United CoolAir VariCool VAV, AVW08, AVW60, AVW10, AVW12 Installation, Operation And Maintenance Manual

...Page 1

®

VariCool

VAV

Installation, Operation and Maintenance Manual

Effective August 2018

Water-Cooled and Chilled Water,

Variable Air Volume

Page 2

Page 3

Contents

Installation, Operation and Maintenance Manual

VariCool® VAV

Contents � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

Wiring Diagram � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

Important Notice� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Use of Symbols� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

General Information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

EQUIPMENT INSPECTION. . . . . . . . . . . . . . . . . . . . . . 6

HANDLING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

LOCATION AND CLEARANCES . . . . . . . . . . . . . . . . . . 6

UNIT DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

UNIT WEIGHT � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

UNIT INSTALLATION � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

Vibration Absorbers . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Refrigerant Connections . . . . . . . . . . . . . . . . . . . . . . . 10

Duct Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Water Piping / Water Flow . . . . . . . . . . . . . . . . . . . . . . 12

Water Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Recommended Field Installed Externally� � � � � � � � � � � 12

Condensate Drain Connection . . . . . . . . . . . . . . . . . . . 12

ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . 13

SINGLE POINT DISCONNECT (OPTION) . . . . . . . . . 13

SERVICE DISCONNECT. . . . . . . . . . . . . . . . . . . . . . . 13

Supply Air Temperature Sensor . . . . . . . . . . . . . . . . . . 14

Return Air Temperature Sensor (Option) . . . . . . . . . . . 14

Duct Mount Installation. . . . . . . . . . . . . . . . . . . . . . . . . 14

Wall Mount Installation . . . . . . . . . . . . . . . . . . . . . . . . . 14

Return Air Sensor Wiring . . . . . . . . . . . . . . . . . . . . . . . 15

Return Air RH Sensor (Option). . . . . . . . . . . . . . . . . . . 15

Outdoor Air Sensor (Option). . . . . . . . . . . . . . . . . . . . . 15

Duct Mount Installation. . . . . . . . . . . . . . . . . . . . . . . . . 15

Outdoor Air Sensor Wiring . . . . . . . . . . . . . . . . . . . . . . 15

Return Air RH Sensor (Option). . . . . . . . . . . . . . . . . . . 15

High Static Pressure Switch. . . . . . . . . . . . . . . . . . . . . 15

Remote Alarm Output (Option). . . . . . . . . . . . . . . . . . . 16

Remote Water Pump (Option) . . . . . . . . . . . . . . . . . . . 16

O/A Damper Control (Option). . . . . . . . . . . . . . . . . . . . 16

Smoke Detector/Fire Stat (Option). . . . . . . . . . . . . . . . 16

Remote On/Off Control (Option) . . . . . . . . . . . . . . . . . 16

SEQUENCE OF OPERATION . . . . . . . . . . . . . . . . . . . 16

MARVEL PLUS CONTROLLER. . . . . . . . . . . . . . . . . . 16

Maintenance Procedures� � � � � � � � � � � � � � � � � � � � � � � � 17

Filters� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

Cleaning The Water-Cooled Condenser� � � � � � � � � � � � 17

Blowers � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

Blower Motors� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

Blower Speed Adjustment � � � � � � � � � � � � � � � � � � � � � � � 18

Blower Bearing Lubrication� � � � � � � � � � � � � � � � � � � � � � 18

Belts� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

Refrigerant Systems� � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

Evaporator And Air-Cooled Condenser Coils � � � � � � � 19

Finned Coil Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Water Side Economizer Coil . . . . . . . . . . . . . . . . . . . . 20

Water Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Hard Start Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Checking Hot Gas Bypass Valve . . . . . . . . . . . . . . . . . 20

Adjustment Of Hot Gas Bypass Valve . . . . . . . . . . . . . 20

Sequence Of Operation Cooling - - Air-Cooled . . . . . . 21

Cooling - - Water-Cooled . . . . . . . . . . . . . . . . . . . . . . . 21

Cooling - - Chilled Water . . . . . . . . . . . . . . . . . . . . . . . 21

Heating (Other Than Heat Pump) . . . . . . . . . . . . . . . . 21

Heating (Heat Pump, Water Source) . . . . . . . . . . . . . . 21

Troubleshooting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

Limited Warranty � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

Limited Warranty for Hermetic Compressors � � � � � � � 27

Limited Warranty Condensing Section � � � � � � � � � � � � 28

Limited Warranty for Hermetic Compressors � � � � � � � 29

Air-Cooled Unit � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 30

Start-Up Procedures (R-410a Systems). . . . . . . . . . 30–31

Air-Cooled Unit � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 32

Water-Cooled Unit � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 34

Start-Up Procedures (R-410a Systems). . . . . . . . . . 34–35

Water-Cooled Unit � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 36

VARICOOL - Model Number Designation � � � � � � � � � � � 38

Subject to change without notice. 10.20-IM (0818)

3

Page 4

Installation, Operation and Maintenance Manual

VariCool® VAV

Wiring Diagram

United CoolAir provides a wiring schematic for each unit produced. To retrieve the diagram for your unit please visit

www�unitedcoolair�com, on your computer or mobile device, scroll to the footer section or Home/industry-resources,

enter your serial number in the Serial Search eld and press return to retrieve your product-wiring diagram.

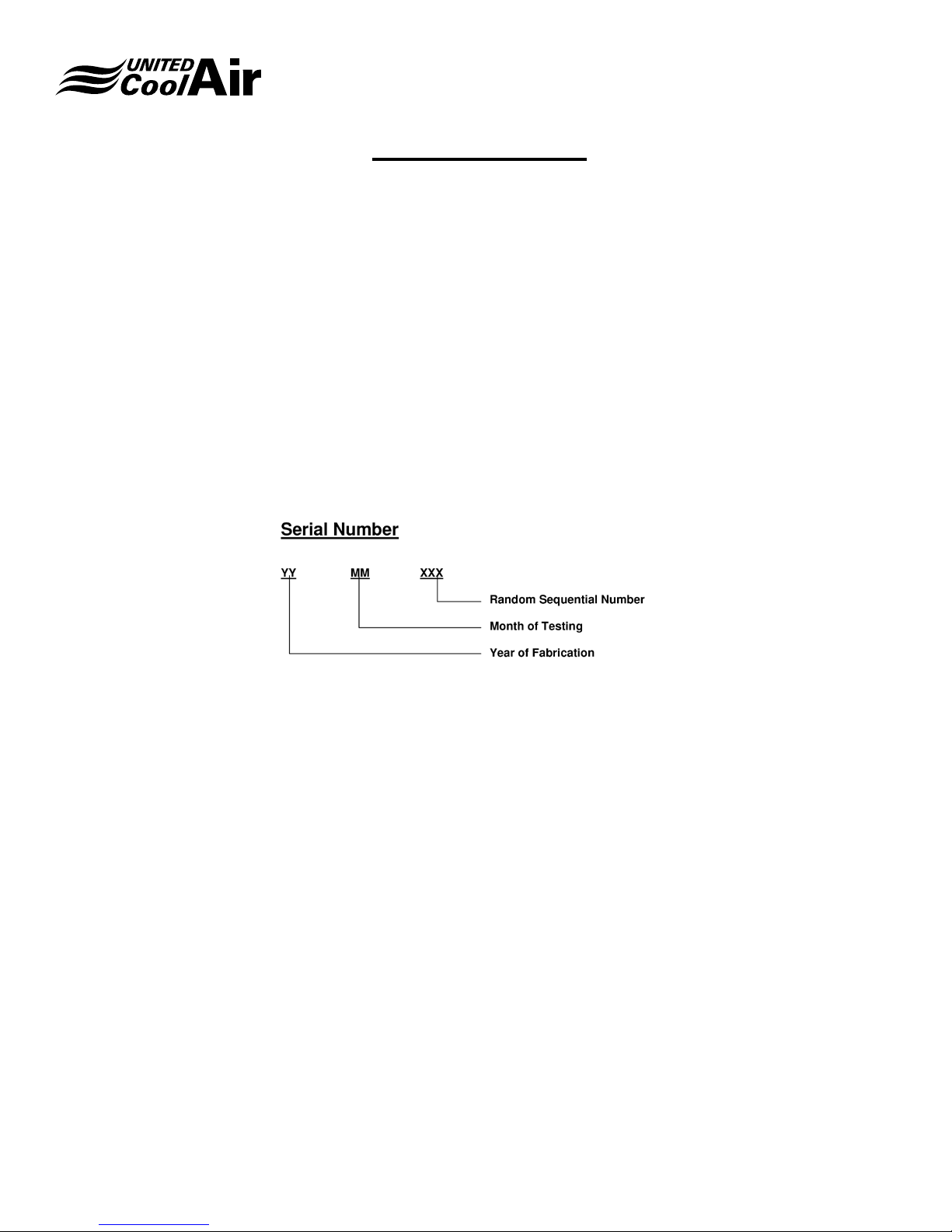

Your serial number is a combination of the year, month and sequential order of build date.

This action will return the Model number, Job Number and the wiring diagram for viewing as well as downloading.

NOTE: Only units shipped since November 2016 are available on the site, for older units please contact the factory directly

at 717-843-4311.

Subject to change without notice. 10.20-IM (0818)

4

Page 5

Installation, Operation and Maintenance Manual

Important Notice

This manual is the property of the owner�

Please be sure to leave it with the owner when you leave the job�

VariCool® VAV

NOTE: If the unit design was ordered specic to the

application or installation, please refer to the Addendum

at the end of this product literature� The unit may have

features or options specic to this job or application so

please refer to the addendum for details� The addendum

will also list the specic United CoolAir Job Number

or eld reference Job Name. Examples of unit design

specic to unit ordered will include product dimensions,

special control sequences and remote condenser /

condensing sections�

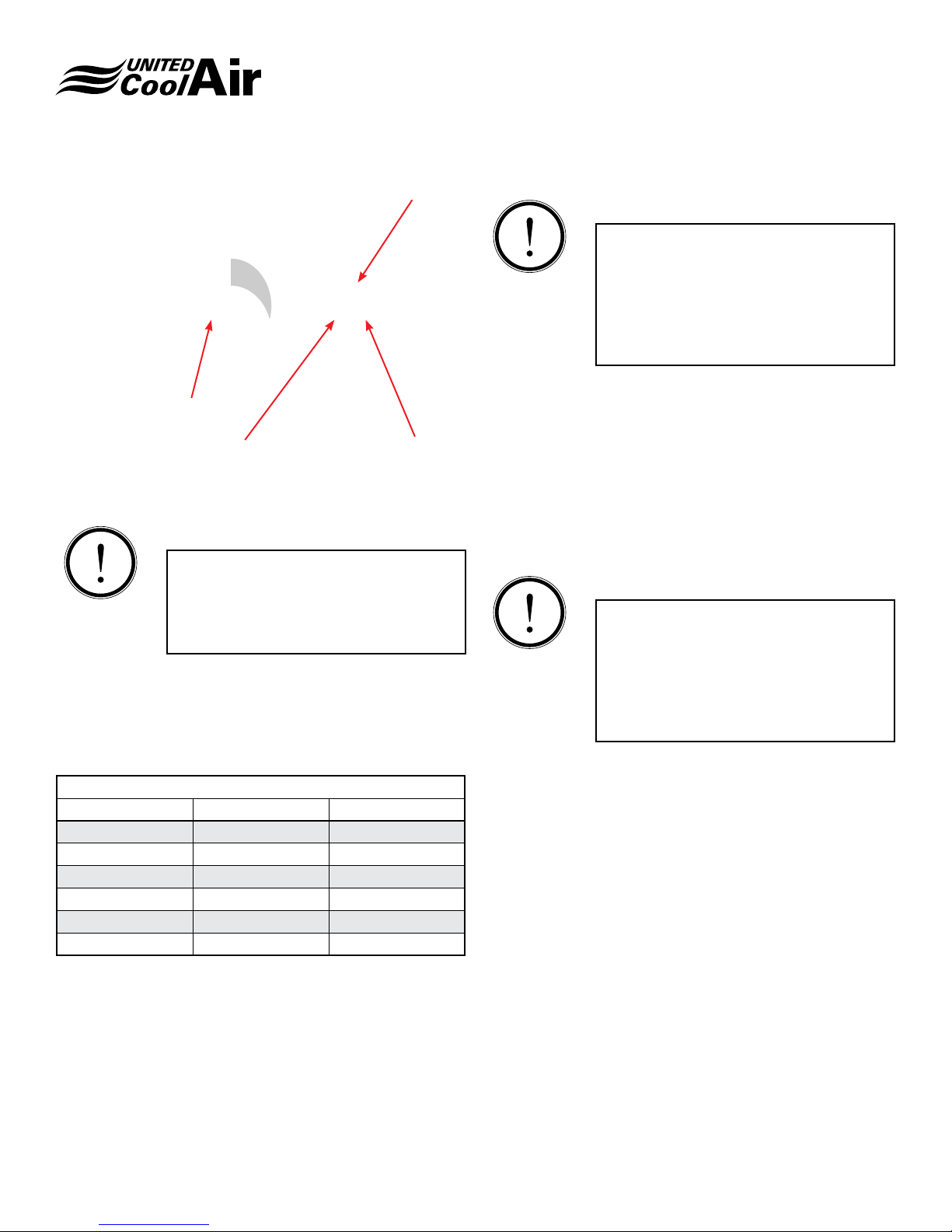

Use of Symbols

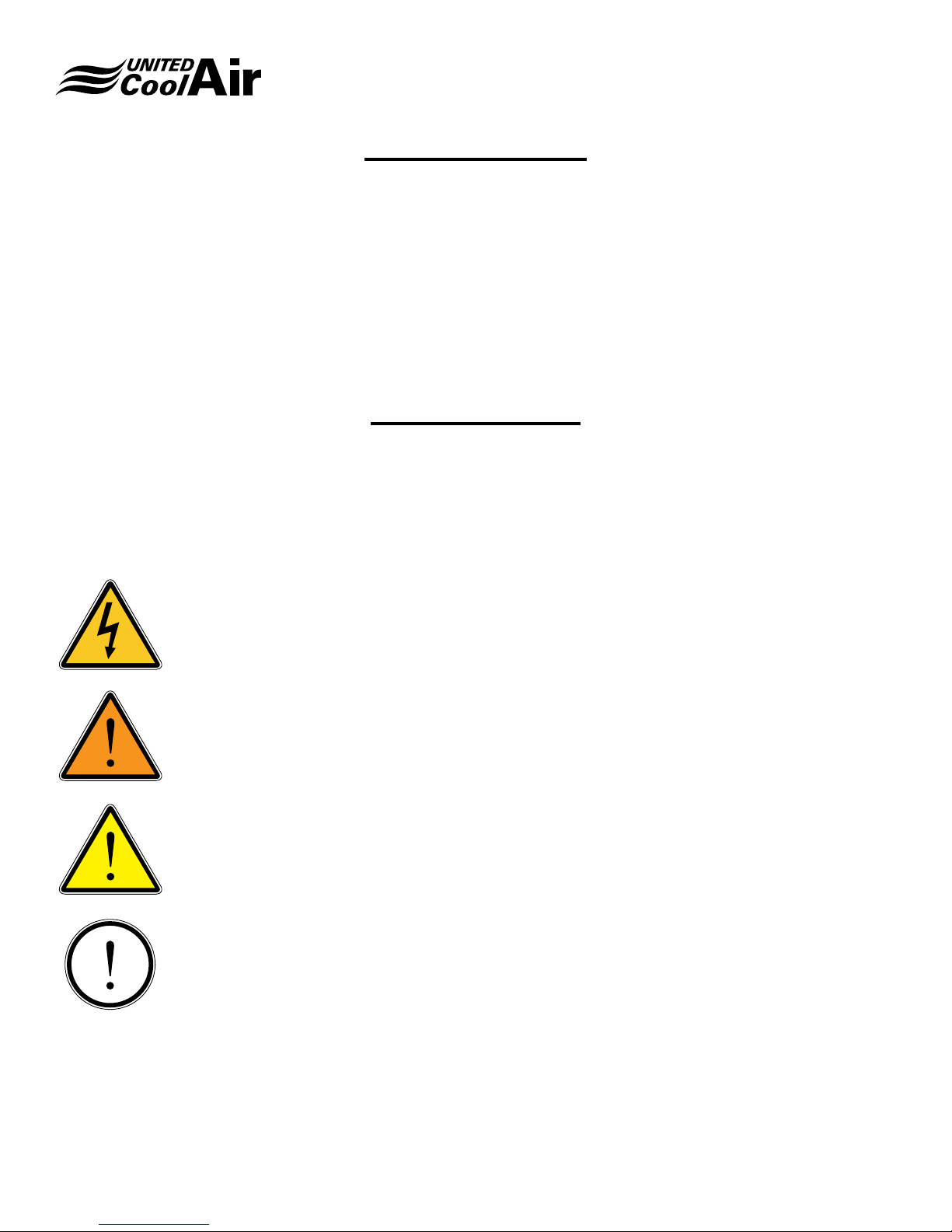

This publication includes warnings, cautions and information icons that point out safety related issues or conditions as well

as other pertinent information relative to a safe installation, service or maintenance situation. The following icons should be

interpreted as follows:

ELECTRICAL

HAZARD

WARNING

The electrical hazard icon indicates the presence of an electrical hazard which

could result in electrical shock or death.

The warning icon indicates a potentially hazardous situation which could result

in death or serious bodily injury if not avoided.

CAUTION

INFORMATION

Subject to change without notice. 10.20-IM (0818)

The caution icon indicates a potentially hazardous situation which may result in

minor or moderate injury if not avoided.

The information icon indicates a situation that may result in equipment or

property damage. The information provided alerts the reader to relevant facts

and/or conditions.

5

Page 6

Installation, Operation and Maintenance Manual

General Information

VariCool® VAV

VariCool units are cooling and optional heating systems

designed to effectively and efciently maintain tenant

occupied spaces within oor by oor building structures.

Each VariCool unit delivers continuous air ow at varied

air volumes and constant temperature to maintain tenant

occupied space settings through eld supplied VAV terminal

outlet boxes. Each unit is designed for optimal energy

efciency, reliability, IAQ, and lowered sound levels. Each

occupant then controls their specic zone by adjusting

temperature setting allowing the VAV terminal outlet box to

open to provide conditioned air. As the VAV box opens, the

VariCool automatically adjusts to maintain the systems static

pressure set point.

Multiple VariCool Systems may be networked together for

unit lead lag, back up/assist, and system rotation. Options

are available for linking each system through a facilities

Building Management System (BMS).

Each unit is shipped in two/three pieces (depends on model

size) for ease on movement to the location of installation.

EQUIPMENT INSPECTION

Upon receiving the unit, carefully inspect all sections for visible

or concealed interior/exterior damage. If damage occurred

during transit, contact the freight carrier immediately and le

a damage claim report. Inspect the unit data plate to verify

that the model unit that was ordered is the correct unit being

received. All accessory components for the application that

must be eld installed are shipped loose in one or several

boxes in the compressor section.

may be moved to the location of installation by crane, fork lift,

hand truck, or roller bars. Units are provided with lifting rings

for rigging and movement by crane. Spreader bars must be

used to protect section cabinet structure during movement.

Protection must be used so that damage to the cabinet

does not occur when using cables or slings. Be certain each

section is well supported when moving. When using dollies,

fork lifts, hand trucks, or roller bars, make sure the sections

base rails are well supported and the weight of the sections

are distributed evenly so that dropping or damage does not

occur during movement.

LOCATION AND CLEARANCES

The unit should be installed in an equipment room located

away from occupied tenant spaces. Careful consideration

should be taken during system layout and installation to allow

for minimum required service clearances for the VariCool

unit. Minimum clearances provided are worst case scenario.

If the clearances were less around the cooling coil section

and a cooling coil had to be replaced, it would be difcult to

maneuver the coil around the unit unless a service access

door(s) to the mechanical room were located next to the

VariCool’s cooling coil end. Figure 1 – Service Clearances

and Table 1 show minimum clearance requirements for each

model unit. If the unit has an optional water side economizer

coil, the distance for service clearance must be maintained

from the edge of the lter rack which will mount onto the

economizer section on larger units but DX cooling coil

on smaller units as the economizer coil will be mounted

internally on smaller systems.

HANDLING

Use extreme caution so that damage does not occur when

moving each section to the location of installation. The unit

Subject to change without notice. 10.20-IM (0818)

6

Page 7

Installation, Operation and Maintenance Manual

VariCool® VAV

FIGURE 1 – Service Clearances

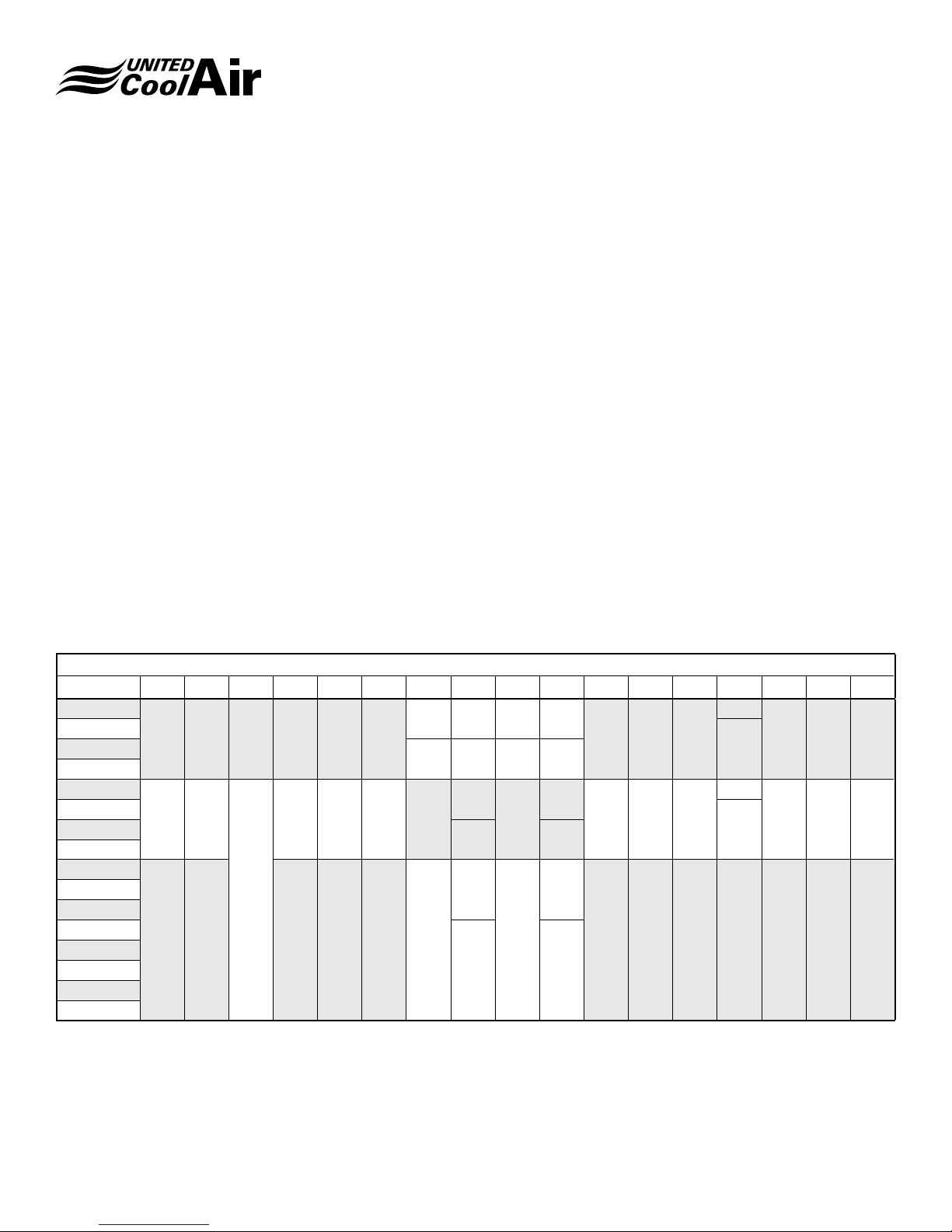

TABLE 1- SERVICE CLEARANCES

Unit Model (A) Dim (B) Dim

AV*8 – AV*16 30” 30”

AV*20-AV*30 42” 36”

AV*32-AV*60 50” 36”

UNIT DIMENSIONS

Figure 2 – Unit Dimensions and Table 2 show the dimensions

of each unit section. Note: If the System has the Water Side

Economizer Coil option, the unit will have a fourth section

that will be attached onto the Cooling Coil/Return Air Inlet

end of the unit. This has been labeled with the dimension

Tx on the diagram and it will vary depending on the lter

options desired.

Subject to change without notice. 10.20-IM (0818)

7

Page 8

Installation, Operation and Maintenance Manual

VariCool® VAV

FIGURE 2 – Unit Dimensions

TABLE 2 – Unit Dimensions

MODEL A B C D E F G H I J K L M N P R S

AV*08

AV*10

AV*16

AV*20

AV*24

AV*30

68 68 32 32 38 30

80 80

35 48 32 20

16 26 8 21

18 32 7 18

36

7.5

44 18

AV*32

AV*36

AV*40

AV*44

AV*48

AV*52

35

98 100 52 62 36 30

42

11

52 24

AV*56

AV*60

Tx – Filter Rack dimensions are as follows:

T1 – 7” width when a standard 2” Filter is ordered

T2 – 9.5” width with extra ltration option includes a 2” plus 4” lter back to back

TBD TBD 21.5

22

TBD TBD 21

29

1.5 97 4 80 10.5 4.5 86

20

TBD 5 50

40AV*12

40

TBD 5 66

60AV*26

Subject to change without notice. 10.20-IM (0818)

8

Page 9

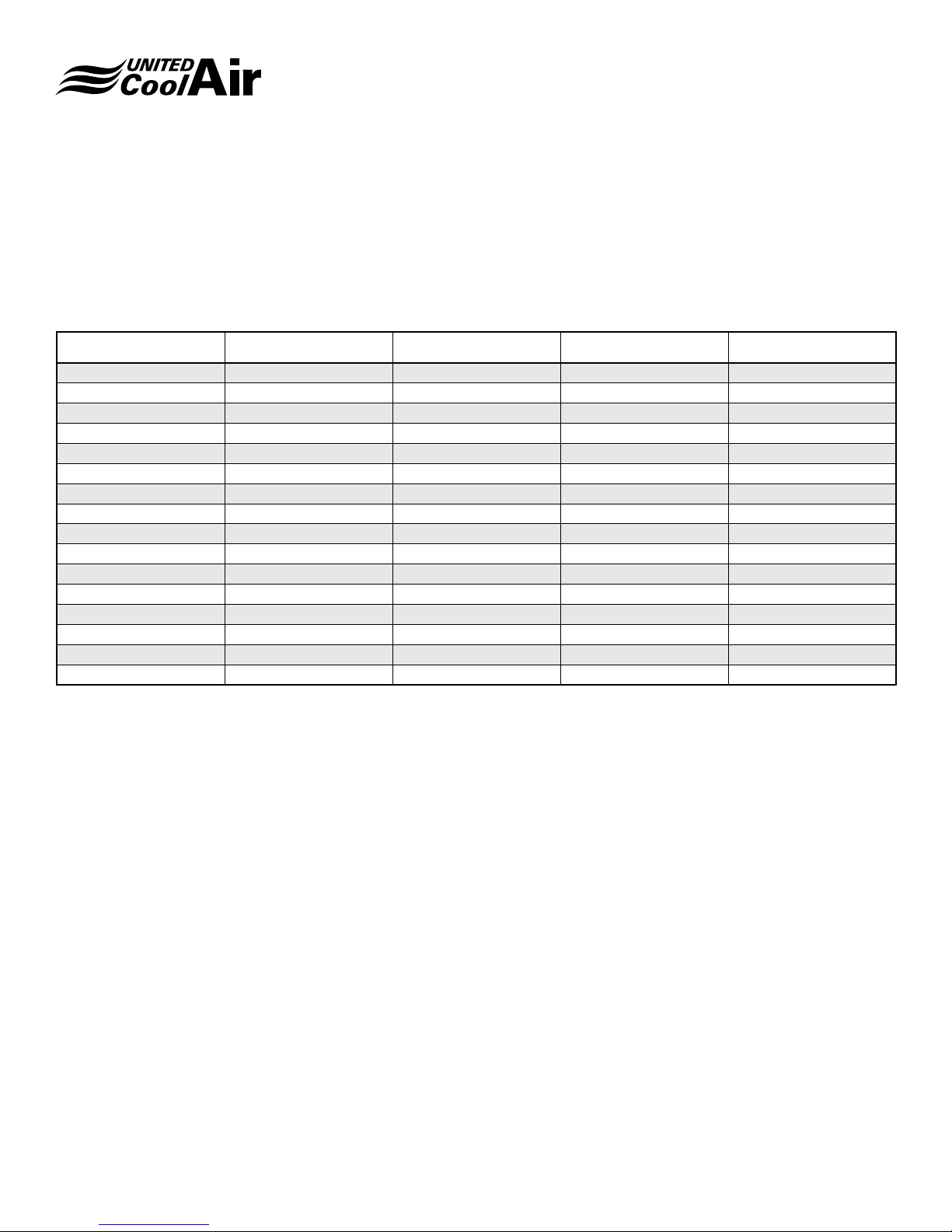

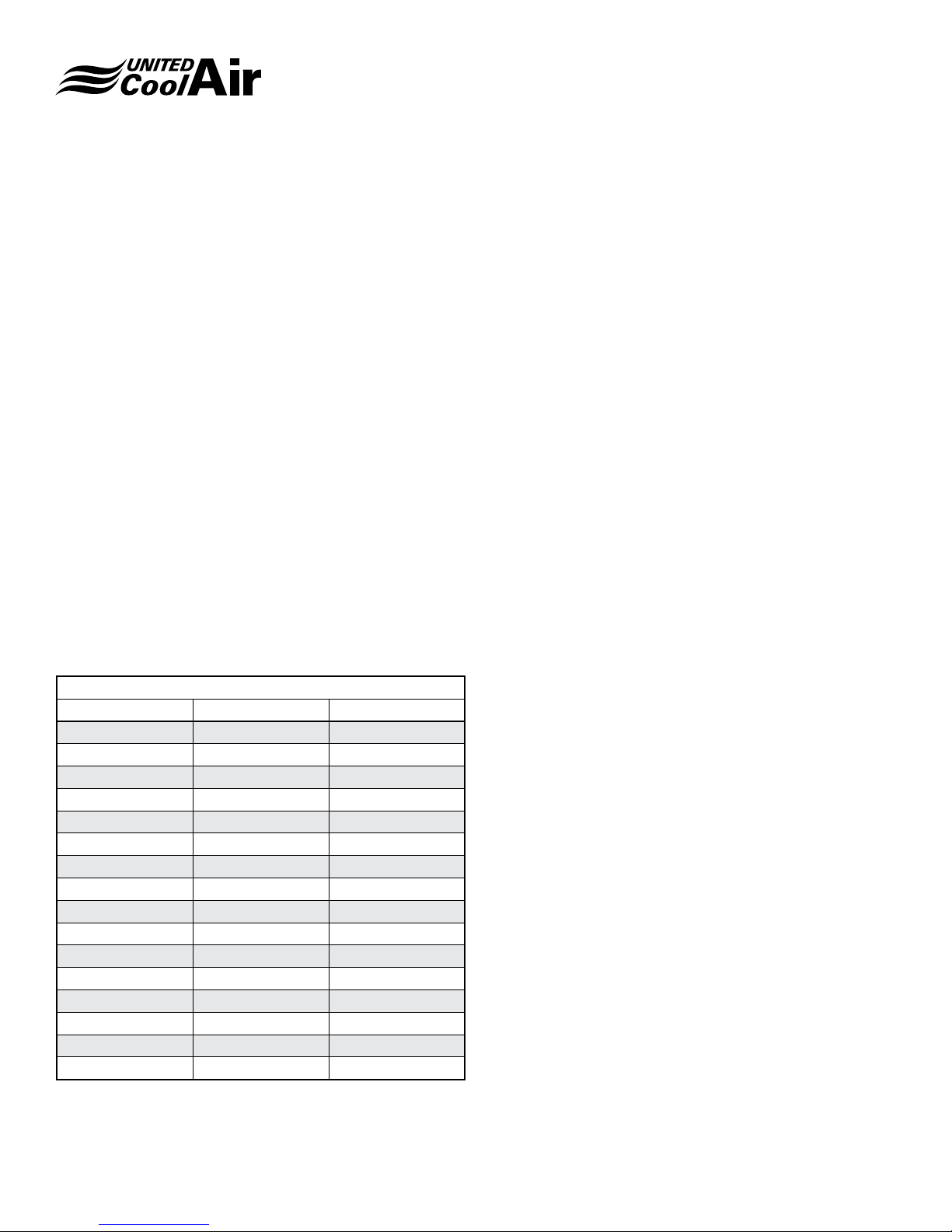

UNIT WEIGHT

Table 3 – Unit Weight shows the weights of each model. The

weight of each unit is listed as a standard VariCool without

options. Table 4 – Optional Component Weight references

the weights of each optional component or upgrade package.

MODEL BLOWER (lbs) EVAPORATOR (lbs) CONDENSER (lbs) TOTAL (lbs)

AVW08 588 521 592 1701

AVW10 617 550 642 1809

AVW12 699 562 732 1993

AVW16 757 619 796 2172

AVW20 1134 856 910 2900

AVW24 1270 954 1046 3270

AVW26 1305 954 1196 3455

AVW30 1305 989 1216 3510

AVW32 1735 1256 1697 4688

AVW36 1787 1325 1673 4785

AVW40 1805 1387 1847 5039

AVW44 1953 1422 1899 5274

AVW48 1953 1479 1942 5374

AVW52 2087 1489 2227 5803

AVW56 2155 1535 2247 5937

AVW60 2155 1593 2287 6035

Installation, Operation and Maintenance Manual

VariCool® VAV

When calculating the weight for each unit, the weight of each

optional component must be added to the standard VariCool

unit weight shown in Table 3.

Table 3 – Unit Weight

Subject to change without notice. 10.20-IM (0818)

9

Page 10

Installation, Operation and Maintenance Manual

VariCool® VAV

UNIT INSTALLATION

Install the unit using the following procedures. Consideration

must be taken for proper condensate drain installation. Slight

elevation of the VariCool unit may be required for installation

of the condensate drain. Methods for elevating the VariCool

units are support rails, concrete pad(s), or spring isolators.

1� Once the unit’s sections have been moved to the

location of installation, locate the factory provided

mounting hardware, which has been pre-installed in the

holes where the sections will be connected together.

2� Using the appropriate size wrenches, remove the

mounting hardware and set in a safe location for

connecting the sections together during installation.

Vibration Absorbers

When installing the VariCool on a concrete pad, support

rails, or other methods other then spring isolation, use of

vibration absorbers is recommended to prevent transmission

of possible vibration.

3� Figure 3 – Vibration Pads shows the recommended

points for vibration absorbent pads (eld provided). We

recommend the use of a minimum 1” thick Neoprene

vibration absorbent pad under each point shown in

Figure 3. Models AV*09 through AV*16 only require the

pads under the corners only.

4� Place each vibration isolator into positions shown in

Figure 3, and then move the compressor and cooling

coil section into the location of installation being careful

not to damage the quick connect refrigerant piping.

5� Fasten the cooling coil section bottom half to the

compressor section using the mounting hardware

removed in Step 2.

6� Allow the hardware to remain only hand tight until the

Blower Section is installed.

INFORMATION

IMPORTANT: Before proceeding with

the installation of the Supply Air Blower

Section, we recommend connecting the

refrigerant quick connect connections

otherwise it may be difcult to make the

connections.

Refrigerant Connections

The DX Cooling Coil section refrigerant circuit is connected

to the compressor/condenser section using quick-connect

refrigerant connections. If the VariCool unit is a split system

with a Remote Air Cooled Condenser, refer to the section on

Split Systems. If the VariCool was ordered as a packaged

system, connecting refrigerant tubing will be fairly simple.

The quick connect ttings are self-sealing so they do not

permit refrigerant ow until they are completely tight. Follow

these steps for a packaged system:

7� Remove the caps on the quick connect refrigerant

lines.

8� Using a small amount of National 150 or 3G brand

refrigerant oil, lightly lubricate the threads of the

quick connect ttings. (5 to 6 droplets of oil are

recommended)

9� Align each quick connect tting and hand thread the

Female Quick Connect ttings onto the Male Quick

Connect ttings as shown in Figure 4 – Quick Connect.

FIGURE 3 – Vibration Pads

Subject to change without notice. 10.20-IM (0818)

10

Page 11

Installation, Operation and Maintenance Manual

VariCool® VAV

Female Fitting

Clockwise Rotation

Apply oil to male threads

Male Fitting

FIGURE 4 – Quick Connect

INFORMATION

NOTE: Be certain to count the number

of complete thread rotations. Observe

the number of turns reference Table 6 to

determine how tight to make the quick

connect couplings

10� Continue to hand thread until slight resistance is

observed.

11� Once slight resistance is evident, continue to tighten

the ttings using appropriate size wrenches listed in

Table 5.

TABLE 5

QC-Size Wrench # Full Turns

3/8” 1-3/16” 6

1/2” 1-3/16” 6

5/8” 1-5/8” 7-3/4

3/4” 1-5/8” 7-3/4

7/8” 1-5/8” 8

1-1/8” 2” 8

12� If the quick connect still feels loose, tighten just a bit

more until complete resistance is evident.

INFORMATION

NOTE: Once tight, refrigerant should be

able to pass through the quick connect

couplings. If problems with low refrigerant

pressure appear during system startup,

double check the tightness of these quick

connect couplings as loose ttings will

restrain full refrigerant ow.

13� Move the Blower Section into position of installation

making sure the side that the blower can be seen will

mate up with the large opening in the Cooling Coil

Section.

14� Lift the blower section up onto the Compressor Section.

15� Use the remaining mounting hardware to connect the

Blower Section to the Cooling Coil Section.

16� Using the appropriate size wrenches, hand-tighten all

mounting hardware.

INFORMATION

Note: seismic isolators are shipped

completely locked into position. Once

the blower section is installed the spring

isolators adjusted to loosen the blower on

isolators. The blower should be allowed to

oat on the isolators approximately ½" to

1" side to side and back and fourth.

17� Once the supply air blower is installed, the spring

isolators under the supply air blower must be

loosened. It is the responsibility of the installing

contractor to loosen the spring isolators. These

isolators are tightened for shipping purposes only.

They must be loosened for proper operation.

Subject to change without notice. 10.20-IM (0818)

11

Page 12

Installation, Operation and Maintenance Manual

VariCool® VAV

Duct Connections

A supply air plenum must be eld fabricated and attached

to the supply air outlet with a exible duct collar. Follow

appropriate guidelines for typical ducting installation.

Provide a duct length that is 3 to 4 times the diameter of

the plug fan wheel before making the rst transition. Provide

turning vanes when required. Attach the supply air plenum

Water Piping / Water Flow

As a standard, units shall have a shell and tube water cooled

condenser. The end plates of the shell and tube condenser

are fully removable for brush cleaning when soft deposits or

scale have formed internal to the condenser coil. Table 6 lists

the water ow and water pressure drops for each model unit.

Tube and tube water cooled condensers may be substituted.

Water Connections

Do not reduce water inlet and outlet connections as this will

restrain water ow and increase water pressure. The inlet

water line should have a strainer accessible for periodic

cleaning. Both the inlet and outlet water lines should have

eld installed water shut-off valves (Gate or Ball type valves).

The shutoff valves are required for maintenance, system

repairs, or long periods of system shut down.

TABLE 6 – Flow Rates/PSI Drop

Model GPM PSI

AVW8 24 4

AVW10 30 6

AVW12 36 7

AVW16 48 8

AVW20 60 6

AVW24 72 8

AVW26 78 10

AVW30 90 14

AVW32 96 8

AVW36 108 10

AVW40 120 6

AVW44 132 7

AVW48 144 8

AVW52 162 10

AVW56 168 12

AVW60 180 14

Recommended Field Installed

Externally

Condensate Drain Connection

Each VariCool unit has a condensate drain connection on

the Cooling Coil section. For systems with the Water Side

Economizer coil option, condensate drain connections are

provided

A condensate drain trap must be eld fabricated and

installed onto the 1" IPS drain connection. Each trap must

then be piped to a common waste drain. Refer to Figure

5 – Condensate Trap for reference dimensions. Units are

equipped with a 1" male IPS connection.

For systems with the Water Side Economizer coil option,

each individual section (Cooling Coil and Water Side

Economizer sections) must be piped individually with a

separate drain trap. Once each section has a drain trap, they

may be connected together by a tee and piped to a common

waste drain.

The depth of the condensate trap will vary due to the model of

the unit ordered and eld requirements. The purpose of the

trap is to neutralize the negative pressure created within the

blower cabinet. Refer to the order specications for external

static pressure (ESP) to calculate the depth required for the

“A” Dimension shown in Figure 5. The A Dimension must

equal or exceed the negative pressure developed by the

supply air blower. If it does not, the condensate will not drain

properly and may allow the drain pan to overow. The lower

leg of the trap must maintain a minimum depth of 3-1/2” to

maintain a water seal on during all operating conditions.

Plug each section’s (Cooling Coil and optional Water Side

Econo Coil) opposite side drain connection as shown.

Subject to change without notice. 10.20-IM (0818)

12

Page 13

FIGURE 5 – CONDENSATE TRAP

ELECTRICAL CONNECTIONS

All electrical wiring must be in accordance with NEC (National

Electrical Code) and state and local building codes. Refer to

the specications section or the unit’s data tag for the unit’s

power requirements. The main power entrance for each

VariCool unit is located directly above the electrical box.

SINGLE POINT DISCONNECT (OPTION)

If the VariCool unit has through the door single point power

disconnect option, turn the disconnect switch to the ON

position.

SERVICE DISCONNECT

A eld installed fused single point power service disconnect

is required. Install the service disconnect in accordance

with NEC, State, and Local building codes. NEC guidelines

require the unit’s disconnect be installed within sight of the

unit.

A factory provided power block is installed internal to the

VariCool’s electrical control panel. Route the main power

wires in accordance with electrical codes to the eld provided

unit disconnect and terminate them on the line side of the

disconnect. Route the power wires from the Load side of

the eld provided service disconnect to the unit power block

inside the electrical panel.

A ground termination point is located within the VariCool’s

electrical control panel.

Installation, Operation and Maintenance Manual

VariCool® VAV

INFORMATION

NOTE: Conduit is not an acceptable

ground source. A separate ground conduct

must be connected from Earth Ground to

the factory supplied ground lug internal to

the unit.

SENSOR FIELD MOUNTING & WIRING

All sensors and optional components that must be eld

installed and wired to the electrical control panel must be

wired as shown on the electrical diagram provided with the

unit and the instructions listed below.

Static Pressure Transducer

The static pressure transducer is factory installed internal to

the main electrical panel and wired back to the main control

board. Pneumatic tubing (eld supplied) must be connected

from the “HIGH” connection to a point approximately 2/3rds

the distance down the straightest length of supply air ducting.

NOTE: Make certain there are no kinks in the pneumatic

tubing.

1� Drill a hole into the ducting at a right angle. Place

approximately 1/8” of the high pressure tube into the

duct at a right angle. The end of the pneumatic tubing

must be cut at and make a right angle for the tube to

pick up the correct air pressure reading.

2� Use a clamp to secure the tube to the ducting.

3� Make certain the end of the tube is cut ush at a 90

degree right angle. This tube must be located in

ambient air.

The static pressure transducer is preset to read from 0”

to 2.5” W.C. The VariCool’s controller will read the preset

conguration. If a lower pressure conguration is desired,

use the manufacturer’s provided literature to re-congure for

the sensor to read the desired lower pressure setting.

INFORMATION

NOTE: The VariCool’s controller for sensor

calibration must also be readjusted. This

is explained under sensor calibration in

the Marvel Plus controller section.

Subject to change without notice. 10.20-IM (0818)

13

Page 14

Installation, Operation and Maintenance Manual

VariCool® VAV

Supply Air Temperature Sensor

The supply air temperature sensor is typically factory

installed. If the sensor is factory installed, it will be connected

to terminal strip TB2 terminals 3 and 4. It will have a

label around the sensor wire stating “SUPPLY SENSOR

FACTORY INSTALLED”.

In some cases, the sensor must be eld installed in the

straightest length of supply air duct for uniform air ow. The

location of the sensor must be relatively close to the duct

pressure transducer but must not impede the airow to the

inlet of the transducer. A few feet from the transducer is

recommended.

1� Cut out the mounting template provided with the

sensor.

2� Select the location to mount the sensor and drill a hole

through the supply air duct at least ¾” in diameter.

3� Using a 7/64” drill bit; drill the three fastening screw

holes located on the template for the fastening ring.

4� Remove the duct sensor’s mounting ring from the duct

probe and position it over the holes previously drilled in

the duct.

5� Use three #6 x ¾” Pan Head sheet metal screws and

fasten bracket to the duct.

6� Place the probe into the supply air duct.

7� Use the screw provided to tighten the clamping ring.

Using a minimum 18-20 AWG 300 volt rated two conductor

shielded cable with drain wire make the following electrical

connections.

8� The supply air temperature sensor is non-polarity

observant. Connect from one NTC terminal inside the

supply air temperature sensor to TB2-3.

9� Connect the other NTC terminal inside the temperature

sensor to TB2-4.

10� Connect the drain wire to ground at the VariCool’s

electrical control panel end only.

Airside Economizer option or optional Humidication/

Dehumidication, a Humidity Sensor will also be provided.

The unit Return Air Sensor must be eld installed in the return

air ducting, Return Air Plenum, Open Return Air Plenum as

close to the VariCool unit’s Filter Rack as possible. Since

United CoolAir may not know the application, please specify

the type of sensor (wall or duct mount) required for eld

installation. Typically if the return air is Open Plenum, a wall

mount sensor is recommended. If the return air is ducted

into the unit, a duct mount sensor is recommended.

BE AWARE: If the unit has optional humidity control,

polarity must be observed when making

electrical connections�

1� Cut out the mounting template provided with the

sensor.

Duct Mount Installation

2� Select the location to mount the sensor and drill a hole

through the supply air duct at least ¾” in diameter.

3� Using a 7/64” drill bit; drill the three fastening screw

holes located on the template for the fastening ring.

4� Remove the duct sensor’s mounting ring from the duct

probe and position it over the holes previously drilled in

the duct.

5� Use three #6 x ¾” Pan Head sheet metal screws and

fasten bracket to the duct.

6� Place the probe into the supply air duct.

7� Use the screw provided to tighten the clamping ring.

Wall Mount Installation

If mounting directly to drywall, use the enclosed template

and the screws and wall anchors enclosed with the sensor.

A switch box may also be used. A three position switch box

is recommended but a single position switch box rotated

90 degrees and mounted to a rigid surface will also sufce.

Return Air Temperature Sensor (Option)

The Return Air Temperature Sensor is provided for units

with the Morning Warmup option. If the unit has the

Subject to change without notice. 10.20-IM (0818)

14

Page 15

Installation, Operation and Maintenance Manual

VariCool® VAV

Return Air Sensor Wiring

Using a minimum 18-20 AWG 300 volt rated two conductor

shielded cable with drain wire make the following electrical

connections.

Note: Use a minimum two conductor cable for temperature

only. Use a minimum ve conductor for the temperature and

humidity sensor.

8� The supply air temperature sensor is non-polarity

observant. Connect from one NTC terminal inside the

supply air temperature sensor to TB3-NTC.

9� Connect the other NTC terminal inside the temperature

sensor to TB3-NTC.

10� Connect the drain wire to ground at the VariCool’s

electrical control panel end only.

Return Air RH Sensor (Option)

If the Return Air Sensor has the Humidity Sensor for optional

humidity control or Airside Economizer, continue with steps

11, 12, and 13.

11� Connect the terminal marked G+ to terminal TB3-G+.

12� Connect the terminal marked TB3- M to M.

13� Connect terminal Hout to terminal TB3-Hout.

Outdoor Air Sensor (Option)

The outdoor air temperature and humidity sensor is required

for Airside Economizer function. An outdoor air temperature

sensor is required for the Heat Pump option. The unit

Outdoor Air Sensor must be eld installed in the outdoor air

ducting.

BE AWARE: If the unit has optional humidity sensor

because of the Airside Economizer control,

polarity must be observed when making

electrical connections�

14� Cut out the mounting template provided with the

sensor.

Duct Mount Installation

15� Select the location to mount the sensor and drill a hole

through the supply air duct at least ¾” in diameter.

16� Using a 7/64” drill bit; drill the three fastening screw

holes located on the template for the fastening ring.

17� Remove the duct sensor’s mounting ring from the duct

probe and position it over the holes previously drilled in

the duct.

18� Use three #6 x ¾” Pan Head sheet metal screws and

fasten bracket to the duct.

19� Place the probe into the supply air duct.

20� Use the screw provided to tighten the clamping ring.

Outdoor Air Sensor Wiring

Using a minimum 18-20 AWG 300 volt rated two conductor

shielded cable with drain wire make the following electrical

connections.

Note: Use a minimum two conductor cable for temperature

only. Use a minimum ve conductor for the temperature and

humidity sensor.

21� The supply air temperature sensor is non-polarity

observant. Connect from one NTC terminal inside the

supply air temperature sensor to TB4-NTC.

22� Connect the other NTC terminal inside the temperature

sensor to TB4-NTC.

23� Connect the drain wire to ground at the VariCool’s

electrical control panel end only.

Return Air RH Sensor (Option)

If the Return Air Sensor has the Humidity Sensor for optional

humidity control or Airside Economizer, continue with steps

24, 25, and 26.

24� Connect the terminal marked G+ to terminal TB4-G+.

25� Connect the terminal marked TB4- M to M.

26� Connect terminal Hout to terminal TB4-Hout.

High Static Pressure Switch

The high static pressure switch is factory installed in the

electrical control box. This switch is factory wired into the

electrical controls for alarm if a high duct pressure condition

occurs. Pneumatic tubing must be eld installed from this

switch to a location ½ to 2/3rds the distance down the

straightest length of the supply air duct.

INFORMATION

Make certain there are no kinks in the

pneumatic tubing.

Subject to change without notice. 10.20-IM (0818)

15

Page 16

Installation, Operation and Maintenance Manual

VariCool® VAV

1� Drill a hole large enough to insert the pneumatic tubing

into the ducting at a 90 degree right angle.

2� Place approximately 1/8” of the high pressure tube into

the duct at the 90 degree right angle. The end of the

pneumatic tubing must be cut at and make a right

angle for the tube to pick up the correct air pressure

reading.

3� Use a clamp to secure the tube to the ducting and

route it back to the high static pressure switch.

4� Place the other end of this tubing onto the high

pressure end of the switch.

5� Install a second tube onto the low pressure side of the

pressure switch and route it to a room neutral pressure

location.

6� Again, make certain the end of the tube is cut ush at

a 90 degree right angle. This tube must be located in

ambient air.

Remote Alarm Output (Option)

A dry contact closure on alarm option may be provided

upon request. During an alarm condition, the Remote Alarm

output can be used to energize a eld provided and installed

alarm indicator light or buzzer.

If the system has this option, wire the electrical hot or

common side of the device being energized into terminals

TB2- 9 and TB2-10. The control circuit voltage must be 24

VAC and less than 1 amp inductive.

Remote Water Pump (Option)

If the system has the Remote Water Pump ON/OFF control

option, the hot or common side of the water pump’s starter

must be wired to terminals TB2-7 and TB2-8. The control

circuit voltage must be less than 250 VAC and not exceed

10 amps inductive loading.

O/A Damper Control (Option)

If the system has the Optional Outdoor Air Damper control,

the control signal to drive the eld provided damper actuator

must be wired through the factory provided terminals TB2-11

and TB2-12. The control circuit voltage must be 24 VAC and

not exceed1 amp inductive loading.

Smoke Detector/Fire Stat (Option)

If Smoke Detector or Fire Stat shutdown option is required,

a voltage free dry normally closed contact opens on alarm

must be eld provided from the device and wired back to the

VariCool’s Control Panel. Terminate from the device contact

termination points to the factory provided terminals TB2-18

and TB2-19.

Remote On/Off Control (Option)

With the Remote On/Off Control option, the unit will start

when a voltage free dry contact closure is provided to

Terminals TB2-20 and TB2-21. This closure may be provided

by a eld provided building management system or switch.

SEQUENCE OF OPERATION

DANGER: Be aware that fast moving fan drives and high

horsepower blowers/motors can cause injuries. Before

applying power to the VariCool unit, make sure all service

access doors are closed and latched to prevent injuries from

doors from blowing open or fast moving drives. Connect

power to the unit at the main power supply. Next, apply

power at the eld installed service disconnect switch and/

or optional factory supplied single point power disconnect.

MARVEL PLUS CONTROLLER

The VariCool system is designed to operate using a double

microprocessor design control system called a Marvel Plus.

The Marvel Plus control system incorporates a Marvel Plus

Main Board Control and a Marvel Plus Wall Mount Control

and display.

The Marvel Plus Main Board microprocessor is a 16 bit

microprocessor programmable controller with onboard

ash memory (6 Megabytes) to ensure better performance.

An onboard real time clock card allows for setting up of

occupancy schedules and recording of alarm occurrence for

storing of alarm history. Each Marvel Plus has the ability to

record up to 36 alarms/faults under an alarm history page to

allow technicians to view alarm history and temperatures

when the alarm occurred. Marvel Plus Main Boards allow

for connection some of the more widely used Building

Management Systems without requiring a Gateway to

interface.

The Marvel Plus Wall Controller is a terminal unit used to

interface with the Marvel Plus Main Board Controller through

the onboard display and keypad. The software stored in the

ash memory of the Marvel Plus Main Board was designed

with menu driven pages allowing customers to easily

navigate through the menus and submenus for setup of their

systems.

Note: See Our Marvel manual for operating instructions�

http://www.unitedcoolair.com/user-les/le/controls/

Marjiom.pdf

Subject to change without notice. 10.20-IM (0818)

16

Page 17

Installation, Operation and Maintenance Manual

Maintenance Procedures

VariCool® VAV

ELECTRICAL HAZARD

Turn OFF power and lockout service

before conducting any maintenance. Keep

hands, clothing and tools clear of electrical

terminals.

WARNING

Make sure to keep hands and clothing

clear of any moving belts, blowers and

motors while performing any maintenance.

Failure to do so could result in death or

serious bodily injury.

CAUTION

Any maintenance should be conducted

by qualied HVAC service personnel only.

Potentially hazardous situations which

may result in personal injury, equipment or

property damage.

Filters

Do NOT run unit without lters.

Throwaway lters are supplied which are pleated extended

surface type. Filters should be checked monthly for dirt

accumulation and changed when necessary. Replacement

lters must be the same type as originally supplied.

INFORMATION

Unit must be shut off at the disconnect

switch before the lters are serviced. Be

sure to check that the air ow direction

arrows on the lters point in the correct

direction of air ow.

Cleaning The Water-Cooled

Condenser

Any uid that is used to carry the heat away through the

condenser contains, minerals, dust from a cooling tower or

other foreign materials. Over time these contaminants will

build up on the walls of the heat exchanger.

This scale or fouling will result in a reduction in water ow,

less water temperature difference between inlet and outlet,

high condensing temperature and higher uid pressure drop.

All of these affect the operating performance and efciency

of the system and need to be addressed.

Cleaning a water-cooled condenser helps to improve the

heat transfer rate, reduce operational cost, restore efciency,

prolong heat exchanger life and reduce pressure drop

pumping costs. Deposits from water or water treatments,

such as scale, lime, rust or mud are removed.

Each installation is unique. Therefore, the uid quality and

operating conditions will dictate when the heat exchanger

needs to be cleaned.

During the start-up process record the water pressure drop

across the heat exchanger. Also record the inlet and outlet

water temperatures. After a period of time these values can

be checked to see how much loss of operating performance

has occurred. If a 10% or greater change has occurred, it

would be benecial to clean the heat exchanger.

There are a number of commercially available products for

cleaning a heat exchanger. Follow all industry practices to

safely and effectively clean the heat exchanger.

Blowers

Disconnect power and lockout the service before doing any

service or maintenance.

Air-cooled units are provided with adjustable belt drive

blower packages for both the evaporator and condensing

sections. Check that the blower wheel is tight on the shaft

and does not contact the housing. Bearings are permanently

sealed, but should be checked periodically for signs of wear.

Check for restrictions or foreign material in the air circuit.

The drive may be adjusted for different static pressures. If

such an adjustment is made, check that the motor current

draw does not exceed the motor nameplate current by more

than 10%.

Blower Motors

All blower motors are equipped with thermal overload

protectors.

WARNING

Open disconnects to unit before doing

any service or maintenance. A motor that

is off on thermal overload can start any

time when the automatic thermal overload

resets.

Subject to change without notice. 10.20-IM (0818)

17

Page 18

Installation, Operation and Maintenance Manual

VariCool® VAV

Blower Speed Adjustment

Blower speed may be changed by adjusting the variable

diameter sheave provided on the blower drive motor.

Sheave may be adjusted by removing the belt and loosening

the setscrew located in the hub of the outer ange. With the

setscrew loosened, the ange may be turned clockwise

to increase blower speed or counter-clockwise to reduce

blower speed.

Typically the motor and drive packages have been sized and

designed for the specic CFM and external static pressure

(ESP) of the application. Before making any changes conrm

what the performance was designed for and what the actual

performance is.

INFORMATION

Setscrew must be positioned directly

above the at section of the threaded

sheave shaft before tightening to hold

adjustment.

INFORMATION

Reduction of airow through excessive

external air friction losses, lowered blower

speed operation with dirty lters, or

obstructed air ow may result in excessive

condensation at air outlets, short cycling,

or total unit shut- down due to evaporator

coil icing.

INFORMATION

Verify that the motor current draw does

not exceed the motor nameplate current

by more than 10%.

Blower Bearing Lubrication

INFORMATION

Unit must be shut off at the disconnect

switch before the blowers are serviced.

Bearings on the smaller units are permanently sealed, but

should be checked periodically for signs of wear.

Larger units have pillow block bearings. Bearings will need

to be lubricated based on the use of the equipment.

Duty Grease Interval

Low Usage 12 Months

Periodic 6 Months

Continuous 1 – 2 Months

Use a high quality lithium grease for blower pillow block

bearings. Wipe off the “Zerk” tting with a rag before adding

grease so as not to introduce dirt into the bearing.

Slowly rotate the shaft while pumping it in. Pump the grease

in slowly so as not to blow out the bearing seal. When the

grease starts to “seep” out of the bearing you have put in

enough new lubricant.

Over lubricating can cause a bearing to fail from overheating

or it can blow out the seal.

Both excessive or inadequate grease may cause premature

failure. Provided there is some grease in the bearings for

lubrication, under lubrication is better than over lubrication

as grease can easily be added but not removed. Always

allow a slight bead around the circumference of the seals to

protect the bearing from foreign matter and helps ush out

the bearing as well.

Wipe off the “Zerk” tting with a rag after adding grease

Belts

Excessive belt tension is the number one cause for blower

bearing failure. Proper belt tension and pulley alignment are

essential for trouble free operation.

Deection is the amount the belt gives when force is applied,

usually by nger, to the belt at the approximate center point

to the belt span.

Insufcient deection indicates that the belt tension is

entirely too tight, and if not loosened somewhat, noise due

to excessive vibration, premature bearing failure, shortened

belt life, and a reduction in supply air blower performance

may result. Tight belts may also overload the motor and

cause the efciency to drop considerably or even premature

motor failure as well.

Excessive deection is an indication that the belt is not tight

enough. If not corrected, slippage may occur causing loss of

blower speed and belt failure. The belts will glaze then crack

or even break due to increased temperatures caused by

slippage. Belts may slip during start-up, but slipping should

stop as soon as the fan reaches full speed.

If the midpoint (midway between the blower and motor shaft)

of the belt is pressed inward, there should be about 1/2” to a

1” of deection when the belt is properly tensioned.

Subject to change without notice. 10.20-IM (0818)

18

Page 19

Installation, Operation and Maintenance Manual

VariCool® VAV

Refer to Figure 10 – Belt Tensioning below.

Deection Point

Belt Span

Figure 10 – Belt Tensioning

For proper tensioning, an excellent method to use is listed in

the following equation.

Deection = Belt Span

Belt span is in inches from center pulley to center pulley (see

Figure 10).

Belt tension is adjusted by using the adjusting bolt on the

end of the motor mounting frame.

Check the alignment of the sheaves to make sure that the

sheave faces are in the same plane. Check this by placing

a straight edge across the face of the sheaves. Any gap

between the edge and sheave faces indicates misalignment

64

If the color of this indicator is blue, the refrigerant is okay.

When the indicator is pink or purple, an abnormal condition

exists, servicing is required.

INFORMATION

After installation and during equipment

start-up, the sight glass may appear pink

or purple. This occurs during prolonged

periods of non-operation and should turn

blue after several hours (up to 12) of

operation.

Evaporator And Air-Cooled

Condenser Coils

The nned coils in a unit should be checked at least every

six (6) months or more frequently based on experience of

the specic application.

Evaporator nned coils can become “fouled” due to a build

up of contaminants in the air path that are not caught or

captured in the air lters. Over time this build up on the n

surface can reduce heat transfer and increased resistance

to air ow. The end result might be higher operating costs or

occupant discomfort

A dirty condenser coil will cause high condensing pressures,

resulting in higher power consumption and possibly system

shut-down by high pressure safety control. A dirty evaporator

coil will reduce unit capacity and eventually will cause system

shut-down by the low pressure safety control.

Finned Coil Cleaning

Note: This alignment method is only valid when the width of

the surfaces between the belt edges is the same for

both sheaves� When they are not equal or when using

adjustable pitch pulleys, adjust so that the belts have

approximately equal tension� Both shafts should be

at right angles to the belt� Check the setscrew and/or

bushing bolt tightness�

Belts tend to stretch somewhat after installation. Recheck

belt tension after several hours of operation.

Refrigerant Systems

All refrigerant circuits contain a liquid line sight glass. If

bubbles appear in the sight glass, the system is either

undercharged with refrigerant or there may be a restriction in

the liquid line upstream of the sight glass. However, bubbles

will appear every now and then in units with the hot gas

bypass option. Bubbles will also appear upon compressor

start up, but normally clear to pure liquid after a few minutes

of operation.

The sight glass contains a moisture indicator which changes

color when moisture is present in the refrigerant circuit. This

indicator is the circular dot in the center of the sight glass.

Subject to change without notice. 10.20-IM (0818)

Before cleaning any nned coils, remove the lters. Remove

any large debris or visible dirt accumulation.

WARNING

Make sure to follow all safety precautions

when cleaning any coil with a commercially

available coil cleaner. Follow all

recommendations for safety clothing and

gear. Failure to follow all safety instructions

could result in death or serious injury.

CAUTION

Clean coils only with cold water and a

suitable detergent or a commercially

available coil cleaner. DO NOT use hot

water or steam to clean a coil containing

refrigerant as this may cause a high

pressure situation that could damage

the coil and associated safety devices or

refrigerant components.

19

Page 20

Installation, Operation and Maintenance Manual

VariCool® VAV

CAUTION

Conrm that any coil cleaning agents,

detergents or solutions are suitable for

use on a copper tube/aluminum n coil. If

the cleaning agent is to acidic or alkaline,

damage to the coil ns may result.

Rinse all coils thoroughly after any coil cleaning.

Use a suitable n comb after the coil cleaning to straighten

any bent ns.

Water Side Economizer Coil

If a unit contains the optional water side economizer coil it

may also require a periodic cleaning. These coils will need

to be cleaned using a chemical solution. These are available

commercially. Follow all manufacturer recommendations

and safety warnings.

Water Valves

At least once a quarter check the water vales to make sure

that no leaks are present. Look at the valve stem and all

piping joints.

If any leaks are found follow the manufacturers

recommendations for tightening any seals or replacing any

gaskets.

Hard Start Kit

A start assist device is utilized on all single phase units. The

purpose of this device is to assist the compressor in starting

under low voltage conditions.

A capacitor in conjunction with a Positive Temperature

Coefcient (PTC) relay is installed across the run and

start windings of the motor. The PTC device utilizes a

ceramic element with a predictable thermal response to

the introduction of electric current. When the compressor is

called upon to start, the start capacitor provides a voltage

boost to the start winding of the motor and causes the motor

to turn. As the starting current is introduced across the start

windings, the PTC element begins to warm. When the PTC

device reaches approximately 250° F (corresponding to 0.6

- 0.8 seconds), the resistance in the element increases and

creates an open switch that releases the start winding from

the circuit and the motor continues to run. If the compressor

does not start before the device heats to 250° F, it will not

start until the PTC device cycles through a cool-down period

(usually 2 - 3 minutes). A compressor off-cycle timer is

included in the electrical circuit for this purpose.

The time delay also helps the refrigerant system pressures

to equalize at the end of the run cycle. This helps the

compressor during the starting process in that it is not

attempting to start against a high discharge pressure.

INFORMATION

Verify that this timer is set for 3 or more

minutes.

Checking Hot Gas Bypass Valve

1� Connect a calibrated thermocouple lead to the outlet

line at the hot gas bypass valve. Tie wrap and insulate

the lead.

2� Connect a low pressure refrigerant gauge to the suction

line.

3� Connect a high pressure refrigerant gauge to the liquid

line.

4� Operate the air conditioner in the cooling mode until the

system is stabilized. (Approximately 15 minutes)

5� If the high side pressure is not at or above 400 psig,

block off the condenser inlet air stream until the

pressure is above this threshold. This will simulate

system performance level close to the design condition

of 95° F ambient.

6� The hot gas bypass valve setting is 104 psig.

A� If the suction pressure is 104 psig the

thermocouple reading should be approximately

117° F or higher. Please note that it may be

necessary to block off some of the evaporator air in

order to check this condition.

B� If the suction pressure is above 104 psig the

thermocouple reading should be less than 117° F.

C� If the suction pressure is below 104 psig the hot

gas bypass valve should be adjusted to raise the

pressure.

Adjustment Of Hot Gas Bypass Valve

The function of the hot gas bypass valve is to prevent the

suction pressure from falling below a predetermined set

point, thereby balancing the system. The set point is typically

104 psig (R-410a).

1� Connect a low pressure refrigerant gauge to the suction

line.

2� Operate the air conditioner in the cooling mode until

system is stabilized. (Approximately 15 minutes)

3� Remove the seal cap that covers the adjustment screw

of the hot gas bypass valve.

4� Adjust the valve by turning the stem. A CLOCKWISE

turn will increase the pressure setting. A

COUNTERCLOCKWISE turn will decrease the

pressure setting. One complete turn is equal to

approximately 4 psi change.

Subject to change without notice. 10.20-IM (0818)

20

Page 21

Installation, Operation and Maintenance Manual

VariCool® VAV

Adjustments should be made in small increments,

allowing the system to stabilize after each turn�

5� Vary the evaporator load to test at various conditions

that the suction pressure does not fall below the set

point (104 psig for R-410a).

6� Replace the seal cap on the hot gas bypass valve.

Sequence Of Operation Cooling - - Air-Cooled

The following sequence is based on the unit being controlled

by a suitable room thermostat. If another control type is being

utilized, reference the instructions for that device.

a� Raise thermostat set point to highest level.

b� Set System switch to “OFF” position.

c� Set Fan switch to the “AUTO” position.

d� Moving the Fan switch to the “ON” position should

cause the evaporator blower motor to run. Moving the

Fan switch back to “AUTO” should stop the blower.

e� Move the System switch to the “COOL” position.

Slowly lower the thermostat setting to call for cooling.

The evaporator blower should start (assuming the

Fan switch is set to “AUTO”) and the System lead

compressor should start. The condenser blower on an

air-cooled unit should start when the compressor is

activated.

f� On those units with multiple compressors, if the

thermostat set point continues to be lowered, the

second compressor should then start. Please note that

there may be a time delay between stages.

g� Set room thermostat at desired space temperature and

the Fan switch to “AUTO” or “ON”. The unit will cycle as

required to maintain conditions.

Cooling - - Water-Cooled

A water-cooled unit sequence will be the same as above,

except that air-cooled blower will be replaced by a pump or

valve being activated for water ow through the condenser.

Cooling - - Chilled Water

Chilled water unit sequence is the same as the above,

except that the compressor and condenser blower activation

is replaced by the chilled water valve function.

Heating (Other Than Heat Pump)

The following sequence is based on the unit being controlled

by a suitable room thermostat. If another control type is being

utilized, reference the instructions for that device.

a� Lower thermostat set point to lowest level.

b� Set System switch to “OFF” position.

c� Set Fan switch to the “AUTO” position.

d� Moving the Fan switch to the “ON” position should

cause the evaporator blower motor to run. Moving the

Fan switch back to “AUTO” should stop the blower.

e� Move the System switch to the “HEAT” position. Slowly

raise the thermostat setting to call for heating. The

evaporator blower should start (assuming the Fan

switch is set to “AUTO”) and the heat type (electric, hot

water or steam) should start.

f� On those units with multiple heat stages, if the

thermostat set point continues to be raised, the

additional heat stages should then start. Please note

that there may be a time delay between stages.

g� Set room thermostat at desired space temperature and

the Fan switch to “AUTO” or “ON”. The unit will cycle as

required to maintain conditions.

Heating (Heat Pump, Water Source)

The following sequence is based on the unit being controlled

by a suitable heat pump room thermostat. If another control

type is being utilized, reference the instructions for that

device.

a� Lower thermostat set point to lowest level.

b� Set System switch to “OFF” position.

c� Set Fan switch to the “AUTO” position.

d� Moving the Fan switch to the “ON” position should

cause the evaporator blower motor to run. Moving the

Fan switch back to “AUTO” should stop the blower.

e� Move the System switch to the “HEAT” position.

Slowly raise the thermostat setting to call for heating.

The evaporator blower should start (assuming the

Fan switch is set to “AUTO”) and the System lead

compressor should start. A pump or valve should also

be activated for water ow through the condenser.

f� On those units with multiple compressors, if the

thermostat set point continues to be raised, the

additional heat stages should then start. Please note

that there may be a time delay between stages.

g� Set room thermostat at desired space temperature and

the Fan switch to “AUTO” or “ON”. The unit will cycle as

required to maintain conditions.

Subject to change without notice. 10.20-IM (0818)

21

Page 22

Installation, Operation and Maintenance Manual

Troubleshooting

WARNING

Turn OFF power to unit before conducting any troubleshooting, unless the tests you are performing require

system operation. Keep hands, clothing and tools clear of electrical terminals and rotating components.

ITEM CODE PROBLEM PROBABLE CAUSE SOLUTION

1 Control is erratic.

2 Blower fails to start.

3 Compressor fails to start.

4 Compressor short cycles.

Wired improperly or connections are broken Check wiring connections against schematic

diagram.

Defective contactor

Overload tripped

Marvel alarm

Thermostat set too high

Complete loss of refrigerant charge

Head pressure too high

(high pressure switch open)

PTCR will keep compressor OFF

for 3 - 5 minutes

Low line voltage causing compressor to

overheat and trip on thermal overload

Drain pan switch open

Low line voltage causing compressor to

overheat

Dry or icy evaporator coil (reduced air ow)

Lack of refrigerant (bubbles in sight glass)

Short cycling of conditioned air

Repair or replace contactor.

Reset and check cause.

Clear alarm(s) after correcting problem.

Adjust to desired temperature.

Repair leak and recharge refrigerant system.

Check condenser for obstructions and remove.

Check for the required water ow through the water

regulating valve and the condenser coil. Manually

reset thermostat. With Marvel, turn off alarm and

reset.

Wait for PTCR to cool off. Compressor should start

in 3 - 5 minutes.

Stop unit and troubleshoot power supply and

compressor circuit for low voltage. Please note that

it may take the compressor an hour or more for the

thermal overload to reset itself.

Check if the unit is draining properly.

Check power source for cause of electric variation

of line voltage.

Defrost and clean coil and replace dirty lters.

Check for leak. Repair and recharge the system

Make sure that duct connections are proper for

return air and supply air and ensure that they do not

mix with each other.

VariCool® VAV

NOTE: For operating and troubleshooting instructions for Marvel Controller or

humidier, refer to specic operating instructions that accompany the unit.

Subject to change without notice. 10.20-IM (0818)

22

Page 23

Installation, Operation and Maintenance Manual

ITEM CODE PROBLEM PROBABLE CAUSE SOLUTION

Lack of proper air quantity

Check lters: Clean or replace if necessary. Check

for obstruction across coil. Check rotation of evaporator blower to ensure correct rotation of evaporator

blowers.

5 Evaporator coil ices.

Low return air temperature

Raise return air set point or check for short cycling

of supply air.

Low refrigerant charge

Check for leaks and repair and recharge the

system.

VariCool® VAV

6 Noisy compressor

7 System short of capacity

Expansion valve stuck in open position

(cold suction line)

Broken compressor valve (compressor

knocking)

Worn or scarred compressor bearings

Liquid slugging

Excessive head pressure

Flash gas in liquid line

(bubbles in sight glass)

Expansion valve stuck open or possibly

obstructed

Clogged lter drier

Ice or dirt on evaporator coil

Head pressure control valve not fully open

Condenser coil dirty

Ensure thermal expansion valve bulb is tight on

suction line. Con- rm that bulb is located properly

on suction line. Check operation and superheat.

Replace compressor.

Replace compressor.

System overcharged. Reclaim excess refrigerant

from the high side of the system

Reduce head pressure (see item 8 below).

Check for leaks. Repair and re- charge the system.

Check sub- cooling.

Replace Valve.

Replace with new lter-drier.

Defrost or clean evaporator coil or replace dirty

lter.

Make sure that the required GPM of water ows

through the condensing section

Clean condenser coil

Subject to change without notice. 10.20-IM (0818)

23

Page 24

Installation, Operation and Maintenance Manual

ITEM CODE PROBLEM PROBABLE CAUSE SOLUTION

Air or other non-condensable gas in system

Evacuate system and recharge. Install new

lter-drier.

Condenser air intake blocked

Overcharge of refrigerant

Clean away debris.

Reclaim excess from high pressure side of the

system.

8 Head pressure too high

Condenser fan not operating

Check power to motor and ensure correct rotation

of blower.

Condenser water not circulating

Condenser blower running backwards

Check water regulating valve and adjust

Check phase of incoming power to unit (3 ph units

only). Reverse any two incoming power supply

wires (except ground).

9 Head pressure too low See Item 3, 4, & 7 above Correct as indicated

Flash gas in liquid line (bubbles in sight

Repair leak and recharge.

glass) due to a leak.

10 Suction pressure too low

Obstructed expansion valve

Loss of uid within expansion valve bulb.

Clogged lter-drier

Ice or dirt on evaporator coil

Evaporator blower running backwards

Repair or replace valve.

Replace power head and valve.

Replace with new lter-drier.

Defrost and clean evaporator coil and replace lter.

Check phase of incoming power to unit (3 ph units

only). Reverse any two incoming power supply

wires (except ground).

VariCool® VAV

Thermostat set too low

Circuit breaker tripped or blown

Adjust thermostat to the desired temperature.

Check for electrical short. . Replace breaker if

defective.

11 Heater inoperative

Heater high limit switch open

Insufcient air across heater elements. Check for

obstructed or dirty lters.

Heat elements burned out

Check continuity with OHM meter. Replace heater

element.

12 Water carry over Excessive air through unit Reduce CFM to unit specications.

Subject to change without notice. 10.20-IM (0818)

24

Page 25

Installation, Operation and Maintenance Manual

ITEM CODE PROBLEM PROBABLE CAUSE SOLUTION

13

System short of capacity in

free cool (water coil) mode

Check for control wiring to the free cool

solenoid valve.

Low water ow rate

Check wiring diagram and rewire.

Check source of water ow.

VariCool® VAV

14

15

Condensate Pump does

not run

Condensate Pump runs with

no discharge

16 Lock out relay tripped

Check to see that power to the pump is

Locate and repair electrical connection problem.

present.

Float not able to move freely.

Dirt or algae not allowing oat to activate

Clean pump and oat.

Clean pump and oat.

pump.

Tubing blocked or kinked

Check valve blocked

Inpeller blocked

Tubing elevation or run exceeds head

Inspect, clean or straighten as necessary.

Clean check valve.

Remove debris from pump impeller.

Verify tubing run is within pump head limitations.

capability

High or low pressure condition exists Refer to items 8 & 10 above.

Manually turn off system at thermostat and then

back on to reset. Manually reset high pressure

switch if tripped.

Subject to change without notice. 10.20-IM (0818)

25

Page 26

Installation, Operation and Maintenance Manual

Limited Warranty

VariCool® VAV

Important Notice!

This Limited Warranty specically provides that all installation,

operation and repairs of product and parts covered under

this limited warranty must be made with authorized parts

and by a licensed HVAC service provider. The product(s)

must be properly installed, and maintained by a licensed

HVAC service provider in accordance with the installation,

operation, and maintenance instructions provided by United

CoolAir Corporation. Failure to conform to such specications

and/or instructions shall void this limited warranty. United

CoolAir may request written documentation showing the

proper preventative maintenance.

United CoolAir warrants this product to be free from defects

in factory workmanship and material under normal use and

service and will, at its option, repair or replace any parts that

prove to have such defects within a period of one (1) year

from the date of product installation. This warranty extends

only to the original consumer purchaser in accordance

with the then current Terms and Conditions and is nontransferable.

For this warranty to apply, the product must be installed

according to United CoolAir recommendations and

specications, and in accordance with all local, state,

national and provincial codes. The product must not be

moved from its original place of installation. The replacement

part assumes the unused portion of this warranty.

This limited warranty applies only to products installed in the

continental United States, Alaska, Hawaii and Canada.

Exclusions

This Limited Warranty does not cover any:

1� Shipping, labor or material charges.

2� Damages resulting from transportation, installation or

servicing.

3� Damages resulting from accident, abuse, re, ood,

alteration or acts of God.

4� Tampering with, altering, defacing or removing the

product serial number will serve to void this warranty.

5� Damages resulting from use of the product in a

corrosive atmosphere (such as concentrations of acids

or halogenated hydrocarbons).

6� Damages resulting from inadequacy or interruption of

electrical service, improper voltage conditions, blown

fuses, or other like circumstances.

7� Cleaning or replacement of lters or belts.

8� Damages resulting from failure to properly and

regularly clean air and/or water side of condenser and

evaporator.

9� Damages resulting from: (I) freezing of condenser

water or condensate; (II) use of corrosive water; (III)

fouling or restriction of the air/water circuit by foreign

material or like causes.

10� Damages resulting from operation with inadequate or

interrupted supply of air or water.

11� Damages resulting from use of components or

accessories not approved by United CoolAir.

12� This warranty does not apply to the installation,

plumbing and wiring not integral to the product.

13� Damages resulting from improper application or sizing

of unit.

This warranty is in lieu of all other warranties, expressed or

implied, including the implied warranties of merchantability

and tness for a particular purpose.

Some states (provinces) do not allow the disclaimer of

implied warranty, so that the above disclaimer may not apply

to you.

Some states (provinces) allow only a partial limitation on

implied warranties to limit the duration of implied warranties

to the duration of the express warranty. In such states

(provinces), the duration of implied warranties is hereby

expressly limited to the duration of the express warranty on

the face hereof.

In no event, whether as a result of breach of warranty or

contract, tort (including negligence) strict liability or otherwise,

shall United CoolAir be liable for special, incidental, or

consequential damages, including but not limited to loss

of use of the equipment or associated equipment, lost

revenues or prots, cost of substitute equipment or cost of

fuel or electricity. The above limitations shall inure to the

benet of United CoolAir’s suppliers and subcontractors.

The above limitation on consequential damages shall not

apply to injuries to persons in the case of consumer goods.

Some states (provinces) do not allow the exclusion or

limitation of liability for consequential damages, or for strict

liability in tort, so that the above exclusions and limitations

may not apply to you.

United CoolAir does not assume, or authorize any other

person to assume for United CoolAir, any other liability for

the sale of this product.

This warranty gives you specic legal rights. You may also

have other rights which vary from state to state (province to

province).

To obtain warranty service

Contact the installing or servicing contractor with the details

of the problem. Provide the model number, serial number

and date of installation. Warranty requests directed to the

factory will be referred back through the local distribution

network.

Model: ______________ Serial Number: _______________ Date of Installation: ________

Subject to change without notice. 10.20-IM (0818)

26

Page 27

Installation, Operation and Maintenance Manual

Limited Warranty for Hermetic Compressors

VariCool® VAV

United CoolAir warrants the hermetic compressor in this

product to be free from defects in factory workmanship and

material under normal use and service and will, at its option,

repair or replace the hermetic compressor if it proves to

have such defects within a period of ve (5) years from the

date of product installation. This warranty extends only to

the original consumer purchaser in accordance with the then

current Terms and Conditions and is non-transferable. If a

United CoolAir unit is matched with another manufacturers

unit the compressor warranty is limited to 1 year form the

date of product installation.

For this warranty to apply, the product must be installed

according to United CoolAir recommendations and

specications, and in accordance with all local, state,

national and provincial codes. The product must not be

moved from its original place of installation. The replacement

part assumes the unused portion of this warranty.

This limited warranty applies only to products installed in the

continental United States, Alaska, Hawaii and Canada.

Exclusions

This Limited Warranty does not cover any:

1� Shipping, labor or material charges.

2� Damages resulting from transportation, installation or

servicing.

3� Damages resulting from accident, abuse, re, ood,

alteration or acts of God.

4� Tampering with, altering, defacing or removing the

product serial number will serve to void this warranty.

5� Damages resulting from use of the product in a

corrosive atmosphere (such as concentrations of acids

or halogenated hydrocarbons).

6� Damages resulting from inadequacy or interruption of

electrical service, improper voltage conditions, blown

fuses, or other like circumstances.

7� Cleaning or replacement of lters or belts.

8� Damages resulting from failure to properly and

regularly clean air and/or water side of condenser and

evaporator.

9� Damages resulting from: (I) freezing of condenser

water or condensate; (II) use of corrosive water; (III)

fouling or restriction of the air/water circuit by foreign

material or like causes.

10� Damages resulting from operation with inadequate or

interrupted supply of air or water.

Model: ______________ Serial Number: _______________ Date of Installation: ________