United States Stove Company ASA7 User Manual

Owner’s

Manual

4027 & ASA7

Free-Standing Coal Heater

This is a COAL ONLY Room Heater

Tested to: UL 1482 and CAN/ULC S627-M93

CAUTION:

READ ALL INSTRUCTIONS CAREFULLY BEFORE STARTING THE

INSTALLATION OR OPERATING

THE HEATER

UNITED STATES STOVE COMPANY

E

227 Industrial Park Road

South Pittsburg, TN 37380

I

N

U

U

T

A

E

T

S

S

D

E

T

S

C

O

M

S

N

A

P

S

T

C

Y

O

V

P.O.Box 151

IMPROPER INSTALLATION MAY VOID

YOUR WARRANTY

DO NOT USE THIS HEATER

IN A MOBILE HOME OR TRAILER

C

R

US

(423) 837-2100

USSC 1

851523

SAFETY PRECAUTIONS

PLEASE READ THIS ENTIRE MANUAL BEFORE YOU INSTALL AND USE YOUR NEW HEATING APPLIANCE. FAILURE TO FOLLOW INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE, BODILY INJURY, OR EVEN DEATH.

THIS HEATING APPLIANCE SHOULD BE INSTALLED ONLY BY AN EXPERIENCED COAL HEATER INSTALLER. IF

THIS HEATING APPLIANCE IS NOT PROPERLY INSTALLED, A HOUSE FIRE MAY RESULT. TO REDUCE THE RISK

OF FIRE, FOLLOW THE INSTALLATION INSTRUCTIONS. CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT

RESTRICTIONS AND INSTALLATION INSPECTION REQUIREMENTS IN YOUR AREA.

THIS HEATING APPLIANCE IS DESIGNED TO BURN COAL. THE USE OF ANY OTHER FUEL EXCEPT FOR COAL

IGNITION IS A VIOLATION OF FEDERAL LAW. BURN COAL ONLY.

INSTALL SMOKE DETECTORS IN YOUR HOME. EACH SMOKE DETECTOR SHOULD BE INSPECTED REGULARLY

AND KEPT IN GOOD WORKING CONDITION.

SAVE THESE INSTRUCTIONS. THESE INSTRUCTIONS SHOULD BE REVIEWED BY ALL FUTURE USERS OF THIS

HEATING APPLIANCE TO ENCOURAGE ITS PROPER OPERATION AND MAINTENANCE.

SAFETY STANDARDS AND BUILDING CODES

This appliance has been safety tested in accordance with UL safety standard 1482 by Warnock Hersey, a company in the

Quality Systems Division of Intertek Testing Services which is an international conformity assessment organization with

North American headquarters and offices worldwide. The Warnock Hersey listing mark on this appliance signifies that the

design and manufacturing of this appliance comply with Intertek Testing Services' comprehensive safety assessment

standards for solid fuel type room heaters. (There may be additional requirements to be met in order to comply with local

building codes or regulations. Before installing this appliance, check with building or fire officials to assure compliance with

local codes and regulations.)

MATERIALS NEEDED FOR PROPER INSTALLATION

THE FOLLOWING MATERIALS ARE NEEDED TO PROPERLY INSTALL THIS HEATER IN A RESIDENTIAL TYPE HOME.

THE CHIMNEY USED MUST BE CAPABLE OF PROVIDING A MINIMUM OF .06 INCHES WATER COLUMN DRAFT.

1. Chimney Connector (also known as stove pipe): The chimney connector joins the heater to the chimney. The chimney

connector pipes should be 6-inches in diameter 24-gauge minimum black steel. (Note: The number of 90 degree bends in

the chimney connector installation for appliances, such as this heater, which have a top exit flue collar should be restricted

to one. More than one 90 degree bend in the chimney connector could negatively affect chimney draft.)

2. Chimney: A code-approved masonry chimney. See the "MASONRY CHIMNEY REQUIREMENTS" portion of this

manual for details.

OR

A chimney complying with the requirements for Type 103-HT chimneys in the Standard for Chimneys, Factory Built,

Residential Type and Building Appliance, UL 103. See the "METAL PREFABRICATED CHIMNEY REQUIREMENTS"

portion of this manual for details.

3. Wall Thimble: A manufactured or site constructed device installed in combustible walls through which the chimney

connector passes to connect to a masonry chimney. The wall thimble is intended to keep walls from igniting. A wall

thimble is needed only if the chimney connector must pass through a combustible wall between the heater and the masonry

chimney. See Figure 5 for wall thimble options.

4. Floor Protector: If the floor on which the heater is to be installed is wood or any other combustible material , the heater

must be placed on a floor protector. The floor protector is to prevent the floor from catching fire from sparks or embers that

might escape the heater or drop from the joints of the chimney connector pipe. The floor protector must protect the floor

beneath and around the heater and chimney connector pipe as shown in Figure 9. The floor protector for this heater may be

larger than the floor protector shown in Figure 9 but it must not be smaller than the floor protector shown in Figure 9. The

floor protector must be a listed floor protector or a floor protector made of noncombustible inorganic material equal to or

better than 3/4-inch thick material having a thermal conductivity R value of 1.5.

5. Chimney Shield: See step 11 of the "TO INSTALL THE HEATER" portion of this manual for details.

THIS HEATER IS NOT APPROVED FOR MOBIL HOME INSTALLATION.

HOT WHILE IN OPERATION. KEEP CHILDREN, CLOTHING AND FURNITURE AWAY. CONTACT MAY CAUSE SKIN

BURNS. DO NOT USE CHEMICALS OR FLUIDS TO START THE FIRE. DO NOT BURN GARBAGE OR FLAMMABLE

FLUIDS. DO NOT CONNECT TO ANY AIR DISTRIBUTION DUCT SYSTEM.

2 USSC

ASSEMBLY

Before Assembly, inspect the heater thoroghly for

missing parts or shipping damage. If any damage or

missing parts are detected, report it to your heater dealer.

DO NOT INSTALL OR USE A DAMAGED OR

INCOMPLETE HEATER

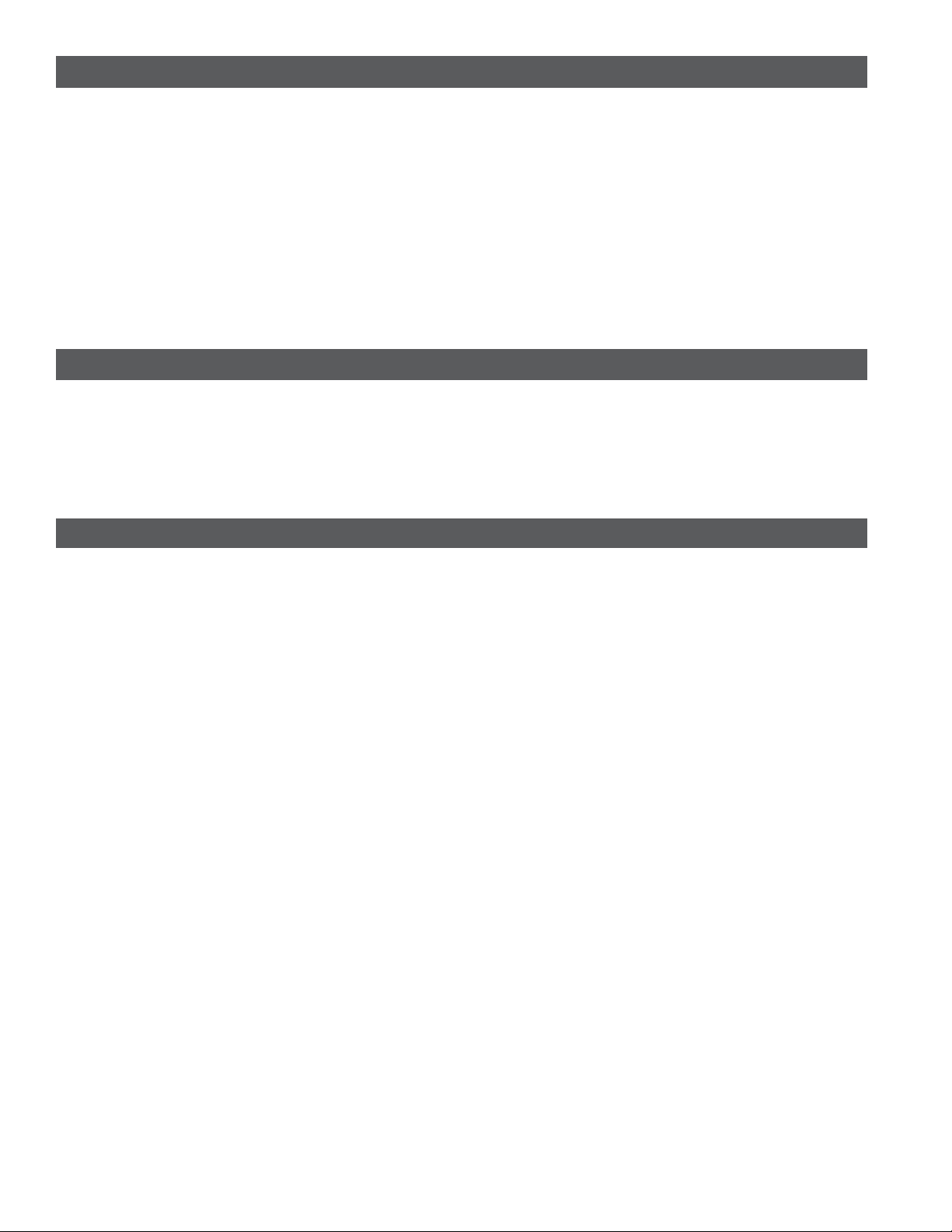

Shaker Handle Assembly:

1. First, remove the two(2) bolts from the left side of the

unit where the shaker handle is to be mounted.

2. Next, spin the shaker plate (a) counteclockwise until

it stops. Slide the shaker handle through the hole and on

to the shaker grate. NOTE: Make sure that the shaker

handle is in a 90 degree position and that the shaker

grates are lying flat.

3. Rotate the shaker plate (a) clockwise until it touches

the unit.Then give it another 1/2 turn or until the mounting

holes coincide with the unit.

(A)

4. Attach to the unit with the bolts removed in step 1.

5. Screw one(1) of the spring handles, from the parts

box, on to the shaker handle 3/4” -1” down in a clockwise

motion.

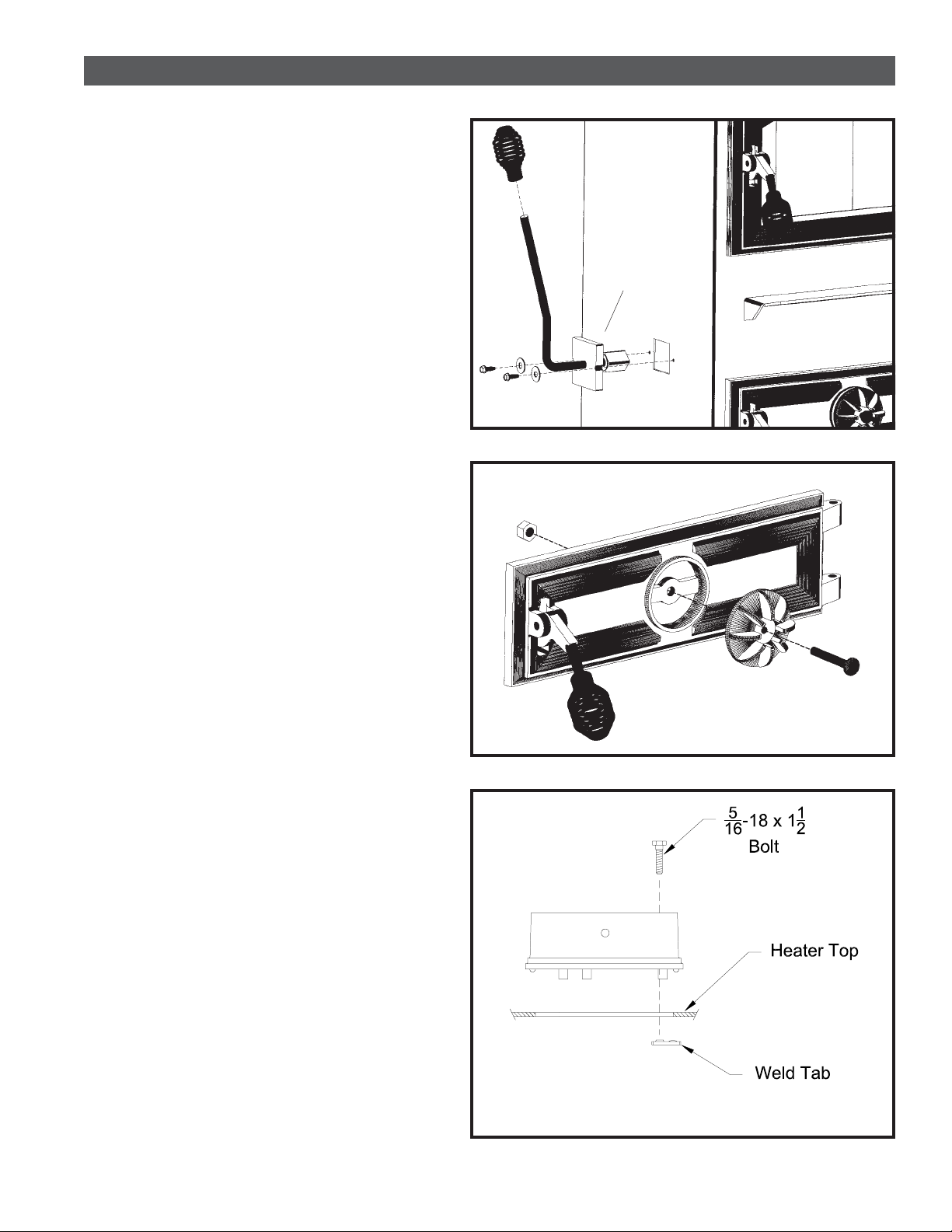

Feed & Ash Door Assemblies:

Feed Door-

1. Screw one(1) of the spring handles, from the parts

box, on to the Feed Door handle.

Ash Door-

1. Screw one(1) of the spring handles, from the parts

box, on to the Feed Door handle.

2. Insert the 2-1/2” Carriage Bolt into the spin damper.

3. Then screw it in into the Ash Door as shown and Attach the Lock Nut provided to the Carriage Bolt.

Flue Collar Assembly:

1. Mount the flue collar to the top of the unit using the (3)

5/16-18 x 1-1/2 bolts, (3) washers, and (3) weld tabs provided in the parts box as shown

Side view of flue collar

mount to heater top

USSC 3

SELECTING A LOCATION FOR YOUR HEATER

1. When locating the heater , consider safety, convenience, traffic flow, and the fact that the heater will need a

chimney,chimney connector,and possibly a floor protector. Make sure none of these materials will be obstructed.

2. The heater should be located away from door ways and central heat outlets to reduce the chances of drafts, blowing

smoke, ashes or sparks out of the heater during refueling or ash removal.

3. The heater should be located in an open area to allow for necessary clearances as specified within this manual.

4. Keep furniture, drapes, curtains, wood, paper and other combustibles far away from the heater.

5. Never install the heater in locations where gasoline, kerosene, charcoal lighter, or any other flammable liquids are

stored

6. The heater should be located where a small supply of wood may be kept conveniently close but not within 36-inches of

the heater.

7. The heater should not be located beneath overhanging shelves, low ceilings or other structures or elevated so that less

clearance is created above the heater than is provided when the heater is normally installed in a room with a 7 foot

minimum ceiling.

8. Be sure the chimney will be at least 10 feet from flammable gas or liquid storage tanks.

DANGER: DO NOT CONNECT THIS HEATER TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE. THERE IS A

SERIOUS SAFETY RISK IF TWO APPLIANCES ARE CONNECTED TO THE SAME CHIMNEY FLUE.

CAUTION: The operation of exhuast fans such as bath room fans, attic fans, etc. might starve the heater of combustible

air creating a negative pressure in the room. Provide adequate ventilation in the room occompaning the heater.

MASONRY CHIMNEY REQUIREMENTS

If the heater is to be connected to a masonry chimney, the heater should not be installed until it is determined that the

chimney is safe for use. Before installing the heater, have the chimney inspected by a building inspector, fire department,

or qualified heating engineer. To prevent risk of walls, roof, or other combustibles catching fire from the extremely hot fire,

smoke, and flue gases, and to obtain a proper draw, a chimney must meet the minimum standards for masonry chimneys

established by the National Fire Protection Association (NFPA). Make certain the inspection agency is familiar with NFPA

No. 211 and all local codes. Some of those minimum standards are listed here for your convenience.

1. The chimney must not be obstructed or clogged. An obstructed or clogged chimney could cause smoke and the

dangerous carbon monoxide in smoke to spill back into your home.

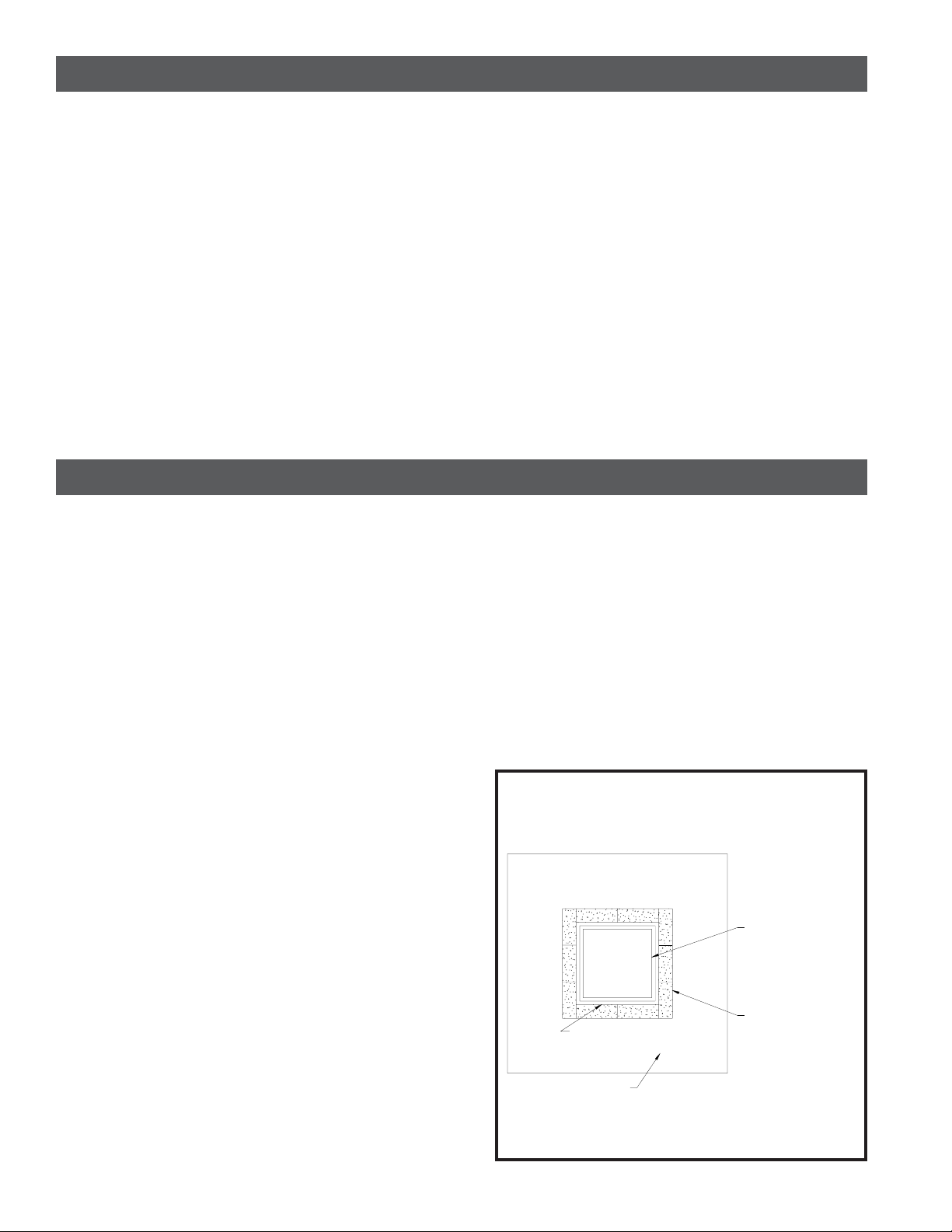

2. Your masonry chimney must be supported on an adequate foundation and must have either a 5/8" thick fireclay or

stainless steel lining. There must be at least 1/2-inch air space between the flue liner and the chimney wall. (See Figure 1.)

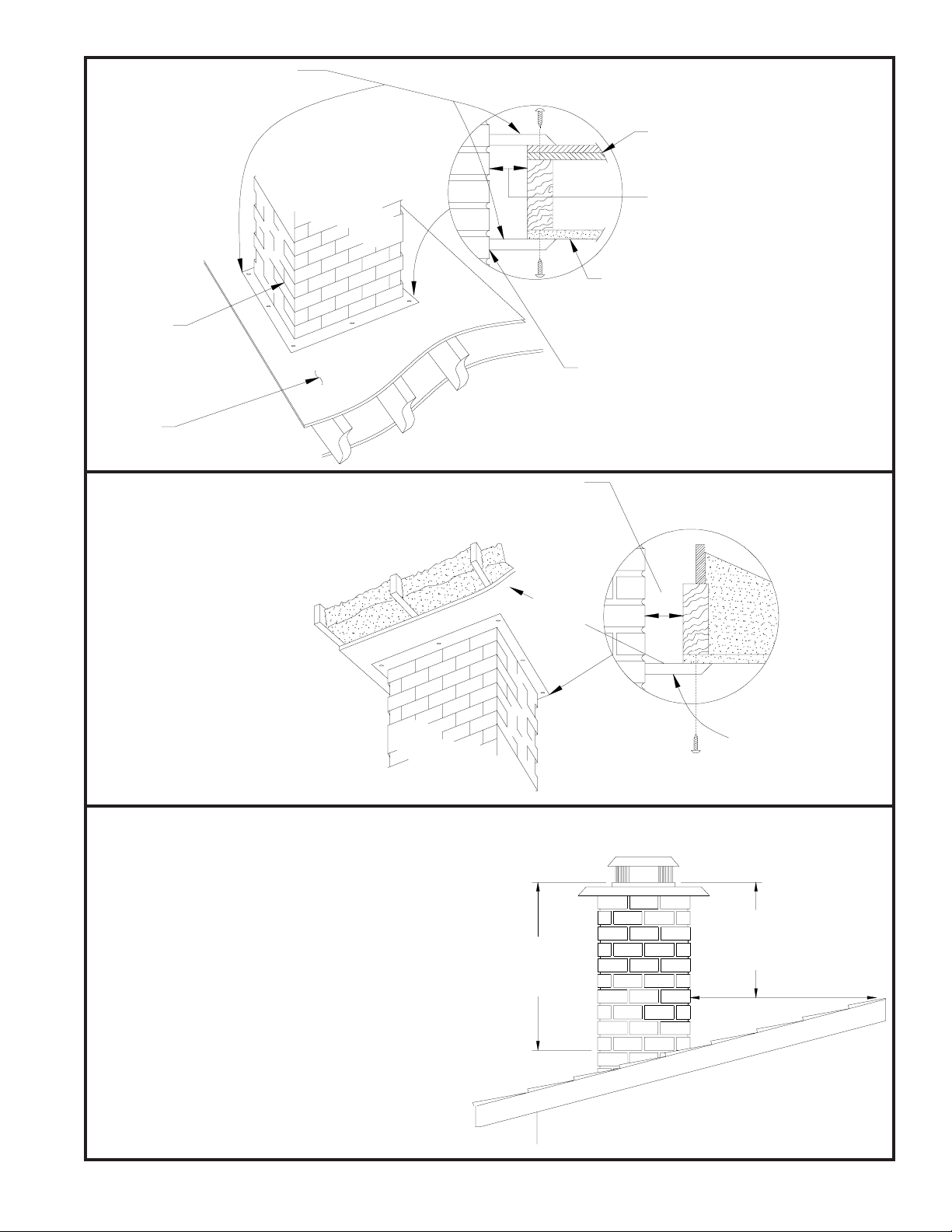

3. A chimney inside the house must have at least 2 inches of clearance to the combustible structure. A chimney outside

the house must have at least 1 inch clearance to the combustible structure. Fire stops must be installed at the spaces

where the chimney passes through floors and/or ceilings. (See Figure 2.) Insulation should be at least 2 inches from the

chimney to leave an air space around the chimney. (See Figure 3.)

4. The flue lining of a masonry chimney must be smooth and

have no leaks. The inside of the chimney flue liner should be no

FIGURE 1 MASONRY CHIMNEY

REQUIREMENTS

smaller than 8 inches square or 6 inches round; a smaller chimney flue liner will be too restrictive to the flow of smoke and

gases. A 6 inch diameter round liner is preferred because round

flues draw better than square flues.

5. Since an oversized chimney flue contributes to the accumulation of creosote, the size of the chimney flue liner must be

checked to determine that it is not too large for the heater. For

FLUE

5/8" FIRECLAY OR

STAINLESS STEAL

FLUE LINER

this heater, the inside cross-sectional area of the chimney should

be no more than 85 square inches to assure proper venting.

6. The top of the chimney must be at least 3 feet above the

point where it comes through the roof, and at least 2 feet higher

MINIMUM 1/2" AIR SPACE

CHIMNEY WALL 4"

NOMINAL

than any obstruction within a 10 foot radius.(See Figure 4.)

7. If the heater has insufficient draft, the draft may be improved

FOUNDATION

by extending the height of the chimney.

8. Make certain the chimney is kept clean and it is not blocked.

Check for limbs overhanging the top of the chimney periodically.

4 USSC

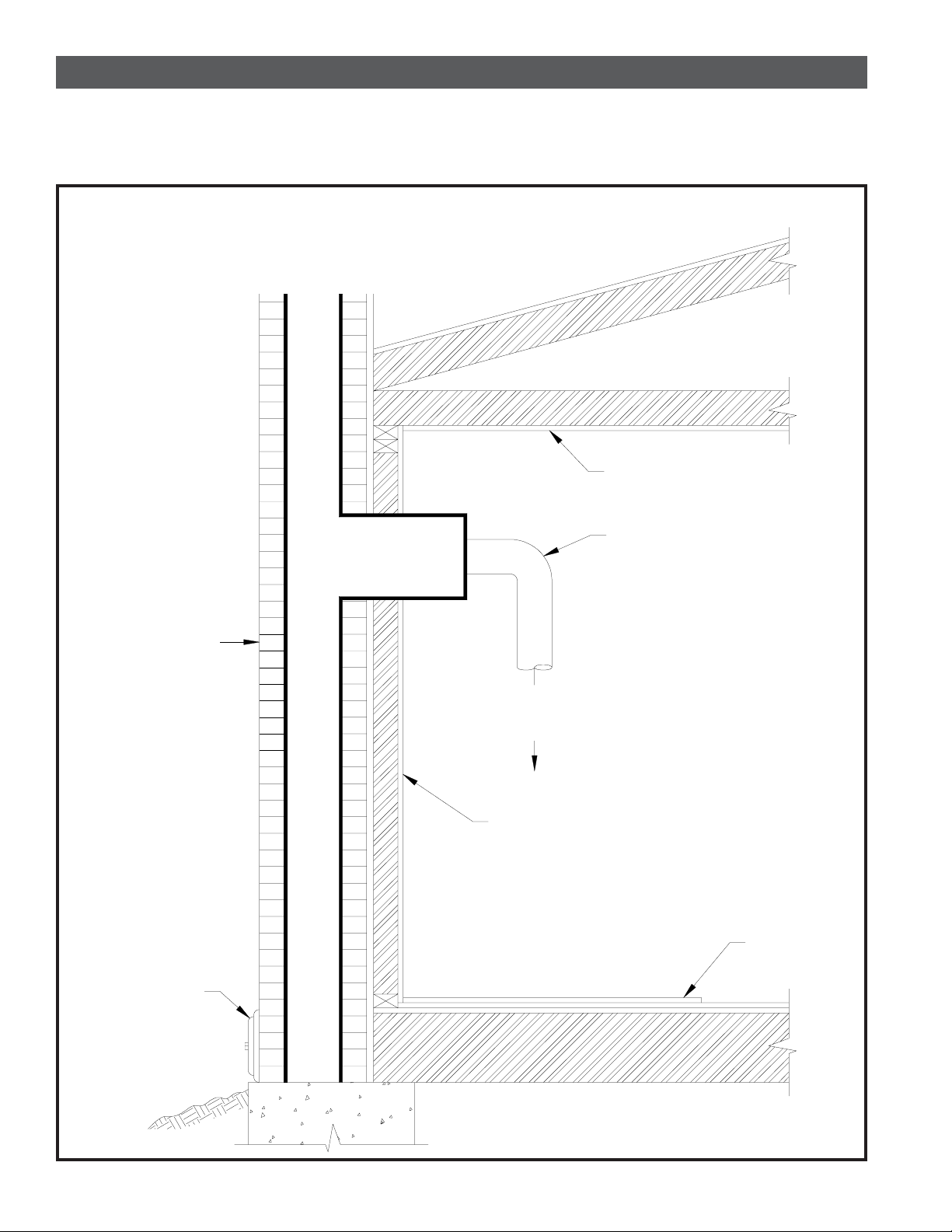

NONCOMBUSTIBLE

FIRE-STOPPING

MATERIAL

CHIMNEY

FLOOR

MINMUM 2 INCH CLEARANCE

FOR INTERIOR CHIMNEY.

MINIMUM 1 INCH CLEARANCE

FOR EXTERIOR CHIMNEY TO

SHEATHING

CEILING

CAULKING

FLOOR

(SECOND STORY)

FIGURE 2MASONRY CHIMNEY REQUIREMENTS

Minimum 2 Inch Clearance

From Combustible Material

and Insulation

Ceiling

Noncombustible

Fire-Stopping Material

FIGURE 3MASONRY CHIMNEY REQUIREMENTS

FIGURE 4CHIMNEY HEIGHT REQUIREMENTS

A Chimney must be the required height above the roof

or other obstruction for safety and for proper draft operation. The requirement is that the chimney must be at

least 3 feet higher than the highest point where it passes

through the roof and at least 2 feet higher than the highest part of the roof or structure that is within 10 feet of

the chimney, measured horizontally.

The above chimney heights are the minimum required

AT LEAST

3 FEET

AT LEAST

3 FEET

10 FEET

by codes for safety purposes to allow sparks existing in

chimney time to cool before they land on the roof. Additional height will generally increase draft, improve heater

operating characteristics and reduce back drafting and

puffing problems due to wind

A masonry chimney is shown above. However, height

requirements are the same for a metal prefabricated

chimney.

USSC 5

CONNECTION OF CHIMNEY TO A MASONRY CHIMNEY THROUGH A COMBUSTIBLE WALL

Figure 5 shows how to connect the chimney connector of a heater to a masonry chimney through a combustible wall.

There are five allowable ways that a chimney connector can be connected to a masonry chimney by passing through a

combustible wall. NFPA Standard 211 allows the following wall pass-through systems.

FIGURE 5 CONNECTION OF CHIMNEY CONNECTOR TO A

MASONRY CHIMNEY THROUGH A COMBUSTIBLE

WALL

MASONRY CHIMNEY

CONSTRUCTED TO

NFPA 211

LINED CHIMNEY FLUE

SEE PARTS A, B, C,

D, AND E OF THIS

FIGURE FOR

OPTIONS.

CEILING

CHIMNEY CONNECTOR

TO

HEATER

COMBUSTIBLE WALL

FLOOR

PROTECTOR

AIRTIGHT

CLEANOUT

DOOR

(FIGURE 5 CONTINUED ON NEXT PAGE)

6 USSC

Loading...

Loading...