Page 1

查询UC1620供应商

Switchmode Driver for 3-∅ Brushless DC Motors

UC1620

UC3620

FEATURES

• 2A Continuous, 3A Peak Output

Current

• 8V to 40V Operation

• Internal High Gain Amplifier for

Velocity Control Applications

• TTL Compatible Hall Inputs

• Mask Programmable Decode Logic

• Pulse-by-Pulse Current Limiting

• Internal Thermal Shutdown Protection

• Under-Voltage Lockout

• Available in SP Hermetic Package

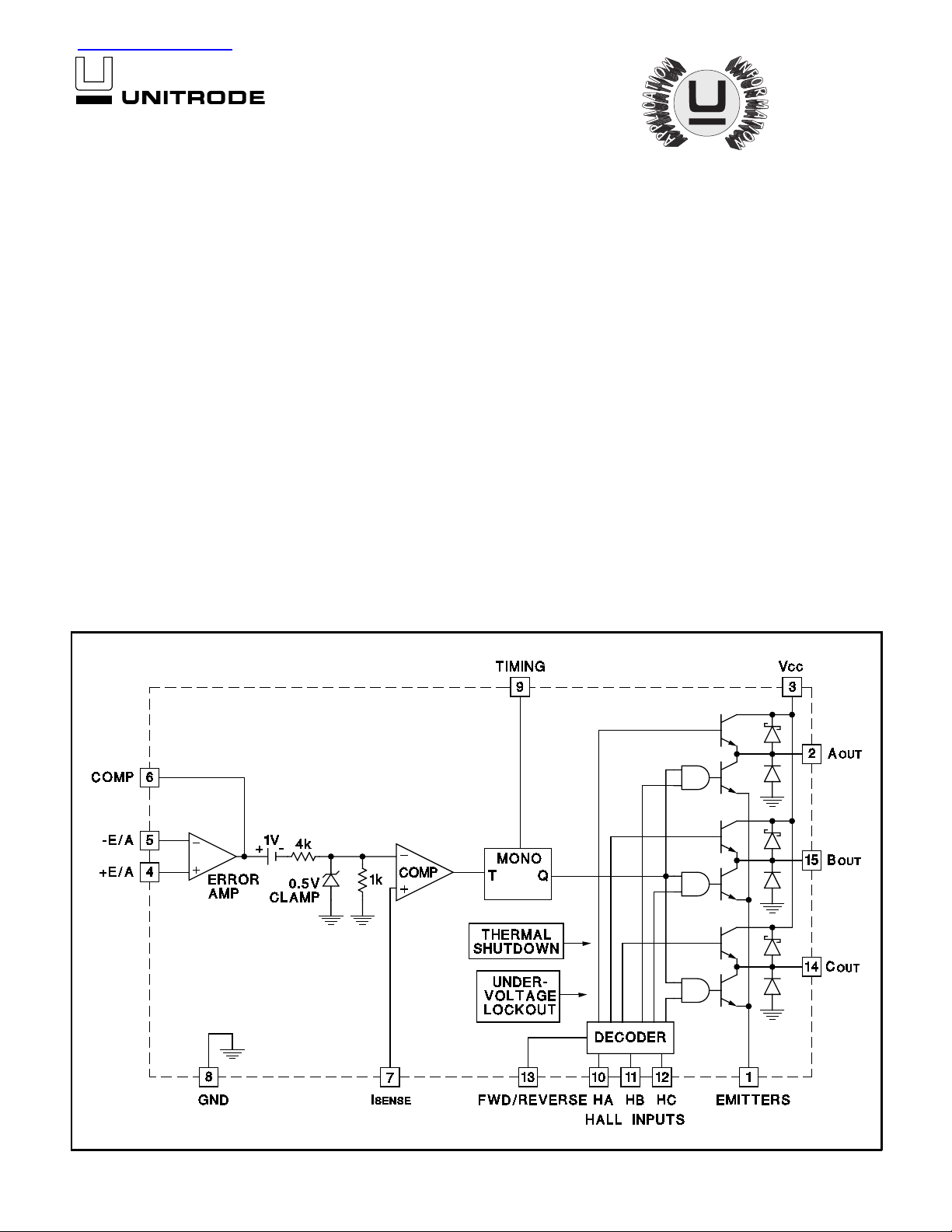

BLOCK DIAGRAM

DESCRIPTION

The UC3620 is a br ushless DC motor driver capable of decoding and

driving al l 3 windings of a 3-phase br ushles s DC motor. In addition, an

on-board c urrent comp arator, oscillator, and high gain Op-Amp provide

all necessar y circuitr y for implementing a high performance, chopped

mode servo amplifier. Full protection, including thermal shutdown,

pulse-by-pulse current limiting, and under-voltage lockout aid in the

simple implementation of reliable designs. Both conducted and radiated

EMI have been grea tly redu ced by limi ting the output dv/dt to 150V /µs

for any load condition.

The UC1620SP is characterized for operation over the full military temperature range of -55°C to +125°C, while the UC3620SP is characterized for 0°C to +70°C.

3/97

1

Page 2

UC1620

UC3620

ABSOLUTE MAXIMUM RATINGS

(Note 1)

Supply Voltage, VCC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40V

Output Current, Source or Sink

CONNECTION DIAGRAMS

SP Hermetic Power DIL

Non-Repetitive (t = 100µsec), lo . . . . . . . . . . . . . . . . . . . . 3A

Repetitive (80% on - 20% off; tON = 10ms) . . . . . . . . . . 2.5A

DC Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2A

Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3 to +Vcc

Logic Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3 to +Vcc

Total Power Dissipation (at T

CASE

= 75° C)

for SP Package (Note 2). . . . . . . . . . . . . . . . . . . . . . . . . . 15W

Storage Temperature . . . . . . . . . . . . . . . . . . . . -65°C to +150°C

Operating Junction Temperature . . . . . . . . . . . -55°C to +150°C

Note 1: All voltages are with respect to g round. Currents are

positive into, negative out of the specified terminal.

Note 2: Consult Packaging Section of Databook for thermal

limitations and considerations of package.

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated, these spec ifications apply for TA = 0°C to 70°C for 3620; T

= 55°C to +125°C for UC1620; VCC = 20V, RT = 20V, RT = 10k, C

-2.2nF. TA=T

T =

PARAMETER TEST CONDITIONS UC3620 UC1 620 UNIT

MIN TYP MAX MIN TYP MAX

Error Amplifier Section

Input Offset Voltage 1.5 10 1.5 10 mV

Input Bias Current -.25 -2.0 -.25 -2.0 µA

Input Offset Current 15 250 15 250 nA

Common Mode Range Vcc = 8V to 40V 0 V

Open Loop Gain ∆V

Unity Gain Bandwidth T

Output Sink Current V

Output Source Current V

= 1V to 4V 80 100 75 100 dB

COMP

= 25°C, Note 2 0.8 0.8 MHz

J

= 1V 2 2 mA

COMP

= 4V 8 8 mA

COMP

-2 0 VIN-2 V

IN

Current Sense Section

Input Bias Current -2.0 -5 -2.0 -5 µA

Internal Clamp .425 0.5 .575 .405 0.5 .595 V

Divider Gain .180 0.2 .220 .170 0.2 .230 V/V

Internal Offset Voltage .8 1.0 1.2 .75 1.0 1.25 V

Timing Section

Output Off Tim e 18 20 22 17 20 23 µs

Upper Mono Threshold 5.0 5.0 V

Lower Mono Threshold 2.0 2.0 V

Decoder Section

High-Level Input Voltage 2.2 2.5 V

Low-Level Inpu t Vol ta ge 0.8 0.8 V

High-Level Input Current 10 10 µA

Low-Level Input Curre nt -10 -10 µA

Output Section

Output Leakage Curre nt V

VF1 Schottky Diode I

VF1 Substrat e Diode I

Total Output Voltage Drop I

= 40V 500 1500 µ A

CC

= 2A 1.5 2.0 1.5 2.0 V

O

= 2A 2.2 3.0 2.2 3.0 V

O

= 2A, Note 3 3.0 3.6 3.0 3.6 V

O

A

J.

2

Page 3

UC1620

UC3620

ELECTRICAL CHARACTERISTICS:

PARAMETER TEST CONDITIONS UC3620 UC1 620 UNIT

Output Section (cont.)

Output Rise Time R

Output Fall Time R

Under Voltage Lock ou t

Startup Threshold 8.0 8.0 V

Threshold Hysteresis 0.5 0.5 V

Thermal Shutdown

Junction Temperature Note 2 150 180 150 180 °C

Total Standby Current

Supply Current 32 55 32 55 mA

Note 2: These paramete rs , al th ou gh gu aranteed over the recommend ed op erating conditi on s , ar e no t 10 0% tes te d in prod uc ti on .

Note 3: The total voltage drop is defined as the sum of both top and bottom side driver.

TABLE 1

STEP FWD/

REV

1 1 101 H L O

2 1 100 H O L

3 1 110 O H L

4 1 010 L H O

5 1 011 L O H

6 1 001 O L H

1 0 101 L H O

2 0 100 L O H

3 0 110 O L H

4 0 010 H L O

5 0 011 H O L

6 0 001 O H L

H = HIGH OUTPUT

L = LOW OUTPUT

O = OPEN OUTPUT

Ha Hb Hc A

OUT

Unless otherwise stated, these spec ifications apply for T

= 55°C to +125°C for UC1620; VCC = 20V, RT = 20V, RT = 10k, C

MIN TYP MAX MIN TYP MAX

= 44Ω 150 150 ns

L

= 44Ω 150 150 ns

L

Hall lines require pull-up resistors.

B

OUT

C

OUT

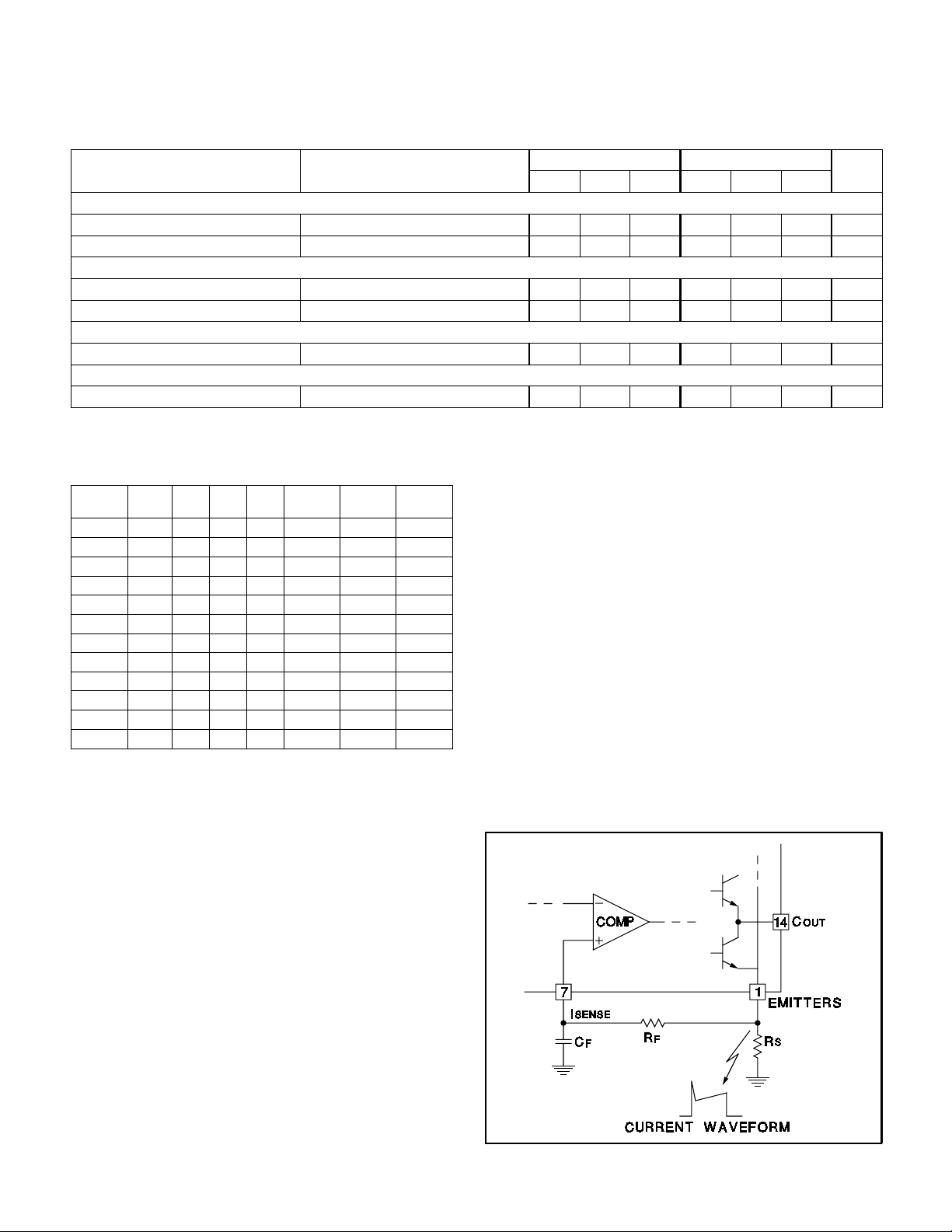

CURRENT SENSING

Referring to Figure 1, emitter current is sensed across R

and fed back through a low pass filter to the current

sense pin 7. This filter is required to eliminate false triggering of the monostable due to leading edge current

spikes. Actual filter values, although somewhat dependent on external loads, will generally be in the 1kΩ and

1000pF range.

TIMING

An R-C time constant on pin 9 is used by the monostable

to generate a fixed off time at the outputs according to the

formula:

T

OFF

=

As the peak current in the emitters approaches the value

at the minus (-) input of the on-board comparator, the

= 0°C to 70°C for 3620; T

A

T =

.916RTC

T

-2.2nF. TA=T

monostable is tr i gg er e d, c au s in g t he outputs to be tur ned

A

J.

S

CIRCUIT DESCRIPTION

The UC3620 is designed for implementation of a complete 3-∅ brushless DC servo drive using a minimum

number of external components. Below is a functional description of each major circuit feature.

DECODER

Table 1 shows the dec oding sc heme used in the UC3620

to decode and drive each of three high current totem pole

output sta ge s. A forward/reverse signal, pin 13, is used to

provide direc tion. At any point in time, one driver is sourcing, one dr iver is sin king, an d the rem aining driver is off

or tri-s tated. Pulse width modulation is acc omplished by

turning the sink driver off during the monostable reset

time, producing a fixed off-time chop mode. Controlled

output rise and fall times help reduce electrical switching

noise while maintaining re latively small switching loss es.

Figure 1.

3

Current Sense Filter

Page 4

CIRCUIT DESCRIPTION (cont.)

off. On time is det er m ined by the amount of time required

for motor current to increase to the value required to retrip the mono stable. A timing sequence of these events is

shown in Figure 2.

UC1620

UC3620

tive (-) input will limit peak current to a maximum value. A

fixed 0.5V internal clamp has been included on the

UC3620, and any current spike in the output which generates a sensed voltage greater than 0.5V will immediately shut down the outputs. Actual peak current values

may be programmed by selecting the appropriate value of

R

according to the formula:

S

Figure 2.

Chopped Mode Timi ng D iag ram

CURRENT LIMIT

Since peak current is being controlled at all times by the

internal comparator, a simple voltage clamp at its negative (-) input will limit peak current to a maximum value. A

fixed 0.5V internal clamp has been included on the

UC3620, and any current spike in the output which generates a sensed voltage greater than 0.5V will immediately

shut down the outputs. Actual peak current values may be

programmed by selecting the appropriate value of R

S

ac-

cording to the formula:

R

=

S

0.5

I

CURRENTLIMIT

Since peak current is being controlled at all times by the

internal comparator, a simple voltage clamp at its nega-

R

=

S

0.5

I

CURRENTLIMIT

ERROR AMPLIFIER LIMIT

A high perfor mance, on-board e rror amplifier is included

to facilitate implementing closed loop motor control. Error

voltage generati on and loop compe nsation are easily accomplished by appropriately configuring the gain and

feedback of this amplifier . To provide a larger dynamic signal range at the output of the er ror amplifier, a divide by 5

resistor net work is used to reduce the error signal level

before applying to the internal comparator. In addition, a

one volt offset has been introduced at the output of the

error amplifier to guarantee control down to zero current

in the output stages. Since this offset is divided by the

open loop gain of the feedback loop, it has virtually no effect on closed loop performance.

PROTECTION FUNCTIONS

Protective functions including under-voltage lockout, peak

current limiting, and thermal shutdown, provide an extremely rugged device capable of surviving under many

types of fault conditions. Under-voltage lockout guarantees the out puts will be off or tri- slated until V

is suffi-

CC

cient for proper operation of the chip. Current limiting

limits the peak current for a stalled or shorted motor,

whereas thermal shutdown will tr i-state the outputs if a

temperature above 150°C is reached.

4

Page 5

TYPICAL APPLICATIONS

UC1620

UC3620

*Both VCC PWR and VCC LOGIC pins must be connected together when using the SP package.

3-∅ Brushless DC Open Loop Motor Drive

*Both VCC PWR and VCC LOGIC pins must be connected together when using the SP package.

3-∅ Brushless DC Open Loop Motor with Current Limit at 2A.

5

Page 6

UC1620

UC3620

*Both VCC PWR and VCC LOGIC pins must be connected together when using the SP package.

Closed Loop Speed Control Servo

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

6

Page 7

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...