United CoolAir VertiCool Classic Series Engineering Manual

VertiCool

Engineering Guide

Effective August 2016

™

CLASSIC

Chilled Water and Water Source Heat Pump

Air-Cooled, Water-Cooled,

Engineering Guide

VertiCool ™ Classic

Contents

Product Features ��������������������������������������������������������������������������������������������������� 3

UNIT FEATURES �������������������������������������������������������������������������������������������� 3

OPTIONS: ������������������������������������������������������������������������������������������������������������������������������ 3

Physical Data����������������������������������������������������������������������������������������������������� 4–5

Air-Cooled Performance Data (a) (b) (c) ��������������������������������������������������������������� 6

Water-Cooled Performance Data (a) (c) (d) (e) ����������������������������������������������������� 7

Water Source Heat Pump Performance Data (a) (c) (d) (e) ���������������������������������� 8

Blower Performance Data ������������������������������������������������������������������������������������� 9

Evaporator (a) (b) �������������������������������������������������������������������������������������������� 9

Condenser ������������������������������������������������������������������������������������������������������� 9

Steam Coil ������������������������������������������������������������������������������������������������������� 9

Hot Water Coil Performance (a) (b) (c) (d) (e) (f) (g) ������������������������������������������� 10

Chilled Water Coil Performance (a) (b) (c) (d) (e) (f) ������������������������������������������� 10

Electrical Data ����������������������������������������������������������������������������������������������������� 11

Cooling Only: ������������������������������������������������������������������������������������������������� 11

Electrical Data ����������������������������������������������������������������������������������������������������� 12

Cooling Only: ������������������������������������������������������������������������������������������������� 12

Electrical Data ����������������������������������������������������������������������������������������������������� 13

Cooling with Electric Heat: ���������������������������������������������������������������������������� 13

Electrical Data ����������������������������������������������������������������������������������������������������� 14

Compressor RLA Electrical Data: ������������������������������������������������������������������ 14

Evaporator Motor FLA: ���������������������������������������������������������������������������������� 14

Condenser Motor FLA: ���������������������������������������������������������������������������������� 14

Electric Heat FLA:

Electrical Data Air-Cooled (c) (d) (e)��������������������������������������������������������������������15

Electrical Data Air-Cooled (c) (d) ������������������������������������������������������������������������� 16

Electrical Data Water-Cooled (c) (d) (e) ��������������������������������������������������������������17

Electrical Data Water-Cooled (c) (d) ��������������������������������������������������������������������18

Basic Unit Congurations ������������������������������������������������������������������������������������ 19

Basic Unit Dimensions����������������������������������������������������������������������������������������� 20

Cabinet Congurations and Unit Drawings���������������������������������������������������� 21–23

Service Clearance ����������������������������������������������������������������������������������������������� 24

Application Data �������������������������������������������������������������������������������������������������� 25

Miscellaneous Technical Data ����������������������������������������������������������������������������� 25

Shipment Congurations ������������������������������������������������������������������������������� 26–28

BASIC MODEL DESIGNATION ��������������������������������������������������������������������������� 32

�������������������������������������������������������������������������������� 14

Subject to change without notice. 20.10-TD (0816)

2

Product Features

Engineering Guide

VertiCool ™ Classic

The VertiCool™ Classic Series of units are splittable,

self-contained, oor mounted, single package units.

They are available as air-cooled, water-cooled or as

water source heat pump congurations. The units offer

a variety of evaporator air ow patterns for application

exibility. Additionally, the units are available as standard

congurations or they can be tailored for a specic

application as a made-to-order unit�

UNIT FEATURES

• Air-Cooled, Water-Cooled, Chilled Water or Water Source Heat

Pump Congurations

• R-410a Refrigerant, Factory Charged

• 12 thru 30 Ton Units are Splittable using Resealable Refrigerant

Fittings

• Fits through 32” doorways

• ½” Fiberglass Lined Cabinet (Thermal/Acoustical, min� density of

2 Pounds)

• Rugged cabinet construction

• Duct Flanges Factory Installed

• Drain Connections on Both Evaporator and Condensing Sections

• 304 Stainless Steel “V” Style Drain Pan in Evaporator Section

• �25” ESP Capability (1” ESP Option for Evaporator and

Condensing Sections)

• Belt Driven Blowers (Evaporator and Condensing Sections)

• Ball Bearing Motors

• Resiliently Mounted Ball Bearings for Blowers

• Cast Iron Pulleys and Sheaves

• Variable Pitch Motor Sheaves

• All shafts, sheaves & pulleys keyed

• Adjustable Motor Mounts in Evaporator and Condensing Sections

• High (Manual Reset) and Low (Auto Reset) Refrigerant Pressure

Safety Switches

• Loss of Air Safety Switch (when electric heat used)

• Scroll Compressors

• Adjustable Expansion Valve with External Equalizer (MOP Type)

• Sight Glass / Moisture Indicators

• Filter Driers

• High and Low Side Schrader Access Fittings

• Draw Through Air Flow Conguration

• Interlaced Evaporator Coils

• Single Electrical Control Box

• 24 Volt Control Circuits

• Transformer with Built In Circuit Breaker

• Individual Contactor for each Stage of Electric Heat

• Individual Contactor for each Motor and Compressor

• Co-axial Counter Flow Heat Exchanger(s) on Water-Cooled Units

• Limited Warranty 1 Year on Parts and 5 Years on Compressors

• Functionally Run Tested at the Factory

OPTIONS: (Items underlined are factory installed):

• Powder Coated Cabinet

• Plenum w/ Discharge Grilles or Duct Flange

• Condensate Pump

• Electric Heat

• Protective Coil Coatings

• SCR Controllers

• Air or Water Side Economizer

• Hot Water, Chilled Water and Steam Coils

• Variable Frequency Drive (Evaporator)

• Drain Pan Overow Switch

• Head Pressure Control Valves

• Double Wall Construction (Solid or Perforated)

or Acoustic Foam Package

• Hot Gas Bypass (Standard or Modulating)

• Low Ambient Operation (VFD or Flooded

Condenser)

• Freezestat

• Non-Fused Disconnects

• Thermostats

• Marvel Microprocessor Controls

• Upgraded Motors / Drive Sets

• Compressor Anti-Short Cycle Timer

• Quench Valve w/ Suction Accumulator

• Suction Line Accumulator

• Oil Separator

• Liquid Receivers

• Hot Gas Reheat

• Condenser Filter Box

• Return Air Grilles

• Chilled Water and Hot Water Valves

• Smoke Detectors

• Firestats

• Dry Contacts

• Steam Canister Humidier

CONTACT THE FACTORY FOR OTHER

OPTIONAL FEATURES

Subject to change without notice. 20.10-TD (0816)

3

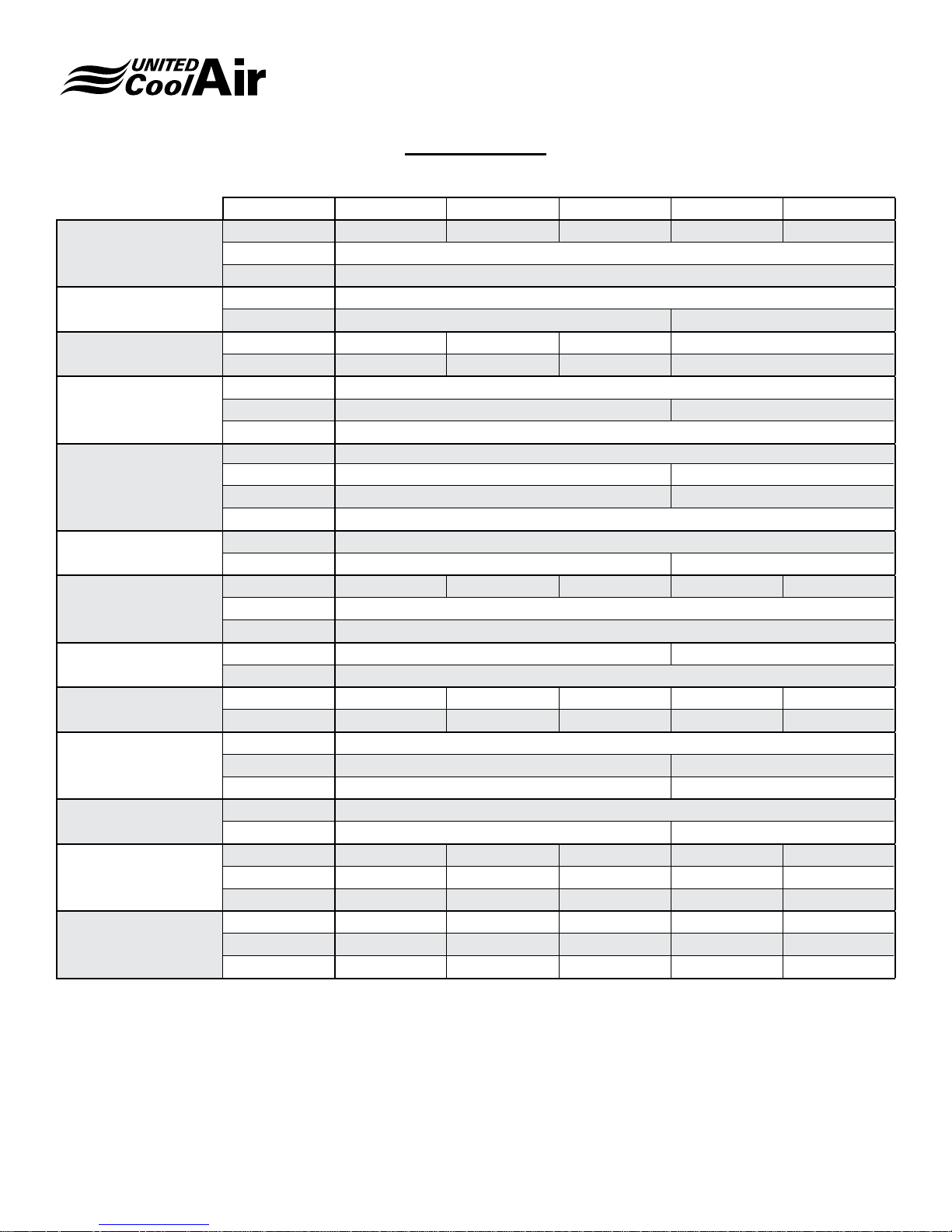

Evaporator Supply Air

Evaporator Blower

Evaporator Motors

Evaporator Coil

Filter

Compressor

Condenser Air

Condenser Blower

Condenser Motors

Condenser Coil

Water Cooled Cond. (f)

Weight (Net Operating) (b)

Available Voltages (e)

Engineering Guide

VertiCool ™ Classic

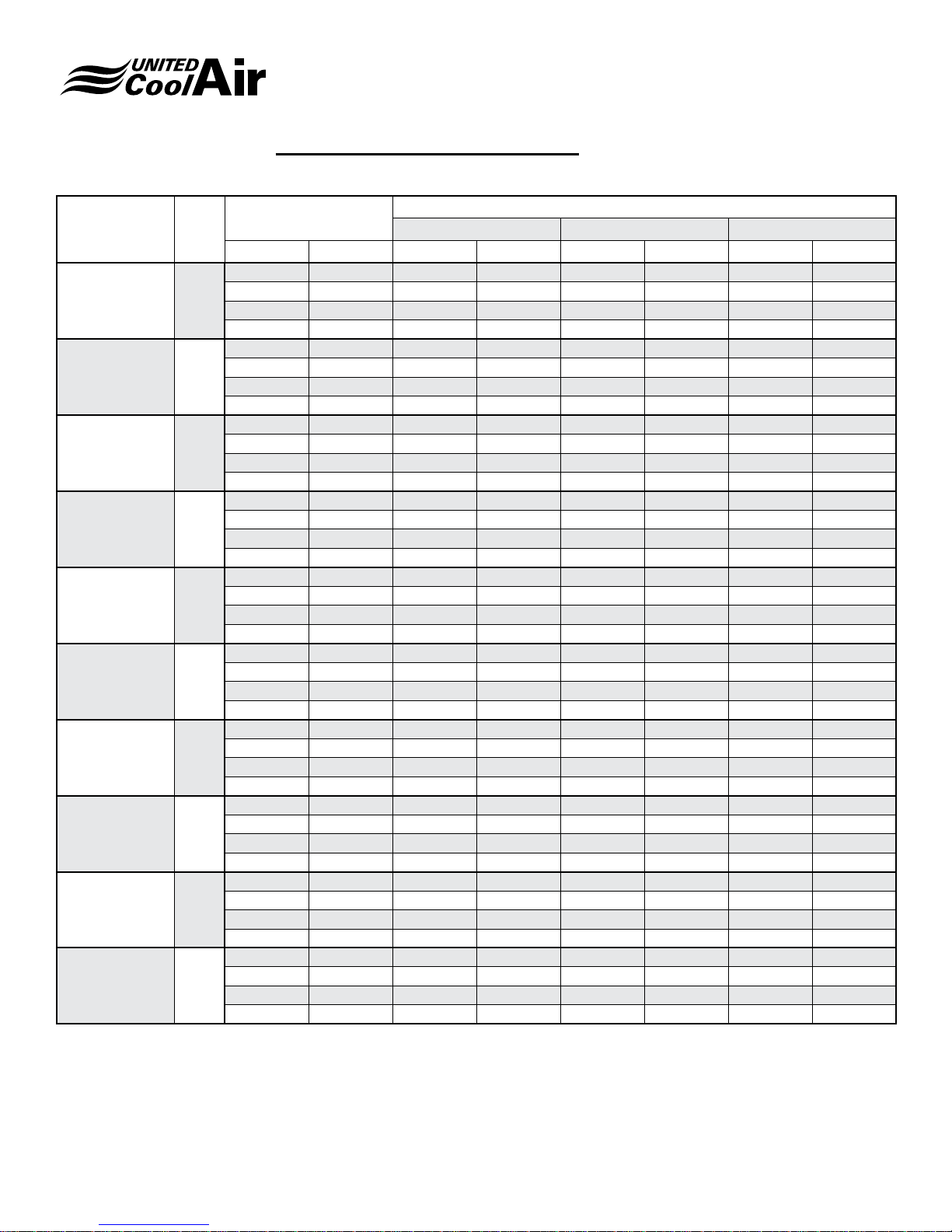

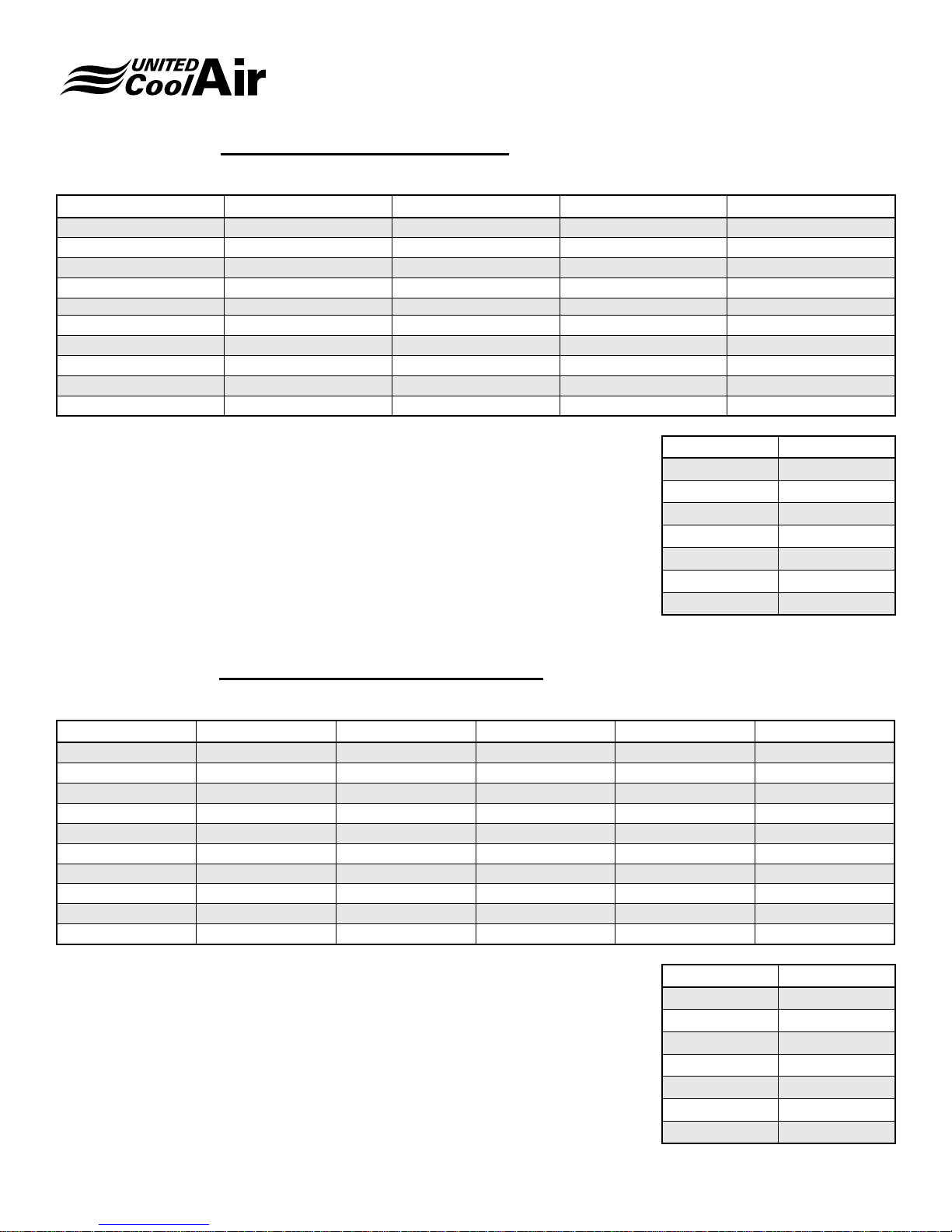

Physical Data

Tons 3 4 5 8 10

CFM 1200 1600 2000 3200 4000

Std� ESP 0�25”

Max� ESP (a) 1�0”

Size 10 - 8

Qty 1 2

Std� HP ½ ¾ ¾ 1�5

Opt� HP ¾ 1 1 2

Rows 4

Face Area 4�44 9

FPI 12

Type Pleated Throwaway

Qty 2 ½

Dimensions 20 x 20 x 2 16 x 25 x 2 / 20 x 25 x 2

Efciency MERV 8

Type Scroll

Qty 1 2

CFM 2100 2800 3500 6000 7500

Std� ESP 0�25”

Max� ESP (a) 1�0”

Size 10 - 8 15 - 9

Qty 2

Std� HP ½ ¾ 1 2 3

Opt� HP ¾ 1 1�5 3 5

Rows 4

Face Area 6 11�25

FPI 14 12

Type Co-axial

Qty 1 2

Air-Cooled 655 655 655 1150 1150

Water-Cooled

Water Source HP

208/230-1-60 • • •

208/230-3-60 • • • • •

460-3-60 • • • • •

480 480 480 940 940

505 505 505 1000 1000

Notes:

(a) Requires optional motor / drive upgrade�

(b) Net operating weight is for basic unit only� Options will add weight�

(c) Refrigerant circuit components will impact unit performance�

(d) Pulley & Belt upgrade only�

(e) 575 volt available� Consult factory�

(f) Contact factory for geothermal applications�

(g) R-410a Refrigerant charge is for base unit conguration. Addition of some options may alter refrigerant amount

Subject to change without notice. 20.10-TD (0816)

4

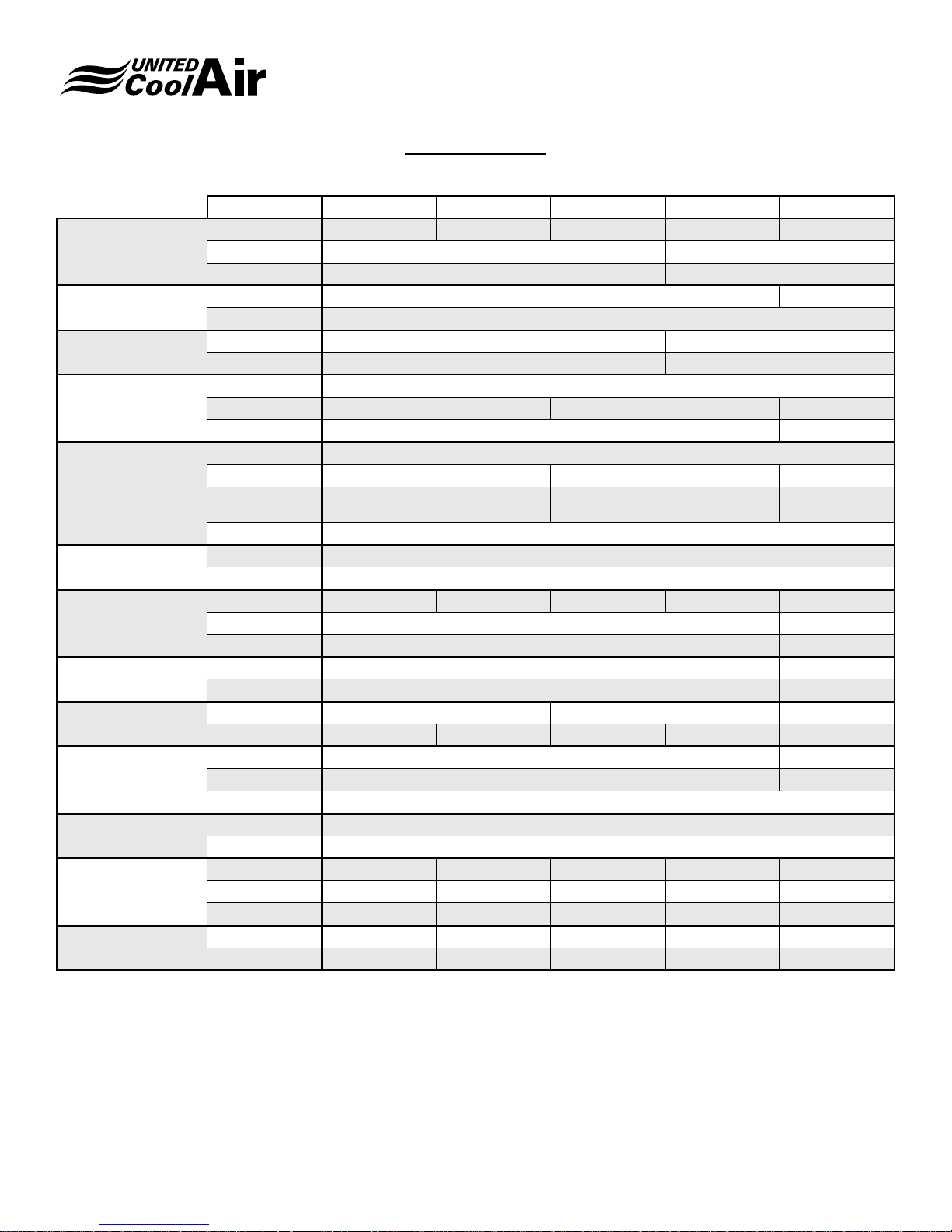

Evaporator Supply Air

Evaporator Blower

Evaporator Motors

Evaporator Coil

Filter

Compressor

Condenser Air

Condenser Blower

Condenser Motors

Condenser Coil

Water Cooled Cond. (e)

Weight (Net Operating)

(b)

Available Voltages (d)

Engineering Guide

VertiCool ™ Classic

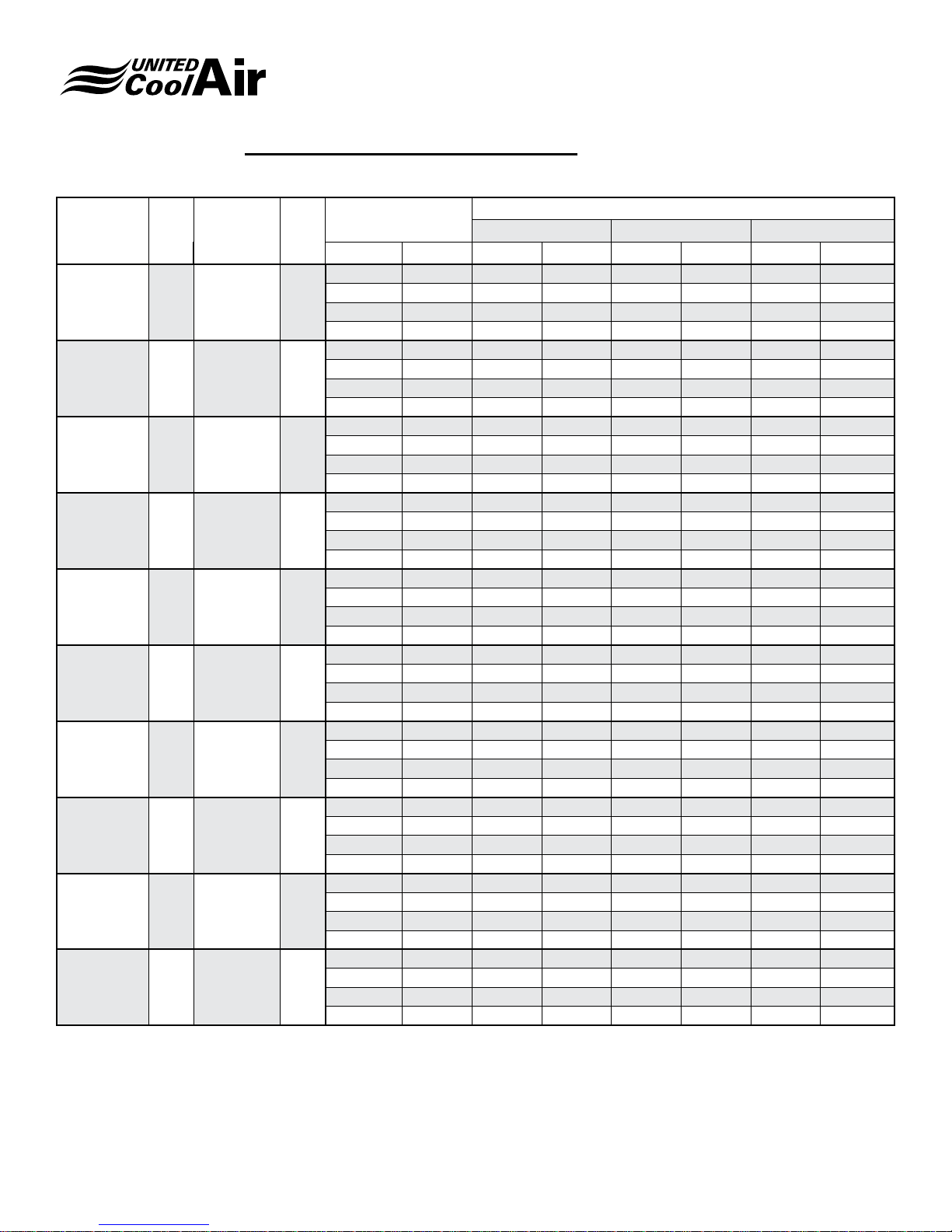

Physical Data

Tons 12 15 20 25 30 (g)

CFM 4800 6000 8000 9770 12000

Std� ESP 0�25” 1�0”

Max� ESP (a) 1�0” 2�0”

Size 15-9 15 - 15

Qty 2

Std� HP 3 10

Opt� HP 5 15

Rows 4

Face Area 13�33 17�8 22�6

FPI 10 12

Type Pleated Throwaway

Qty 4 8 4 / 4

Dimensions 20 x 24 x 2 16 x 20 x 2

Efciency MERV 8

Type Scroll

Qty 2

CFM 7200 9000 12000 15000 16000

Std� ESP 0�25” 1�0”

Max� ESP (a) 1�0” 2�0”

Size 15 - 9 18 - 18

Qty 3 2

Std� HP 5 10 15

Opt� HP 5 (d) 7�5 7�5 15 15 (h)

Rows 4 6

Face Area 20 22�7

FPI 12

Type Co-axial

Qty 2

Air-Cooled 1895 1895 1945 1980 3400

Water-Cooled 1435 1435 1485 1520 2700

Water Source HP 1495 1495 1545 1580 3000

208/230-3-60 • • • • •

460-3-60 • • • • •

20 x 20 x 2 / 20 x

25 x 2

Notes:

(a) Requires optional motor / drive upgrade�

(b) Net operating weight is for basic unit only� Options will add weight�

(c) Refrigerant circuit components will impact unit performance�

(d) 575 volt available� Contact factory�

(e) Contact factory for geothermal applications�

(f) R-410a Refrigerant charge is base unit conguration. Addition of some options may alter refrigerant amount.

(g) Units always shipped split�

(h) Pulley & Belt upgrade only�

Subject to change without notice. 20.10-TD (0816)

5

Air-Cooled Performance Data (a) (b) (c)

Engineering Guide

VertiCool ™ Classic

Entering Air Temp. (°F)

75 95 115

Entering Air Temperature (°F)

Tons CFM DB WB Total Sensible Total Sensible Total Sensible

86 72 49530 32460 44430 30450 39570 28440

VA3G*ASTA 1200

80 67 45720 31730 41090 29770 36570 27750

75 62�5 42250 31390 38020 29460 33800 27410

72 60 40370 30880 36350 28980 32310 26920

86 72 59350 4400 53410 38020 47310 35580

VA4G*ASTA 1600

80 67 54780 39490 49450 37130 43860 34610

75 62�5 51120 39170 46230 36740 41000 34110

72 60 49160 38580 44460 36120 39400 33410

86 72 74040 49210 67700 46820 60370 43800

VA5G*ASTA 2000

80 67 67610 48140 61740 45610 55220 42570

75 62�5 62820 47760 57260 45000 51300 41850

72 60 60490 47110 55050 44220 49330 41000

86 72 122010 81650 110080 76870 97240 72070

VA8G*ATA 3200

80 67 112840 80150 101810 75280 90110 70080

75 62�5 104520 79520 94180 74560 83340 69030

72 60 99940 78350 89920 73400 79490 67730

86 72 148100 98720 133100 93280 117790 87300

VA10G*ATA 4000

80 67 137410 97040 123950 91360 110360 85260

75 62�5 127200 96280 114900 90300 102590 84030

72 60 121400 94730 109670 88630 97980 82300

86 72 186390 119960 170190 113980 151910 107220

VA12G*ATA 4800

80 67 173180 118360 158140 111630 141850 104270

75 62�5 161770 117900 147580 110750 132730 103150

72 60 155570 116310 141760 109120 127580 101530

86 72 225520 143950 204470 135610 182760 126740

VA15G*ATA 6000

80 67 209910 141970 190830 133400 171330 124390

75 62�5 195180 141140 177540 132320 159660 123130

72 60 186910 139180 169990 130240 152900 120990

86 72 300680 192350 274770 181380 244950 168900

VA20G*ATA 8000

80 67 279060 189450 254000 177860 225690 164880

75 62�5 260010 188340 235590 176070 208400 162540

72 60 249800 185820 225630 173180 198960 159360

86 72 334060 216720 311970 207290 282980 194850

VA25G*ATA 10000

80 67 313120 214000 290510 203170 262260 189640

75 62�5 292590 213540 269940 201530 242520 187030

72 60 280950 211260 258300 198650 231330 183690

86 72 441490 294480 403140 279420 361840 262540

VA30G*ATA 12000

80 67 413100 290100 376410 274030 337790 256410

75 62�5 383920 287380 349040 270240 313000 251830

72 60 367140 282490 333340 264850 298770 246090

Notes:

(a) Capacities are gross values, not adjusted for motor heat�

(b) Some refrigerant circuit components may impact on unit capacities�

(c) Applications with ambient conditions 75° F and lower may require additional refrigerant circuit components�

Consult factory for details�

Subject to change without notice. 20.10-TD (0816)

6

Water-Cooled Performance Data (a) (c) (d) (e)

Engineering Guide

VertiCool ™ Classic

Entering Air Temp. (°F)

PD

Tons GPM CFM DB WB Total Sensible Total Sensible Total Sensible

(Ft. H2O) (b)

80 85 90

Entering Water Temperature (°F)

86 72 50170 32820 48920 32290 47670 31770

VW3G*ASTA 9 9�8 1200

80 67 46180 32010 45070 31480 43950 30970

75 62�5 42800 31690 41780 31170 40760 30660

72 60 41010 31230 40030 30720 39060 30220

86 72 62130 41510 60600 40930 59030 40330

VW4G*ASTA 12 14�7 1600

80 67 57730 40500 56270 39880 54780 39240

75 62�5 53560 40080 52170 39410 50763 38730

72 60 51250 39480 49900 38800 48530 38100

86 72 78660 51540 75350 50110 73550 49350

VW5G*ASTA 15 10�9 2000

80 67 71930 49950 68770 48430 67080 47620

75 62�5 67300 49560 64330 47950 62740 47110

72 60 63820 48270 62360 47440 60840 46580

86 72 125900 83930 122580 82710 119200 81460

VW8G*ATA 24 8�8 3200

80 67 116250 81660 113240 80380 110170 79070

75 62�5 107950 80730 105170 79370 102350 77980

72 60 103490 79550 100830 78140 98120 76700

86 72 157390 103200 153710 101620 149900 99970

VW10G*ATA 30 10�2 4000

80 67 152700 110740 140010 98180 136450 96550

75 62�5 132260 98100 129010 96520 125660 94890

72 60 126550 96420 123400 94850 120150 93220

86 72 194460 123580 189820 121710 185110 119810

VW12G*ATA 36 8�8 4800

80 67 178880 120820 174630 118890 170310 116940

75 62�5 166040 119950 162090 117950 158080 115930

72 60 159460 118550 155660 116530 151800 114470

86 72 236600 148890 230900 146700 224980 144460

VW15G*ATA 45 14�0 6000

80 67 215530 144944 210560 142770 205420 140550

75 62�5 199860 143670 195460 141510 190910 139300

72 60 192310 141970 188200 139820 183950 137620

86 72 309690 196820 302830 194000 295810 191120

VW20G*ATA 60 11�0 8000

80 67 287370 193460 280700 190450 273900 187390

75 62�5 128120 192490 261620 189300 255020 186070

72 60 257760 190230 251360 186960 244860 183630

86 72 361890 227730 355210 225000 348190 222160

VW25G*ATA 75 13�0 10000

80 67 332270 222840 326080 220020 319600 217100

75 62�5 308820 221240 303000 218330 296920 215310

72 60 297010 218600 294380 215630 285510 212570

86 72 462560 306240 455220 303160 440290 296510

VW30G*ATA 90 8�0 12000

80 67 425770 296320 417770 292700 401640 285040

75 62�5 397690 293530 389350 289460 372610 280970

72 60 384130 290540 375660 286270 358740 277380

Notes:

(a) Capacities are gross values, not adjusted for motor heat�

(b) Pressure drop is for heat exchanger only and does not include piping, valves, ttings, etc.

(c) Some refrigerant circuit components may impact on unit capacities�

(d) Applications with water conditions 75° F and lower may require additional refrigerant circuit components�

Consult factory for details�

(e) Contact factory for geothermal applications�

Subject to change without notice. 20.10-TD (0816)

7

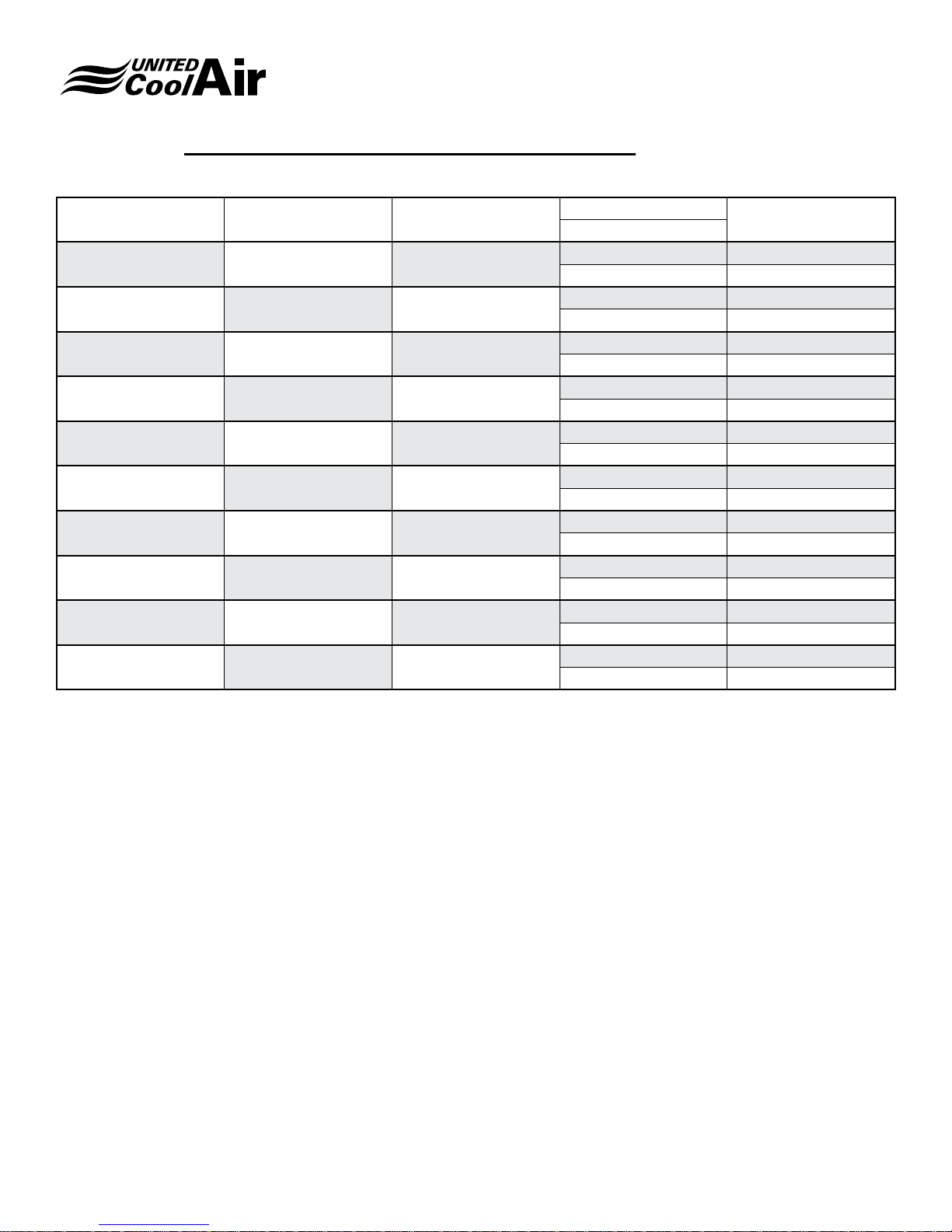

Water Source Heat Pump Performance Data (a) (c) (d) (e)

Tons GPM CFM

VW3G*ATA 9 1200

VW4G*ATA 12 1600

VW5G*ATA 15 2000

VW8G*ATA 24 3200

VW10G*ATA 30 4000

VW12G*ATA 36 4800

VW15G*ATA 45 6000

VW20G*ATA 60 8000

VW25G*ATA 75 10000

VW30G*ATA 90 12000

Entering Air Temp. (°F)

DB

70 50100

60 51100

70 62500

60 64000

70 78400

60 80100

70 94500

60 96500

70 116600

60 119100

70 136500

60 139400

70 178500

60 182300

70 225800

60 230700

70 275800

60 281800

70 358400

60 366200

Engineering Guide

VertiCool ™ Classic

Heating Capacity

Notes:

(a) Capacities are gross values, not adjusted for motor heat�

(b) Pressure drop is for heat exchanger only and does not include piping, valves, ttings, etc.

(c) Some refrigerant circuit components may impact on unit capacities�

(d) Values at 70° F Entering Water Temperature�

(e) Contact factory for geothermal applications�

Subject to change without notice. 20.10-TD (0816)

8

Evaporator (a) (b)

Tons CFM ≤0.25” 0.25” to 1.0”

3 1200 0�33 0�5

4 1600 0�5 1�0

5 2000 1�0 1�5

8 3200 1�0 1�5

10 4000 2�0 3�1�5

12 4800 1�5 2

15 6000 2�0 3

20 8000 5 5 (c)

25 9770 7�5 10

30 12000 7�5 10

Engineering Guide

VertiCool ™ Classic

Blower Performance Data

External Static Pressure (ESP)

≤ 1.0” 1�0” to 2�0”

Condenser

External Static Pressure (ESP)

Tons CFM ≤0.25” 0.25” to 1.0”

3 0�5 1�0

4 1�0 1�5

5 1�5 2�0 (@ 0�9” max)

8 4800 2 3

10 6000 5 5

12 7200 2 3

15 9000 3�0 5

20 12000 7�5 7�5 (c)

25 15000 15 15

≤ 1.0” 1�0” to 2�0”

30 16000 10 15

Notes:

(a) Blower performance of basic unit with 2”, MERV 8 pleated throwaway lter and wet coil 80 / 67 / 95 and “A” air path.

(b) Performance with nominal CFM. For other CFM or ESP contact the factory for your specic application.

(c) Pulley & Belt upgrade only�

Steam Coil

Notes:

(a) Contact factory with steam pressure and operating parameters�

(b) Low pressure, less than 10 psig�

(c) Steam valves and components by others, eld installed

(d) Requires addition of optional discharge plenum for 12 thru 30 Ton units if steam coil is being used for reheat and air path is “A” or

“B” (top supply)�

Subject to change without notice. 20.10-TD (0816)

9

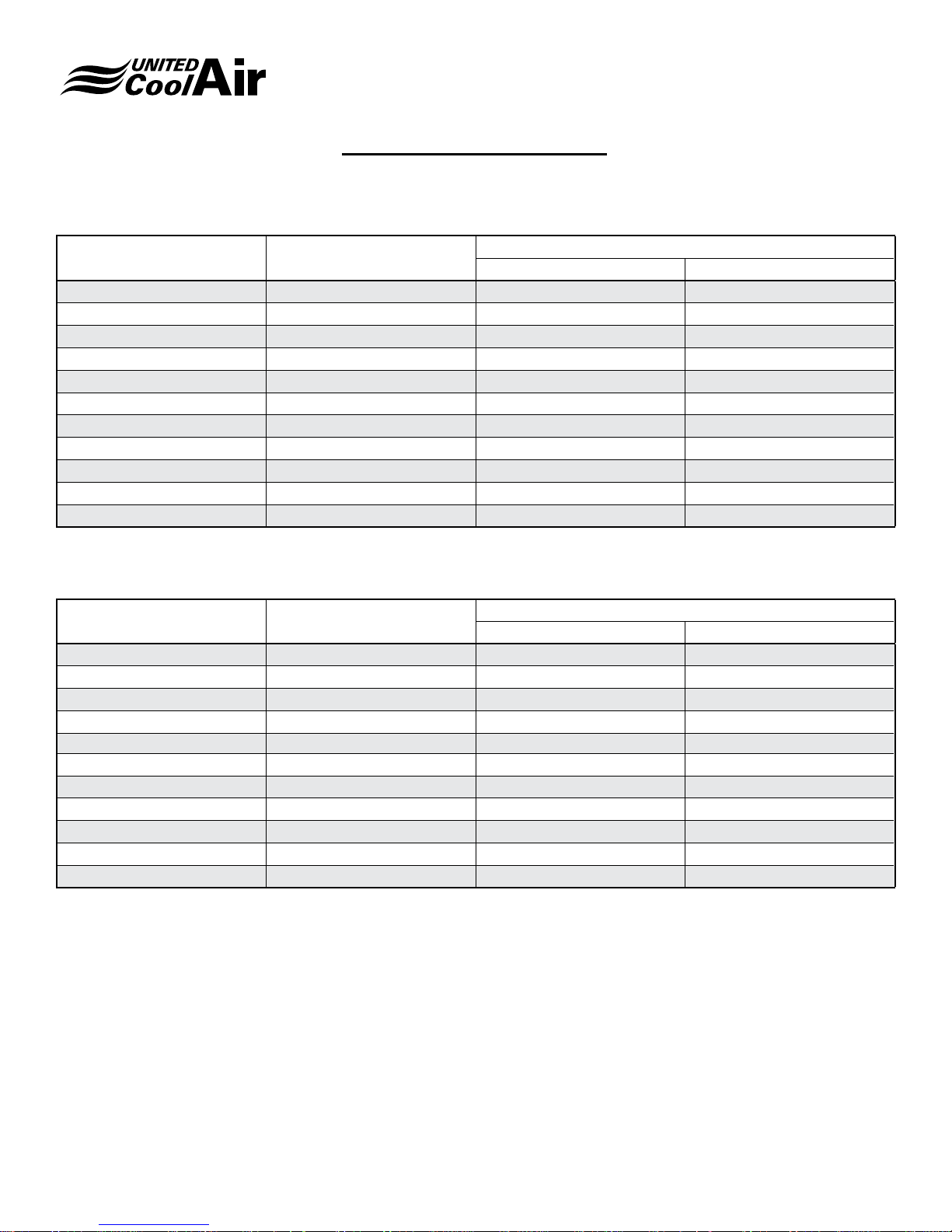

Engineering Guide

VertiCool ™ Classic

Hot Water Coil Performance (a) (b) (c) (d) (e) (f) (g)

Tons CFM GPM PD Ft. H2O Capacity (MBH)

3 1200 5 2.6 48900

4 1600 5.9 3.6 58000

5 2000 6.8 4.7 66200

8 3200 18�1 3�4 174000

10 4000 21�0 4�4 204400

12 4800 23�5 5�4 228500

15 6000 27�0 7�0 262500

20 8000 32�0 9�7 312400

25 9770 35�0 12�4 340700

30 12000 36�0 14�8 350500

Notes:

(a) Hot Water Coil Valves are optional�

(b) Valves are spring return, On / Off operation only�

(c) Entering water at 180° F� Leaving water at approximately 160° F�

(d) Entering air temperature 65° F�

(e) For other operating conditions or uid type, contact the factory for performance.

(f) Requires addition of optional discharge plenum for 12 thru 30 Ton units if hot water

coil is being used for reheat and air path is “A” or “B” (top supply)�

(g) Hot Water Coil Valve Sizes:

Chilled Water Coil Performance (a) (b) (c) (d) (e) (f)

Tons CFM GPM PD Ft. H2O Total (MBH) Sensible (MBH)

3 1200 10 4�4 46900 33200

4 1600 12 6�1 57000 41700

5 2000 13 7�1 64700 49100

8 3200 19 19 5�0 75700

10 4000 24 24 8�0 90700

12 4800 30 30 5�5 114700

15 6000 35 35 7�0 135400

20 8000 45 45 5�0 180300

25 10000 62 62 7�5 230800

30 12000 72 72 8�0 276300

Tons Valve Size

8 3/4”

10 1”

12 1-1/4”

15 1-1/4”

20 1-1/4”

25 1-1/2”

30 Contact Factory

Notes:

(a) Capacity based on 80° F DB / 67° F WB with 45° F EFT�

(b) Chilled water entering at 45° F�

(c) For other operating conditions or uid type, contact the factory for performance.

(d) Chilled Water Coil Valves are optional�

(e) Valves are spring return, On / Off operation only�

(f) Chilled Water Coil Valve Sizes:

Subject to change without notice. 20.10-TD (0816)

Tons Valve Size

8 1-1/4”

10 1-1/4”

12 1-1/2”

15 2”

20 2-1/2”

25 2-1/2”

30 2-1/2”

10

Loading...

Loading...