Page 1

USSC 1

Page 2

INTRODUCTION

Your LONGVIE heater is especially designed to provide maximum comfort to you and your home. Its large solid injected

aluminum front grill assures the optimum use of the generated heat in the ambient, maintains normal temperatures behind

the heater to avoid sticking of particles, which would soil the wall. You can feel safe with absolute security guaranteed by:

Its thermocouple security valve, which cuts the supply of gas in the event of the heater extinguishing due to strong air

•

currents, momentary interruption of the supply of gas.

Its gas pressure regulator assures an optimum operational; function, avoiding peak pressures in the gas supply

•

affecting normal combustion.

Its gas tight combustion chamber, totally enameled, avoids gases which are caused by combustion, to contaminate

•

the air and ensures a useful , long lasting working life.

Long lasting working life...Guaranteed by the quality of its components and high technology applied in the process of

fabrication, and especially by the traditional vocation of LONGVIE to produce durable products for your maximum comfort

and satisfaction.

LOCAL CODES

Install and use the heater with care. The installation must conform with local codes or in the absence

of local codes, use the latest edition of The National Fuel Gas Code ANSI Z223.1/NFPA 54*. Natural

Gas and Propane Installation Code, CSA B149.1.

A manufactured home (USA only) or mobile home OEM installation must conform with the Manufac-

tured Home Construction and Safety Standard, Title 24 CFR, Part 3280, or, when such a standard is

not applicable, the Standard for Manufactured Home Installation, ANSI Z225.1, or Standard for Gas

Equipped recreational Vehicles and Mobile Housing, CSA Z240.4.

*Available from:

American National Standards Institute, Inc.

1430 Broadway

New York, NY 10018

National Fire Protection Association, Inc.

Batterymarch Park

Quincy, MA 02269

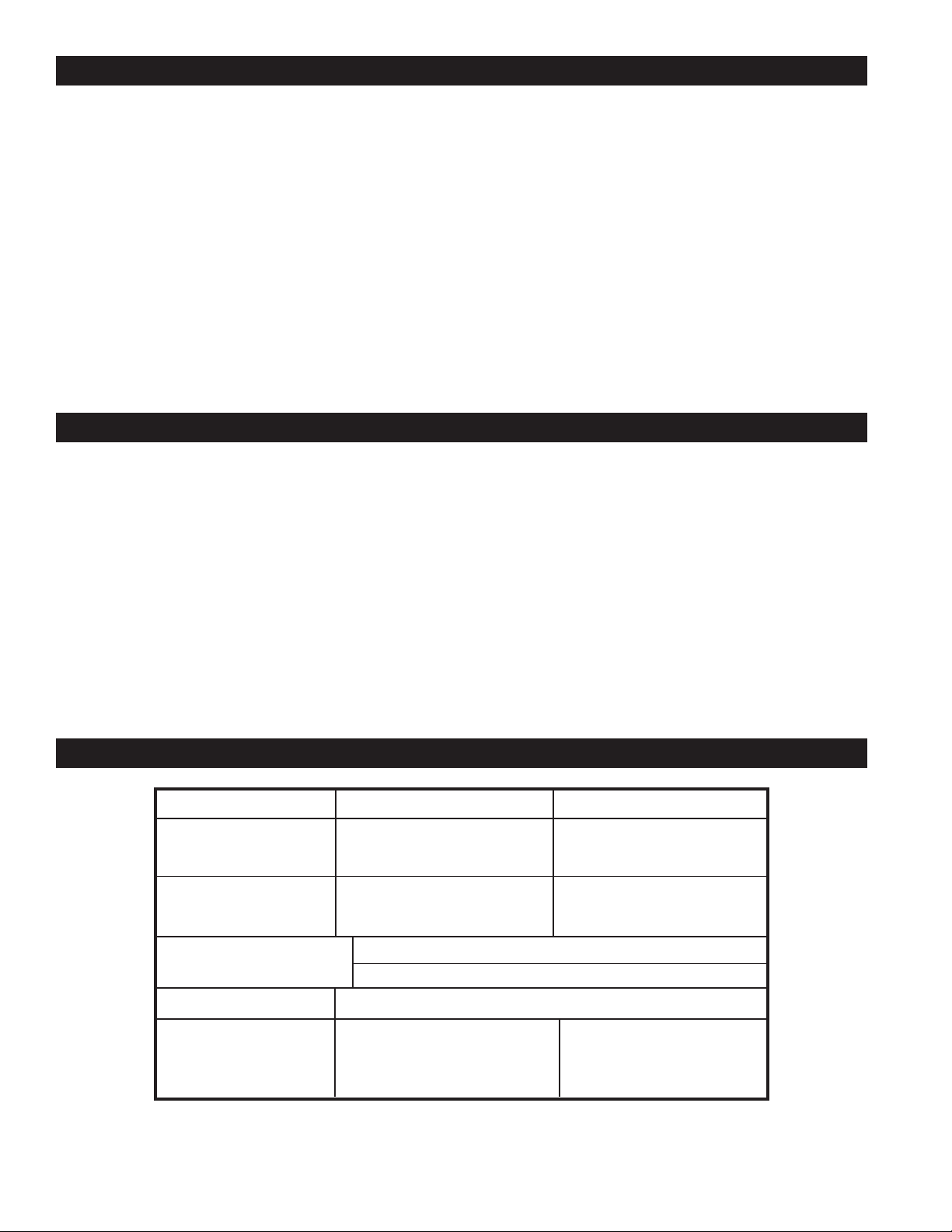

GAS SPECIFICATIONS

MODEL FUEL MAXIMUM INPUT

DV12 Natural 10,000 BTU/hr

Liquid Propane 10,000 BTU/hr

DV20 Natural 18,000 BTU/hr

Liquid Propane 18,000 BTU/hr

MANIFOLD PRESSURE Natural Gas - DV12 - 5.8” w.c. DV20 - 5.2” w.c.

Propane / LP Gas - DV12 - 10.8” w.c. DV20 - 10.6” w.c.

GAS INLET 3/8” NPT

SUPPLY MIN. PRESSURE MAX. PRESSURE

Natural 7” W.C.P. 10.5” W.C.P.

Propane / LP 11.0” W.C.P. 13.0” W.C.P.

USE ONLY THE TYPE GAS SPECIFIED ON THE RATING PLATE

2 USSC

Page 3

SAFETY RULES

Due to high temperatures, the appliance should located out of traffic and away from furniture and draperies.

1.

Children and adults should be alerted to the hazards of high surface temperatures and should stay away to

2.

avoid burns or clothing ignition.

Young children should be carefully supervised when they are in the same room as the appliance

3.

Clothing or other flammable material should not be placed on or near the appliance.

4.

Any safety screen or guard removed for servicing an appliance must be replaced prior to operating the

5.

appliance.

Installation and repair should be done by a qualified service person. The appliance should be inspected

6.

before use and at least annually by a qualified service person. More frequent cleaning may be necessary due

to excessive lint from carpeting, bedding material, etc. It is imperative that control compartments, burners

and circulating air passageways of the appliance be kept clean.

WARNING: Do not operate appliance with the panel removed, cracked or broken. Replacement of the panel

7.

should be done by a licensed or qualified service person.

Do not spray any aerosol near heater when functioning. Do not store these elements near appliance.

8.

Do not touch the grill to avoid burning yourself.

9.

Do not touch the gases outlet cap while heater is in operation to avoid burning yourself.

10.

Avoid blocking air inlet and hot air outlet.

11.

Do not spill water over the heater as it may cause corrosion.

12.

Allow heater to thoroughly cool before servicing.

13.

Input ratings are shown in BTU per hour and are for elevations up to 2,000 feet. For elevations above 2,000 feet, input

14.

ratings should be reduced 4 percent for each 1,000 feet above see level. Refer to the National Fuel Gas Code.

The appliance and its appliance main gas valve must be disconnected from the gas supply piping system during any

15.

pressure testing of that system at test pressures in excess of 1/2 psig (3.5 kPa).

The appliance must be isolated from the gas supply piping system be closing its equipment shutoff valve during any

16.

pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig (3.5 kPa).

This gas appliance must not be connected to a chimney flue serving a separate solid-fuel burning appliance.

17.

The installation make provisions for adequate combustion and ventilation air.

18.

The installation must provide adequate accessibility clearances for servicing.

19.

The efficiency rating of this appliance is a product thermal efficiency rating determined under continuous operating

20.

conditions and was determined independently of any installed system.

The minimum inlet gas supply for the purpose of input adjustment.

21.

Do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect

22.

the appliance and to replace any part of the control system and any gas control that has been under water.

USSC 3

Page 4

4 USSC

Page 5

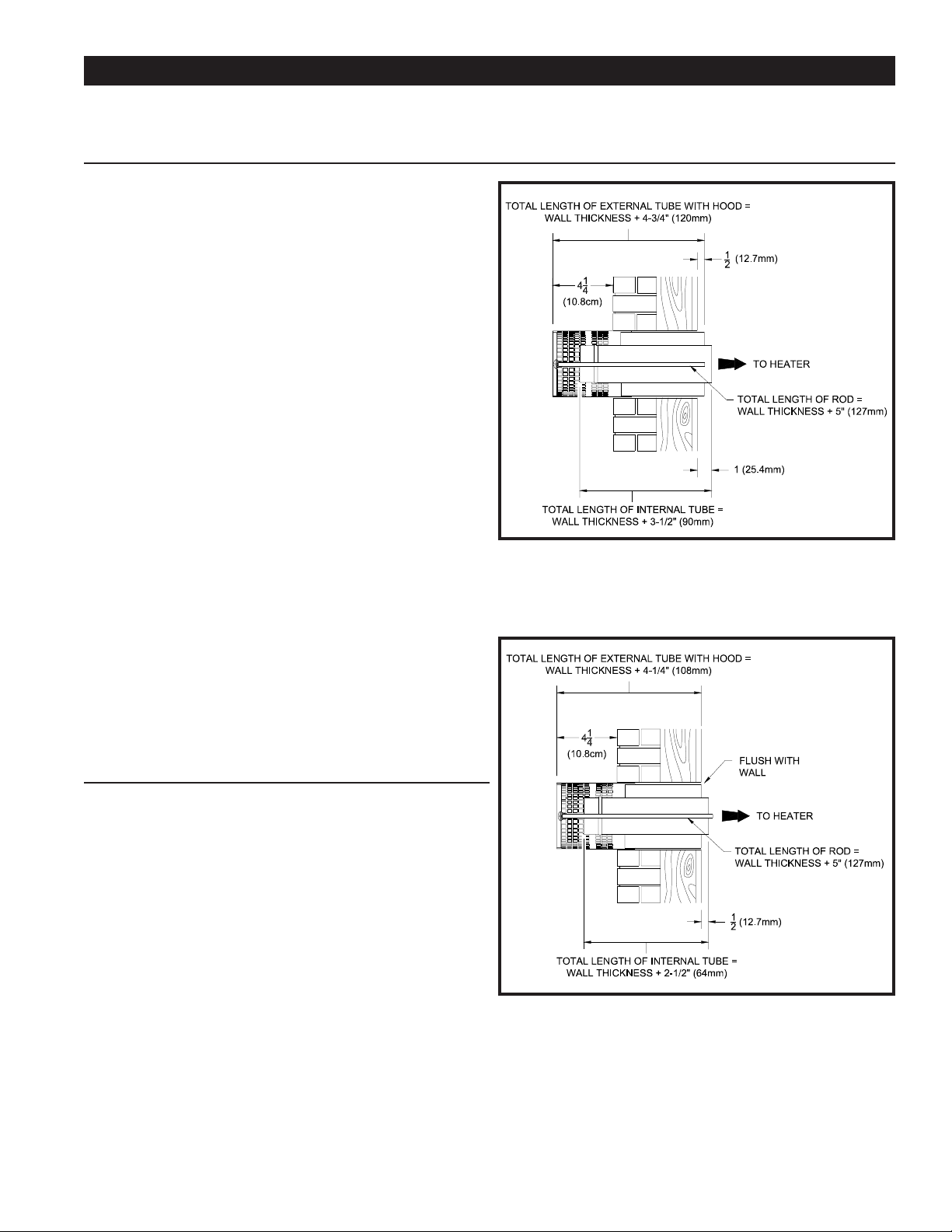

VENTILATION INSTALLATION

The ventilation system consist of:

1_External Tube - Air incoming tube with enamel hood riveted in place. 1_Threaded Mounting Rod

1_Internal Tube - Outgoing flue gases 1_Adjusting Nut

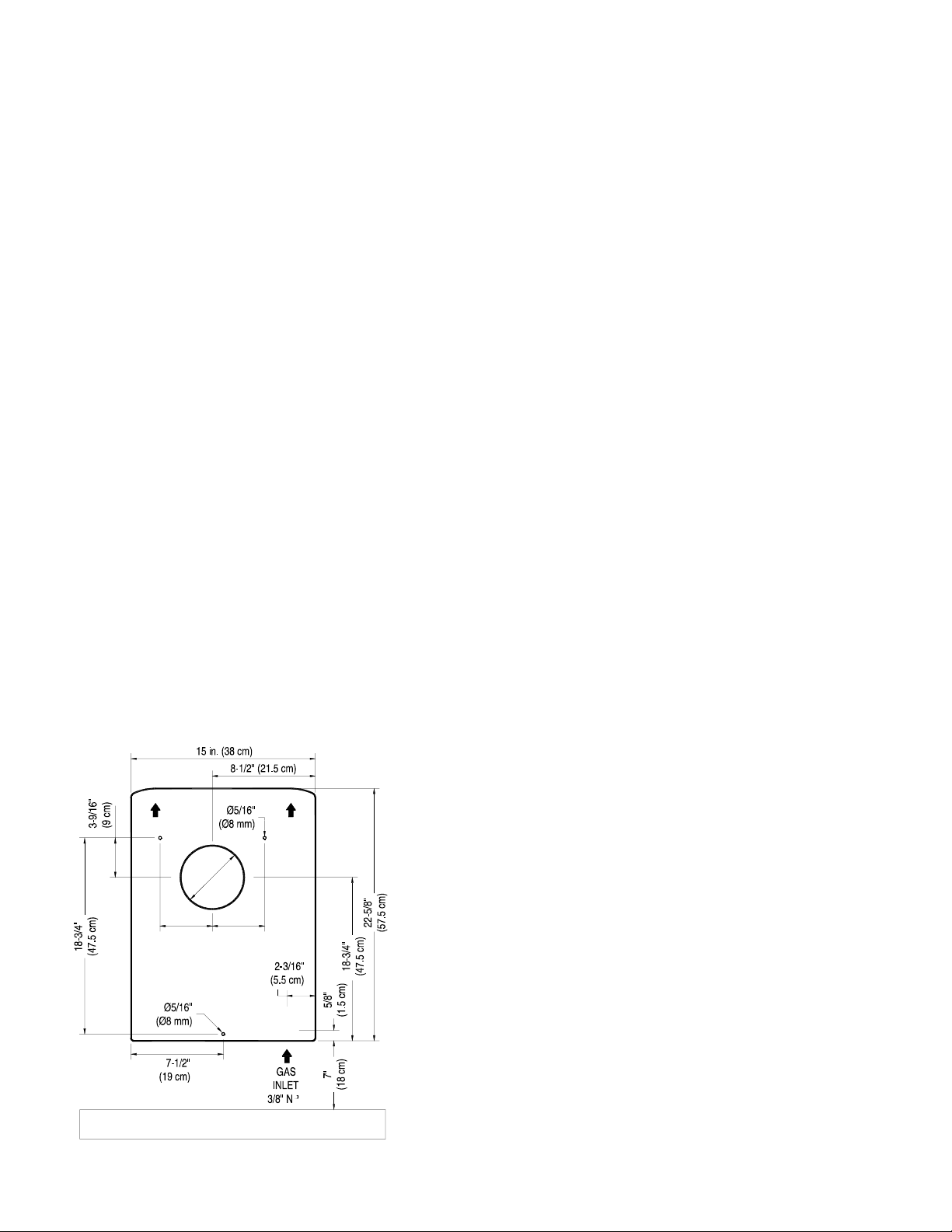

For Model DV12:

Mark the three 5/16” (8mm) holes and drill

Insert the three plastic plugs provided in the previously drilled

holes.

Mark the hole for the 4-1/2” (11.5cm) dia. ventilation tube.

This must be rectilinear and with a slight fall towards the exterior of approx. 2 degrees to avoid the entering of rain water.

Take into consideration the area indicated for the gas connection.

The wall’s thickness cannot be less than 4-1/2” (11.5 cm) nor

can it exceed 13-1/2” (35cm). (See Diagram Nº 5) Tube lengths

and threaded mounting rod should be trimmed to comply to

the dimensions shown in Diagram Nº 3.

For Model DV20:

Mark the four(4) 5/16” (8mm) holes and drill

Insert the four(4) plastic plugs provided in the previously drilled

holes.

Mark the hole for the 6 1/4” (16cm) dia. ventilation tube. This

must be rectilinear and with a slight fall towards the exterior

of approx. 2 degrees to avoid the entering of rain water.

Take into consideration the area indicated for the gas connection.

The wall’s thickness cannot be less than 4-1/2” (11.5 cm) nor

can it exceed 13-1/2” (35cm). (See Diagram Nº 5) Tube lengths

and threaded mounting rod should be trimmed to comply to

the dimensions shown in Diagram Nº 4.

Diagram Nº 3

Final Assembly

Remove the front cover of the heater by removing the control

knob and the two(2) screws on the top of the cover. Slide the

front upwards.

After tubes have been cut to length, slide the tubes and the

rod into position on the heater and adjust with the nut provided until you get a compact unit.

Slide the heater and ventilation assembly through the hole

until the heater reaches the wall. For the model DV12, se-

cure to the wall with the three(3) screws provided. For the

model DV 20, secure to the wall with the four(4) screws provided.

Check that hood protrudes the intended 4 1/4” (10.8 cm) from the exterior wall.

Seal any imperfections between wall and vent hood with putty, making sure that nothing falls inside the hood. (See

Diagram Nº 6)

A protection plate resistant to high temperatures is available at extra cost for use with external combustible walls. (See

Diagram Nº 7)

Diagram Nº 4

USSC 5

Page 6

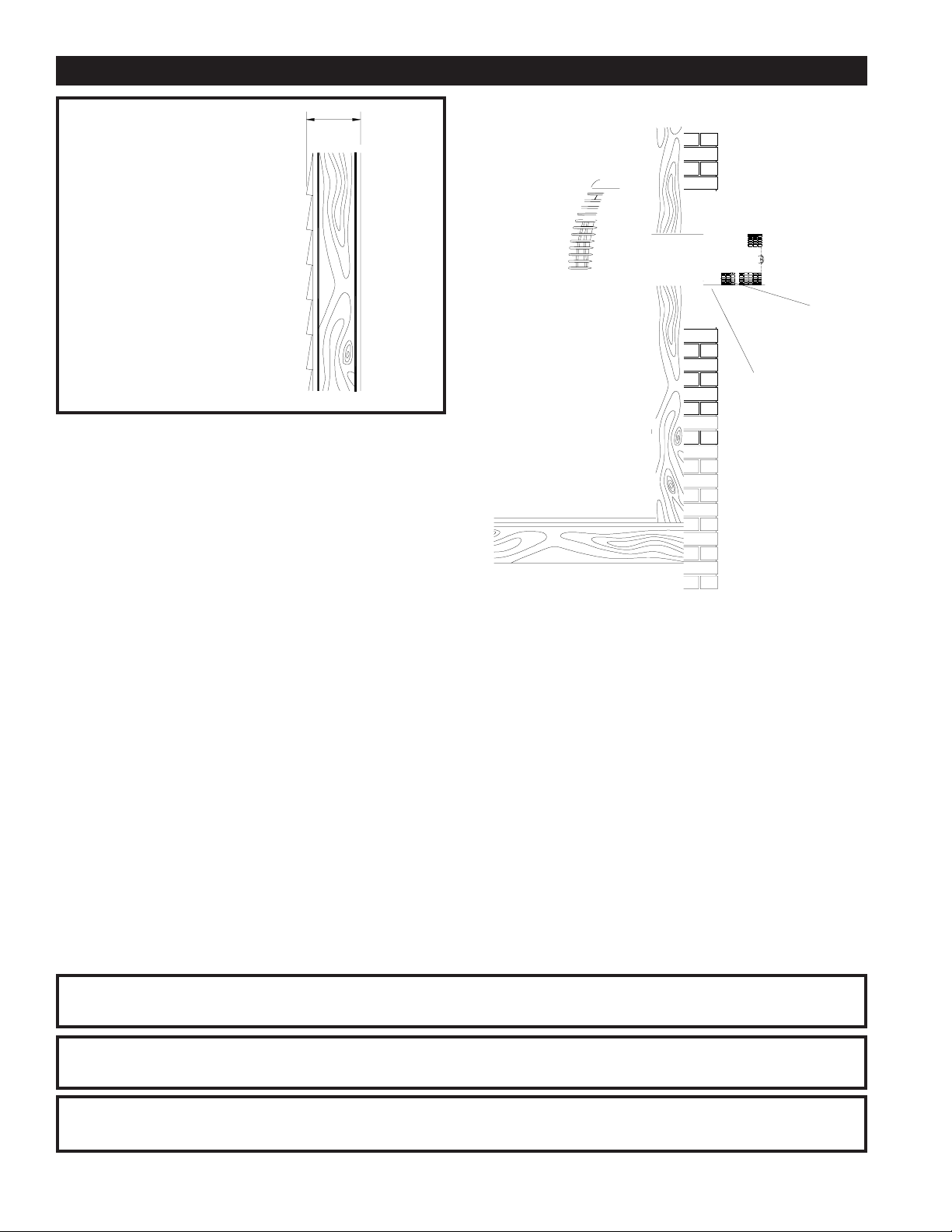

Minimum wall thickness:

4-1/2” (11.5cm)

Maximum wall thickness:

13-1/2” (35 cm)

Diagram Nº 5

VENTILATION INSTALLATION continued...

Diagram Nº 6

Diagram Nº 7

IMPORTANT: The appliance’s vent cap should be at least 24 in.(61 cm) from any outside

adjacent or intersecting wall.

IMPORTANT: The appliance’s venting system should be inspected at least once a year and

cleaned if necessary.

IMPORTANT: THE VENT-AIR INTAKE SYSTEM MUST BE PROPERLY INSTALLED TO INSURE PROPER AND SAFE OPERATION.

6 USSC

Page 7

VENTILATION INSTALLATION continued...

Canadian Installation

Clearance above grade, veranda, porch,

A =

deck, or balcony

Clearnace to window or door that may be

B =

opened

Clearance to permanently closed window

C =

Vertical clearance to ventilated soffit lo-

D =

cated above the terminal within a horizontal distance of 2 feet (61 cm) from the center line of the terminal

Clearnace to unventilated soffit

E =

Clearance to outside corner

F =

Clearnace to inside corner

G =

Clearnace to each side of center line ex-

H =

tended above meter/regulator assembly

Clearance to service regulator vent outlet

I =

Clearance to nonmechanical air supply in-

J =

let to building or the combustion air inlet to

any other appliance

Clearance to a mechanical air supply inlet

K =

Clearnace above paved sidewalk or paved

L =

driveway located on publis property

Clearance under veranda, porch, deck, or

M =

balcony

1

In accordance with the current CSA B149.1, Natural Gas and Propane Installation Code.

2

In accordance with the current ANSI Z223.1/NFPA 54, National Fuel Gas Code.

† A vent shall not terminate directly above a paved sidewalk or paved driveway that is located between two single family dwellings and serve both dwellings.

‡ Permitted only if verdana, porch, deck, or balcony is fully open on a minimum of two sides beneath the floor.

* For clearnaces not specified in ANSI Z223.1/NFPA 54 or CSA B149.1, one of the following shall be indicated.

(a) A minimum clearances valve determined by testing in accordance with section 2.19.6, or ;

(b) A reference to the following footnote:

“ Clearance in accordance with local installation codes and the requirements of the gas supplier.”

12 inches (30 cm)

6 inches (15 cm) for appliance < 10,000 BTU/hr

(3 kW), 12 inches (30 cm) for appliance > 10,000

BTU/hr (3 kW) and <100,000 BTU/hr (30 kW),

36 inches (91 cm) for appliances > 100,000 BTU/

hr (30 kW)

3 feet (91 cm) within a hieght 15 feet (4.5 m)

above the meter/regulator assembly

3 feet (91 cm)

6 inches (15 cm) for appliance < 10,000 BTU/hr

(3kW), 12 inches (30 cm) for appliance > 10,000

BTU/hr (3kW) and < 100,000 BTU/hr (30 kW),

36 inches (91 cm) for appliance > 100,000 BTU/

hr (30 kW)

6 feet (1.83 m)

7 feet (2.13 m) †

12 inches (30 cm) ‡

1

*

*

*

*

*

US Installation

12 inches (30 cm)

6 inches (15 cm) for appliance < 10,000 BTU/hr

(3 kW), 9 inches (23 cm) for appliance > 10,000

BTU/hr (3 kW) and < 50,000 BTU/hr (15 kW), 12

inches (30 cm) for appliances > 50,000 BTU/hr

(15 kW)

6 inches (15 cm) for appliance < 10,000 BTU/hr

(3kW), 9 inches (23 cm) for appliance > 10,000

BTU/hr (3kW) and < 50,000 BTU/hr (15 kW), 12

inches (30 cm) for appliance > 50,000 BTU/hr

(15 kW)

3 feet (91 cm) above if within 10 feet (3 m)

2

*

*

*

*

*

*

*

horizontally

*

*

USSC 7

Page 8

VENTILATION INSTALLATION continued...

Diagram Nº 8

8 USSC

Page 9

GAS CONNECTION

A qualified gas appliance installer must connect the heater to the

gas supply. Consult all local codes.

NOTICE

Use new black iron or steel pipe only. Internally tinned copper tubing can be

used in some areas when permitted by local codes. Only use pipe of 1/2" or

greater diameter to allow full gas volume to heater. Excessive pressure loss will

occur if the pipe is too small.

A manual shutoff valve, union and plugged 1/8" NPT pressure tapping point

must be installed upstream of the heater (FIGURE 6).

CAUTION

A sediment trap must be installed upstream of the heater to prevent moisture

and contaminants from passing through the pipe to the heater controls and

burners. Failure to do so could prevent the heater from operating reliably

(FIGURE 8).

IMPORTANT: Loosen the pipe adapter

on the flex tube before installing to the

system piping.

Diagram Nº 9. Gas Connection

CHECK GAS TYPE: The gas supply must be the same as stated on heater's rating plate. If the

gas supply is different, DO NOT INSTALL the heater. Contact your dealer for the correct model.

Connecting directly to an unregulated propane/LPG tank can

cause an explosion.

WARNING

Reattach the front to the unit. Use the same screws removed in the instructions on page 5. Reinstall

the control knob.

USSC 9

Page 10

OPERATING INSTRUCTIONS

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

This appliance has a pilot which can be light with the equipped piezo ignitor. When lighting the pilot, follow these

A.

instructions exactly.

BEFORE LIGHTING smell all around the appliance area for gas. Be sure to smell next to the floor because some

B.

gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not attempt to light any appliance.

• Do not touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Use only your hand to push in or turn the gas control knob. Never use tools. If the knob will not push in or turn by

C.

hand, don't try to repair it, call a qualified service technician. Force or attempted repair may result in a fire or

explosion.

Do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect

D.

the appliance and to replace any part of the control system and any gas control which has been under water.

LIGHTING INSTRUCTIONS

STOP! Read the safety information above on this page.

1.

Press the knob lightly and turn clockwise to the “OFF” position.

2.

Wait five (5) minutes to clear out any gas. If you then smell gas, STOP! Follow

3.

“B” in the safety information above on this page. If you don’t smell gas, go to the

next step.

Find the pilot by looking through the viewing window on the front of the unit.

4.

Press the knob down lightly and turn counterclockwise to the “Pilot”.

5.

Press again downwards.

Press the Piezo Ignition button to light the pilot. Repeat this operation with the

6.

knob pressed down until the pilot has lit. When the pilot lights, continue holding

pressure for another 10 seconds. Release the knob. If the pilot goes out, repeat

the process 1 through 6.

If the knob does not pop up when released, stop and immediately call your ser-

!

vice technician or gas supplier.

If the pilot will not stay lit after several tries, turn the gas control knob to OFF and

!

call your service technician or gas supplier.

Press down and turning the control knob counterclockwise to the

7.

desired temperature. The temperature can be regulated between HI and LO

capacity, according to the indicated scale marked on the knob.

When the heater is first started after installation or if the heater has not been used for a long period of time, there is a

normal delay of gas from the gas supply through the gas control on the heater. In this case, maintain pressure on the knob

at the “Pilot” position for 30-40 seconds and then try the piezo lighter.

TURN OFF GAS TO APPLIANCE

When the heater is not to be in use for a long period of time or for servicing, turn the control knob clockwise to

the OFF position and close the main gas supply valve.

10 USSC

Page 11

MAINTENANCE INSTRUCTIONS

As with all fuel burning appliances, it is important to conduct periodic maintenance functions that will allow for continued safe, efficient operation of the unit. We suggest that before every heating season, or at least once a year, conduct

the following minimum service functions.

STEP 1: The gas supply should be turned OFF at the shutoff valve in the supply line leading to the appliance or at the

gas source. The gas to the unit should then be disconnected so the unit can be removed from the wall.

STEP 2: Remove the front cover by removing the control knob and the two(2) screws on the top of the front. Then slide

the front upwards.

STEP 3: Carefully examine the interior of the vent pipe. If you notice any blockages or obstruction that was not part of

the unit when it was installed. Clean the pipes and prepare them for reattachment to the unit.

The vent system should be inspected periodically, or at least once a year and cleaned if necessary. If removal of the

venting is required, follow the instructions in the “Ventilation Installation” section of this manual for reassembly.

STEP 4: Look inside the openings of the rear of the unit and check for foreign materials. Remove any objects which may

block or obstruct the free flow of combustion and ventilation air.

STEP 5: Visually check the pilot and the main burner for signs of excessive dirt or debris through the heat exchanger

front glass. If you find any of these, follow the directions below to reach the components to clean, otherwise continue to the

next step.

To Remove Pilot: Find the pilot. Loosen the head of thermocouple, disconnect the pilot gas supply line, (only on the side

of the pilot, not on the valve side). Remove the two(2) M4 screws that hold the pilot in place. Clean with a vacuum cleaner

or use a can of compressed air.

To Remove Burner: Loosen the gas line from the burner (on the right side of the unit). On the left side of the unit,

unscrew the nut that holds the burner in place. Then remove the burner. Clean with a vacuum cleaner or use a can of

compressed air. Note: You can remove the main burner-pilot assembly if you don’t unscrew the M4 screws that hold the

pilot to the burner.

Before reinstalling the assembly, check the ceramic fiber sealing gasket. If it is damaged or worn, replace with new gasket

available from your dealer.

STEP 6: Reassembly the unit back to its original state and mount the unit to the wall. Properly reassemble and reseal

the vent-air intake system.

STEP 7: Reconnect the gas supply and check for leaks using a soapy water solution. Bubbles on any of the joints

indicate a leak is present and must be repaired. Turn off the gas when making such repairs. Check to make sure that the

piezo ignitor still lights the pilot.

STEP 8:

12)

Note: After maintenance, the first few minutes of the heater operation will probably have some yellowish flying traces in

the flame due to the burning of particles left behind during the cleaning operation.

** Liquid Propane will have some evidence of yellow tips on the flame.

While the main burner is ON, Check the flames to verify that they are burning a clean blue color. (See Diagrams 10-

Any safety screen or guard removed for servicing an appliance must be replaced prior to

operating the appliance

Before completing your periodic maintenance check, ensure the heater area is kept clean and

free from combustible materials, gasoline and other flammable vapors and liquids. Also,

check to see that the flow of combustion and ventilation air around the vent cap on the outside

of the structure is not obstructed.

USSC 11

Page 12

Diagram Nº 10. Correct Flame Pattern

Diagram Nº 11. Correct Flame Pattern

Optional Blower - DVBS (DV12) and DVBL (DV20)

CAUTION: Label all wires prior to

disconnection when servicing

controls. Wiring errors can cause

improper and dangerous operation.

Diagram Nº 12. Incorrect Flame Pattern

If any of the original wire as supplied

Wiring Diagram

with the appliance must be replaced,

it must be replaced with 600 volt - 150

degree C. wire or its equivalent.

Verify proper operation after

servicing.

Permanently lubricated bearing

system.

WARNING: ELECTRICAL

GROUNDING INSTRUCTIONS.

This appliance is equipped with a

three-prong (grounding) plug for your

protection against shock hazard and

should be plugged directly into a

properly grounded three-prong receptacle. Do not cut or remove the

grounding prong from this plug.

Wiring Schematic

12 USSC

Page 13

DV20 - REPAIR PARTS

USSC 13

Page 14

DV20 - REPAIR PARTS LIST

KEY PART # DESCRIPTION QTY.

1.1 2478 Glass Support 2

2.1 17501 Combustion Chamber Glass 1

3.1 2484 Ceramic Fibre Glass Gasket (Long) 2

4.1 2482 Ceramic Fibre Glass Gasket (Short) 2

5.1 354 Combustion Chamber 1

6.1 2472 Ceramic Fibre Washer (D57 / D43) 14

7.1 16374 Air Intake Tube 7

8.1 15901 Spacing Bolt 2

9.1 2471 Ceramic Fibre Washer (D71 / D57) 4

10.1 16377 Flue Gas Exit Tube (Large) 2

11.1 16376 Flue Gas Exit Tube (Small) 1

12.1 2472 Ceramic Fibre Washer (D57 / D43) 2

13.1 2473 Burner Assembly Gasket 1

14.1 16360 Gas Intake Fitting 1

15.1 15756 Gas Intake Lock Fitting 2

16.1 2466 Gas Fitting Support 1

17.1 2465 Control Insulation 1

18.1 - Piezo Ignitor Nut 1

19.1 2463 Control Bracket 1

20.1 2464 Piezo Ignitor Bracket 1

21.1 12455 Piezo Ignitor 1

22.1 11699 Piezo Ignitor Button 1

23.1 11698 Knob Frame 1

FOR MODEL: DV20

24.1 16365 Control Rod 1

25.1 11626 Control Knob 1

26.1 2477 Cabinet Back 1

27.1 2432 Top Deflector 1

28.1 2442 Left Side Deflector 1

29.1 2433 Right Side Deflector 1

30.1 350 Air Chamber 1

31.1 2429 Cabinet Front 1

32.1 2413 Cabinet Glass Support 6

33.1 17768 Cabinet Glass 1

34.1 423 Grill, Cast Aluminum 1

35.1 17912 LONGVIE Logo 1

36.1 11634 Cabinet Slide 2

37.1 11315 Loop 1

14 USSC

Page 15

DV12 - REPAIR PARTS

USSC 15

Page 16

DV12 - REPAIR PARTS LIST

KEY PART # DESCRIPTION QTY.

1.2 2469 Glass Support 2

2.2 17507 Combustion Chamber Glass 1

3.2 2483 Ceramic Fibre Glass Gasket (Long) 2

4.2 2482 Ceramic Fibre Glass Gasket (Short) 2

5.2 342/CC Combustion Chamber 1

6.2 2472 Ceramic Fibre Washer (D57 / D43) 6

7.2 16374 Air Intake Tube 3

8.2 15951 Spacing Bolt 2

9.2 2471 Ceramic Fibre Washer (D71 / D57) 4

10.2 2473 Burner Assembly Gasket 1

11.2 16360 Gas Intake Fitting 1

12.2 15756 Gas Intake Lock Fitting 2

13.2 2462 Gas Fitting Support 1

14.2 2465 Control Insulation 1

15.2 - Piezo Ignitor Nut 1

16.2 2463 Control Bracket 1

17.2 2464 Piezo Ignitor Bracket 1

18.2 12455 Piezo Ignitor 1

19.2 11699 Piezo Ignitor Button 1

20.2 11698 Knob Frame 1

21.2 16365 Control Rod 1

22.2 11626 Control Knob 1

FOR MODEL: DV12

23.2 2461 Cabinet Back 1

24.2 2419 Top Deflector 1

25.2 2421 Left Side Deflector 1

26.2 2420 Right Side Deflector 1

27.2 342/CA Air Chamber 1

28.2 2411 Cabinet Front 1

29.2 2413 Cabinet Glass Support 4

30.2 17767 Cabinet Glass 1

31.2 383 Grill, Cast Aluminum 1

32.2 17912 LONGVIE Logo 1

33.2 11634 Cabinet Slide 2

34.2 11315 Loop 1

16 USSC

Page 17

BURNER ASSEMBLY - REPAIR PARTS

USSC 17

Page 18

BURNER ASSEMBLY - REPAIR PARTS LIST

KEY PART # DESCRIPTION QTY.

1.3 14399 Control Rod Plate 1

2.3 10381 Control Rod Set Screw (1/8” x 15) 1

3.3 16353 Eurosit Valve By Pass 50 (for model DV12-LP) 1

4.3 16354 Eurosit Valve By Pass 90 (for model DV20-LP) 1

5.3 16355 Eurosit Valve By Pass 70 (for models DV20-N and DV12-N) 1

6.3 14397 Eurosit Gas Control Valve - Liquid Propane 1

7.3 14398 Eurosit Gas Control Valve - Natural 1

8.3 16362 Gas Inlet Fitting 3/8” NPT x 1/4” BSP 2

9.3 15707 5/16” Compression Nut 1

10.3 16322 Tube Nut 5/16” x G1/4” 1

11.3 2466 Gas Inlet Supply Line 1

12.3 16322 Tube Nut 5/16” x 1/4” 1

13.3 14400 Thermocouple 1

14.3 12456 Piezo Ignitor Cable 1

15.3 2468 Pilot Supply Tube 1/4” 1

16.3 15707 5/16” Compression Sleeve 1

17.3 16322 Tube Nut 5/16” x G1/4” 1

18.3 2467 Burner Supply Tube- 3/8” dia. 1

19.3 16364 5/16” Tube Fitting 1

20.3 15707 5/16” Compression Nut 1

21.3 16367 Burner Orifice - DV12-Natural 1

22.3 16368 Burner Orifice - DV12-Liquid Propane 1

23.3 16370 Burner Orifice - DV20-Natural 1

24.3 16369 Burner Orifice - DV20-Liquid Propane 1

25.3 16357 1/4” Compression Sleeve 1

26.3 16356 1/4” Compression Nut 1

FOR MODEL: DV20 and DV12

27.3 14396 Pilot Orifice - Natural 1

28.3 14395 Pilot Orifice - Liquid Propane 1

29.3 16358 Electrode Fitting 1

30.3 12457 Piezo Electrode 1

31.3 14394 Pilot Hood 1

32.3 16359 Pilot Thermocouple Fitting 1

33.3 8199 Burner Base 1

34.3 345 DV20 Burner 1

35.3 343 DV12 Burner 1

18 USSC

Page 19

VENTING - REPAIR PARTS LIST

KEY PART # DESCRIPTION QTY.

1.4 2480 Outgoing Flue Gases Tube - DV20 (Internal) 1

2.4 2479 Air Incoming Tube - DV20 (External) 1

3.4 347 Enameled Vent Cap - DV20 1

4.4 2470 Connecting Rod 1

5.4 16371 Connecting Rod Nut 1

6.4 2475 Outgoing Flue Gases Tube - DV12 (Internal) 1

7.4 2474 Air Incoming Tube - DV12 (External) 1

8.4 344 Enameled Vent Cap - DV12 1

USSC 19

Page 20

Keeping America Warm Since 1869

DV12, DV20

Owner's Manual

When writing, always give the full model number which is on the nameplate

attached to the fireplace.

When ordering repair parts or options, always give the following information as

shown in this list:

1. The PART NUMBER

2. The PART DESCRIPTION

3. The MODEL NUMBER: DV12 DV20

4. The SERIAL NUMBER _____________________

Save this manual for future reference.

United States Stove Company

227 Industrial Park Road

P.O. Box 151

South Pittsburg, TN 37380

(423) 837-2100

20 USSC

Loading...

Loading...