United States Stove BCAC User Manual

OMNI-TEST LABORATORIES, INC.

LISTED BY

PORTLAND

OREGON, USA

C

S

S

U

C

O

M

P

A

N

Y

U

N

I

T

E

D

S

T

A

T

E

S

S

T

O

V

E

website: www.usstove.com

COAL BURNING CIRCULATOR HEATER

MODELS CAC/BCAC

Installation, Operation and Maintenance Instructions

SAFETY NOTICE:

If this heater is not properly installed, a house fi re may result.

For your safety, follow the installation directions.

Contact local building or fi re offi cials about restrictions and

inspection requirements in your area.

Please Read this entire manual before you install and use your new room heater. Failure to

follow instructions may result in property damage, bodily injury, or even death.

United States Stove Company • 227 Industrial Park Road • P.O. Box 151 • South Pittsburg, TN 37380

CAC 1

Report #: 215-S-16-4

CAUTION:

Read all instructions carefully before starting the installation

or operation of this heater.

Improper installation may void your warranty.

DO NOT USE THIS HEATER IN A MOBILE HOME OR TRAILER

This unit was tested and listed to UL 1482-1996 by OMNI-Test Laboritories

851396 E

TABLE OF CONTENTS

IMPORTANT SAFETY INFORMATION ............................................................................................................................................................2

BUILDING CODES AND SAFETY STANDARDS .............................................................................................................................................3

HOW THIS HEATER OPERATES ....................................................................................................................................................................3

SELECTING A LOCATION FOR THE HEATER ...............................................................................................................................................3

FLOOR PROTECTION ......................................................................................................................................................................................5

CHIMNEY CONNECTOR AND CHIMNEYS .....................................................................................................................................................5

HEATER INSPECTION .....................................................................................................................................................................................9

TOOLS AND SUPPLIES NEEDED FOR INSTALLATION ................................................................................................................................9

HEATER INSTALLATION .................................................................................................................................................................................9

MINIMUM CLEARANCES TO COMBUSTIBLE WALLS AND CEILINGS ...................................................................................................9

TO SAFELY AND PROPERLY INSTALL THIS HEATER .........................................................................................................................10

HEATER OPERATION ....................................................................................................................................................................................11

TO BUILD A FIRE ......................................................................................................................................................................................11

FIRETENDING ..........................................................................................................................................................................................12

MINIMUM FIRE ADJUSTMENT ......................................................................................................................................................................13

COAL FACTS ............................................................................................................................................................................................13

HOW TO TAKE CARE OF THE HEATER AND VENTING SYSTEM (ROUTINE MAINTENANCE) ..............................................................13

HEATER MAINTENANCE .........................................................................................................................................................................13

DISPOSAL OF ASHES ..............................................................................................................................................................................13

VENTING SYSTEM ( CHIMNEY AND CHIMNEY CONNECTOR) ............................................................................................................14

CHIMNEY CONNECTOR PIPE-CORROSION INSPECTION ..................................................................................................................14

TROUBLESHOOTING ....................................................................................................................................................................................14

THE VENTING SYSTEM-KEY TO GOOD HEATER PERFORMANCE ....................................................................................................14

WHAT TO DO IF THE HEATER SMOKES, BURNS POORLY OR EXCESSIVE CREOSOTE ACCUMULATES IN THE CHIMNEY ..............

WHAT TO DO IF THE HEATER BURNS TO RAPIDLY OR OVERHEATS ..............................................................................................15

QUICK REFERENCE TO THE MOST COMMON SOLUTIONS FOR THE MOST COMMON HEATER OPERATIONAL PROBLEMS ...........16

FINAL CHECKLIST OF DO’S AND DON’TS .......................................................................................................................................................16-17

REPAIR PARTS DIAGRAM AND LIST ...............................................................................................................................................................18-19

WARRANTY CLAIM INFORMATION AND REPAIR PARTS ...................................................................................................................................20

15

IMPORTANT SAFETY INFORMATION

To assure that satisfactory and safe service is received from this heater:

1. Read these instructions entirely before beginning any part of the installation.

2. Use these instructions as a guide during the installation of the heater.

3. Be sure these instructions become the property of and are reviewed by all future users of this heater to encourage proper operation and

mainte-..........................................................................................................................................................................................................................

nance of this appliance.

THIS HEATER IS ONLY FOR BURNING COAL. USE OF ANY OTHER SOLID FUEL EXCEPT FOR COAL IGNITION PURPOSES IS A VIOLATION OF FEDERAL LAW.

Soot – Formation and Need for Removal

When coal is burned, the products of combustion combine with moisture to form a soot residue which accumulates on

the fl ue lining. When ignited, this soot makes an extremely hot fi re.

The chimney connector and chimney should be inspected at least once every two months during the heating season to

determine if a soot buildup has occurred.

If soot has accumulated, it should be removed to reduce the risk of a chimney fi re.

This heater is designed to burn stove size bituminous or anthracite coal and to provide heat to one or more rooms. Because of its radiating characteristics, this heater must be installed as an unenclosed, freestanding unit with clearances to combustibles as specifi ed by these instructions.

This heater must be connected to a Listed Factory-Built Residential Type and Building Heating Appliance Chimney or a properly constructed and

maintained masonry chimney.

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE.

This heater is not designed to burn lignite coal, liquid fuels, and gaseous fuels or household refuse. Any attempt to burn these type fuels, to enclose

the heater or to attach the heater to an air circulation system or a stoking device can be very hazardous.

THIS HEATER IS NOT DESIGNED TO BE USED IN A MOBILE HOME.

Do Not Overfi re - if Heater or Chimney Connector Glows, You are Overfi ring.

Improper installation or use of this heater can cause:

1. Damage to the heater from overheating.

2. Hazardous temperatures to develope on combustible materials adjacent to the heater, chimney connector or chimney.

3. Possible hazardous accumulation of coal gases within the heater.

4. Release of hazardous gas into the dwelling.

2 CAC

BUILDING CODES AND SAFETY STANDARDS

These instructions comply with the applicable

National Fire Protection Association and Underwriters’ Laboratories, Inc.

Standards for the installation and operation of this type heater. Before beginning the installation, you should check with

local building offi cials to assure compliance with local regulations and codes.

This heater is safety listed by Omni Test Laboratories as specifi ed by the listing label attached to the heater.

HOW THIS HEATER OPERATES

The chimney draft draws in combustion air through an adjustable air inlet thermostat located inside the cabinet. Air fl ows

through and across the bed of fuel, causing the fi re to progress through the fuel bed. Heat is transferred to the air that

fl ows between the cabinet and the fi rebox. Any attempt to alter this air by connecting this heater to a duct system or air

movement fans other than the optional B36 listed blower, available from your heater dealer, can lead to improper and

possibly hazardous operation of this heater.

SELECTING A LOCATION FOR THE HEATER

When selecting a location for the heater, be sure attention is given to the following considerations:

1.

If the heater is to be vented into a Listed High Temperature Type HT Factory-Built Residential Type And Building

Heating Appliance Chimney, review the installation instructions for the chimney to comply with requirements for

proper chimney location, height, space requirements, etc.

2.

If the heater is to be vented into a masonry chimney, the heater should be located as near the chimney as possible

without failing to comply with the requirements for minimum spacing between the chimney connector, heater and

combustibles. (Be sure chimney is constructed according to NFPA standards.)

3.

The location of the heater must provide at least the minimum clearances between the heater, chimney connector

and combustible materials as specifi ed by fi gures 1, 2, 3, 4.

4.

If the heater is to be located on a combustible fl oor, there must be suitable fl oor space to install a fl oor protector

beneath and extending beyond the heater as shown by fi gure 5 and as described by the Floor Protection section of

this manual.

5.

The heater should be located centrally within the area where heat is desired but out of traffi c areas to minimize the

likelihood of persons accidentally contacting the hot surface of the heater.

6.

The heater should be located away from doorways and central heat outlets and inlets to reduce the chance of drafts

blowing smoke, ashes or sparks out of the heater during refueling or ash removal.

7.

The heater should be located where a small supply of fuel may be kept conveniently close but not within 36 inches

of the heater.

8.

Locate the heater so that drapes, curtains, furniture and other combustible materials will not be closer than the clearances shown by fi gures 1, 2, 3, and 4 OR install a clearance reduction system. See MINIMUM CLEARANCES TO

COMBUSTIBLE WALLS AND CEILINGS section of this manual for details.

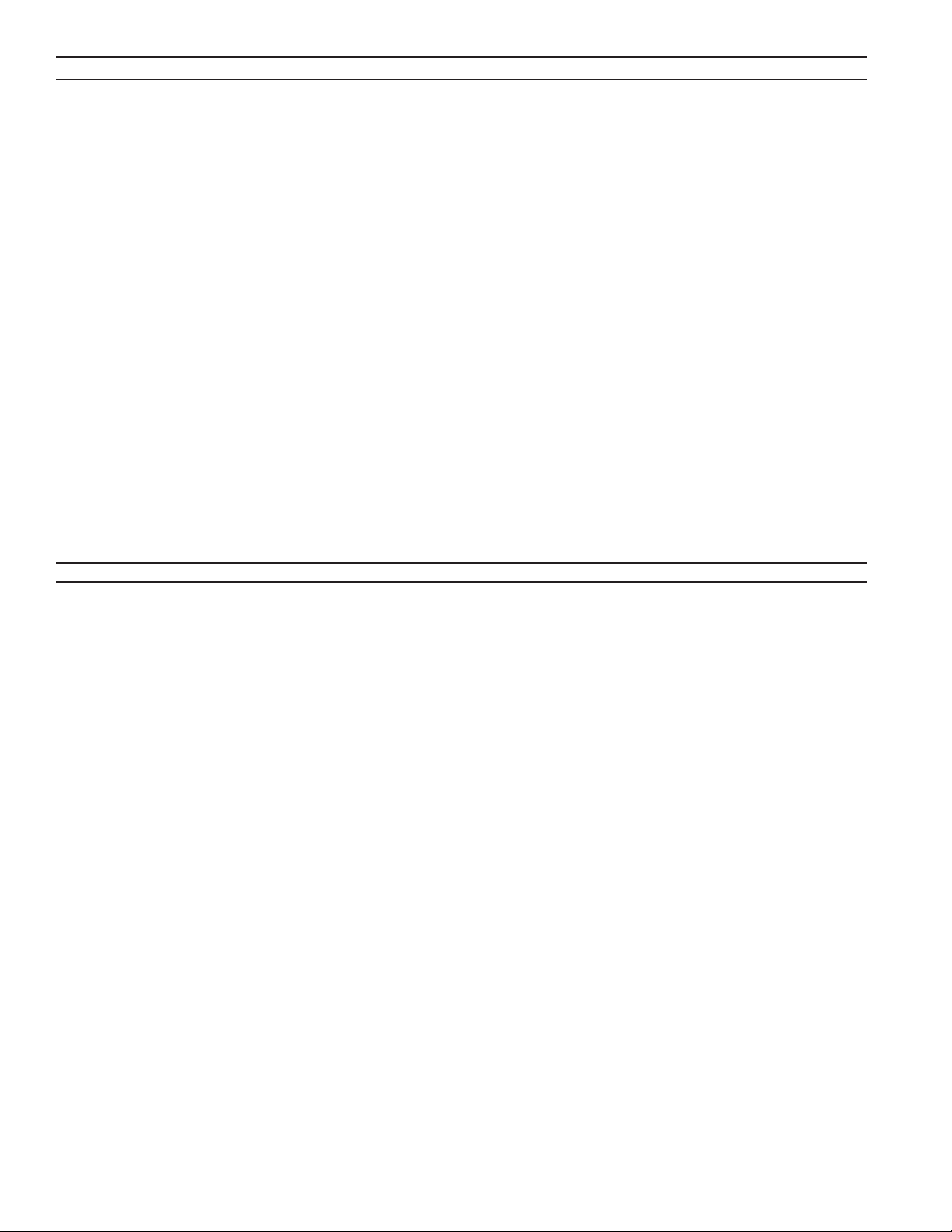

FIGURE 1 - MINIMUM CLEARANCES

TO COMBUSTIBLES

FIGURE 2 - MINIMUM CLEARANCES TO

COMBUSTIBLES

CAC 3

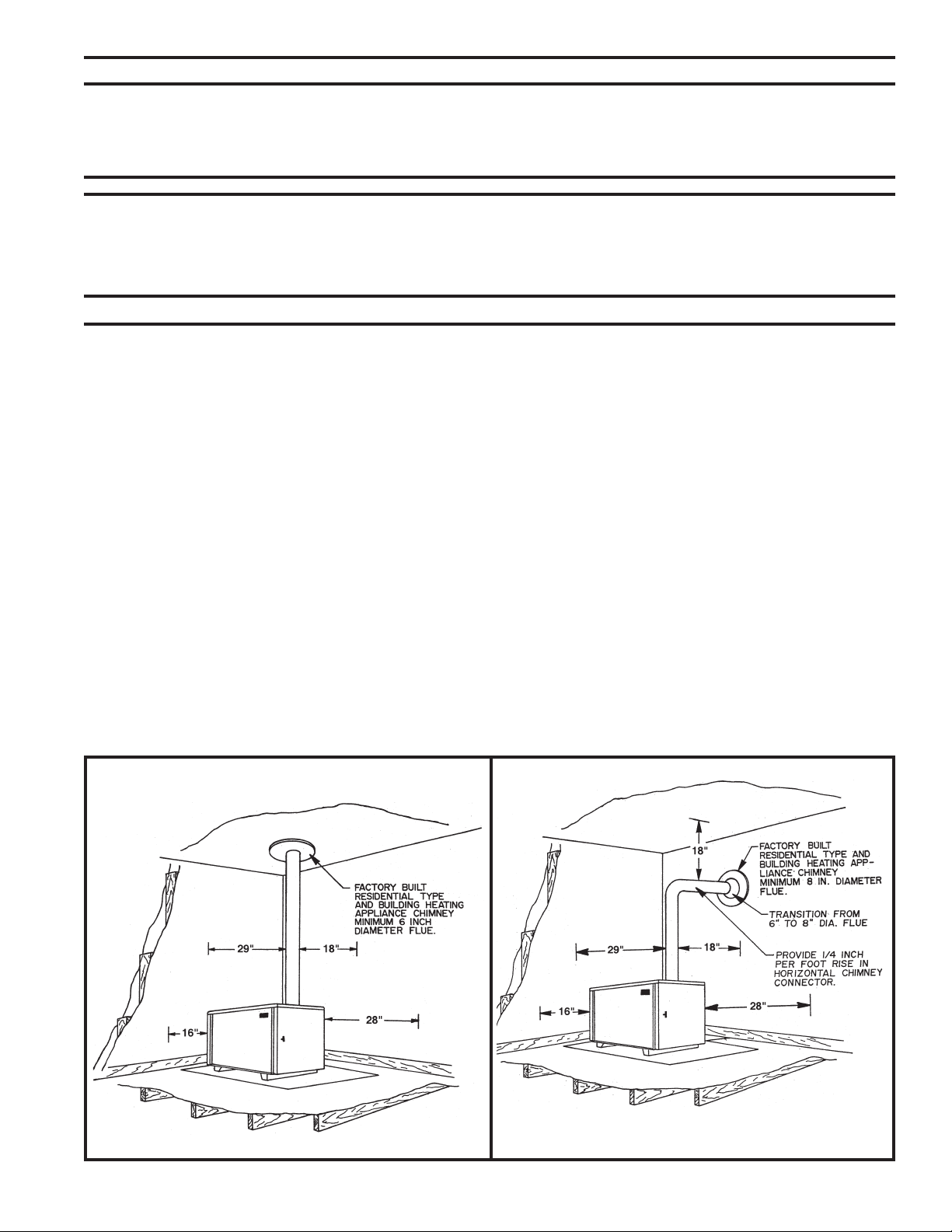

FIGURE 3 - MINIMUM CLEARANCES TO COMBUSTIBLES

SIDE SECTION VIEW

FIGURE 4 - MINIMUM CLEARANCES TO COMBUSTIBLES

PLAN SECTION VIEW

4 CAC

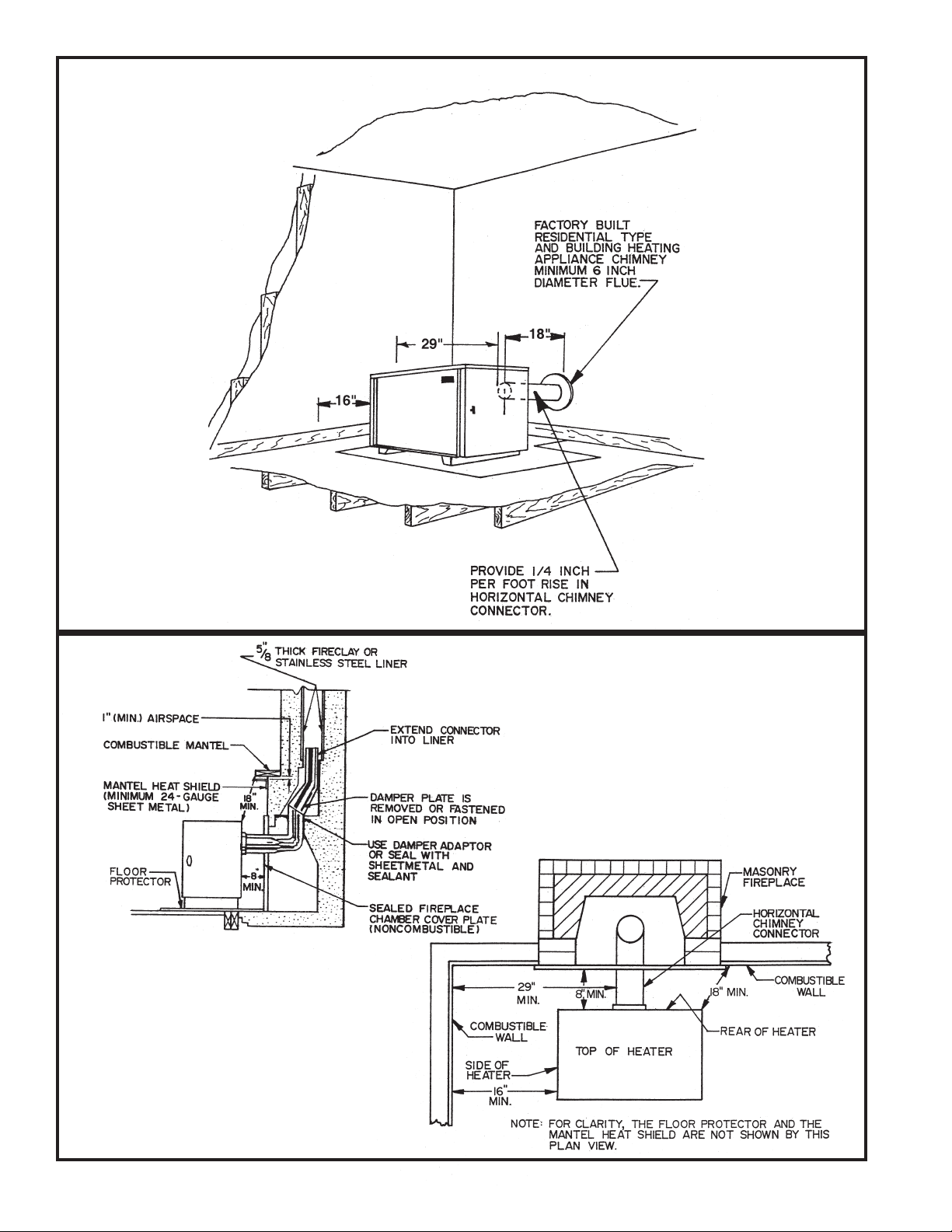

FIGURE 5 - FLOOR PROTECTION

FLOOR PROTECTION

This heater has been designed to prevent excessive temperatures on the fl oor beneath the heater. It is important, however, that a

combustible fl oor be protected by a 3/8 inch minimum thick noncombustible inorganic millboard having a thermal conductivity of k=0.43

BTU/ft.2/in./hr./°F or a listed fl oor protector beneath the heater extending beyond the heater as shown by fi gure 5. The fl oor covering

is required to prevent damage or possible ignition from sparks or glowing embers that might escape the heater during refueling or

ash removal or drop from the joints of the chimney connector.

CHIMNEY CONNECTOR AND CHIMNEYS

It is very important to assure safe and satisfactory performance from

your heater that it be properly connected to a correctly constructed

and maintained chimney. If a Listed High Temperature Type HT

Factory-Built Residential and Building Heating Appliance Chimney

is used, follow the chimney manufacturer’s installation instruc-

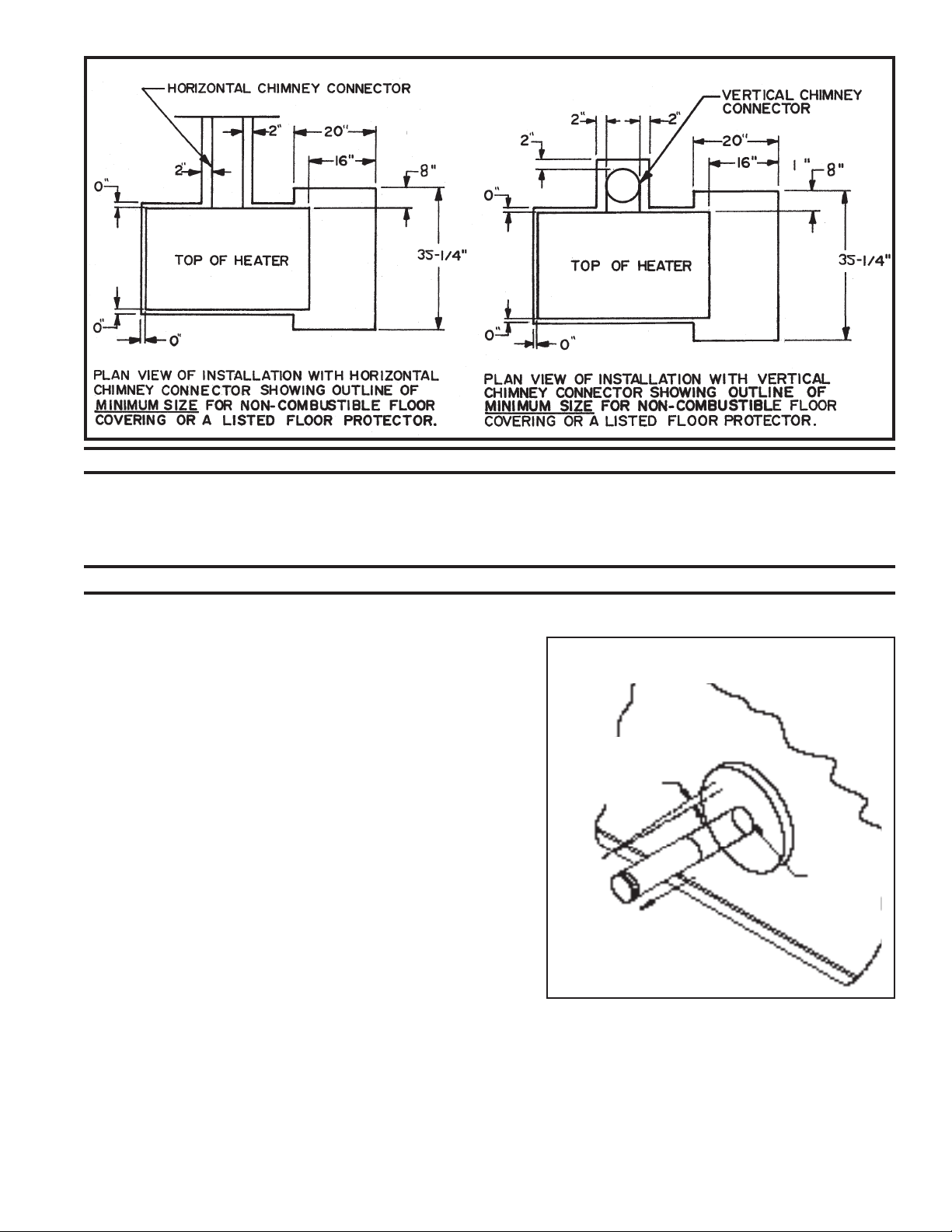

FIGURE 6 - RISE OF HORIZONTAL

CHIMNEY CONNECTOR PIPE

tions carefully. If a masonry chimney is to be used, be sure it is

constructed to the National Fire Protection Association (N.F.P.A)

and local code standards. A copy of the N.F.P.A 211 Chimney,

Fireplaces, Vents and solid Fuel Burning Appliances may be obtained from N.F.P.A., Inc. Batterymarch Park, Quincy, MA 02269.

The Chimney connector (pipe from heater to chimney) must be 6 inches

in diameter and made from 24 gauge or heavier steel. The length of the

chimney connector and number of elbows* used should be kept to a

minimum. Moisture that might collect in the chimney should be directed

to the heater by providing a slope of 1/4 inch per foot in a horizontal run

of the chimney connector and installing all pipes with the crimped end

toward the heater, (See fi gure 6). The chimney connector should extend

at least two inches into the fl ue of a factory-built chimney. When mak-

ing a horizontal connection to a masonry chimney, the connector should

extend to the inside face of the vertical fl ue liner, (see fi gures 7 and 8).

When connecting the heater to a masonry fi replace, the chimney connector

should extend into the chimney’s liner as shown by the side section view

of fi gure 4. All chimney connector joints should be sealed with furnace

cement and secured with No. 8 sheet metal screws as described by the

TO SAFELY AND PROPERLY INSTALL THIS HEATER section of this

manual. *Use Corrugated Elbows.

DO NO USE MORE THAN TWO 90 DEGREE ELBOWS IN THE Chimney CONNECTOR. Installations which require two degree

elbows must be vented into a fl ue of at least 8” diameter or 8” square to prevent chimney draft restrictions, (see fi gure 2).

DO NOT PASS A CHIMNEY CONNECTOR THROUGH A FLOOR OR CEILING OF ANY KIND. Only Listed Factory-Built Residential

Type and Building Heating Appliance Chimneys or masonry chimneys constructed to N.F.P.A. standards should pass through a fl oor

or ceiling.

RISE:

1/4” FOR EACH FOOT

OF CONNECTOR

LENGTH

PIPE ANGLE UP

HORIZONTAL

TO HEATER

TO CHIMNEY

CAC 5

There are fi ve allowable ways that a chimney connector can be connected to a masonry chimney by passing

through a combustible wall. NFPA Standard 211 allows the following wall pass-through systems.

1.

Use a minimum 3-1/2” thick brick masonry wall framed into the combustible wall. A fi reclay liner (ASTM C315 or

equivlent) having a 5/8” minimum wall thickness must be used and it must be at least 12” away from any material

that could catch fi re. The inside diameter of the fi reclay liner shall be sized for the proper snug fi t of a 6” diameter

chimney con nector pipe. The fi reclay liner shall run from the outer surface of the brick wall to, but not beyond, the

inner surface of the chimney fl ue and shall be fi rmly cemented in place. See Part A of Figure 7.

2.

Use a solid insulated listed factory-built chimney (UL 103 HT) length having an inside diameter of 6” and having 1” or

more of solid insulation. There must be at least a 9” air space between the outer wall of the chimney length and any

combustible materials. The inner end of the chimney length shall be fl ush with the inside of the masonry chimney

fl ue shall be sealed to the fl ue and to the brick masonry penetration with nonwater-soluble refractory cement. Sheet

steel supports which are at least 24 gauge(0.024”) in thickness shall be securely fastened to wall surfaces on all sides.

Fasteners between supports and the chimney length shall not penetrate the chimney liner. See Part B of Figure 7.

3.

Use a 10” diameter ventilated thimble made of at least 24 gauge(0.024”) steel having two 1” air channels. The ventilated thimble must be separated from combustible materials by a minimum of 6” glass fi ber insulation. The opening

in the combustible wall shall be covered and the thimble supported with sheet steel supports which are at least 24

gauge (0.024”) in thickness. The sheet steel supports shall be securely fastened to wall surfaces on all sides and

shall be sized to fi t and hold the chimney section. Fasteners used to secure chimney sections shall not penetrate

chimney fl ue liner. See Part C of Figure 7.

4.

Use an 8” inside diameter solid insulated listed factory-built chimney length which has 1” or more of solid insulation.

The minimum length of this chimney section shall be 12” and will serve as a pass-through for the 6” diameter chimney

connector. There must be at least a 12” air space between the outer wall of the chimney section and any combustible materials. The chimney section shall be concentric with and spaced 1” away from the chimney connector by

means of sheet steel support plates on both ends of the chimney section. The opening in the combustible wall shall

be covered and the chimney section supported on both sides with sheet steel supports which are at least 24 gauge

(0.024”) in thickness. The sheet steel supports shall be securely fastened to wall surfaces on all sides and shall be

sized to fi t and hold the chimney section. Fasteners used to secure chimney sections shall not penetrate chimney

fl ue liner. See Part C of Figure 7.

5.

A listed factory-built wall pass-through system may be purchased and installed according to the instructions packaged with it to provide a safe method of passing the chimney connector through a combustible wall for connection

to a masonry chimney.

Additional requirements pertaining to Figure 5 and the above wall pass-through systems:

Insulation material used as part of wall pass-through system shall be of noncombustible material and shall have a thermal

1.

conductivity of 1.0 Btu • in./ft.² • °F (4.88 kg • cal/hr • m² • °C) or less

All clearances and thicknesses are minimums: larger clearances and thickness are acceptable.

2.

A chimney thimble, as shown for 3” and 4” above (Parts C and D respectively of Figure 7) shall be for types “3” and “4”

3.

connections to facilitate removal of the chimney connector for cleaning. The chimney thimble shall be of ASTM C315

fi reclay with 5/8” minimum wall thickness , or material or equivalent durability. The inside diameter of the thimble shall

be sized for the proper snug fi t of a 6” diameter chimney connector pipe. The thimble shall be installed without damage

to the chimney fl ue. The thimble shall extend through the chimney wall to, but not beyond, the inner surface of the

chimney fl ue and shall be permanently cemented in place with high temperature cement.

A chimney connector to a masonry chimney, except for 2” above (Part B of Figure 7), shall extend through the wall pass-

4.

through system to the inner face of the chimney fl ue, but not beyond. It does not have to be fastened in place so long

as it cannot accidently be pulled out of the chimney or shoved into the chimney fl ue. If fasteners are used to secure the

chimney connector to a masonry chimney, the fasteners shall not penetrate the chimney fl ue liner.

Any material used to close up any opening for the connector shall be noncombustible.

5.

If the chimney connector does not have to pass through a combustible wall to get to a masonry chimney, connect the chimney

connector to the masonry chimney as shown in fi gure 8. The fi reclay liner shown by fi gure 8 should be sized for the proper

snug fi t of a 6” diameter chimney connector pipe. The fi reclay liner should be fi rmly cemented in place as shown. As previ-

ously stated, any metal prefabricated chimney this heater is connected to must be a listed Hi-Temp Type HT Factory Built

Residential Type and Building Heating Appliance Chimney.

When a metal prefabricated chimney is used, the manufacturer’s installation instructions must be followed precisely. You

must also purchase (from the same manufacturer) and install the ceiling support packageor wall pass through and “T” section

package, fi restops (when needed), insulation shield, roof fl ashing, chimney cap, etc. Maintain the proper clearance to the

structure as recommended by the manufacturer. This clearance is usually a minimum of 2 inches, although it may vary by

manufacturer or for certain components.

A listed chimney cap should be installed to prevent entrance of rain and help elimnate down drafts. An unapproved chimney

cap, protector or spark arrester can become clogged when leaves or other matter. This blocks the chimney and causes smoke,

and the dangerous carbon monoxide in smoke, to spill back into your home where it can kill you.

6 CAC

Loading...

Loading...