United States Stove Company 1800GC User Manual

U

N

I

T

E

D

S

T

A

T

E

S

S

T

O

V

UNITED STATES

E

STOVE COMPANY

U

S

C

O

S

M

P

C

N

A

Keeping America Warm

Since 1869

Y

CANADACANADA

CANADA

MODEL: 1600GC / 1800GCMODEL: 1600GC / 1800GC

MODEL: 1600GC / 1800GC

MODEL: 1600GC / 1800GCMODEL: 1600GC / 1800GC

THE WOOD AND COAL FURNACE

SAFETY NOTICE: IF THIS FURNACE IS NOT PROPERLY INSTALLED, A HOUSE FIRESAFETY NOTICE: IF THIS FURNACE IS NOT PROPERLY INSTALLED, A HOUSE FIRE

SAFETY NOTICE: IF THIS FURNACE IS NOT PROPERLY INSTALLED, A HOUSE FIRE

SAFETY NOTICE: IF THIS FURNACE IS NOT PROPERLY INSTALLED, A HOUSE FIRESAFETY NOTICE: IF THIS FURNACE IS NOT PROPERLY INSTALLED, A HOUSE FIRE

MAY RESULT. FOR YOUR SAFETY, FOLLOW THE INSTALLATION DIRECTIONS.MAY RESULT. FOR YOUR SAFETY, FOLLOW THE INSTALLATION DIRECTIONS.

MAY RESULT. FOR YOUR SAFETY, FOLLOW THE INSTALLATION DIRECTIONS.

MAY RESULT. FOR YOUR SAFETY, FOLLOW THE INSTALLATION DIRECTIONS.MAY RESULT. FOR YOUR SAFETY, FOLLOW THE INSTALLATION DIRECTIONS.

CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS ANDCONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND

CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND

CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS ANDCONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND

INSTALLATION REQUIREMENTS IN YOUR AREA.INSTALLATION REQUIREMENTS IN YOUR AREA.

INSTALLATION REQUIREMENTS IN YOUR AREA.

INSTALLATION REQUIREMENTS IN YOUR AREA.INSTALLATION REQUIREMENTS IN YOUR AREA.

Installation/Operator's Manual # 851502Installation/Operator's Manual # 851502

Installation/Operator's Manual # 851502

Installation/Operator's Manual # 851502Installation/Operator's Manual # 851502

CANADACANADA

ONLYONLY

ONLY

ONLYONLY

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

Introduction .......................................................................................................3

Locating Your Furnace......................................................................................3

Clearances ........................................................................................................3

Chimney Requirements.....................................................................................3-4

Smoke Pipe Installation.....................................................................................4-5

Add-on Series Installation .................................................................................5-7

Assembly Instructions .......................................................................................7-10

Wiring Diagram for Series Installation with Existing Electric Furnace ...............11

Wiring Diagram for Series Installation with Existing Gas or Oil Furnace...........12

Testing and Operating Procedures ...................................................................13-14

Trouble Shooting and Problem Solving.............................................................15

Parts Lists

Model 1600/1800 ..............................................................................................16-17

Motorized Natural Draft .....................................................................................18

Installation of Optional Equiptment ...................................................................19

2

INTRODUCTIONINTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

CLEARANCESCLEARANCES

CLEARANCES

CLEARANCESCLEARANCES

Thank you for your purchase of a U.S. Stove Woodburning

furnace. Your decision to buy a Hotblast Furnace was undoubtedly reached after much careful thought and consideration. We

are very proud you chose the U.S. Stove furnace and trust you

will receive the comfort and economy that others realize when

heating with a U.S. Stove product.

Your dealer is important in your experience with the Furnace not

only in your purchase, but in his recommendations for professional installation in your home. The qualified professional

installer (as recommended by your dealer) has been expertly

trained in solid-fuel furnace installation to assure the safety and

comfort for your family while saving you money. Trust your

experienced installer. He is a specialist in his field.

IMPORTANTIMPORTANT

IMPORTANT

IMPORTANTIMPORTANT

Before installing and using your Hotblast Furnace, please

read the following pages thoroughly and carefully. If you

follow the instructions, your Hotblast furnace will give you safe

and more dependable service in the years to come.

! First step; check your local codes. This installation must

comply with their rulings.

! Do not install this furnace in a mobile home or trailer.

! Always have a smoke or ionization detector installed in

your home.

! To prevent injury or damage, do not allow anyone who is

unfamiliar with the furnace to operate it.

! Spend some time with your furnace to become well

acquainted with different settings and how each will

affect its burning patterns. It is impossible to state just

how each setting will affect your furnace because of

the variations in each installation.

DISCLAIMER NOTICEDISCLAIMER NOTICE

DISCLAIMER NOTICE

DISCLAIMER NOTICEDISCLAIMER NOTICE

The BTU ranges and heating capacity specifications are

provided as a guide only and in no way guarantee the output

or capacity of the units. The actual BTU output depends on the

type of fuel being burned and its conditions, the thermostat

setting, the draft adjustment and the chimney that the unit is

hooked up to. The actual area that the unit will heat depends

on factors such as the conditions of the building, heat loss,

type of construction, amount of insulation, type of air movement, and the location of the unit.

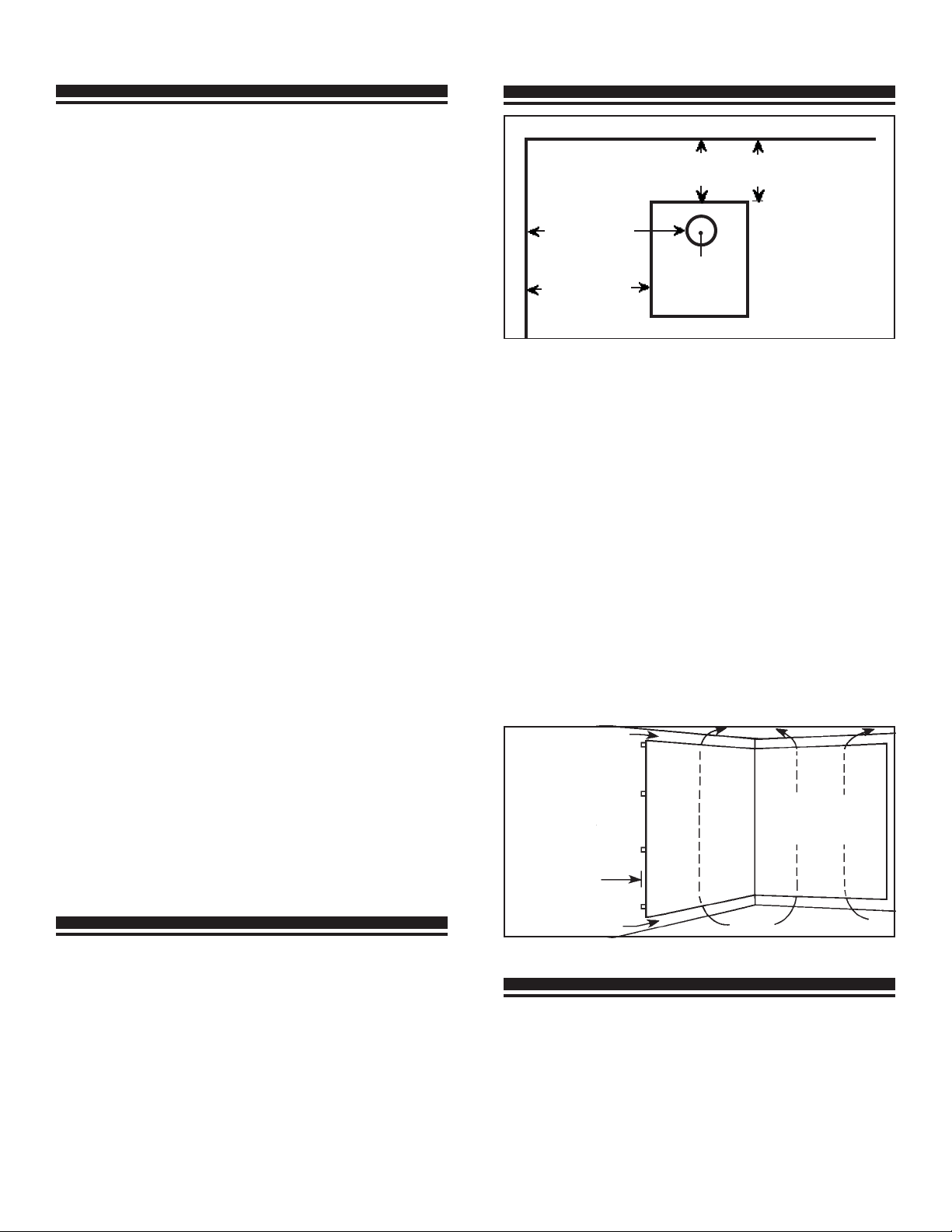

FLAMMABLE WALL

MODEL 1600 - 20"(50.8cm)

MODEL 1800 - 25"(63.5cm)

MODEL

1600 - 22"(55.88cm)

1800 - 19"(48.26cm)

MODEL

1600 - 12"(30.48cm)

1800 - 8"(20.32cm)

REDUCED CLEARANCESREDUCED CLEARANCES

REDUCED CLEARANCES

REDUCED CLEARANCESREDUCED CLEARANCES

NFPA guidelines and most codes permit reduced clearances

to combustible walls and ceilings if adequate protection is

added. A common mistake is to assume that sheet metal,

masonry, or asbestos board placed directly against a wall

protects it. Materials installed in this manner give very little

protection. These materials are good heat conductors, so they

will be almost as hot on their back side as they are on the

exposed side. Therefore, the combustible wall behind is still a

fire hazard.

A wall can be kept cool using these items but only if they're

mounted and spaced out from the wall by an inch or two to

allow free circulation of room air behind the protective panel.

The protective panel should start within a few inches of floor

level.

The three rules to follow when constructing wall protectors:

1. Non-combustibility of all materials including mounting

or supporting.

2.A well ventilated air space between protector or wall.

3.Sufficient strength and rigidity so that the protector and

air space will be durable.

2" FROM CEILING

CONSTRUCTINGCONSTRUCTING

CONSTRUCTING

CONSTRUCTINGCONSTRUCTING

NON-FLAMMABLENON-FLAMMABLE

NON-FLAMMABLE

NON-FLAMMABLENON-FLAMMABLE

WALLSWALLS

WALLS

WALLSWALLS

FLUE

MODEL 1600 - 15"(38.1cm)

MODEL 1800 - 18"(45.72cm)

(TOP VIEW)

MINIMUMMINIMUM

MINIMUM

MINIMUMMINIMUM

CLEARANCE TOCLEARANCE TO

CLEARANCE TO

CLEARANCE TOCLEARANCE TO

FLAMMABLE WALLSFLAMMABLE WALLS

FLAMMABLE WALLS

FLAMMABLE WALLSFLAMMABLE WALLS

CAUTION: Do not

store combustible or

flammable material

near furnace.

PROTECTIVE COVERING

AND ALL SUPPORTS MUST

BE NON-COMBUSTIBLE.

LOCATING YOUR FURNACELOCATING YOUR FURNACE

LOCATING YOUR FURNACE

LOCATING YOUR FURNACELOCATING YOUR FURNACE

The furnace is to be installed maintaining clearances as shown

in illustration.

Do not place the furnace directly on a combustible floor. If you're

placing it on a combustible floor, an approved fire retardant

material equivalent to 3/8" asbestos millboard should be placed

under the furnace. The material must extend at least 16" (40.64cm)

in front of and 8" (20.32cm) on either side of the fuel-loading and

ash-removal doors, and underneath the chimney connector and

extending at least 2" (5.05cm) on either side of the chimney

connector.

1" AIR SPACE

2" FROM FLOOR

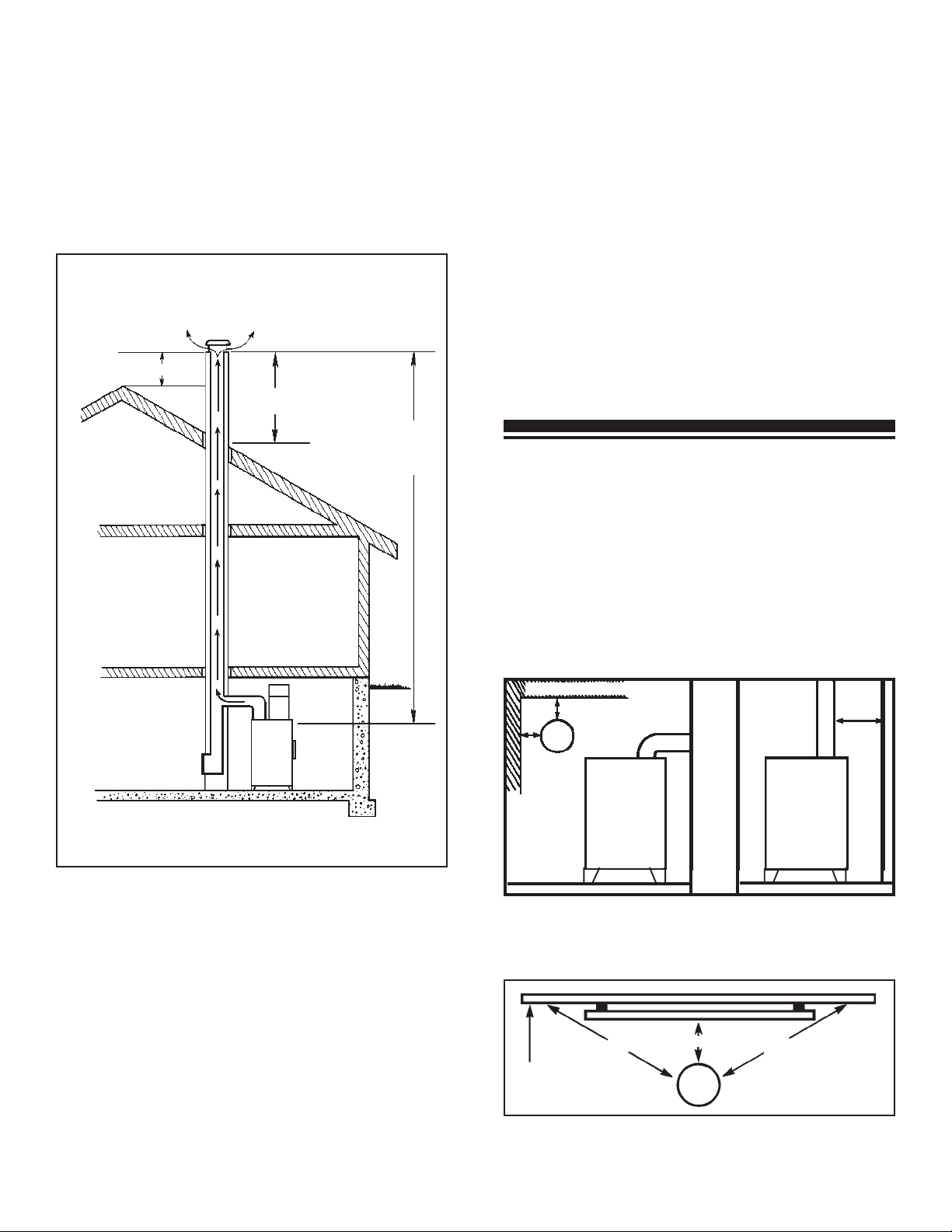

CHIMNEY REQUIREMENTSCHIMNEY REQUIREMENTS

CHIMNEY REQUIREMENTS

CHIMNEY REQUIREMENTSCHIMNEY REQUIREMENTS

A masonry or Class A All-Fuel Metal Insulated Chimney must be

used in all airtight wood furnace installations. The minimum

recommended flue size for the U.S. Stove Hotblast Furnace is 6"

(15.24cm) (inside diameter) for round flues, and 7" x 7" (17.78cm)

for square flues. When making new chimney installations,

always follow the chimney manufacturers instructions.

3

NOTE: Type of chimney: Class A All-Fuel also referred to as

Low-Heat appliance type chimney per Uniform Mechanical

Code:

Chimney, low-heat appliance type is a factory built, masonry

or metal chimney suitable for removing the products of

combustion from fuel-burning low-heat appliances producing combustion gases not in excess of 1000°F (538°C) under

normal operating conditions but capable of producing com

bustion gases of 1400°F (760°C) during intermittent forced

firing for periods up to one hour. All temperatures are

measured at the appliance flue outlet.

TOP OF CHIMNEY MUST BE

2 FT. (60.96cm) ABOVE

HIGHEST POINT OF ROOF

2 FT. (60.96cm) MINIMUM

MINIMAL 3 FT.

(91.44cm) FROM TOP

OF CHIMNEY TO

POINT AT WHICH IT

PASSES THROUGH

THE ROOF.

CHIMNEY FLUE

SHOULD BE

CONSTANT DIAMETER

THROUGHOUT ITS

ENTIRE HEIGHT.

APPROVED

CHIMNEY

CLEANOUT DOOR

SHOULD HAVE

AIRTIGHT FIT. DO

NOT LEAVE OPEN

WHEN FURANCE IS

IN OPERATION.

CAP SHOULD HELP

PREVENT DOWNDRAFT

WHILE STILL PROVIDING

ADEQUATE EXHAUST.

3 FT. (91.44cm)

MINIMUM

RECOMMENDED

MINIMAL 20 FT.

(6.10m) HEIGHT

CHIMNEY FLUE

MUST BE AS

LARGE OR

LARGER THAN

FURNACE FLUE

PIPE

8.The portion of an all-fuel metal chimney that extends

above the roof should be well secured.

9.A masonry chimney should be built on footings and not

attached to the house.

10. A rain cap, complete with an animal or bird screen,

should be installed on top of the chimney.

CREOSOTE — FORMATION AND NEEDCREOSOTE — FORMATION AND NEED

CREOSOTE — FORMATION AND NEED

CREOSOTE — FORMATION AND NEEDCREOSOTE — FORMATION AND NEED

FOR REMOVALFOR REMOVAL

FOR REMOVAL

FOR REMOVALFOR REMOVAL

When wood is burned slowly, it produces tar and other

organic vapors, which combine with expelled moisture to form

creosote. The creosote vapors condense in the relatively cool

chimney flue of a slow-burning fire. As a result, creosote

residue accumulates on the flue lining. When ignited, this

creosote makes an extremely hot fire.

The chimney connector and chimney should be inspected at

least twice monthly during the heating season to determine if a

creosote build-up has occurred. If creosote has accumulated, it

should be removed to reduce the risk of a chimney fire.

SMOKE PIPE INSTALLATIONSMOKE PIPE INSTALLATION

SMOKE PIPE INSTALLATION

SMOKE PIPE INSTALLATIONSMOKE PIPE INSTALLATION

Clearances to combustible materials (i.e. paneling, ceiling tile,

sheet rock, plaster, draperies, casements or wood trim, etc.)

will vary with the type of flue connection used. Be sure to

maintain the specified clearances for your type of installation.

TYPE OF FLUE REQUIRED

CONNECTION CLEARANCE

24 Gauge or Heavier 18" (45.72cm)

Single Wall Stainless Steel

or Black Pipe

Double Wall Stainless Steel 6" (15.24cm) Model 1600

8" (20.32cm) Model 1800

Class A All-Fuel or Equivalent 2" (5.08cm)

COMBUSTIBLES

SMOKE PIPE

CHIMNEY THIMBLE SHOULD BE

CONSTRUCTED OF FIRE CLAY, AND

SHOULD FIT TIGHTLY TO FLUE PIPE.

1.The wood furnace should be the only heating appliance

using a chimney flue. One furnace per flue.

2.A masonry chimney should have a tile or stainless steel

liner.

3.The masonry chimney should not have any missing

mortar or loose bricks.

4.There should be no mortar or parts of the chimney

blocking the chimney flue.

5.There should be a two inch clearance between any

chimney (masonry or metal) and combustibles (such

as the house).

6.The chimney should extend at least 2' above the

highest point of the house, or 2' above the point at

which the chimney is 10' from the roof.

7.The chimney should be relatively straight and vertical.

According to NFPA standards, single wall stove pipes can be

within 9" (22.86cm) of combustibles provided an approved fire

retardant material covered with 28 gauge sheet metal, spaced

out 1" (2.54cm) on non-combustible spacers, is utilized. See

illustration.

18" (45.72cm)

CEILING OR WALL

When using a Class A or double wall flue pipe connection,When using a Class A or double wall flue pipe connection,

When using a Class A or double wall flue pipe connection,

When using a Class A or double wall flue pipe connection,When using a Class A or double wall flue pipe connection,

follow the manufacturer's instructions.follow the manufacturer's instructions.

follow the manufacturer's instructions.

follow the manufacturer's instructions.follow the manufacturer's instructions.

9" (22.86cm)

18" (45.72cm)

4

When constructing a single wall smoke pipe, the followingWhen constructing a single wall smoke pipe, the following

When constructing a single wall smoke pipe, the following

When constructing a single wall smoke pipe, the followingWhen constructing a single wall smoke pipe, the following

guidelines must be observed.guidelines must be observed.

guidelines must be observed.

guidelines must be observed.guidelines must be observed.

1.The smoke pipe should be 24 gauge or heavier stain less

steel or black pipe.

2.Secure all joints with three #8 screws.

3.If the smoke pipe must pass through a wall, an approved

insulated or ventilated thimble, at least three times the

diameter of the smoke pipe must be used. (i.e. a 6"

(15.24cm) diameter smoke pipe needs an 18" (45.72cm)

thimble).

4.The smoke pipe should not be used as a chimney.

IMPORTANT INFORMATION FORIMPORTANT INFORMATION FOR

IMPORTANT INFORMATION FOR

IMPORTANT INFORMATION FORIMPORTANT INFORMATION FOR

ALL SMOKE PIPESALL SMOKE PIPES

ALL SMOKE PIPES

ALL SMOKE PIPESALL SMOKE PIPES

The smoke pipe must be constructed and installed so that it

maintains clearances, keeps condensation and creosote

within the pipe, and is capable of withstanding a 2000°F to

3000°F (1093°C to 1649°C) chimney fire.

1.The smoke pipe should slant down toward the furnace a

minimum of 1/4" to the foot. At no time should the pipe

turn downward toward the chimney or run horizontal.

2.There should be no more than two 90 degree elbows.

3.The smoke pipe should never be longer than 6 feet.(1.83m)

If it is absolutely necessary to make a run of more than

six feet (not recommended) use extra support brackets

every 3 feet (.91m).

4.The smoke pipe should never be reduced to a smaller

size than flue opening on the furnace.

5.The smoke pipe should not block the flue of the

chimney or extend into it in any way.

6.A good airtight thimble should be used to hold the

smoke pipe in the chimney. It should be constructed so

the smoke pipe can be removed for cleaning.

7.The smoke pipe should not leave the heated portion of

the building to reach the chimney.

8.The smoke pipe should not pass from one story to the

next before entering the chimney, nor should it pass

through any closed or enclosed space.

9.Heat reclaimers should not be installed or used in the

smoke pipe.

10. The smoke pipe should not be located near or in a walk

way or well traveled area.

11. All male ends of smoke pipe should run or point towards

the furnace.

When you have installed the smoke pipe connecting your furnace

to the chimney, tap the pipe hard with your fingernail. Remember

the sound it makes - it will be a "ting" echoing inside the stove pipe.

If later you tap and hear a muffled thud, you are building up soot

in the pipe and should clean it. This pipe should be cleaned at

least once or twice during the heating season.

DO NOT CONNECT TWO HEATERS TO THE SAME CHIMNEY

FLUE. The National Fire Prevention Association recommends

that woodburning appliances vent into a separate chimney from

gas or oil furnaces. If such an installation is contemplated, first

check with a local building inspector to find out if a separate flue

for a woodburner is required.

If codes allow, use extreme care in making such installations. Be

sure that one pipe is higher than the other so that the two openings

will not be opposite each other. Also, when connecting two

heaters into the same chimney flue, the flue size should be large

enough to handle both heaters. Very few codes and

standards allow same flue connection. Such installations can

cause severe problems. Gas hoods and barometric dampers

allow excess air into the chimney causing cooling of the flue

gases and a greater creosote build-up potential. If the same flue

connections are used, chimneys must be inspected more frequently and the chimney should be cleaned any time the

creosote deposits exceed 1/4" thickness. A creosote fire in such

a chimney can burn out of control because of the air leak through

the barometric damper or gas hood. Keeping the chimney clean

and burning well-seasoned wood is absolutely necessary. This

type of installation does require more frequent inspection and

maintenance.

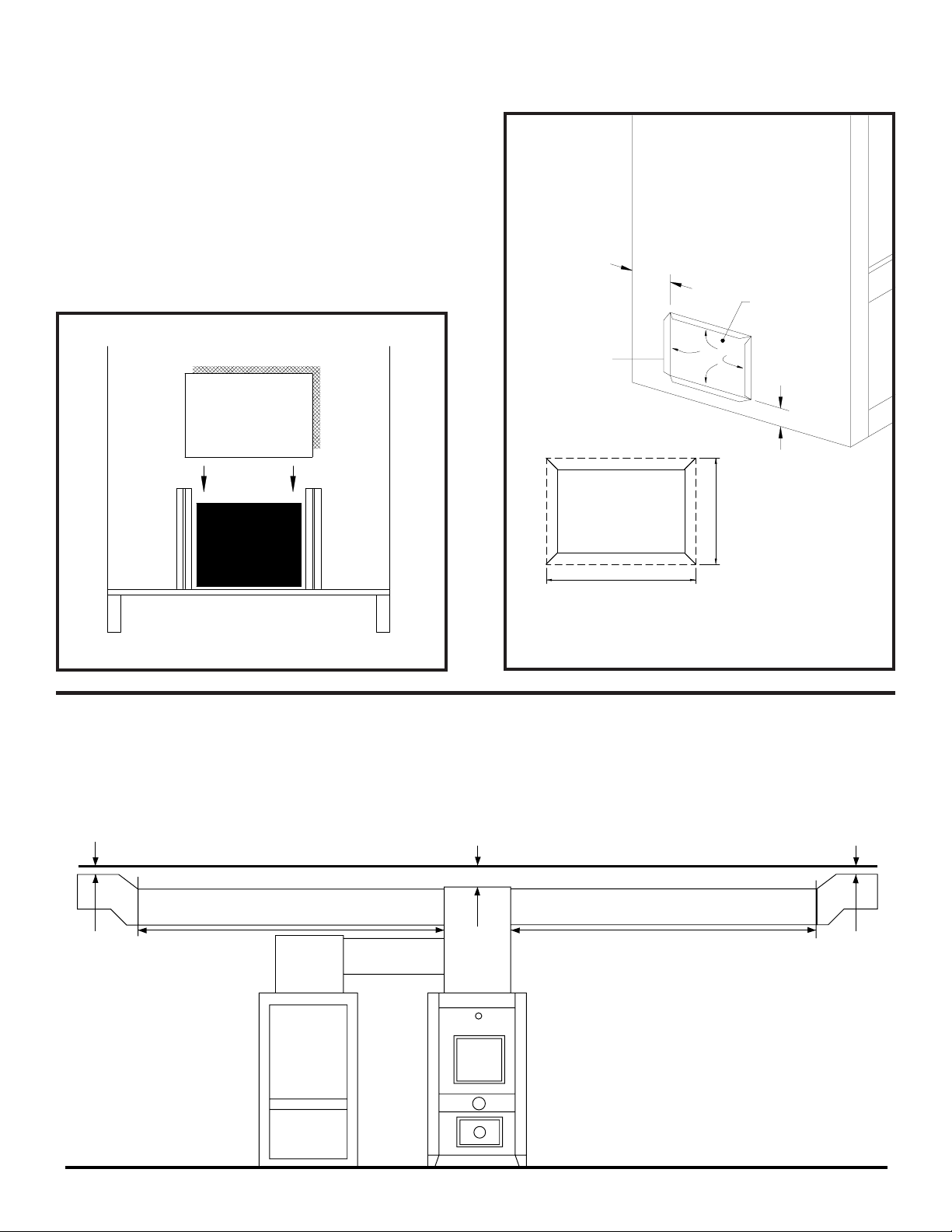

ADD-ON SERIESADD-ON SERIES

ADD-ON SERIES

ADD-ON SERIESADD-ON SERIES

INSTINST

INST

INSTINST

The downstream series techniqueis the onlyapproved method

for using the 1600 and 1800 furnaces in combination with an

existing gas, oil or electric forced air furnace. While it requires

reworking the main duct system, it typically results in a simpler,

less restrictive installation.

Certification testing establishes the minimum cross-sectional

area for the transfer duct permitted for a specific add-on. A large

transfer duct will allow freer flow of air through the additional

elbows involved in the add-on installation.

Additional space will be required in the furnace room for an addon. There must be a room beside the existing furnace for the addon and the transfer duct which runs from the hot air plenum of the

existing furnace down to the cold air inlet of the add-on.

While oil, gas and electric furnaces may be connected to

combustible return air ducts in the form of joist panning, wood

furnaces normally require noncombustible return air duct work.

Combustible return ducts connected to an existing oil, gas or

electric furnace need not to be replaced with noncombustible

ducts when an add-on is installed; the add-on connections make

reverse flow during a power failure very unlikely.

Major changes to the main distributionduct system are normally

required in order to route the existing duct over the new hot

plenum of the add-on. Any indivdual ducts connected directly to

registers from the existing plenum also have to be routed over to

the add-on plenum because all of the air must pass through the

add-on before reaching any distribution ductwork.

There are two options for managing the duct alternations. In

some cases, it is more practical to move the existing furnace and

place the add-on in the location it previously occupied. By

locating the add-on where the original furnace was, fewer supply

duct alterations will be needed. On the other hand, alterations to

the return ducts will be needed to re-route them to the new

location of the cold air plenum.

The other option is to leave the existing furnace in its original

location and re-route the supply ducts to the new add-on plenum.

In your design of add-on installations, always choose the approach

that involves using the least elbows. By keeping the number of

elbows to a minimum, duct restrictions and blower noise will be

reduced.

5

ALLAALLA

ALLA

ALLAALLA

TIONTION

TION

TIONTION

The connection of the add-on to an existing furnace imposes a

greater work-load on the air-circulating blower. Unless

compensating adjustments are made, the additional restriction

will reduse air flow, and overheating of the existing furnace can

result. To provide a reference point for later adjustments,you

must test air flow before any installation work begins.

There are two methods of evaluating existing air flow: the static

pressure drop method and the temperature rise method.

HOTBLAST FURNACE MODIFICATIONSHOTBLAST FURNACE MODIFICATIONS

HOTBLAST FURNACE MODIFICATIONS

HOTBLAST FURNACE MODIFICATIONSHOTBLAST FURNACE MODIFICATIONS

1. Cut and insert a piece of sheet metal of sufficient thickness to

provide a tight fit over the opening on the back of the Hotblast

furnace.

2. Cut an opening in the side of the Hotblast furnace that will face

your existing furnace. (see illustration)

6"

(15.24 cm)

FINISHED

OPENING

10" x 16"

BEND BACK

FLANGE

CUTOUT

8" H x 14" W

(20.32 x 35.56 cm)

1" (2.54 cm)

10" (25.4 cm)

CONNECTING HOT AIR DUCT TO FURNACECONNECTING HOT AIR DUCT TO FURNACE

CONNECTING HOT AIR DUCT TO FURNACE

CONNECTING HOT AIR DUCT TO FURNACECONNECTING HOT AIR DUCT TO FURNACE

We strongly recommend that the hot airduct work be installed by a home

heating specialist. If doing the installation yourself, before you decide

which installation will best suit your needs, we recommend that you consult

a qualified heating technician and follow his recommendations as to the

most safe and efficient method of installation.

2" MIN.

1" MIN.

(2.54 cm)

6' (182.88cm)

EXISTING

FURNACE

(if used)

HOT AIR

PLENUM

(5.08 cm)

HOTBLAST

FURNACE

16" (40.64 cm)

6' (182.88cm)

DUCTWORKDUCTWORK

DUCTWORK

DUCTWORKDUCTWORK

INSTALLATIONINSTALLATION

INSTALLATION

INSTALLATIONINSTALLATION

HOT AIR DUCT

And MinimumAnd Minimum

And Minimum

MINIMUM CLEARANCES

TO COMBUSTIBLES

And MinimumAnd Minimum

ClearancesClearances

Clearances

ClearancesClearances

1" MIN.

(2.54 cm)

6

Loading...

Loading...