United States Stove 24AF, 24AG, 24AZ User Manual

Wood & Coal Burning Furnace

Owners Manual

Models: 24AF, 24AG, 24AZ

TESTED TO UL 391

All installations must be made in accordance with local and state codes

which may differ from this manual.

UNITED STATES STOVE COMPANY

227 Industrial Park Road

P.O. Box 151

South Pittsburg, TN 37380

USSC Page 1851224C

R

US

CHIMNEY INSTALLATION

Your new furnace must be installed into a "Class A" Chimney only.

This type of chimney consists of a flue lined brick chimney, or an

approved "Class A" all fuel factory built (prefabricated) type. Any

other installation guarantees an immediate fire hazard.

Do not install the furnace into the same chimney serving other appliances.

When using 8" flue pipe, the chimney should have an 8" to 10" round

flue liner or 9"x9" square liner.

The chimney should have a minimum height of 3' from the top of the

chimney to the point at which it passes through the roof.

The top of the chimney must be at least 2' higher than the peak or the

highest portion of the roof within 10' horizontally.

A chimney that rises within the house is better insulated than a chimney that is located outside the house and exposed to the weather, the

north side of the house is the worst position.

Check manual for proper installation of flue pipe into chimney.

FURNACE INSTALLATION

Install your furnace as close to the chimney as possible with a minimum

of elbows, no more than two and a flue pipe run of no more than 6 feet

horizontally. Also, the flue pipe should contain a 1/2" rise per foot and

NEVER be installed closer than 18" from combustibles.

WOOD BURNING: Install a manual flue pipe draft damper at a safe,

convenient location between your furnace and chimney.

COAL BURNING: Install a barometric damper set at .05 Water Column.

AIR FLOW: Solid Fuel furnaces produce much hotter air than oil or gas

fired appliances so all clearances are mandatory.

AIR DUCT INSTALLATION: This furnace provides a 12" round (113 sq.

in.) opening, because of efficiency and general convenience.

United States Stove Company recommends a Parallel Furnace Installation with direct (ducted) feed or return air to your furnace. NOTE:

Cold air duct intake must be at least 25% larger than hot air duct

outlet.

FURNACE ASSEMBLY

U.S. Stove provides easy step by step pictures, therefore, the furnace assembly procedure should be understandable.

FIRING YOUR FURNACE

Start on a conservative basis. Your new furnace, when properly fired

with hard dry wood will achieve approximately 6 to 8 hours of burn time

per load of wood, much longer with coal. If the furnace is being fired

hot constantly with full flames and only provides a 3 hour burn cycle,

the furnace is being overfired. Possibly your heating requirements are

too much for the size of furnace purchased. Certainly allowing your

existing furnace to assist in extremely cold weather is no crime. Remember, your furnace can be damaged if fired continually at extremely

high temperatures and this procedure will void your warranty.

CAUTION: OVERFIRING YOUR

FURNACE VOIDS WARRANTY.

Page 2 USSC

OVER FIRING

This generally occurs when the following procedures are not followed, ash door is open (even partially open), the feed door pressure

relief flap is open, the feed door is open or the manual draft spinner

is open. Open the ash and feed doors only when in attendance,

never leave the furnace unattended when doors are open. This

furnace has an automatic draft fan so use the manual draft with a

specific purpose. Also, an overfilled ash drawer can cause grate

warpage, keep ash drawer clean. Don't use furnace if distribution

fan isn't functioning properly, and keep air filter clean. Draft fan

opening should be set at 1/2" open as a point of start, depending on

condition of fuel.

U. S. Stove recommends a very active fire at all times for

maximum results, but only as instructed.

SOME HELPFUL HINTS

•Your furnace will hold logs approximately 2" shorter than the length

of the firebox. Don't force in oversized logs.

•Unsplit, dry logs will provide longer burn time than split logs.

•Don't ever try to burn trash or garbage.

•Keep flue pipe stack temperature between 300 and 400 degrees.

This will reduce creosote build-up. A magnetic surface thermometer

can be obtained from your dealer.

•Weather is the most important determinant in how you operate your

furnace (assuming you have dry wood).

•The colder it is the stronger the draft, warm weather reduces draft.

Set your draft fan rheostat and manual draft accordingly.

•Open manual smoke damper only when starting the fire and when

chimney draft is marginal.

•Always place logs so air can flow between them.

•Shake gently (up to 10 o'clock down to 8 o'clock) don't try to loose

weight shaking down ashes!

•Wood ash is useful as a fertilizer because it contains potassium,

ashes also decrease the acidity of the soil. Coal ashes will provide

good traction on ice or snow, otherwise they are useless.

•Always store ashes in a metal container with a lid.

•Ashes are a good thermal insulator and will keep enough oxygen

away so embers will not burn out.

•Never, never let ashes accumulate up to grate level, this will greatly

reduce the life span of your grate.

•Coal produces much more ash than wood.

•Keep your chimney and flue pipe clean, check monthly.

•Smoke detectors and fire extinguishers should always be a part of

your equipment.

•Never use chemicals or fluids such as gasoline, charcoal lighter, drain

oil or kerosene to light a fire.

•Oil the air fan motors yearly. They do not contain bearings, sleeves

with felt. Therefore keeping fan air clean is more important than

oiling.

•Turn on your regular furnace once every month to keep it tuned up.

•Always shut the furnace down gradually to prevent excessive stress

on steel.

WARPAGE OF STEEL IS COMMON, AGGRESSIVE BUT GENTLE

FIRING CAN MINIMIZE WARPAGE.

•There is no substitute for dry hard wood. Wood requires 6 months

to a year to air dry to 25% moisture content or less.

•Don't throw heavy, wet wood into your Jensen, it could crack the

firebox and bricks.

•Treat your furnace with the proper respect and it will reward you

with much comfort, and a lifetime of central heat.

Welcome...

...to the world of solid fuel heating! Your new furnace has been designed and built

with a high grade of materials and the strictest regard to quality.

Before you start installing your new furnace, take the time to read these installation

and operating instructions. We have prepared them for your benefit to save time and

provide some helpful knowledge on wood and coal burning.

Save the instructions for future use. It won't take long for you to realize the benefit of

solid fuel heating, however, maintenance is the key to a long lasting relationship with

your new furnace. These instructions can help you now as well as in the future.

Note: This owners manual is provided for Forced Air add on furnaces. United States

Stove Company is constantly developing and improving its product line, therefore, we

reserve the right to change specifications without notice.

Table Of Contents

General Rules ..............................................................................................................................................................................4

How It Works ...............................................................................................................................................................................5

Parts List .................................................................................................................................................................................. 6-7

Installation Instructions ........................................................................................................................................................ 8-11

Assembly ..............................................................................................................................................................................12-16

Accessories ................................................................................................................................................................................17

Wiring ................................................................................................................................................................................... 18-23

Trouble Shooting .......................................................................................................................................................................24

Notes .................................................................................................................................................................................... 25-26

Warranty ....................................................................................................................................................................................27

How To Order Repair Parts ......................................................................................................................................................28

USSC Page 3

General Rules

Rules for the Safe Installation and Operation of Your

Furnace...

Check local codes, the installation must comply with strict

conformance in regard to clearances.

The Furnace must be installed on a noncombustible floor.

Connect the furnace to tile lined inside masonry chimney or

approved insulated all fuel prefabricated chimney only.

Keep smoke pipe connection as short as possible, using a

minimum 24 gauge pipe with a minimum 1/2" per foot rise

from the flue collar to the chimney opening.

Be sure there is a sufficient supply of combustion

air to the area where the furnace is to be located.

Do not over draft the furnace! It is designed to operate at

.04 to .06 inches of water column and must be set with a

draft gauge to maintain a steady draft.

Do not use flammable liquids for starting a fire.

Do not store fuel or combustibles near the furnace. Some

areas of the furnace are hot and could cause an explosion

and possible bodily or property damage.

Store all ashes in a metal container with a tight sealing lid

and allow ashes to cool before disposing of them, possibly

a week.

In the event of a chimney fire call the fire department, then be sure the furnace doors are closed

tightly and the power to the unit is turned off.

The furnace is designed to burn air dried wood and coal at

a predetermined firing rate. Over firing could result in damage to the heat exchanger and cause dangerous operation. Over firing occurs when the ash door is left open

during operation or a highly volatile fuel, such as large

amounts of small kindling, is used. Note: This action voids

all warranty.

Follow a regular service and maintenance schedule of the

furnace and chimney for efficient and safe operation.

Do not leave the ash door open when the fire is burning.

Do not let ashes build up closer than 2" to the grate.

With new steel, there is a small amount of oil or dirt on the

metal. You may smell an odor. This is normal during the

first operation. You should assemble the furnace out of

doors and build a small fire in it to "burn off" this dirt and

oil before installing the unit.

During the first few fires, heat may slightly warp

the front and back panels. This is normal and will

not hamper your unit's operation.

Familiarize yourself with the furnace's solid fuel burning

characteristics before leaving unit unattended for long periods of time.

The loading door and ash door must be tightly closed during furnace operation to insure safety and efficiency.

CAUTION The furnace has hot surfaces. Keep Children Away.

Do not touch during operation.

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE.

BURN WOOD OR COAL ONLY IN MODEL 24AF. DO NOT

MIX OTHER THAN THE USE OF WOOD TO START A COAL

FIRE.

DANGER - Risk of Fire or Explosion: Do not burn garbage, gasoline, drain oil or other flammable liquids.

WARNING - Risk of Fire:

Do not operate with flue draft exceeding 6 inches

water column.

Do not operate with fuel loading or ash removal

doors open.

Do not store fuel or other combustible material

within marked installation clearances.

Inspect and clean flues and chimney regularly.

This Furnace Must Be Installed By A Qualified Installer.

Page 4 USSC

How...

How Your New Furnace Works

Unlike conventional heating (gas, oil, electric), wood or coal

heating requires more user attention. Your furnace, with

its automatic combustion air blower, alleviates the constant

need for adjusting the burning rate common to other units

on the market. The fire, however, must be started and

subsequent fuel added by the user.

Conventional heating system produce heat only when the

thermostat calls for heat. This way of heating is inefficient

and often leaves part of the home either too hot or too

cold. Your furnace is designed to deliver heat as long as

there is a fire in it. The fire intensity is regulated by the

room thermostat, high or low, the fire continues to produce heat. This heat is continuously distributed throughout

the home by a distribution blower. This constant supply of

heat is uniform and prevents drafts.

WARNING

Note: Improper firing. Wood or coal over firing occurs when the ash door is left open during operation

or a highly volatile fuel is used. Coal that exceeds the

fire brick line will cause overfiring...this type of operation will immediately void any warranty.

USSC Page 5

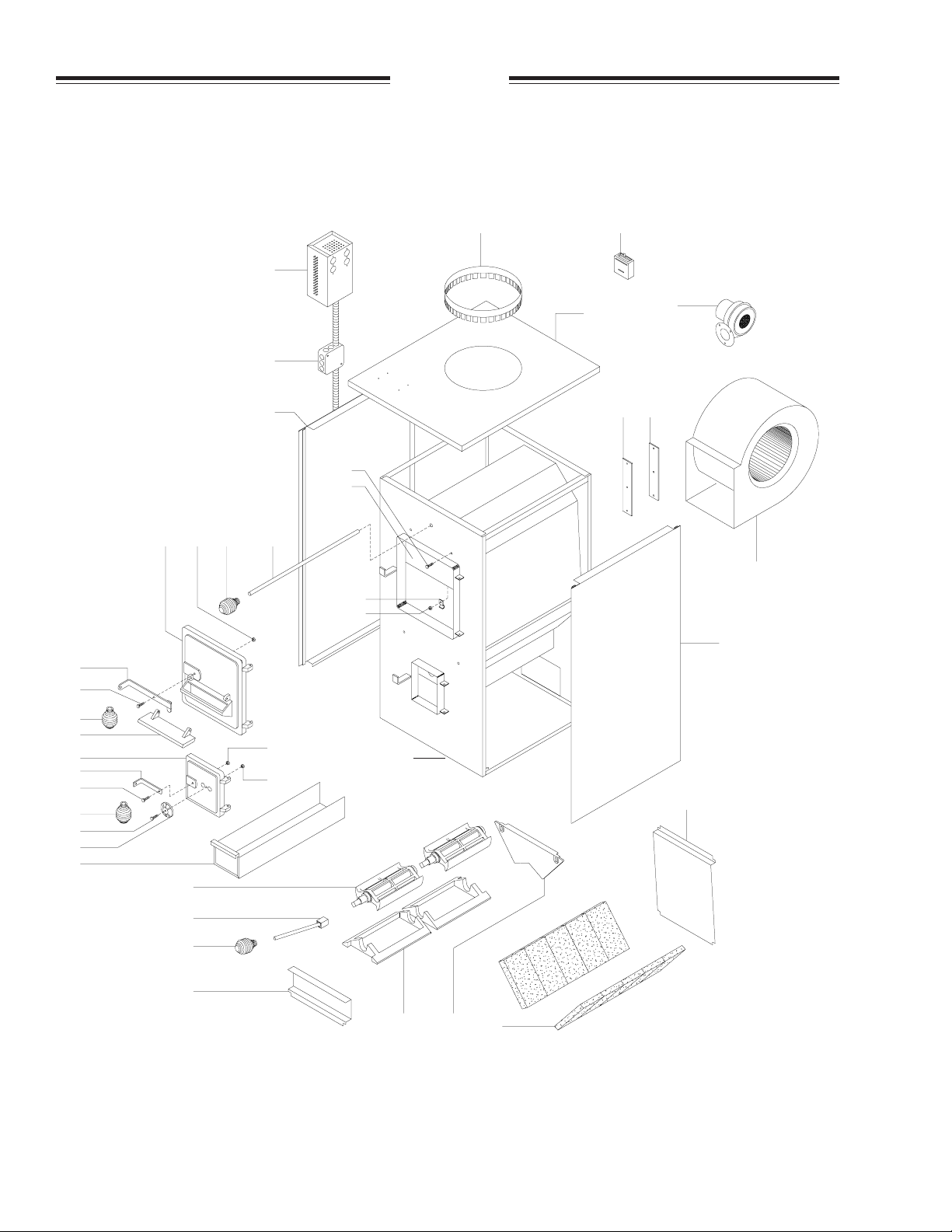

23

Parts

FOR MODEL(S): 24AF

2521

27

10

11

27

14

13

16

36

28

38

18

17

4 8 26 22

20

19

6

7

5

9

31

12

15

1

24

23

39

37

34

29

26

33

30 32

Page 6 USSC

35

Parts

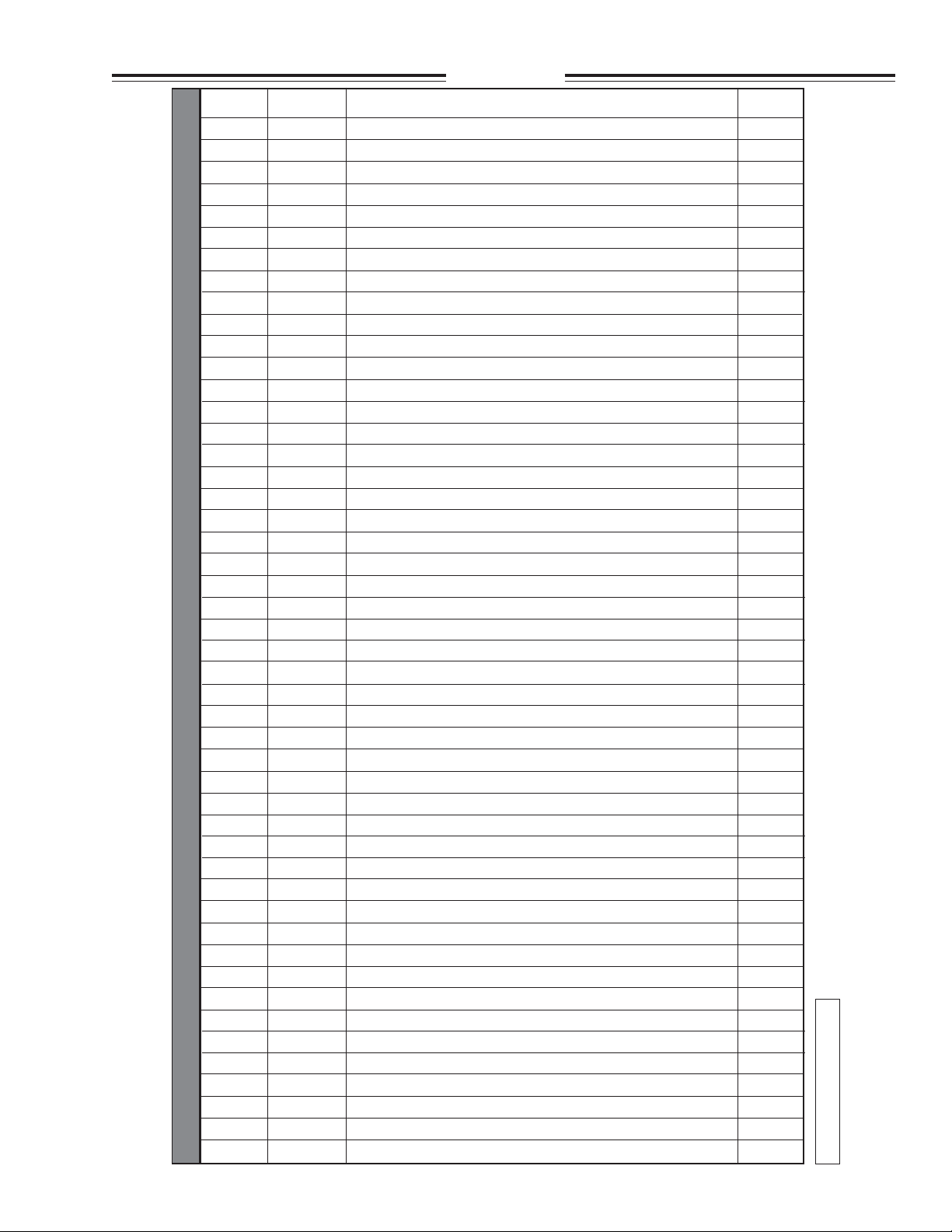

KEY PART # DESCRIPTION QTY.

1 69072 FIREBOX WELDMENT 1

2 C97999 WATER COIL COVER GASKET 1

3 24220 INSIDE COVER PLATE 1

N/S C23799 12 x 3/4" TEKS SCREW 3

N/S 83236 1/4-20 x 3/4" HX SCREW 4

4 25085 FEED DOOR 1

N/S 88033 3/8" ROPE GASKET (FEED DOOR) 4.25 FT.

N/S C21390 7/32 x 1 ROLL PIN (FEED DOOR) 2

5 24482 PRESSURE FLAP 1

N/S 88075 3 /4 F L A T R O P E G A S KE T 1 FT.

N/S C21390 7/32 x 1 ROLL PIN (PRESSURE FLAP) 2

6 69077 FEED DOOR HANDLE ASSY. 1

7 83379 1/4-20 x 1 BOLT 1

8 83261 1/4-20 LOCK NUT 1

9 24485 ASH DOOR 1

N/S 88033 3/8 ROPE GASKET 2.29 FT.

10 24486 ASH DOOR HANDLE 1

N/S C21390 7/32 x 1 ROLL PIN (ASH DOOR) 2

11 83379 1/4-20 x 1 BOLT 1

12 83261 1/4-20 LOCK NUT 1

13 24382 SPIN DAMPER 1

14 83471 5/16-18 x 1-3/4" CARR. BOLT 1

15 83423 5/16-18 HEX LOCK NUT 1

16 69068 ASH DRAWER ASSY. 1

17 24501 SMOKE CURTAIN 1

18 83445 1/4-20 x 1-1/4" BOLT 2

19 83261 1/4-20 LOCK NUT 2

FOR MODEL(S): 24AF

20 23787 SMOKE DOOR CLIP 2

21 89799 STUB COLLAR 1

22 24528 DAMPER ROD 1

N/S 83874 1/8 DIA. x 1-1/2" COTTER PIN 1

23 69080 CONTROL CENTER 1

24 69097 FORCED DRAFT BLOWER ASSY. 1

25 80129 THERMOSTAT 1

26 89574 SPRING HANDLE (DAMPER ROD, SHAKER) 2

27 89849 HOOK SPRING HANDLE (FEED, ASH DOOR) 2

28 69082 JUNCTION BOX ASSY. 1

29 69069 SHAKER GRATE HANDLE 1

30 40369 SHAKER GRATE FRAME 2

31 40349 SHAKER GRATE 2

32 40366 FIREBOX LINER 2

33 24496 FRONT HEAT PLATE 1

34 24487 FURNACE HEAT PLATE 1

35 89066 FIREBRICK 10

36 24488 CABINET TOP 1

37 24489 CABINET RIGHT SIDE 1

38 24490 CABINET LEFT SIDE 1

39 C60456 1050 CFM DISTRIBUTION BLOWER 1

USSC Page 7

N/S = NOT SHOWN

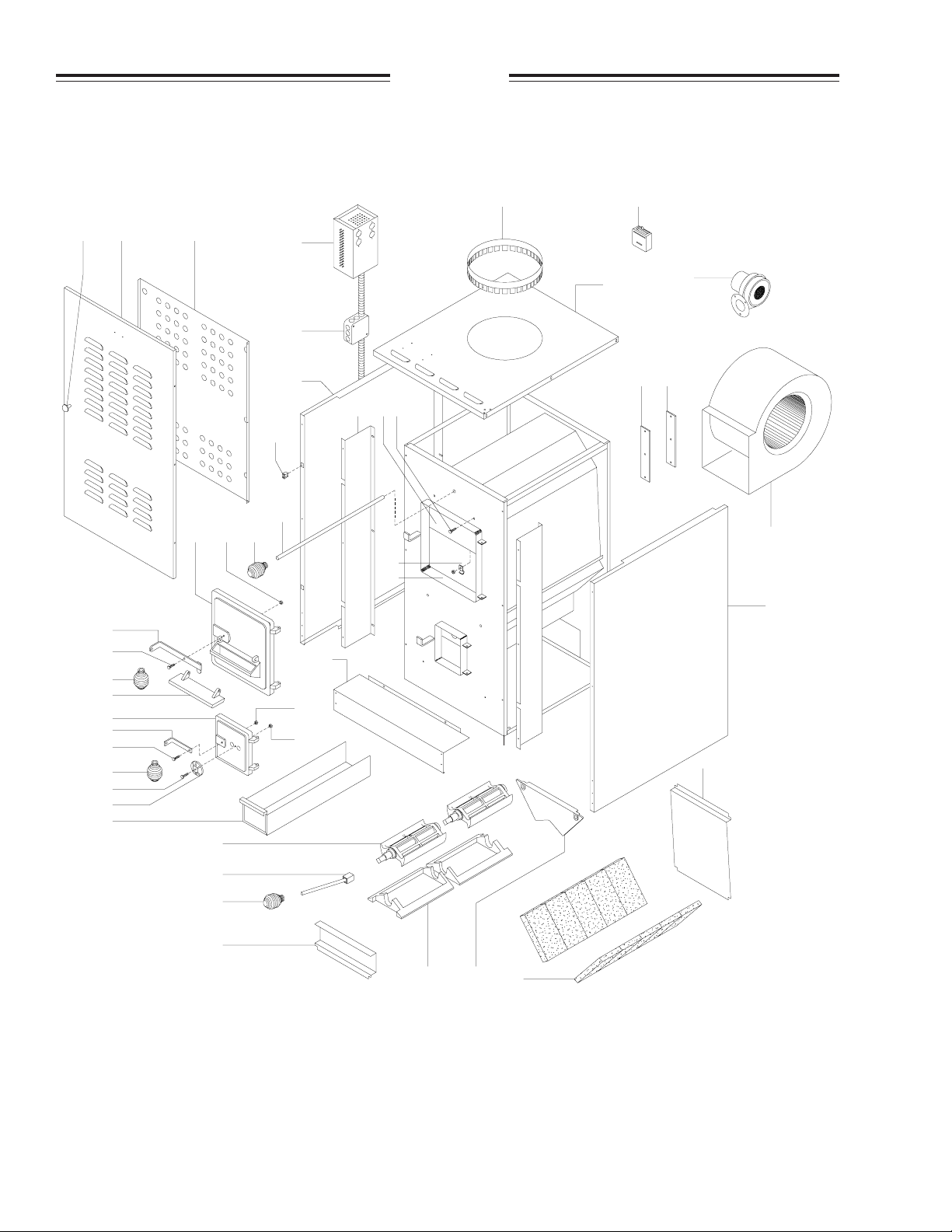

Parts

FOR MODEL(S): 24AG, 24AZ

2521

27

10

11

27

14

13

16

434244

4826

6

7

5

9

31

41

22

23

28

38

12

15

40

39

20

19

36

1817

1

24

23

45

37

34

29

26

33

30 32

Page 8 USSC

35

Parts

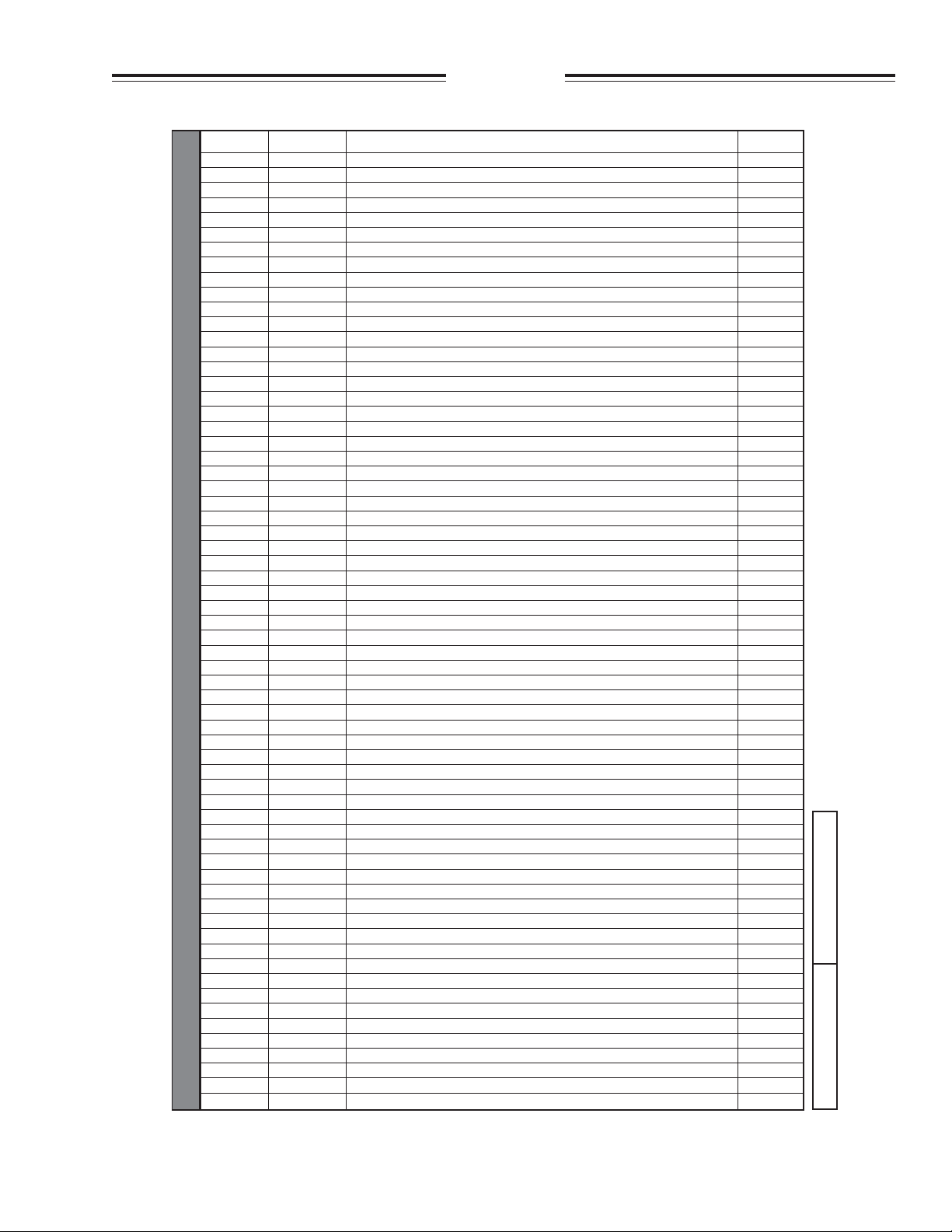

KEY PART # DESCRIPTION QTY.

1 69315 FIREBOX WELDMENT 1

2 C97999 WATER COIL COVER GASKET 1

3 2422 0 INSIDE COVER PLATE 1

N/S C23799 12 x 3/4" TEKS SCREW 3

N/ S 83236 1/4-20 x 3/4" HX SCREW 4

4 250 85 FEED DOOR 1

N /S 88033 3/8" ROPE GASKET (FEED DOOR) 4.25 FT.

N/S C21390 7/32 x 1 ROLL PIN (FEED DOOR) 2

5 24482 PRESSURE FLAP 1

N / S 8807 5 3/4 FLAT ROPE GASKET 1 FT.

N/S C21390 7/32 x 1 ROLL PIN (PRESSURE FLAP) 2

6 69326B FEED DOOR HANDLE ASSY. 1

7 83379 1/4-20 x 1 BOLT 1

8 83261 1/4-20 LOCK NUT 1

9 24485 ASH DOOR 1

N /S 880 33 3/8 ROPE GASKET 2.29 FT.

10 25047B ASH DOOR HANDLE 1

N/S C21390 7/32 x 1 ROLL PIN (ASH DOOR) 2

11 83379 1/4-20 x 1 BOLT 1

12 83261 1/4-20 LOCK NUT 1

1 3 2438 2 SPIN DAMPER 1

14 83471 5/16-18 x 1-3/4" CARR. BOLT 1

15 83423 5/16-18 HEX LOCK NUT 1

16 69068 ASH DRAWER ASSY. 1

1 7 24501 SMOKE CURTAIN 1

18 83445 1/4-20 x 1-1/4" BOLT 2

19 83261 1/4-20 LOCK NUT 2

20 2 3787 SMOKE DOOR CLIP 2

2 1 8979 9 STUB COLLAR 1

2 2 24528 DAMPER ROD 1

N/ S 83874 1/8 DIA. x 1-1/2" COTTER PIN 1

2 3 69321G CONTROL CENTER 1

* * 69323 CONTROL CENTER (STAINLESS STEEL) 1

24 69097 FORCED DRAFT BLOWER ASSY. 1

2 5 8 0 129 THERMOSTAT 1

26 8 9 574 SPRING HANDLE (DAMPER ROD, SHAKER) 2

27 8 9849 HOOK SPRING HANDLE (FEED, ASH DOOR) 2

28 6908 2 JUNCTION BOX ASSY. 1

2 9 6 9 0 6 9 SHAKER GRATE HANDLE 1

FOR MODEL(S): 24AG, 24AZ

3 0 40369 SHAKER GRATE FRAME 2

3 1 40349 SHAKER GRATE 2

32 40366 FIREBOX LINER 2

3 3 24496 FRONT HEAT PLATE 1

3 4 24487 FURNACE HEAT PLATE 1

35 89066 FIREBRICK 10

3 6 25014G CABINET TOP 1

* * 25 015 CABINET TOP (STAINLESS STEEL) 1

3 7 25016G CABINET RIGHT SIDE 1

* * 25017 CABINET RIGHT SIDE (STAINLESS STEEL) 1

3 8 25018G CABINET LEFT SIDE 1

* * 25019 CABINET LEFT SIDE (STAINLESS STEEL) 1

39 25025B SIDE FILLER 2

4 0 25020G BOTTOM FRONT 1

* * 25021 BOTTOM FRONT (STAINLESS STEEL) 1

41 891049 CATCH 2

N/S 891048 BALL STRIKE 2

4 2 25022G CABINET DOOR 1

* * 25 023 CABINET DOOR (STAINLESS STEEL) 1

N/S 69318B TOP CABINET DOOR HINGE 1

N/S 69319B TOP CABINET DOOR HINGE 1

N/S 851405 ASHLEY SCRIPT LOGO 1

43 25024B LINER, CABINET DOOR 1

4 4 89943 DOOR KNOB 1

45 C60456 1050 CFM DISTRIBUTION BLOWER 1

N/S = NOT SHOWN ** = USED ON 24AZ

USSC Page 9

Loading...

Loading...