite directions. If not, adjustment is made

by loosening two bolts on the outside back of the machine, at the opposite end of

the Drive Roll Shaft and moving forward and back as required.

Page 28

Page 29

SECTION 5 TECHNICAL

VACUUM HEAD FUNDAMENTALS

Fig 26`

Variables Affecting Vacuum Head Performance

C = as small as possible w/o the Vacuum Head hitting the Peeler Plate (typically

1/32”).

V = Enough Vacuum Pressure to hold the Label on w/o inhibiting label advance.

O = enough to deflect label slightly downward (typically 1/32”).

P = Enough Air Pressure to force label up and onto Vacuum Head.

α = Direct Air Assist Tube so Leading edge of label remains in contact with Vacuum

Head during label advancement.

Page 29

Page 30

TECHNICAL SUPPORT

When calling for Technical Support:

have your Model #: L60

and the Serial Number ready (located on the side opposite the roll of labels).

Email: fjones@universal1.com

Web Site: http://www.universal1.com

Page 30

Page 31

DRAWINGS AND BILL OF MATERIALS

MAIN ASSEMBLY

See Drawing L60-I-00D

FRONT SIDE PANEL ASSEMBLY

See Drawing L60-I-10D

REAR SIDE PANEL ASSEMBLY

See Drawing L60-I-20D or L60-I-20D1**

BELT TENSIONER ASSEMBLY

See Drawing SL1-I-20

TAMP ASSEMBLY

See Drawing L60-I-30D

BLOW ASSEMBLY

See Drawing L60-I-31D

GAUGE ASSEMBLY

See Drawing L60-I-40D

FRONT PANEL ASSEMBLY

See Drawing L60-I-50D

FRONT PANEL (PLC) ASSEMBLY

See Drawing L60-I-51D

GUIDE ASSEMBLY

See Drawing L60-I-60D

VALVE ASSEMBLY

See Drawing L60-I-70D

UNWIND ASSEMBLY

See Drawing UWA-13R-I-00

WEBBING DIAGRAM

See Drawing L60-W-00D

TAMP PNEUMATIC DIAGRAM

See Drawing L60-P-00D

BLOW PNEUMATIC DIAGRAM

See Drawing L60-P-01D

LION EYE OPTICAL LABEL SENSOR ASSEMBLY

See Drawing OLS-I-04

DATA LOGIC OPTICAL LABEL SENSOR ASSEMBLY

See Drawing OLS-I-05

RECOMMENDED SPARE PARTS

See List

POWER MODULE SETUP SHEET

See Drawing L15-D-02

ELECTRICAL DIAGRAM

See Drawing L60-E-00D or L60-E-00D1**

ELECTRICAL DIAGRAM (PLC)

See Drawing L60-E-01D or L60-E-01D1**

** Note: If your “serial number” ends with D1 then look at the drawings above that end in D1.

Page 31

Page 32

Bill of Material

(D)

A

)

A

)

A

)

A

)

A

)

A

)

A

)

)

A

A

)

A

)

)

A

)

A

)

A

)

A

)

A

)

L60 LABEL APPLICATOR

L60

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01

02(D

02(D

03(E

04 L-128-C CLIP, (4-1/2 WEB) RETENTION 1

04(B

05 L-128-D SPOOL, (4-1/2 WEB) REWIND 1

05(B

06 L-137-D ROLL, DRIVE 1

07(D

08(D

08(A)(D

09 100234 FTNG, EXHAUST MUFFL ER 2

10 L60-0018

11 L-154-C-02 COVER, TOP REAR SS 1

12 L-153-C-02 COVER, TOP CENTER SS 1

13 L-152-C-02 COVER, TOP FRONT SS 1

14 L-108-T1 BAR, REAR ACCESSORY MOUNTING 1

15 L60-1014 SPACER, MOUNT 2

16 L60-1013 MOUNT, 4 STATION BASE 1

17(D

18 SC-006 COLLAR, SET .376 X .62 X .250 3

19 L-139-P-2 SHAFT, REW I ND 1

20 200255 STRIP, 12 TERMINAL EURO 1

21 L-172-01 WASHER, ALUM. 062 x 375 x 625 2

22 L-212 BLOCK, INBOARD REWIND BEARING 1

23 L-172-02 WASHER, UHMW 031 X 375 X 625 1

24 L-140-F-3 COLLAR, REWIND SLIP 1

25 L60-0028 SHAFT, (4-1/2 WEB) DRIVE 1

25(B

26 L-108-T BAR, ACCESSORY MOUNTING 1

27(D

27(D

28 L-155-C-02 COVER, BOTTOM SS 1

29 L-114-T BAR, LOWER REAR TIE 1

30 L-113-T BAR, LOWER FRONT TIE 1

31(D

32(D

32(C)(D

L60-I-60D

L60-I-30D

L60-I-31D

VH-L60

L-128-CL-128-DL60-I-10D

UWA-13R-I-00ASSEMBLY, R. H. 13" UNWIND 1

UWA-13L-I-00

L60-I-70D

L60-0028-W SHAFT, (6-1/2 WEB) DRIVE 1

L60-I-20D

L60-I-20D1

L60-I-40D

L60-I-50D

L60-I-51D

SSEMBLY, GUIDE 1

SSEMBLY, TAMP 1

SSEMBLY, BLOW 1

SSEMBLY, L-60 VACUUM HEAD 1

CLIP, (6-1/2 WEB) RETENTION 1

SPOOL, (6-1/2 WEB) REWIND 1

SSEMBLY, FRONT SIDE PANEL 1

SSEMBLY, L. H. 13" UNWIND 1

PANEL, BACK 1

SSEMBLY, VALVE 1

SSEMBLY, REAR SIDE PANEL 1

SSEMBLY, REAR SIDE PANEL 1

SSEMBLY, GUAGE 1

SSEMBLY, FRONT PANEL 1

SSEMBLY, FRONT PANEL (PLC

1

(A) = Left Hand Machine

(B) = Wide Label

(C) = PLC Models

(D) = See Drawing

(E) = Custom, Per Label Size

F:\LABELERS\L-60\MANUAL\L60-I-00D.dwg

Page 33

Page 34

Bill of Material

)

)

)

)

)

)

A

)

A

)

A

)

A

A

)

A

)

)

)

)

)

)

)

ASSEMBLY, FRONT SIDE PANEL

L60

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 SC-006 COLLAR, SET .376 X .62 X .250 6

02 L-172-02 WASHER, UHMW 031 X 375 X 625 4

03 L60-0036 ROLL, (4-1/2 WEB) UPPER IDLER 2

03(A

04 L-121-D STUD, (4-1/2 WEB) STAND OFF 1

04(A

05 L-143 ROLLER, 3" LOWER IDLER (ALUM.

05(A

06 L60-0093 PANEL, FRONT SIDE 1

06(D

07 L60-0008 BAR, COVER SUPPORT 1

08 L60-0007R

08(A

08(B

08(C

09 L60-0008A BAR, COVER SUPPORT 1

10 L-167 BLOCK, COMP SPRING RETAINING 1

11 L-165 FOLLOWER, SPRING 1

12 420185 SPRING,.42X1-1/2 COMP MW 1

13 L-104-FR

13(B

14 L-172-03 WASHER, UHMW 062 X 380 X 625 1

15 L-172-04 WASHER, UHMW 125 X 380 X 625 1

16 856002 RING, 3/8" EXT. RETAINING 1

17(F

18(F

18(A)(F

19 L-162 SUPPORT, TOP COVER 1

20 200009 RELAY, 12VDC 10AMP DPDT 1

21 200011 SOCKET, 10 AMP RELAY 1

22 MD-722 BRACKET, RELAY 1

23 200028 CONNECTOR, MALE 9 PIN MOLEX 1

23(E

24 L-151-M-R BRACKET, RIGHT MOLEX CONNECTOR 1

24(B

24(E

25 L-133-P STUD, PIVOT ARM 1

26 L-144-M-1 BLOCK, WITH BEARING 1

27 L-123-M BRACKET, UNWIND MOUNTING 1

28(F

(A) = Wide Label

(B) = Left Hand Machine

(C) = Left Hand Wide Label

(D) = Stainless Steel Machine

(E) = PLC Models

(F) = Reference Only

L60-0037 ROLL, (6-1/2 WEB) UPPER IDLER 2

L-121-D-1 STUD, (6-1/2 WEB) STAND OFF 1

L-143-1 ROLLER, 6" LOWER IDLER (ALUM.

L60-0093S PANEL, STAINLESS FRONT SIDE 1

SS'Y, (4-1/2 WEB) RH IDLER 1

L60-0007RW

L60-0007L

L60-0007LW

L-104-FL

SC-006 COLLAR, SET .376 X .62 X .250 2

L60-0028 SHAFT, (4-1/2 WEB) DRIVE 1

L60-0028-W SHAFT, (6-1/2 WEB) DRIVE 1

200148 CONNECTOR, MALE 12 PIN MOLEX 1

L-151-M-L BRACKET, LEFT MOLEX CONNECTOR 1

SL1-005 BRACKET, MOLEX CONNECTOR 1

L-139-P-2 SHAFT, REWIND 1

SS'Y, (6-1/2 WEB) RH IDLER 1

SS'Y, (4-1/2 WEB) LH IDLER 1

SS'Y, (6-1/2 WEB) LH IDLER 1

SS'Y, RIGHT PIVOT ARM 1

SS'Y, LEFT PIVOT ARM 1

1

1

F:\LABELERS\L-60\MANUAL\L60-I-10D.dwg

Page 35

Page 36

Bill of Material

(D)

A

)

)

)

A

)

)

A

A

A

)

A

ASSEMBLY, REAR SIDE PANEL

L60

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01

02 SL1-023

03 400010 RETAINER, 3/8" HARDENED BRNG. 2

04 400009 BEARING, 3/8" THRUST 1

05 420170 SPRING, .54 X 1.5 COMP. S.STL 1

06 L-140-F RETAINER, SLIP CLUTCH SPRING 1

07 L-140-F-1 BLOCK, SLIP CLUTCH RETAINER 1

08 100345 FTNG, SWVL EL 1/8 X 1/4" 9

09 100300 REGULATOR, AIR 2

10 100299 FTNG, 1/8" NPT BLACK PLUG 6

11(D

11(A)(D

12 210065 RELIEF, BANNER STRAIN 1

13 300066 MOTOR, AC SYNC SUPERIOR 1

14 L60-0029B PULLEY, DRIVE 1

15 600184 BELT, TIMING 1

16 L60-0089 ROLLER, IDLER 1

17 L60-0008 BAR, COVER SUPPORT 2

18 L-172-16 WASHER, UHMW 063 X 505 X 750 3

19 SC-007-1 COLLAR, SET .501 X .75 X .297 1

20 L60-0088 MANIFOLD, AIR 1

21 100373 FTNG, STRT 1/4 X 3/8 2

22 400165 PULLEY, 30XLB037 TIMING 1

23 SC-006 COLLAR, SET .376 X .62 X .250 1

24 L-144-M-1 BLOCK, WITH BEARING 1

25 SL1-019 STUD, MOTOR STAND-OFF 3

26(B

27 100250 FILTER, VACUUM WITH 1/4" FTGS 1

28 100251 ELEMENT, FILTER (REPLACEMENT

29 L60-0026 BRACKET, CAPACITOR 1

30 200117 CAPACITOR, 15VF 370VAC 1

31 L60-0094 PANEL, REAR SIDE 1

31(C

32 100125 VACUUM EJECTOR W/1/4" PORTS 1

33 L-162 SUPPORT, TOP COVER 1

34 200032C

35 200015

36 200019

37 UNIV-02 PLATE, UNIVERSAL SERIAL NUMBER 1

38 100321 NUT, PANEL MOUNT AIR REGULATOR 2

39 100415-120

40 100211 FTNG, 1/8 TO 1/4 STRT CONN. 1

L-140-F-3 COLLAR, REWIND SLIP 1

SS'Y, REWIND HUB 1

L60-0028 SHAFT, (4-1/2 WEB) DRIVE 1

L60-0028-W SHAFT, (6-1/2 WEB) DRIVE 1

SL1-I-20

L60-0094S PANEL, STAINLESS REAR SIDE 1

SS'Y, BELT TENSIONER 1

SS'Y, PRODUCT SWITCH 1

MPHENOL, 4 PIN FEMALE 1

MPHENOL, 6 PIN (FEMALE

IRLINE, 3/8" X 10'CLEAR 1

1

1

(A) = Wide Label

(B) = See Drawing

(C) = Stainless Steel Machine

(D) = Reference Only

F:\LABELERS\L-60\MANUAL\L60-I-20D

Page 37

Page 38

Bill of Material

(D)

A

)

)

)

A

)

)

A

A

A

)

A

ASSEMBLY, REAR SIDE

L60

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01

02 SL1-023

03 400010 RETAINER, 3/8" HARDENED BRNG. 2

04 400009 BEARING, 3/8" THRUST 1

05 420170 SPRING, .54 X 1.5 COMP. S.STL 1

06 L-140-F RETAINER, SLIP CLUTCH SPRING 1

07 L-140-F-1 BLOCK, SLIP CLUTCH RETAINER 1

08 100345 FTNG, SWVL EL 1/8 X 1/4" 9

09 100300 REGULATOR, AIR 2

10 100299 FTNG, 1/8" NPT BLACK PLUG 6

11(D

11(A)(D

12 210065 RELIEF, BANNER STRAIN 1

13 300066-TEMP MOTOR 1

14 L60-0029B PULLEY, DRIVE 1

15 600184 BELT, TIMING 1

16 L60-0089 ROLLER, IDLER 1

17 L60-0008 BAR, COVER SUPPORT 2

18 L-172-16 WASHER, UHMW 063 X 505 X 750 3

19 SC-007-1 COLLAR, SET .501 X .75 X .297 1

20 L60-0088 MANIFOLD, AIR 1

21 100373 FTNG, STRT 1/4 X 3/8 2

22 400165 PULLEY, 30XLB037 TIMING 1

23 SC-006 COLLAR, SET .376 X .62 X .250 1

24 L-144-M-1 BLOCK, WITH BEARING 1

25 SL1-019 STUD, MOTOR STAND-OFF 3

26(B

27 100250 FILTER, VACUUM WITH 1/4" FTGS 1

28 100251 ELEMENT, FILTER (REPLACEMENT

29 210118 RESISTOR, KIT 1

30 L60-0095 PLATE, CAPACITOR/RESISTOR MNT. 1

31 L60-0094 PANEL, REAR SIDE 1

31(C

32 100125 VACUUM EJECTOR W/1/4" PORTS 1

33 L-162 SUPPORT, TOP COVER 1

34 200032C

35 200015

36 200019

37 UNIV-02 PLATE, UNIVERSAL SERIAL NUMBER 1

38 100321 NUT, PANEL MOUNT AIR REGULATOR 2

39 100415-120

40 100211 FTNG, 1/8 TO 1/4 STRT CONN. 1

41 210119 CAPACITOR 1

42 100250-1 MOUNT, FILTER 1

L-140-F-3 COLLAR, REWIND SLIP 1

SS'Y, REWIND HUB 1

L60-0028 SHAFT, (4-1/2 WEB) DRIVE 1

L60-0028-W SHAFT, (6-1/2 WEB) DRIVE 1

SL1-I-20

L60-0094S PANEL, STAINLESS REAR SIDE 1

SSY. BELT TENSIONER 1

SS'Y, PRODUCT SWITCH 1

MPHENOL, 4 PIN FEMALE 1

MPHENOL, 6 PIN (FEMALE

IRLINE, 3/8" X 10'CLEAR 1

1

1

(A) = Wide Label

(B) = See Drawing

(C) = Stainless Steel Machine

(D) = Reference Only

F:\LABELERS\L-60\MANUAL\L60-I-20D1.dwg

MSACCESS X:\SALES\BOM

Page 39

Page 40

Bill of Material

ASSEMBLY, BELT TENSIONER

L60

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 430140 BUSHING, 313 X 250 X 750 1

02 L-132-P-2 PIN, IDLER ROLL 1

03 L-132-P-1 BRACKET, IDLER ASSY 1

04 856001 RING, 1/4" EXT. RETAINING 1

05 L-172-09 WASHER, UHMW 032 X 257 X 500 1

06 400015 BEARING, 1/4" ROLLER 2

F:\LABELERS\SL-1000\MANUAL\SL1-I-20.dwg

Page 41

Page 42

Bill of Material

)

)

A

)

)

A

)

)

)

)

)

A

)

)

)

)

A

)

)

)

)

)

ASSEMBLY, TAMP

L60

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 SS-115 GUSSET, SUPPORT 1

02 L60-0036 ROLL, (4-1/2 WEB) UPPER IDLER 1

02(B

03 L-172-02 WASHER, UHMW 031 X 375 X 625 2

04 850041T THUMBSCREW, 8-32 X 5/8" 1

05 L60-0010 PLATE, SIDE RAIL PEELER 1

06 MP-2500-9 PLATE, WEB DRAG PRESSURE 1

07 L60-0035 BLOCK, WEB DRAG 1

08 L60-0011 SHAFT, WEB DRAG 1

08(B

09 L-150-209(B

10 L60-0003A BRACKET, AIR CYLINDER MOUNTING 1

10(B

11 L60-0003B BRACKET, AIR CYLINDER ADJUST 1

12 L-105-DA

11(E

13 L60-0019 PLATE, RH (4-1/2 WEB) PEELER 1

13(B

13(A

13(C

14 210052-1B

15 L60-0092 CUSHION, 1/8 X 3/8 X 2 1

16 L60-0091 CUSHION, 1/8 X 3/8 X 3/4 2

17 L60-0090 CUSHION, 1/8 X 3/8 X 1-1/2 1

18 L60-0062 BRACKET, L60 VACUUM HEAD 1

19 100078 FTNG, METRIC ELBOW 2

20(D

20(D

20(D

20(D

21 100071C

22(D

22(D

22(D

23 L60-0060 BRACKET, AIR CYLINDER ADJUST 1

24 400098 WASHER,1/2 FLAT S.S. 1

25 851001 SCREW, 1/2-13 X 1" HHMS 1

26 L60-0014 TUBE, 5" AIR ASSIST 1

26(B

27 L60-0013 BRACKET, BLOW TUBE MNTG. 1

28 100326 VALVE, METER-IN 1/4" X 10-32 1

29 600300-4.50 UHMW, TAPE, 1" x 4-1/2" 1

29(B

30 L60-0009 PLATE, SW ING 1

(A) = Left Hand Machine

(B) = Wide Label

(C) = Left Hand Wide Label

(D) = Per Stroke Size

(E) = When Needed

L60-0037 ROLL, (6-1/2 WEB) UPPER IDLER 1

L60-0011-W SHAFT, WEB DRAG 1

BAR, (4-1/2 WEB) PEELER TIE 1

L-150-2-B BAR, (6-1/2 WEB) PEELER TIE 1

L60-0003W BRACKET, (6-1/2" WEB) AIR CYL. 1

SS'Y, WEB GUIDE CLAMP 2

L60-0003F BRACKET,LONG LABEL (2'-8'

L60-0019-W PLATE, RH (6-1/2 WEB) PEELER 1

L60-0020 PLATE, LH (4-1/2 WEB) PEELER 1

L60-0020-W PLATE, LH (6-1/2 WEB) PEELER 1

SSY. PROX SENSOR W/ CONNECTOR 1

100027 CYLINDER, SMC 2" STROKE 1

100025 CYLINDER, SMC 4" STROKE 1

100070 CYLINDER, SMC 6" STROKE 1

100026 CYLINDER, SMC 8" STROKE 1

SSY. PROX SENSOR W/ CONNECTOR 1

L60-0061E PLATE, 2 & 4" CYL. MOUNTING 1

L60-0061 PLATE, 6" CYLINDER MOUNTING 1

L60-0061A PLATE, 8" CYLINDER MOUNTING 1

L60-0014-W TUBE, 7" AIR ASSIST 1

600300-6.75 UHMW, TAPE, 1" x 6-3/4" 1

1

F:\LABELERS\L-60\MANUAL\L60-I-30D.dwg

Page 43

Page 44

Bill of Material

)

)

A

)

A

)

A

A

)

)

)

)

A

)

)

ASSEMBLY, BLOW

L60

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 SS-115 GUSSET, SUPPORT 1

02 L60-0036 ROLL, (4-1/2 WEB) UPPER IDLER 1

02(B

03 L-172-02 WASHER, UHMW 031 X 375 X 625 2

04 850041T THUMBSCREW, 8-32 X 5/8" 1

05 L60-0010 PLATE, SIDE RAIL PEELER 1

06 MP-2500-9 PLATE, WEB DRAG PRESSURE 1

07 L60-0035 BLOCK, WEB DRAG 1

08 L60-0011 SHAFT, WEB DRAG 1

08(B

09 L-150-209(B

10 L60-0003

10(B

11 L60-0003B BRACKET, AIR CYLINDER ADJUST 1

12 L-105-D

13 L60-0019 PLATE, RH (4-1/2 WEB) PEELER 1

13(B

13(A

13(C

14(D

15 L60-0061B PLATE, VACUUM HEAD MOUNTING 1

16 L60-0060 BRACKET, AIR CYLINDER ADJUST 1

17 400098 WASHER,1/2 FLAT S.S. 1

18 L60-0054 BRACKET, BLOW TUBE MNT 1

19 L60-0014 TUBE, 5" AIR ASSIST 1

19(B

20 L60-0054 BRACKET, BLOW TUBE MNT 1

21 100326 VALVE, METER-IN 1/4" X 10-32 1

22 600300-4.50 UHMW, TAPE, 1" x 4-1/2" 1

22(B

23 L60-0009 PLATE, SWING 1

L60-0037 ROLL, (6-1/2 WEB) UPPER IDLER 1

L60-0011-W SHAFT, WEB DRAG 1

BAR, (4-1/2 WEB) PEELER TIE 1

L-150-2-B BAR, (6-1/2 WEB) PEELER TIE 1

BRACKET, AIR CYLINDER MOUNTING 1

L60-0003W BRACKET, (6-1/2" WEB) AIR CYL. 1

SS'Y, WEB GUIDE CLAMP 2

L60-0019-W PLATE, RH (6-1/2 WEB) PEELER 1

L60-0020 PLATE, LH (4-1/2 WEB) PEELER 1

L60-0020-W PLATE, LH (6-1/2 WEB) PEELER 1

VH-L60-B

L60-0014-W TUBE, 7" AIR ASSIST 1

600300-6.75 UHMW, TAPE, 1" x 6-3/4" 1

SS'Y, BLOW VACUUM HEAD 1

(A) = Left Hand Machine

(B) = Wide Label

(C) = Left Hand Wide Label

(D) = Custom, Per Label Size

F:\LABELERS\L-60\MANUAL\L60-I-31D

MSACCESS X:\SALES\BOM

Page 45

Page 46

Bill of Material

)

)

)

)

)

ASSEMBLY, GAUGE

L60

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 100351 FTNG, 1/4 X 10-32 ELBOW 2

02 100319 GAUGE, PANEL MOUNT PRESSURE 2

03(A

03(B

04(B

05(A

05(B

(A) Tamp Machine

(B) Blow Machine

L60-0017 PANEL, (TAMP) PNUMTIC FRONT 1

L60-0017-B PANEL, (BLOW) PNUMTIC FRONT 1

100310 FTNG, 3/8 BULKHEAD UNION 1

100309 FTNG, 1/4 BULKHEAD UNION 4

100309 FTNG, 1/4 BULKHEAD UNION 2

F:\LABELERS\L-60\MANUAL\L60-I-40D.dwg

MSACCESS X:\SALES\BOM

Page 47

Page 48

Bill of Material

(C)

A

)

A

)

)

)

)

A

A

A

)

A

)

)

A

ASSEMBLY, FRONT PANEL

L60

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01

02(C

03 200057 VARISTOR 1

04 L-100-R2 PANEL, R.H. FRONT 1

04(A

05 200006 SWITCH, DPST ROCKER (MAIN

06 210067 PLUG, 5/16 HOLE 1

07(C

08 200035 RELIEF, 1/8" STRAIN 1

09 200005 HOLDER, PANEL MOUNT FUSE 1

10 200042 FUSE, AGC 3 A 1

11 200036 CORD, 18/3 8FT. SJT POW ER 1

11(B

12 200013

13 200017

14 200007 SWITCH, SPST ROCKER ( MOTOR

15 200029 CONNECTOR, FEMALE 9 PIN MOLEX 1

16 200160 TRANSFORMER, 12-VOLT 1

17 600345

18 L-181-B BRACKET, EDGE CARD 1

19 200022 CONNECTOR, 15 PIN EDGE 1

20 200198 MODULE, POWER 1

21 200023 CLAMP, 1/4" CABLE-AMBER 2

(A) = Left Hand Machine

(B) = Machine on Conveyor

(C) = Optional

200216C

200216B

L-100-L2 PANEL, L.H. FRONT 1

200192 DIAL, 10 TURN POT 3

200279

SS'Y, CYLINDER DWELL TIME 1

SS'Y, TIME DELAY ON / OFF 1

SSY. CONVEYOR POWER CABLE 1

MPHENOL, 3 PIN (FEMALE

MPHENOL, 5 PIN (FEMALE

RUBBER, CIRCUIT CARD BACKING 1

1

2

1

1

F:\LABELERS\L-60\MANUAL\L60-I-50D.dwg

MSACCESS X:\SALES\BOM

Page 49

Page 50

Bill of Material

)

)

)

A

)

)

)

)

A

A

ASSEMBLY, FRONT PANEL (PLC)

L60

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 209021-1 CLIP, RELAY SOCKET 2

02 100541 SUPPLY, 120Vac TO 24Vdc POWER 1

03 240261 PLC, 14I/0 RELAY (AROMAT

04 209020 RELAY, 24VDC 10AMP DPDT 1

05 200228 DIODE 1

06 209021 SOCKET, RELAY 1

07 200314 STOP, DIN RAIL (WAGO

08 200308-4.375 RAIL, 4-3/8" DIN 1

09 L60-0072 PLATE, PLC MOUNTING 1

10 200061 CLAMP, 1/8 CABLE 1

11 200025 CLAMP, 3/8" CABLE-AMBER 1

12 200149 CONNECTOR, FEMALE 12 PIN MOLEX 1

13 200007 SWITCH, SPST ROCKER ( MOTOR

14 200013

15 200057 VARISTOR 1

16 L-100-R2 PANEL, R.H. FRONT 1

16(A

17 200006 SWITCH, DPST ROCKER (MAIN

18 210067 PLUG, 5/16 HOLE 1

19 700050 PLUG, 3/8 HOLE 3

20 200035 RELIEF, 1/8" STRAIN 1

21 200005 HOLDER, PANEL MOUNT FUSE 1

22 200042 FUSE, AGC 3 A 1

23 200036 CORD, 18/3 8FT. SJT POW ER 1

23(B

(A) = Left Hand Machine

(B) = Machine on Conveyor

L-100-L2 PANEL, L.H. FRONT 1

200279

MPHENOL, 3 PIN (FEMALE

SSY. CONVEYOR POWER CABLE 1

1

4

1

3

1

F:\LABELERS\L-60\MANUAL\L60-I-51D

MSACCESS X:\SALES\BOM

Page 51

Page 52

Bill of Material

)

A

A

A

A

)

)

)

)

A

)

)

A

)

ASSEMBLY, GUIDE

L60

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 L-168-A COVER, RIGHT STAR WHEEL 1

01(A

02 430165 BUSHING, 375 X 250 X 750 1

03 L-109-S-3 PIN, STARWHEEL PIVOT ARM 1

04 L-170 PIN, STARWHEEL PIVOT ARM ASSY. 1

05 L-129-S-1 WHEEL, STAR 1

06 200109 SWITCH, MICRO 1

07 L-164 SPACER, MICRO SWITCH 1

08 L-109-S-2

09 L-105-L

10 L-105-RA

11 L-107-D-1 BRACKET, CHANNEL 1

11(B

11(C

12 200016

13 853003 WASHER, 1/4" .050 THK 5/8 ODFW 2

14 L-205 STAND-OFF, STARWHEEL ADJUST 2

15 850007T THUMBSCREW, 1/4-28 X 2-1/4" 2

16 L-107-D-2 PLATE, (4-1/2" WEB) GUIDE SUP. 1

16(B

17 L60-0016 BRACKET, LABEL SENSE MOUNTING 1

17(B

18 856109 PIN, 3/32 X 1 ROLL 1

19 420173 SPRING, 3/16 X 1-1/4 EXTENS SS 1

(A) = Left Hand Machine

(B) = Wide Label

(C) = Left Hand Wide Label

L-168-B COVER, LEFT STAR WHEEL 1

RM, STARWHEEL PIVOT 1

SSY. L.H. WEB GUIDE CLAMP 1

SSY. R.H. WEB GUIDE CLAMP 1

L-107-D-3-R BRACKET, CHANNEL (RIGHT

L-107-D-3-L BRACKET, CHANNEL (LEFT

MPHENOL, 4 PIN (MALE

L-107-D-2-

L60-0016-W BRACKET, W.L. SENSE MOUNTING 1

PLATE, (6-1/2" WEB) GUIDE SUP. 1

1

1

1

F:\LABELERS\L-60\MANUAL\L60-I-60D.dwg

Page 53

Page 54

Bill of Material

)

)

)

)

)

A

)

A

A

)

ASSEMBLY, VALVE

L60

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 100158 BASE, 3 STATION 1

01(D

02(A

02(B

03(B

04(A

04(B

05 100220 FTNG, 1/4M - 1/4 TUBE 2

06 100166 WIRE, LEAD W/COVER 1.5m 2

07 100155

07(C

08 100161 SPACER, SUPPLY 1

09 100163 PLATE, BLANK COVER 1

10 100214 FTNG, 3/8 M TO 1/8 F REDUCER 1

11 100233 FTNG, 1/4" NPT BRASS PLUG 2

12 100345 FTNG, SWVL EL 1/8 X 1/4" 1

13 100175 MANIFOLD, EXHAUSE 1

(A) Tamp Machine

(B) Blow Machine

(C) PLC Models

(D) If Needed

100159 BASE, 4 STATION 1

100162 PLUG, PORT 3

100162 PLUG, PORT 4

100164 FTNG, 3/8 PORT 1

100164

100164

100155 VALVE, 24VDC SOLENOID 2

FTNG, 1/4 PORT 3

FTNG, 1/4 PORT 1

VALVE, 12VDC SOLENOID 2

Note: Quantities can Varie

F:\LABELERS\L-60\MANUAL\L60-I-70D.dwg

Page 55

Page 56

Bill of Material

A

)

ASSEMBLY, R. H. 13" UNWIND

L60

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 UND-001 BAR, LABEL REEL MOUNTING 1

02 UND-002 SHAFT, UNWIND 1

03 UND-003

04 UND-004 SHAFT, BRAKE ARM 1

05 UND-006 BLOCK, BELT FASTENER 1

06 UND-007 CLAMP, BELT 2

07 UND-008 STUD, BRAKE ARM 1

08 UND-009-1 STRAP, BRAKE 1

09 UND-011C HUB, MAIN UNWIND 1

10 UND-013 DISC, REMOVABLE LABEL 1

11 UND-015 DISC, UNWIND BACKING 1

12 UND-038 ROLLER, BRAKE IDLER 1

13 UND-037 BEARING, BRAKE ARM ROLLER 2

14 UND-019 CLAMP, INNER BACKING DISC 1

15 200409 CLIP, CORE (FOR HUB

16 UND-042 CLAMP, OUTER BACKING DISC 1

17 UND-027 BEARING, END CAP ROLLER 1

18 430306 BUSHING, 750 X 500 X 625" 1

19 420210 SPRING, 1/2 X 3.125" EXTENSION 1

20 UND-046 BEARING, END CAP ROLLER 1

21 820000 THUMBSCREW, 1" BLACK NYLON 1

22 400059 BEARING, 5/8" THRUST W/WASHERS 1

23 856005 RING, 1/2" EXT. RETAINING 1

24 853003 WASHER, 1/4" .050 THK 5/8 ODFW 1

25 851002 SCREW, 1/4-20 X 1/2" HHMS 1

26 853001 WASHER, 5/16" FW SS 1

27 851003 SCREW, 5/16-18 X 1/2" HHMS SS 1

28 852001 SCREW, 10-32 X 1/2" FHMS PHIL 6

29 850001 SCREW, 1/4-20 X 1" L SHCS 1

30 850002 SCREW, 10-32 X 1" L SHCS 2

31 854001 NUT, 10-32 HEX 2

32 850003 SCREW, 5/16-18 X 1-1/4" L SHCS 1

33 850006 SCREW, 6-32 X 5/8" L SHCS 2

34 850004 SCREW, 5/16-18 X 1" L SHCS 1

35 852501 SCREW, 4-40 X 1/4" L PHMS PHIL 4

36 854007 NUT, 4-40 HEX SS 4

RM, UNWIND BRAKE 1

4

F:\ACCESSORIES\UND\MANUAL\UWA-13R-I-00.dwg

Page 57

Page 58

Page 59

Page 60

Page 61

Bill of Material

)

)

A

)

A

)

A

ASSEMBLY, LION EYE OPTICAL LABEL SENSOR

L60

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 210077 SENSOR, CLEAR LABEL 1

02 OLS-029 BRACKET, LION MOUNTING 1

03 L-172-03 WASHER, UHMW 062 X 380 X 625 1

04 700015 GUIDE, 1" SPLIT NYLON WEB 2

05 OLS-005-1 SHAFT, SENSOR BRACKET 1

05(A

06 OLS-023 ROLLER, LOWER IDLER 1

06(A

07 L60-0035 BLOCK, WEB DRAG 1

08 OLS-024 PLATE, WEB DRAG PRESSURE 1

09 L-172-02 WASHER, UHMW 031 X 375 X 625 1

10 OLS-021 SHAFT, PINCH ROLLER 1

10(A

11 L60-0011 SHAFT, WEB DRAG 1

11(A

12 OLS-007-1 BRACKET, SLIDE 1

13 OLS-009

14 OLS-008 BRACKET, MOUNTING 1

15 OLS-003 SHAFT, MAIN SUPPORT W/ FLAT 1

16 OLS-004 SHAFT, MAIN SUPPORT 1

17 OLS-015 BUSHING, 500 X 375 HEX. X 1.12 2

18 500081 HANDLE, 10-32 MALE RATCHET 2

(A) = Wide Label

OLS-005-5 SHAFT, SENSOR BRACKET 1

OLS-023

OLS-021

OLS-006 STUD, WEB DRAG STAND-OFF 1

ROLLER, LOWER IDLER 1

SHAFT, PINCH ROLLER 1

BRACKET, WEB SUPPORT 1

F:\ACCESSORIES\OLS\MANUAL\OLS-I-04.dwg

Page 62

Page 63

Bill of Material

A

)

)

A

)

A

)

A

ASSEMBLY, DATA LOGIC OPTICAL LABEL SENSOR

L60

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 OLS-029

02 200376 CABLE, 4-PIN >>> 1

03 OLS-015 BUSHING, 500 X 375 HEX. X 1.12 1

04 200374 SENSOR, DATALOGIC SLOT 1

05 L-172-03 WASHER, UHMW 062 X 380 X 625 1

06 700015 GUIDE, 1" SPLIT NYLON WEB 2

07 OLS-005-1 SHAFT, SENSOR BRACKET 1

07(A

08 OLS-023 ROLLER, LOWER IDLER 1

08(A

09 L60-0035 BLOCK, WEB DRAG 1

10 OLS-024 PLATE, WEB DRAG PRESSURE 1

11 L-172-02 WASHER, UHMW 031 X 375 X 625 1

12 OLS-021 SHAFT, PINCH ROLLER 1

12(A

13 L60-0011 SHAFT, WEB DRAG 1

13(A

14 OLS-007-1 BRACKET, SLIDE 1

15 OLS-009

16 OLS-008 BRACKET, MOUNTING 1

17 OLS-004 SHAFT, MAIN SUPPORT 1

18 OLS-003 SHAFT, MAIN SUPPORT W/ FLAT 1

19 500080 HANDLE, 1/4 MALE RATCHET 1

20 500081 HANDLE, 10-32 MALE RATCHET 1

(A) = Wide Label

OLS-005-5 SHAFT, SENSOR BRACKET 1

OLS-023

OLS-021

OLS-006 STUD, WEB DRAG STAND-OFF 1

BLOCK, MOUNTING 1

ROLLER, LOWER IDLER 1

SHAFT, PINCH ROLLER 1

BRACKET, WEB SUPPORT 1

F:\ACCESSORIES\OLS\MANUAL\OLS-I-05.dwg

Page 64

Page 65

L60 TAMP OR BLOW-ON APPLICATOR

RECOMMENDED SPARE PARTS

PART # PART DESCRIPTION

200160 TRANSFORMER, 12 VAC

100155 VALVE, 24VDC SOLENOID

100155A VALVE, 12VDC SOLENOID

100105 VALVE, 12 VDC 4-WAY AIR

100110 VALVE, 12 VDC 3-WAY MAC AIR

100300 REGULATOR, AIR

100125 VACUUM EJECTOR WITH ¼” PORTS

600300 PEELER PLATE TAPE (50’ ROLL)

200117 CAPACITOR, 15VF 370VAC

200198 POWER MODULE

200109 MICRO SWITCH

240261 PLC, 141/0 RELAY (AROMAT)

200009 RELAY, DPDT 12 VDC 10A

L-105- LA ASSY. LH WEB GUIDE CLAMP

L-105- RA ASSY. RH WEB GUIDE CLAMP

L-128- C CLI P, (4 ½ WEB) RETENTION

L-137- D ROLL, DRIVE

L-143 ROLLER, 3” LOWER IDLER (ALUM)

L-143- D ASSY, LOWER IDLER ROLLER

L-129-S STARWEEL LABEL SENSING

209020 RELAY, 24VDC 10AMP DPDT

100334 CYLINDER, 6” AIR

210052- 1B ASSY. PROX SENSOR WITH CONNECTOR

100541 SUPPLY, 120VAC TO 24VDC POWER

100251 ELEMENT, FILTER (REPLACEMENT)

100070 CYLINDER, SMC 6” STROKE

100071C ASSY. PROX SENSOR WITH CONNECTOR

200010 RELAY, DPDT 12VDC 3A

42 0173 SPRING, STARWHEEL

300066 MOTOR, AC SYNC SUPERIOR

400016 BEARING, 3/8” SEALED

200042 FUSE, AGC 3A

420210 SPRING, UNWIND

200006 ON / OFF SWITCH

60018H BELT, TIMING 200XL037

Page 66

Page 67

Page 68

Page 69

Page 70

Loading...

Loading...