Page 1

™

VertiCool

Single Package Vertical Unit (SPVU)

CLASSIC

Installation, Operation and Maintenance Manual

Effective June 2017

Chilled Water and Water Source Heat Pump

Air-Cooled, Water-Cooled,

Page 2

Page 3

Contents

Installation, Operation and Maintenance Manual

VertiCool Classic

Important Notice ������������������������������������������������������������������4

Use of Symbols �������������������������������������������������������������������4

General Information �������������������������������������������������������������5

Inspection Of Equipment �����������������������������������������������������5

Handling ������������������������������������������������������������������������������5

Mounting And Setting In Place ��������������������������������������������5

Unit Vibration Isolation ���������������������������������������������������������6

Location �������������������������������������������������������������������������������6

Clearance ����������������������������������������������������������������������������6

Louver And Ducting �������������������������������������������������������������6

Length of Ductwork for Discharge Air ����������������������������7

Application Data ������������������������������������������������������������8

Installation ���������������������������������������������������������������������������8

Air-Cooled Single Package �������������������������������������������8

General Ductwork Recommendations ��������������������������9

Plenum Installation ��������������������������������������������������������9

Condensate Drain Connection ��������������������������������������9

Refrigerant Connections ������������������������������������������������������9

Electrical ����������������������������������������������������������������������������10

Transformer �����������������������������������������������������������������11

Wiring �������������������������������������������������������������������������������11

Three Phase Power ����������������������������������������������������������� 11

Electric Heat ����������������������������������������������������������������������11

Voltage Unbalance �����������������������������������������������������12

Chilled Water Coil Valves Or

Hot Water Coil Valves ��������������������������������������������������������12

Pressure Switches ������������������������������������������������������������12

High Pressure / Low Pressure �������������������������������������12

Water-Cooled Units �����������������������������������������������������������12

Water Piping and Connections �����������������������������������13

Chilled Water Sections ������������������������������������������������������13

System Options �����������������������������������������������������������������14

Humidier ��������������������������������������������������������������������14

Auxiliary Coils (Hot Water or Steam) ���������������������������14

Water Side Economizer (Free Cooling Coil) ����������������14

Air Side Economizer ����������������������������������������������������14

Split Systems ���������������������������������������������������������������������15

Evaporator Mounting ���������������������������������������������������15

Interconnecting Refrigerant Tubing �����������������������������15

Condensate Pump �������������������������������������������������������17

Controls �����������������������������������������������������������������������������18

Thermostat ������������������������������������������������������������������18

Microprocessor Controller �������������������������������������������18

Subject to change without notice. 20.10-IM (0617)

Flooded Condenser �����������������������������������������������������������18

Maintenance Procedures���������������������������������������������������19

Filters ���������������������������������������������������������������������������������19

Cleaning The Water-Cooled Condenser����������������������������19

Blowers ������������������������������������������������������������������������������19

Blower Motors��������������������������������������������������������������������19

Blower Speed Adjustment �������������������������������������������������20

Blower Bearing Lubrication������������������������������������������������20

Belts�����������������������������������������������������������������������������������20

Refrigerant Systems ����������������������������������������������������������21

Evaporator And Air-Cooled Condenser Coils ��������������������21

Finned Coil Cleaning ���������������������������������������������������21

Water Side Economizer Coil ����������������������������������������22

Water Valves ���������������������������������������������������������������22

Hard Start Kit ���������������������������������������������������������������22

Checking Hot Gas Bypass Valve ���������������������������������22

Adjustment Of Hot Gas Bypass Valve �������������������������22

Sequence Of Operation Cooling - - Air-Cooled �����������23

Cooling - - Water-Cooled ���������������������������������������������23

Cooling - - Chilled Water ���������������������������������������������23

Heating (Other Than Heat Pump) �������������������������������23

Heating (Heat Pump, Water Source) ���������������������������23

Troubleshooting Guide ������������������������������������������������������24

Limited Warranty ���������������������������������������������������������27–30

Air-Cooled Unit �����������������������������������������������������������������31

Start-Up Procedures (R-410a Systems) ����������������������������31

Optional Heating Start Up: ������������������������������������������32

Air-Cooled Unit �����������������������������������������������������������������33

Start-Up Procedures ����������������������������������������������������33

Cooling Mode ��������������������������������������������������������������34

Electrical ����������������������������������������������������������������������34

Heating Mode (Optional) ���������������������������������������������34

Water-Cooled Unit ������������������������������������������������������������35

Start-Up Procedures (R-410a Systems) ����������������������������35

Optional Heating Start Up: ������������������������������������������36

Water-Cooled Unit ������������������������������������������������������������37

Start-Up Procedures ����������������������������������������������������37

Cooling Mode ��������������������������������������������������������������38

Electrical ����������������������������������������������������������������������38

Heating Mode (Optional) ���������������������������������������������38

Verticool Classic Basic Model Designation������������������������39

LIMITED WARRANTY �������������������������������������������������40

FACTORY TESTED ����������������������������������������������������40

3

Page 4

Installation, Operation and Maintenance Manual

VertiCool Classic

Important Notice

This manual is the property of the owner.

Please be sure to leave it with the owner when you leave the job.

Use of Symbols

This publication includes warnings, cautions and information icons that point out safety related issues or conditions as well

as other pertinent information relative to a safe installation, service or maintenance situation� The following icons should be

interpreted as follows:

ELECTRICAL

HAZARD

WARNING

CAUTION

INFORMATION

The electrical hazard icon indicates the presence of an electrical hazard which

could result in electrical shock or death�

The warning icon indicates a potentially hazardous situation which could result

in death or serious bodily injury if not avoided�

The caution icon indicates a potentially hazardous situation which may result in

minor or moderate injury if not avoided�

The information icon indicates a situation that may result in equipment or

property damage� The information provided alerts the reader to relevant facts

and/or conditions�

Subject to change without notice. 20.10-IM (0617)

4

Page 5

Installation, Operation and Maintenance Manual

General Information

VertiCool Classic

Inspection Of Equipment

Upon receipt of the unit, inspect for visible or concealed

interior / exterior damage� Report any damage to the carrier,

and le a damage claim.

Inspect the unit data plate to verify the model unit that was

ordered is what has been received�

Some options / accessory items may have been shipped

loose in one or more boxes� These may have been delivered

to another location, or possibly within the unit� If shipped with

the unit there will be a sticker that identies where in the

unit the shipped loose items are located. Conrm that all of

these options / accessory items are also available and that

no damage has occurred�

Handling

To facilitate handling, the unit is set on a wooden skid so

that it may be picked up with a two-wheel hand truck or fork

lift� Under no circumstances should the unit or the skid be

“walked” on the corners� Use dolly trucks, pipe rollers or

suitable means to move the unit to its proper location�

If a crane, cables or slings are used to move a unit or module,

spreader bars must be used to protect each section’s

cabinet structure� Some units or modules will be provided

with either lifting eyelets or brackets that should be used to

lift the sections�

When vertical style units are shipped split, or will be split in

the eld and then reassembled in the space, the condensing

section has refrigerant lines that extend above the top of the

cabinet�

When the unit is assembled these ttings are recessed into

the evaporator section . These ttings extend approximately

5” for all models (Figure 1)�

The space height needs to be sufcient to handle not only

the combined unit height, but also the refrigerant tting

clearance height�

5"

Mounting And Setting In Place

CAUTION

Unit should not be located in space subject

to freezing temperatures�

The VertiCool Classic has been designed to be installed as

a single package oor mounted unit.

Unit is to be mounted on a solid oor or supported on a

full 100% perimeter frame. Attention must be given to oor

loading limitations� Floor should be level in both horizontal

planes�

Before the unit is installed, a thorough study should be made

of the structure and proposed installation location� Careful

consideration must be given to location of wiring, condensate

disposal, ductwork and accessibility for maintenance

or service� It is necessary that a minimum clearance of

36” be allowed on the front of the cabinet� Some air path

congurations will also require side access to the evaporator

section. Sufcient clearance must be provided to slide the

air lter(s) out, either the left or right side.

Consideration must be made for condensate removal, either

with a trap or condensate pump�

The units might be shipped as a single package or they

might be shipped split� Units that have been ordered with

the optional resealable refrigerant ttings can be split in the

eld to accommodate moving into position. Sections are

also bolted together�

When re-assembling the evaporator section to the

condensing section, use a sling or other suitable means that

is sufcient to hold the weight of the section. Use spreader

bars to keep the cabinet from being deformed�

Make sure that the evaporator section is positioned correctly

for the desired air pattern� Care must be taken when lowering

the evaporator section that the refrigerant resealable ttings

are lined up properly and that they are not damaged in this

process� Re-install the fasteners if removed prior�

Figure 1

Subject to change without notice. 20.10-IM (0617)

5

Page 6

Installation, Operation and Maintenance Manual

VertiCool Classic

Unit Vibration Isolation

When installing any oor mounted unit, it is generally not

necessary to provide any unit vibration isolation� However,

some form of vibration isolation may be requested� Please

note that the unit frames have not been designed for corner

point only loading with vibration isolation methods�

1. If spring mounts are to be used, fabricate a frame to

provide support around the entire perimeter of the unit�

Allow sufcient clearance for any door or panel access

that is required to provide eld service or maintenance

on the unit� The frame will also need to be designed

with suitable cross bracing� (Figure 2)

2. If wafe pad or other similar sound vibration materials

are going to be used, the material needs to be placed

under the entirety of the unit base�

Figure 2

Location

Strategically located intake and discharge louvers help to

prevent recirculation of discharge and contaminated air

into the intake air stream. Airow around a building and

prevailing wind direction can adversely affect the potential for

recirculation and should be factored into louver placement�

In some areas, local codes dictate louver location� Maximize

the distance of intake louvers from any exhaust outlet and

other contaminants, people, property lines, etc� Avoid placing

intakes near idling vehicles�

The bottom of the intake louver should be raised a minimum

of 12" from a horizontal surface (roof, sidewalk, etc�) to

prevent blockage from debris� If snow accumulations are

expected to be greater than 12", raise the bottom of the

louver above the average snowfall depth�

If more than one VertiCool unit will be installed in the same

area, then the minimum separation of one unit adjacent

to another should be 6 feet� A 10 foot separation distance

should be maintained where two units are installed one

above the other� It is best to direct discharge air up and away

from pedestrian walkways as well�

We do not recommend multiple installations between closely

situated buildings where discharge air could collect and be

directed back to the intake� Again, recirculation will cause

the unit to trip on high head pressure�

Clearance

Clearance of 36" is required on the front side of all units for

service and maintenance access�

If a unit has front return, 30" clearance on each side of

the unit must be provided for access to the motor and / or

refrigerant circuit components, such as the thermostatic

expansion valve(s)�

Filters can be accessed from either side of the unit. Sufcient

space must be provided for removal and replacement of all

lters. This can be from one side only or from both sides.

Louver And Ducting

Carefully choosing the right condensing section intake/

exhaust louver(s) and determining the best location for them

are critical components to a successful VertiCool installation�

and/or discharge unit openings to allow for optimum velocity

and reasonable pressure drop across the louver�

1. Select a louver design that will safely separate the

discharge from the intake air stream to ensure that air

recirculation will not occur�

2. The intake louver should be designed to minimize and

virtually eliminate water penetration at a reasonable

face area velocity (fpm)�

3. The discharge duct must be as short and straight as

possible but of sufcient length to guarantee uniform

airow distribution through the louver for maximum

velocity�

4. In most cases, the cross-sectional “free area” of the

louver must be equal to or larger than the crosssectional areas of the intake and/or discharge unit

openings to allow for optimum velocity and reasonable

pressure drop across the louver�

5. Ducts should be insulated if the unit is installed and

operating in cold climates�

6. Adequate access to both the evaporator and condenser

coils as well as the louver must be available for

cleaning purposes�

7. All louver manufacturer instructions, local codes, and

industry accepted guidelines must be followed for all

installations�

Subject to change without notice. 20.10-IM (0617)

6

Page 7

Installation, Operation and Maintenance Manual

VertiCool Classic

INFORMATION

Discharge air from the condenser air

outlet should be deected away from the

condenser air inlet, to prevent recirculation�

The intake and discharge louver can be in separate frames

or combined in one frame�

The combination intake/discharge louver design (Figure 3)

offers an advantage over separate louvers because it requires

only one wall opening which decreases installation costs�

However, the blades cannot be of uniform conguration (i.e.

the same blade design and angle)� The discharge louver

blades should be angled to direct the airow straight out

horizontally from the unit and the intake blades should be

angled down at approximately 45°�

Combination Intake/Discharge

D

“D”

“D” Discharge“I” Intake

“I”

It is also benecial to angle the bottom of the intake ductwork

up from the louver toward the unit opening to minimize the

possibility of water carryover reaching the unit and allow for

proper drainage Figure 4)�

Figure 4

Discharge Louver

Access panel for condenser coil cleaning�

Inlet Louver

Louvers should be inspected and cleaned on a regular

basis� A bird screen is required to deter animals and debris

from entering the duct system�

3" Separation Plate

4"

[101�5 mm]

W

Figure 3

It is critical that the two air streams be directed in different

directions so that no recirculation of discharge air is allowed to

enter the inlet air stream� In some cases it may be necessary

to provide a deector vane or separator between the two air

streams� If recirculation of the discharge air does occur, the

unit will likely trip on high head pressure and continue to fail

until the louver design is corrected�

Louvers may be manufactured of aluminum (14 gauge) or

steel (18 gauge)� Louver widths of 30 inches or more should

have additional bracing midway along the blades to maintain

proper blade separation� If the louvers are to be installed

in a coastal application or any location with environmental

concerns, then the louvers should be treated�

Length of Ductwork for Discharge Air

The VertiCool Classic unit should be located a minimum

distance from the louvered wall to maximize efciency of the

blower� Certain conditions and obstructions at the fan inlet

and outlet adversely affect fan performance (i�e� elbows,

guards, dampers, etc�)� “System Effect” is a term used by the

industry to describe these adverse conditions� It is best to

design the inlet and discharge ductwork to provide minimum

sufcient straight length of duct to reduce system effect and

allow for uniform air discharge�

Figure 5 below illustrates the discharge air velocity prole at

various distances from the centrifugal blower� It is important

to determine the 100% Effective Duct Length to ensure

uniform air discharge�

Subject to change without notice. 20.10-IM (0617)

7

Page 8

Installation, Operation and Maintenance Manual

VertiCool Classic

Based on formulas in ASHRAE Fundamentals – Duct Design,

Chapter 34, the following minimum intake and discharge

100% Effective Duct Lengths (EDL) are recommended:

3 thru 5 tons = 3�5 feet

6 & 8 tons = 4 feet

10 thru 15 tons = 5�5 feet

Outlet Area

Blast Area

Cutoff

100% Effective Duct Length

20 tons = 6�5 feet

25 tons = 8 feet

30 & 35 tons = 8�5 feet

25%

50%

75%

Discharge Duct

Figure 5

The VertiCool units are supplied with a standard motor

and drive package which provides approximately 0�25”

ESP� Upgrades (optional) are available that can raise this

capability to 1” ESP or more� The drive packages have some

ability to be adjusted in the eld. You must know the overall

duct design in order to determine what drive package will

be required� Normal start-up procedures should be followed

including balancing the system following the completed unit

installation�

Application Data

Voltage 208 / 230 460 575

Variation 187 / 253 414 / 504 518 / 632

Cooling

(Air Entering Evaporator)

Water-Cooled

DB

(min./max.)

WB

(min./max.)

GPM / Ton

(min./max.)

Leaving Water

(min./max.)

65 / 110

57 / 72

2.5 / 3.5

60 / 115

Installation

The VertiCool Classic units can be shipped as a single

package or as a split package which is assembled in the

eld.

Air-Cooled Single Package

1. Move the unit to the desired installation location�

2. Unit contains a full charge of R-410a refrigerant�

3. Install the unit so that controls and access panels are

accessible to the operator and maintenance personnel�

4. Install the condensing section ductwork following the

guidelines and industry accepted practices for the

condenser air inlet and discharge�

5. Install ductwork on the evaporator as required� If the

unit was provided with a discharge plenum having

grilles, no ductwork would be required�

6. Install the condensate trap as outlined below�

7. Wire the unit as outlined below�

Air-Cooled Units Shipped Split or Split In The

Field For Unit Locating

1. Move the unit to the desired installation location�

2. Unit contains a full charge of R-410a refrigerant�

3. Install the unit so that controls and access panels are

accessible to the operator and maintenance personnel�

4. Install the condensing section ductwork following the

guidelines and industry accepted practices for the

condenser air inlet and discharge�

5. When re-assembling the evaporator section to the

condensing section, use a sling or other suitable means

that is sufcient to hold the weight of the section.

Use spreader bars to keep the cabinet from being

deformed�

6. Make sure that the evaporator section is positioned

correctly for the desired air pattern� Care must be

taken when lowering the evaporator section that the

refrigerant resealable ttings are lined up properly and

that they are not damaged in this process� Re-install

the fasteners if removed prior� Systems shipped split

from the factory will have the mounting hardware

located inside the evaporator section�

7. Install ductwork on the evaporator as required� If the

unit was provided with a discharge plenum having

grilles, no ductwork would be required�

8. Install the condensate trap as outlined below�

9. Wire the unit as outlined below�

Note: Not all combinations may be valid.

Subject to change without notice. 20.10-IM (0617)

8

Page 9

Installation, Operation and Maintenance Manual

VertiCool Classic

General Ductwork Recommendations

1. Please make sure that all duct work, evaporator return

and supply air and for air-cooled units the condensing

section inlet and discharge air, is connected to the units

using eld supplied exible duct connectors.

2. Make sure that all duct work is supported

independently from the equipment�

These two installation requirements are meant to minimize

or isolate any unit vibration to help assure that it is not

transmitted into the duct work, to the structure and/or out

into the space�

All ductwork must be designed in accordance with industry

accepted practices� Consult ASHRAE, AMCA or SMACNA

guidelines or standards for details� Use of turning vanes is

recommended�

Verify that the designed duct external static pressure is in

line with the capability of the unit blower / motor provided�

Ducts should be insulated in accordance with applicable

industry standards or per local codes, particularly if the unit

will be operated during cold weather� The condensing unit

intake duct should include a provision to access the inlet

side of the coil for periodic cleaning� It is also best to design

for sufcient clearances for servicing the blower motors,

expansion valves, lters, and any additional accessories

installed�

This negative pressure can vary from less than 1” up to 2”

column. The condensate trap must be of sufcient depth in

water column to permit the condensate to ow from the drain

pan�

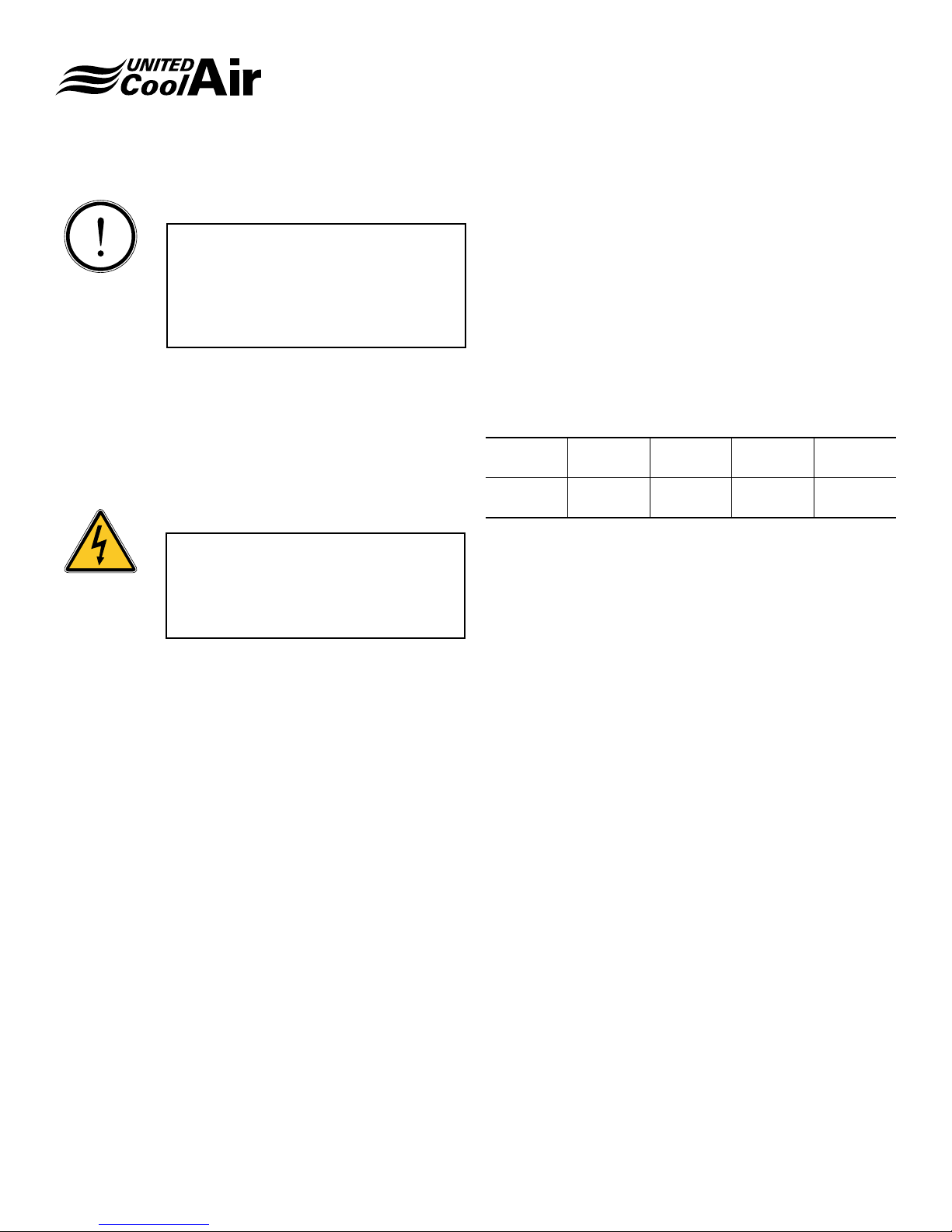

The “A” dimension (Figure 6) must equal or exceed the

negative static pressure developed by the supply air blower�

If it does not, the condensate will not drain properly and

may overow the drain pan. The trap must be at least 2-1/2”

deep to maintain a water seal under all operating conditions,

especially during blower start-up�

It is highly recommended that the trap be primed with water

prior to unit start-up�

Each trap must be piped to a suitable waste drain�

Unit

“A”

2-1/2"

Figure 6

Plenum Installation

The plenum is typically installed at the factory� However, it

may need to be removed to move the unit into position� The

plenum is held in position with drive screws�

If the plenum has discharge grilles, the grilles will have to

be removed to take the plenum off for re-installation on the

evaporator section�

Condensate Drain Connection

Install a eld fabricated condensate trap and drain line or

a condensate pump as required� Route the condensate

disposal tubing to a suitable location�

Units are equipped with two 3/4” IPS evaporator drain

connections� It is only necessary that one drain connection

be utilized� Make sure that the drain connection not being

used is plugged�

The drain line must be trapped because the coils are

located on the negative side of the blower(s)� The purpose

of the condensate trap is to neutralize the negative pressure

created within the cabinet by the blower�

Subject to change without notice. 20.10-IM (0617)

Refrigerant Connections

All units are shipped from the factory with a full factory

refrigerant charge. The resealable refrigerant ttings must

be connected and properly tightened to facilitate refrigerant

ow between the evaporator and compressor / condenser

section�

If the unit has been shipped split or has been split to

accomplish installation, the resealable refrigerant ttings

must be connected as follows:

1. On the refrigerant resealable ttings, if not already

accomplished, apply a few drops (5 to 6 droplets are

recommended) of refrigerant oil to the male coupling

halves before starting the assembly (Ref� to Figure 7)�

2. Align each resealable tting and hand thread the

female tting onto the male tting (Ref. to Figure 7).

Continue to hand thread until resistance is observed�

Continued on next page

9

Page 10

Installation, Operation and Maintenance Manual

VertiCool Classic

3. Once slight resistance is evident, continue to tighten

the ttings using the appropriate size wrenches listed in

Table 1� Please note that it is important to support the

male side of the tting with a wrench when tightening

the female side with a wrench�

4. If the resealable ttings still feel loose, tighten a bit

more as required�

Figure 7

Clockwise Rotation

Female Fitting

Apply oil to male threads Male Fitting

INFORMATION

Count the number of threaded rotations�

Use Table 1 to determine how many total

rotations are required for proper sealing of

the ttings.

Size Wrench Full Turns Required

3/8" 1-3/16" 6

1/2" 1-3/16" 6

5/8" 1-5/8" 7-3/4

3/4" 1-5/8" 7-3/4

7/8" 1-5/8" 8

1-1/8" 2" 8

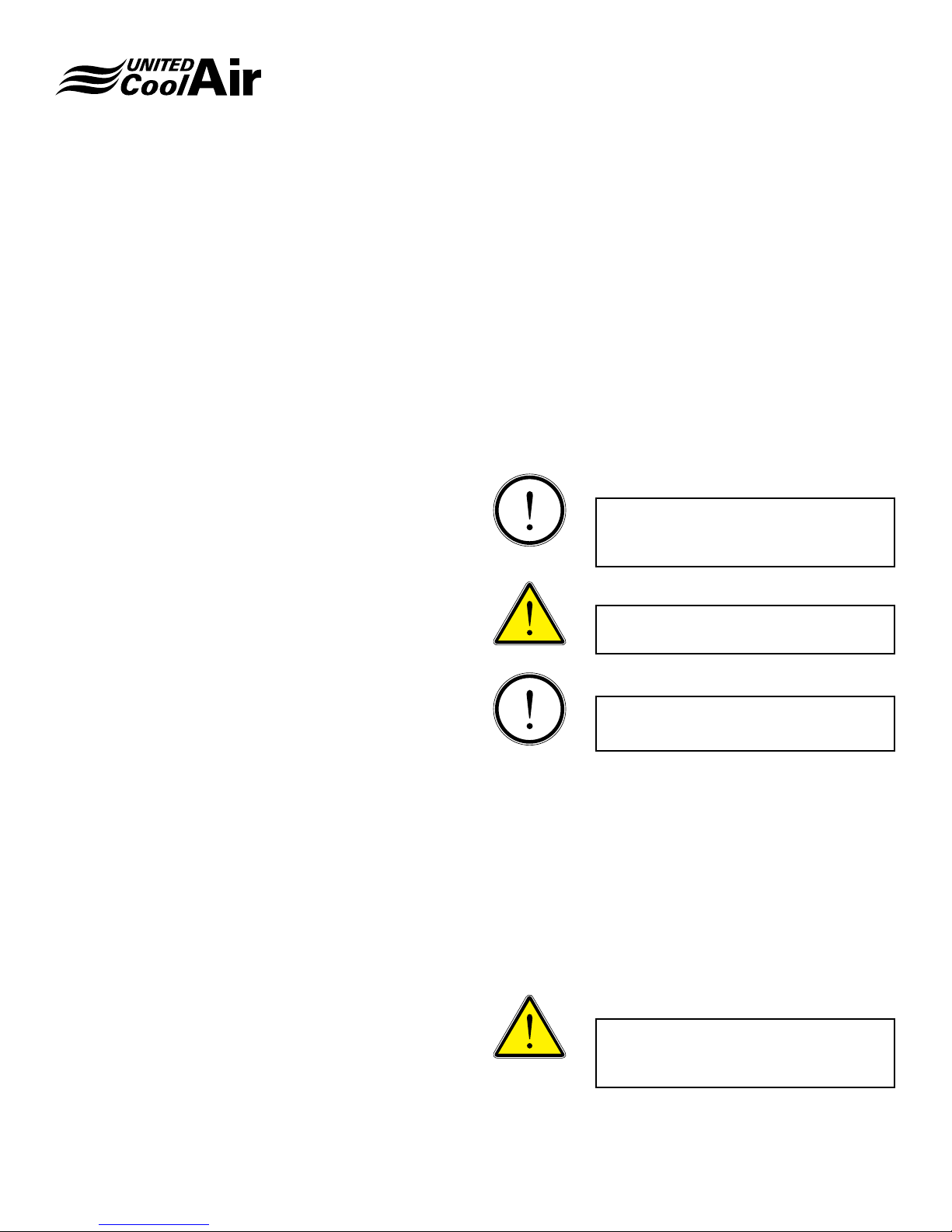

Electrical

ELECTRICAL HAZARD

Only a qualied licensed electrician or

other individual that is properly trained in

handling live electrical components should

perform the wiring installation� Failure to

follow all electrical safety precautions and

industry accepted practices when exposed

to live electrical components could result

in death or serious injury�

INFORMATION

Use Copper Conductors Only� Failure

to use copper conductors may result in

equipment damage�

INFORMATION

All electrical wiring must be in accordance

with NEC (National Electrical Code), NFPA

(National Fire Protection Agency) most

current versions as well as any applicable

state or local codes�

INFORMATION

The correct phase sequence of the

incoming power supply is a requirement�

If the phase sequence is not correct it

could cause damage or failure to electrical

components� Reverse the incoming wiring

to resolve the issue� Do not switch any

internal unit wiring�

INFORMATION

INFORMATION

If low refrigerant pressure is evident during

the start-up process, check the tightness

of all resealable ttings. A tting that is not

fully open will restrict refrigerant ow.

Subject to change without notice. 20.10-IM (0617)

Conrm that the incoming power supply

matches the unit data tag�

10

Page 11

Installation, Operation and Maintenance Manual

VertiCool Classic

INFORMATION

Unit wiring and components have been

designed for the specic unit application

and factory assigned controls� Do not use

the unit transformers or alter the unit wiring

to interface any eld supplied accessories

or controls�

A factory provided power block is installed internal to the

unit’s electrical control panel� Route the main power wires

in accordance with all codes from the disconnect to the unit

power block�

A proper ground termination lug has been provided in the

unit control panel�

ELECTRICAL HAZARD

Conduit is not an acceptable grounding

source� A separate ground conductor must

be connected from Earth Ground to the

factory supplied grounding lug internal to

the unit�

Transformer

Dual voltage units, 208/230, are wired from the factory

for the 208 volt power supply� If the power supply will be

consistently above 220 volts the transformer should be wired

on the 230 volt tap�

Wiring

1. Refer to the wiring diagram that was included with the

unit�

2. Units are completely internally wired at the factory�

3. All units are provided with terminal blocks�

4. Check the unit data tag for the required voltage,

minimum circuit ampacity and maximum fuse size�

5. Route the power wiring through one of the holes

provided in the front corner posts�

6. Power wiring must comply with all National or Local

codes� The power supply must be suitably fused for

wire protection�

7. Use copper conductors only� The unit must be earth

grounded using the ground lug provided in the electrical

box�

8. Select a location to install the thermostat to avoid

vibration, drafts, sun exposure or internal heat sources�

Use an inside wall�

9. Route the correct low voltage wire type and size back

to the unit and through one of the holes provided in the

front corner posts� Connect to the low voltage terminal

block per the wiring diagram supplied�

Wire Size1 AWG. Gauge

22 20 19 18 16

40 120 150 190 305

Maximum Wire Length2 Feet

Notes:

1. Soilid, Class II copper wire

2. Based on a voltage drop of 1�2 volts per wire�

3. Total wire length is from unit to room thermostat, and

back to unit�

Three Phase Power

On units with three phase power supply, check for proper

blower rotation� If they are running backwards, interchange

two of the incoming power leads�

Do not rewire any components inside the unit�

Electric Heat

On larger units having a high amount of electric heat, a

second power supply may be required� Run the second

power supply to the connections located with the heater�

Follow all National Electrical Codes and Local Codes as

required� Make sure to run a ground wire to the supplied lug�

Route the low voltage wiring for the heater control to the low

voltage terminal block located with the heater�

Subject to change without notice. 20.10-IM (0617)

11

Page 12

Installation, Operation and Maintenance Manual

VertiCool Classic

Voltage Unbalance

Voltage unbalance occurs when the RMS line voltages on

a 3-phase power supply are unequal� Voltages are never

balanced between phases, but if the level of the unbalance

becomes excessive it will create problems for not only

motors but also controls�

The maximum desirable voltage unbalance is 2�0%�

When testing for voltage unbalance, the phase-to-phase

voltages should be measured rather than the phase-toneutral voltages since 3-phase motors are connected across

phases� Use the following formula to determine the percent

of voltage unbalance:

Percent Voltage Unbalance = 100 x (Maximum Voltage

Deviation / Average Voltage)

Example:

Phase-Phase voltages

A-B = 479V

B-C = 472V

C-A = 450V

Average Voltage = (479 + 472 + 450) / 3 = 467

Maximum Voltage Deviation from Average =

467 - 450 = 17 (Must always be positive)

Voltage Unbalance = 100 x (17/467) = 3�6%

In this example the percent of voltage unbalance exceeds the

desired maximum of 2%� Additional checks should be made

at the unit disconnect to conrm the values. Use accepted

industry practices to check or test the quality of the power

supply� Often, it is just a matter of repairing malfunctioning

equipment or redistributing loads to improve the unbalance�

If no cause can be located and resolved for the unit power

supply, the building manager or owner should be notied of

the issue to get the proper power supplied to the unit�

It should be noted that the inclusion of a variable frequency

drive (VFD) with an unbalanced power supply may result in

nuisance tripping and 3rd harmonic currents�

Chilled Water Coil Valves Or

Hot Water Coil Valves

Chilled water or hot water valves, if supplied by United

CoolAir, are typically 2-way� The optional valves are shipped

loose for installation in the eld. The valves are to be mounted

in the outlet line of the coil�

Pressure Switches

High Pressure

This switch shuts the unit down in the event of excessive high

pressure in the discharge line� A manual reset is required at

the high pressure switch�

Low Pressure

This switch shuts the unit down in the event of low pressure

in the suction line� This switch is auto-reset�

Water-Cooled Units

INFORMATION

Do not reduce the water inlet or outlet

connection size as this will restrict water

ow and increase water pressure drop.

CAUTION

Ensure that the water pressure to the unit

does not exceed any valve rating�

INFORMATION

All eld installed piping must conform to

applicable local, state and federal laws�

The following items are to be eld supplied and applied:

A. Water shut-off valves (Gate or Ball Type)

B. Inlet water strainer with isolation shut off valves on

each side for periodic cleaning�

The standard condenser heat exchangers are co-axial type�

These are tube-in-tube type that are chemically cleanable�

The inner tube carries the water and the outer tube the

refrigerant� When designing and installing the water piping,

some consideration for the chemical cleaning should be

made, if desired, for future maintenance�

CAUTION

The condensate drain line should not be

connected to the condenser outlet, as

ooding will occur.

Subject to change without notice. 20.10-IM (0617)

12

Page 13

Installation, Operation and Maintenance Manual

VertiCool Classic

INFORMATION

It is advantageous to record the inlet and

water outlet temperatures and the heat

exchanger pressure drop during the unit

start-up procedure� These are then a

valid reference point for maintenance

considerations in the future�

INFORMATION

Field supplied water piping must include

a pet cock or other suitable means at the

highest point to bleed air from the water

piping�

INFORMATION

High inlet water temperature or low water

ow rate may result in nuisance tripping of

the refrigerant high pressure switch�

INFORMATION

Water-cooled units with a glycol cooling

uid will require a higher GPM / Ton ow

rate� Contact the factory for details�

WARNING

Water-cooled units have been designed

for use with fresh water application only�

Do not use for brackish water or salt water

unless appropriate condenser and water

piping has been applied�

INFORMATION

Units have been tested at the factory

before shipment. The test uid at the

factory contains a glycol mixture� It is

important to ush the internal unit piping

and heat exchangers at the job site prior to

start-up or connection to the cooling uid

circuit being used�

Water Piping and Connections

Both the water inlet and outlet of the condensing section

should be equipped with eld supplied shut off valves. This

is needed for shutdown of water supply during long periods

of unit shutdown and/or condenser removal, if required�

If the unit does not have water regulating valves or head

pressure control valves, eld supplied balancing valves may

be required�

INFORMATION

Optional Head Pressure Control Valve(s)

should be incorporated into the unit water

circuit(s) if the cooling uid will be less

than 65° F�

Install and connect a fresh water strainer (eld supplied) to

the water inlet line� Strainer should be readily accessible for

periodic cleaning� Shut off valves on both strainer inlet and

outlet are recommended to facilitate cleaning�

Chilled Water Sections

The chilled water section may be supplied with the lower

section for oor mounting. The chilled water section can also

be supplied as a standalone section�

When being used as a standalone chilled water section, care

must be taken to properly support the section if suspended�

It is advisable to provide a full perimeter frame to assure that

the sheet metal does not buckle�

Provide eld supplied and installed vibration isolation as

required�

Care must be taken when mounting the chilled water section

to assure that adequate service clearance is provided for

access to the components� Make sure that the access

panels can be removed�

The chilled water section will have a control panel�

Dependent upon the system components, this control panel

may be located internal to the evaporator or externally� Wire

high and low voltage to this section as required following

National Electrical Codes or Local Codes�

On larger units having a high amount of electric heat, a

second power supply is required� Run the second power

supply to the connections located with the heater� Follow

all National Electrical Codes and Local Codes as required�

Make sure to run a ground wire to the supplied lug�

Install the chilled water valve per industry accepted practices�

Subject to change without notice. 20.10-IM (0617)

13

Page 14

Installation, Operation and Maintenance Manual

VertiCool Classic

System Options

Humidier

The optional steam humidier that comes with the unit

functions on the electrode principle. As water lls the plastic

steam generator, it immerses metal electrodes then permits

electrical current ow through the water. This current ow

produces heat which then boils the water into steam� This

steam is then injected on the downstream side of the cooling

coil to provide humidication for the area being served by

the unit� Water is replenished through tubing and the 1/4”

are located on the evaporator section structure. For further

information refer to the Humidier Installation Instruction

which accompanies the unit�

INFORMATION

The humidier should not be subjected

to freezing air conditions� If the unit will

be used for outside air applications an

externally mounted humidier should be

used�

Auxiliary Coils (Hot Water or Steam)

A hot water coil or steam coil when used as heat will be

located in the return air stream between the lters and the

evaporator coil� These are typically installed at the factory�

Some units will include Jack Stands to support the auxiliary

coil / lter box. If the unit is shipped as a single package the

jack stands will be attached� Care should be taken when

moving the unit from the skid to the installation location so

as not to tear or loosen the jack stand where it is attached

to the cabinet�

If the evaporator section is shipped loose the auxiliary coil

section will be attached to the evaporator� The jack stands,

if required, will be placed inside the auxiliary coil section�

The mounting hard- ware will be attached to the jack stand

ange.

If an optional hot water valve is ordered, this will be shipped

loose for installation in the eld.

Control wiring will need to be installed from the hot water

valve back to the unit control panel� Follow all National

Electrical Codes and Local Codes as required�

Any steam valves and other adjunct steam components are

to be eld supplied and installed by others.

Control wiring will need to be installed from the steam valve

back to the unit control panel� Follow all National Electrical

Codes and Local Codes as required�

A pan is included under any hot water coil or steam coil� A

condensate trap will need to be installed for this drain pan� A

trap will need to be installed since this line is in a negative air

stream� Follow the same procedures for this line as for the

unit condensate drain line outlined on page 6�

Pipe the hot water coil or steam coil per industry accepted

practices�

Water Side Economizer (Free Cooling Coil)

A water side economizer coil will be located in the return air

stream between the lters and the evaporator coil. These

are typically installed at the factory�

Some units will include Jack Stands to support the water

side economizer / lter box. If the unit is shipped as a single

package the jack stands will be attached� Care should be

taken when moving the unit from the skid to the installation

location so as not to tear or loosen the jack stand where it is

attached to the cabinet�

If the evaporator section is shipped loose the water side

economizer section may or may not be attached to the

evaporator� The jack stands, if required, will be placed inside

the water side economizer section� The mounting hardware

will be attached to the jack stand ange.

If the unit is shipped as a single package, the water piping

from the unit to water side economizer coil will be factory

installed�

If the water side economizer is shipped as a separate section

or if the unit comes with the evaporator and water side

economizer as a section, the water piping will be shipped

loose for eld attachment.

Air Side Economizer

The air side economizer option is installed on the rear of the

cabinet�

Some units will include Jack Stands to support the air side

economizer / lter box. If the unit is shipped as a single

package the jack stands will be attached� Care should be

taken when moving the unit from the skid to the installation

location so as not to tear or loosen the jack stand where it is

attached to the cabinet�

If the evaporator section is shipped loose the air side

economizer section may or may not be attached to the

Continued on next page

Subject to change without notice. 20.10-IM (0617)

14

Page 15

Installation, Operation and Maintenance Manual

VertiCool Classic

evaporator� The jack stands, if required, will be placed inside

the air side economizer section� The mounting hardware will

be attached to the jack stand ange.

The enthalpy sensors for the return air and the outside air

are shipped loose for eld mounting. Follow the instructions

with each sensor for the proper location and mounting�

Field supplied low voltage wiring must be installed between

the two sensors and the terminal blocks located in the unit

control panel� Make sure to use the correct type and wire

gauge size�

When ducting to the air side economizer, exible duct collars

should be utilized to avoid any transmission of vibration into

the duct work�

Split Systems

Systems can be eld modied as a split system option.

Evaporator Mounting

In some situations it is necessary to install the system split�

The evaporator section may be supplied with the lower

section for oor mounting. The evaporator can also be

supplied as a standalone section�

When being used as a standalone evaporator section, care

must be taken to properly support the section if suspended�

It is advisable to provide a full perimeter frame to assure that

the sheet metal does not buckle�

Provide eld supplied and installed vibration isolation as

required�

Care must be taken when mounting the evaporator to assure

that adequate service clearance is provided for access to

the components� Make sure that the access panels can be

removed�

The evaporator section will have a control panel� Dependent

upon the system components this control panel may be

located internal to the evaporator or externally� Wire high

and low voltage to this section as required following National

Electrical Codes or Local Codes�

INFORMATION

Make sure to use the appropriate gauge

of low voltage wire based on the total wire

length so that no more than a 1�2 volt drop

is experienced�

On larger units having a high amount of electric heat, a

second power supply may be required� Run the second

power supply to the connections located with the heater�

Follow all National Electrical Codes and Local Codes as

required� Make sure to run a ground wire to the supplied lug�

Interconnecting Refrigerant Tubing

After the two system sections have been installed, the eld

supplied interconnecting tubing can be run�

(a) Units 10-ton and smaller are provided as standard without

the resealable ttings. In this situation the sections may

be provided with stubbed copper tubing� Follow industry

accepted practices for brazing the eld supplied tubing to the

unit copper tube stubs�

(b) For units supplied with the resealable refrigerant ttings follow

instructions below�

Units are provided with unique self-sealing ttings (Optional

on 10-ton and smaller, standard on 12-ton and larger) on

the refrigerant lines between the sections. These ttings or

couplings allow the two section unit to be separated and

reconnected without loosing the refrigerant charge�

When installed as a split system, an optional interconnect kit

is required for each refrigerant circuit or hot gas bypass line�

If the unit was dened as a split system when ordered, the

ttings will be male on both sections. The interconnect kit will

then consist of the matching female ttings. An interconnect

kit is required for the installer to connect refrigerant lines

between both sections� Refrigerant piping between the

sections is eld supplied.

Systems not ordered from the factory to be installed as a

split system, and that contain resealable ttings, will include

Female Fittings on the evaporator section and Male Fittings

on the condensing section� An optional Interconnect kit(s)

must be ordered indicating that a Male / Female Kit is

required�

The interconnect kit also contains four (4) Schrader ttings.

The installer can place at least one in each refrigerant line or

at one end of the refrigerant line� These enable the refrigerant

line to be evacuated and charged as needed, based on the

size and length�

In some situations, the desired refrigerant line size may

differ from the self-sealing tting size provided. The line size

should be reduced or enlarged at the self-sealing ttings as

necessary�

INFORMATION

On units with more than one refrigerant

circuit, be careful not to intermix liquid,

suction and/or hot gas lines of the various

circuits�

Subject to change without notice. 20.10-IM (0617)

15

Page 16

Installation, Operation and Maintenance Manual

VertiCool Classic

1. Temporarily hand thread the female halves of the selfsealing couplings (supplied with the interconnect kit)

onto the male couplings, approximately 1 to 1-1/2 turns�

This is to make sure that the interconnecting tubing will

be routed and brazed with the self-sealing couplings

in their nal proper location, so that there will be no

difculty when the nal coupling assembly is made.

2. If there is a hot gas bypass option, connect that

coupling the same way�

3. Run the interconnecting tubing required� Always follow

accepted industry practices for sizing refrigerant

lines based on line length and elevation differences�

Disconnect the self-sealing couplings that were

temporarily installed in step 1 above�

4. The suction line should be pitched downward to the

compressor, sloping approximately 1/4” every ten feet

to facilitate oil return�

5. “P” traps (eld supplied) are required for all suction

line risers every 15 feet� When the evaporator is above

the condensing section, an inverted “P” trap should be

incorporated as close as possible to the evaporator

(this minimizes ood back / oil slugging during the off

cycle)� If the condensing section is more than 40 feet

above the evaporator, consult the factory for specic

refrigerant components�

INFORMATION

On units with more than one circuit, be

careful not to intermix liquid, suction, and/

or hot gas lines of the various circuits�

7. Leak check line sets with nitrogen at 500 psig� After

brazing the tubing to the self-sealing coupling halves,

evacuate each line to 300 microns� Check to make

sure that each line holds a vacuum after removal of the

vacuum pump (indicating no leaks) (micron level should

not go above 500 microns within 10 minutes)� Wipe

off coupling seals and threaded surfaces with a clean

cloth to prevent the inclusion of dirt or foreign material

into the system� Lubricate rubber seal and metal seal in

the male halves with refrigeration oil� Thread coupling

halves together by hand to insure proper mating of

threads� Continue to hand-thread each half-coupling

to its mating half until resistance is felt (approximately

1-1/2 to 1-3/4 turns)� Complete the connection of the

mating half-couplings with a wrench� If the resealable

ttings still feel loose, tighten a bit more as required.

INFORMATION

Count the number of threaded rotations�

Use Table 1 to determine how many total

rotations are required for proper sealing of

the ttings.

Size Wrench Full Turns Required

3/8" 1-3/16" 6

1/2" 1-3/16" 6

5/8" 1-5/8" 7-3/4

3/4" 1-5/8" 7-3/4

7/8" 1-5/8" 8

1-1/8" 2" 8

Table 1 - Resealable Fitting Turns

INFORMATION

When brazing tubing to the self-sealing

couplings, use a water soaked wet rag,

running water bath or chill blocks on the

quick-connects to prevent overheating the

valves and damaging the seals� Always

apply heat toward the eld installed

refrigerant line� Do not apply heat toward

the coupling valve and seal�

6. Install the Schrader valve ttings into the tubing before

brazing the couplings onto the ends of the tubing� Use

a 1/4" hole to mount the valve� Clean and debur the

tubing before doing any brazing to ensure that no chips

or debris are left in the refrigerant circuit� Remove the

Schrader valve cap and core before doing any brazing�

Subject to change without notice. 20.10-IM (0617)

INFORMATION

If low refrigerant pressure is evident during

the start-up process, check the tightness

of all resealable ttings. A tting that is not

fully open will restrict refrigerant ow.

The drawing below illustrates a typical piping arrangement

for factory ordered split systems

A - Male self-sealing ttings on unit sections

B - Refrigerant piping between sections (eld-supplied)

C - Female self-sealing ttings in interconnect kit (4)

D - Schrader ttings in interconnect kit (4)

16

Page 17

Installation, Operation and Maintenance Manual

VertiCool Classic

A

Evaporator

Section

A

D

C

D

C

D

B

D

B

C

C

A

Condensing

Section

A

8. Size refrigerant lines per industry accepted practices�

9. Refrigerant piping shall be insulated in accordance with

local codes and / or applicable ASHRAE Standards�

Insulation exposed to weather shall be suitable for

outdoor use� Provide protection from water and

shielding from solar radiation as necessary�

10. Max. total equivalent line length is 100 feet.

(a)

Max. elevation difference between Evap. And Cond.

Is 40 feet.

(a) Contact the factory for installations with elevation

differences greater than 40 feet or total equivalent

lengths greater than 100 feet� Alternate line sizes and

specic additional refrigerant circuit components may be

required�

(b) If condensing section is 20 feet or more above the

evaporator an oil separator is to be included for each

circuit�

(a) (b)

11. Split must contain refrigerant circuit items as follows:

Equivalent Feet

Oil Separator

Accumulator

Quench Valve

Solenoid Valve

Liquid Line

c. For 5/8” liquid line – add 1�8 oz� per foot

d. For 7/8” liquid line – add 2�4 oz� per foot

Condensate Pump

If an optional condensate pump is to be used, it will be

mounted external to the unit�

Follow pump manufacturer instructions�

A 115 volt power supply must be eld supplied for the pump.

INFORMATION

The condensate line out of the unit must be

trapped before going into the condensate

pump�

Refer to Figure 8 for the termination of the condensate tubing

inside the pump�

Refer to Figure 9 for the inverted “U” trap that is to be installed

for the condensate line�

Cut tubing at an angle so

that bottom of reservoir

doesn’t close it� Be sure

tubing does not interfere

with oat.

Discharge Line > 100 X

Ext. Hot Gas Bypass Line > 50 X

Liquid Line Net Down >50 X

Suction Line >100 X X X

Suction Line Ambient > 100° F >50 X X

Suction Line Down > 50 X

12. Add the appropriate charge of R-410a Refrigerant

using the Schrader valves to compensate for the

additional interconnecting tubing as follows:

a. For 3/8” liquid line – add 0�6 oz� per foot

b. For 1/2” liquid line – add 1�2 oz� per foot

Subject to change without notice. 20.10-IM (0617)

Max� Pump Lift

17

Figure 8

To

Drain

Inverted

“U” Trap

Figure 9

Page 18

Installation, Operation and Maintenance Manual

VertiCool Classic

Controls

Thermostat

Conrm that the correct thermostat is being applied based

on the number of cooling stages and heating if applicable�

Follow the thermostat manufacturer instructions�

Microprocessor Controller

For units controlled by a microprocessor refer to the specic

instructions for that device�

Flooded Condenser

When the outdoor ambient temperature falls, the condensing

pressure falls� This causes the discharge pressure to fall�

Since the pressure differential across the thermostatic

expansion valve port affects the rate of refrigerant ow, low

discharge pressure generally causes insufcient refrigerant

to be fed to the evaporator. Failure to have sufcient head

pressure will result in low suction pressure and/or iced

evaporator coils�

The purpose of a ooded condenser is to hold back enough

of the condensed liquid refrigerant so that some of the

condenser coil surface is rendered inactive� This reduction

of active condensing surface results in a rise in condensing

pressure and sufcient liquid line pressure for normal system

operation�

The effective range for this option is down to –30° F�

A three–way modulating valve and a receiver tank make up

the ooded condenser refrigerant components.

The valve is placed in the liquid line after the condenser coil�

The receiver is downstream of the valve� The valve limits

the ow of liquid refrigerant from the condenser while at the

same time regulating the ow of discharge gas around the

condenser to the receiver�

During periods of low ambient operation, the receiver

pressure falls until it approaches the setting of the control

point of the valve (typically 295 psig for R-410a)� The valve

then throttles to restrict the ow of liquid from the condenser.

This raises the condenser pressure� Since it is the receiver

pressure that is being maintained, the valve will then start

to throttle open the discharge port when the differential

between the condensing pressure and the receiver pressure

exceeds 20 psi� The hot discharge gas serves to heat up the

cold liquid being passed from the condenser to the receiver�

Thus the liquid reaches the receiver warm and with sufcient

pressure to assure proper expansion valve operation�

The receiver is required to hold all the excess/additional

liquid refrigerant in the system, since the refrigerant will be

returned to the receiver when the high ambient conditions

exist�

In the off-cycle the refrigerant can “migrate” to the condenser,

during periods of low outdoor ambient� On a call for startup, the evaporator pressure may not build up to the cut-in

point of the low pressure control� The result may be a failure

of the compressor to start or to short cycle� To eliminate

this potential problem, a time delay is added to bypass the

low pressure switch during start-up to allow the discharge

pressure to build, in turn increasing the suction pressure�

Subject to change without notice. 20.10-IM (0617)

18

Page 19

Installation, Operation and Maintenance Manual

Maintenance Procedures

VertiCool Classic

ELECTRICAL HAZARD

Turn OFF power and lockout service

before conducting any maintenance� Keep

hands, clothing and tools clear of electrical

terminals�

WARNING

Make sure to keep hands and clothing

clear of any moving belts, blowers and

motors while performing any maintenance�

Failure to do so could result in death or

serious bodily injury�

CAUTION

Any maintenance should be conducted

by qualied HVAC service personnel only.

Potentially hazardous situations which

may result in personal injury, equipment or

property damage�

Filters

Do NOT run unit without lters.

Throwaway lters are supplied which are pleated extended

surface type� Filters should be checked monthly for dirt

accumulation and changed when necessary� Replacement

lters must be the same type as originally supplied.

INFORMATION

Unit must be shut off at the disconnect

switch before the lters are serviced. Be

sure to check that the air ow direction

arrows on the lters point in the correct

direction of air ow.

Cleaning The Water-Cooled

Condenser

Any uid that is used to carry the heat away through the

condenser contains, minerals, dust from a cooling tower or

other foreign materials� Over time these contaminants will

build up on the walls of the heat exchanger�

This scale or fouling will result in a reduction in water ow,

less water temperature difference between inlet and outlet,

high condensing temperature and higher uid pressure drop.

All of these affect the operating performance and efciency

of the system and need to be addressed�

Cleaning a water-cooled condenser helps to improve the

heat transfer rate, reduce operational cost, restore efciency,

prolong heat exchanger life and reduce pressure drop

pumping costs� Deposits from water or water treatments,

such as scale, lime, rust or mud are removed�

Each installation is unique. Therefore, the uid quality and

operating conditions will dictate when the heat exchanger

needs to be cleaned�

During the start-up process record the water pressure drop

across the heat exchanger� Also record the inlet and outlet

water temperatures� After a period of time these values can

be checked to see how much loss of operating performance

has occurred� If a 10% or greater change has occurred, it

would be benecial to clean the heat exchanger.

There are a number of commercially available products for

cleaning a heat exchanger� Follow all industry practices to

safely and effectively clean the heat exchanger�

Blowers

Disconnect power and lockout the service before doing any

service or maintenance�

Air-cooled units are provided with adjustable belt drive

blower packages for both the evaporator and condensing

sections� Check that the blower wheel is tight on the shaft

and does not contact the housing� Bearings are permanently

sealed, but should be checked periodically for signs of wear�

Check for restrictions or foreign material in the air circuit�

The drive may be adjusted for different static pressures� If

such an adjustment is made, check that the motor current

draw does not exceed the motor nameplate current by more

than 10%�

Blower Motors

All blower motors are equipped with thermal overload

protectors�

WARNING

Open disconnects to unit before doing

any service or maintenance� A motor that

is off on thermal overload can start any

time when the automatic thermal overload

resets�

Subject to change without notice. 20.10-IM (0617)

19

Page 20

Installation, Operation and Maintenance Manual

VertiCool Classic

Blower Speed Adjustment

Blower speed may be changed by adjusting the variable

diameter sheave provided on the blower drive motor�

Sheave may be adjusted by removing the belt and loosening

the setscrew located in the hub of the outer ange. With the

setscrew loosened, the ange may be turned clockwise

to increase blower speed or counter-clockwise to reduce

blower speed�

Typically the motor and drive packages have been sized and

designed for the specic CFM and external static pressure

(ESP) of the application. Before making any changes conrm

what the performance was designed for and what the actual

performance is�

INFORMATION

Setscrew must be positioned directly

above the at section of the threaded

sheave shaft before tightening to hold

adjustment�

INFORMATION

Reduction of airow through excessive

external air friction losses, lowered blower

speed operation with dirty lters, or

obstructed air ow may result in excessive

condensation at air outlets, short cycling,

or total unit shut- down due to evaporator

coil icing�

INFORMATION

Verify that the motor current draw does

not exceed the motor nameplate current

by more than 10%�

Blower Bearing Lubrication

INFORMATION

Unit must be shut off at the disconnect

switch before the blowers are serviced�

Bearings on the smaller units are permanently sealed, but

should be checked periodically for signs of wear�

Larger units have pillow block bearings� Bearings will need

to be lubricated based on the use of the equipment�

Duty Grease Interval

Low Usage 12 Months

Periodic 6 Months

Continuous 1 – 2 Months

Use a high quality lithium grease for blower pillow block

bearings. Wipe off the “Zerk” tting with a rag before adding

grease so as not to introduce dirt into the bearing�

Slowly rotate the shaft while pumping it in� Pump the grease

in slowly so as not to blow out the bearing seal� When the

grease starts to “seep” out of the bearing you have put in

enough new lubricant�

Over lubricating can cause a bearing to fail from overheating

or it can blow out the seal�

Both excessive or inadequate grease may cause premature

failure� Provided there is some grease in the bearings for

lubrication, under lubrication is better than over lubrication

as grease can easily be added but not removed� Always

allow a slight bead around the circumference of the seals to

protect the bearing from foreign matter and helps ush out

the bearing as well�

Wipe off the “Zerk” tting with a rag after adding grease

Belts

Excessive belt tension is the number one cause for blower

bearing failure� Proper belt tension and pulley alignment are

essential for trouble free operation�

Deection is the amount the belt gives when force is applied,

usually by nger, to the belt at the approximate center point

to the belt span�

Insufcient deection indicates that the belt tension is

entirely too tight, and if not loosened somewhat, noise due

to excessive vibration, premature bearing failure, shortened

belt life, and a reduction in supply air blower performance

may result� Tight belts may also overload the motor and

cause the efciency to drop considerably or even premature

motor failure as well�

Excessive deection is an indication that the belt is not tight

enough� If not corrected, slippage may occur causing loss of

blower speed and belt failure� The belts will glaze then crack

or even break due to increased temperatures caused by

slippage� Belts may slip during start-up, but slipping should

stop as soon as the fan reaches full speed�

If the midpoint (midway between the blower and motor shaft)

of the belt is pressed inward, there should be about 1/2” to a

1” of deection when the belt is properly tensioned.

Subject to change without notice. 20.10-IM (0617)

20

Page 21

Installation, Operation and Maintenance Manual

VertiCool Classic

Refer to Figure 10 – Belt Tensioning below�

Deection Point

Belt Span

Figure 10 – Belt Tensioning

For proper tensioning, an excellent method to use is listed in

the following equation�

Deection = Belt Span

64

Belt span is in inches from center pulley to center pulley (see

Figure 10)�

Belt tension is adjusted by using the adjusting bolt on the

end of the motor mounting frame�

Check the alignment of the sheaves to make sure that the

sheave faces are in the same plane� Check this by placing

a straight edge across the face of the sheaves� Any gap

between the edge and sheave faces indicates misalignment

When the indicator is pink or purple, an abnormal condition

exists, servicing is required�

INFORMATION

After installation and during equipment

start-up, the sight glass may appear pink

or purple� This occurs during prolonged

periods of non-operation and should turn

blue after several hours (up to 12) of

operation�

Evaporator And Air-Cooled

Condenser Coils

The nned coils in a unit should be checked at least every

six (6) months or more frequently based on experience of

the specic application.

Evaporator nned coils can become “fouled” due to a build

up of contaminants in the air path that are not caught or

captured in the air lters. Over time this build up on the n

surface can reduce heat transfer and increased resistance

to air ow. The end result might be higher operating costs or

occupant discomfort

A dirty condenser coil will cause high condensing pressures,

resulting in higher power consumption and possibly system

shut-down by high pressure safety control� A dirty evaporator

coil will reduce unit capacity and eventually will cause system

shut-down by the low pressure safety control�

Finned Coil Cleaning

Note: This alignment method is only valid when the width of

the surfaces between the belt edges is the same for

both sheaves. When they are not equal or when using

adjustable pitch pulleys, adjust so that the belts have

approximately equal tension. Both shafts should be

at right angles to the belt. Check the setscrew and/or

bushing bolt tightness.

Belts tend to stretch somewhat after installation� Recheck

belt tension after several hours of operation�

Refrigerant Systems

All refrigerant circuits contain a liquid line sight glass� If

bubbles appear in the sight glass, the system is either

undercharged with refrigerant or there may be a restriction in

the liquid line upstream of the sight glass� However, bubbles

will appear every now and then in units with the hot gas

bypass option� Bubbles will also appear upon compressor

start up, but normally clear to pure liquid after a few minutes

of operation�

The sight glass contains a moisture indicator which changes

color when moisture is present in the refrigerant circuit� This

indicator is the circular dot in the center of the sight glass�

If the color of this indicator is blue, the refrigerant is okay�

Subject to change without notice. 20.10-IM (0617)

Before cleaning any nned coils, remove the lters. Remove

any large debris or visible dirt accumulation�

WARNING

Make sure to follow all safety precautions

when cleaning any coil with a commercially

available coil cleaner� Follow all

recommendations for safety clothing and

gear� Failure to follow all safety instructions

could result in death or serious injury�

CAUTION

Clean coils only with cold water and a

suitable detergent or a commercially

available coil cleaner� DO NOT use hot

water or steam to clean a coil containing

refrigerant as this may cause a high

pressure situation that could damage

the coil and associated safety devices or

refrigerant components�

21

Page 22

Installation, Operation and Maintenance Manual

VertiCool Classic

CAUTION

Conrm that any coil cleaning agents,

detergents or solutions are suitable for

use on a copper tube/aluminum n coil. If

the cleaning agent is to acidic or alkaline,

damage to the coil ns may result.

Rinse all coils thoroughly after any coil cleaning�

Use a suitable n comb after the coil cleaning to straighten

any bent ns.

Water Side Economizer Coil

If a unit contains the optional water side economizer coil it

may also require a periodic cleaning� These coils will need

to be cleaned using a chemical solution� These are available

commercially� Follow all manufacturer recommendations

and safety warnings�

Water Valves

At least once a quarter check the water vales to make sure

that no leaks are present� Look at the valve stem and all

piping joints�

If any leaks are found follow the manufacturers

recommendations for tightening any seals or replacing any

gaskets�

Hard Start Kit

A start assist device is utilized on all single phase units� The

purpose of this device is to assist the compressor in starting

under low voltage conditions�

A capacitor in conjunction with a Positive Temperature

Coefcient (PTC) relay is installed across the run and

start windings of the motor� The PTC device utilizes a

ceramic element with a predictable thermal response to

the introduction of electric current� When the compressor is

called upon to start, the start capacitor provides a voltage

boost to the start winding of the motor and causes the motor

to turn� As the starting current is introduced across the start

windings, the PTC element begins to warm� When the PTC

device reaches approximately 250° F (corresponding to 0�6

- 0�8 seconds), the resistance in the element increases and

creates an open switch that releases the start winding from

the circuit and the motor continues to run� If the compressor

does not start before the device heats to 250° F, it will not

start until the PTC device cycles through a cool-down period

(usually 2 - 3 minutes)� A compressor off-cycle timer is

included in the electrical circuit for this purpose�

The time delay also helps the refrigerant system pressures

to equalize at the end of the run cycle� This helps the

compressor during the starting process in that it is not

attempting to start against a high discharge pressure�

INFORMATION

Verify that this timer is set for 3 or more

minutes�

Checking Hot Gas Bypass Valve

1. Connect a calibrated thermocouple lead to the outlet

line at the hot gas bypass valve� Tie wrap and insulate

the lead�

2. Connect a low pressure refrigerant gauge to the suction

line�

3. Connect a high pressure refrigerant gauge to the liquid

line�

4. Operate the air conditioner in the cooling mode until the

system is stabilized� (Approximately 15 minutes)

5. If the high side pressure is not at or above 400 psig,

block off the condenser inlet air stream until the

pressure is above this threshold� This will simulate

system performance level close to the design condition

of 95° F ambient�

6. The hot gas bypass valve setting is 104 psig�

A. If the suction pressure is 104 psig the

thermocouple reading should be approximately

117° F or higher� Please note that it may be

necessary to block off some of the evaporator air in

order to check this condition�

B. If the suction pressure is above 104 psig the

thermocouple reading should be less than 117° F�

C. If the suction pressure is below 104 psig the hot

gas bypass valve should be adjusted to raise the

pressure�

Adjustment Of Hot Gas Bypass Valve

The function of the hot gas bypass valve is to prevent the

suction pressure from falling below a predetermined set

point, thereby balancing the system� The set point is typically

104 psig (R-410a)�

1. Connect a low pressure refrigerant gauge to the suction

line�

2. Operate the air conditioner in the cooling mode until

system is stabilized� (Approximately 15 minutes)

3. Remove the seal cap that covers the adjustment screw

of the hot gas bypass valve�

4. Adjust the valve by turning the stem� A CLOCKWISE

turn will increase the pressure setting� A

COUNTERCLOCKWISE turn will decrease the