United CoolAir Marvel Plus Installation, Operation And Maintenance Manual

Marvel Plus

DISCONTINUED

For Reference Only

MICROPROCESSOR CONTROLLER

Installation, Operation and Maintenance Manual

Effective October 2018

***Interactive PDF***

Contents

Installation, Operation and Maintenance Manual

Marvel Plus

Contents ������������������������������������������������������������������������������2

Use of Symbols �������������������������������������������������������������������3

ELECTRICAL HAZARD �������������������������������������������������������3

WARNING ���������������������������������������������������������������������������3

CAUTION ����������������������������������������������������������������������������3

INFORMATION ��������������������������������������������������������������������3

Display Mounting Location ��������������������������������������������4

Connecting Cable ����������������������������������������������������������4

OPERATING THE CONTROLLER ��������������������������������������5

Unoccupied Mode ���������������������������������������������������������6

Unoccupied Override Mode �������������������������������������������6

System Operation ����������������������������������������������������������6

Supply Air Temperature Control ������������������������������������6

Return Air Temperature Control (Option) �����������������������6

Sequence of Operation �������������������������������������������������6

Humidication (Option) ��������������������������������������������������7

Dehumidication (Option) ����������������������������������������������7

Reheat Mode (Option) ���������������������������������������������������7

Air Side Economizer (Option) ����������������������������������������7

Air Side Economizer - Compressor Assist Mode �����������7

Water Side Economizer (Option) �����������������������������������7

Water Side Economizer - Compressor Assist Mode ������7

STATIC PRESSURE TRANSDUCER

(DUCT MOUNT) WITH VAV OPTION ���������������������������������8

MOUNTING �������������������������������������������������������������������8

WIRING �������������������������������������������������������������������������8

Chilled Water Coil (Option) ��������������������������������������������9

Freezestat (Option) �������������������������������������������������������9

Marvel Plus Display Screen Information �����������������������9

System Status ���������������������������������������������������������������9

Blower / Motor Screen ���������������������������������������������������9

Compressor Discharge Pressure Screen ��������������������10

System Status Screen �������������������������������������������������10

Water Status Screen ���������������������������������������������������10

Compressor Status Screen �����������������������������������������10

Compressor Minimum On Status Screen �������������������� 11

Compressor Minimum Off Status Screen ��������������������11

Analog Outputs Status Screen ������������������������������������ 11

Occupied / Unoccupied Override Screen �������������������� 11

Menu and Sub-Menu Areas �����������������������������������������12

Enables �����������������������������������������������������������������������12

System Enables ����������������������������������������������������������12

Constant or Variable Air Flow Enables ������������������������12

Set Points ��������������������������������������������������������������������������12

Set Points (continued) �������������������������������������������������13

Cooling Mode ��������������������������������������������������������������13

Heating Mode ��������������������������������������������������������������13

Set Points (continued) �������������������������������������������������14

Morning Warm-up ��������������������������������������������������������14

Warm-Up Set Points ����������������������������������������������������14

Morning Cool Down �����������������������������������������������������14

Cool Down Set Points �������������������������������������������������14

Set Points (continued) �������������������������������������������������15

Alarm Set Points ����������������������������������������������������������15

Run Hours �������������������������������������������������������������������15

Day Min/Max Screen ���������������������������������������������������16

Alarm History Screen ��������������������������������������������������16

Set Day, Time, Date and Daylight Savings Screen �����16

Schedule ���������������������������������������������������������������������16

Morning Warm-up Time �����������������������������������������������17

Unoccupied Humidity Control Screen �������������������������17

BMS Setup Screen ������������������������������������������������������18

BMS Reset Function Screen ���������������������������������������18

Change Password Screen �������������������������������������������18

Technicians Menu ��������������������������������������������������������18

Temperature Unit Screen ��������������������������������������������18

Manual Analog & Digital Control ����������������������������������19

Sensor Calibration �������������������������������������������������������20

Digital Inputs ����������������������������������������������������������������22

Alarm Logic Manual Reset Screen ������������������������������22

Economizer Setup Screen �������������������������������������������22

BMS Economizer Interface Screen �����������������������������23

Water Flush Mode Screen �������������������������������������������23

Water Valve Position Screen ���������������������������������������23

Duct Static Pressure Screen ���������������������������������������23

High Duct Static Pressure Screen �������������������������������24

Change Passwords Screen �����������������������������������������24

Software Version Screen ���������������������������������������������24

Control Board Screen ��������������������������������������������������24

LIMITED WARRANTY �������������������������������������������������25

FACTORY TESTED ����������������������������������������������������25

Subject to change without notice. 120.5-IM (1018)

2

Installation, Operation and Maintenance Manual

Marvel Plus

Use of Symbols

This publication includes warnings, cautions and information icons that point out safety related issues or conditions as well

as other pertinent information relative to a safe installation, service or maintenance situation� The following icons should be

interpreted as follows:

ELECTRICAL HAZARD

WARNING

CAUTION

INFORMATION

The electrical hazard icon indicates the presence of an electrical hazard which

could result in electrical shock or death�

The warning icon indicates a potentially hazardous situation which could result

in death or serious bodily injury if not avoided�

The caution icon indicates a potentially hazardous situation which may result in

minor or moderate injury if not avoided�

The information icon indicates a situation that may result in equipment or

property damage� The information provided alerts the reader to relevant facts

and/or conditions�

Subject to change without notice. 120.5-IM (1018)

3

ELECTRICAL HAZARD

Only a qualied licensed electrician or other individual that

is properly trained in handling live electrical components

should perform the wiring installation� Failure to follow all

electrical safety precautions and industry accepted practices

when exposed to live electrical components could result in

death or serious injury�

INFORMATION

All electrical wiring must be in accordance with NEC

(National Electrical Code), NFPA (National Fire Protection

Agency) most current versions as well as any applicable

state or local codes�

INFORMATION

Unit wiring and components have been designed for the

specic unit application and factory assigned controls.

Do not use the unit transformers or alter the unit wiring to

interface any eld supplied accessories or controls.

Installation, Operation and Maintenance Manual

Marvel Plus

ash memory (4 Megabytes). An on-board real time clock

maintains programming during a loss of power� All critical

control points such as system set points, system schedules,

alarm set points, and alarm history are stored in non-volatile

memory� Each Marvel Plus controller has the ability to

record up to 50 alarms/faults under an alarm history page

to allow technicians to scroll through alarm history to view

critical operating data temperatures and optional discharge

refrigerant pressure (units with head pressure control option)

at the time of failure�

The Marvel Plus wall mount terminal is used to interface

with the Marvel Plus Main Board microprocessor through

the on-board display and keypad� The software stored in the

ash memory of the Marvel Plus Main Board microprocessor

was designed with menu/sub-menu driven dis- play screens

allowing customers to easily navigate through the menus

and sub-menus for setup of their systems�

Marvel Plus Main Board microprocessors allow for connection

to some of the more widely used Building Management

Systems without requiring a Gateway to interface� For

optional communications with BACnet™, Modbus, or

Lonworks®, an add-on Serial or IP based communications

card is required�

Display Mounting Location

The wall display does not provide any temperature or

humidity sensing functions� Therefore, the display can be

mounted either in the space being conditioned or in a remote

location�

Connecting Cable

The Marvel Plus is supplied with a factory provided

WARNING

Moving fan drives and high horsepower blowers/motors can

cause injuries� Before applying power to the unit, make sure

all service access panels/doors are closed and fastened/

latched to prevent injuries from the moving drives or from

blowing open� Connect power to the unit at the main power

supply. Next, apply power at the eld in- stalled service

disconnect switch�

The Marvel Plus controller is designed to control United

CoolAir Variable Air Volume congured units. The Marvel

Plus controller package consists of a double microprocessor

design control system made up of a Marvel Plus main control

board and a Marvel Plus wall mount terminal “display and

keypad” (standard conguration).

The Marvel Plus microprocessor main board is a 16 bit

microprocessor programmable controller with on-board

Subject to change without notice. 120.5-IM (1018)

communications cable� A factory supplied cable MUST be

used when connecting the Marvel Plus display to the Marvel

Plus control board�

The standard cable length provided is 100 feet� Any excess

length can be placed where practical� It should be noted

that any excess cable should not be coiled up as this may

generate EMF that could affect the control operation� As

always, care must be taken not to place this control cable in

proximity to any high voltage power wiring�

The maximum length of cable in the standard conguration

will be 500 feet� Beyond 500 feet a different type of cable

and cable gauge must be used�

If a longer length of cable (i�e� more than 100 feet) is required,

please contact a United CoolAir Distributor�

4

Installation, Operation and Maintenance Manual

Marvel Plus

Please note that if at the time of installation or start-up it is

found that the 100 feet is not sufcient, the system can still

be started and set up� The required length of cable can then

be ordered as necessary from United CoolAir�

1. The display can be located next to the unit or other

suitable location temporarily�

2. The display is required for monitoring the system or for

making changes to the set points and also to have the

audible alarm function�

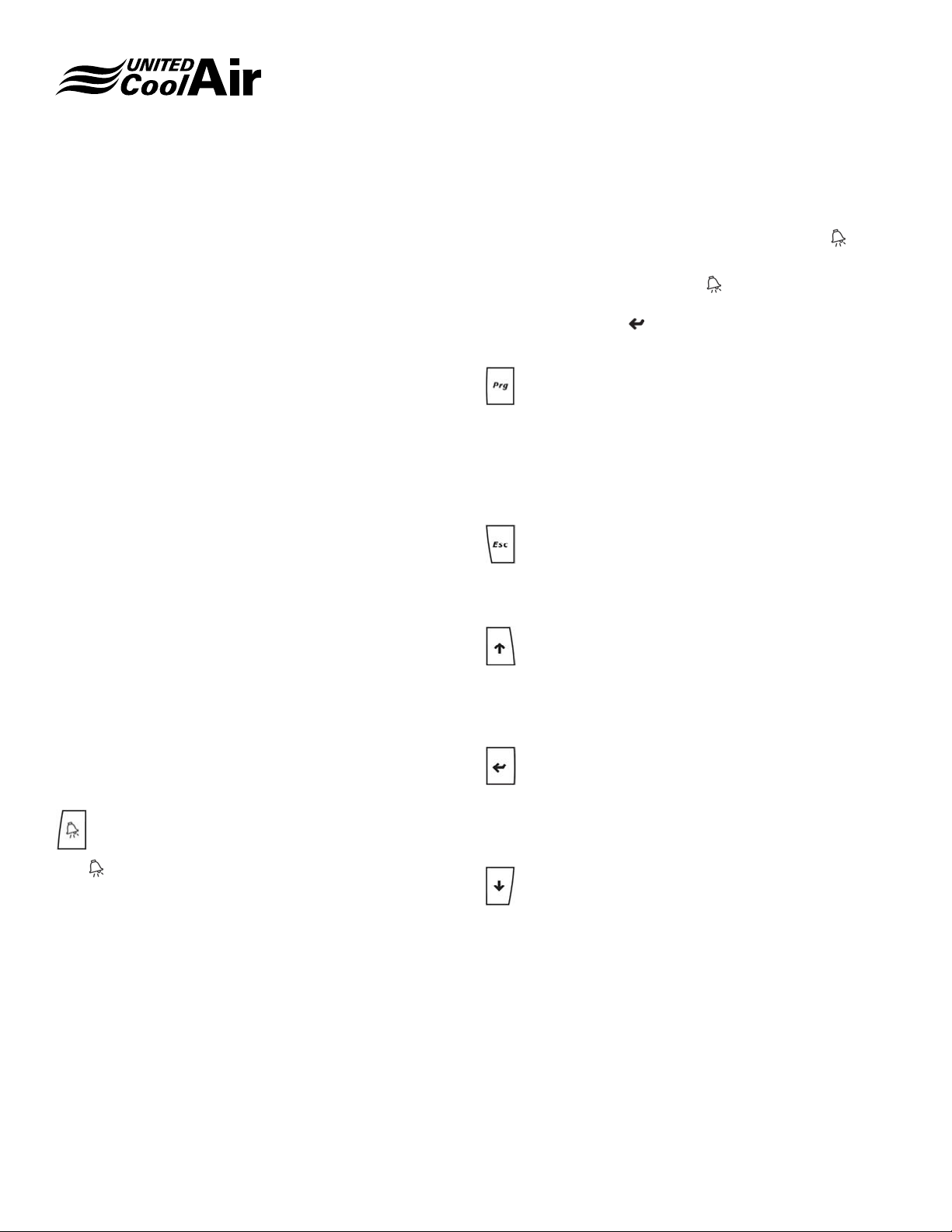

OPERATING THE CONTROLLER

To operate the control system, there are six basic buttons

on the Marvel Plus wall mount terminal which are used to

change settings, time schedules, system setup, and view

alarms critical and non-critical alarms� (Refer to Figure 1)

Some alarms are just simple faults known as indicators

which are not harmful to the operation of the unit but may

require attention in the near future� Pressing the

will reveal what alarm caused the system to shut down�

To reset an alarm, press the

displays “NO MORE ALARMS, Press ENTER to RESET”�

Simply pressing the button will reset the alarm when on

the NO MORE ALARMS screen�

button until the screen

button

PROGRAM BUTTON

The Prg button is used to program the system’s set

points, alarm thresholds, view alarm history, adjust sensor

calibration, enable system operation, view run hours,

set occupied/unoccupied schedules, and much more� A

complete listing is under the section called menus�

ESCAPE BUTTON

The escape button is used to go back to the previous menu

screen�

UP BUTTON

The up button is used to scroll upward through the screens

and menus, increase the value of a setting, or to toggle a

component ON/OFF�

Figure 1 - Wall Display / Keypad

An explanation of each button is as follows:

ALARM BUTTON

The button is used for viewing the present alarms with

the system� There is a built in watch-dog alarm constantly

monitoring for alarm conditions with each of the system

safeties. It will constantly ash on and off to show that the

watch-dog alarm is operating� During an alarm condition, the

button illuminates a continuous Red� Depending on the type

of alarm, the system may shut down or continue to operate�

ENTER BUTTON

The enter button is used to conrm temperature, humidity,

or pressure settings, and conrm selected components. It is

also used to clear alarms once the alarm is viewed�

DOWN BUTTON

The down button is used to scroll downward through the

screens and menus, decrease the value of a setting, or to

toggle a component ON/OFF�

Subject to change without notice. 120.5-IM (1018)

5

Installation, Operation and Maintenance Manual

Marvel Plus

Unoccupied Mode

When the unit is in the Unoccupied Mode, the supply air

blower will ramp back to minimum speed and the unit will

maintain the return air temperature between the High and

Low Temperature Night Set Back Temperature Set Points�

Any optional Outdoor Air Dampers and Airside Economizer

Dampers connected to the system are closed� When the unit

is in the Occupied Mode, the system will be fully operational�

Any interlocked fresh outdoor air dampers shall be open and

airside economizer dampers shall be modulated based on

economizer availability status demand�

Unoccupied Override Mode

Unoccupied Override is available to override the Unoccupied

Mode of operation during after hours tenant occupancy�

When activated, the system returns to the Occupied mode

for the specied adjustable (1 hour increments) time period.

System Operation

There are two methods of control depending on the

application, options ordered, and functions of the system�

The two methods of control are Supply Temperature Control

and Return Temperature Control� Please refer to each

specic method of control for details of operation of each

function within the system� The method of control is preset

at United CoolAir specic to customer ordered application.

Supply Air Temperature Control

Supply Temperature Control monitors the supply

temperature to determine if the supply air temperature is

above the supply air temperature set point� If the supply

air temperature is above the supply temperature set point

plus Band set point, mechanical cooling, optional waterside

economizer, or optional airside economizer is sequenced to

maintain the supply air temperature based on a percentage

of cooling demand required� The amount of cooling demand

is determined by how far the supply air temperature is above

the supply air temperature set point�

If the system has the Morning Warm Up Option, morning

Warm Up is sequenced based on return air temperature and

morning Warm Up set points�

If the system has the Morning Cool Down Option, morning

Cool Down is sequenced based on the return air temperature

and morning cool down set points�

sensor is factory provided but must be eld installed. The

return air sensor will be used to determine the mode of

operation Cooling, Heating, Humidication, Dehumidication

and/or Reheat�

Sequence of Operation

After power is applied to the system from the main power

supply, the unit must be started through the Marvel Plus wall

mount terminal� To start the unit, press and hold the ENTER

button for 5 seconds� To stop the unit, press the ENTER

button again and hold for 5 seconds�

Once the system is started through the Marvel Plus Wall

Control, the supply air blower will start after the factory

default 15 second time delay (eld adjustable) times out.

When the unit is in the occupied mode, the supply air

blower will start at the minimum blower speed to supply the

minimum required amount of air ow. Once at the minimum

speed, the controller will verify that the blower is operating by

checking the airow proving switch. The high duct pressure

safety switch is also veried for possible high duct pressure

conditions� If both safety switches are closed, the controller

will ramp the VFD to maintain the supply air blower at the

static pressure set point�

If the pressure in the ducting increases above the high duct

static pressure switch setting, the system will shut down all

modes of operation� The supply air blower will be shut down

and an audible alarm will be generated and displayed in text

on the Marvel Plus wall mount terminal under the

The bottom line of the opening screen for System Status

will also display “Off by High Press AL” before entering the

button�

At any time, if the Marvel Plus controller monitors that there

is a loss of air ow, the controller will shut down all modes

of operation to protect the system� The supply air blower will

shut down and an audible alarm is generated and displayed

in text on the Marvel Plus wall mount terminal under the

button� The bottom line of the opening screen for System

Status will also display “Off by Airow Alarm” before entering

the button�

If both switches are veried and no alarms exist, the controller

will continue with the cooling or optional modes of operation

heating, humidication, dehumidication, morning warm up

or morning cool down�

button�

Return Air Temperature Control (Option)

If the application requires both cooling and heating or

requires humidication or dehumidication, a return air

Subject to change without notice. 120.5-IM (1018)

6

Installation, Operation and Maintenance Manual

Marvel Plus

Humidication (Option)

If the system has the Humidication Option, humidication

will operate based on return air humidity� When the return air

humidity is less then the return air humidity set point minus

the Band set point, humidication is enabled. Humidication

is then sequenced ON and OFF based on the return

air humidity requirement or humidication demand. The

percentage of humidication demand is determined by how

far the return air humidity is below the return air humidity set

point�

Dehumidication (Option)

If the system has the Dehumidication Option,

dehumidication is sequenced based on return air humidity.

When the return air humidity is greater than the return air

humidity set point plus the Band set point, dehumidication

mode is enabled. Dehumidication is then sequenced /

staged ON and OFF by cycling compressors based on the

dehumidication requirement or dehumidication demand.

The percentage of dehumidication demand is determined

by how far the return air humidity is above the return air

humidity set point�

Reheat Mode (Option)

If the system has the Dehumidication Option and the

optional factory provided heaters or hot gas reheat coil and

valve, the heaters/hot gas reheat coils are available for the

Reheat Mode Option� The heater(s) will be activated for the

Reheat Function during the Dehumidication Mode. Reheat

function is based on both Return Air Temperature and

Supply Air Temperature and their respective set point� If the

return air temperature falls below the return air temperature

set point or the supply air temperature falls below the supply

air temperature set point, the reheat is brought on and

applied based on whichever demand for heating is greater�

The reheat demand is based on how far the temperature is

from the set point and whichever demand is greater (reheat

demand based on supply air temperature or reheat demand

based on return air temperature)� For systems with multiple

stages of heater, the quantity of heaters for Reheat Mode

is determined by the heating demand based on return air

temperature�

Air Side Economizer (Option)

If the system has the Airside Economizer Option, the system

will utilize the airside economizer when the outdoor air

enthalpy is less than return air enthalpy and the outdoor

air temperature is less than the outdoor air temperature set

point minus the Band set point� Once the outdoor air enthalpy

is veried, the Marvel Plus controller sends a modulating

signal (0-10vdc) to the eld interlock terminal strip as shown

on the electrical diagram provided with the unit� The signal

provided will maintain the supply air temperature as close

to the supply air temperature set point as possible until the

return air temperature (cooling requirement) is satised.

INFORMATION

The minimum position damper setting may in some

instances affect system operation if too much outdoor air is

continuously introduced to the space being controlled�

Air Side Economizer - Compressor Assist Mode

Mechanical Cooling Assist is a function available for

applications where the outdoor air temperature cannot meet

the cooling demand requirements� The Mechanical Cooling

Assist function has an adjustable time delay (minutes) before

mechanical cooling compressor stages are energized to

assist with the Airside Economizer option�

Water Side Economizer (Option)

The Water Side Economizer Option provides an economical

method of cooling when a free-cool coil can be utilized� If the

system has a free-cool coil and a cooling tower available,

the system will use free cooling when the water temperature

is below the free-cool temperature setting� If the water

temperature is above the free-cool setting, the system will

use mechanical cooling� If the water temperature is below

the free-cool setting, the water valve for free-cool mode will

modulate open to satisfy the cooling requirement�

Water Side Economizer - Compressor Assist Mode

Mechanical Cooling Assist is a function available for

applications where the waterside economizer function cannot

meet the cooling demand requirements� The Mechanical

Cooling Assist function has an adjustable time delay

(minutes) before mechanical cooling compressor stages are

energized to assist with the Water Side Economizer option�

Subject to change without notice. 120.5-IM (1018)

7

Installation, Operation and Maintenance Manual

Marvel Plus

STATIC PRESSURE TRANSDUCER (DUCT MOUNT) WITH VAV OPTION

MOUNTING

The static pressure transducer shown in Figure 3 – Pressure

Transducer must be installed in the main supply air ducting

at a location approximately two-thirds of the distance down

the straightest duct run from the supply air outlet of the unit�

The location must be a non-turbulent area of supply air ow.

Mount the pressure transducer as follows:

1. Remove the pressure transducer’s cover plate screws

using a Phillips head screw driver�

2. Select the mounting location� Install the sensor at the

approximate mid-point/center of the vertical plane of

the ducting�

3. The sensor must be mounted vertically with the

electrical entrance/strain relief facing downward�

4. Drill a 1/2” hole through the face of the duct�

5. Before installing the duct pressure transducer, make

sure the gasket at the base where the duct probe

meets the transducer housing is intact and sealed to

the sensor (so that it will seal the perimeter of the hole

drilled)�

6. Insert the probe into the duct and mount the pressure

transducer using two (2) eld provided #8 sheet metal

screws�

WIRING

Using a minimum 18-20 AWG 300 volt rated two conductor

shielded cable with drain wire make the following electrical

connections�

IMPORTANT: Please observe polarity of this sensor� The “+”

is +24 vdc and the “–“ is the output (4-20 mA) to the Analog

Input of the controller�

7. Connect from the positive terminal “+” inside the

pressure transducer to the unit’s electrical terminal

block TB-DMPT +�

8. Connect from the negative terminal “–” inside the

pressure transducer to the unit’s electrical terminal

block TB-DMPT –�

9. Connect the drain wire to ground at the unit end only�

FIGURE 1 – PRESSURE TRANSDUCER

Subject to change without notice. 120.5-IM (1018)

8

Loading...

Loading...