United States Stove 8500 User Manual

UNITED STATES STOVE COMPANY

“Keeping North America Warm Since 1869”

MULTI-FUEL FURNACE MODEL SP8500

US and Canadian use.

Approved for

Safety tested and listed to UL

391-2010, ASTM E1509-04,

and CSA-B366.1-11

C

ertifi ed for installation in a

residential or mobile home as a

stand-alone or add-on furnace

(ductwork connection only).

TESTED &

LISTED BY

Report #: 215-S-22b-2

PORTLAND,

OREGON, USA

Owner’s Manual

Please read this entire manual before installation and use of this appliance. Failure to follow

these instructions could result in property damage, bodily injury, or even death.

Contact your local building or fi re offi cials about restrictions and installation inspection

requirements in your area.

SAVE THESE INSTRUCTIONS.

French version is available for download from the U. S. Stove website: http://www.Breckwell.com/

UNITED STATES STOVE COMPANY • 227 INDUSTRIAL PARK ROAD • SOUTH PITTSBURG, TENNESSEE 37380 • WWW.USSTOVE.COM

FOR TECHNICAL ASSISTANCE: PHONE: (800) 750-2723 FAX: (423) 837-2109

USSC 1

Part No.: 851976 B

Table of Contents

TABLE OF CONTENTS .............................................................................................. 2

SAFETY PRECAUTIONS ........................................................................................... 3

SPECIFICATIONS .......................................................................................................4

Heating Specifi cations .....................................................................................4

Dimensions ...................................................................................................... 4

Electrical Specifi cations ................................................................................... 4

Safety and EPA Compliance ............................................................................4

Fuel Considerations .........................................................................................5

INSTALLATION .......................................................................................................... 5

Installation Options .......................................................................................... 6

Floor Protection ...............................................................................................6

Clearances ...................................................................................................... 7

Venting Requirements ..................................................................................... 8

Maximum Venting Distance ............................................................................. 8

Pellet Vent Type ............................................................................................... 8

Pellet Vent Installation ..................................................................................... 8

Pellet Vent Termination .................................................................................... 8

Vent Termination Clearances ...........................................................................9

Through the Wall Installation ......................................................................... 10

Through the Roof/Ceiling Installation............................................................. 10

Primary and Secondary Furnace Illustrations ................................................ 11

OPERATION ............................................................................................................. 12

How Your Furnace Works .............................................................................. 12

Damper Control Adjustment ........................................................................... 12

Control Panel ................................................................................................. 13

Unit Preparation ............................................................................................. 14

Start-Up Procedure ........................................................................................ 14

Shut Down Procedure .................................................................................... 14

Daily Operation .............................................................................................. 15

Safety and Convenience Features ................................................................15

MAINTENANCE ........................................................................................................ 15

Exhaust System ............................................................................................. 15

Interior Chambers .......................................................................................... 16

Ash Disposal .................................................................................................. 16

Hopper Cleaning ............................................................................................ 16

Main Door Gaskets ........................................................................................ 16

Fan Motors ..................................................................................................... 16

Painted Surfaces ........................................................................................... 16

Glass .............................................................................................................. 16

Fall Start-Up ................................................................................................... 16

Spring Shut Down ..........................................................................................16

Yearly Servicing ............................................................................................. 16

REPAIR PARTS DIAGRAM & LIST .....................................................................17-18

WIRING DIAGRAM ................................................................................................... 19

TROUBLE SHOOTING ............................................................................................. 20

ERROR CODES ........................................................................................................21

FLASHING INDICATORS ......................................................................................... 21

NOTES .................................................................................................................22-23

2 USSC

Safety Precautions

IMPORTANT: Read this entire manual before installing

and operating this product. Failure to do so may

result in property damage, bodily injury, or even death.

Proper installation of this furnace is crucial for safe and

effi cient operation.

Contact your local building officials to obtain a

permit and information on any additional installation

restrictions or inspection requirements in your area.

DO NOT throw this manual away. This manual has

important operation and maintenance instructions

that you will need at a later time. Always follow the

instructions in this manual.

Never try to repair or replace any part of the furnace

unless instructions for doing so are given in this

manual. All other work should be done by a trained

technician.

Install appliance and venting at clearances specifi ed

in this manual.

DO NOT connect the pellet exhaust vent to a vent

serving any other appliance or furnace.

DO NOT install a fl ue damper in the exhaust venting

system of this unit.

Use of outside air is not required for this unit, but

is highly recommended. If installed into a tightly

constructed home, (Mobile Home) a fresh air opening

of at least 2 in. diameter (150mm) into the room where

the unit is installed is required. However return air

make-up is required for maximum heat distribution

throughout your home.

This heater is designed and approved as a multi-fuel

(corn or wood pellets) furnace. Use only dried shelled

corn with a moisture content of 11% or less (which

provides the best results). Pellet fuel used should have

an ash content of 1% or less. If not, performance and

effi ciency of the unit will suffer, and your warranty may

be voided.

Never use gasoline, gasoline-type lantern fuel,

kerosene, charcoal lighter fl uid, or similar liquids to

start or ’freshen up’ a fi re in this furnace. Keep all such

liquids well away from the furnace while it is in use.

A working smoke detector must be installed in the same

room as this product.

DO NOT unplug the furnace if you suspect a

malfunction. Turn the ON/OFF SWITCH to ”OFF’ and

contact your dealer.

Your furnace requires periodic maintenance and

cleaning (see ”MAINTENANCE ”). Failure to maintain

your furnace may lead to improper and/or unsafe

operation.

DANGER: Risk of Fire or Explosion - DO NOT BURN

GARBAGE, GASOLINE, NAPTHA, ENGINE OIL, OR

OTHER INAPPROPRIATE MATERIALS.

USSC 3

Disconnect the power cord before performing any

maintenance! NOTE: Turning the ON/OFF Switch to

”OFF” does not disconnect all power to the electrical

components of the furnace.

Allow the furnace to cool before performing any

maintenance or cleaning. Ashes must be disposed

of in a steel container with a tight fi tting lid. The

closed container of ashes should be placed on a noncombustible surface or on the ground, well away from

all combustible materials, pending fi nal disposal.

The exhaust system should be checked monthly during

the burning season for any build-up of soot or creosote.

Creosote in your exhaust can potentially cause a

chimney fi re. In the event of a chimney fi re, contact

your fi re department immediately and press the “OFF”

button on your furnace. Have a clearly understood plan

to handle a chimney fi re.

CAUTION: Keep children away. Do not touch during

operation. Educate all children on the dangers of a

high-temperature furnace. Young children should be

supervised when they are in the same room as the

furnace.

A power surge protector is recommended. This unit

must be plugged into a 110 - 120V, 60 Hz grounded

electrical outlet. Do not use an adapter plug or sever

the grounding plug. Do not route the electrical cord

underneath, in front of, or over the furnace. Do not

route the cord in foot traffi c areas or pinch the cord

under furniture.

The furnace will not operate during a power outage.

If a power outage does occur, check the furnace for

smoke spillage and open a window if any smoke spills

into the room.

The feed door and ash pan must be closed and sealed

during operation to keep products of combustion from

escaping the furnace. Keep all seals in good condition.

Never block free fl ow of air through the open vents

of the unit.

Keep foreign objects out of the hopper.

The moving parts of this furnace are propelled by high

torque electric motors. Keep all body parts away from

the auger while the furnace is plugged into an electrical

outlet. These moving parts may begin to move at any

time while the furnace is plugged in.

Do not place clothing or other fl ammable items on or

near this furnace.

This appliance is not intended for commercial use.

WARNING: DO NOT INSTALL IN SLEEPING ROOM.

CAUTION: THE STRUCTURAL INTEGRITY OF

THE MANUFACTURED HOME FLOOR, WALL, AND

CEILING/ROOF MUST BE MAINTAINED.

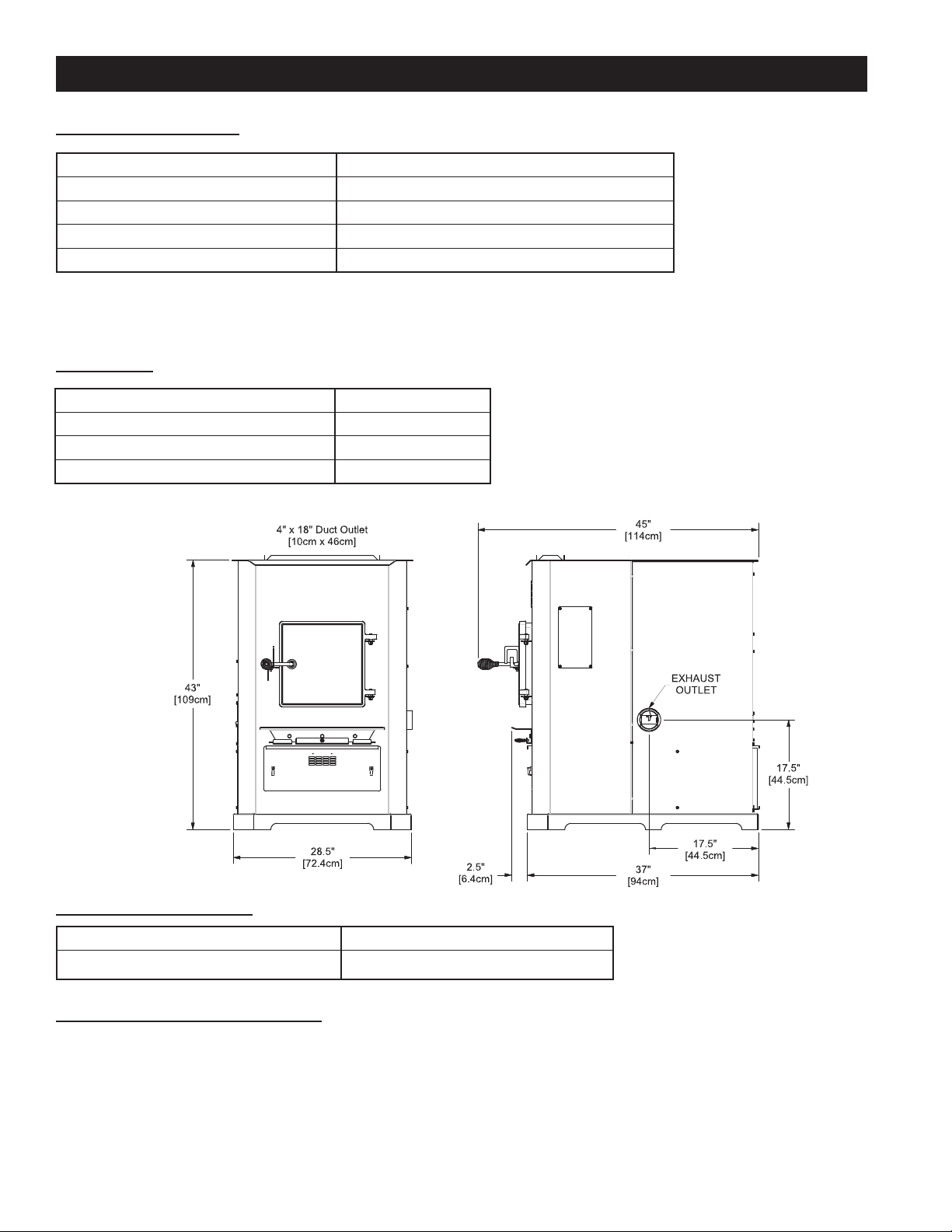

Heating Specifi cations

Speci cations

Input BTU/Hr

Heating Capacity

Fuel Burn Rate

1

2

3

50,000 to 105,000 BTU/hr.

1,200 - 2,800 sq. ft.

5.0 - 13.0 lbs./hr.

Burn Time (lowest setting) 70 hours continuous

Hopper Capacity 160 lbs

1

BTU output will vary depending on the quality and type of fuel. Use PFI listed fuels for the best results.

2

Heating capacity will vary depending on fl oor plan layout of your home, degree of insulation, and the outside temperature.

3

Fuel size may effect the actual rate of fuel feed and burn times. Fuel feed rates may vary by as much as 20%. Use PFI listed fuel for best results.

Dimensions

Height 43 in. [109cm]

Width 28-1/2 in. [72.4cm]

Depth 45 in. [114cm]

Weight 250 lbs.

Electrical Specifi cations

Electrical Rating

Watts (operational)

110-120 volts, 60 HZ, 9.5 Amps

1150 (max. approx.)

SAFETY AND EPA COMPLIANCE

Your Breckwell Furnace has been safety tested and listed to UL 391-2010, ASTM E1509-04, and CSA-B366.1-11, by

OMNI-Test Laboratories, Inc. Portland, Oregon USA. It is also exempt from EPA Phase II requirements.

4 USSC

Fuel Considerations

SHELLED CORN (Dry, preferably corn with 11% or less moisture content)

Optimum moisture content of corn should be 11% or less. Wet corn will rapidly deteriorate furnace components,

•

reduce effi ciency and void all warranties. Purchase a moisture tester if in doubt.

Corn must be clean and free from debris. Never burn corn right from the fi eld. Damage caused by dirty corn is not

•

covered by the product warranty. Ask for clean fi ltered, bagged corn only. Stalk parts, excessive fi nes and cob

remnants will clog the auger.

NEVER BURN SEED CORN IN YOUR FURNACE. Seed corn is treated with chemical pesticides that are harmful

•

or fatal if swallowed, therefore, seed corn is dangerous to have in the house, especially where children can reach it.

Never burn “Deer Corn.” It frequently contains molasses/sugars.

•

Store your corn supply in a dry place and keep bags or container sealed to prevent your corn from absorbing excess

•

moisture. Test the moisture content periodically to ensure proper dryness.

There are many varieties of corn grown around the world. Each variety has unique characteristics including the

•

shape and size of the kernel. Your furnace will burn more consistently with a small to midsize kernel corn. If the

kernel size of the corn varies greatly or if you switch sources frequently, you will get a less consistent burn. Therefore, purchasing corn from the same source will help achieve a more consistent burn. DO NOT USE CORN WITH

A HIGH WAX CONTENT!

Oyster shell is highly recommended for best burn operations and to reduce clinker build-up

•

WOOD PELLETS

As with corn, be consistent with your pellet supplier. Pellets will vary in content and burn characteristics from sup-

•

plier to supplier. A consistent supply of pellets will result in a more consistent and effi cient burn.

Check your pellets for foreign objects. Your furnace warranty will not cover damage done to your furnace due to

•

foreign objects in the fuel supply.

Store your pellets in a dry place to prevent them from absorbing added moisture.

•

To decrease sawdust buildup, the hopper will need to be vacuumed out after every 6-8 bags of pellets or more often

•

if the pellets are poor quality. You may have to screen-sift each bag of pellets if sawdust becomes a problem.

Wood Pellets vary in size and ash content from less than 1% to 3% or more. Your furnace will burn more effi ciently

•

with small to midsize pellets. Low ash content pellets will allow you to burn the furnace longer between cleanings.

Only wood pellets manufactured to the Pellet Fuel Industries (P.F.I.) standard for residential pellet fuels are recommended. Performance will suffer if nonstandard pellets are used. Consult your local Breckwell reseller for more

information on approved wood pellet fuel.

If fans are used in the fuel storage area, they should be installed so as not to create a negative pressure in the room

where your furnace is located.

CAUTION: DO NOT PLACE SUCH FUELS WITHIN THE SPACE HEATER’S INSTALLATION

CLEARANCES OR WITHIN THE SPACE REQUIRED FOR REFUELING AND ASH REMOVAL.

USSC 5

Installation

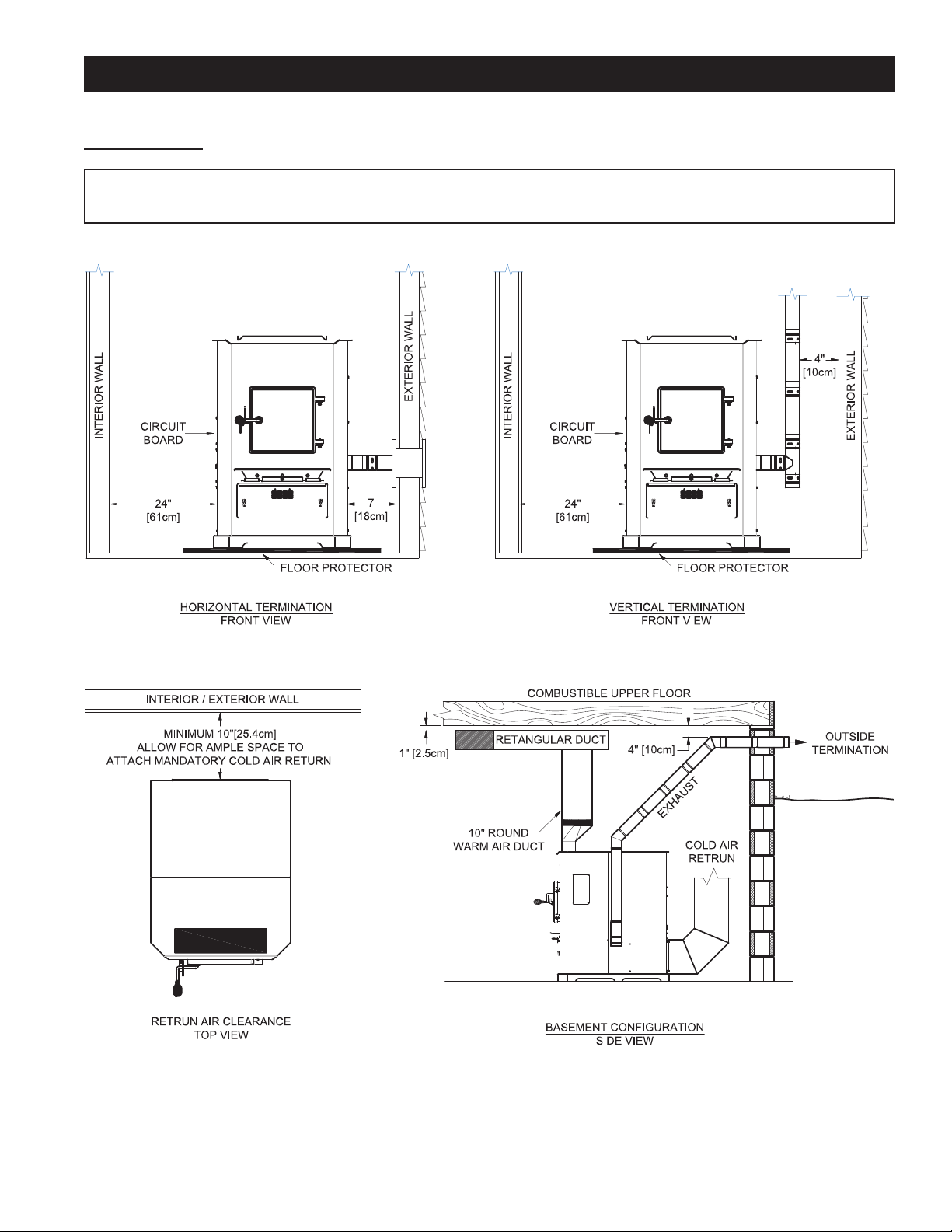

INSTALLATION OPTIONS

Read this entire manual before you install and use your Multi-Fuel Furnace. Failure to follow instructions

may result in property damage, bodily injury, or even death!

(See specifi c installation details for clearances and other installation requirements)

Certifi ed for installation in a Residentail Type home in the USA and Canada. Also may be installed into a Manufactured

or Mobile Home.

As a Primary Furnace—the unit functions independently of any other system. The “Room Air” blowers will come on

when the plenum and exhaust temperatures reach a preset point programmed into the furnace’s circuit board (PCB). Unit

may also be used as a stand-alone shop heater. This is the only approved installation confi guration in which ductwork

or return air is not required. All other confi gurations utilizing a ductwork system must supply return air to the appliance.

As a Secondary (Add-On) Furnace—the unit aids an existing gas/electric furnace helping cut down on operation time.

It is recommended that only a authorized technician install your Multi-Fuel Furnace, preferably an NFI certifi ed specialist.

Canada requires that the installation of the pellet-fuel furnace shall comply with the applicable requirements of CSA-B365.

IMPROPER INSTALLATION: The manufacturer will not be held responsible for damage caused by the mal-

function of a furnace due to improper venting or installation. Call (800) 750-2723 and/or consult a professional

installer if you have any questions.

ADDITIONAL ITEMS REQUIRED FOR INSTALLATION

• UL listed 3 inch or 4 inch (Depending on application) “PL” pellet venting exhaust system.

• Air distribution duct work. Transition from 4.5 inch x 18.5 inch rectangle to 10 inch round is provided.

• Air fi lter (Optional). Size: 10 x 20 x 1

• Floor Protection (If not installed on a non-combustible fl oor)

• Fresh air for combustion: 2 inches[5cm] diameter - If installed in a manufactured / mobile home or located in a small,

tightly constructed room.

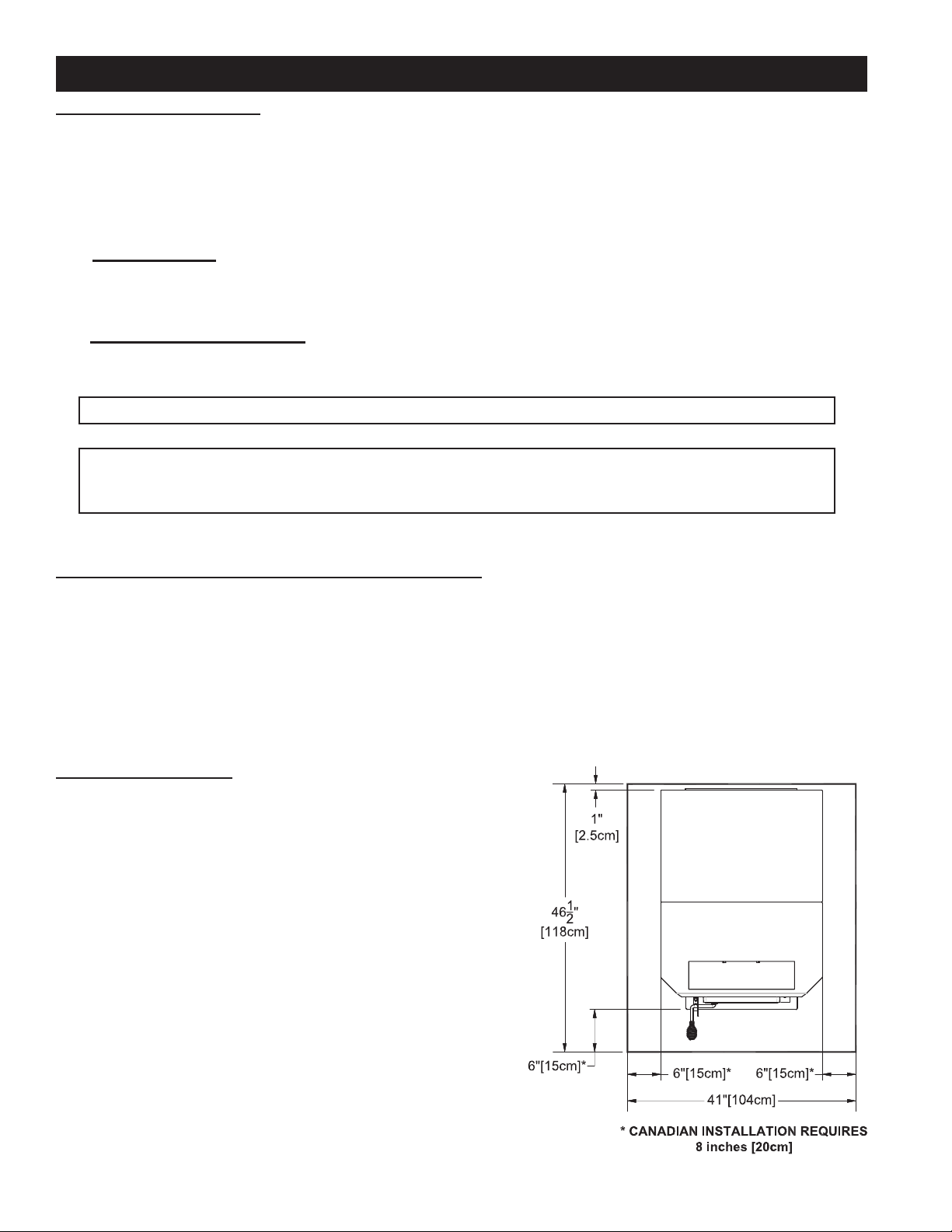

FLOOR PROTECTION

This unit must be installed on a non-combustible fl oor surface. If a

fl oor pad is used, it should be UL listed or equal. The fl oor pad or

non-combustible surface should be large enough to extend a minimum

of 6-inches in front, 6-inches on each side, and 1-inch behind the

furnace for horizontal termination.

Floor protection must extend under and 2-inches to each side of the

chimney tee for an interior vertical termination.

A 1 inch thick Floor Protector is recommended with installation.

6 USSC

Installation

CLEARANCES

NOTE: Distance on the left-hand side of your Multi-Fuel Furnace is set at 24 inches for suitable access to

the control panel and for fuel loading. This distance may be less, but not less than 7 inches.

USSC 7

Installation

VENTING REQUIREMENTS

Install vent at clearances specifi ed by the vent manufacturer.

Do not connect the pellet vent to a vent serving any other appliance or furnace.

Do not install a fl ue damper in the exhaust venting system of this unit.

INSPECT EXHAUST VENTING (joints, seals, etc.) REGULARLY TO ENSURE THAT SMOKE AND FLUE GASES

ARE NOT DRAWN INTO AND CIRCULATED BY THE AIR CIRCULATION SYSTEM.

The following installation guidelines must be followed to ensure conformity with both the safety listing of this furnace

and to local building codes.

IMPORTANT! This unit is equipped with a negative draft system that pulls through the burn pot and pushes

the exhaust out of the dwelling. If this unit is connected to a fl ue system other than the way explained in this

manual, it will not function properly.

MAXIMUM VENTING DISTANCE

Installation MUST include at least 3-feet of vertical pipe. This will create a natural draft to reduce the possibility of smoke

or odor escaping during appliance shutdown and keep exhaust from causing a nuisance or hazard by exposing people

or shrubs to high temperatures. The maximum recommend vertical venting height is 12-feet for 3-inch type “PL” vent.

Total length of horizontal vent MUST NOT exceed 4-feet (this does not include the clean-out tee). Use no more than 180

degrees of elbows (two 90-degree elbows, or two 45-degree and one 90-degree elbow, etc.) to maintain adequate draft.

PELLET VENT TYPE

A UL listed 3-inch or 4-inch type “PL” pellet vent exhaust system must be used for installation and attached to the pipe

connector provided on the back of the furnace (use a 3-inch to 4-inch adapter for 4-inch pipe). Use 4-inch vent if the

vent height is over 12-feet or if the installation is over 2,500 feet above sea level.

We recommend the use of Simpson Dura-Vent® or Metal-Fab® pipe (if you use other pipe, consult your local building

codes and/or building inspectors). Do not use Type-B Gas Vent pipe or galvanized pipe with this unit. The pellet vent

pipe is designed to be disassembled for cleaning and should be checked several times during the burning season. Pellet

vent pipe is not furnished with the unit and must be purchased separately.

PELLET VENT INSTALLATION

The installation must include a clean-out tee to enable collection of fl y ash and to permit periodic cleaning of the exhaust

system. 90-degree elbows accumulate fl y ash and soot thereby reducing exhaust fl ow and performance of the furnace.

Each elbow or tee reduces draft potential by 30% to 50%.

All joints in the vent system must be fastened by at least 3 screws, and all joints must be sealed with HI-TEMP RTV

silicone sealant to be airtight. The area where the vent pipe penetrates to the exterior of the home must be sealed with

silicone or other means to maintain the vapor barrier between the exterior and the interior of the home.

Vent surfaces can get hot enough to cause burns if touched by children. Noncombustible shielding or guards may be

required.

PELLET VENT TERMINATION

Do not terminate the vent in an enclosed or semi-enclosed area, such as; carport, garage, attic, crawl space, under a

sun deck or porch, narrow walkway, or any other location that can build up a concentration of fumes.

The termination must exist above the outside air inlet elevation.

The termination must not be located where it could become plugged by snow or other materials.

8 USSC

Loading...

Loading...