Page 1

1

UNITEST

®

Instruction Manual

Cat. No. 9095

®

TELARIS 0751

Page 2

Content ............................................................................................Page

1.0 Introduction ....................................................................................4

1.1 Model and Type Designation/Identification ......................................4

1.2 Product Description ........................................................................4

1.3 Scope of Supply ..............................................................................5

1.4 Optional Accessories ......................................................................5

2.0 Transport and Storage......................................................................6

3.0 Safety Measures ..............................................................................6

3.1 Appropriate Usage ..........................................................................7

4.0 Operation Elements and Display ......................................................8

4.1 Front Panel ......................................................................................8

4.2 LC Display........................................................................................10

5.0 General Information to Perform Measurements ..............................10

5.1 Explanations of Terms......................................................................11

5.2 Performing the Tests ......................................................................14

5.3 Performing Tests in compliance with ..............................................15

DIN VDE 0701, Part 1 (issue 2000-09) ............................................15

5.4 Performing tests in compliance with ..............................................16

DIN VDE 0702, Part 1 (issue 1995-11) ............................................16

5.5 Durchführung von Prüfungen nach DIN VDE 0751,

Teil 1 (Ausgabe 2001-10) ................................................................17

6.0 Performing Individual Tests ............................................................20

6.1 Measuring the PE Resistance (Earth Bond) ......................................20

6.2 Measuring the Insulation Resistance................................................25

6.3 Measuring the Substitute Leakage Current ......................................28

6.4 Measuring the Touch Current ..........................................................31

6.5 Measuring the Protection Level of

Overvoltage Protection Devices (varistors) ....................................34

2

Content

Page 3

6.6 Measuring the PE earth leakage current

(PE current) and the Differential Current

with Schuko Measurement Adapter (Option) ..................................36

6.7 Function Test, Measurement of the Load Current with

Schuko Measurement Adapter (Option) ..........................................40

6.8 Current Measurement using external

Current Clamp Adapters, with Current Clamp Adapter (Option)........42

6.9 UUTs equipped with Three-phase Connection ..................................44

6.10 Messung des Ersatz-Geräteableitstromes ........................................45

6.11 Messung des Ersatz- Patientenableitstromes ..................................47

7.0 Storing, Printing, and Data Transfer ................................................50

7.1 Entering the UUT Number ..............................................................50

7.2 Saving Measurement Data ..............................................................50

7.3 Viewing Measurement Data ............................................................51

7.4 Printing Measurement Data ............................................................51

7.5 Deleting Saved Measurement

Data/View the Memory Location Number ........................................52

7.6 Infrared Interface, send Measurement Data ....................................53

8.0 Maintenance ....................................................................................53

8.1 Cleaning ..........................................................................................53

9.0 Internal fuses ..................................................................................54

9.1 Display after Fuse Blown ..................................................................54

9.2 Description of the built-in Fuses ......................................................54

10.0 Calibration Interval ..........................................................................54

11.0 Technical Data..................................................................................55

24 month Warranty ..........................................................................61

3

Content

Page 4

References marked on appliance or in

instruction manual:

Warning of a potential danger, comply with instruction manual.

Reference. Please use utmost attention.

Caution! Dangerous voltage. Danger of electrical shock.

Continuous double or reinforced insulation

complies with Class II according IEC 61140.

Symbol for the marking of electrical and electronic equipment (WEEE Directive

2002/96/EC).

Conformity symbol, the appliance complies

with the valid directives. It complies with the

EMC Directive (89/336/EEC). It also complies

with the Low Voltage Directive (73/23/EEC).

The instruction manual contains information

and references necessary for safe operation

and maintenance of the appliance. Prior to

using the appliance (commissioning / assembly) the user is kindly requested to thoroughly

read the instruction manual and comply with it

in all sections.

Failure to read the instruction manual or to

comply with the warnings and references contained herein can result in serious bodily injury

or appliance damage.

1.0 Introduction

You have acquired a sophisticated appliance by Ch.

BEHA GmbH allowing the operator to perform reproducible measurements over a very long time period. The company Ch. BEHA GmbH is a member of

the worldwide operating BEHA group. The headquarters are located in Glottertal/Black Forest. The

technological centre is also situated in Glottertal.

The BEHA-Group is one of the leading companies

for test and measurement appliances.

1.1 Model and Type Designation/Identification

The serial number label and the order number are

located on the appliance bottom. If you have any

questions, you are kindly asked to always indicate

the product designation, the order number and the

serial number.

1.2 Product Description

The UNITEST TELARIS 0751 is a multi-function test

instrument for regular monitoring and control of

electrical equipment in compliance with BGV A 2

(VBG 4), DIN VDE 0701, DIN VDE 0702, and DIN

VDE 0751.

The measurements required to determine the electrical safety in compliance with DIN VDE 0701 and

DIN VDE 0702 can be performed.

Furthermore, the auxiliary instrument leakage current and the auxiliary patient leakage current for medical instruments can be performed in compliance

with DIN VDE 0751.

An additional external Schuko Measurement

Adapter may be connected to the TELARIS 0751 to

measure PE resistance currents, differential currents, and load currents. Optionally you may also

connect a current clamp adapter to measure PE resistance currents.

The appliance UNITEST TELARIS 0751 is characterised by the following features:

• PE resistance measurement

• Insulation resistance measurement

• Substitute leakage curren

4

Introduction/Product Description

Page 5

• Touch current measurement

• Substitute housing leakage current

• Substitute patient leakage current

• Response voltage of excess voltage protection

devices (varistors)

• Connection facility for external "Schuko Mea-

surement Adapter to measure PE resistance currents, differential currents, and load currents.

• Connection facility for external current clamp

adapter to measure PE resistance currents, also

for three-phase UUTs

1.3 Scope of Supply

1pc TELARIS 0751

1pc Test lead equipped with test probe

(appliance mounted)

2pcs Test leads

2pcs Test probes

2pcs crocodile clamps

1pc Bag with sample labels

1pc Quick reference guide

1pc Instruction manual

1.4 Optional Accessories

(not included in the scope of supply)

Schuko Measurement Adapter Cat. No. 1296

Current clamp adapter Cat. No. 1245

Adapter for current clamp adapter Cat. No. 1277

Software es control 0751 Cat. No. 1255

es control complete package Cat. No. 1250

Protocol printer Cat. No. 1196

Interface adapter Cat. No. 1157

Measurement adapter (to test appliances equipped

with a three-phase connection):

CEE 5 pole, 16 A Cat. No. 1240

CEE 5 pole, 32 A Cat. No. 1241

Measurement adapter

(to measure the PE resistance current together with

the current clamp adapter):

"Schuko”-"Schuko” Cat. No. 1233

CEE 3 pole, 16 A Cat. No. 1234

CEE 5 pole, 16 A Cat. No. 1235

CEE 5 pole, 32 A Cat. No. 1236

5

Scope of Supply

Page 6

2.0 Transport and Storage

Please keep the original packaging for later transport, e.g. for calibration. Any transport damage due

to faulty packaging will be excluded from warranty

claims.

In order to avoid appliance damage, we recommend

that accumulators are removed when not using the

appliance over a certain period of time. However,

should the appliance be contaminated by leaking

battery cells, you are kindly requested to return it to

the factory for cleaning and inspection.

Appliances must be stored in dry and closed areas.

In the case of an appliance transported in extreme

temperatures, a recovery time of at least 2 hours is

required prior to appliance operation.

3.0 Safety Measures

The UNITEST TELARIS 0701/0702 has been designed and checked in accordance with the safety

regulations for Electronic test and Measurement

Appliances EN 61010 and IEC 61010, and left our

factory in a safe and perfect condition. The instruction manual contains information and references

necessary for safe operation and maintenance of the

appliance.

In order to avoid electrical shock, the valid safety and VDE regulations regarding excessive

touch voltages must receive the utmost attention when working with voltages exceeding

120V (60V) DC or 50V (25V)rms AC. The values in brackets are valid for limited areas (as

for example medicine and agriculture).

Measurements in dangerous proximity of electrical installations are only to be executed when

instructed by a responsible electrical specialist, and never alone.

Prior to usage, inspect the appliance and test

leads for external damage. Prior to any operation, ensure that connecting leads used and appliances are in perfect condition. The appliance

may no longer be used if one or several functions fail or if the appliance does not appear to

be ready to function.

Only touch test leads and test probes at handle

surface provided. Never directly touch test

probes.

If the operator’s safety is no longer guaranteed,

the appliance is to be put out of service and protected against use. The safety can no longer be

guaranteed if the appliance (or leads):

• shows obvious damage

• does not carry out the desired measurements

• has been stored for too long under unfavourable conditions

• has been subjected to mechanical stress during transport.

The appliance may only be used within the operating ranges as specified in the technical data

section.

Avoid any heating up of the appliance by direct

sunlight to ensure perfect functioning and long

appliance life.

6

Transport and Storage/Safety Measures

Page 7

3.1 Appropriate Usage

The appliance may only be used under those

conditions and for those purposes for which it

was built.

The appliance may not be used for measurements in electrical distribution systems!

The appliance may only be connected to correctly wired and protected mains sockets, protected with maximum 16 A!

When modifying or changing the appliance, the

operational safety is no longer guaranteed.

Any maintenance and calibration tasks may

only be carried out by our repair service staff.

If the appliance is subjected to an extremely

high electro-magnetic field, its functioning

ability may be impaired.

7

Appropriate Usage

Page 8

4.0 Operation Elements and Display

4.1 Front Panel

Explanation of the individual operation and

display elements

Figure 4.1: Appliance view

8

Operation Elements and Display

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

18

16

17

Page 9

1. Mains connection plug, to connect the test appliance to the power supply 230 V +10%/-15%,

50 Hz. The test appliance may only be connected to a mains plug protected with a fuse of

maximum 16 A!

2. Probe, fixed test lead with test probe. Test connection for PE resistance test and touch current. The test probe is used for connecting the

test appliance and the UUT casing or the touchable conductive casing parts.

3. Test socket, in compliance with DIN VDE

0701/0702. To connect UUTs equipped with

earthed mains sockets for the following measurement functions: PE resistance, insulation

resistance, and substitute leakage current.

Connections L and N are short-circuited

within the test socket.

4. Socket ‘L/N’ (red), parallel connection to the

test socket L/N, to connect UUTs not equipped

with a earthed mains plug.

5. Socket ‘PE’ (blue), parallel connection to the

test socket PE, to connect UUTs not equipped

with a earthed mains plug.

6. Digital LCD, to display measurement values,

pre-set limit values, stored data.

7. Key”LIMIT”, to set limit values within the

different measurement functions.

8. Key “NEW TEST”, to connect a new UUT to

which the subsequent measurements are

assigned.

9. Key “Start”, to start a measurement.

10. Key “Store”, to save a measurement.

11. Key “Send”, for data transfer of stored data to

the PC via interface adapter (optional).

12. RS-232 interface (infrared).

13. Key “Clear/Recall”, to delete or view the stored

measurement data and created UUTs.

14. Key “Print”, to print stored data via protocol

printer (optional).

15. Rotary switch "Measurement function” , to select the desired measurement function. This

switch directly activates the selected measurement function.

16. Key “COMP”. To compensate test lead resistance.

17. Key ”Display”, to select the different measurement values within the function RPE and

VProt.level.

18. Measurement adapter connector, to connect

the external Schuko Measurement Adapter

(1196) or the external current clamp adapter

(1245).

9

Operation Elements and Display

Page 10

4.2 LC-Display

Figure 4.2: Display

19. Attention warning symbol.

20. External voltage present.

21. "Limit” symbol for limit exceeding.

22. Reference: "Turn mains plug at UUT”.

23. Unit display.

24. Unit display for the small result field.

25. Measurement value display, small result field.

26. Limit value display, small result field.

27. Symbol for compensated test lead resistance.

28. Symbol for memory entry.

29. True RMS measurement (TRMS).

30. Display for AC voltage / DC voltage.

31. Over temperature, overheating of the appliance.

5.0 General Information to Perform

Measurements

The test appliance may not be used for measurements in electrical distribution systems!

The maximum admissible mains input voltage

amounts to 230 V +10%/-15%, 50 Hz.

The test appliance and the Schuko Measurement Adapter may only be operated on a correctly wired and earthed mains socket, protected with maximum 16 A!

The test socket, the measurement connectors

in parallel to the test socket, and the PE test

connector may not be connected to external

voltage to avoid test appliance damage.

The probe for connecting the touch current

may not be connected to an external voltage

> 230 V AC/DC to avoid test appliance damage.

You may use only the original test leads supplied or the pertaining safety measurement accessories!

At differential or PE current measurement an external magnetic field can affect the measurement.

Please take care to use the Schuko-Measurement

Adapter as most as possible away from appliances

with high magnetic fields (i.e monitors with CRT,

UUT with big tranformers, welding machines, currents tracks).

At measurements with faulty appliances or appliances with high leakage currents a preceding RCD (Residual Current Device) could trip.

Prior to any use, check the test appliance and

the test leads for perfect function.

The test leads and test probes may only be held

at the handles provided. Imperatively avoid

touching the test probes.

The measurements for checking the electrical

safety must be performed in compliance with

the respectively valid standards or regulations.

10

LC-Display/General Information to Perform Measurements

19 20 21 22

23

2425262728

29

30

31

Page 11

The measurements used to check the electrical safety must be performed in compliance

with the respectively valid standards and regulations.

5.1 Explanations of Terms

Leakage Current:

The leakage current describes the current which

flows via the insulation of a UUT. This happens either via the casing or via touchable, conducitve

parts, via the PE, or via additional earth connections

(e.g. antenna, water supply) of a UUT.

Contact surfaces:

A part of the instrument, when used appropriately:

• must come in physical (corporal) contact with the

patient, if required, so that the instrument can fulfill its function, or

• can be brought in contact with the patient, or

• must be touched by the patient.

Contact surface of type B:

A contact surface ensuring a protection against

electrical shock, in compliance with the requirements stipulated within VDE 0750/IEC 60601-1, in

particular when observing the admissible leakage

current. It is characterised by the symbol .

NOTE: Contact surfaces of type B are not appropriate for direct applications to the heart.

Contact surface of type BF:

A contact surface of type F allowing a superior protection against electrical shock in compliance with

the requirements stipulated in DIN VDE 0750/IEC

60601-1 than contact surfaces of type B and characterised by the symbol

NOTE: Contact surfaces of type BF are not appropriate for direct application to the heart.

Touch Current:

Here, a current measurement towards earth at

touchable, conductive parts of a UUT is performed.

The limit value in compliance with DIN VDE

0701/0702 amounts to 0.5 mA. The measurement

may be performed either directly or applying the differential current procedure. The touch current

measurement will be performed for appliances of

protection class II, containing touchable, conductive parts or for appliances of protection class I,

which are equipped with touchable parts not connected with the PE. The measurement must be performed for both positions of mains plug.

The appliance UNITEST TELARIS 0701/0702

easy and the appliance UNITEST TELARIS

0701/0702 use the direct measurement procedure for touch current measurement

11

Explanations of Terms

Page 12

Differential Current:

In compliance with DIN VDE 0701/0702, this is a

measurement procedure to determine the PE current or the touch current, performing a summation

current measurement for all active conductors (L N) of an UUT. Thus, the total leakage current for a

UUT can be determined.

The measurement must be applied if the UUT is

equipped with additional earth connections or if an

insulated UUT installation is not possible.

The Schuko Measurement Adapter (Option) of

the appliance UNITEST TELARIS 0701/0702 allows to perform the measurement using with

the differential current procedure.

Electrical Safety:

Condition of instruments for which the repercussions of electrical current on patients, users, or third

parties are limited, in compliance with DIN EN

60601-1 (VDE 0750 Part 1).

Earth leakage current:

Current flowing from the power supply through or

via the insulation to the protective earth.

Substitute Leakage Current:

In compliance with DIN VDE 0701, this is an alternative measurement procedure to determine the PE

resistance current or the touch current.

In compliance with DIN VDE 0702, this measurement is a substitute measurement for the insulation

measurement which can be performed if appliances

equipped with heating of protection class I do not

match the required insulation values.

This measurement procedure determines without

mains voltage the leakage current conducted via the

PE resistance, or a touchable part.

Auxiliary instrument leakage current:

Current flowing when connecting the instrument in

compliance with Figure 6.21 or Figure 6.22 and

using the measurement circuit MD (in compliance

with DIN VDE 0750 Part 1, En 60601-1) at which the

nominal value or mains voltage and the nominal

value of the mains frequency are present.

Auxiliary patient leakage current:

Current flowing when connecting the instrument in

compliance with Figure 6.25 or Figure 6.26 using a

measurement circuit MD in compliance with Figure

C.1 at which the nominal value of mains voltage and

the nomimal value of the mains frequency are present.

Fixed instruments:

Instrument connected to the mains by means of

fixed connections which can only be removed using

tools.

Casing leakage current:

Current flowing from the casing or casing parts, excluding contact surfaces, which can be touched by

the patients during appropriate usage, whereby it is

deviated via another external conductible connection than the protective earth to the ground or to another part of the casing.

Instrument leakage current:

Current flowing from the power supply via the insulation of the casing and/or the contact surface to

the protective earth (PE), if a conductible connection is realised between the contact surfaces and the

casing.

Insulation Measurement:

A measurement of the insulation resistance is performed between the active parts (L1-L2-L3-N) and

the protection earth conductor (PE) within a system,

an appliance, or a machine. For this purpose, a test

voltage of 500 V DC is used, in compliance with DIN

VDE 0701/0702.

Medical, electrical instrument

Electrical instrument equipped with only one connector for a certain supply network destined for diagnosis, treatment, or patient observation under

medical supervision and being in corporal or electrical contact with the patient and/or transmits energy to or from the patient and/or indicates such a

transfer of energy to or from the patient.

12

Explanations of Terms

Page 13

Medical, electrical system:

Combination of several instruments of which at

least one instrument is a medical, electrical instrument and which are inter-connected via functional

connection or portable multiple sockets.

Patient leakage current:

Current flowing from the contact surface via the patient to the ground, or current which is generated at

the patient by an unforeseeable external voltage and

which is flowing to the ground either via the patient

or a contact surface of type F.

Patient connection:

Every individual part of the contact surface via

which current may flow either in normal condition

or in condition of the first occuring error between

the patient and the instrument.

Test to make sure that the system is not live:

Also called "Leakage current during operation”. This

leakage current is determined by current measurement on touchable, conductible part of a UUT towards ground, in compliance with DIN VDE 0701,

Part 240. According to DIN VDE 0701, Part 240, the

limit value is 0.25 mA. This measurement is similar

to the contact voltage measurement.

Protection Class I :

appliances of protection class I are UUTs provided

with a basic insulation between active (live) parts

and the casing. The metal casing or metal casing

parts must be appropriately connected to the protection earth conductor. The mains plug of appliances of protection class I are equipped with an

earth connector.

Protection Class II :

Appliances of protection class II are equipped with

a continuously reinforced or supplementary insulation between the active (live) parts and the casing.

Such appliances may, however, have touchable,

metal parts. The mains plug of UUTs to protection

class II are not equipped with an earth connector.

Protection Class III :

Appliances of protection class III are made either for

connection to safety extra low voltage (SELV) current circuits or are only supplied with SELV via an

internal power supply.

Earth leakage current (PE current):

This is a part of the UUT leakage current, flowing in

the PE (protection earth conductor). According to

DIN VDE 0701/0702, the limit value amounts to 3.5

mA. The protection earth conductor current is either

determined by direct current measurement within

the UUT PE or by applying the differential current

measurement. The direct measurement is performed if the UUT is not equipped with an additional earth connection or if the insulation of the UUT

against earth is possible. The measurement has to

be performed in both positions of the mains plug.

In compliance with DIN VDE 0701:2000-09, the PE

current measurement represents an additional

measurement to determine the insulation capacitance for appliances of protection class I.

In compliance with DIN VDE 0702, this measurement is a substitute for the insulation measurement

for appliances of protection class I and for which the

insulation measurement cannot or may not be performed.

The Schuko Measurement Adapter (option) of

the appliance UNITEST TELARIS 0701/0702

allows the PE resistance current measurement

in compliance with the direct measurement

procedure and the differential current procedure.

13

Explanations of Terms

Page 14

PE resistance (earth bond):

We are dealing with the PE resistance of the mains

connection point (earth connector of the mains

plug) to all touchable, metal UUT casing parts which

have to be connected to the PE resistance. During

PE or resistance measurement, the connecting lead

has to be moved over the total lengths in sections.

This measurement can only be performed for appliances of protection class I.

Visual Check:

Here, you must make sure that the appliance parts

contributing to the electrical safety are undamaged

and appropriate. The following must be checked:

• Casing, protection covers

• Connecting leads and plugs

• Condition of insulations

• Strain relief, antikink protection, and arrange-

ment of wiring

• Signs for overload or inappropriate use

• Forbidden interventions or modifications

• Fuse holders and fuses, accessible for the user

• Cooling openings and air filters

• Protection covers

• Overpressure valves

• Fixtures

• Contamination or corrosion which might impair

the safety

• Safety labelling

5.2 Performing the Tests

The accident prevention prescriptions (German

Unvallverhütungsvorschrift BGV A 2 for "Electrical

Systems and Equipment", issued by the professional associations (German Berufsgenossenschaft) defines the conditions for testing electrical

appliances:

• Prior to first commissioning and after any mod-

ification, after repair, prior to repeated commissioning, as well as in regular TIME INTERVALS.

• For portable appliances, these TIME INTER-

VALS generally amount to 6 months (for use on

building sites reduced to 3 months).

Depending on the use, this interval is flexible,

provided the appliance safety is ensured. The

test interval can be extended to maximum 12

months for building sites and to maximum 24

months for the use in offices.

The DIN VDE regulations of the series DIN VDE

0701 and DIN VDE 0702 define the test procedure and the limit values.

14

Explanations of Terms / Performing the Tests

Page 15

5.3 Performing Tests in compliance with

DIN VDE 0701, Part 1 (issue 2000-09)

DIN VDE 0701 defines the requirements regarding

the electrical safety for electrical appliances. It contains the tests and limit values for repaired or modified appliances. After repair or modification, it must

be ensured that there will be no risk of danger for

the user if the appliance is used appropriately.

The test order is as follows:

1.) Visual Check

2.) Test of PE resistance (for appliances of protection class I)

The limit value amounts to:

0.3 Ωfor appliances equipped with mains leads

up to 5 m, plus 0.1 Ω for every further 7.5 m,

however, maximum 1.0 Ω.

3.) Insulation resistance measurement (if applicable) The limit value amounts to:

1 MΩ for appliances of protection class I

2 MΩ for appliances of protection class II* Remark 1

0.25 MΩ for appliances of protection class III

0.3 MΩ for appliances of protection class I with

switched on heating elements * Remark 2

Remark 1: This is also applicable for conductive

parts of class I appliances which are NOT connected to PE.

Remark 2: For appliances of class I (with heating elements) at which the required limit values for insulation resistance is not fulfilled, the appliance test

could be considered as passed, if the PE current is

within the limits.

4a.) Measurement of PE resistance Current

(for appliances of protection class I)

The limit value amounts to 3.5 mA.

-at appliances with heating elements and a

rated power of > 3.5 kW the PE current may not

exceed 1 mA/1 kW.

-for ovens/cooking facilities, etc. up to 6 kW 7

mA, more than 6 kW 15 mA.

The PE resistance current may be measured either

directly via the substitute leakage current method or

via the differential current method

4b.) Measurement of the touch current (for appli-

ances of protection class II)

The limit value amounts to 0.5 mA

The touch current may be measured directly

either via the substitute leakage current

method or via the differential current method.

These measurements must also be carried out

for appliances of protection class I equipped

with touchable, conductive parts.

5.) Functional Test

6.) Test of Markings

15

Performing Tests in compliance with DIN VDE 0701

Page 16

5.4 Performing tests in compliance with

DIN VDE 0702, Part 1 (issue 1995-11)

DIN VDE 0702 defines the test procedures and limit

values for repeat tests. A repeat test is defined as a

test performed in regular time intervals used as

proof for the electrical safety on electrical appliances. It must be ensured that the protection is effective against direct and indirect touch. DIN VDE

0702 is valid for all electrical appliances which can

be disconnected from an electrical system by

means of a plug-in system.

The test order is as follows:

1.) Inspection, visual check

2.) Measuring the PE resistance ( for appliances of

protection class I)

The limit value amounts to:

0.3 Ωfor appliances equipped with mains leads

up to 5 m, plus 0.1 Ω for every further 7.5 m.

3.) Insulation resistance measurement

The limit value amounts to:

0.5 MΩ for appliances of protection class I

2 MΩ for appliances of protection class II

0.25 MΩ for appliances of protection class III.

If the insulation measurement does not test all

active UUT parts, a PE resistance current or

touch current may be performed as a substitute measurement. These measurements may

also be carried out as substitute measurements

for appliances for which the performance of an

insulation measurement gives reasons to

reservations.

4.) Measurement of substitute leakage current

The limit value amounts to:

7 mA for appliances of protection class I with a

heating capacity of < 6 kW,

15 mA for appliances of protection class I with

a heating capacity of > 6 kW

A substitute leakage current measurement

must be performed for appliances of protection

class I equipped with heating elements and for

which the requested insulation resistance is

not obtained,

5.) Measurement of the PE resistance current (for

appliances of protection class I)

The limit value amounts to 3.5 mA.

This is a substitute measurement to the insulation measurement for appliances of protection

class I.

6.) Touch current measurement (for appliances of

protection class II)

The limit value amounts to 0.5 mA.

This is a substitute measurement to the insulation measurement for appliances of protection

class II or for appliances of protection class I

equipped with touchable, conductive parts.

16

Performing Tests in compliance with DIN VDE 0702

Page 17

5.5 Performing Tests in compliance with

DIN VDE 0751, Part 1 (Edition 2001-10)

DIN VDE 0751 stipulates the requirements for the

electrical safety on medical, electrical instruments

or systems. Mention is made here regarding tests

and limit value for tests prior to commissioning, during repair, changes, modifications, or repetition

tests on medical instruments.

When performing measurements prior to commissioning, the first measured values must be determined and documented whilst indicating the measurement procedure. This documentation will be

used as reference for future measurements (source: translated from DIN VDE 0751, Part 1:2001-10,

Section 4.2).

When performing measurements for repetition

tests, the measured values must be documented

whilst indicating the measurement procedure. The

values must then be evaluated. If the leakage current measurement values exceed factor 0.9 of the

admissible values, the first measurement values are

to be taken as reference for evaluation (please refer

to DIN VDE 0751, Part 1:2001-10, Section 4.3).

The test sequence is as follows:

1.) Inspection

- fuse insert parts, accessible from outside, for current values and characteristics

- inscriptions

- does the mechanical condition allow further and

safe use

- no safety-impairing damages or pollutions

- also check and assess accessories used (e.g.

mains cable) or one-off parts (patient cable, tubes)

- required documentation availabe and complete

2.) - Measurement of protective earth conductor

resistance (for instruments pertaining to protection class I)

The limit value is:

- 0.3 Ω for instruments with fixed mains connection (or for instruments with removable

mains connection cable at the instrument, together with the mains connection cable)

- 0.2 Ω for instruments with removable mains

connection cable (between the protective earth

contact of the instrument plug and the conductible and touchable parts).

- 0,1 Ω only for the removable mains connection cable.

3) - Measurement of leakage currents

The leakage current measurement for instruments pertaining to protection class I, may

only be performed once the protective earth

conductor test has been successful.

Measurement has to be made of instrument and patient leakage currents, whereby the following measurement procedures may be used:

- Measurement of the auxiliary leakage current

- Direct measurement of the leakage current

- Measurement of the leakage current in complian-

ce with the differential current procedure

3a.) Measurement of the auxiliary instrument lea-

kage current in compliance with Figure 6.21

and Figure 6.22 (or Figure C4 of DIN VDE

0751).

3b.) Measurement of the auxiliary patient leakage

current in compliance with Figure 6.25 and Figure 6.26 (or Figure C7, C8, and C9 of DIN VDE

0751).

3c.) Measurement of the instrument leakage cur-

rent during instrument operation (measurement in compliance with Figure C5, C6 of DIN

VDE 0751).

3d.) Measurement of the patient leakage current du-

ring instrument operation (measurement in

compliance with Figure C8, C10 of DIN VDE

0751).

17

Performing Tests in compliance with DIN VDE 0751

Page 18

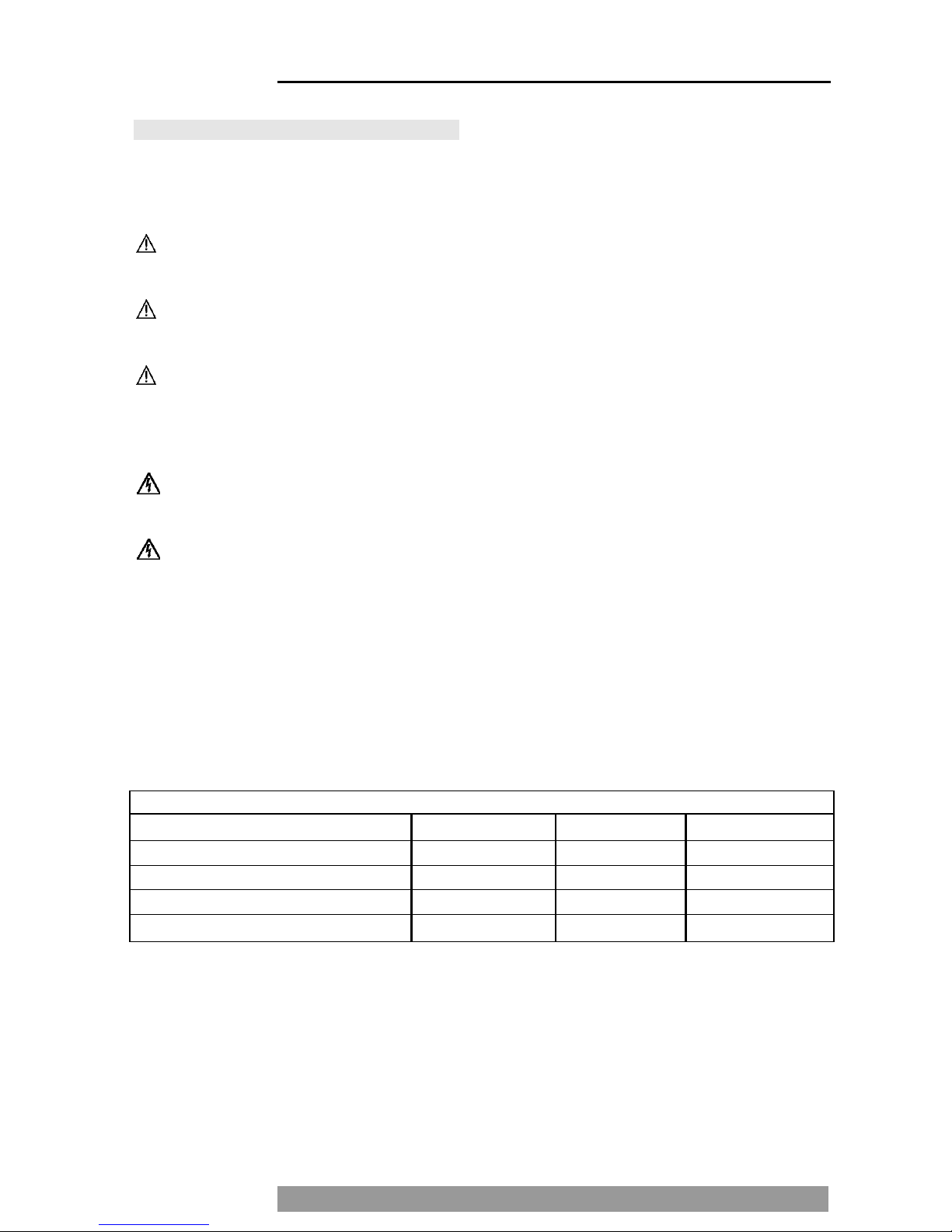

Table 1: Limit values for leakage currents

18

Performing Tests in compliance with DIN VDE 0751

Source: Table F.1 off DIN VDE 0751 TPart 1:2001-10

Leakage current in mA in mA

Contact surface TYP B TYP BF

Instrument leakage current, in general 0.5 0.5

Instrument leakage current for instruments in compliance

with remarks 1 and 3 2.5 2,5

Instrument leakage current for instruments in compliance with remark 2 5.0 5,0

Instrument leakage current for instruments 0.1 0.1

pertaining to protection class II and for instruments with conductible,

touchable parts which are not connected to the protective earth

conductor, pertaining to protection class I

Auxiliary instrument leakage current

- within protective earth conductor or parts connected to the

protective earth 1.0 1,0

- Instruments with mineral insulation and instruments in compliance

with remark 1 5,0 5,0

- in compliance with remark 2 10.0 10-0

Mobile X-ray instruments with 5.0 5.0

additional protective earth

Mobile X-ray instruments without additional protective earth 2.0 2.0

Patient leakage current

DC current 0.01 0.01

AC current 0.1 0.1

Auxiliary patient leakage current - 5.0

Mains voltage on contact surface

Auxiliary patient leakage current - 5.0

REMARK 1: instrument systems which are not equipped with the touchable parts that are not connected with

the protective earth conductor and which are in compliance with the requirements for instrument leakage current, and, if applicable, for the patient leakage current.

Example: Electronic data processing devices with shielded power supply.

REMARK 2: Instruments destined for fixed connection and which are equipped with a protective earth conductor being connected in such a way or being mechanically secured in a certain place that it can only be removed using tools.

Examples for such instruments are:

- the main components of an x-ray system such as the x-ray generator, the table for medical examination.

- Instruments equipped with mineral-insulated heating elements.

- Instruments showing superior ground leakage current values than the admissible values in

"Ground Leakage Current, in general" due to the requirement to meet radio protection conditions.

REMARK 3: Mobile x-ray instruments and mobile instruments with mineral insulation.

Page 19

4.) Measurement of the insulation resistance

Only for old generation medical devices, please refer to DIN VDE 0751 Part 1, Appendix E.

In case of doubt regarding the perfect condition of

the quality of the instrument insulation, an insulation resistance measurement can be performed.

The limit value is:

2 MΩ for instruments pertaining to protection

class I

7 MΩ for instruments pertaining to protection

class II.

5.) Function test

Afterwards, a specialised person in electrotechnics

and medical device technology with particular

knowledge in the respective instrument must perform a safety evaluation.

The tests must be documented.

6 ) –Evaluation of the Documentation and Tests

6.1) Evaluation

The safety evaluation of INSTRUMENTS/SYSTEMS

must be performed by a specialised person in electrotechnics and medical device technology with

particular knowledge in the respective instrumnet..

If the safety of the INSTRUMENT/SYSTEM is not

guaranteed, e.g. by failing the acceptance test in

compliance with section 5, the INSTRUMENT/SYSTEM must be marked accordingly and the USER

must be informed in writing about the DANGERS

emanating from the INSTRUMENT/SYSTEM.

6.2) Documentation

The tests are to be documented. The documentation must fulfill the following minimum requirements:

a) –Designation of the executing site (e.g. company, department);

b) Name of tester and evaluating person;

c) Designation of the INSTRUMENT/SYSTEM (e.g.

type, manufacture number, inventory number)

and the respective accessories in compliance

with section 4.1. The assignment of test documentation to the INSTRUMENT/SYSTEM must

be unambigous.

d) –Tests and measurements:

- Date, type scope, and results of the visual inspections.

- Measurement (measurement procedure, measurement equipment, measurement values),

- Function checks.

e) Total evaluation.

f) Date and signature of the evaluating person,

when using data processing, indicate the personal coding.

19

Performing Tests in compliance with DIN VDE 0751

Page 20

6.0 Performing Individual Tests

6.1 Measuring the PE Resistance (Earth Bond)

6.1.1 General Information regarding the PE

resistance Measurement

Before any PE resistance measurement it must

be ensured that the UUT is not connected to live

voltages.

During the measurement, the mains lead must

be moved across the total length in sections,

whereby no measurement result fluctuation

must occur. A fluctuating measurement result

indicates an error.

For appliances equipped with additional metal

connections, such as e.g.

• water connection (e.g. washing machine)

• gas connection (e.g. warm water heating unit)

or

• antenna connection (e.g. SAT-Receiver) the

measurement result might be falsified due to

the additional connection to the PE resistance.

The PE resistance connection via an additional

connection must be removed when performing

the measurement.

For the appliance UNITEST TELARIS 0751 the

test current is an AC current. The key ”Display”

(17) is used to display the measurement values for both polarities during active measurement. Measurement results showing high differences for the two polarities indicate an

insufficient PE connection. Thus, corroded

connections to the PE resistance can be determined.

In compliance with DIN VDE 0701, Part 1 and

DIN VDE 0702, Part 1, the minimum test current is 200 mA.

For appliances equipped with mains lines of up

to 5 m, the limit value amounts to 0.3 Ω in compliance with DIN VDE 0701/0702 0,3 Ω, i.e. for

active limit value display ‘LIMIT 0.3 Ω’ the symbols and ‘LIMIT’ may not be displayed!

When dealing with longer connection cables,

the limit value is to be defined in accordance

with the standard applied.

According to DIN VDE 0751 the limit value is

0,3 Ω, i.e., if the limit value indicator is switched on ‘LIMIT 0,3 Ω’ the symbols and ‘LIMIT’

must not appear! If the connection lines are of

a certain length, the limit value must be defined

in accordance with the respective standard

applied.

20

Measuring the PE Resistance

Page 21

6.1.2 PE Resistance Measurement (RPE)

Performing the measurement:

Before performing the PE resistance measurement,

the user may proceed with the compensation of the

test lead resistance (please refer to chapter 6.1.4).

Connect the UNITEST TELARIS 0751 via the

mains plug (1) to a functional and correct wired

and grounded mains socket.

Turn the ‘Measurement function” selection

switch (15) to position ‘RPE’.

Set the limit for the PE resistance using the key

“LIMIT” (7).

Plug the UUT mains plug into the test socket

(3).

Connect the PE test connector ‘Probe’ (2) to

touchable, conductive appliance parts of the

UUT, in compliance with Figure 6.1. Ensure a

good contact with the surface of the casing

parts.

Press the key “Start” (9). The unit symbol

which is blinking on the display is an indication

for the active measurement procedure.

Read the measurement value from the LC dis-

play (6). If the limit value display is active, the

symbol ‘LIMIT’ (21) indicates that the limit

value has been exceeded.

The appliances displays the AC resistance of

the PE resistance. The key ”Display” (17) is

used to subsequently display the measurement values for the positive and negative test

current during the measurement (display symbol Ω+ and Ω-).

Measurement results showing high differences for the two polarities indicate an insufficient PE resistance. Thus, corroded connections to the PE resistance can be determined.

Continue with the PE resistance test for all

other touchable, conductive parts of the UUT.

The measurement results can be saved by

pressing the key “Store” (10). For any references regarding saving of measurement values, please refer to sections 7.1 and 7.2.

Figure 6.1: Measurement of the PE resistance

21

Measuring the PE Resistance

Page 22

6.1.3 Measurement of the PE resistance

(RPE) for fix installed appliances not

equipped with a Mains Plug

Performing the measurement:

Before performing the PE resistance measurement,

the user should proceed with the compensation of

the resistance for the additional test lead (connection of the PE (5) socket to the protection earth conductor connection of the UUT), please refer to chapter 6.1.4.

Connect the UNITEST TELARIS 0751 via the

mains plug (1) to a functional and correct wired

and grounded mains socket.

Turn the ‘Measurement function” selection

switch (15) to position ‘RPE’.

Set the limit for the PE resistance using the key

LIMIT(7).

For fixed installed appliances, connect the PE

connection of a neighbouring socket with the

blue ‘PE’ socket (5), please refer to Figure 6.2.

For appliances not equipped with a mains plug,

connect the PE connection of the UUT to the

blue ‘PE’ socket (5), please refer to Figure 6.3.

Connect the PE test connection ‘Probe’ (2) to

touchable, conductive appliance parts of the

UUT, in compliance with Figures 6.2 or 6.3. Ensure a good contact with the surface of the casing parts.

Press the key “Start” (9). The unit symbol

which is blinking on the display is an indication

for the active measurement procedure.

Read the measurement value from the LC dis-

play (6). If the limit value display is active, the

symbol ‘LIMIT’ (21) indicates that the limit

value has been exceeded.

The appliances displays the AC resistance of

the PE resistance connection. The key ”Display” (17) is used to subsequently display the

measurement values for the positive and negative test current during the measurement (display symbol Ω+ and Ω-).

Measurement results showing high differences for the two polarities indicate an insufficient PE resistance. Thus, corroded connections to the PE resistance can be determined.

Continue with the PE resistance test for all

other touchable, conductive parts of the UUT.

The measurement results can be saved by

pressing the key “Store” (10). For any references regarding saving of measurement values, please refer to sections 7.1 and 7.2.

22

Measurement of the PE resistance

Page 23

Figure 6.2: Measurement of the PE resistance for

fixed installed appliances

Figure 6.3: Measurement of the PE resistance for

appliances not equipped with a mains plug

Prüfling

L1

N

PE

Prüfling

benachbarte

Steckdose

23

Measurement of the PE resistance

Page 24

6.1.4 Compensation of the Test Lead Resistance

The appliance TELARIS 0751 allows to compensate

the test lead resistance and the resistance of test accessories resistance up to a value of 1,00 Ω. For

compensation, please proceed as follows:

Connect the PE test connection ‘Probe’ (2) or

the blue ‘PE’ socket (5) to the additional test

lead and test accessories.

Short-circuit the connected test leads in com-

pliance with Figure 6.4, or connect the probe

(2) to the PE of the test socket (3) in compliance with Figure 6.4. Ensure a good contact.

Turn the ‘Measurement function’ selection

switch (15) to position ‘RPE’.

Press the key “COMP” (16).

Now, the measurement is started. The resist-

ance of the test lead is measured and compensated. The "COMP” symbol (27) is displayed on

the LCD. 0,00 is displayed and a signal is audible.

If the test lead and test accessory resistance is

higher than 1,00 Ω, no test lead compensation

is performed. Instead "- - -” is displayed on the

LCD.

The compensation value is deleted when

switching off the appliance.

To delete the compensation value, press again

the key “COMP” (16). The ‘COMP’ symbol is no

longer displayed on the screen.

Figure 6.4: Compensation of the test lead resistance

24

Compensation of the Test Lead Resistance

Page 25

6.2 Measuring the Insulation Resistance

6.2.1 General Information regarding the

Measurement of the Insulation Resistance

The insulation resistance may only be performed after successful PE resistance test.

Before any insulation measurement, ensure

that the UUT is not connected to live voltage.

During insulation measurement, all switches of

the UUT must be switched on to ensure that all

circuits inside are considered when performing the measurement.

Do not touch the UUT during active measurement, danger of electrical shock!

The insulation measurement may cause a

charging of capacitive UUTs, due to the measurement voltage.

6.2.2 Measuring the Insulation Resistance

(RINS)

Performing the measurement:

Connect the UNITEST TELARIS 0751 via the

mains plug (1) to a functional and correctly

wired and grounded mains socket.

Turn the ‘Measurement function” selection

switch (15) to position ‘RINS’.

Set the limit for the insulation resistance using

the key LIMIT(7); for the limit values, please

refer to table 1.

Plug the mains plug of the UUT into the test

socket (3), please refer to Figure 6.5.

Switch on the UUT.

Press the key “Start” (9). The unit symbol

which is blinking on the display is an indication

for the active measurement procedure.

Read the measurement value from the LC dis-

play (6). If the limit value display is active, the

symbol ‘LIMIT’ (21) indicates that the measurement value has fallen below the limit value.

* only for old generation medical instruments, ple-

ase refer to DIN VDE 0751 Part 1 Appendix E

25

Measuring the Insulation Resistance

Table 1: Limit values of the insulation resistance

UUT description DIN VDE 0701 DIN VDE 0702 DIN VDE 0751

UUT of protection class I

1MΩ 0,5 MΩ 2 MΩ

UUT of protection class II 2MΩ 2MΩ 7 MΩ

UUT of protection class III 0,25 MΩ 0,25 MΩ -

UUT of protection class I with heating element 0,3 MΩ - -

Page 26

For appliances of protection class II or III connect, in addition, the ‘PE’ socket (5) to all touchable, conductive casing parts of the UUT,

please refer to Figure 6.6.This is also applicable for conductive parts of class I appliances

which are NOT connected to PE.

Continue the insulation test for all other touch-

able, conductive casing parts of the UUT.

The measurement results can be saved by

pressing the key “Store” (10). For references

regarding the saving of measurement values,

please refer to section 7.1 and 7.2.

The measurement can be started and stopped

manually. After approx. 2 minutes, the measurement is automatically completed.

Figure 6.5: Insulation resistance measurement for

appliances of protection class I

Figure 6.6: Insulation resistance measurement for

appliances of protection class II

26

Measuring the Insulation Resistance

Page 27

6.2.3 Insulation Resistance Measurement

(RINS) for fix installed appliances or

appliances not equipped with a mains

plug

Performing the measurement:

Connect the UNITEST TELARIS 0751 via the

mains plug (1) to a functional and correct wired

and grounded mains socket.

Turn the ‘Measurement function” selection

switch (15) to position ‘RINS’.

Set the limit for the insulation resistance using

the key LIMIT(7); for the limit values, please

refer to table 1.

Switch on the UUT.

Connect the UUT PE connection to the blue ‘PE’

socket (5), in compliance with C in Figure 6.7.

For appliances of protection class I or II, additionally connect the ‘PE’ socket (5) to all touchable, conductive casing parts of the UUT, in

compliance with D, E in Figure 6.7. This is also

applicable for conductive parts of class I appliances which are NOT connected to PE.

Connect the socket ‘L/N’ (4) to all active con-

nectors of the UUT, in compliance with A, B in

Figure 6.7.

Press the key “Start” (9). The unit symbol

which is blinking on the display is an indication

for the active measurement procedure.

Read the measurement value from the LC dis-

play (6). If the limit value display is active, the

symbol ‘LIMIT’ (21) indicates that the measurement value has fall below the limit value.

Continue the insulation test for all other touch-

able, conductive casing parts of the UUT.

The measurement results can be saved by

pressing the key “Store” (10). For references

regarding the saving of measurement values,

please refer to section 7.1 and 7.2.

Figure 6.7: Insulation resistance measurement for

fixed installed appliances or appliances not

equipped with a mains plug.

L1

N

PE

A

B

C

D

E

Prüfling

27

Measuring the Insulation Resistance

Page 28

6.3 Measuring the Substitute Leakage

Current

6.3.1 General Information regarding the

Substitute Leakage Current

In compliance with DIN VDE 0701:2000-09,

the substitute leakage current measurement is

an alternative measurement procedure to determine the PE resistance or touch current. According to DIN VDE 0702, this is a substitute

measurement for the insulation measurement

when dealing with UUTs equipped with heating

elements.

Before any substitute leakage current measurement, ensure that the UUT is not connected to live voltage.

During the substitute leakage current measurement, all switches of the UUT must be

switched on to ensure that the all circuits inside are be considered when performing the

measurement.

6.3.2 Measuring the Substitute Leakage

Current (IPE SUBS)

Performing the measurement:

Connect the UNITEST TELARIS 0751 via the

mains plug (1) to a functional and correct wired

and grounded mains socket.

Turn the ‘Measurement function” selection

switch (15) to position ‘IPE SUBS’.

Set the limit for the insulation resistance using

the key LIMIT(7); for the limit values, please

refer to table 2.

Plug the UUT mains plug into the test socket

(3), please refer to Figure 6.8.

Switch on the UUT.

Press the key “Start” (9). The unit symbol

which is blinking on the display is an indication

for the active measurement procedure.

Read the measurement value from the LC dis-

play (6). If the limit value display is active, the

symbol ‘LIMIT’ (21) indicates that the limit

value has been exceeded.

For appliances of protection class II or III, additionally connect the ‘PE’ socket (5) to all

touchable, conductive parts of the UUT; please

refer to Figure 6.9. This is also applicable for

conductive parts of class I appliances which

are NOT connected to PE.

Continue the substitute leakage current meas-

urement for all other touchable, conductive

casing parts of the UUT.

The measurement results can be saved by

pressing the key “Store” (10). For references

regarding the saving of measurement values,

please refer to section 7.1 and 7.2.

28

Measuring the Substitute Leakage Current

Table 2: Limit value of the substitute leakage current

Description of the UUTs according to DIN VDE 0701 according to DIN VDE 0702

UUT of protection class I 3,5 mA

UUT of protection class II 0,5 mA

UUT of protection class I with heating element >3,5 kW 1 mA/kW

UUT of protection class I with heating element up to 6 kW 7 mA (see appendix G) 7 mA

UUT of protection class I with heating element

> 6 kW 15 mA (see appendix G) 15 mA

Page 29

Figure 6.8: Measuring the substitute leakage current for appliances of protection class I

Figure 6.9: Measuring the substitute leakage current for appliances of protection class II

29

Measuring the Substitute Leakage Current

Page 30

6.3.3 Measuring the Substitute Leakage

Current (IPE SUBS) for fixed installed

appliances or appliances not equipped

with a mains plug

Performing the measurement:

Connect the UNITEST TELARIS 0751 via the

mains plug (1) to a functional and correctly

wired and grounded mains socket.

Turn the ‘Measurement function” selection

switch (15) to position ‘IPE SUBS’.

Set the limit for the substitute leakage current

using the key LIMIT(7); for the limit values,

please refer to table 2.

Switch on the UUT.

Connect the UUT PE connection to the blue ‘PE’

socket (5), in compliance with C in Figure 6.10.

For appliances of protection class II or III, additionally connect the ‘PE’ socket (5) to all

touchable, conductive casing parts of the UUT,

in compliance with D, E in Figure 6.10.

Connect the ‘L/N’ socket (4) to all active con-

nectors of the UUT, in compliance with A, B in

Figure 6.10.

Press the key “Start” (9). The unit symbol

which is blinking on the display is an indication

for the active measurement procedure.

Read the measurement value from the LC dis-

play (6). If the limit value display is active, the

symbol ‘LIMIT’ (21) indicates that the limit

value has been exceeded.

Continue the substitute leakage current test for

all other touchable, conductive casing parts of

the UUT.

The measurement results can be saved by

pressing the key “Store” (10). For references

regarding the saving of measurement values,

please refer to section 7.1 and 7.2.

Figure 6.10: Measuring the substitute leakage current for fixed installed appliances or appliances not

equipped with a mains plug.

L1

N

PE

A

B

C

D

E

Prüfling

30

Measuring the Substitute Leakage Current

Page 31

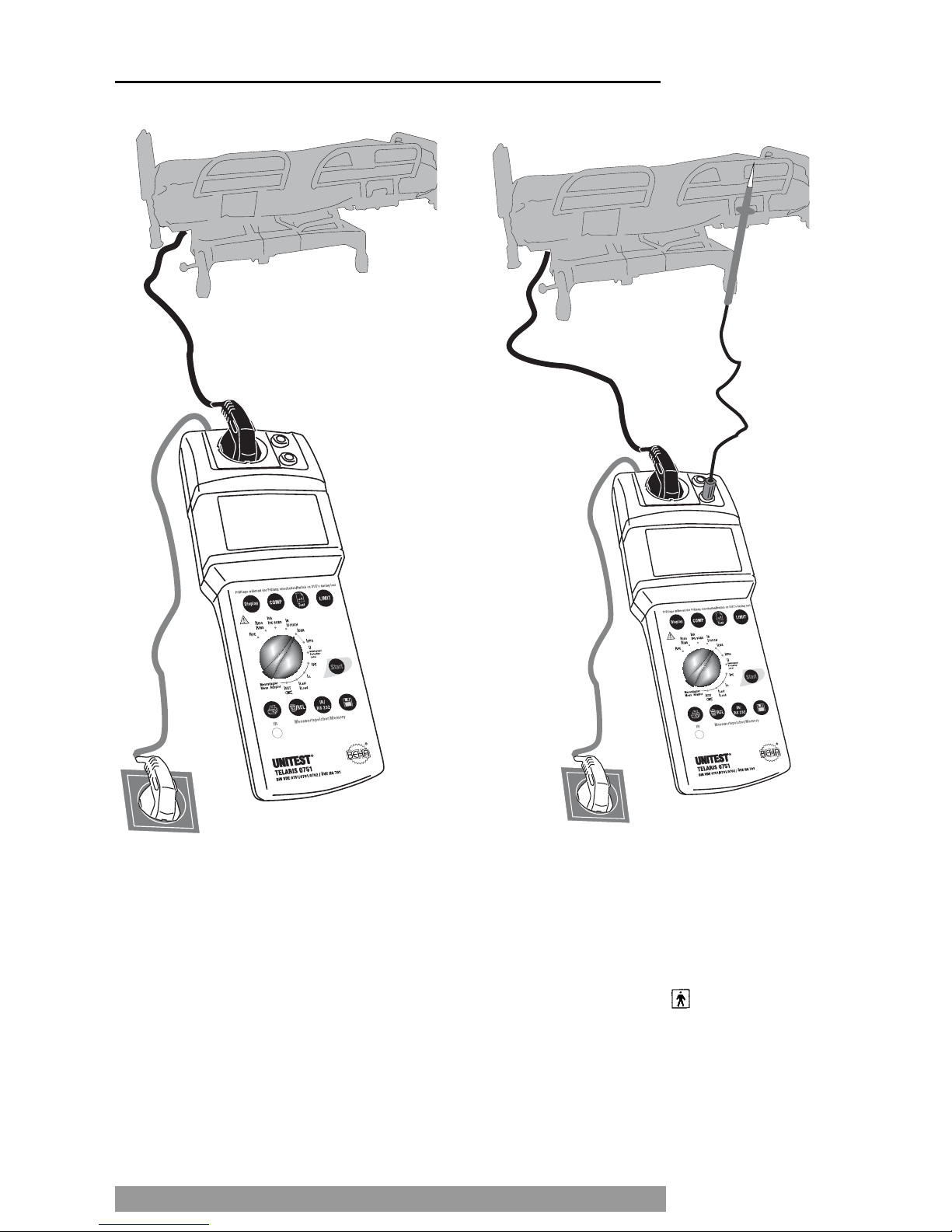

6.4 Measuring the Touch Current

6.4.1 General Information regarding the

Touch Current

The touch current measurement for appliances

of protection class I may only be performed

after successful PE resistance test.

The UUT is put into operation during this test,

i.e. the UUT will be supplied with mains voltage. Therefore, the UUT must be switched on.

UUTs equipped with motor drives or with heating units may present a danger to the controller

(please observe the instruction manual of the

UUT!).

In compliance with DIN VDE 0701:2000-09,

the touch current measurement represents an

additional measurement to determine the insulation properties for appliances of protection

class I and II. In compliance with DIN VDE

0702, this represents a substitute measurement to the insulation measurement for appliances of protection class II, for which the insulation measurement may not or cannot be

performed.

The touch current measurement is performed

for appliances of protection class II with touchable, conductive parts or for appliances of protection class I, equipped with touchable, conductive parts, not connected to the PE.

The measurement has to be performed for both

positions of the mains plug . The higher of both

values has to be considered. The UNITEST

TELARIS 0751 displays the symbol (22)

as a reference.

The touch current measurement using the

UNITEST TELARIS 0751 is performed by

means of the direct measurement procedure in

compliance with DIN VDE 0701/0702. The

UNITEST TELARIS 0751 measures the current, flowing from the probe (2) to the PE connector of the mains plug (1).

The limit value for the touch current in compliance with DIN VDE 0701/0702 amounts to 0.5

mA. In compliance with DIN VDE 0701, Part

240, the limit value amounts to 0,25 mA. The

measurement has to be performed for both positions of the mains plug.

At measurements with faulty appliances or appliances with high leakage currents a preceding RCD (Residual Current Device) could trip.

31

Measuring the Touch Current

TaTable 3 Limit Values

Touch current in compliance with DIN VDE 0701/0702, Part 1 0,5 mA

Touch current in compliance with DIN VDE 0701/0702, Part 240 0,25 mA

Page 32

For this measurement, the test probe (2)is connected via the internal resistor (approx. 2 kΩ)

to the blue "PE” socket (5). The blue "PE” socket (5) is during the measurement directly connected to the PE resistance of the mains plug

(1).

During this measurement, no test leads may be

connected to the measurement sockets "PE”

(5) or L/N” (4 ).

The appliance TELARIS 0751 automatically

stops the measurement function, if a current of

more than approx. 1.99 mA is flowing via the

"Probe” test lead (2) during the test.

If a part is touched during test, which is connected directly to mains voltage, a leakage current is flowing which could trip a preceding

RCD (Residual Current Device).

The warning symbol at the appliance for an external voltage is only present during measurements in order to avoid erroneous displays

caused by the high input impedance of the

probe when deactivated.

6.4.2 Measuring the Touch Current (ILEAK)

Performing the measurement:

Connect the UNITEST TELARIS 0751 via the mains

plug (1) to a functional and correctly wired and

grounded mains socket.

Turn the ‘Measurement function” selection

switch (15) to position ‘IB’.

Set the limit for the insulation resistance using

the key LIMIT(7); for the limit values, please

refer to table 3.

Plug in the mains plug of the UUT into a func-

tional and correctly wired and grounded mains

socket.

Switch on the UUT.

Connect the ‘Probe’ test socket (2) to the touch-

able conductive casing parts of the UUT, in

compliance with Figure 6.11.

Press the key “Start” (9). The unit symbol

which is blinking on the display is an indication

for the active measurement procedure.

32

Measuring the Touch Current

Page 33

Read the measurement value from the LC dis-

play (6). If the limit value display is active, the

symbol ‘LIMIT’ (21) indicates that the limit

value has been exceeded.

Continue the touch current test for all other

touchable, conductive casing parts of the UUT.

Turn the mains plug of the UUT and repeat the

measurement.

Read the measurement value from the LC dis-

play (6). The highest measured value is the

value to be recorded.

The measurement results can be saved by

pressing the key “Store” (10). For references

regarding the saving of measurement values,

please refer to section 7.1 and 7.2.

Figure 6.11: Measuring the touch current

33

Measuring the Touch Current

Page 34

6.5 Measuring the Protection Level of

Overvoltage Protection Devices (varistors)

6.5.1 General Information for Measuring

the Protection Level

The protection level or the response voltage of overvoltage protection devices can be measured using

the TELARIS 0751 (Cat. No. 9091).

This is a method to check and measure overvoltage

protection devices at the UUT mains input, which

have generated a measurement result too low during insulation measurement.

The measurement is performed using a DC

voltage, to obtain a overvoltage protection devices response. The DC value displayed during

the measurement corresponds to the actually

measured DC voltage.

The AC voltage value may be displayed during

the measurement using the key ”Display” (17).

This value corresponds to the AC voltage value

to which the checked overvoltage protection

devices may be connected.

When calculating the maximum AC voltage, a safety factor of approx. 14 % will be considered, resulting into the following formula: UAC = UDC/1,6.

This measurement may only be performed on

UUTs which are not connected to live voltage!

6.5.2 Measuring the Protection Level

Carrying out measurement:

Connect the UNITEST TELARIS 0751 via the

mains plug (1) to a functional and correct wired

and grounded mains socket.

Turn the ‘Measurement function” selection

switch (15) to position VProt level”.

When dealing with UUTs at which the overvolt-

age protection devices are connected between

L and N, connect the phase (L) of the mains

input to the red "L/N” socket (4) and the neutral conductor (N) to the blue socket (5), please

refer to Figure 6.12.

When dealing with UUTs with the overvoltage

protection devices between L towards PE or N

towards PE, connect the blue socket (5) with

the PE and the red socket (4) to L or N of the

UUT, please refer to Figure 6.13.

If the overvoltage protection devices is in-

stalled after the mains switch, you must switch

on the UUT.

Press the key “Start” (9). The unit symbol

which is blinking on the display is an indication

for the active measurement procedure.

Read the measurement value from the LC dis-

play (6). The appliance displays the DC voltage

value of the response voltage.

The key ”Display” (17) is used to display the AC

voltage value during the active measurement.

The measurement results can be saved by

pressing the key “Store” (10). For references

regarding the saving of measurement values,

please refer to section 7.1 and 7.2.

34

Measuring the Protection Level of Overvoltage Protection Devices (varistors)

Page 35

35

Measuring the Protection Level of Overvoltage Protection Devices (varistors)

The measurement may be started and stopped

manually. After approx. 15 seconds, the measurement is automatically terminated to avoid

any overload of the tested overvoltage protection devices.

Figure 6.12: Measuring the protection level for UUTs

with overvoltage protection devices between L and

N

Figure 6.13: Measuring the protection level for UUTs

with overvoltage protection devices L towards PE

or N towards PE

B

B

Prüfling

PE

L

N

A

A

B

Prüfling

PE

L

N

Page 36

6.6 Measuring the PE earth leakage current

(PE current) and the Differential Current

with Schuko Measurement Adapter

(Option)

6.6.1 General Information regarding the PE

earth leakage current and Differential

Current

In compliance with DIN VDE 0701:2000-09, the PE

resistance measurement is considered as an additional measurement to determine the insulation capacity for appliances of protection class I.

According to DIN VDE 0702, this is a substitute

measurement for the insulation measurement regarding appliances of protection class I, for which

no insulation measurement may or can be performed.

The PE current may be determined either via direct

current measurement within the PE resistance of a

UUT or via the differential current procedure. The

direct measurement may be applied, if the UUT is

not equipped with additional earth connections or if

an insulated UUT installation is possible. The measurement must be performed for both mains plug positions.

In compliance with DIN VDE 0701/0702, the differential current measurement is a measurement principle to determine the PE resistance current or the

touch current. The result is obtained by performing

a summation current measurement of all active conductors (L-N) pertaining to a UUT. Thus, the total

leakage current of a UUT can be picked up.

The differential current measurement must be applied if the UUT is equipped with additional earth

connections of if an insulated UUT installation is not

possible. This measurement must also be performed for both positions of the mains plug.

An external Schuko Measurement Adapter must be

connected to the TELARIS 0751 (Cat. No. 9091) to

measure the PE resistance current, the differential

current, and the load current. This Schuko Measurement Adapter allows the measurement of the

PE current in compliance with the direct measurement principle and the differential current procedure.

The PE resistance current measurement may

only be performed after successful PE resistance test.

The UUT is put into operation for this test, i.e.

it will be supplied with mains voltage. For this,

the UUT must be switched on. Motor driven

UUTs or UUTs equipped with heating units may

cause a danger for the controller (observe the

UUT instruction manual!).

Observe that mains voltage is already present

when plugging in the mains plug of the Schuko

Measurement Adapter! UUTs that are already

switched on are put into operation immediately after the plug-in!

The Schuko Measurement Adapter is not

equipped with built-in fuses. Observe that over

current and short-circuit protection must be

ensured by the supplying mains system.

Therefore, the Schuko Measurement Adapter

may only be connected to a functional and correctly wired and grounded mains socket, protected at maximum 16 A!

The maximum output current for the mains

socket of the Schuko Measurement Adapter

amounts to 16A! The test appliance may not be

used for permanent measurements.

At measurements with faulty appliances or appliances with high leakage currents a preceding RCD (Residual Current Device) could trip.

36

Measuring the PE earth leakage current

Page 37

The measurement must be performed for both

positions of the mains plug. The higher of both

values have to be considered. As a reference,

the UNITEST TELARIS 0751 displays the symbol (22).

The limit value for the PE current DIN VDE

0701/0702 amounts to 3.5 mA.

There is an additional possibility to measure

the actual leakage current. Using a highly sensitive AC current clamp, surround all active

conductors of the mains feeding lines of a UUT.

For single-phase appliances, these are L1 and

N, for three-phase appliances, these are L1, L2,

L3, and N. Now, in compliance with Kirchhoff,

the cumulating of the currents must equal zero.

If a current is measured, we are dealing with a

"true” leakage current, flowing either via the PE

resistance and/or via the casing or possible gas

or water pipes, etc. connected to the casing.

Consequently, the differential current is measured. This type of current clamp is also available within the UNITEST range. The leakage

current clamp CHB 3, Cat. No. 93481, offers a

resolution of 10 µA. This method allows the

fast, simple, and safe measurement of the

"true” leakage current.

37

Measuring the PE earth leakage current

Page 38

6.6.2 Measuring the PE Current (IPE)

Performing the measurement:

Connect the UNITEST TELARIS 0751 via the

mains plug (1) to a functional and correctly

wired and grounded mains socket.

Connect the Schuko Measurement Adapter via

the mains plug to a function and correctly wired

and grounded mains socket. This socket may

be protected at maximum 16 A!

Connect the Schuko Measurement Adapter to

the measurement adapter connector (18) of the

UNITEST TELARIS 0751.

Turn the ‘Measurement function” selection

switch (15) to position "IPE”.

Set the limit value for PE resistance current

using the key LIMIT(7). In compliance with DIN

VDE 0701/0702 the limit value amounts to 3.5

mA.

Connect the UUT mains plug to the mains sock-

et of the Schuko Measurement Adapter.

Switch on the UUT.

Press the key “Start” (9). The unit symbol

which is blinking on the display is an indication

for the active measurement procedure.

Read the measurement value from the LC dis-

play (6). The symbol ‘LIMIT’ (21) indicates an

exceeding of the limit values, if the limit value

display is switched on.

Turn the UUT mains plug and repeat the meas-

urement.

Read the second value from the LC display

(16). The higher measurement value of both

measurement values has to be considered and

recorded.

The measurement results can be saved by

pressing the key “Store” (10). For references

regarding the saving of measurement values,

please refer to section 7.1 and 7.2.

Figure 6.14: Measuring the PE current using Schuko

Measurement Adapter (option)

Prüfling isoliert aufgestell

t

38

Measuring the PE Current (IPE)

Page 39

6.6.3 Measuring the Differential Current (IΔ)

Performing the measurement:

Connect the UNITEST TELARIS 0751 via the

mains plug (1) to a functional and correctly

wired and grounded mains socket.

Connect the Schuko Measurement Adapter via

the mains plug to a function and correctly wired

and grounded mains socket. This socket may

be protected at maximum 16 A!

Connect the Schuko Measurement Adapter to

the measurement adapter connector (18) of the

UNITEST TELARIS 0751.

Turn the ‘Measurement function” selection

switch (15) to position ‘IΔ’.

Set the limit value for PE current using the key

LIMIIT (7). In compliance with DIN VDE

0701/0702 the limit value amounts to 3.5 mA.

Connect the UUT mains plug to the mains sock-

et of the Schuko Measurement Adapter.

Switch on the UUT.

Press the key “Start” (9). The unit symbol

which is blinking on the display is an indication

for the active measurement procedure.

Read the measurement value from the LC dis-

play (6). The symbol ‘LIMIT’ (21) indicates an

exceeding of the limit values, if the limit value

display is switched on.

Turn the UUT mains plug and repeat the meas-

urement.

Read the second value from the LC display

(16). The higher measurement value of both

measurement values has to be considered and

recorded.

The measurement results can be saved by

pressing the key “Store” (10). For references

regarding the saving of measurement values,