Page 1

查询5962-9168901MXA供应商

Brushless DC Motor Controller

FEATURES

Drives Power MOSFETs or Power Darlingtons

•

Directly

50V Open Collector High-Side Drivers

•

Latched Soft Start

•

High-speed Current-Sense Amplifier with Ideal

•

Diode

Pulse-by-Pulse and Average Current Sensing

•

Over-Voltage and Under-Voltage Protection

•

Direction Latch for Safe Direction Reversal

•

Tachometer

•

Trimmed Reference Sources 30mA

•

Programmable Cross-Conduction Protection

•

• Two-Quadrant and Four-Quadrant Operation

DESCRIPTION

The UC3625 family of motor controller ICs integrate most of the

functions required for high-performance brushless DC motor con

trol into one package. When coupled with external power

MOSFETs or Darlingtons, these ICs perform fixed-frequency PWM

motor control in either voltage or current mode while implementing

closed loop speed control and braking with smart noise rejection,

safe direction reversal, and cross–conduction protection.

Although specified for operation from power supplies between 10V

and 18V, the UC1625 can control higher voltage power devices

with external level-shifting components. The UC1625 contains fast,

high-current push-pull drivers for low-side power devices and 50V

open-collector outputs for high-side power devices or level shifting

circuitry.

The UC1625 is characterized for operation over the military tem

perature range of –55°C to +125°C, while the UC2625 is charac

terized from –40°C to +105°C and the UC3625 is characterized

from 0°C to 70°C.

application

INFO

available

(NOTE: ESD Protection to 2kV)

UC1625

UC2625

UC3625

-

-

-

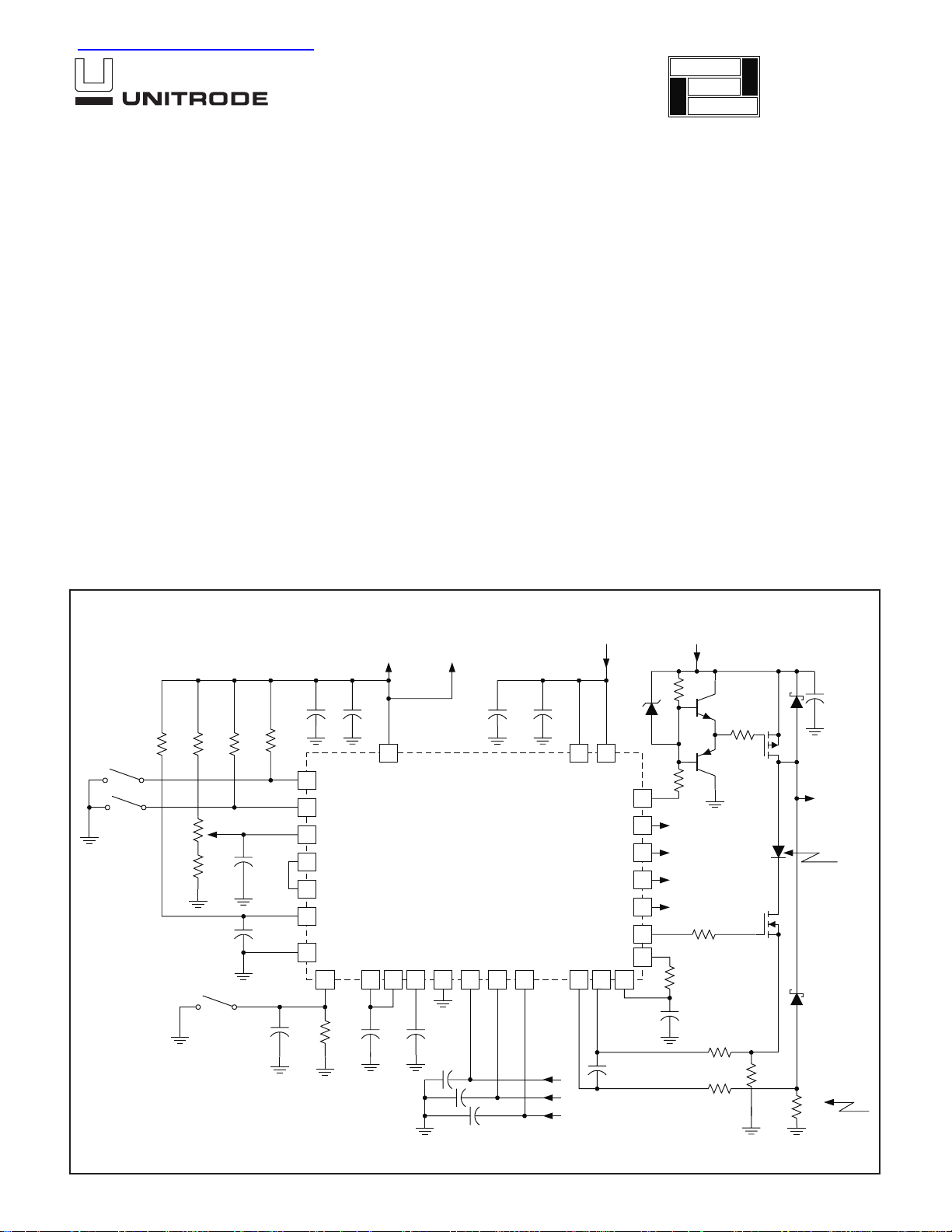

TYPICAL APPLICATION

10kΩ

3kΩ

R

QUAD

DIR

OSC

33kΩ

1k

4kΩ

BRAKE

100nF

2200pF

C

OSC

10kΩ

3nF

C

16

17

18

14

13

12

20

VMOTOR+15V

3kΩ

3kΩ

TO OTHER

CHANNELS

TO OTHER

CHANNELS

10Ω

10kΩ

100nF

2N3904

2N3906

IRF532

240Ω

240Ω

10Ω

IRF9350

0.02Ω

R

S

+

100µF

TO

MOTOR

REQUIRED

FOR BRAKE

AND FAST

REVERSE

REQUIRED

FOR

AVERAGE

CURRENT

SENSING

0.02Ω

R

D

+5V TO HALL

VREF

100nF

20µF

22

6

1

28

27

25

15

21

68kΩ

T

R

T

5nF 100nF

SENSORS

100nF

2 19

UC3625

24326

23 8 9 10 4 5 7

2nF

2nF

2nF

+

20µF

FROM

HALL

SENSORS

11

5nF

SLUS353A - NOVEMBER 1999

UDG-99045

Page 2

ABSOLUTE MAXIMUM RATINGS

VCC Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +20V

Pwr V

PWM In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 to 6V

E/A IN(+), E/A IN(–) . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 to 12V

I

SENSE1

OV–Coast, Dir, Speed-In, S

H1, H2, H3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 to 12V

PU Output Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 to 50V

PU Output Current . . . . . . . . . . . . . . . . . . +200 mA continuous

PD Output Current . . . . . . . . . . . . . . . . . .±200 mA continuous

E/A Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . .±10 mA

I

SENSE

Tach Out Output Current . . . . . . . . . . . . . . . . . . . . . . . .±10 mA

V

REF

Operating Temperature Range UC1625. . . . . . –55°C to 125°C

Operating Temperature Range UC2625. . . . . . –40°C to 105°C

Operating Temperature Range UC3625. . . . . . . . . 0°C to 70°C

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . +20V

CC

, I

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . –1.3 to 6V

SENSE2

START, Quad Sel . . . . . . –0.3 to 8V

Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . –10 mA

Output Current . . . . . . . . . . . . . . . . . . –50 mA continuous

UC1625

UC2625

UC3625

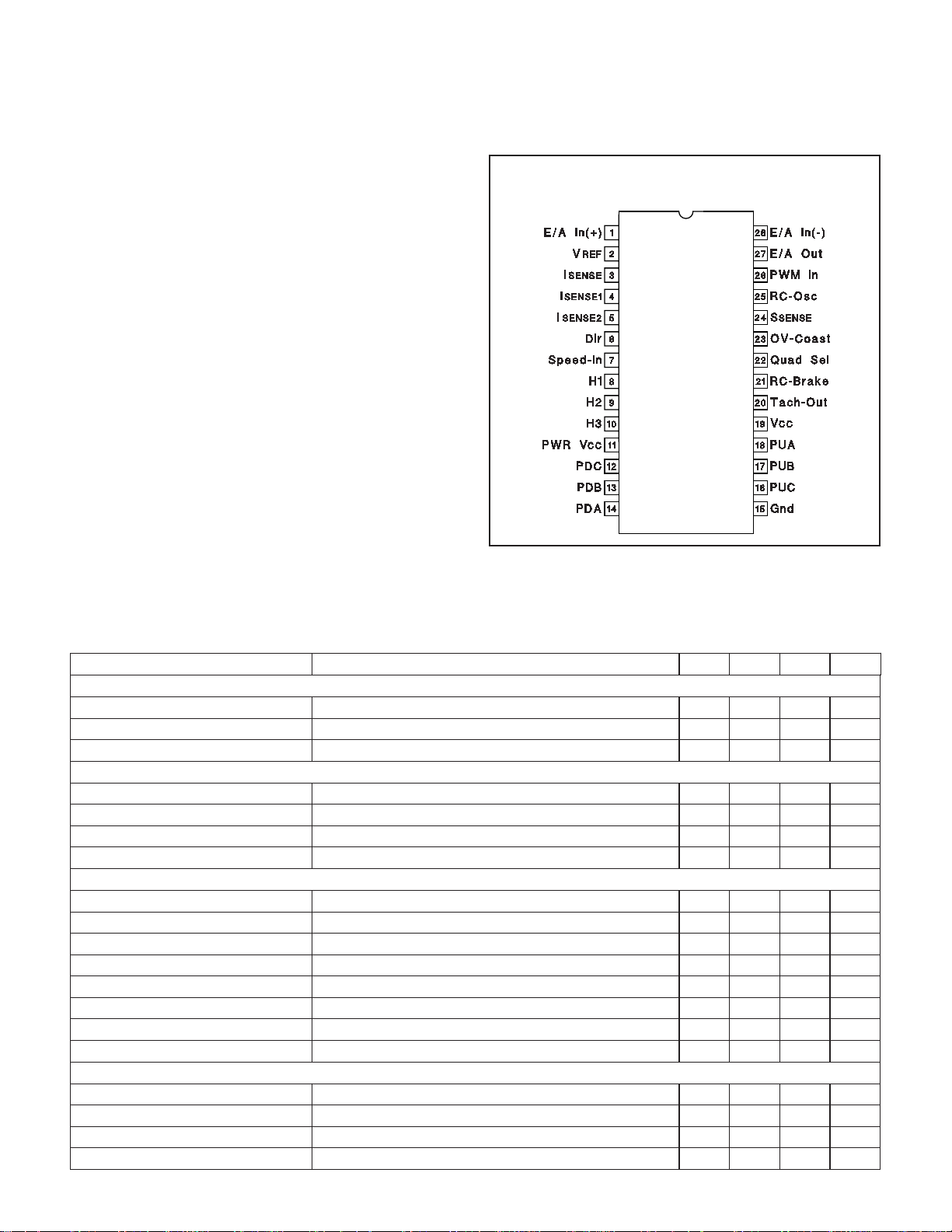

CONNECTION DIAGRAM

DIL-28 (TOP VIEW)

J or N PACKAGE

Note 1: Currents are positive into and negative out of the spec

-

ified terminal.

Note 2: Consult Unitrode Integrated Circuits databook for infor

mation regarding thermal specifications and limitations

of packages.

Note 3: This pinout applies to the SOIC (DW), PLCC (Q), and

LCC (L) packages (ie. pin 22 has the same function on all

packages.)

ELECTRICAL CHARACTERISTICS: Unless otherwise stated, these specifications apply for: TA= 25°C; Pwr VCC= VCC= 12V;

R

OSC

20k to V

=

REF

; C

OSC

= 2nF; R

TACH

= 33k; C

= 10nF; and all outputs unloaded. TA= T

TACH

.

J

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Overall

Supply current Over Operating Range 14.5 30.0 mA

Turn-On Threshold Over Operating Range 8.65 8.95 9.45 V

V

CC

V

Turn-Off Threshold Over Operating Range 7.75 8.05 8.55 V

CC

Overvoltage/Coast

OV-Coast Inhibit Threshold Over Operating Range 1.65 1.75 1.85 V

OV-Coast Restart Threshold 1.55 1.65 1.75 V

OV-Coast Hysteresis 0.05 0.10 0.15 V

OV-Coast Input Current –10 –1 0 µA

Logic Inputs

H1, H2, H3 Low Threshold Over Operating Range 0.8 1.0 1.2 V

H1, H2, H3 High Threshold Over Operating Range 1.6 1.9 2.0 V

H1, H2, H3 Input Current Over Operating Range, to 0V -400 -250 –120 µA

Quad Sel, Dir Thresholds Over Operating Range 0.8 1.4 2.0 V

Quad Sel Hysteresis 70 mV

Dir Hysteresis 0.6 V

Quad Sel Input Current –30 50 150 µA

Dir Input Current –30 –1 30 µA

PWM Amp/Comparator

E/A In(+), E/A In(–) Input Current To 2.5V –5.0 –0.1 5.0 µA

PWM In Input Current To 2.5V 0 3 30 µA

Error Amp Input Offset 0V < V

COMMON-MODE

< 3V –10 10 mV

Error Amp Voltage Gain 70 90 dB

2

Page 3

UC1625

UC2625

UC3625

ELECTRICAL CHARACTERISTICS: Unless otherwise stated, these specifications apply for: TA= 25°C; Pwr VCC= VCC= 12V;

R

20k to V

=

OSC

PWM Amp/Comparator (cont.)

E/A Out Range 0.25 3.50 V

S

S

S

Pull-up Current To 0V –16 –10 –5 µA

START

Discharge Current To 2.5V 0.1 0.4 3.0 mA

START

START Restart Threshold

Current Amp

Gain I

; C

REF

OSC

= 2nF; R

TACH

= 33k; C

= 10nF; and all outputs unloaded. TA= T

TACH

.

J

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

0.1 0.2 0.3 V

SENSE1

= .3V, I

SENSE2

= .5V to .7V 1.75 1.95 2.15 V/V

Level Shift I

Peak Current Threshold I

Over Current Threshold I

I

I

Range I

SENSE1

SENSE1

, I

SENSE2

, I

SENSE2

SENSE1

Input Current To 0V –850 –320 0 µA

Offset Current To 0V

, I

SENSE2

SENSE1

SENSE1

SENSE1

= .3V, I

SENSE2

= 0V, Force I

= 0V, Force I

= .3V 2.4 2.5 2.65 V

SENSE2

SENSE2

0.14 0.20 0.26 V

0.26 0.30 0.36 V

±

±

2

12 µA

–1 2 V

Tachometer/Brake

Tach-Out High Level Over Operating Range, 10k to 2.5V 4.7 5 5.3 V

Tach-Out Low Level Over Operating Range, 10k to 2.5V 0.2 V

On Time 170 220 280 µs

On Time Change With Temp Over Operating Range 0.1 %

RC-Brake Input Current To 0V –4.0 –1.9 mA

Threshold to Brake, RC-Brake Over Operating Range 0.8 1.0 1.2 V

Brake Hysteresis, RC-Brake 0.09 V

Speed-In Threshold Over Operating Range 220 257 290 mV

Speed-In Input Current –30 –5 30 µA

Low-Side Drivers

Voh, –1mA, Down From V

CC

V Voh, –50mA, Down From V

Over Operating Range 1.60 2.1

Over Operating Range 1.75 2.2 V

CC

Vol, 1mA Over Operating Range 0.05 0.4 V

Vol, 50mA Over Operating Range 0.36 0.8 V

Rise/Fall Time 10% to 90% Slew Time, into 1nF 50 ns

High-Side Drivers

Vol, 1mA Over Operating Range 0.1 0.4 V

Vol, 50mA Over Operating Range 1.0 1.8 V

Leakage Current Output Voltage = 50V 25 µA

Fall Time 10% to 90% Slew Time, 50mA Load 50 ns

Oscillator

Frequency 40 50 60 kHz

Frequency Over Operating Range 35 65 kHz

Reference

Output Voltage 4.9 5.0 5.1 V

Output Voltage Over Operating Range 4.7 5.0 5.3 V

Load Regulation 0mA to –20mA Load –40 –5 mV

Line Regulation 10V to 18V V

CC

–10 –1 10 mV

Short Circuit Current Over Operating Range 50 100 150 mA

3

Page 4

UC1625

UC2625

UC3625

ELECTRICAL CHARACTERISTICS: Unless otherwise stated, these specifications apply for: TA= 25°C; Pwr VCC= VCC= 12V;

R

OSC

=

20k to V

REF

; C

OSC

= 2nF; R

TACH

= 33k; C

= 10nF; and all outputs unloaded. TA= T

TACH

.

J

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Miscellaneous

Output Turn-On Delay 1 µs

Output Turn-Off Delay 1 µs

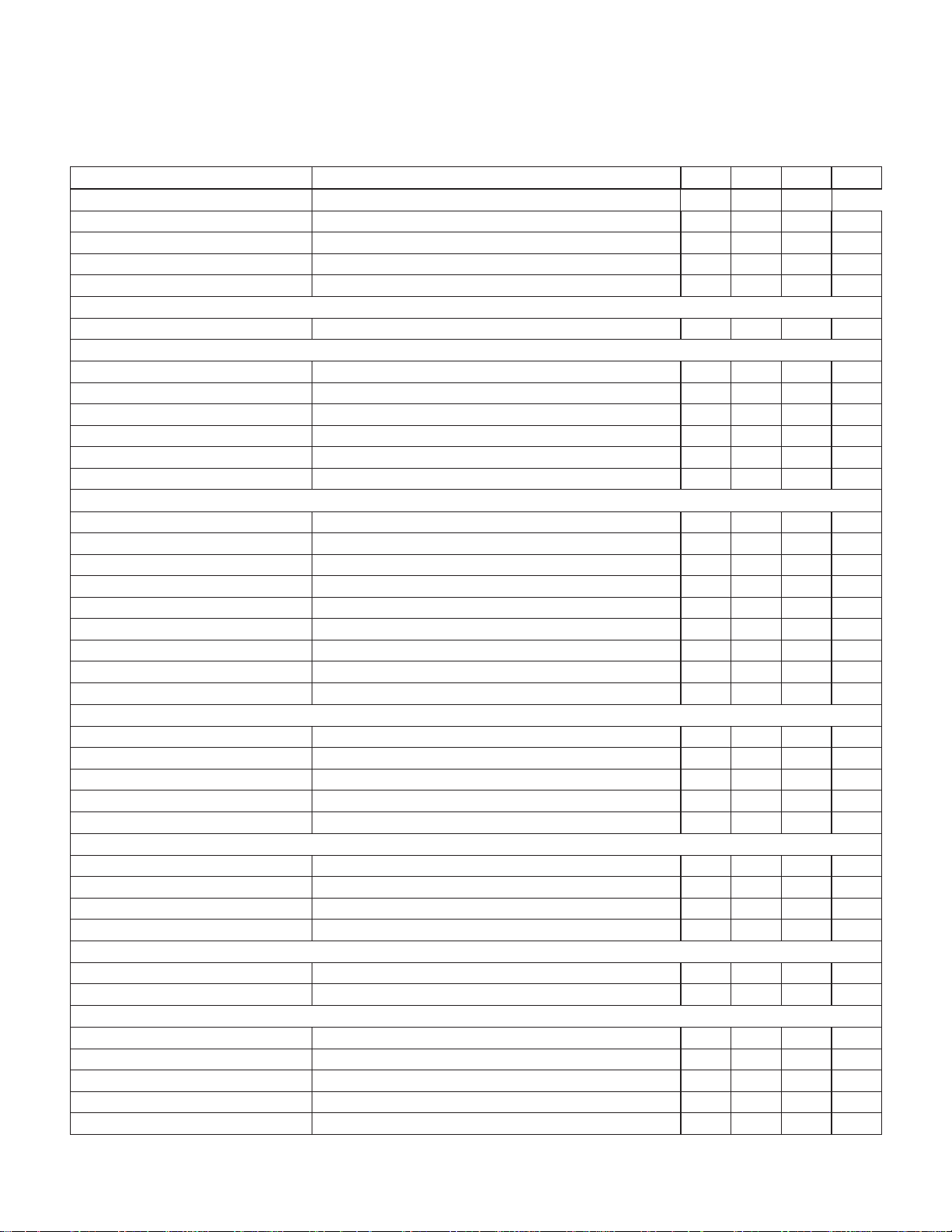

BLOCK DIAGRAM

Quad Sel

RC-Osc

PWM In

E/A Out

E/A In(+)

E/A In (–)

22

25

26

27

1

28

24SSTART

3ISENSE

4ISENSE1

5ISENSE2

19VCC

23OV-Coast

6Dir

7Speed-In

8H1

1.75V

9V

0.25V

+5V

+5V

ABS VALUE

2X

PWM CLOCK

OSC

DIRECTION

PWM CLOCK

2.9V

2.5V 250Ω

3.1V

LATCH

QD

L

SQ

R

0.2V

DIR COAST CHOP QUAD

H1

QR

S

PWM

CLOCK

REFERENCE

Q1

CROSS

CONDUCTION

PROTECTION

LATCHES

10µA

5V

2

VREF

18 PUA

17 PUB

16 PUC

11 Pwr Vcc

14 PDA

9H2

+5V

9H3

EDGE

DETECT

21RC-Brake

2k

1V

ONE

SHOT

QD

L

QD

L

H2

H3

DECODER

BRAKE

+5V

13 PDB

12 PDC

15 GND

20 Tach-Out

UDG-99044

4

Page 5

PIN DESCRIPTIONS

Dir, Speed-In: The position decoder logic translates the

Hall signals and the Dir signal to the correct driver sig

nals (PUs and PDs). To prevent output stage damage,

the signal on Dir is first loaded into a direction latch,

then shifted through a two-bit register.

H1, H2, H3: The three shaft-position sensor inputs con

sist of hysteresis comparators with input pull-up resis

tors. Logic thresholds meet TTL specifications and can

be driven by 5V CMOS, 12V CMOS, NMOS, or

open-collectors.

UC1625

UC2625

UC3625

-

-

As long as Speed-In is less than 250mV, the direction

latch is transparent. When Speed-In is higher than

250mV, the direction latch inhibits all changes in direc

tion. Speed-In can be connected to Tach-Out through a

filter, so that the direction latch is only transparent when

the motor is spinning slowly, and has too little stored en

ergy to damage power devices.

Additional circuitry detects when the input and output of

the direction latch are different, or when the input and

output of the shift register are different, and inhibits all

output drives during that time. This can be used to allow

the motor to coast to a safe speed before reversing.

The shift register guarantees that direction can't be

changed instantaneously. The register is clocked by the

PWM oscillator, so the delay between direction changes

is always going to be between one and two oscillator periods. At 40kHz, this corresponds to a delay of between

25µs and 50µs. Regardless of output stage, 25µs dead

time should be adequate to guarantee no overlap

cross-conduction. Toggling DIR will cause an output

pulse on Tach-Out regardless of motor speed.

E/A In(+), E/A In(–), E/A Out, PWM In: E/A In(+) and

E/A In(–) are not internally committed to allow for a wide

variety of uses. They can be connected to the I

SENSE

,to

Tach-Out through a filter, to an external command volt

age, to a D/A converter for computer control, or to an

other op amp for more elegant feedback loops. The

error amplifier is compensated for unity gain stability, so

E/A Out can be tied to E/A In(–) for feedback and major

loop compensation.

E/A Out and PWM In drive the PWM comparator. For

voltage-mode PWM systems, PWM In can be connected

to RC-Osc. The PWM comparator clears the PWM latch,

commanding the outputs to chop.

The error amplifier can be biased off by connecting E/A

In(–) to a higher voltage than E/A In(+). When biased

off, E/A Out will appear to the application as a resistor to

ground. E/A Out can then be driven by an external am

plifier.

GND: All thresholds and outputs are referred to the

GND pin except for the PD and PU outputs.

Connect these inputs to motor shaft position sensors

that are positioned 120 electrical degrees apart. If noisy

-

signals are expected, zener clamp and filter these inputs

with 6V zeners and an RC filter. Suggested filtering

components are 1kΩ and 2nF. Edge skew in the filter is

-

not a problem, because sensors normally generate

modified Gray code with only one output changing at a

time, but rise and fall times must be shorter than 20µs

for correct tachometer operation.

Motors with 60 electrical degree position sensor coding

can be used if one or two of the position sensor signals

is inverted.

I

SENSE1,ISENSE2,ISENSE

: The current sense amplifier

has a fixed gain of approximately two. It also has a

built-in level shift of approximately 2.5V. The signal appearing on I

I V ABS I I

SENSE SENSE SENSE

I

SENSE1

=+•25 2

and I

is:

SENSE

.–

()

SENSE2

()

12

are interchangeable and can be

used as differential inputs. The differential signal applied

can be as high as±0.5V before saturation.

If spikes are expected on I

SENSE1

best filtered by a capacitor from I

or I

SENSE

SENSE2

to ground. Fil

tering this way allows fast signal inversions to be cor

rectly processed by the absolute value circuit. The

peak-current comparator allows the PWM to enter a cur

rent-limit mode with current in the windings never ex

ceeding approximately 0.2V/R

SENSE

The over current

.

comparator provides a fail-safe shutdown in the unlikely

case of current exceeding 0.3V/R

SENSE

.

Then, soft start

is commanded, and all outputs are turned off until the

high current condition is removed. It is often essential to

use some filter driving I

SENSE1

and I

SENSE2

treme spikes and to control slew rate. Reasonable start

ing values for filter components might be 250Ω series

resistors and a 5nF capacitor between I

I

SENSE2

. Input resistors should be kept small and

matched to maintain gain accuracy.

OV-Coast: This input can be used as an over-voltage

shutdown in put, as a coast input, or both. This input

can be driven by TTL, 5V CMOS, or 12V CMOS.

, they are

to reject ex

SENSE1

and

-

-

-

-

-

-

5

Page 6

PIN DESCRIPTIONS (cont.)

PDA, PDB, PDC: These outputs can drive the gates of

N-Channel power MOSFETs directly or they can drive

the bases of power Darlingtons if some form of current

limiting is used. They are meant to drive low-side power

devices in high-current output stages. Current available

from these pins can peak as high as 0.5A. These out

puts feature a true totem-pole output stage. Beware of

exceeding IC power dissipation limits when using these

outputs for high continuous currents. These outputs pull

high to turn a “low-side” device on (active high).

PUA, PUB, PUC: These outputs are open-collector,

high-voltage drivers that are meant to drive high-side

power devices in high-current output stages. These are

active low outputs, meaning that these outputs pull low

to command a high-side device on. These outputs can

drive low-voltage PNP Darlingtons and P-channel

MOSFETs directly, and can drive any high-voltage de

vice using external charge-pump techniques, trans

former signal coupling, cascode level-shift transistors, or

opto-isolated drive (high-speed opto devices are recommended). (See applications).

PWR V

by the PD outputs. When connecting PD outputs directly

to the bases of power Darlingtons, the PWR V

be current limited with a resistor. Darlington outputs can

also be "Baker Clamped" with diodes from collectors

back to PWR V

Quad Sel: The IC can chop power devices in either of

two modes, referred to as “two-quadrant” (Quad Sel low)

and “four-quadrant” (Quad Sel high). When

two-quadrant chopping, the pull-down power devices

are chopped by the output of the PWM latch while the

pull-up drivers remain on. The load will chop into one

commutation diode, and except for back-EMF, will ex

hibit slow discharge current and faster charge current.

Two-quadrant chopping can be more efficient than

four-quadrant.

When four-quadrant chopping, all power drivers are

chopped by the PWM latch, causing the load current to

flow into two diodes during chopping. This mode exhibits

better control of load current when current is low, and is

preferred in servo systems for equal control over accel

eration and deceleration. The Quad Sel input has no ef

fect on operation during braking.

RC-Brake: Each time the Tach-Out pulses, the capaci

tor tied to RC-Brake discharges from approximately

3.33V down to 1.67V through a resistor. The tachometer

pulse width is approximately T = 0.67 R

and CTare a resistor and capacitor from RC-Brake to

: This supply pin carries the current sourced

CC

pin can

CC

. (See Applications)

CC

, where R

TCT

ground. Recommended values for R

T

500kΩ, and recommended values for C

100nF, allowing times between 5µs and 10ms. Best ac

curacy and stability are achieved with values in the cen

ters of those ranges.

RC-Brake also has another function. If RC-Brake pin is

pulled below the brake threshold, the IC will enter brake

mode. This mode consists of turning off all three

high-side devices, enabling all three low-side devices,

and disabling the tachometer. The only things that in

hibit low-side device operation in braking are

low-supply, exceeding peak current, OV-Coast com

mand, and the PWM comparator signal. The last of

these means that if current sense is implemented such

that the signal in the current sense amplifier is propor

tional to braking current, the low-side devices will brake

-

the motor with current control. (See applications) Sim

-

pler current sense connections will result in uncontrolled

braking and potential damage to the power devices.

RC-Osc: The UC3625 can regulate motor current using

fixed-frequency pulse width modulation (PWM). The

RC-Osc pin sets oscillator frequency by means of timing

resistor R

tor C

OSC from the RC-Osc pin to V

from RC-Osc to Gnd. Resistors 10kΩ to

OSC

REF

100kΩ and capacitors 1nF to 100nF will work best, but

frequency should always be below 500kHz. Oscillator

frequency is approximately:

F

=

()

2

RC

•

OSC OSC

Additional components can be added to this device to

cause it to operate as a fixed off-time PWM rather than

a fixed frequency PWM, using the RC-Osc pin to select

the monostable time constant.

-

The voltage on the RC-Osc pin is normally a ramp of

about 1.2V peak-to-peak, centered at approximately

1.6V. This ramp can be used for voltage-mode PWM

control, or can be used for slope compensation in cur

rent-mode control.

S

sensed current exceeds the over-current threshold, the

soft-start latch is set. When set, it turns on a transistor

that pulls down on S

: Any time that VCCdrops below threshold or the

START

Normally, a capacitor is con

.

START

nected to this pin, and the transistor will completely dis

charge the capacitor. A comparator senses when the

NPN transistor has completely discharged the capacitor,

and allows the soft-start latch to clear when the fault is

removed. When the fault is removed, the soft-start ca

T

pacitor will charge from the on-chip current source.

UC1625

UC2625

UC3625

are 10kΩ to

are 1nF to

T

and capaci-

-

-

-

-

-

-

-

-

-

-

6

Page 7

PIN DESCRIPTIONS (cont.)

A

A

S

START

lowing the error amplifier output voltage to exceed

S

START

be applied to PWM In and compared to E/A Out. With

S

START

being approximately 1.0V, the PWM comparator will

keep the PWM latch cleared and the outputs off. As

S

START

duty-cycle modulate the PWM latch until the error ampli

fier inputs overcome the clamp. This provides for a safe

and orderly motor start-up from an off or fault condition.

Tach-Out: Any change in the H1, H2, or H3 inputs loads

data from these inputs into the position sensor latches.

At the same time data is loaded, a fixed-width 5V pulse

is triggered on Tach-Out. The average value of the volt

age on Tach-Out is directly proportional to speed, so

this output can be used as a true tachometer for speed

feedback with an external filter or averaging circuit

which usually consists of a resistor and capacitor.

Whenever Tach-Out is high, the position latches are inhibited, such that during the noisiest part of the commu-

clamps the output of the error amplifier, not al

regardless of input. The ramp on RC-Osc can

discharged below 0.2V and the ramp minimum

rises, the PWM comparator will begin to

tation cycle, additional commutations are not possible.

Although this will effectively set a maximum rotational

speed, the maximum speed can be set above the high

est expected speed, preventing false commutation and

chatter.

: This device operates with supplies between 10V

V

CC

and 18V. Under-voltage lockout keeps all outputs off be

low 7.5V, insuring that the output transistors never turn

on until full drive capability is available. Bypass V

ground with an 0.1µF ceramic capacitor. Using a 10µF

electrolytic bypass capacitor as well can be beneficial in

applications with high supply impedance.

: This pin provides regulated 5 volts for driving

V

REF

Hall-effect devices and speed control circuitry. V

reach +5V before V

devices powered from V

the UC3625 drives any output. Although V

enables, ensuring that Hall-effect

CC

will become active before

REF

REF

limited, operation over 30mA is not advised. For proper

performance V

should be bypassed with at least a

REF

0.1µF capacitor to ground.

UC1625

UC2625

UC3625

to

CC

will

REF

is current

-

-

APPLICATION INFORMATION

Cross Conduction Prevention

The UC3625 inserts delays to prevent cross conduction

due to overlapping drive signals. However, some thought

must always be given to cross conduction in output stage

design because no amount of dead time can prevent fast

slewing signals from coupling drive to a power device

through a parasitic capacitance.

The UC3625 contains input latches that serve as noise

blanking filters. These latches remain transparent

through any phase of a motor rotation and latch immedi

ately after an input transition is detected. They remain

latched for two cycles of the PWM oscillator. At a PWM

oscillator speed of 20kHz, this corresponds to 50µsto

100µs of blank time which limits maximum rotational

speed to 100kRPM for a motor with six transitions per ro

tation or 50kRPM for a motor with 12 transitions per rota

tion.

This prevents noise generated in the first 50µs of a tran

sition from propagating to the output transistors and

causing cross–conduction or chatter.

The UC3625 also contains six flip flops corresponding to

the six output drive signals. One of these flip flops is set

every time that an output drive signal is turned on, and

-

-

-

-

cleared two PWM oscillator cycles after that drive signal

is turned off. The output of each flip flop is used to inhibit

drive to the opposing output (see below). In this way, it is

impossible to turn on driver PUA and PDA at the same

time. It is also impossible for one of these drivers to turn

on without the other driver having been off for at least

two PWM oscillator clocks.

PULL UP

FROM

DECODER

PULL

DOWN

EDGE

FINDER

PWM

CLK

SHIFT

REG

SQ

QR

SQ

QR

PU

PD

Figure 1. Cross conduction prevention.

7

Page 8

C(F)

OSC

µ

TYPICAL CHARACTERISTICS

R - 500k

T

R - 100k

T

R - 30k

T

R - 10k

T

1MHz

100kHz

Rosc -10k

UC1625

UC2625

UC3625

10kHz

1kHz

Oscillator Frequency

100Hz

0.001 0.01 0.1

Rosc -30k

Rosc -100k

C(F)

OSC

Figure 2. Oscillator frequency vs. C

100ms

On Time

10ms

1ms

100 sµ

T

R - 500k

T

R - 100k

T

R - 30k

T

R - 10k

µ

OSC

and R

OSC

.

Figure 4. Supply current vs. temperature.

10 sµ

1sµ

0.001 0.01 0.1

C(F)

T

µ

Figure 3. Tachometer on time vs RTand CT.

Figure 5. Soft start pull-up current vs temperature.

8

Page 9

TYPICAL CHARACTERISTICS (cont.)

UC1625

UC2625

UC3625

Figure 6. Soft start discharge current vs.

temperature.

APPLICATION INFORMATION (cont.)

Power Stage Design

The UC3625 is useful in a wide variety of applications,

including high-power in robotics and machinery. The

power output stages used in such equipment can take a

number of forms, according to the intended perfor

mance and purpose of the system. Below are four differ

ent power stages with the advantages and

disadvantages of each shown.

For high-frequency chopping, fast recovery circulating

diodes are essential. Six are required to clamp the wind

ings. These diodes should have a continuous current

rating at least equal to the operating motor current,

since diode conduction duty-cycle can be high. For

low-voltage systems, Schottky diodes are preferred. In

higher voltage systems, diodes such as Microsemi

UHVP high voltage platinum rectifiers are recom

mended.

In a pulse-by-pulse current control arrangement, current

sensing is done by resistor R

sistor's currents are passed (Fig. A, B, and C). In these

, through which the tran

S

Figure 7. Current sense amplifier transfer function.

cases, R

is not needed. The low-side circulating di-

D

odes go to ground and the current sense terminals of

the UC3625 (I

SENSE1

and I

SENSE2

) are connected to R

through a differential RC filter. The input bias current of

the current sense amplifier will cause a common mode

offset voltage to appear at both inputs, so for best accu

racy, keep the filter resistors below 2k

The current that flows through R

and matched.

is discontinuous be

S

cause of chopping. It flows during the on time of the

power stage and is zero during the off time. Conse

quently, the voltage across R

consists of a series of

S

pulses, occurring at the PWM frequency, with a peak

value indicative of the peak motor current.

To sense average motor current instead of peak cur

rent, add another current sense resistor (R

-

measure current in the low-side circulating diodes, and

D

operate in four quadrant mode (pin 22 high). The nega

tive voltage across R

value current sense amplifier. Within the limitations im

-

is corrected by the absolute

D

posed by Table 1, the circuit of Fig. B can also sense

average current.

S

-

-

-

-

in Fig. D) to

-

-

9

Page 10

APPLICATION INFORMATION (cont.)

UC1625

UC2625

UC3625

FIGURE A

R

S

FIGURE C

TO

MOTOR

TO

MOTOR

FIGURE B

R

S

FIGURE D

TO

MOTOR

TO

MOTOR

R

R

S

R

S

D

2 4 SAFE POWER CURRENT SENSE

QUADRANT QUADRANT BRAKING REVERSE PULSE BY PULSE AVERAGE

FIGURE A YES NO NO NO YES NO

FIGURE B YES YES NO IN 4-QUAD MODE ONLY YES YES

FIGURE C YES YES YES IN -4QUAD MODE ONLY YES NO

FIGURE D YES YES YES IN-4QUADMODE ONLY YES YES

10

Page 11

APPLICATION INFORMATION (cont.)

Figure 8. Fast high-side P-channel driver.

UC1625

UC2625

UC3625

Figure 9. Optocoupled N-channel high-side driver.

Figure 11. Power NPN low-side driver.

For drives where speed is critical, P-Channel MOSFETs

can be driven by emitter followers as shown in Fig. 8.

Here, both the level shift NPN and the PNP must withstand high voltages. A zener diode is used to limit

gate-source voltage on the MOSFET. A series gate resistor is not necessary, but always advisable to control

overshoot and ringing.

High-voltage optocouplers can quickly drive high-voltage

MOSFETs if a boost supply of at least 10 volts greater

than the motor supply is provided (See Fig. 9.) To protect

the MOSFET, the boost supply should not be higher than

18 volts above the motor supply.

For under 200V 2-quadrent applications, a power NPN

driven by a small P-Channel MOSFET will perform well

as a high-side driver as in Fig. 10. A high voltage

small-signal NPN is used as a level shift and a high volt

age low-current MOSFET provides drive. Although the

NPN will not saturate if used within its limitations, the

base-emitter resistor on the NPN is still the speed limiting

component.

-

Figure 10. Power NPN high-side driver.

Fig. 11 shows a power NPN Darlington drive technique

using a clamp to prevent deep saturation. By limiting sat

uration of the power device, excessive base drive is mini

mized and turn-off time is kept fairly short. Lack of base

series resistance also adds to the speed of this ap

proach.

11

-

-

-

Page 12

APPLICATION INFORMATION (cont.)

UC1625

UC2625

UC3625

+12V

3

PUA

33kΩ

7

UC3724N UC3725N

28

1

1nF5kΩ 100nF

6

4

5

1:2

7

8

Figure 12. Fast high-side N-channel driver with transformer isolation.

Fast High-Side N-Channel Driver with Transformer

Isolation

A small pulse transformer can provide excellent isolation

between the UC3625 and a high-voltage N-Channel

MOSFET while also coupling gate drive power. In this

circuit (shown in Fig. 12), a UC3724 is used as a transformer driver/encoder that duty-cycle modulates the

transformer with a 150kHz pulse train. The UC3725 recti-

These ICs operate with position sensor encoding that

has either one or two signals high at a time, never all low

or all high. This coding is sometimes referred to as “120°

Coding” because the coding is the same as coding with

position sensors spaced 120 magnetic degrees about

the rotor. In response to these position sense signals,

only one low-side driver will turn on (go high) and one

high-side driver will turn on (pull low) at any time.

fies this pulse train for gate drive power, demodulates the

signal, and drives the gate with over 2 amp peak current.

Both the UC3724 and the UC3725 can operate up to

Table I. Computational truth table.

INPUTS OUTPUTS

500kHz if the pulse transformer is selected appropriately.

To raise the operating frequency, either lower the timing

resistor of the UC3724 (1kΩ min), lower the timing ca

pacitor of the UC3724 (500pF min) or both.

If there is significant capacitance between transformer

primary and secondary, together with very high output

slew rate, then it may be necessary to add clamp diodes

from the transformer primary to +12V and ground. Gen

eral purpose small signal switching diodes such as

1N4148 are normally adequate.

The UC3725 also has provisions for MOSFET current

limiting. Consult the UC3725 data sheet for more infor

mation on implementing this.

Computational Truth Table

This table shows the outputs of the gate drive and open

collector outputs for given hall input codes and direction

DIR H1 H2 H3 Low-Side High-Side

-

-

-

6 8 9 10 12 13 14 16 17 18

1001LHLLHH

1011LLHLHH

1010LLHHLH

1110HLLHLH

1100HLLHHL

1101LHLHHL

0101LLHHLH

0100LLHLHH

0110LHLLHH

0010LHLHHL

0011HLLHHL

0001HLLHLH

X111LLLHHH

X000LLLHHH

signals. Numbers at the top of the columns are pin

numbers.

3126

VMOTOR

4

TO MOTOR

UDG-99047

12

Page 13

APPLICATION INFORMATION (cont.)

UC1625

UC2625

UC3625

QUAD

DIR

R

OSC

33kΩ

3kΩ

1k

4kΩ

BRAKE

10kΩ

100nF

2200pF

C

OSC

10kΩ

3nF

C

16

17

18

14

13

12

20

VMOTOR+15V

3kΩ

3kΩ

TO OTHER

CHANNELS

TO OTHER

CHANNELS

10Ω

10kΩ

100nF

2N3904

2N3906

IRF532

240Ω

240Ω

10Ω

IRF9350

0.02Ω

R

S

+

100µF

TO

MOTOR

REQUIRED

FOR BRAKE

AND FAST

REVERSE

REQUIRED

FOR

AVERAGE

CURRENT

SENSING

0.02Ω

R

D

+5V TO HALL

VREF

100nF

20µF

22

6

1

28

27

25

15

21

68kΩ

T

R

T

5nF 100nF

SENSORS

100nF

2 19

UC3625

24326

23 8 9 10 4 5 7

2nF

2nF

2nF

+

20µF

FROM

HALL

SENSORS

11

5nF

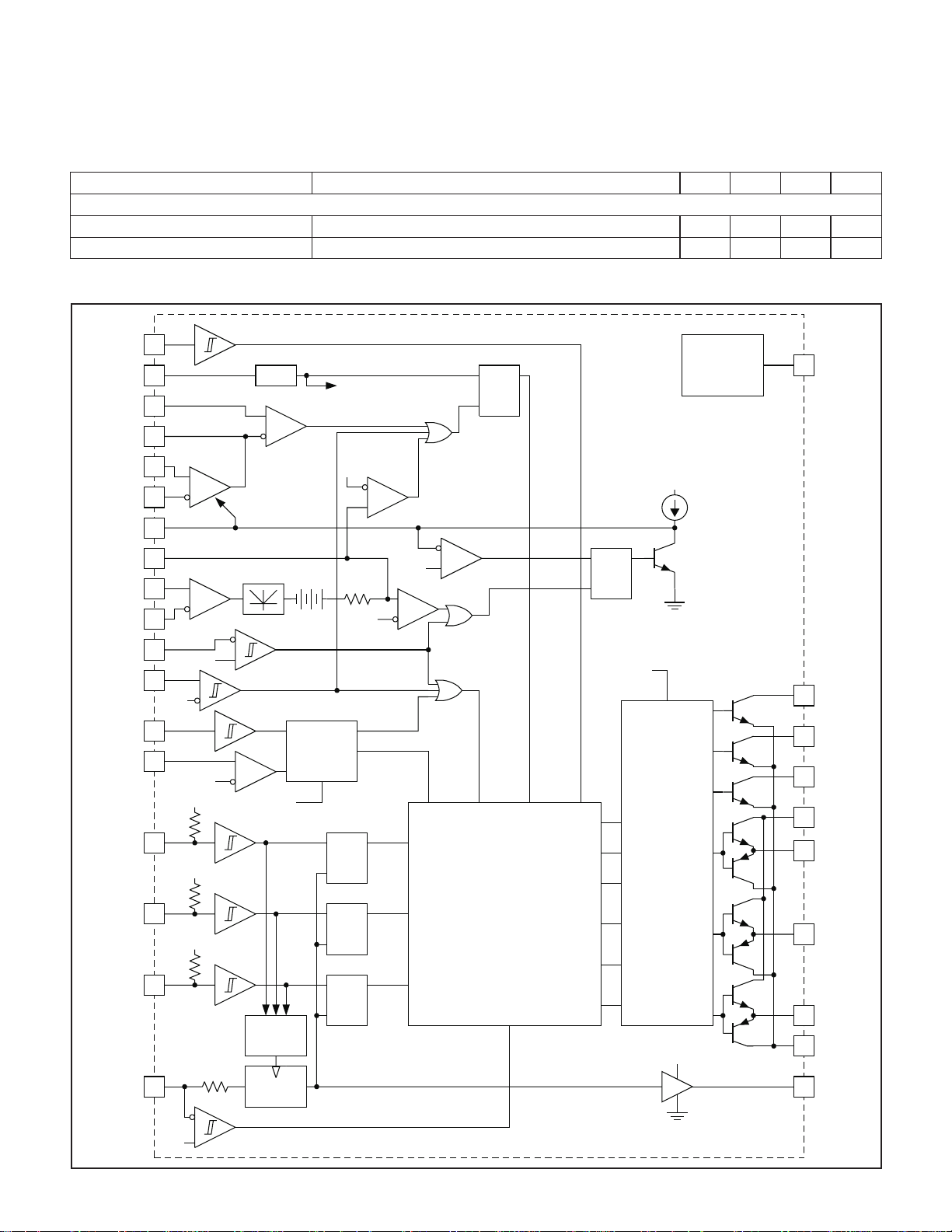

Figure 13. 45V/8A brushless DC motor drive circuit.

N–Channel power MOSFETs are used for low–side driv

ers, while P–Channel power MOSFETs are shown for

high–side drivers. Resistors are used to level shift the

UC3625 open–collector outputs, driving emitter follow

ers into the MOSFET gate. A 12V zener clamp insures

that the MOSFET gate–source voltage will never exceed

12V. Series 10Ω gate resistors tame gate reactance,

preventing oscillations and minimizing ringing.

The oscillator timing capacitor should be placed close to

pins 15 and 25, to keep ground current out of the capac

itor. Ground current in the timing capacitor causes oscil

lator distortion and slaving to the commutation signal.

The potentiometer connected to pin 1 controls PWM

duty cycle directly, implementing a crude form of speed

control. This control is often referred to as “voltage

mode” because the potentiometer position sets the aver

age motor voltage. This controls speed because

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

-

steady–state motor speed is closely related to applied

voltage.

Pin 20 (Tach-Out) is connected to pin 7 (SPEED IN)

through an RC filter, preventing direction reversal while

the motor is spinning quickly. In two–quadrant opera

tion, this reversal can cause kinetic energy from the mo

tor to be forced into the power MOSFETs.

A diode in series with the low-side MOSFETs facilitates

PWM current control during braking by insuring that

braking current will not flow backwards through low–side

MOSFETs. Dual current–sense resistors give continu

ous current sense, whether braking or running in

four–quadrant operation, an unnecessary luxury for

two–quadrant operation.

The 68kΩ and 3nF tachometer components set maxi

mum commutation time at 140µs. This permits smooth

operation up to 35,000 RPM for four–pole motors, yet

gives 140µs of noise blanking after commutation.

13

UDG-99045

-

-

-

-

Page 14

PACKAGE OPTION ADDENDUM

www.ti.com

19-Jul-2005

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

5962-9168901MXA OBSOLETE CDIP J 28 TBD Call TI Call TI

UC1625J OBSOLETE CDIP J 28 TBD Call TI Call TI

UC1625J883B OBSOLETE CDIP J 28 TBD Call TI Call TI

UC1625L OBSOLETE LCCC FK 28 TBD Call TI Call TI

UC1625L883B OBSOLETE LCCC FK 28 TBD Call TI Call TI

UC2625DW ACTIVE SOIC DW 28 20 Green(RoHS &

no Sb/Br)

UC2625DWTR ACTIVE SOIC DW 28 1000 Green (RoHS &

no Sb/Br)

UC2625N ACTIVE PDIP N 28 13 TBD Call TI Level-NA-NA-NA

UC2625Q ACTIVE PLCC FN 28 37 TBD Call TI Level-2-220C-1 YEAR

UC2625QTR ACTIVE PLCC FN 28 750 TBD Call TI Level-2-220C-1 YEAR

UC3625DW ACTIVE SOIC DW 28 20 Green(RoHS &

no Sb/Br)

UC3625DWTR ACTIVE SOIC DW 28 1000 Green (RoHS &

no Sb/Br)

UC3625N ACTIVE PDIP N 28 13 TBD Call TI Level-NA-NA-NA

UC3625Q ACTIVE PLCC FN 28 37 TBD Call TI Level-2-220C-1 YEAR

UC3625QTR ACTIVE PLCC FN 28 750 TBD Call TI Level-2-220C-1 YEAR

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

(3)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS) or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

Page 15

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2005, Texas Instruments Incorporated

Loading...

Loading...