United CoolAir VariCool EZ-Fit 15, VariCool EZ-Fit 35, VariCool EZ-Fit 25, VariCool EZ-Fit 30, VariCool EZ-Fit 40 Installation, Operation And Maintenance Manual

...

®

VariCool

EZ-Fit Series

Installation, Operation and Maintenance Manual

Effective January 2018

Water-Cooled and Chilled Water

Variable Air Volume

Contents

Installation, Operation and Maintenance Manual

VariCool EZ-Fit

Important Notice ������������������������������������������������������������������4

Use of Symbols �������������������������������������������������������������������4

General Information �������������������������������������������������������������5

Inspection of Equipment ������������������������������������������������5

Handling ������������������������������������������������������������������������5

Location �������������������������������������������������������������������������5

Application Data ������������������������������������������������������������5

Service Clearances �������������������������������������������������������������6

Condensate Drain����������������������������������������������������������������7

Physical Data������������������������������������������������������������������� 8-9

Mounting and Placement ���������������������������������������������������10

Suggested Assembly Sequence ����������������������������������������10

Mounting Options ��������������������������������������������������������������10

Evaporator Section ������������������������������������������������������������12

Gasket Material �����������������������������������������������������������������12

Compressor / Condenser Section �������������������������������������12

3D-Intelliclamps �����������������������������������������������������������������12

Refrigerant Connections ����������������������������������������������������16

Supply Air Blower Section �������������������������������������������������16

Duct Connections ��������������������������������������������������������������16

Water Piping ����������������������������������������������������������������������17

Water requirements �����������������������������������������������������������17

Transformer �����������������������������������������������������������������19

High Static Pressure Switch ����������������������������������������19

Inter-Module Control Power ����������������������������������������19

Evaporator Control Wiring �������������������������������������������19

Wall Display �����������������������������������������������������������������19

Static Pressure Transducer �����������������������������������������20

Supply Air Temperature Sensor �����������������������������������20

Return Air Temperature Sensor �����������������������������������20

Voltage Unbalance ������������������������������������������������������������20

Electric Heat ����������������������������������������������������������������������20

Maintenance Procedures���������������������������������������������������21

Filters ���������������������������������������������������������������������������������21

Blowers ������������������������������������������������������������������������������21

Lubrication �������������������������������������������������������������������������21

Belt Driven (DWDI) ������������������������������������������������������21

Frequency of Lubrication ���������������������������������������������21

Belt Tensioning ������������������������������������������������������������������22

Direct Drive Blowers ����������������������������������������������������������22

Drain Pan���������������������������������������������������������������������������23

Evaporator Coil ������������������������������������������������������������������23

Coil Cleaning ���������������������������������������������������������������23

Condenser Cleaning ����������������������������������������������������������23

Water Side Economizer Coil ����������������������������������������������23

Water Valves����������������������������������������������������������������������23

Refrigerant Systems ����������������������������������������������������������24

Operations Verication Check List�������������������������������������25

Troubleshooting Guide ������������������������������������������������������26

Limited Warranty ���������������������������������������������������������������29

Important Notice! ���������������������������������������������������������29

Exclusions �������������������������������������������������������������������29

To obtain warranty service �������������������������������������������29

Limited Warranty for Hermetic Compressors ��������������������30

Exclusions �������������������������������������������������������������������30

To obtain warranty service �������������������������������������������30

Limited Warranty Condensing Section ������������������������������31

EXCLUSIONS �������������������������������������������������������������31

To obtain warranty service �������������������������������������������31

Limited Warranty for Hermetic Compressors ��������������������32

EXCLUSIONS �������������������������������������������������������������32

To obtain warranty service �������������������������������������������32

Air-Cooled Unit �����������������������������������������������������������������33

Start-Up Procedures (R-410a Systems) ���������������������� 33-34

Optional Heating Start Up: ������������������������������������������34

Air-Cooled Unit �����������������������������������������������������������������35

Start-Up Procedures ����������������������������������������������������35

Cooling Mode ��������������������������������������������������������������36

Electrical ����������������������������������������������������������������������36

Heating Mode (Optional) ���������������������������������������������36

Water-Cooled Unit ������������������������������������������������������������37

Start-Up Procedures (R-410a Systems) ���������������������� 37-38

Water-Cooled Unit ������������������������������������������������������������39

Start-Up Procedures ����������������������������������������������������39

Cooling Mode ��������������������������������������������������������������40

Electrical ����������������������������������������������������������������������40

Heating Mode (Optional) ���������������������������������������������40

Subject to change without notice. 40.20-IM (0118)

3

Installation, Operation and Maintenance Manual

VariCool EZ-Fit

Important Notice

This manual is the property of the owner.

Please be sure to leave it with the owner when you leave the job.

Use of Symbols

This publication includes warnings, cautions and information icons that point out safety related issues or conditions as well

as other pertinent information relative to a safe installation, service or maintenance situation� The following icons should be

interpreted as follows:

ELECTRICAL

HAZARD

WARNING

CAUTION

INFORMATION

The electrical hazard icon indicates the presence of an electrical hazard which

could result in electrical shock or death�

The warning icon indicates a potentially hazardous situation which could result

in death or serious bodily injury if not avoided�

The caution icon indicates a potentially hazardous situation which may result in

minor or moderate injury if not avoided�

The information icon indicates a situation that may result in equipment or

property damage� The information provided alerts the reader to relevant facts

and/or conditions�

Subject to change without notice. 40.20-IM (0118)

4

Installation, Operation and Maintenance Manual

General Information

VariCool EZ-Fit

NOTE: This manual covers the standard unit congurations.

Since many units are built-to-order some of the

information provided may not directly apply to this

specic unit.

Inspection of Equipment

Upon receiving of the unit, carefully inspect all sections for

visible or concealed interior / exterior damage� If damage

occurred during transit, contact the freight carrier immediately

and le a damage claim report.

Inspect the unit data plate to verify the model unit that was

ordered is what has been received�

Some options / accessory items may have been shipped

loose in one or more boxes� These may have been delivered

to another location, or possibly within the unit� If shipped with

the unit there will be a sticker that identies where in the

unit the shipped loose items are located. Conrm that all of

these options / accessory items are also available and that

no damage has occurred�

Handling

To help facilitate handling, most units or modules are set on a

wooden skid� Use caution when moving the unit or modules

so that damage does not occur when moving each piece to

the nal installation location within the structure.

The units or modules can be moved by the use of a crane,

fork lift, pallet jack or roller bars as appropriate� Under no

circumstances should the unit or modules be “walked” on

the corners of the skid or unit�

If a crane, cables or slings are used to move a unit or module,

spreader bars must be used to protect each section’s cabinet

structure�

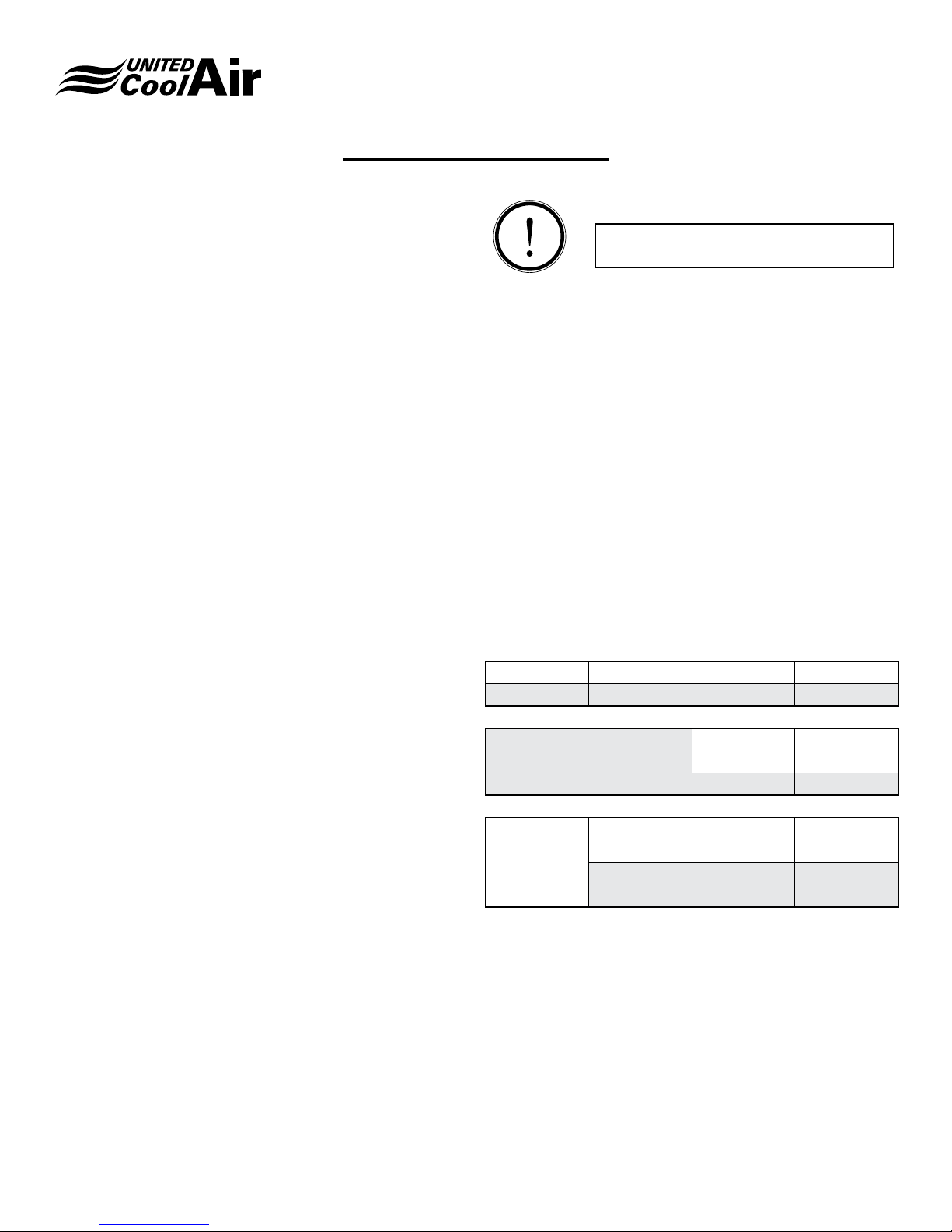

INFORMATION

Unit should NOT be located in space

subject to freezing temperatures�

Location

Before unit can be installed, a thorough study should be

made of the structure� Attention must be given to:

A. Floor, ceiling or wall load limitations as appropriate

B. Required service clearances

C. Condensate removal, trapping and disposal

D. Location of wiring and safety devices

E. Ductwork sizing and connections are per industry

standards

F. Maintenance access

G. Mounting location is level in both horizontal planes

H. If appropriate, water piping location and connection

conguration

Application Data

Voltage 208 / 230 460 575

Variation 187 / 253 414 / 504 518 / 632

Cooling

(Air Entering Evaporator)

Water-Cooled

DB

(min./max.)

WB 57 / 72

GPM / Ton

(min./max.)

Leaving Water

(min./max.)

65 / 110

2.5 / 3.5

60 / 115

Subject to change without notice. 40.20-IM (0118)

Note: Not all combinations may be valid.

5

Installation, Operation and Maintenance Manual

Service Clearances

VariCool EZ-Fit

36

24

24

TOP

Single DWDI Modules

TOP

36

24

24

24

36

24

TOP TOP

36

24

242424

Dual Modules Single DDP Modules

Notes:

(a) Service clearances apply to all air path congurations.

(b) Service clearances apply to all size units�

(c) Service clearances apply to both DWDI and DDP blower models in dual module conguration.

Subject to change without notice. 40.20-IM (0118)

6

Condensate Drain

Each EZ-Fit evaporator has a condensate drain connection

in the base frame (Ref� Figure 1)� If the application contains

dual modules two (2) drain traps are required�

Traps will need to be connected to the 1-1/4” NPT drain

connection(s) (Ref� Figure 1)�

A condensate drain trap must be eld fabricated and

installed� The purpose of the trap is to neutralize the negative

pressure created within the blower cabinet�

The negative pressure can vary from less than 1” up to 3”

column. The condensate trap must be of sufcient depth

in water column to permit the condensate to ow from the

drain pan. Failure to have a sufcient drain trap will cause

the condensate to overow the drain pan or to cause the unit

to shut down on the drain pan overow safety.

The “A” dimension (Ref� Figure 2) must equal or exceed the

negative static pressure developed by the supply air blower�

The “A” dimension will be unique for each unit application�

The trap must be 2-1/2” deep to maintain a water seal under

all operating conditions, especially during blower start-up�

It is highly recommended that the trap be primed with water

prior to start-up�

Each trap must be piped to a suitable waste drain�

Installation, Operation and Maintenance Manual

VariCool EZ-Fit

1�047

Condensate Drain

1-1/4" NPT

4�276

Figure 1 - Condensate Drain Location

Plugged

Removable

Cleanout

A

2�5

Min

3�5

Figure 2 - Condensate Trap Dimensions

Subject to change without notice. 40.20-IM (0118)

7

Installation, Operation and Maintenance Manual

VariCool EZ-Fit

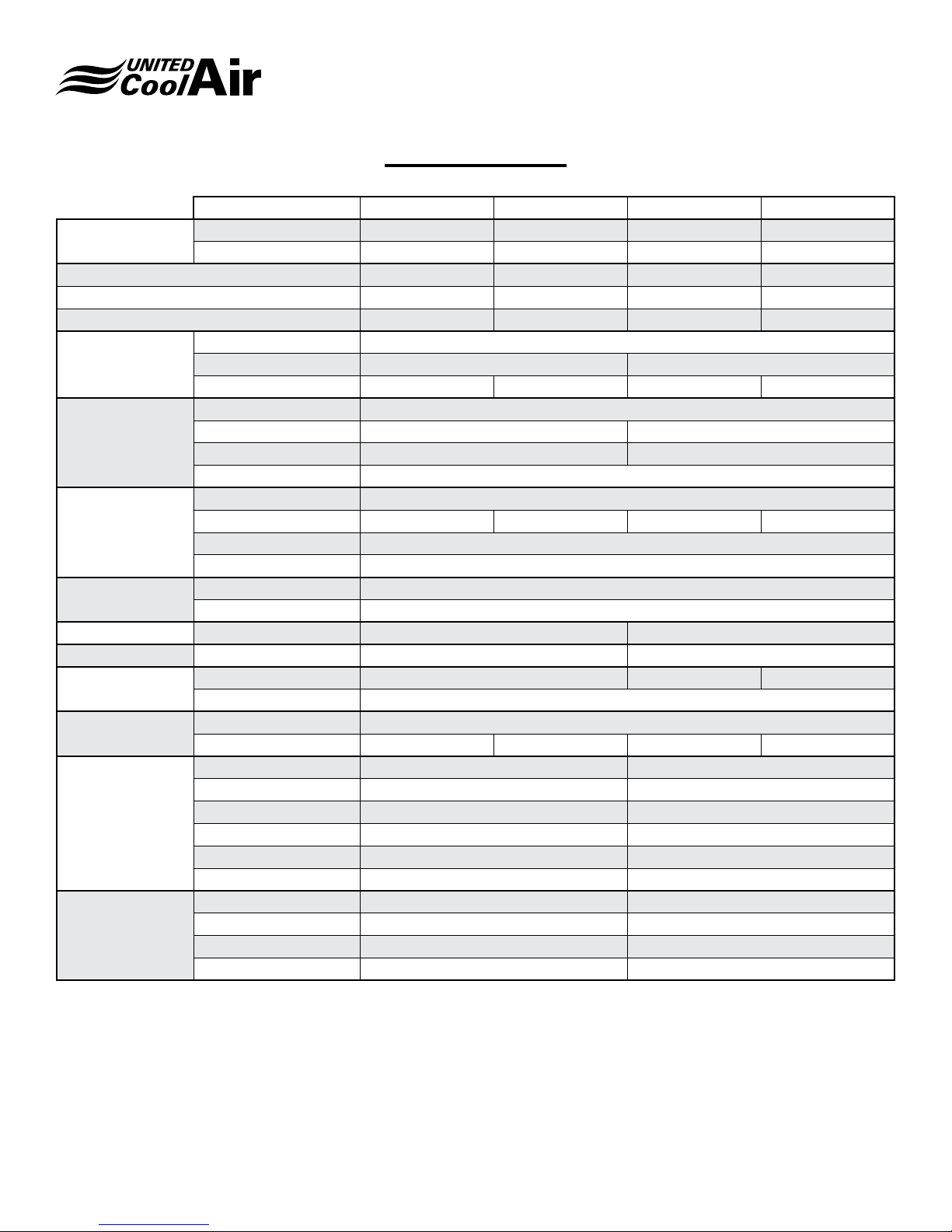

Physical Data

Model 12 15 20 25

Capacity (a) (MBH)

CFM 4800 6000 8000 9000

GPM 36.0 45.0 60.0 72.0

EER 15.1 14.4 14.8 14.1

Blower

Filter

Evaporator

Coil

Condenser

Return Air Duct Size 51-3/8” H x 40” W 55” H x 50-1/2” W

Supply Air Duct Size 16-1/4” H x 18-7/8” W 19” H x 22-3/16” W

Compressor

Refrigerant

Weight (b)

(Net Operating)

Dimensions

(a) Capacity based on 80° F DB / 67° F WB with 85° F EFT

(b) Basic unit only� Options will add weight for general purposes only actual charge may vary due to options and available heat

exchangers as ordered�

Total 165.8 202.0 260.2 300.9

Sensible 117.1 143.5 187.7 213.0

Type (QTY) DWDI

Size (Dia.) 15 - 15 18 - 18

CFM Range 2200-5800 2600-6900 3500-9500 3500-9500

Type Pleated Throwaway

Size (All 2” Thick.) 15 x 20 / 20 x 20 18 x 25

Qty 4 / 2 6

Efciency MERV 8

Type Interlaced

Face Area (Sq. Ft.) 10.6 12.7 17.3 17.3

Rows 4

FPI 12

Type Co-Axial

Working Pressure - Fluid 400 psig

Type Hermetic Scroll

Qty 2

Type R-410a

Lbs-Ozs 10.5 13 15 17

Evaporator 375 525

Condensing 800 1075

Blower (DWDI) 475 575

Blower (DDP) 500 650

Assembly w/ DWDI 1650 2175

Assembly w/ DDP 1675 2250

Evap. & Filter 54” W x 21-1/2” D x 56” H 64” W x 21-1/2” D x 59” H

Comp. & Cond. 54” W x 31-1/2” D x 56” H 64” W x 34” D x 59” H

Blower 54” W x 48” D x 32” H 64” W x 50-1/2” D x 34” H

Assembly 54” W x 53” D x 88” H 64” W x 55-1/2” D x 93” H

Subject to change without notice. 40.20-IM (0118)

8

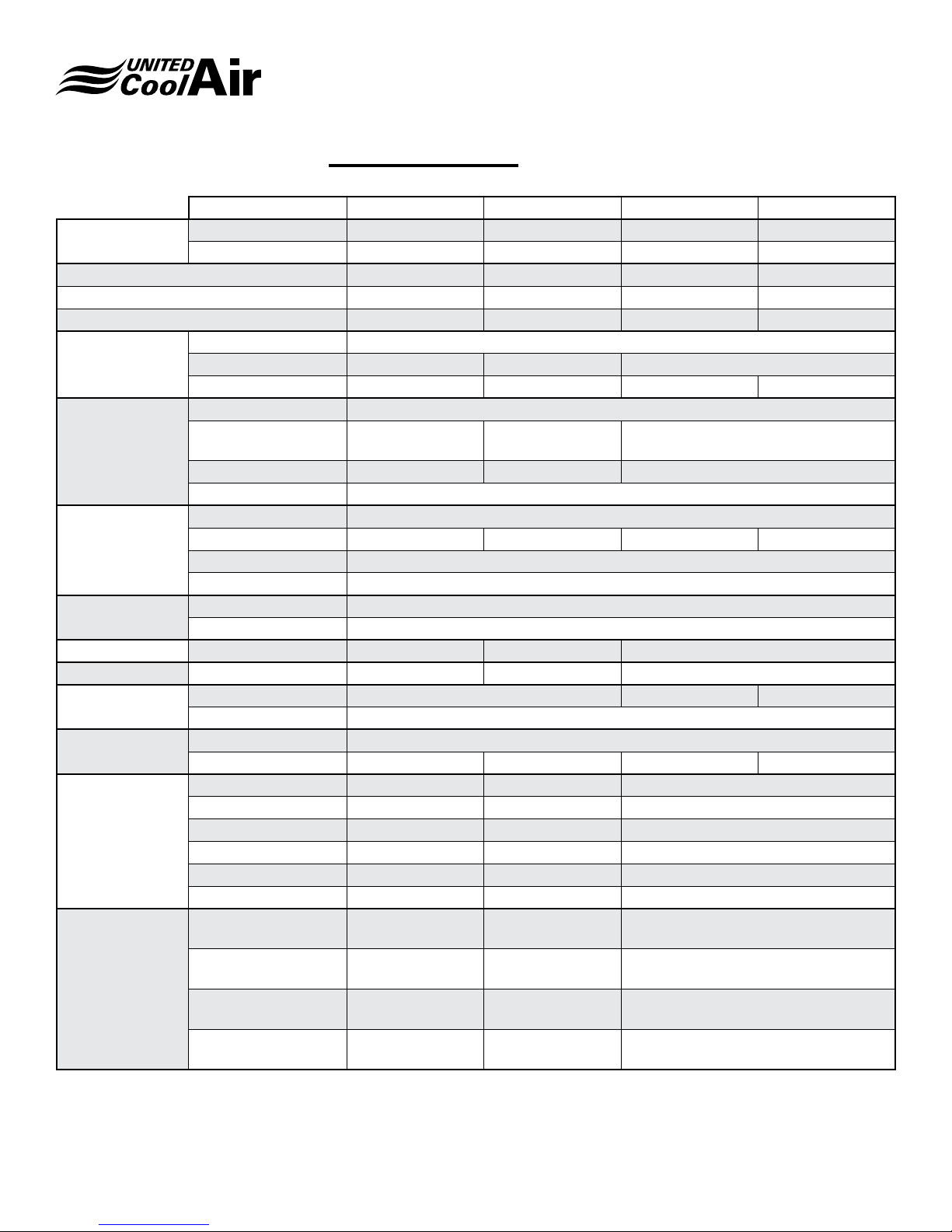

Installation, Operation and Maintenance Manual

Physical Data continued

Model 30 35 40 45

Capacity (a) (MBH)

CFM 12000 14000

GPM 90.0 105.0

EER 14.0 14.0

Blower

Filter

Evaporator

Coil

Condenser

Return Air Duct Size 69” H x 60” W 69” H x 64” W

Supply Air Duct Size 24-7/8” H x 15-1/2” W 24-7/8” H x 19” W

Compressor

Refrigerant

Weight (b)

(Net Operating)

Total 382.2 451.6

Sensible 283.5 330.7

Type (QTY) DDP (2)

Size (Dia.) 16.5 18.2

CFM Range 4800-13000 5500 - 14900

Type Pleated Throwaway

Size (All 2” Thick.) 24 x 20 / 20 x 20

Qty 6 / 3 2 / 5 / 2

Efciency MERV 8

Type Interlaced

Face Area (Sq. Ft.) 23.9 27.1

Rows 5

FPI 10

Type Co-Axial

Working Pressure - Fluid 400 psig

Type Hermetic Scroll

Qty 2

Type R-410a

Lbs-Ozs 30 40

Evaporator 1000 1170

Condensing 1340 1570

Blower (DWDI) X X

Blower (DDP) 800 (2) 1040 (2)

Assembly w/ DWDI X X

Assembly w/ DDP 3940 4820

Evap. & Filter

69” W x 27-1/2”

D x 71” H

20 x 20 / 20 x 24

/ 24 x 24

76” W x 29-1/2”

D x 71” H

VariCool EZ-Fit

Comp. & Cond. 69” W x 34” D x 71” H 76” W x 34” D x 71” H

Dimensions

Blower

Assembly

(a) Capacity based on 80° F DB / 67° F WB with 85° F EFT

(b) Basic unit only� Options will add weight for general purposes only actual charge may vary due to options and available heat

exchangers as ordered�

Subject to change without notice. 40.20-IM (0118)

34-1/2” W x 56-1/2”

D x 34” H

69” W x 56-1/2”

D x 105” H

38” W x 58-1/2”

D x 34” H

76” W x 58-1/2”

D x 105” H

9

Installation, Operation and Maintenance Manual

Mounting and Placement

VariCool EZ-Fit

Suggested Assembly Sequence

1. Set Evaporator section in place�

2. Set Compressor / Condensing section in place�

a. On Dual Module systems connect the water pipes�

3. Connect resealable refrigerant ttings.

4. Attach tie plates

5. Set Blower section in place�

6. Attach tie plates�

a. On Dual Module systems connect the electrical from

one module to the other�

NOTE: If space is limited in the mechanical room it may

be advantageous to suspend the blower section(s)

temporarily as the initial step.

Each module has three or more sections� If the system is

comprised of dual modules, there will be left hand and right

hand sections�

Each section will be labeled as to which system it is� These

labels are typically something such as AC-1, AC-2 or AHU1, AHU-2, etc� Make sure when mating up the sections that

each section is correctly matched for the appropriate module�

Additionally, when a dual module system is being assembled

there will also be an indication as to which sections are

left hand (LH) or right hand (RH)� Left and Right hand is

determined when viewing the unit from the control box side

(side opposite the lters).

Each section is also alphabetically labeled so that each

section can be mated properly� Set the sections so that point:

A aligns to A

B aligns to B

C aligns to C

etc�

Please ensure that it is recognized that the ezt requires

support on the bottom middle of the unit� This means that

corner loading is insufcient for the task of placing an ez t

unit. The ez-t requires support on the corners, the middle

of each section, and wherever sections come together� This

observation is critically important, if these methods are not

followed refrigeration pipe breakage will occur and UCA will

refuse warranty of any kind of pipe breakage or leaks if an ez

t module is not supported by the means supplied herein this

section. The UCA Recommended way is shown on gure 3B

notice where the middle beam supports the mid-section of

the unit�

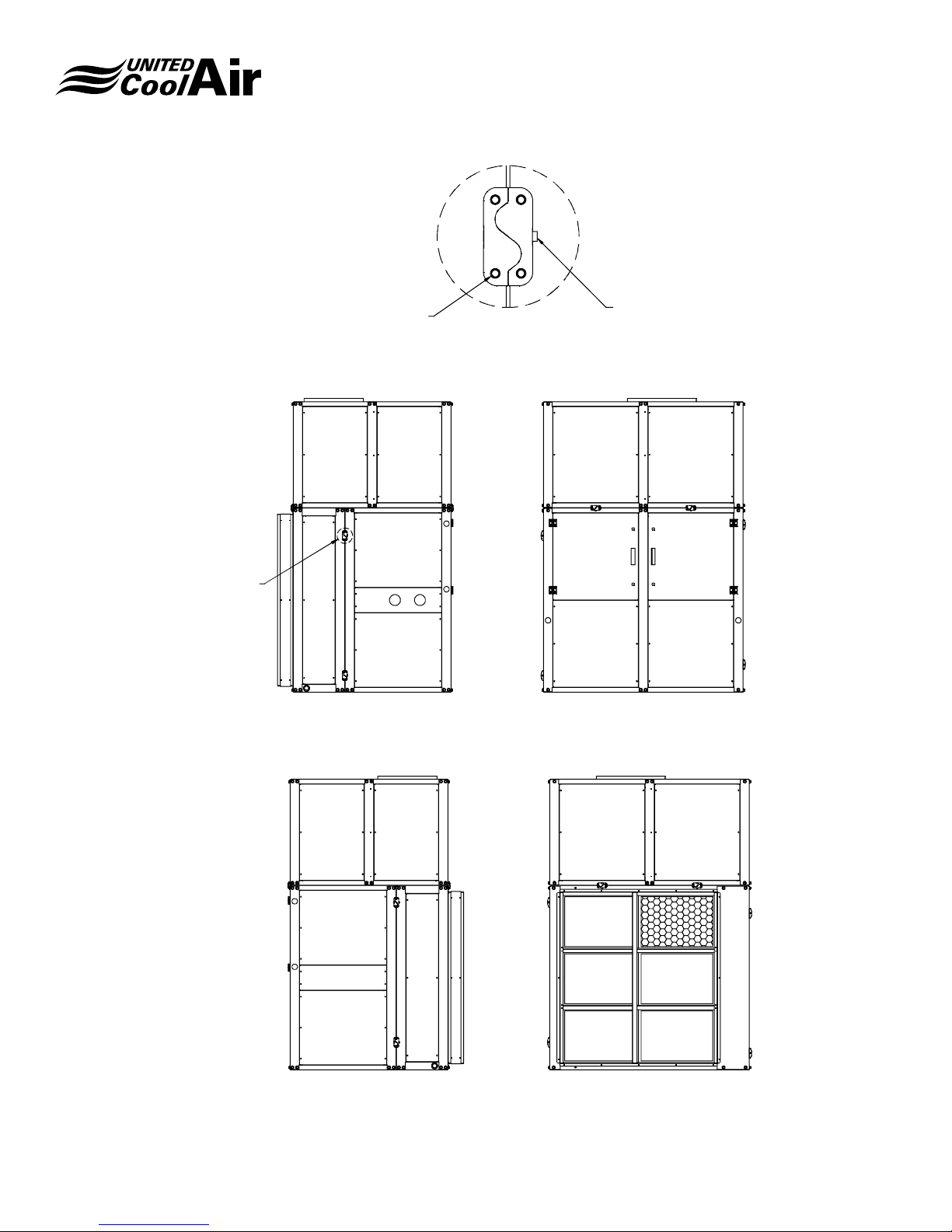

Figure 3A -Spring Isolation Base

Mounting Options

When installing any oor mounted unit, it is sometimes

desirable to include some form of vibration isolation� Please

note that the unit frames have not been designed for corner

point only loading with vibration isolation methods�

Vibration isolation can be achieved by use of wafe pads

or spring isolation. These are eld supplied and applied

accessory items� The selected choice of vibration isolation

should be placed as appropriate in the sequence of

placement of the unit sections�

Subject to change without notice. 40.20-IM (0118)

Figure 3B -Unit Positioned On Spring Isolation Base

10

Installation, Operation and Maintenance Manual

VariCool EZ-Fit

Another equally recognized and recommended base support

of the ez t is shown on gure 3C which is channel steel

of an approved gauge to support the weight, simply placed

underneath the unit in 4 locations per module or 7 locations

per dual module pairing. Place wafe pad type furnace pads

underneath the channel iron inside the C facing down for

sound dampening� It is important that the channel does not

touch the ground or sound dampening will not occur� It is

also important that all the channels are level before placing

the unit atop them� Please note the locations of the pads�

If height and other reasons prevent adequate space for

framing wafe pads alone may be used reference gure

3E� It is highly recommended that each pad be of identical

height and that the pads are kept no smaller than 4”x 4”� You

will need at minimum 30 pads to support the ezt properly.

Additional pads; more than the specied count can only help

the units support, the goal is to keep the middle of the unit

from sagging, support under the compressors and water

coils is key�

Figure 3E - Base Option 3 Bottom View

Figure 3C - Base Option 2 Bottom View

Figure 3D - Base Option 2 Unit View

Figure 3F - Base Option 3 Unit View

Subject to change without notice. 40.20-IM (0118)

11

Installation, Operation and Maintenance Manual

VariCool EZ-Fit

Evaporator Section

Start by locating the evaporator section rst. Set each section

as needed, making sure that in dual module applications the

evaporator sections are placed correctly as left hand and

right hand�

Gasket Material

Gasket material has been factory supplied for eld

installation between each unit section� The gasket material

must be installed to minimize air leakage and to help reduce

transmission of noise�

Before applying any gasket material make sure the surface

is clean and dry�

Gasket material, 3” wide, should be applied to those surfaces

identied as “3” in Figure 4 (evaporator and compressor /

condensing section)�

Gasket material, 2” wide, should be applied to those surfaces

identied as “2” in Figure 4 (evaporator and compressor /

condensing section)�

Blower

Section

Compressor / Condenser Section

Next, locate the compressor / condenser section(s)� Again,

make sure the labels align properly for either the single or

dual module applications�

On the refrigerant resealable ttings, apply a few drops of

refrigerant oil to the male coupling halves before starting the

assembly (Ref� to Figure 6)�

3D-Intelliclamps

Each section of a single module is furnished with

3D-Intelliclamps to facilitate connection to the adjacent

section� These have been installed at the factory during

production and consist of two interlocking halves that mate

and are then bolted together� Once tightened, they ensure

perfect alignment of the mating section surfaces�

Once adjacent sections have been put into place, use the

included hardware to pull sections together until the curved

surfaces of the 3D-Intelliclamps are completely mated�

Evaporator

Section

3

Figure 4 - Gasket Material

Subject to change without notice. 40.20-IM (0118)

2

Condensing

Section

3D-Intelliclamp

12

Installation, Operation and Maintenance Manual

VariCool EZ-Fit

DETAIL "A"

TYP 8 PLCS

MOUNTING SCREWS

MOTOR

IN OUT

LEFT

DETAIL "A"

TIGHTENING SCREW

ELECT

FRONT

VFD

Subject to change without notice. 40.20-IM (0118)

RETURN

AIR

REARRIGHT

Figure 5A 20 - 70 Ton Single

13

Installation, Operation and Maintenance Manual

TY

VariCool EZ-Fit

DETAIL "A"

P 16 PLCS

LEFT

MOUNTING SCREWS

MOTOR

IN OUT

DETAIL "A"

ELECT

TIGHTENING SCRE W

VFD

VFD

FRONT

ELECT

MOTOR

Subject to change without notice. 40.20-IM (0118)

NRUTERNRUTER

RIARIA

RAER THGIR

Figure 5B 20 - 70 Ton Dual

14

Loading...

Loading...