Page 1

Z12

STEREO MICROSCOPE

MANUAL

73 Mall Drive, Commack, NY 11725 • 631-543-2000 (P) • 631-589-6975 (F)

www.unitronusa.com • info@unitronusa.com

Page 2

Page 3

Z12 ZOOM STEREO MICROSCOPE

CONTENTS

SAFETY NO TES ................................................................................................................... 3

CARE AND MAINTENANCE ................................................................................................ 3

INTRODUCTION .................................................................................................................. 4

UNPACKING AND COMPONENTS ..................................................................................... 4

COMPONENT DIAGRAMS .................................................................................................. 5

ASSEMBLY DIAGRAM ......................................................................................................... 6

DETAILED ASSEMBLY ..................................................................................................... 7-9

OPERATION

ILLUMINATION ........................................................................................................................ 10

REFLECTOR............................................................................................................................ 10

FOCUSING TENSION .............................................................................................................. 10

DIOPTER & FOCUSING .......................................................................................................... 11

INTERPUPILLARY DISTANCE ................................................................................................ 11

VIEWING ANGLE ..................................................................................................................... 11

CLICK/CLICK STOP................................................................................................................. 12

EYEGUARDS ........................................................................................................................... 12

APERTURE DIAPHRAGM ....................................................................................................... 13

LIGHT PATH ........................................................................................................................... 13

MOUNTING A MICROSCOPY CAMERA (OPTIONAL) ........................................................... 13

POLARIZER/ANALYZER ......................................................................................................... 14

TROUBLESHOOTING ................................................................................................... 15-16

MAINTENANCE .................................................................................................................. 17

SERVICE ............................................................................................................................ 17

WARRANTY ....................................................................................................................... 17

UNI

TRON

73 Mall Drive, Commack, NY 11725 • 631-543-2000 • www.unitronusa.com 2

Page 4

Z12 ZOOM STEREO MICROSCOPE

SAFETY NOTES

1. Open the shipping carton c ar ef ul ly to prevent any accessory , i.e. objectives or eyepieces, fro m dropping

and being damaged.

2. Do not discard the molded shipping carton; the contain er should be retained should the microscope ever

require reshipment.

3. Keep the instrument out of direct sunlight, high temp er at ur e or humidity, and dusty environments. Ensure

the microscope is located on a smooth, level and firm surface.

4. If any specimen solutions or ot her li qui ds s plash onto the stage, objective or any other component ,

disconnect the power cord immediately and wipe up the spillage. Otherwise, the instrument may be

damaged.

5. All electrical connectors (power cord) should be inse r t ed int o an electrical surge suppressor t o prevent

damage due to voltage fluctuations.

6. LAMP REPLACEMENT -- CAUTION: the glass housing of t he l amp may be extremely hot.

DO NOT attempt to chang e the lamp before it is complete ly c ool ed or w it hout wearing

adequate skin protection.

7. FUSE REPLACEMENT -- For safety when replac in g the fuse (ONLY replace w ith t he same

size, type and rating of origin al fus e) , be sure the main switch is in the off position, disconnect

the power cord from outlet, and r epla ce the fuse. Reconnect the pow er cor d and turn unit on.

8. Confirm that the input voltage indicated on your micr oscope corresponds to your line v olt age. The use of a

different input voltage other than indicated will cause severe damage to the microscope.

CARE AND MA INTE NANCE

1. Do not attempt to disasse mb le a ny component including ey epie ces , objectives or focusing assembly.

2. Keep the instrument clean ; r emov e dirt and debris regularly. Accumulated dirt on metal surfaces should be

cleaned with a damp cloth. M or e per sistent dirt should be removed using a mild soap solution. Do not use

organic solvents for cleansing.

3. The outer surface of the opt ics should be inspected and clean ed periodically using an air stream from an

air bulb. If dirt remains on the optical surface, use a soft cloth or c ot t on swab dampened with a lens

cleaning solution (available at camera stores). All optical lenses should be swabbed using a circular

motion. A small amount of absor bent cotton wound on the end of a tapered stick such as cott on swabs or

Q-tips, makes a useful tool for cleani ng r ecessed optical surface s. Avoid using an excessive am ount of

solvents as this may cause pr oblems with optical coatings or cemented optics or the flowing solvent may

pick up grease making cleani ng more difficult.

4. Store the instrument in a c ool, dr y environment. Cover t he m icroscope with the dust cover when not in

use.

5. UNITRON® microscopes are precision instruments which req uire periodic preventat ive maintenance to

maintain proper perform ance and to compensate fo r nor m al wear . A n annual schedule of preventative

maintenance by qualified personnel is highly recommended. Your authorized UNITRON

arrange for this service.

®

distributor can

UNITRON

73 Mall Drive, Commack, NY 11725 • 631-543-2000 • www.unitronusa.com 3

Page 5

Z12 ZOOM STEREO MICROSCOPE

INTRODUCTION

Congratulations on the purchase of your new UNITRON® microscope. UNITRON® microscopes are

engineered and manufactured to the highest quality standards. Your microscope will last a lifetime if used

and maintained properly. UNITRON

staff of trained technicians in our New York facility. Careful quality control procedures ensure each

microscope is of the highest quality prior to shipment.

®

microscopes are carefully assembled, inspected and tested by our

UNPACKING AND COMPONENTS

Your microscope arrived packed in a molded shipping carton. Do not discard the carton: the carton

should be retained for reshipment of your microscope if needed. Avoid placing the microscope in dusty

surroundings or in high temperature or humid areas as mold and mildew will form. Carefully remove the

microscope from the EPE foam container by its arm and base and place the microscope on a flat,

vibration-free surface. Check the components against the packing list included with your microscope.

UNITRON

73 Mall Drive, Commack, NY 11725 • 631-543-2000 • www.unitronusa.com 4

Page 6

Trinocular

Aperture

Coarse/Fine Focus

Adjustment Knobs

Eyepiece

Stage Insert

Camera/Photo

Port

Focus

Tension

Zoom

Lock Knob

Stage Clip

Light Path

Selection Slider

Objective

Base

Reflector

Microscope

COMPONENTS DIAGRAM

Z12 ZOOM STEREO MICROSCOPE

Diaphragm

Control

Body

Adjustment Collar

Viewing Head

Knob

Drive

Plate

UNITRON

Adjustment

Knob

73 Mall Drive, Commack, NY 11725 • 631-543-2000 • www.unitronusa.com 5

Page 7

Z12 ZOOM STEREO MICROSCOPE

ASSEMBLY DIAGRAM

The diagram below shows how to assemble the various components. The numbers indicate the order of

assembly. Use the 1.5mm and 3mm hex wrenches that are supplied with your microscope when

required. Be sure to keep this wrench for changing out components or making adjustments.

When assembling the microscope, make sure that all parts are free of dust and dirt, and avoid scratching

any parts or touching glass surfaces.

⑤

① Focus Drive

② Microscope Body

④

③

⑥

②

⑦

①

⑨

⑧

③ Objective

④ Trinocular Viewing Head

⑤ Eyepieces

⑥ Stage Insert Plate

⑦ Stage Clips

⑧ Illuminator Light Guide

⑨ Illuminator Power Cord

UNITRON

73 Mall Drive, Commack, NY 11725 • 631-543-2000 • www.unitronusa.com 6

Page 8

Mount the Focus Drive (Fig. 1-2)

①

③

Fig. 1

②

Fig. 2

Correct

X

Wrong!

④

Fig. 3

Fig. 4

① ③ ② ① ②

DETAILED ASSEMBLY

Z12 ZOOM STEREO MICROSCOPE

Loosen the lock knob ① of the focus dri ve ②. Position the

focus drive as shown and gently slide it all the way down

onto the column pole ③ until the bottom of the focus drive is

flush with the column base ④, Fig. 2.

Tighten the lock knob.

WARNING: the focus drive MUST be mounted correctly as

shown in Fig. 2. Mounting it improperly will result in the

microscope tipping over which may cause damage.

Mount the Microscope Body (Fig. 3)

Remove the access cap ① on the side of the focus group

and loosen the screw inside with a 3mm hex wrench.

Carefully slide the microscope body ② onto the dovetail

interface ③ of the focus group as shown.

Tighten the lock screw on the focus group and replace the

access cap.

Install the Objective (Fig. 4)

Carefully position and screw the objective ① into the

bottom ② of the microscope body by rotating it clockwise as

shown until it stops.

DO NOT force it on or overtighten it.

UNITRON

73 Mall Drive, Commack, NY 11725 • 631-543-2000 • www.unitronusa.com 7

Page 9

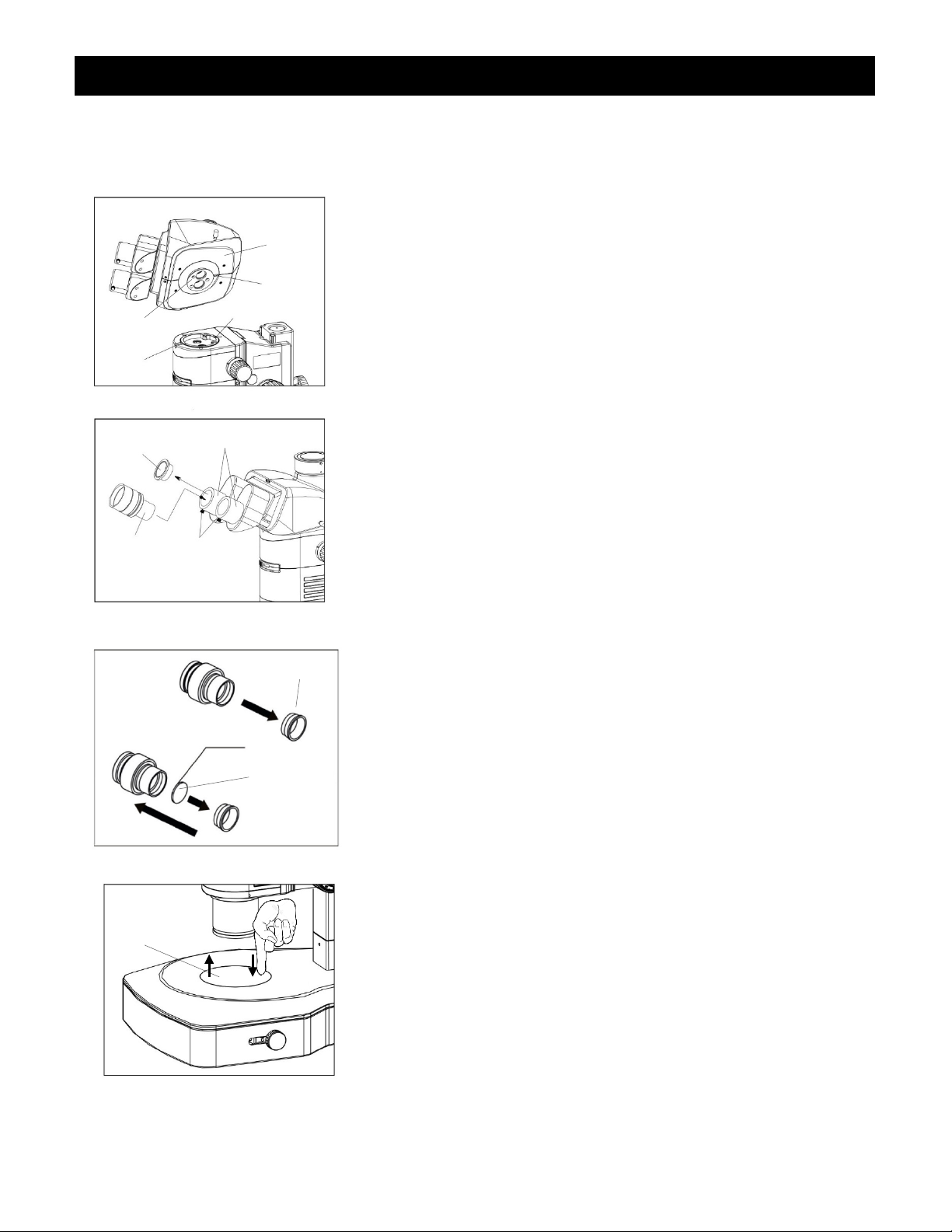

Mount the Viewing Head (Fig. 5-6)

①

⑤

Fig. 5

③

Fig. 6

Fig. 7

Fig. 8

① ② ④ ⑥ ⑦

⑧

⑨

Inscription Side

①

②

DETAILED ASSEMBLY - continued

Z12 ZOOM STEREO MICROSCOPE

Loosen the lock screw ① on the front of the microscope

body with the 3mm mm hex wrench.

With the eyepiece tubes ② facing forward (as shown in

Fig. 6), carefully slide the dovetail ③ (Fig. 5) on the bottom

of the viewing head ④ (Fig. 5) onto the dovetail mount on

the top of the microscope body by aligning the orientation

groove ⑤ with the orientation pin ⑥ of the microscope

body. Make sure it is seated properly (it should be level and

not wobble), then tighten the lock screw.

Install the Eyepieces (Fig. 6)

Remove the eyetube caps ⑦ and insert the eyepieces ⑧

into the eyepiece tubes ②.

Lock in the eyepieces by tightening the thumbs screws ⑨

on each eyepiece tube.

Mount/Unmount the Eyepiece Reticle (Fig. 7)

To mount the reticle: unscrew the mounting ring ① from

the eyepiece by turning it counterclockwise.

Clean the reticle ② and insert it into the mounting ring with

the inscription side as shown.

Screw the mounting ring back onto the eyepiece.

To remove the reticle: unscrew the mounting ring from the

eyepiece, then carefully take out the reticle and wrap it in

clean, soft, lin t-free paper for storage.

Screw the mounting ring back onto the eyepiece.

Install the Stage Insert Plate (Fig. 8)

Gently push the stage insert plate ① with the edge tilted

toward the spring on the inside of the hole in the base and

set it into place.

To remove the stage insert plate, press down with one finger

near the spring – it will pop up on the opposite side and you

can then lift it out.

UNITRON

73 Mall Drive, Commack, NY 11725 • 631-543-2000 • www.unitronusa.com 8

Page 10

Install the Stage Clips (Fig. 9)

①

②

Fig. 9

③

Fig. 10

① ② ④ ⑤ ⑥ ⑦ ⑧

⑨

DETAILED ASSEMBLY - continued

Z12 ZOOM STEREO MICROSCOPE

Insert the stage clip post of the stage clip ① into the hole ②

on the top of the base as shown; repeat for other stage clip.

Connect the LED Illuminat or & P ow er S upply

(Fig. 10)

Make sure the power switch on the illuminator ① is set to

“OFF”.

Align the end of the flat part of the illuminator light guide ②

with the lock screw ③ on the socket ④ on the front of the

illuminator and slide it in and tighten the lock screw.

Insert the other end of the illuminator light guide into the

socket ⑤ on the back of the microscope and tighten the lock

screw on the top of the socket.

Insert one end ⑥ of the power cord on the power supply ⑦

into the socket ⑧ on the back of the illuminator.

Plug the other end ⑨ into the corresponding socket on the

other end of the power supply.

Plug the other end of the power supply into a grounded (3prong) outlet.

NOTE: Always use the power cord that is provided with your

microscope; using a different power cord may damage your

microscope. Should you need a replacement, contact your

authorized UNITRON dealer or call UNITRON at 1-631-5432000 for a dealer nearest you.

UNITRON

73 Mall Drive, Commack, NY 11725 • 631-543-2000 • www.unitronusa.com 9

Page 11

Adjusting the Illuminat ion (Fig. 11)

②

①

Fig. 11

Fig. 12

Fig. 13

① ① ②

③

OPERATION

Z12 ZOOM STEREO MICROSCOPE

Turn the power switch ① to “ON”.

NOTE: For longer lamp lif e always turn the light

intensity control knob ② to the lowest illumination

intensity setting possible before turning the power on or

off.

The light level may need adjustment depending upon

the specimen density and objective magnification.

Adjust the light intensity for comfortable viewing by

turning the light intensity control knob clockwise to

increase brightness. Turn counterclockwise to

decrease brightness.

Adjusting the Reflector (Fig. 12)

The reflector has two sides: one is a plane mirror, the

other is sandblasted aluminum. Both sides reflect light

but the plane mirror is provides a stronger reflection.

You can change the reflector type or the reflection

intensity by rotating the reflector adjustment knob ①.

The reflector adjustment knob can also be moved from

front to back to achieve different lighting effects of the

reflector.

Adjusting the Focusing Tension (Fig. 13)

If the feel is very heavy when focusing with the focusing

knobs ①, or the specimen leaves the focus plane after

focusing, adjust the tension with the tension adjustment

ring ②.

Turn the tension adjustment ring clockwise to tighten or

counterclockwise to loosen according to user

preference.

UNITRON

73 Mall Drive, Commack, NY 11725 • 631-543-2000 • www.unitronusa.com 10

Page 12

Adjusting the Diopter & Focus (Fig. 14)

Left Diopter

Right Diopter

Fig. 14

Fig. 16

Fig. 15

OPERATION (continued)

Z12 ZOOM STEREO MICROSCOPE

Adjustment Ring

Adjustment Ring

Set the dioptor rings of both eyepieces to “0” position.

(Do this when users change, because different users

will have different diopter settings.)

Place an easy-to-observe specimen on the stage plate,

i.e., a coin.

Rotate the zoom knob to the highest magnification, then

turn the focusing knob to focus the specimen.

Rotate the zoom knob to the lowest magnification,

looking only into the left eyepiece, adjust the diopter

ring on left eyepiece to focus the specimen.

Repeat procedure for the right eyepiece.

Adjusting Interpupi llary Distance (Fig. 15)

To adjust the interpupillary distance, hold the left and

right eyetubes while observing a specimen. Rotate the

eyetubes around the central axis until the fields of view

of both eyetubes coincide completely. A complete circle

should be seen in the viewing field when viewing the

specimen slide. An improper adjustment will cause

operator fatigue and will disrupt the objective

parfocality.

Adjusting the Viewing Angle (Fig. 16)

To adjust the viewing angle, hold the eyepiece tubes

with both hands and move them up or down to the

position that feels most comfortable.

The angle can be adjusted from 5° to 45°.

UNITRON

73 Mall Drive, Commack, NY 11725 • 631-543-2000 • www.unitronusa.com 11

Page 13

Changing the Click/Click Stop Feature

down eyeguards.

Click

Fig. 17

Fig. 18

①

OPERATION (continued)

Click Stop

Z12 ZOOM STEREO MICROSCOPE

(Fig. 17)

The microscope is equipped with a Click/Click Stop

feature that enables the user to set the magnification

value indicated on the zoom knob to stop at each fixed

magnification and will make a “click” sound, or to finely

adjust the zoom magnification.

To turn on the Click feature to click at each

magnification value, using a 3mm hex wrench, turn the

Click/Click Stop screw ① clock wise as shown by the

arrow in Fig. 17.

To turn on the Click Stop feature to finely adjust the

zoom magnification, using a 3mm hex wrench, turn the

Click/Click Stop screw ① counterclockwise.

NOTE: Be careful not to overturn the screw for either

position as it may result in damage to the housing and

internal mechanisms of the microscope.

Adjusting the Eyepiece Eyeguards

(Fig. 18)

The eyepieces come standard with rollThe eyeguards should be rolled down ① for users

wearing eyeglasses to prevent them from being too far

from observing through the eyepieces. Or, not rolled

down ② for those who don’t wear glasses to prevent

extraneous light from entering the eyepiece which may

interfere with specimen observation.

UNITRON

73 Mall Drive, Commack, NY 11725 • 631-543-2000 • www.unitronusa.com 12

Page 14

Adjusting the Aperture Di a phragm

screw ⑤.

①

Fig. 19

Fig 20

① ② ① ② ③ ⑥ ④ ⑤ ⑦

Fig 21

OPERATION (continued)

Z12 ZOOM STEREO MICROSCOPE

(Fig. 19)

Adjust the aperture diaphragm by the aperture

diaphragm control ①.

To enlarge the aperture diaphragm, slide the control to

the left until the desired contrast of the observed image

is achieved.

To decrease the aperture diaphragm, slide the control to

the right until the desired contrast of the observed image

is achieved.

Selecting the Light Pat h (Fig. 20)

The Z12 is outfitted with a binocular viewing head with

one photo port for HDMI/digital imaging. You must

select the appropriate light path for observing

specimens.

The light path is set to 100% to the binocular eye-pieces

as the default setting at our facilities where the light path

selection slider ① is pushed all the way in.

Pull the light path selection slider all the way out to send

100% to the top photo port for HDMI/digital imaging and

documentation.

Mounting a Microscop y Camera (Optional)

(Fig. 21)

Loosen the lock screw ① on the camera/photo port un til it

is flush with the inside of the portl remov e the dust cap ②.

Remove the dust caps from both ends of the c-mount ③

and from your camera lens and at tach the top opening ④

on the c-mount to the threaded mount on your camera.

Attach the bottom dovetail mount of the c-mount (with the

mounted camera) onto the camera/photo port and tighten

the lock screw ⑤.

Focus the image in the binocular view then pull the light

path selection lever out ⑥. If the image is not clear,

loosen the lock screw ⑤ and adjust the focusing sc r ew ⑦

until the image is clear on the monitor, then tighten the lock

UNITRON

73 Mall Drive, Commack, NY 11725 • 631-543-2000 • www.unitronusa.com 13

Page 15

①

Fig. 22

② ⑥ ③

⑤

④

Z12 ZOOM STEREO ICAL MICROSCOPE

OPERATION (continued)

Using the Polarizer/Analyzer (Fig. 22)

The simple polarizer includes the polarizer and

analyzer.

Remove the stage insert plate ① (see Fig. 8, p. 3).

Insert the polarizer ② with the flat edge closest to

the column (or aligned with the spring on the inside of

the hole in the base)

3mm hex wrench. Replace the stage insert plate.

Slide the analyzer ③ onto the bottom outside

diameter of the objective ④ and tighten the analyzer

lock screw ⑤.

With the 360° rotating analyzer, you can change the

orthogonal state of the polarized light by rotating the

analyzer adjustment ring ⑥.

, and screw it in place using the

UNITRON

73 Mall Drive, Commack, NY 11725 • 631-543-2000 • www.unitronusa.com 14

Page 16

The brightness is set too low

Set it to the appropriate position

The field diaphragm is not open enough or

closed

Reduce them to the minimum required

Turn the nosepiece into the position where

you can hear it engaged

Dirt or dust has accumulated on the lens

(objective or eyepieces)

Light path selection slider is not in the right

position

The color filter, polarizer or analyzer is not

inserted fully

Dirt/dust on the specimen

Replace with a clean specimen

Cover glass on the specimen slide

Clean the specimen

The specimen is not vertical to the objective

Adjust it

The nosepiece is not in the correct position

Turn the nosepiece into the correct position

The aperture diaphragm is not open correctly

Adjust it

The light path selection slider is not in the

correct position

The objective is not correctly engaged in the

the aperture diaphragm is opened or stopped

down too far in brightfield observation

The lens (condenser, objective, eyepieces)

The objective is not in the center of the light

Insure the nosepiece is in the “clicked”

The specimen is not correctly positioned on

The eyepiece for the right eye is different from

Z12 ZOOM STEREO MICROSCOPE

TROUBLESHOOTING

Under certain conditions, performance of this unit may be adversely affected by factor s other than defects. If a

problem occurs, please re view the following list and take remedial action as needed. If you cannot solve the

problem after checking the ent ire list, please contact your local dealer for assistance.

OPTICAL

PROBLEM CAUSE

The illumination is on, but the

field of view is dark.

The edge of the field of view is

obscured or not evenly

illuminated.

Dirt or dust is visible in the field

of view

The image is not clear

SOLUTION

The bulb is burnt out. Replace it with a new one

Open the field diaphragm

Too many filters are in the optical path

The nosepiece is not in the located position

Dirt/dust on the eyepiece Clean the eyepieces

number

Clean the lens

Pull it into the right position

Push it in all the way

Push it into the correct position

Visibility is poor

Image is not sharp

Contrast is poor

Details are indistinct

One side of the image is dark,

blurred or it moves while

focusing

The eyes tire easily; the right

field of view doesn’t

superimpose with the left

UNITRON

73 Mall Drive, Commack, NY 11725 • 631-543-2000 • www.unitronusa.com 15

light path

are dirty

path

the stage

Interpupillary distance is incorrect Adjust the interpupillary distance

Diopter adjustment is incorrect Adjust the diopter

the left one

Turn the nosepiece into the engaged position

adjust the aperture diaphragm properly

Clean it thoroughly

position

Reposition the specimen on the stage

Use the same eyepieces

Page 17

TROUBLESHOOTING (continued)

MECHANICAL PART

Z12 ZOOM STEREO MICROSCOPE

PROBLEM CAUSE

The coarse adjustment knob is

too difficult to rotate

The image goes out of focus

during observation or the stage

drops by itself

The tension adjustment ring is tightened too

much

The tension adjustment collar is too loose Tighten it

Loosen it

SOLUTION

ELECTRICAL SYSTEM

PROBLEM CAUSE

No power to the lamp Check the power cord is connected correctly

The lamp doesn’t light

The light intensity is not

enough

The lamp keeps burning out The wrong lamp is used Replace the lamp with the correct one

The lamp is not installed correctly Install it correctly

The lamp burns out Replace the lamp

The light intensity control knob is no t set

properly

The wrong lamp is used Replace the lamp with the correct one

Adjust the light intensity control knob

SOLUTION

The lamp flickers or the

brightness is not stable

UNITRON

73 Mall Drive, Commack, NY 11725 • 631-543-2000 • www.unitronusa.com 16

The lamp will burn out soon Replace the lamp

The power supply doesn’t con nect well Connect the power supply correctly

Page 18

Z12 ZOOM STEREO MICROSCOPE

MAINTENANCE

Please remember to never leave the microscope with any of the objectives or eyepieces removed and

always protect the microscope with the dust cover when not in use.

SERVICE

UNITRON® microscopes are precision instruments which require periodic servicing to keep them

performing properly and to compensate for normal wear. A regular schedule of preventative maintenance

by qualified personnel is highly recommended. Your authorized UNITRON

this service. Should unexpected problems be experienced with your instrument, proceed as follows:

1. Contact the UNITRON

®

distributor from whom you purchased the microscope. Some

problems can be resolved simply over the telephone.

2. If it is determined that the microscope should be returned to your UNITRON

UNITRON

®

for warranty repair, pack the instrument in its original Styrofoam shipping carton. If you no

longer have this carton, pack the microscope in a crush-resistant carton with a minimum of three inches

of a shock absorbing material surrounding it to prevent in-transit damage. The microscope should be

wrapped in a plastic bag to prevent Styrofoam dust from damaging the microscope. Always ship the

microscope in an upright position; NEVER SHIP A MICROSCOPE ON ITS SIDE. The microscope or

component should be shipped prepaid and insured.

LIMITED MICROSCOPE WARRANTY

®

distributor can arrange for

®

distributor or to

This microscope is warr anted to be free f rom defects in material and workm anship for a period of five (5) years f or

mechanical and optical components and one (1) year for LED bulb and electrical components from the date of

invoice to the original (end user) purchaser. This warranty does not cover damage caused in-transit, misuse,

neglect, abuse or damage resulting from improper servicing or modification by other than UNITRON

service personnel. This warranty does not cover any routine maintenance work or any other work, which is

reasonably expected to be performed by the purchaser. Normal wear is excluded from this warranty. No

responsibility is assumed for unsatisfactory operating performance due to environmental conditions such as

humidity, dust, corros ive chem icals , deposition of oil or other for eign mat ter, spillage or other cond itions beyond the

control of Unitron Ltd. This warranty expressl y excludes any liabilit y by UNITRON Ltd. for consequ ential loss or

damage on any groun ds, such as (but not lim ited to) the non-availability to the End User of the product(s) under

warranty or the need to repair work processes. Should any defect in material, workmanship or electronic

component occur under thi s warranty contact your UNITRON

warranty is l imited to the c ontinental United States of America. All item s returne d for warrant y repair must be s ent

freight prepaid and insur ed to Unitron Lt d., 73 Mall Dri ve, Comm ack, NY 11725 – USA. All war rant y repair s will be

returned freight prepaid t o any destination with in the continental Unit ed States of Am erica. For all foreign warr anty

repairs, return freight c harges are the responsibility of the individual/com pany who returned the merchandise for

repair.

UNITRON

UNITRON® is a registered trademark of UNITRON, Ltd., Commack, NY 11725

73 Mall Drive, Commack, NY 11725 • 631-543-2000 • www.unitronusa.com 17

®

distributor or UNIT RON® at (631) 543-2000. This

®

approved

Loading...

Loading...