Unitronics UMI-B1 UL Series, UMI-0022BU-B1, UMI-0004BU-B1, UMI-0007BU-B1, UMI-0015EU-B1 Operation Manual

...

UM I-B1 UL Se ri es

Invert er

ww w.un itronicsPLC.com

UMI-B1 UL Series Inverter Contents

Contents

Contents .......................................................................................................................... i

1 Safety precautions ...................................................................................................... 1

1.1 Safety definition ................................................................................................... 1

1.2 Warning symbols ................................................................................................. 1

1.3 Safety guide ......................................................................................................... 2

2 Product overview ........................................................................................................ 5

2.1 Quick start-up ....................................................................................................... 5

2.2 Product specification ............................................................................................ 7

2.3 Name plate ......................................................................................................... 10

2.4 Type designation key ......................................................................................... 10

2.5 Structure diagram............................................................................................... 11

3 Installation guide ...................................................................................................... 12

3.1 Mechanical installation ....................................................................................... 12

3.2 Standard wiring .................................................................................................. 14

3.3 Layout protection ............................................................................................... 19

4 Keypad operation procedure ................................................................................... 21

4.1 Keypad introduction ........................................................................................... 21

4.2 Keypad displaying .............................................................................................. 23

4.3 Keypad operation ............................................................................................... 25

5 Function parameters ................................................................................................ 27

6 Fault Tracking ........................................................................................................... 98

6.1 Maintenance intervals ........................................................................................ 98

6.2 Fault solution.................................................................................................... 103

7 Communication protocol ....................................................................................... 109

7.1 Brief instruction to Modbus protocol ................................................................ 109

7.2 Application of the inverter ................................................................................ 109

7.3 RTU command code and communication data illustration .............................. 115

Appendix A Technical data ....................................................................................... 131

A.1 Ratings ............................................................................................................ 131

A.2 Marking ............................................................................................................ 132

A.3 EMC regulations .............................................................................................. 132

Appendix B Dimension drawings............................................................................. 134

B.1 External keypad (optional) structure ................................................................ 134

B.2 Inverter chart ................................................................................................... 135

Appendix C Further information .............................................................................. 137

C.1 Product and service inquiries .......................................................................... 137

i

UMI-B1 UL Series Inverter Safety precautions

Danger:

Serious physical injury or even death may occur if related

requirements are not followed

Warning:

Physical injury or damage to the devices may occur if related

requirements are not followed

Note:

Physical hurt may occur if related requirements are not

followed

Qualified

electricians:

People working on the device should take part in professional

electrical and safety training, receive the certification and be

familiar with all steps and requirements of installing,

commissioning, operating and maintaining the device to

avoid any emergency.

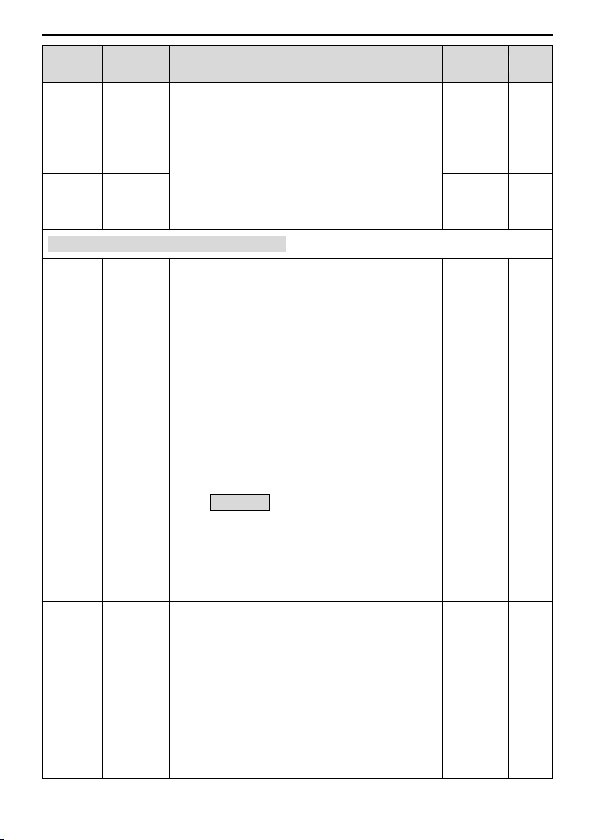

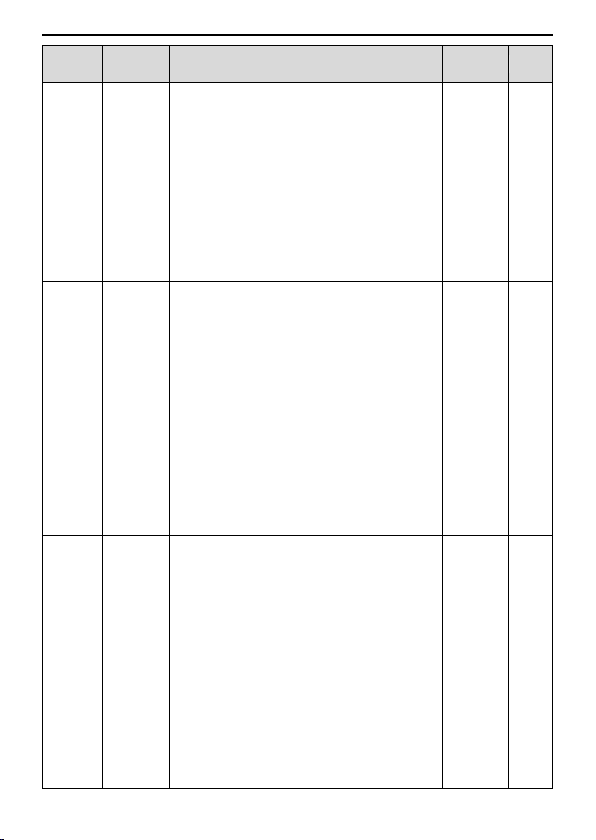

Symbols

Name

Instruction

Abbreviation

Danger

Danger

Serious physical injury or even

death may occur if related

requirements are not followed

Warning

Warning

Physical injury or damage to the

devices may occur if related

requirements are not followed

Do not

Electrostatic

discharge

Damage to the PCBA board may

occur if related requirements are

not followed

Hot sides

Hot sides

Sides of the device may become

hot. Do not touch.

Note

Note

Physical hurt may occur if related

requirements are not followed

Note

1 Safety precautions

Read this manual carefully and follow all safety precautions before moving, installing,

operating and servicing the inverter. If ignored, physical injury or death may occur, or

damage may occur to the devices.

If any physical injury or death or damage to the devices occurs for ignoring to the safety

precautions in the manual, our company will not be responsible for any damages and we

are not legally bound in any manner.

1.1 Safety definition

1.2 Warning symbols

Warnings caution you about conditions which can result in serious injury or death and/or

damage to the equipment, and advice on how to avoid the danger. Following warning

symbols are used in this manual:

1

UMI-B1 UL Series Inverter Safety precautions

• Only qualified electricians are allowed to operate on the inverter.

• Do not carry out any wiring and inspection or changing components

when the power supply is applied. Ensure all input power supplies are

disconnected before wiring and checking and always wait for at least the

time designated on the inverter or until the DC bus voltage is less than

36V. Below is the table of the waiting time:

Inverter module

Minimum waiting time

1PH 220V

0.5~3HP (0.4–2.2kW)

5 minutes

3PH 220V

0.5~1HP (0.4–0.75kW)

5 minutes

3PH 460V

1~3HP (0.75–2.2kW)

5 minutes

• Do not refit the inverter unauthorized; otherwise fire, electric shock or

other injury may occur.

• The base of the radiator may become hot during running. Do not touch

to avoid hurt.

• The electrical parts and components inside the inverter are electrostatic.

Take measurements to avoid electrostatic discharge during relevant

operation.

• Install the inverter on fire-retardant material and keep the inverter

away from combustible materials.

• Connect the braking optional parts (braking resistors, braking units or

feedback units) according to the wiring diagram.

• Do not operate on the inverter if there is any damage or components

loss to the inverter.

• Do not touch the inverter with wet items or body, otherwise electric

shock may occur.

• Solid-state motor overload protection is performed when the inverter

runs at 150% of FLA.

• The inverter does not provide motor over-temperature protection.

1.3 Safety guide

1.3.1 Delivery and installation

Note:

• Select appropriate moving and installing tools to ensure a safe and normal running of

the inverter and avoid physical injury or death. For physical safety, the erector should

take some mechanical protective measurements, such as wearing exposure shoes

and working uniforms.

• Ensure to avoid physical shock or vibration during delivery and installation.

2

UMI-B1 UL Series Inverter Safety precautions

• Disconnect all power supplies applied to the inverter before the

terminal wiring and wait for at least the designated time after

disconnecting the power supply.

• High voltage is present inside the inverter during running. Do not carry

out any operation except for the keypad setting.

• The inverter may start up by itself when P01.21=1. Do not get close to

the inverter and motor.

• The inverter can not be used as "Emergency-stop device".

• The inverter can not be used to break the motor suddenly. A

mechanical braking device should be provided.

• Only qualified electricians are allowed to perform the maintenance,

inspection, and components replacement of the inverter.

• Disconnect all power supplies to the inverter before the terminal

wiring. Wait for at least the time designated on the inverter after

disconnection.

• Take measures to avoid screws, cables and other conductive matters

to fall into the inverter during maintenance and component

replacement.

• Do not carry the inverter by its cover. The cover may fall off.

• Install away from children and other public places.

• The inverter cannot meet the requirements of low voltage protection in IEC61800-5-1

if the altitude of the installation site is above 6562ft (2000m).

• The leakage current of the inverter may be above 3.5mA during operation. Ground

with proper techniques and ensure the grounding resistance is less than 10Ω. The

conductivity of PE grounding conductor is the same as that of the phase conductor

(with the same cross sectional area).

• R, S and T are the input terminals of the power supply, while U, V and W are the

motor terminals. Connect the input power cables and motor cables with proper

techniques; otherwise the damage to the inverter may occur.

1.3.2 Commissioning and running

Note:

• Do not switch on or off the input power supply of the inverter frequently.

• For inverters that have been stored for a long time, check and fix the capacitance and

try to run it again before utilization (see Maintenance and Hardware Fault Diagnose).

• Cover the front board before running, otherwise electric shock may occur.

1.3.3 Maintenance and replacement of components

3

UMI-B1 UL Series Inverter Safety precautions

There are heavy metals in the inverter. Deal with it as industrial effluent.

Note:

• Select proper torque to tighten screws.

• Keep the inverter, parts and components away from combustible materials during

maintenance and component replacement.

• Do not carry out any isolation and pressure test on the inverter and do not measure

the control circuit of the inverter by megameter.

1.3.4 What to do after scrapping

4

UMI-B1 UL Series Inverter Product overview

1. Check whether the packing box is damaged or dampened. If yes, contact local

dealers or UNITRONICS offices.

2. Check the model identifier on the exterior surface of the packing box is consistent

with the purchased model. If no, contact local dealers or UNITRONICS offices.

3. Check whether the interior surface of packing box is abnormal, for example, in wet

condition, or whether the enclosure of the inverter is damaged or cracked. If yes,

contact local dealers or UNITRONICS offices.

4. Check whether the name plate of the inverter is consistent with the model identifier

on the exterior surface of the packing box. If no, contact local dealers or

UNITRONICS offices.

5. Check whether the accessories (including user's manual and control keypad)

inside the packing box are complete. If no, contact local dealers or UNITRONICS

offices.

1. Check the load type to verify that there is no overload of the inverter during work

and check whether the power degree of the inverter needs to be modified.

2. Check that the actual current of the motor is less than the rated current of the

inverter.

3. Check that the control accuracy of the load is the same of the inverter.

4. Check that the incoming supply voltage is correspondent to the rated voltage of the

inverter.

1. Check that the ambient temperature of the inverter is below 104°F (40°C ). If

exceeds, derate 1% for every additional 1.8°F (1°C ). Additionally, the inverter can not

be used if the ambient temperature is above 122°F (50°C ).

Note: For the cabinet inverter, the ambient temperature means the air temperature

inside the cabinet.

2. Check that the ambient temperature of the inverter in actual usage is above 14°F

(-10°C ). If no, add heating facilities.

Note: For the cabinet inverter, the ambient temperature means the air temperature

2 Product overview

2.1 Quick start-up

2.1.1 Unpacking inspection

Check as follows after receiving products:

2.1.2 Application confirmation

Check the machine before beginning to use the inverter:

2.1.3 Environment

Check as follows before the actual installation and usage:

5

UMI-B1 UL Series Inverter Product overview

inside the cabinet.

3. Check that the altitude of the actual usage site is below 3281ft (1000m). If exceeds,

derate1% for every additional 328ft (100m).

4. Check that the humidity of the actual usage site is below 90% and condensation is

not allowed. If no, add additional protection inverters.

5. Check that the actual usage site is away from direct sunlight and foreign objects

can not enter the inverter. If no, add additional protective measures.

6. Check that there is no conductive dust or flammable gas in the actual usage site. If

no, add additional protection to inverters.

1. Check that the load range of the input and output cables meet the need of actual

load.

2. Check that the accessories of the inverter are correctly and properly installed. The

installation cables should meet the needs of every component (including reactors,

input filters, output reactors, output filters, DC reactors, braking units and braking

resistors).

3. Check that the inverter is installed on non-flammable materials and the calorific

accessories (reactors and brake resistors) are away from flammable materials.

4. Check that all control cables and power cables are run separately and the routation

complies with EMC requirement.

5. Check that all grounding systems are properly grounded according to the

requirements of the inverter.

6. Check that the free space during installation is sufficient according to the

instructions in user's manual.

7. Check that the installation conforms to the instructions in user's manual. The

inverter must be installed in an upright position.

8. Check that the external connection terminals are tightly fastened and the torque is

appropriate.

9. Check that there are no screws, cables and other conductive items left in the

inverter. If no, get them out.

1. Autotune. If possible, de-coupled from the motor load to start dynamic autotune. Or

if no, static autotune is available.

2. Adjust the ACC/DEC time according to the actual running of the load.

3. Commission the device via jogging and check that the rotation direction is as

required. If no, change the rotation direction by changing the wiring of motor.

4. Set all control parameters and then operate.

2.1.4 Installation confirmation

Check as follows after the installation:

2.1.5 Basic commissioning

Complete the basic commissioning as follows before actual utilization:

6

UMI-B1 UL Series Inverter Product overview

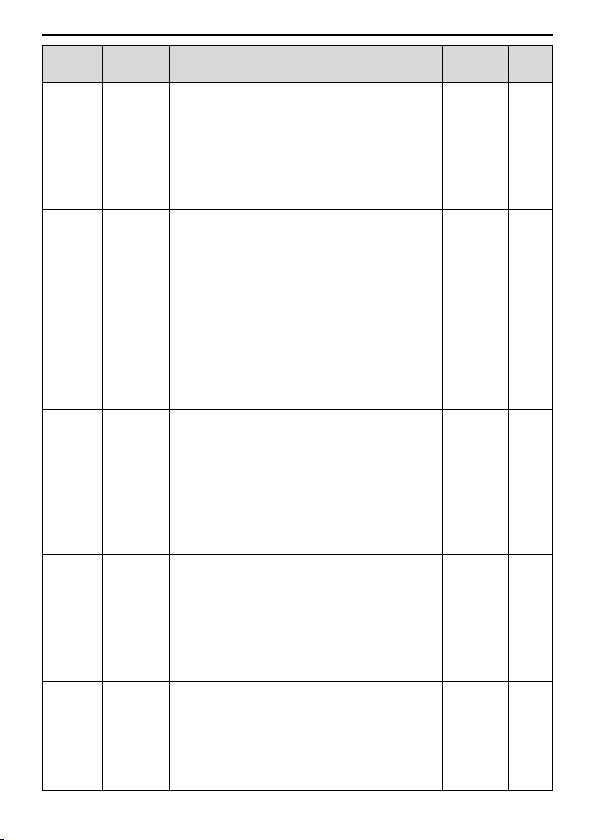

Function

Specification

Power

input

Input voltage (V)

AC 1PH 200V–240V, rated voltage: 220V

AC 3PH 200V–240V, rated voltage: 220V

AC 3PH 380V–480V, rated voltage: 460V

Allowable voltage

fluctuation

-15%–+10%

Input current (A)

Refer to the rated value

Input frequency

(Hz)

50Hz or 60Hz Allowed range: 47–63Hz

Power

output

Output voltage (V)

0–input voltage

Output current (A)

Refer to the rated value

Output power

HP (kW)

Refer to the rated value

Output frequency

(Hz)

0–400Hz

Technical

control

feature

Control mode

SVPWM, SVC

Adjustable-speed

ratio

Asynchronous motor 1: 100 (SVC)

Speed control

accuracy

±0.2% (SVC)

Speed fluctuation

±0.3% (SVC)

Torque response

<20ms (SVC)

Torque control

accuracy

10%

Starting torque

0. 5Hz/150% (SVC)

Overload

capability

150% of rated current: 1 minute

180% of rated current: 10 seconds

200% of rated current: 1 second

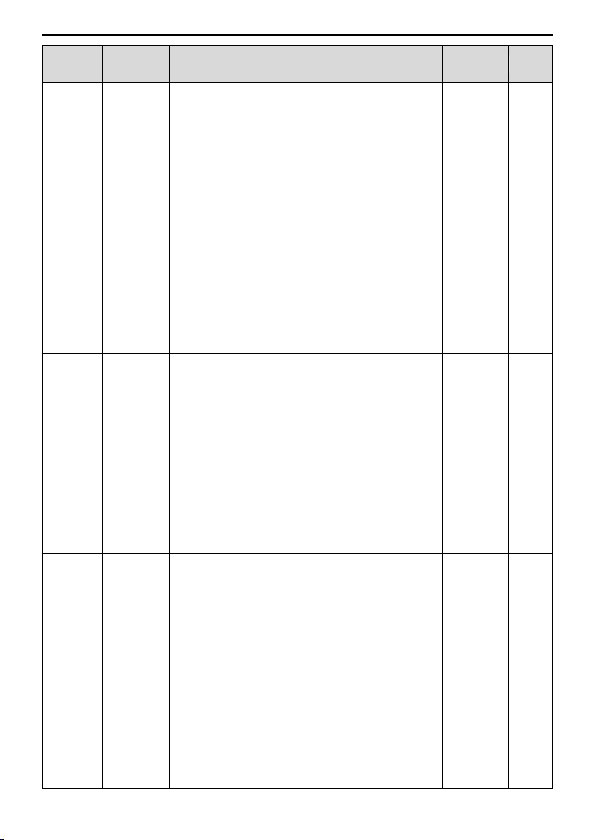

2.2 Product specification

7

UMI-B1 UL Series Inverter Product overview

Function

Specification

Running

control

feature

Frequency setting

method

Digital setting, analog setting, pulse frequency

setting, multi-step speed running setting, simple

PLC setting, PID setting, MODBUS

communication setting

Shift between the set combination and set

channel.

Auto-adjustment

of the voltage

Keep a stable voltage automatically when the

grid voltage transients

Fault protection

Provide comprehensive fault protection

functions: overcurrent, overvoltage,

undervoltage, overheating, phase loss and

overload, etc.

Peripheral

interface

Analog input

1 input (AI2): 0–10V/0–20mA; 1 input (AI3):

-10–10V

Analog output

2 inputs (AO1, AO2): 0–10V/0–20mA

Digital input

4 common inputs, max. frequency: 1kHz;

1 high speed input, max. frequency: 50kHz

Digital output

1 Y1 terminal output; 2 programmable relay

outputs

Relay output

2 programmable relay outputs

RO1A NO, RO1B NC, RO1C common terminal

RO2A NO, RO2B NC, RO2C common terminal

Contact capacity: 3A/AC250V

Others

Mountable

method

Wall and rail mountable

Temperature of

the running

environment

14~122°F (-10–50°C), derate above 104°F

(40°C)

8

UMI-B1 UL Series Inverter Product overview

Function

Specification

Protective degree

Note:

1. The inverter with plastic casing should be

installed in metal distribution cabinet, which

conforms to IP20 and of which the top conforms

to IP3X.

2. Install device in pollution degree 2

environment

Cooling

Air-cooling

Braking unit

Embedded

EMI filter

Optional filter: meet the degree requirement of

IEC61800-3 C2, IEC61800-3 C3

Safety

Meet the requirements of CE, UL and CUL

Overvoltage

category

1PH&3PH 240V: Used in Canada only:

"Transient surge suppression shall be installed

on the line side of this equipment and shall be

rated 240V (phase to ground), 240V (phase to

phase), suitable for overvoltage category III, and

shall provide protection for a rated impulse

withstand voltage peak of 4kV" or equivalent.

3PH: Used in Canada only: "Transient surge

suppression shall be installed on the line side of

this equipment and shall be rated 480V (phase

to ground), 480V (phase to phase), suitable for

overvoltage category III, and shall provide

protection for a rated impulse withstand voltage

peak of 6kV" or equivalent.

9

UMI-B1 UL Series Inverter Product overview

Key

No.

Description

Detailed content

Product line

①

Abbreviation for

product line

UMI for Unitronics Inverters

Rated power

②

Power range

0004:400W

0022:2.2kW(3HP)

Voltage degree

③

Voltage degree

B: 1PH 200V–240V

C: 3PH 200V–240V

E: 3PH 380V–480V

Certification

④

Certification

U: UL

Optional

Braking unit

⑤

Optional Braking

unit

B: Built-in braking unit.

Product series

⑥

Product series

B1: for B1 Series Inverter Family

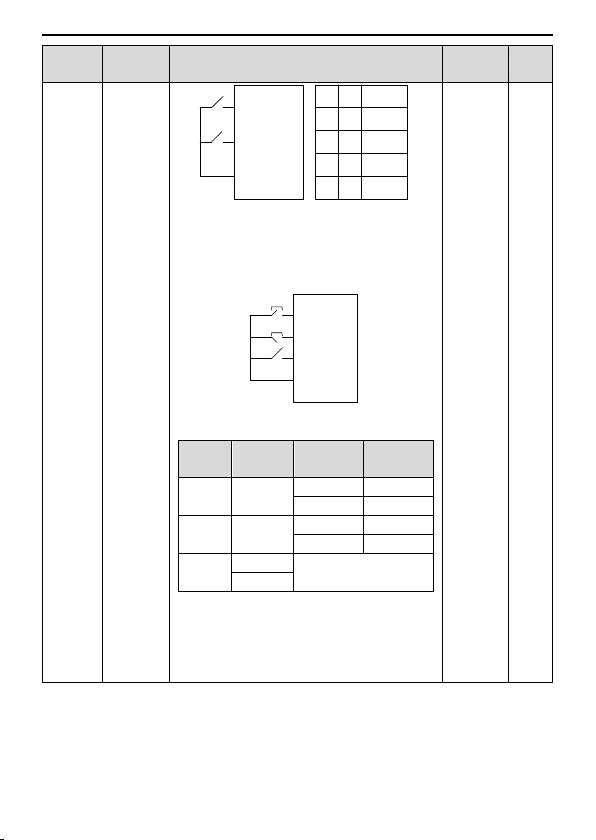

2.3 Name plate

Figure 2-1 Name plate

2.4 Type designation key

The type designation contains information on the inverter. The user can find the type

designation on the type designation label attached to the inverter or the simple name

plate.

UMI – 0022 – E – U – B – B1

① ② ③ ④ ⑤ ⑥

Figure 2-2 Product type

10

UMI-B1 UL Series Inverter Product overview

6

10

11

12

8

9

7

4

351

3

2

1

Serial

No.

Name

Description

1

External keypad port

Connect the external keypad

2

Port cover

Protect the external keypad port

3

Cover

Protect the internal parts and components

4

Hole for the sliding

cover

Fix the sliding cover

5

Trunking board

Protect the inner components and fix the cables

of the main circuit

6

Name plate

See Product Overview for detailed information

7

Potentiometer knob

Refer to the Keypad Operation Procedure

8

Control terminals

See Electric Installation for detailed information

9

Main circuit terminals

See Electric Installation for detailed information

10

Screw hole

Fix the fan cover and fan

11

Cooling fan

See Maintenance and Hardware Fault

Diagnose for detailed information

12

Fan cover

Protect the fan

Note: In above figure, the screws at 4 and 10 are provided with packaging and specific

installation depends on the requirements of customers.

2.5 Structure diagram

Figure 2-3 is the layout figure of the inverter (take the inverter of 1HP (0.75kW) as the

example).

Figure 2-3 Product structure

11

UMI-B1 UL Series Inverter Installation guide

• Only qualified electricians are allowed to carry out what described in

this chapter. Operate as the instructions in Safety Precautions.

Ignoring these may cause physical injury or death or damage to the

devices.

• Ensure the power supply of the inverter is disconnected during the

operation. Wait for at least the time designated after the disconnection

if the power supply is applied.

• The installation and design of the inverter should be complied with the

requirement of the local laws and regulations in the installation site. If

the installation infringes the requirement, our company will exempt

from any responsibility. Additionally, if users do not comply with the

suggestion, some damage beyond the assured maintenance range

may occur.

Environment

Conditions

Installation

site

Indoor

Environment

temperature

14~122°F (-10~50°C), and the temperature changing rate is less

than 0.9°F (0.5°C )/minute.

If the ambient temperature of the inverter is above 104°F (40°C ),

derate 1% for every additional 1.8°F (1°C ).

It is not recommended to use the inverter if the ambient

temperature is above 122°F (50°C ).

In order to improve the reliability of the device, do not use the

inverter if the ambient temperature changes frequently.

Provide cooling fan or air conditioner to control the internal ambient

temperature below the required one if the inverter is used in a close

space such as in the control cabinet.

When the temperature is too low, if the inverter needs to restart to

run after a long stop, it is necessary to provide an external heating

device to increase the internal temperature, otherwise damage to

the devices may occur.

3 Installation guide

The chapter describes the mechanical installation and electric installation.

3.1 Mechanical installation

3.1.1 Installation environment

The installation environment is the safeguard for a full performance and long-term stable

functions of the inverter. Check the installation environment as follows:

12

UMI-B1 UL Series Inverter Installation guide

Environment

Conditions

Humidity

RH≤90%

No condensation is allowed.

Storage

temperature

-40~+158°F (-40°C –+70°C ), and the temperature changing rate is

less than 1.8°F (1°C )/minute.

Running

environment

condition

The installation site of the inverter should:

keep away from the electromagnetic radiation source;

keep away from contaminative air, such as corrosive gas, oil mist

and flammable gas;

ensure foreign objects, such as metal power, dust, oil, water can

not enter into the inverter (do not install the inverter on the

flammable materials such as wood);

keep away from direct sunlight, oil mist, steam and vibration

environment.

Altitude

Below 3281ft (1000m)

If the altitude is above 3281ft (1000m, derate 1% for every

additional 328ft (100m).

Vibration

≤ 5.8m/s

2

(0.6g)

Installation

direction

The inverter should be installed on an upright position to ensure

sufficient cooling effect.

Note:

• UMI-B1 UL series inverters should be installed in a clean and ventilated environment

according to enclosure classification.

• Cooling air must be clean, free from corrosive materials and electrically conductive

dust.

3.1.2 Installation direction

The inverter may be installed in a cabinet.

The inverter needs be installed in the vertical position. Check the installation site

according to the requirements below. Refer to chapter Dimension Drawings in the

appendix for frame details.

3.1.3 Installation manner

The inverter can be installed in two different ways, depending on the frame size:

Figure 3-1: Wall mounting (for all frame sizes)

Figure 3-2: Rail mounting (for all frame sizes, but need optional installation bracket)

13

UMI-B1 UL Series Inverter Installation guide

Figure 3-1 Wall mounting

Figure 3-2 Rail mounting

R

S

T

W

V

U

PE

M

(+)

PB

Three-phase

380V~480V

50/60Hz

Braking resistor

Input

reactor

Input

filter

Fuse

Output

reactor

Output

filter

L

N

W

V

U

PE

M

(+)

PB

Single-phase

200V~240V

50/60Hz

Braking resistor

Input

reactor

Input

filter

Fuse

Output

reactor

Output

filter

Note: The minimum space of A and B is 100mm. H is 36.6mm and W is 35.0mm.

3.2 Standard wiring

3.2.1 Connection diagram of main circuit

Figure 3-3 Connection diagram of main circuit

Note:

• The fuse, braking resistor, input reactor, input filter, output reactor, output filter are

optional parts. Refer to Peripheral Optional Parts for detailed information.

• Remove the yellow warning labels of PB, (+) and (-) on the terminals before

connecting the braking resistor; otherwise, poor connection may occur.

14

UMI-B1 UL Series Inverter Installation guide

Terminal

Terminal name

Function

L

Power input of the main

circuit

1-phase AC input terminals which are generally

connected with the power supply.

N

U

The inverter output

3-phase AC output terminals which are generally

connected with the motor.

V

W

PB, (+)

Braking resistor terminal

PB and (+) are connected to the external

resistor.

PE

Grounding terminal

Each machine should be grounded.

Terminal

Terminal name

Function

R, S, T

Power input of the main

circuit

3-phase AC input terminals which are generally

connected with the power supply.

U, V, W

The inverter output

3-phase AC output terminals which are generally

connected with the motor.

PB, (+)

Braking resistor terminal

PB and (+) are connected to the external

resistor.

PE

Grounding terminal

Each machine should be grounded.

3.2.2 Terminals figure of main circuit

Figure 3-4 1PH terminals of main circuit

Figure 3-5 3PH terminals of main circuit

Note:

• Do not use asymmetrically motor cables. If there is a symmetrically grounding

conductor in the motor cable in addition to the conductive shield, connect the

grounding conductor to the grounding terminal at the inverter and motor ends.

• Route the motor cable, input power cable and control cables separately.

• When selecting C3 input filters, connect the filters in parallel at the input side of the

inverter.

15

UMI-B1 UL Series Inverter Installation guide

Multi-function input terminal 1

Multi-function input terminal 2

Multi-function input terminal 4

High speed pulse input collector

Multi-function input terminal 3

Open collector input optional

Y1 output

Analog output

Analog output

Relay 1 output

Relay 2 output

S1

S2

S3

S4

HDI

COM

PW

+24V

PE

+10V

AI2

AI3

PE

GND

AI2

V I

Y1

COM

AO1

AO2

V I

V

I

AO1

AO2

0–10V/0–20mA

0–10V/0–20mA

COM

COM

RO1A

RO1B

RO1C

RO2A

RO2B

RO2C

Shield layer

Twisted pair

RS485

communication

485+

485-

GND

PE

J5

ON

GND

3.2.3 Wiring of terminals in main circuit

1. Connect the ground line of input power cable to the ground terminal of inverter (PE)

directly, and connect 3PH input cable to R, S and T and fasten up.

2. Connect the ground line of motor cable to the ground terminal of the inverter, and

connect the 3PH motor cable to U, V, W and fasten up.

3. Connect the brake resistor which carries cables to the designated position.

4. Fasten up all the cables on the outside of the inverter if allowed.

3.2.4 Wiring diagram of control circuit

Figure 3-6 Wiring of control circuit

3.2.5 Terminals of control circuit

Figure 3-7 Terminals of control circuit

16

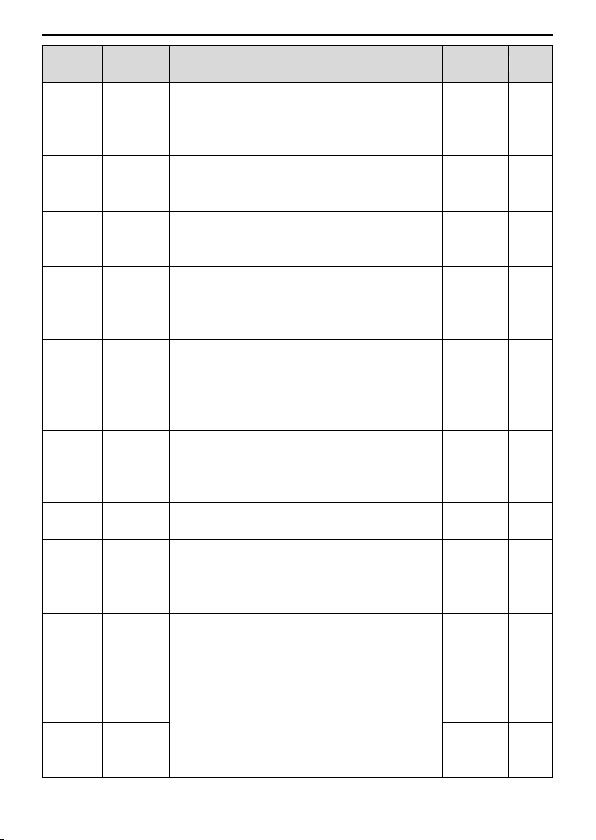

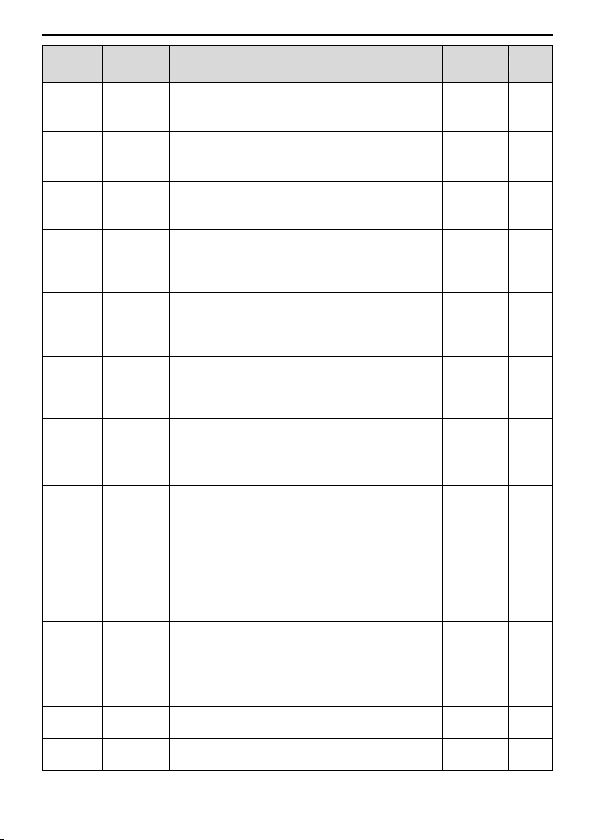

UMI-B1 UL Series Inverter Installation guide

Type

Terminal

name

Function

description

Technical specifications

Communication

485+

485

communication

RS485 communication interface.

In order to ensure stable

communication channel:

• Use shielded twisted pair

cable.

• Connect the HOST RS485

signal ground to one of the

VFD CMD/GND terminals.

• Connect one of the CMD/GND

terminals to PE terminal.

• Earth the cable shield to the

PE terminal.

485-

Digital

input/output

S1

Digital input

1. Internal impedance: 3.3kΩ

2. 12–30V voltage input is

available

3. The terminal is the

dual-direction input terminal

4. Max. input frequency: 1kHz

S2

S3

S4

HDI

High frequency

input channel

Except for S1–S4, this terminal

can be used as high frequency

input channel.

Max. inputfrequency: 50kHz

Duty cycle: 30%–70%

PW

Digital power

supply

To provide the external digital

power supply

Voltage range: 12–30V

Y1

Digital output

Contact capacity: 50mA/30V

COM

Common terminal of the open

collector output

Analog

input/output

+10V

External 10V

reference

power supply

10V reference power supply

Max. output current: 50mA

As the adjusting power supply of

the external potentiometer

Potentiometer resistance: 5kΩ

above

AI2

Analog input

1. Input range: AI2 voltage and

current can be chosen:

0–10V/0–20mA; AI3:

-10V–+10V.

2. Input impedance:voltage

AI3

17

UMI-B1 UL Series Inverter Installation guide

Type

Terminal

name

Function

description

Technical specifications

input:

20kΩ; current input: 500Ω.

3.Voltage or current input can be

set by dip switch.

4. Resolution: the minimum

AI2/AI3 is 10mV/20mV when

10V corresponds to 60Hz.

GND

Analog

reference

ground

Analog reference ground

AO1

Analog output

1. Output range: 0–10V or

0–20mA

2. The voltage or the current

output is depended on the dip

switch.

3. Deviation±1%, 77°F (25°C )

when full range.

AO2

Relay output

RO1A

Relay 1 NO

contact

RO1 relay output, RO1A NO,

RO1B NC, RO1C common

terminal

RO2 relay output, RO2A NO,

RO2B NC, RO2C common

terminal

Contact capacity: 3A/AC250V

RO1B

Relay 1 NC

contact

RO1C

Relay 1

common

contact

RO2A

Relay 2 NO

contact

RO2B

Relay 2 NC

contact

RO2C

Relay 2

common

contact

18

UMI-B1 UL Series Inverter Installation guide

U-shaped contact

tag between

+24V and PW

U-shaped contact

tag between

COM and CME

S1

S2

COM

PW

+ 24V

COM

+24V

S1

S2

COM

PW

+ 24V

COM

+24V

+ 24V

S1

S2

COM

PW

+ 24V

COM

+24V

S1

S2

COM

PW

+ 24V

COM

+24V

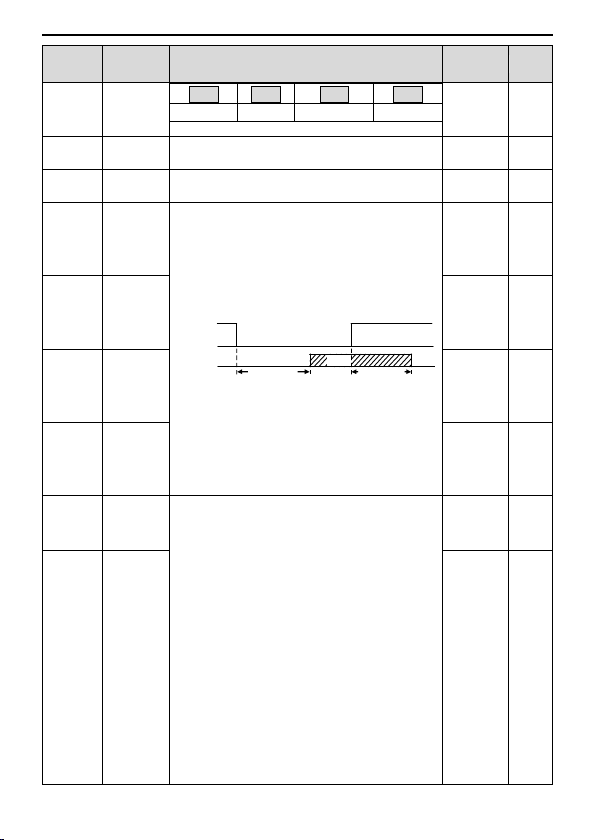

3.2.6 Input/Output signal connection figure

Use U-shaped contact tag to set NPN mode or PNP mode and the internal or external

power supply. The default setting is NPN internal mode.

Figure 3-8 U-shaped contact tag

If the signal is from NPN transistor, set the U-shaped contact tag between +24V and PW

as below according to the used power supply.

Figure 3-9 NPN modes

If the signal is from PNP transistor, set the U-shaped contact tag as below according to

the used power supply.

Figure 3-10 PNP modes

3.3 Layout protection

3.3.1 Protecting the inverter and input power cable in short-circuit situations

Protect the inverter and input power cable in short circuit situations and against thermal

overload.

Arrange the protection according to the following guide.

19

UMI-B1 UL Series Inverter Installation guide

Input cable

Inverter

Fuse

• If the inverter is connected to multiple motors, a separate thermal

overload switch or a circuit breaker must be used for protecting each

cable and motor. These devices may require a separate fuse to cut off

the short-circuit current.

• Never connect the supply power to the inverter output terminals U, V

and W. Power line voltage applied to the output can result in

permanent damage to the inverter.

Note: Select the fuse as the manual indicated. The fuse will protect the input power

Figure 3-11 Fuse configuration

cable from damage in short-circuit situations. It will protect the surrounding devices

when the internal of the inverter is short circuited.

3.3.2 Protecting the motor and motor cables

The inverter protects the motor and motor cable in a short-circuit situation when the

motor cable is dimensioned according to the rated current of the inverter. No additional

protection devices are needed.

3.3.3 Implementing a bypass connection

It is necessary to set power frequency and variable frequency conversion circuits for the

assurance of continuous normal work of the inverter if faults occur in some significant

situations.

In some special situations, for example, if it is only used in soft start, the inverter can be

conversed into power frequency running after starting and some corresponding bypass

should be added.

If frequent shifting is required, employ mechanically connected switches or contactors to

ensure that the motor terminals are not connected to the AC power line and inverter

output terminals simultaneously.

20

UMI-B1 UL Series Inverter Keypad operation procedure

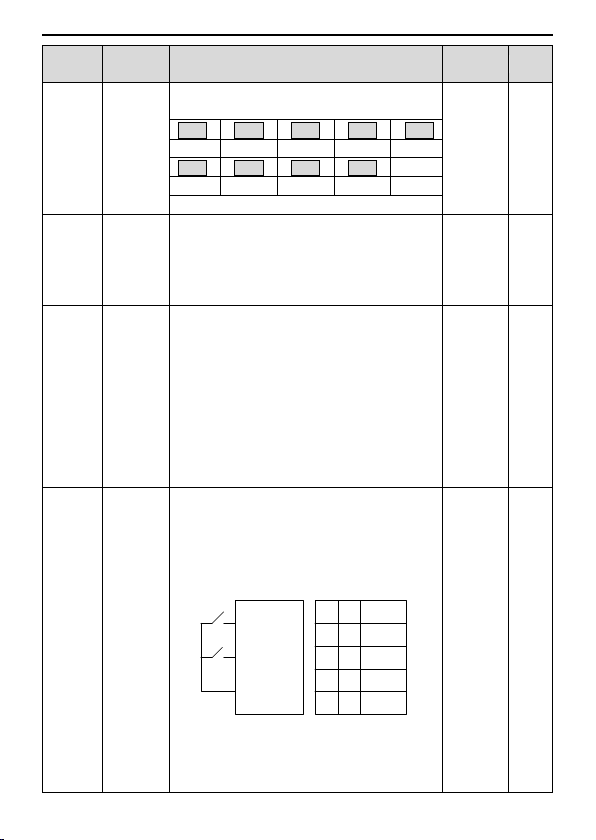

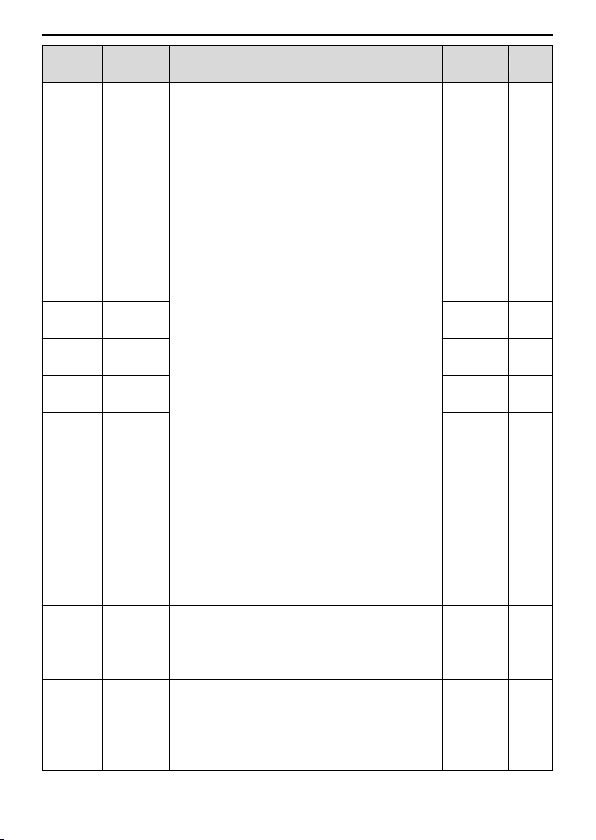

Serial

No.

Name

Description

1

State LED

RUN/TUNE

LED off means that the inverter is in the

stopping state; LED blinking means the

inverter is in the parameter autotune state;

LED on means the inverter is in the running

state.

FWD/REV

FED/REV LED

LED off means the inverter is in the forward

rotation state; LED on means the inverter is

in the reverse rotation state

LOCAL/REMOT

LED for keypad operation, terminals

operation and remote communication

control

LED off means that the inverter is in the

keypad operation state; LED blinking

4 Keypad operation procedure

4.1 Keypad introduction

The keypad is used to control UMI-B1 UL series inverters, read the state data and adjust

parameters.

Note: The external keypads are optional (including the external keypads with and

without the function of parameter copying).

Figure 4-1 Keypad

21

UMI-B1 UL Series Inverter Keypad operation procedure

Serial

No.

Name

Description

means the inverter is in the terminals

operation state; LED on means the inverter

is in the remote communication control

state.

TRIP

LED for faults

LED on when the inverter is in the fault

state; LED off in normal state; LED blinking

means the inverter is in the pre-alarm state.

2

Unit LED

Mean the unit displayed currently

Hz

Frequency unit

RPM

Rotating speed unit

A

Current unit

%

Percentage

V

Voltage unit

3

Code

displaying

zone

5-figure LED display displays various monitoring data and alarm

code such as set frequency and output frequency.

0

3

6

9

C

F

L

O

S

v

1

4

7

A

d

H

N

P

t

.

2

5

8

b

E

l

n

r

U

-

Displayed

character

Displayed

character

Displayed

character

Corresponding

character

Corresponding

character

Corresponding

character

4

Buttons

Programmi

ng key

Enter or escape from the first level menu

and remove the parameter quickly

Entry key

Enter the menu step-by-step

Confirm parameters

22

UMI-B1 UL Series Inverter Keypad operation procedure

Serial

No.

Name

Description

UP key

Increase data or function code

progressively

DOWN key

Decrease data or function code

progressively

Right-shift

key

Move right to select the displaying

parameter circularly in stopping and

running mode.

Select the parameter modifying digit during

the parameter modification

Run key

This key is used to operate on the inverter

in key operation mode

Stop/

Reset key

This key is used to stop in running state

and it is limited by function code P07.04

This key is used to reset all control modes

in the fault alarm state

Quick key

The function of this key is confirmed by

function code P07.02.

5

Keypad

port

External keypad port. When the external keypad with the function

of parameter copying is valid, the local keypad LED is off; When

the external keypad without the function of parameter copying is

valid, the local and external keypad LEDs are on.

Note: Only the external keypad which has the function of

parameters copy owns the function of parameters copy, other

keypads do not have.

6

Analog

potentio

meter

AI1, When the external common keypad (without the function of

parameter copy) is valid, the difference between the local keypad

AI1 and the external keypad AI1 is:

when the external keypad AI1 is set to the Min. value, the local

keypad AI1 will be valid and P17.19 will be the voltage of the local

keypad AI1; otherwise, the external keypad AI1 will be valid and

P17.19 will be the voltage of the external keypad AI1.

Note: If the external keypad AI1 is frequency reference source,

adjust the local potentiometer AI1 to 0V/0mA before starting the

inverter.

4.2 Keypad displaying

The keypad displaying state of UMI-B1 UL series inverters is divided into stopping state

parameter, running state parameter, function code parameter editing state and fault

23

UMI-B1 UL Series Inverter Keypad operation procedure

alarm state and so on.

4.2.1 Displayed state of stopping parameter

When the inverter is in the stopping state, the keypad will display stopping parameters

which is shown in Figure 4-2.

In the stopping state, various kinds of parameters can be displayed. Select the

parameters to be displayed or not by P07.07. See the instructions of P07.07 for the

detailed definition of each bit.

In the stopping state, there are 14 stopping parameters can be selected to be displayed

or not. They are: set frequency, bus voltage, input terminals state, output terminals state,

PID given, PID feedback, torque set value, AI1, AI2, AI3, HDI, PLC and the current stage

of multi-step speeds, pulse counting value, length value. P07.07 can select the

parameter to be displayed or not by bit and 》/SHIFT can shift the parameters from left

to right, QUICK/JOG (P07.02=2) can shift the parameters from right to left.

4.1.2 Displayed state of running parameters

After the inverter receives valid running commands, the inverter will enter into the

running state and the keypad will display the running parameters. RUN/TUNE LED on

the keypad is on, while the FWD/REV is determined by the current running direction

which is shown in Figure 4-2.

In the running state, there are 24 parameters can be selected to be displayed or not.

They are: running frequency, set frequency, bus voltage, output voltage, output torque,

PID given, PID feedback, input terminals state, output terminals state, torque set value,

length value, PLC and the current stage of multi-step speeds, pulse counting value, AI1,

AI2, AI3, HDI, percentage of motor overload, percentage of inverter overload, ramp

given value, linear speed, AC input current. P07.05 and P07.06 can select the

parameter to be displayed or not by bit and 》/SHIFT can shift the parameters from left

to right, QUICK/JOG (P07.02=2) can shift the parameters from right to left.

4.1.3 Displayed state of fault

If the inverter detects the fault signal, it will enter into the fault pre-alarm displaying state.

The keypad will display the fault code by flicking. The TRIP LED on the keypad is on,

and the fault reset can be operated by the STOP/RST on the keypad, control terminals

or communication commands.

4.1.4 Displayed state of function codes editing

In the state of stopping, running or fault, press PRG/ESC to enter into the editing state

(if there is a password, see P07.00 ).The editing state is displayed on two classes of

menu, and the order is: function code group/function code number→function code

parameter, press DATA/ENT into the displayed state of function parameter. On this state,

press DATA/ENT to save the parameters or press PRG/ESC to escape.

24

UMI-B1 UL Series Inverter Keypad operation procedure

Stop parameters Running parameters

Fault display

Figure 4-2 Displayed state

4.3 Keypad operation

Operate the inverter via operation panel. See the detailed structure description of

function codes in the brief diagram of function codes.

4.3.1 How to modify the function codes of the inverter

The inverter has three levels menu, which are:

1. Group number of function code (first-level menu)

2. Tab of function code (second-level menu)

3. Set value of function code (third-level menu)

Remarks: Press both the PRG/ESC and the DATA/ENT can return to the second-level

menu from the third-level menu. The difference is: pressing DATA/ENT will save the set

parameters into the control panel, and then return to the second-level menu with shifting

to the next function code automatically; while pressing PRG/ESC will directly return to

the second-level menu without saving the parameters, and keep staying at the current

function code.

Under the third-level menu, if the parameter has no flickering bit, it means the function

code cannot be modified. The possible reasons could be:

1) This function code is not modifiable parameter, such as actual detected parameter,

operation records and so on;

2) This function code is not modifiable in running state, but modifiable in stop state.

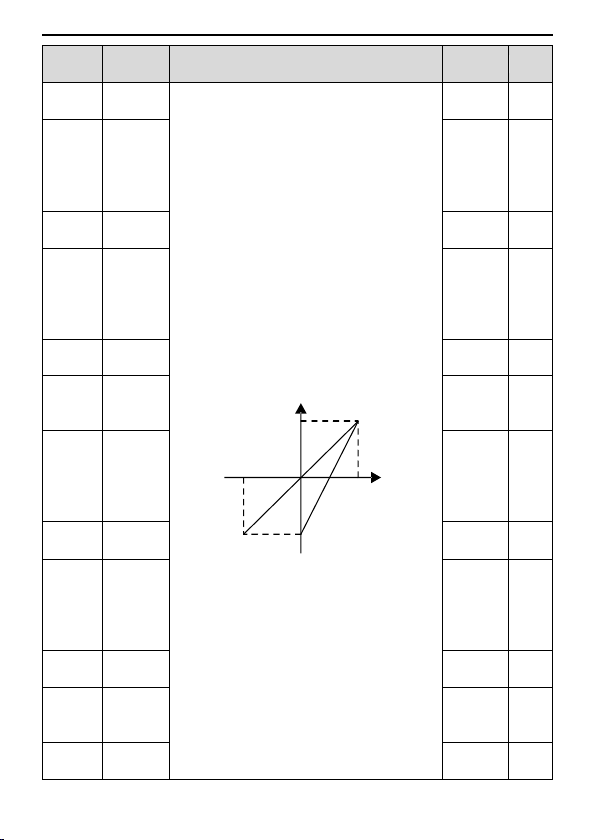

Example: Set function code P00.01 from 0 to 1.

Figure 4-3 Sketch map of modifying parameters

25

UMI-B1 UL Series Inverter Keypad operation procedure

4.3.2 How to set the password of the inverter

UMI-B1 UL series inverters provide password protection function to users. Set P7.00 to

gain the password and the password protection becomes valid instantly after quitting

from the function code editing state. Press PRG/ESC again to the function code editing

state, "0.0.0.0.0" will be displayed. Unless using the correct password, the operators

cannot enter it.

Set P7.00 to 0 to cancel password protection function.

The password protection becomes effective instantly after retreating from the function

code editing state. Press PRG/ESC again to the function code editing state, "0.0.0.0.0"

will be displayed. Unless using the correct password, the operators cannot enter it.

Figure 4-4 Sketch map of password setting

4.3.3 How to watch the inverter state through function codes

UMI-B1 UL series inverters provide group P17 as the state inspection group. Users can

enter into P17 directly to watch the state.

Figure 4-5 Sketch map of state watching

26

UMI-B1 UL Series Inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

P00 Group Basic function group

P00.00

Speed

control

mode

0: SVC 0

.No need to install encoders. Suitable in

applications which need low frequency, big

torque for high accuracy of rotating speed

and torque control. Relative to mode 1, it is

more suitable for the applications which need

small power.

1: SVC 1

1 is suitable in high performance cases with

the advantage of high accuracy of rotating

1

◎

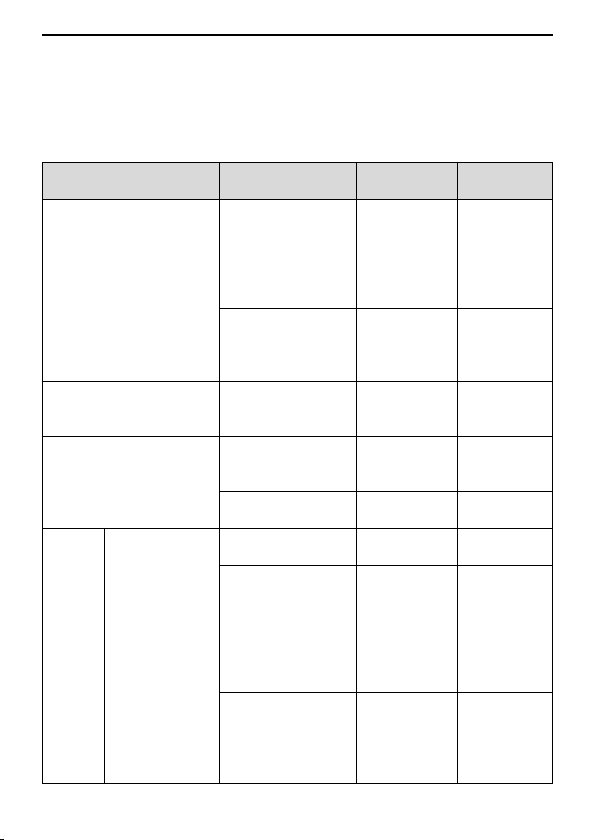

5 Function parameters

The function parameters of UMI-B1 UL series inverters have been divided into 30

groups (P00–P29) according to the function, of which P18–P28 are reserved. Each

function group contains certain function codes applying 3-level menus. For example,

"P08.08" means the eighth function code in the P8 group function, P29 group is factory

reserved, and users are forbidden to access these parameters.

For the convenience of function codes setting, the function group number corresponds

to the first level menu, the function code corresponds to the second level menu and the

function code corresponds to the third level menu.

1. Below is the instruction of the function lists:

The first column "Function code": codes of function parameter group and parameters;

The second column "Name": full name of function parameters;

The third column "Detailed illustration of parameters": Detailed illustration of the

function parameters

The fourth column "Default value": the original factory set value of the function

parameter;

The fifth column "Modify": the modifying character of function codes (the parameters

can be modified or not and the modifying conditions), below is the instruction:

"○": means the set value of the parameter can be modified on stop and running state;

"◎": means the set value of the parameter can not be modified on the running state;

"●": means the value of the parameter is the real detection value which can not be

modified.

27

UMI-B1 UL Series Inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

speed and torque. It does not need to install

pulse encoder.

2: SVPWM control

2 is suitable in applications which do not need

high control accuracy, such as the load of fan

and pump. One inverter can drive multiple

motors.

P00.01

Run

command

channel

Select the run command channel of the

inverter.

The control command of the inverter includes:

start, stop, forward/reverse rotating, jogging

and fault reset.

0: Keypad running command channel

("LOCAL/REMOT" light off)

Carry out the command control by RUN,

STOP/RST on the keypad.

Set the multi-function key QUICK/JOG to

FWD/REVC shifting function (P07.02=3) to

change the running direction; press RUN and

STOP/RST simultaneously in running state to

make the inverter coast to stop.

1: Terminal running command channel

("LOCAL/REMOT" flickering)

Carry out the running command control by

the forward rotation, reverse rotation and

forward jogging and reverse jogging of the

multi-function terminals

2: Communication running command channel

("LOCAL/REMOT" on);

The running command is controlled by the

upper monitor via communication

0

○

P00.03

Max.

output

frequency

This parameter is used to set the maximum

output frequency of the inverter. Users need

to pay attention to this parameter because it

is the foundation of the frequency setting and

the speed of acceleration and deceleration.

Setting range: P00.04–400.00Hz

60.00Hz

◎

P00.04

Upper limit

of the

The upper limit of the running frequency is the

upper limit of the output frequency of the

60.00Hz

◎

28

UMI-B1 UL Series Inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

running

frequency

inverter which is lower than or equal to the

maximum frequency.

Setting range: P00.05–P00.03 (Max. output

frequency)

P00.05

Lower limit

of the

running

frequency

The lower limit of the running frequency is

that of the output frequency of the inverter.

The inverter runs at the lower limit frequency

if the set frequency is lower than the lower

limit.

Note: Max. output frequency ≥ Upper limit

frequency ≥ Lower limit frequency

Setting range: 0.00Hz–P00.04 (Upper limit of

the running frequency)

0.00Hz

◎

P00.06

A

frequency

command

selection

0: Keypad data setting

Modify the value of function code P00.10 (set

the frequency by keypad) to modify the

frequency by the keypad.

1: Analog AI1 setting (corresponding keypad

potentiometer)

2: Analog AI2 setting (corresponding terminal

AI2)

3: Analog AI3 setting (corresponding terminal

AI3)

Set the frequency by analog input terminals.

UMI-B1 UL series inverters provide 3

channels analog input terminals as the

standard configuration, of which AI1 is

adjusting through analog potentiometer, while

AI2 is the voltage/current option

(0–10V/0–20mA) which can be shifted by

jumpers; while AI3 is voltage input

(-10V–+10V).

Note: when analog AI2 select 0–20mA input,

the corresponding voltage of 20mA is 10V.

100.0% of the analog input setting

corresponds to the maximum frequency

(function code P00.03) in forward direction

and -100.0% corresponds to the maximum

frequency in reverse direction (function code

0

○

P00.07

B

frequency

command

selection

2

○

29

UMI-B1 UL Series Inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

P00.03)

4: High-speed pulse HDI setting

The frequency is set by high-speed pulse

terminals. UMI-B1 UL series inverters provide

1 high speed pulse input as the standard

configuration. The pulse frequency range is

0.00–50.00kHz.

100.0% of the high speed pulse input setting

corresponds to the maximum frequency in

forward direction (function code P00.03) and

-100.0% corresponds to the maximum

frequency in reverse direction (function code

P00.03).

Note: The pulse setting can only be input by

multi-function terminals HDI. Set P05.00 (HDI

input selection) to high speed pulse input,

and set P05.49 (HDI high speed pulse input

function selection) to frequency setting input.

5: Simple PLC program setting

The inverter runs at simple PLC program

mode when P00.06=5 or P00.07=5. Set P10

(simple PLC and multi-step speed control) to

select the running frequency running

direction, ACC/DEC time and the keeping

time of corresponding stage. See the function

description of P10 for detailed information.

6: Multi-step speed running setting

The inverter runs at multi-step speed mode

when P00.06=6 or P00.07=6. Set P05 to

select the current running step, and set P10

to select the current running frequency.

The multi-step speed has the priority when

P00.06 or P00.07 does not equal to 6, but the

setting stage can only be the 1–15 stage. The

setting stage is 1–15 if P00.06 or P00.07

equals to 6.

7: PID control setting

The running mode of the inverter is process

PID control when P00.06=7 or P00.07=7. It is

30

UMI-B1 UL Series Inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

necessary to set P09. The running frequency

of the inverter is the value after PID effect.

See P09 for the detailed information of the

preset source, preset value and feedback

source of PID.

8: MODBUS communication setting

The frequency is set by MODBUS

communication. See P14 for detailed

information.

9–11: Reserved

Note: A frequency and B frequency can not

set as the same frequency given method.

P00.08

B

frequency

command

reference

selection

0: Maximum output frequency, 100% of B

frequency setting corresponds to the

maximum output frequency

1: A frequency command, 100% of B

frequency setting corresponds to the

maximum output frequency. Select this

setting if it needs to adjust on the base of A

frequency command.

0

○

P00.09

Combinati

on of the

setting

source

0: A, the current frequency setting is A

frequency command

1: B, the current frequency setting is B

frequency command

2: A+B, the current frequency setting is A

frequency command + B frequency command

3: A-B, the current frequency setting is A

frequency command - B frequency command

4: Max (A, B): The bigger one between A

frequency command and B frequency is the

set frequency.

5: Min (A, B): The lower one between A

frequency command and B frequency is the

set frequency.

Note: The combination manner can be

shifted by P05 (terminal function)

0

○

P00.10

Keypad set

frequency

When A and B frequency commands are

selected as "keypad setting", this parameter

will be the initial value of inverter reference

60.00Hz

○

31

UMI-B1 UL Series Inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

frequency

Setting range: 0.00 Hz–P00.03 (the Max.

frequency)

P00.11

ACC time

1

ACC time means the time needed if the

inverter speeds up from 0Hz to the Max. One

(P00.03).

DEC time means the time needed if the

inverter speeds down from the Max. Output

frequency to 0Hz (P00.03).

UMI-B1 UL series inverters have four groups

of ACC/DEC time which can be selected by

P05. The factory default ACC/DEC time of the

inverter is the first group.

Setting range of P00.11 and P00.12:

0.0–3600.0s

Depend

on model

○

P00.12

DEC time

1

Depend

on model

○

P00.13

Running

direction

selection

0: Runs at the default direction, the inverter

runs in the forward direction. FWD/REV

indicator is off.

1: Runs at the opposite direction, the inverter

runs in the reverse direction. FWD/REV

indicator is on.

Modify the function code to shift the rotation

direction of the motor. This effect equals to

the shifting the rotation direction by adjusting

either two of the motor lines (U, V and W).

The motor rotation direction can be changed

by QUICK/JOG on the keypad. Refer to

parameter P07.02.

Note: When the function parameter comes

back to the default value, the motor's running

direction will come back to the factory default

state, too. In some cases it should be used

with caution after commissioning if the

change of rotation direction is disabled.

2: Forbid to run in reverse direction: It can be

used in some special cases if the reverse

running is disabled.

0

○

32

UMI-B1 UL Series Inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

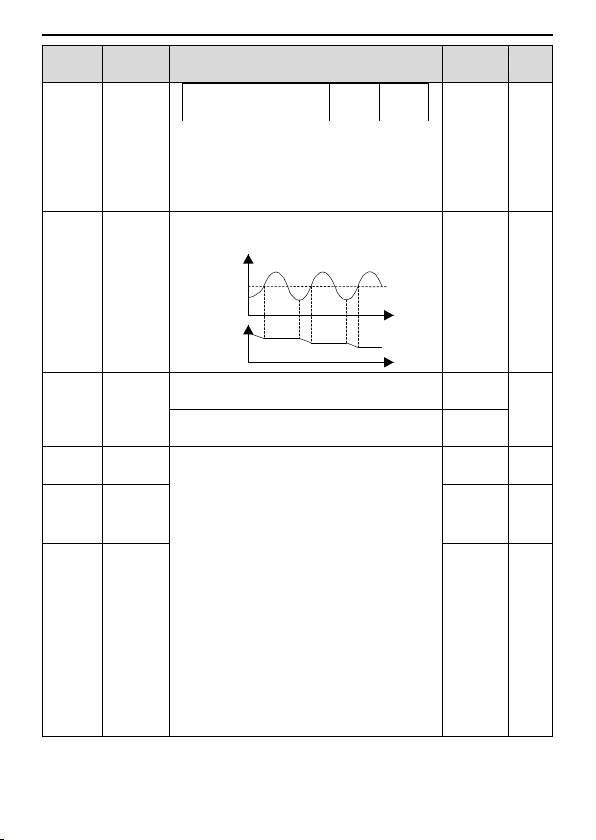

P00.14

Carrier

frequency

setting

Carrier

frequency

Electromagnetic

noise

Noise and leakage

current

Heating

eliminating

High

LowHigh

Low

High

Low

1kHz

10kHz

15kHz

The relationship table of the motor type and

carrier frequency:

Motor type

Factory setting of

carrier frequency

0.5~3HP

(0.4–2.2kW)

8kHz

The advantage of high carrier frequency:

ideal current waveform, little current harmonic

wave and motor noise.

The disadvantage of high carrier frequency:

increasing the switch loss, increasing inverter

temperature and the impact to the output

capacity. The inverter needs to derate on high

carrier frequency. At the same time, the

leakage and electrical magnetic interference

will increase.

Applying low carrier frequency is contrary to

the above, too low carrier frequency will

cause unstable running, torque decreasing

and surge.

The manufacturer has set a reasonable

carrier frequency when the inverter is in

factory. In general, users do not need to

change the parameter.

When the frequency used exceeds the

default carrier frequency, the inverter needs

to derate 20% for each additional 1k carrier

frequency.

Setting range: 1.0–15.0kHz

Depend

on model

○

P00.15

Motor

parameter

0: No operation

1: Rotation autotuning

0

◎

33

UMI-B1 UL Series Inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

autotuning

Comprehensive motor parameter autotune

It is recommended to use rotation autotuning

when high control accuracy is needed.

2: Static autotuning 1 (autotune totally); It is

suitable in the cases when the motor can not

de-couple from the load. The antotuning for

the motor parameter will impact the control

accuracy.

3: Static autotuning 2 (autotune part

parameters); when the current motor is motor

1, autotune P02.06, P02.07, P02.08

P00.16

AVR

function

selection

0: Invalid

1: Valid during the whole procedure

The auto-adjusting function of the inverter

can cancel the impact on the output voltage

of the inverter because of the bus voltage

fluctuation.

1

○

P00.18

Function

restore

parameter

0: No operation

1: Restore the default value

2: Clear fault records

Note: The function code will restore to 0 after

finishing the operation of the selected

function code.

Restoring to the default value will cancel the

user password, use this function with caution.

0

◎

P01 Group Start-up and stop control

P01.00

Start mode

0: Start-up directly:start from the starting

frequency P01.01

1: Start-up after DC braking: start the motor

from the starting frequency after DC braking

(set the parameter P01.03 and P01.04). It is

suitable in the cases where reverse rotation

may occur to the low inertia load during

starting.

2: Reserved.

Note: It is recommended to start the

synchronous motor directly.

0

◎

P01.01

Starting

frequency

Starting frequency of direct start-up means

the original frequency during the inverter

0.50Hz

◎

34

UMI-B1 UL Series Inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

of direct

start-up

starting. See P01.02 for detailed information.

Setting range: 0.00–50.00Hz

P01.02

Retention

time of the

starting

frequency

Set a proper starting frequency to increase

the torque of the inverter during starting.

During the retention time of the starting

frequency, the output frequency of the

inverter is the starting frequency. And then,

the inverter will run from the starting

frequency to the set frequency. If the set

frequency is lower than the starting

frequency, the inverter will stop running and

keep in the stand-by state. The starting

frequency is not limited in the lower limit

frequency.

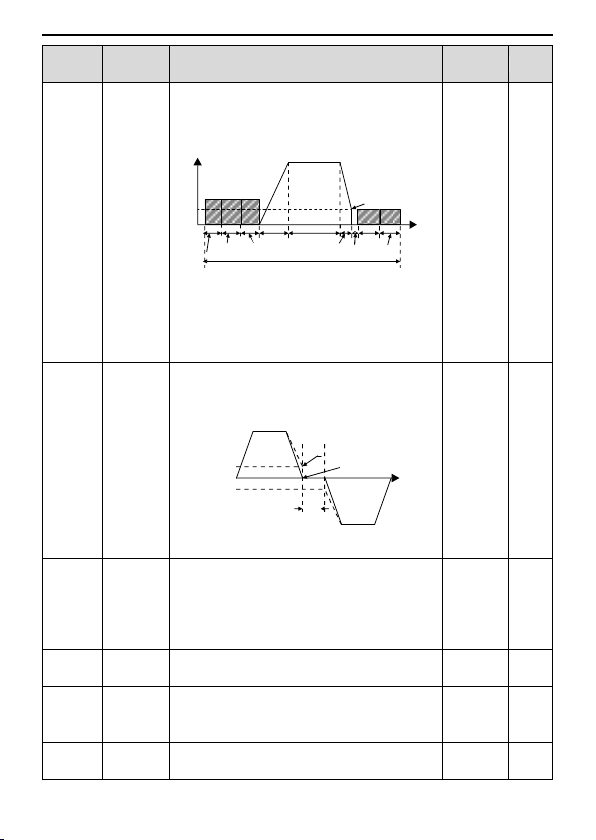

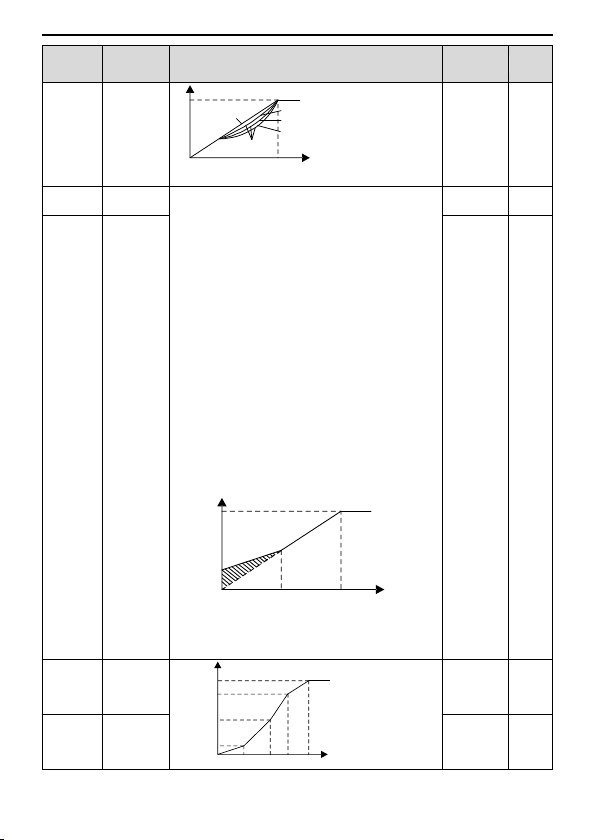

Output frequency

fmax

t1

T

f1 set by P01.01

f1

t1 set by P01.02

Setting range: 0.0–50.0s

0.0s

◎

P01.03

The

braking

current

before

starting

The inverter will carry out DC braking at the

braking current set before starting and it will

speed up after the DC braking time. If the DC

braking time is set to 0, the DC braking is

invalid.

The stronger the braking current, the bigger

the braking power. The DC braking current

before starting means the percentage of the

rated current of the inverter.

The setting range of P01.03: 0.0–100.0%

The setting range of P01.04: 0.00–50.00s

0.0%

◎

P01.04

The

braking

time before

starting

0.00s

◎

P01.05

ACC/DEC

selection

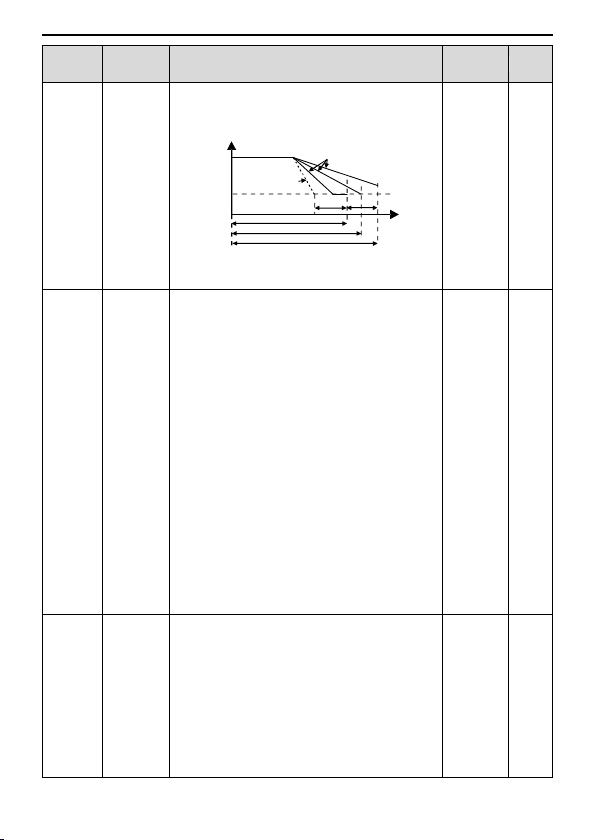

The changing mode of the frequency during

start-up and running.

0: Linear type

The output frequency increases or decreases

linearly.

0

◎

35

UMI-B1 UL Series Inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

fmax

Output frequency

t1 t2

T

1: S curve

P01.06

ACC time

of the

starting

step of S

curve

0.0–50.0s

3

4

t1=P01.06

t2=P01.07

t3=P01.06

t4=P01.07

Output frequency

T

0.1s

◎

P01.07

DEC time

of the

ending

step of S

curve

0.1s

◎

P01.08

Stop

selection

0: Decelerate to stop: after the stop command

becomes valid, the inverter decelerates to

reduce the output frequency during the set

time. When the frequency decreases to 0Hz,

the inverter stops.

1: Coast to stop: after the stop command

becomes valid, the inverter ceases the output

immediately. And the load coasts to stop at

the mechanical inertia.

0

○

P01.09

Starting

frequency

of DC

braking

Starting frequency of DC braking: start the DC

braking when running frequency reaches

starting frequency determined by P1.09.

Waiting time before DC braking: Inverters

blocks the output before starting the DC

braking. After this waiting time, the DC

braking will be started so as to prevent

over-current fault caused by DC braking at

high speed.

DC braking current: the value of P01.11 is the

percentage of rated current of inverter. The

bigger the DC braking current is, the greater

the braking torque is.

0.00Hz

○

P01.10

Waiting

time before

DC braking

0.00s

○

P01.11

DC braking

current

0.0%

○

P01.12

DC braking

time

0.00s

○

36

UMI-B1 UL Series Inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

DC braking time: the retention time of DC

braking. If the time is 0, the DC braking is

invalid. The inverter will stop at the set

deceleration time.

P01.04

ACC

P13.14

P01.23

Constant

speed

In running

DEC

P0110

P13.14

P01.12

P01.09

t

Setting range of P01.09: 0.00Hz–P00.03

(the Max. frequency)

Setting range of P01.10: 0.00–50.00s

Setting range of P01.11: 0.0–100.0%

Setting range of P01.12: 0.00–50.00s

P01.13

Dead time

of

FWD/REV

rotation

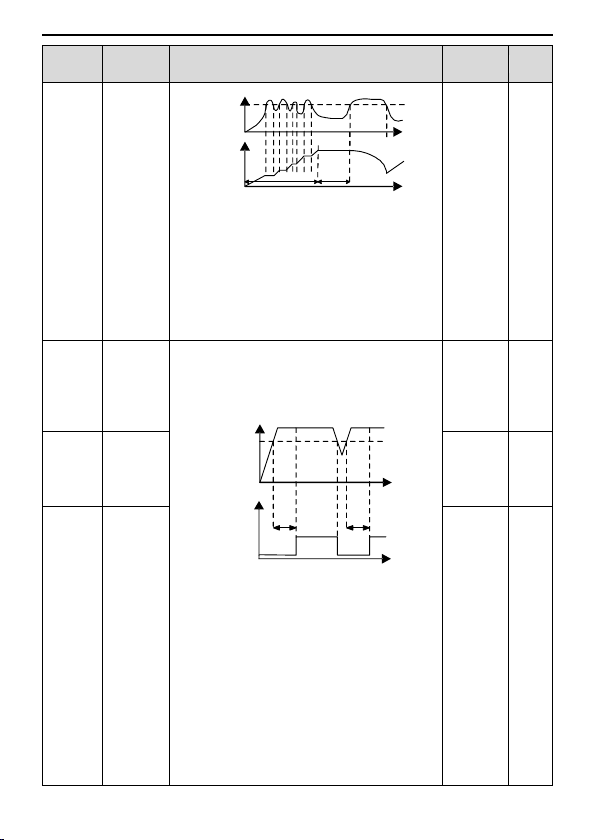

During the procedure of switching FWD/REV

rotation, set the threshold by P01.14, which is

as the table below:

Output frequency

FWD

REV

T

Starting

frequency

Shift after the

Zero frequency

Shift after the

Starting frequency

Setting range: 0.0–3600.0s

0.0s

○

P01.14

Switching

between

FWD/REV

rotation

Set the threshold point of the inverter:

0: Switch after zero frequency

1: Switch after the starting frequency

2: Switch after the speed reach P01.15 and

delay for P01.24

0

◎

P01.15

Stopping

speed

0.00–100.00Hz

0.50Hz

◎

P01.16

Detection

of stopping

speed

0: Detect at the setting speed

1: Detect at the feedback speed (only valid for

vector control)

1

◎

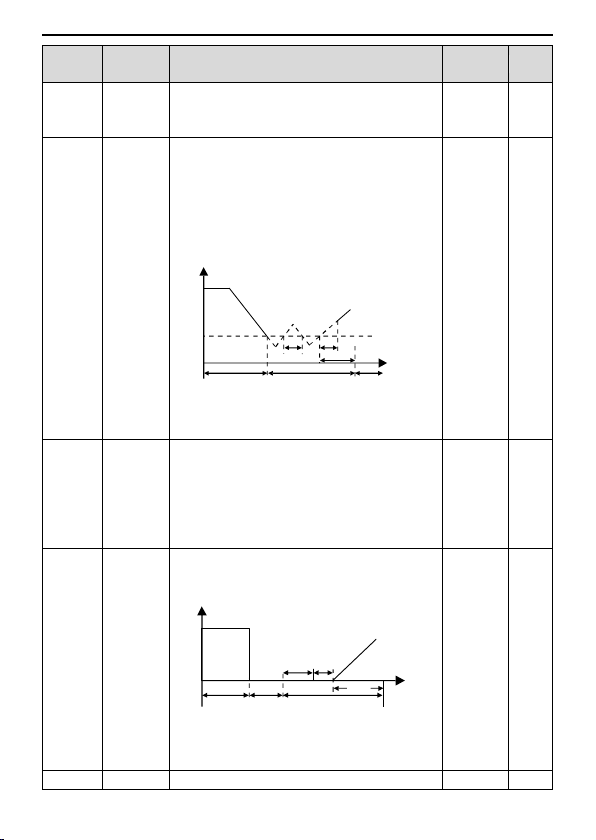

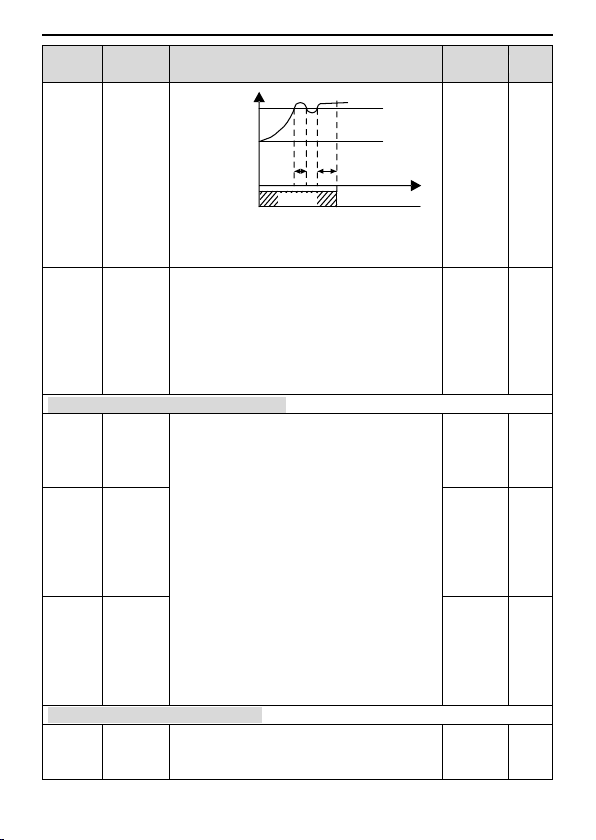

P01.17

Detection

time of the

When P01.16=1, the actual output frequency

of the inverter is less than or equal to P01.15

0.50s

◎

37

UMI-B1 UL Series Inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

feedback

speed

and is detected during the time set by P01.17,

the inverter will stop; otherwise, the inverter

stops in the time set by P01.24.

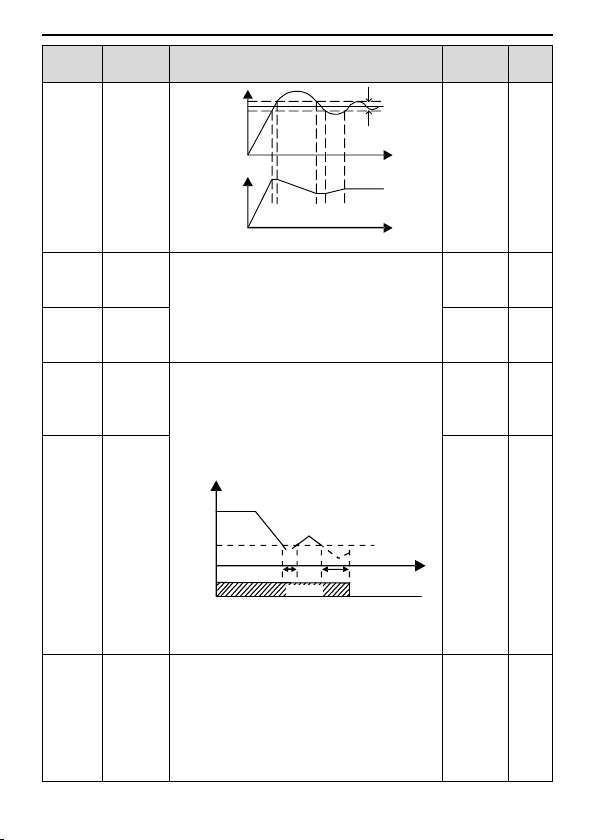

T

Stop

speed

A

Ramp

reference

frequency

Output frequency

Frequency

P01.24 P01.17

B

C

Running A

Running B

Running C

Setting range: 0.00–100.00s (only valid when

P01.16=1)

P01.18

Terminal

running

protection

selection

when

powering

on

When the running command channel is the

terminal control, the system will detect the

state of the running terminal during powering

on.

0: The terminal running command is invalid

when powering on. Even the running

command is detected to be valid during

powering on, the inverter won't run and the

system keeps in the protection state until the

running command is canceled and enabled

again.

1: The terminal running command is valid

when powering on. If the running command is

detected to be valid during powering on, the

system will start the inverter automatically

after the initialization.

Note: This function should be selected with

cautions, or serious result may follow.

0

○

P01.19

The

running

frequency

is lower

than the

lower limit

one (valid

if the lower

limit

This function code determines the running

state of the inverter when the set frequency is

lower than the lower-limit one.

0: Run at the lower-limit frequency

1: Stop

2: Hibernation

The inverter will coast to stop when the set

frequency is lower than the lower-limit one.if

the set frequency is above the lower limit one

0

◎

38

UMI-B1 UL Series Inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

frequency

is above 0)

again and it lasts for the time set by P01.20,

the inverter will come back to the running

state automatically.

P01.20

Hibernatio

n restore

delay time

This function code determines the hibernation

delay time. When the running frequency of

the inverter is lower than the lower limit one,

the inverter will stop to stand by.

When the set frequency is above the lower

limit one again and it lasts for the time set by

P01.20, the inverter will run automatically.

Running

Dormancy

t1 t2

Running

Time

Set frequency

t1<t3, so the inverter does not work

t1+t2=t3, so the inverter works

t3=P01.20

t3

Setting range: 0.0–3600.0s (valid when

P01.19=2)

0.0s

○

P01.21

Restart

after power

off

This function can enable the inverter start or

not after the power off and then power on.

0: Disabled

1: Enabled, if the starting need is met, the

inverter will run automatically after waiting for

the time defined by P01.22.

0

○

P01.22

The

waiting

time of

restart

after power

off

The function determines the waiting time

before the automatic running of the inverter

when powering off and then powering on.

Output frequency

Running

Power off Power on

Running

t

t1 t2

t1=P01.22

t2=P01.23

Setting range: 0.0–3600.0s (valid when

P01.21=1)

1.0s

○

P01.23

Start delay

The function determines the brake release

0.0s

○

39

UMI-B1 UL Series Inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

time

after the running command is given, and the

inverter is in a stand-by state and wait for the

delay time set by P01.23

Setting range: 0.0–60.0s

P01.24

Delay of

the

stopping

speed

Setting range: 0.0–100.0s

0.0s

○

P01.25

0Hz

output

Select the 0Hz output of the inverter.

0: Output without voltage

1: Output with voltage

2: Output at the DC braking current

0

○

P02 Group Motor 1

P02.01

Rated

power of

asynchron

ous motor

0.4–2.2kW (0.5~3HP)

Depend

on model

◎

P02.02

Rated

frequency

of

asynchron

ous motor

0.01Hz–P00.03

60.00Hz

◎

P02.03

Rated

speed of

asynchron

ous motor

1–36000rpm

Depend

on model

◎

P02.04

Rated

voltage of

asynchron

ous motor

0–1200V

Depend

on model

◎

P02.05

Rated

current of

asynchron

ous motor

0.8–6000.0A

Depend

on model

◎

P02.06

Stator

resistor of

asynchron

ous motor

0.001–65.535Ω

Depend

on model

○

40

UMI-B1 UL Series Inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

P02.07

Rotor

resistor of

asynchron

ous motor

0.001–65.535Ω

Depend

on model

○

P02.08

Leakage

inductance

of

asynchron

ous motor

0.1–6553.5mH

Depend

on model

○

P02.09

Mutual

inductance

of

asynchron

ous motor

0.1–6553.5mH

Depend

on model

○

P02.10

Non-load

current of

asynchron

ous motor

0.1–6553.5A

Depend

on model

○

P02.11

Magnetic

saturation

coefficient

1 for the

iron core of

AM1

0.0–100.0%

80.0%

◎

P02.12

Magnetic

saturation

coefficient

2 for the

iron core of

AM1

0.0–100.0%

68.0%

◎

P02.13

Magnetic

saturation

coefficient

3 for the

iron core of

AM1

0.0–100.0%

57.0%

◎

P02.14

Magnetic

saturation

coefficient

0.0–100.0%

40.0%

◎

41

UMI-B1 UL Series Inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

4 for the

iron core of

AM1

P02.26

Motor

overload

protection

selection

0: No protection

1: Common motor (with low speed

compensation). Because the heat-releasing

effect of the common motors will be

weakened, the corresponding electric heat

protection will be adjusted properly. The low

speed compensation characteristic

mentioned here means reducing the

threshold of the overload protection of the

motor whose running frequency is below

30Hz.

2: Frequency conversion motor (without low

speed compensation). Because the

heat-releasing of the specific motors won't be

impacted by the rotation speed, it is not

necessary to adjust the protection value

during low-speed running.

2

◎

P02.27

Motor

overload

protection

coefficient

Times of motor overload M = Iout/(In x K)

In is the rated current of the motor, Iout is the