United cool air C13-Series Installation, Operation And Maintenance Manual

C13-Series

Installation, Operation and Maintenance Manual

Effective August 2018

Air-Cooled, Water-Cooled, Chilled Water and Heat Pump

Horizontal

Contents

Installation, Operation and Maintenance Manual

C13-Series

Contents � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

Wiring Diagram � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

Important Notice� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Use of Symbols� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

C13-Series Air-Cooled Package � � � � � � � � � � � � � � � � � � � 6

C13-Series Water-Cooled Package� � � � � � � � � � � � � � � � � 7

General Information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

Inspection Of Equipment � � � � � � � � � � � � � � � � � � � � � � � � 8

Handling � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

Location � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

Mounting And Setting In Place� � � � � � � � � � � � � � � � � � � � 8

Installation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

Split Systems � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

Separation Of Sections � � � � � � � � � � � � � � � � � � � � � � � � � � 9

Interconnecting Refrigerant Tubing � � � � � � � � � � � � � � � 10

Single Package Unit Wiring� � � � � � � � � � � � � � � � � � � � � � 13

Split System Wiring � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

Duct Connection� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

Pressure Switches � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

High Pressure � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

Low Pressure � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

Water-Cooled Condensing Units � � � � � � � � � � � � � � � � � 13

Water-Cooled Condenser� � � � � � � � � � � � � � � � � � � � � � � 13

Water Piping and Connections� � � � � � � � � � � � � � � � � � � 13

Hook Up � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

Water Connection� � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

Condensate Drain Connection � � � � � � � � � � � � � � � � � � � 14

Maintenance Procedures� � � � � � � � � � � � � � � � � � � � � � � � 15

Filters� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

Cleaning The Water-Cooled Condenser� � � � � � � � � � � � 15

Blowers � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

Blower Motors� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

Blower Speed Adjustment � � � � � � � � � � � � � � � � � � � � � � � 17

Blower Motor Lubrication � � � � � � � � � � � � � � � � � � � � � � � 17

Belts� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

Refrigerant Systems� � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

Evaporator And Air-Cooled Condenser Coils � � � � � � � 18

Minimum Service Access � � � � � � � � � � � � � � � � � � � � � � � 18

Application Data � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

Hard Start Kit � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

Sequence Of Operation � � � � � � � � � � � � � � � � � � � � � � � � � 19

Cooling Sequence Of Operation � � � � � � � � � � � � � � � � � � 19

Heating Sequence Of Operation (Other Than Heat

Pump) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

Heat Pump Heating Sequence Of Operation � � � � � � � � 20

Options � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

Condensate Pump � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

Thermostat � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

Checking Hot Gas Bypass Valve� � � � � � � � � � � � � � � � � � 21

Adjustment Of Hot Gas Bypass Valve � � � � � � � � � � � � � 22

Microprocessor Controller � � � � � � � � � � � � � � � � � � � � � � 22

Humidier � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

Electric Heat � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

Electric Reheat � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

Steam Coil� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

Hot Water Coils� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

Flooded Condenser � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

Buck/Boost Transformer � � � � � � � � � � � � � � � � � � � � � � � � 23

Chilled Water Valves Or Hot Water Valves � � � � � � � � � � 24

Head Pressure Control Valves � � � � � � � � � � � � � � � � � � � 24

Economizer Operation (Airside) � � � � � � � � � � � � � � � � � � 24

Economizer Operation � � � � � � � � � � � � � � � � � � � � � � � � � 24

Economizer Operation – (Waterside) � � � � � � � � � � � � � � 24

Condensing Section Outdoor Modication Kit � � � � � � 24

Split Condenser / Condensing Sections � � � � � � � � � � � 24

C13-Series Air-Cooled Condenser/ Condensing Section

With Outdoor Modication Kit� � � � � � � � � � � � � � � � � � � � 25

Vertical Stacking Unit� � � � � � � � � � � � � � � � � � � � � � � � � � � 26

Troubleshooting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 28

Limited Warranty � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 32

Limited Warranty for Hermetic Compressors � � � � � � � 33

Limited Warranty Condensing Section � � � � � � � � � � � � 34

Limited Warranty for Hermetic Compressors � � � � � � � 35

Air-Cooled Unit � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 36

Start-Up Procedures (R-410a Systems)� � � � � � � � � � 36–37

Air-Cooled Unit � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 38

Start-Up Procedures � � � � � � � � � � � � � � � � � � � � � � � � � � 38

Cooling Mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 39

Electrical� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 39

Heating Mode (Optional) � � � � � � � � � � � � � � � � � � � � � � � 39

Water-Cooled Unit � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 40

Start-Up Procedures (R-410a Systems)� � � � � � � � � � � � � 40

Start-Up Procedures (R-410a Systems) Continued:� � 41

Optional Heating Start Up: � � � � � � � � � � � � � � � � � � � � � � 41

Water-Cooled Unit � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 42

Start-Up Procedures � � � � � � � � � � � � � � � � � � � � � � � � � � 42

Cooling Mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 43

Electrical� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 43

Heating Mode (Optional) � � � � � � � � � � � � � � � � � � � � � � � 43

Basic Model Designation� � � � � � � � � � � � � � � � � � � � � � � � 44

Subject to change without notice. 10.20-IM (0818)

3

Installation, Operation and Maintenance Manual

C13-Series

Wiring Diagram

United CoolAir provides a wiring schematic for each unit produced� To retrieve the diagram for your unit please visit

www�unitedcoolair�com, on your computer or mobile device, scroll to the footer section or Home/industry-resources,

enter your serial number in the Serial Search eld and press return to retrieve your product-wiring diagram.

Your serial number is a combination of the year, month and sequential order of build date�

This action will return the Model number, Job Number and the wiring diagram for viewing as well as downloading�

NOTE: Only units shipped since November 2016 are available on the site, for older units please contact the factory directly

at 717-843-4311�

Subject to change without notice. 10.20-IM (0818)

4

Installation, Operation and Maintenance Manual

C13-Series

Important Notice

This manual is the property of the owner�

Please be sure to leave it with the owner when you leave the job�

Use of Symbols

This publication includes warnings, cautions and information icons that point out safety related issues or conditions as well

as other pertinent information relative to a safe installation, service or maintenance situation� The following icons should be

interpreted as follows:

ELECTRICAL

HAZARD

WARNING

CAUTION

INFORMATION

The electrical hazard icon indicates the presence of an electrical hazard which

could result in electrical shock or death�

The warning icon indicates a potentially hazardous situation which could result

in death or serious bodily injury if not avoided�

The caution icon indicates a potentially hazardous situation which may result in

minor or moderate injury if not avoided�

The information icon indicates a situation that may result in equipment or

property damage� The information provided alerts the reader to relevant facts

and/or conditions�

Subject to change without notice. 10.20-IM (0818)

5

Installation, Operation and Maintenance Manual

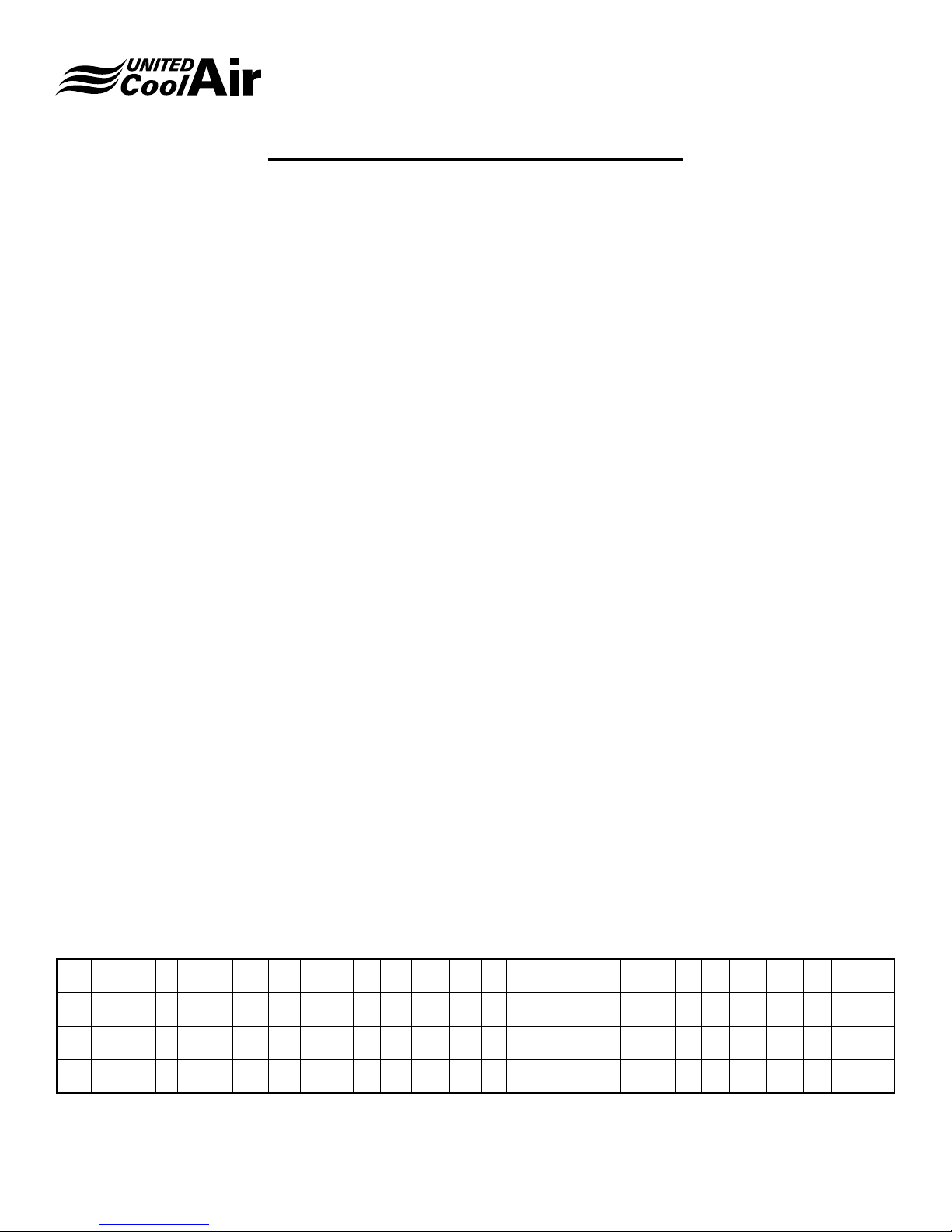

C13-Series Air-Cooled Package

W

S

T R

½

C13-Series

Clearance Hole for

⅜" Hanging Rod

TYP 8 PLS

P

G

H

V

Evap

Return

Evaporator

Section

B

L M N 1 1

Evap

Supply

Air

FRONT RIGHT

Z X Y

Air

J

TOP

F

K

Condensing

Section

1

Service Clearance

All Sizes

Left Side 36"

Right Side 36

Field Installation

Power & Control

Wiring

Elect Box

Motor & Blower

Access Panel

D E 5

Elect Box

Motor & Blower

Access Panel

A

Cond

AA

AB AC

Tons A B C D E F G H J K L M N P Q R S T V W X Y Z AA AB AC AD

2–3 78 56 22 44 34 119⁄16 20 1 59 7 25 1011⁄16 91⁄16 3¼ 57 40½ 1¾ 30½ 91⁄16 3½ 24 35⁄16 13¼ 119⁄16 7 111⁄16 19

4–5 86 64 25 46 40 13 9⁄16 25 0 67 81⁄16 31½ 123⁄8 91⁄16 3 65 42½ 1¾ 36½ 91⁄16 3½ 32 35⁄16 123⁄8 139⁄16 81⁄16 111⁄16 22

6–8 108½ 70½ 32 63 45½ 18¾ 31½ ¼ 73½ 65⁄8 39½ 161⁄16 613⁄16 15⁄8 71½ 59½ 1¾ 42 91⁄16 3½ 24 11⁄16 1811⁄16 16 97⁄16 111⁄16 29

Air

Out

REAR LEFT

Cond

Air

In

Figure 1: Dimension Drawing

Subject to change without notice. 10.20-IM (0818)

AD

1⅛

C

Coil

Access

Panel

Refrigerant

Quick-Connect

Access Panel

Coil

Access

Panel

Condensate

Drain

Filter

Access

6

Installation, Operation and Maintenance Manual

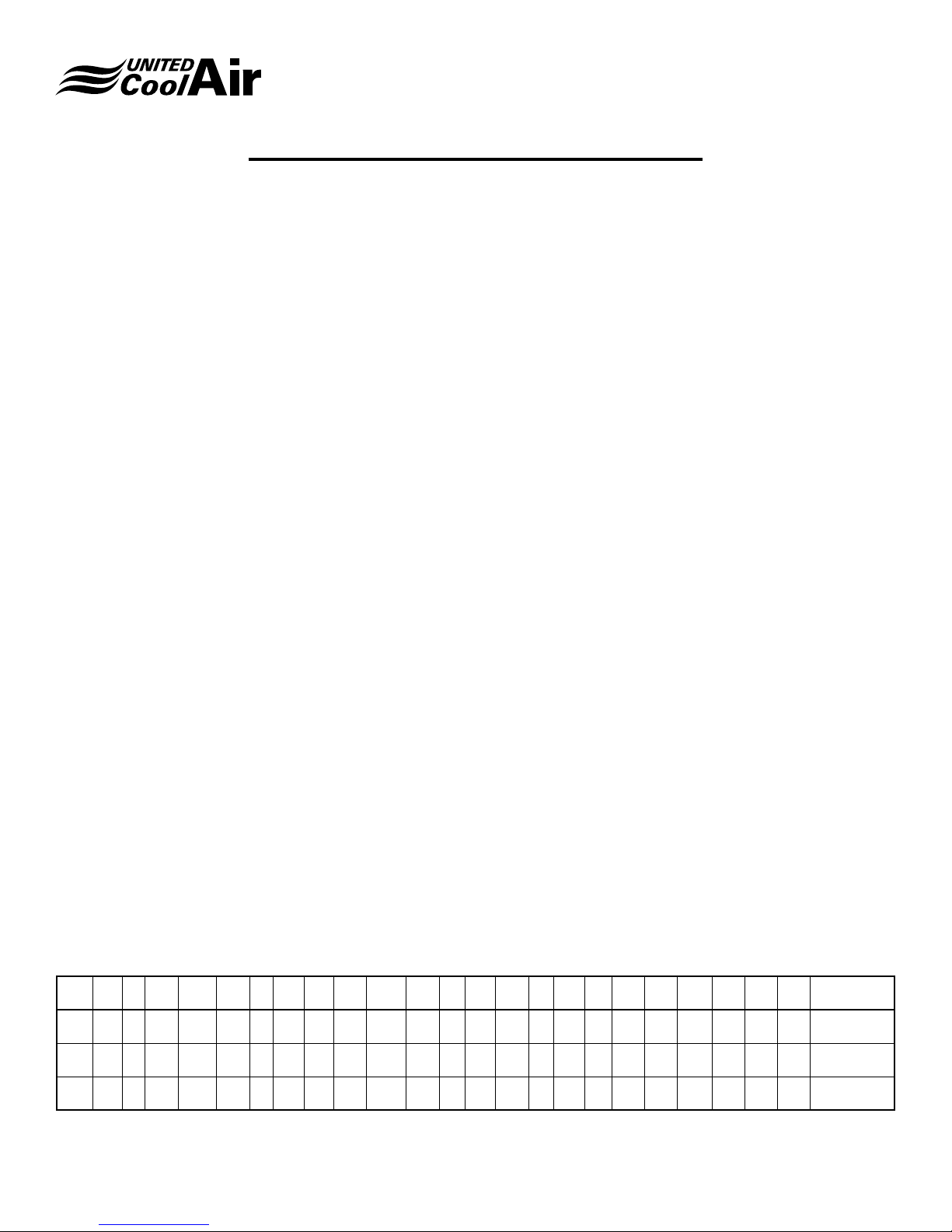

C13-Series Water-Cooled Package

W

S

T

AG

½

C13-Series

Clearance Hole for

⅜" Hanging Rod

TYP 8 PLS

P

G

H

Evap

Air

Cond

Section

TOP

Service Clearance

All Sizes

Left Side 36"

Right Side 36

Field Installation

Power & Control

1 AK

F

K

Wiring

Elect Box

Motor & Blower

Access Panel

Evaporator

Section

B

L M N

Evap

Return

Air

FRONT RIGHT

Supply

J

Out

AJ

In

AH

AE

EAF 5

Elect

Box

Tons B C E F G H J K L M N P Q R S T W AE AF AG AH AJ AK

2–3 56 22 34 119⁄16 20 1 59 7 25 1011⁄16 91⁄16 3¼ 57 40½ 1¾ 30½ 3½ 50 16 12½ 6¼ 91⁄8 13 Ø⅞

4–5 64 25 40 13 9⁄16 25 0 67 81⁄16 31½ 123⁄8 91⁄16 3 65 42½ 1¾ 36½ 3½ 56 16 12½ 6½ 115⁄8 13 Ø11⁄8

6–8 70½ 32 45½ 18¾ 31½ ¼ 73½ 65⁄8 39½ 161⁄16 613⁄16 15⁄8 71½ 59½ 1¾ 42 3½ 56½ 20 16½ 71⁄8 10½ 17 Ø13⁄8

Access Panel

REAR LEFT

Figure 2: Water Cooled Dimension Drawing

Subject to change without notice. 10.20-IM (0818)

Compressor

1⅛

Refrigerant

Quick-Connect

Access Panel

7

Coil

C

Access

Panel

Condensate

Drain

Filter

Access

Water Piping

In & Out

Installation, Operation and Maintenance Manual

General Information

C13-Series

Inspection Of Equipment

Upon receipt of the unit, inspect for visible or concealed

damage. Report any damage to the carrier, and le a

damage claim�

Handling

To facilitate handling, the unit is set on a wooden skid so that

it may be picked up with a two-wheel hand truck or fork lift�

Under no circumstances should the unit be “walked” on the

corners of the skid� Use dolly trucks or pipe rollers to move

the unit to its proper location�

Location

Unit can be installed either as a complete package or split

into two sections. It can be either oor mounted or ceiling

mounted�

Before unit is installed, a thorough study should be made of

the structure� Careful consideration must be given to location

of wiring, condensate disposal, ductwork and accessibility

to the unit for maintenance and servicing� It is necessary

that a minimum clearance space be allowed on each side

of the unit to accommodate maintenance and servicing�

This minimum clearance must be 36" for all units. Attention

must also be given to oor, ceiling or wall load limitations

(See Figure 2)� Location should also provide for condensate

removal, trapping and disposal�

Discharge Air from condenser coil should be deected

away from supply air to condenser, to prevent

recirculation� See also “Condensing Section Outdoor

Modication Kit” on page 27.

CAUTION

Unit should not be located in space subject

to freezing temperatures�

Mounting And Setting In Place

Units can be shipped as an integral package with a tie rail

attached to both sides of the unit at each of the four mounting

channels�

If unit is not to be split but is to be hung, do not remove

tie rail. Use eld supplied (3/8" minimum diameter) hanging

rods, with proper washers and locknuts, then elevate unit to

the exact location where it is to be installed� Fasten the rods

securely to the supporting structure. Install eld supplied

vibration isolation as required� Level unit�

If unit is to be oor mounted and not separated, do not

remove tie rails� Locate on a level pad and secure as

necessary� Field supplied unit isolation can be installed as

required�

Subject to change without notice. 10.20-IM (0818)

8

Installation

Installation, Operation and Maintenance Manual

C13-Series

1� Air conditioner is shipped assembled and ready for

operation�

2� Unit contains a full charge of R-410a refrigerant�

3� Install unit so that controls and side panels are

accessible to the operator and maintenance personnel�

4� Run the condensate drain line by following the

guidelines on page 11�

5� Electrical Wiring

a� Once the unit is installed, refer to the wiring

diagrams which are provided on the backside of the

control box covers�

b� Units are completely internally wired at the factory

for commonly rated supply voltages� Check unit data

tags for required voltage, wire and fuse sizing� The

factory wiring terminates in two boxes; one each

in the evaporator and condensing sections� These

control boxes are located behind the outer access

panels� Each is supplied with an individual control

box cover with a wiring diagram attached inside�

c� All the units are provided with terminal blocks�

d� The power wiring to the unit is to be brought through

one of the available holes for the unit electrical

power connection(s)�

e� The control wiring is brought through the holes

provided in the unit�

f� Supply wiring must comply with all National or Local

codes� The power supply must be suitably fused for

wire protection�

g� Use copper conductors only� The unit must be earth

grounded using the ground lug provided in the

electrical box� Metal conduit is not an acceptable

ground�

h� Run the low voltage wiring from the thermostat to the

unit� Connect to low voltage terminal block supplied�

See “Thermostat” under “Options”, page 20�

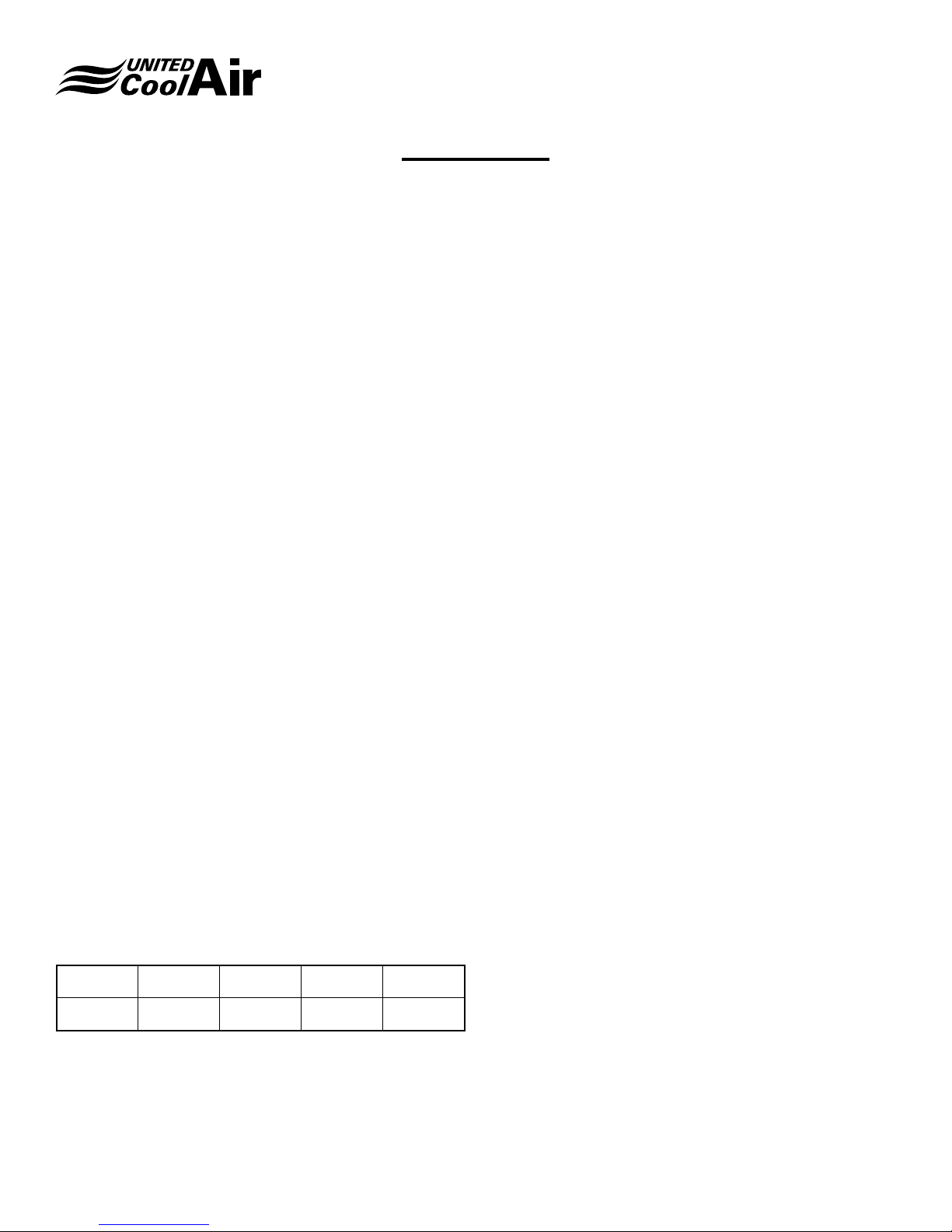

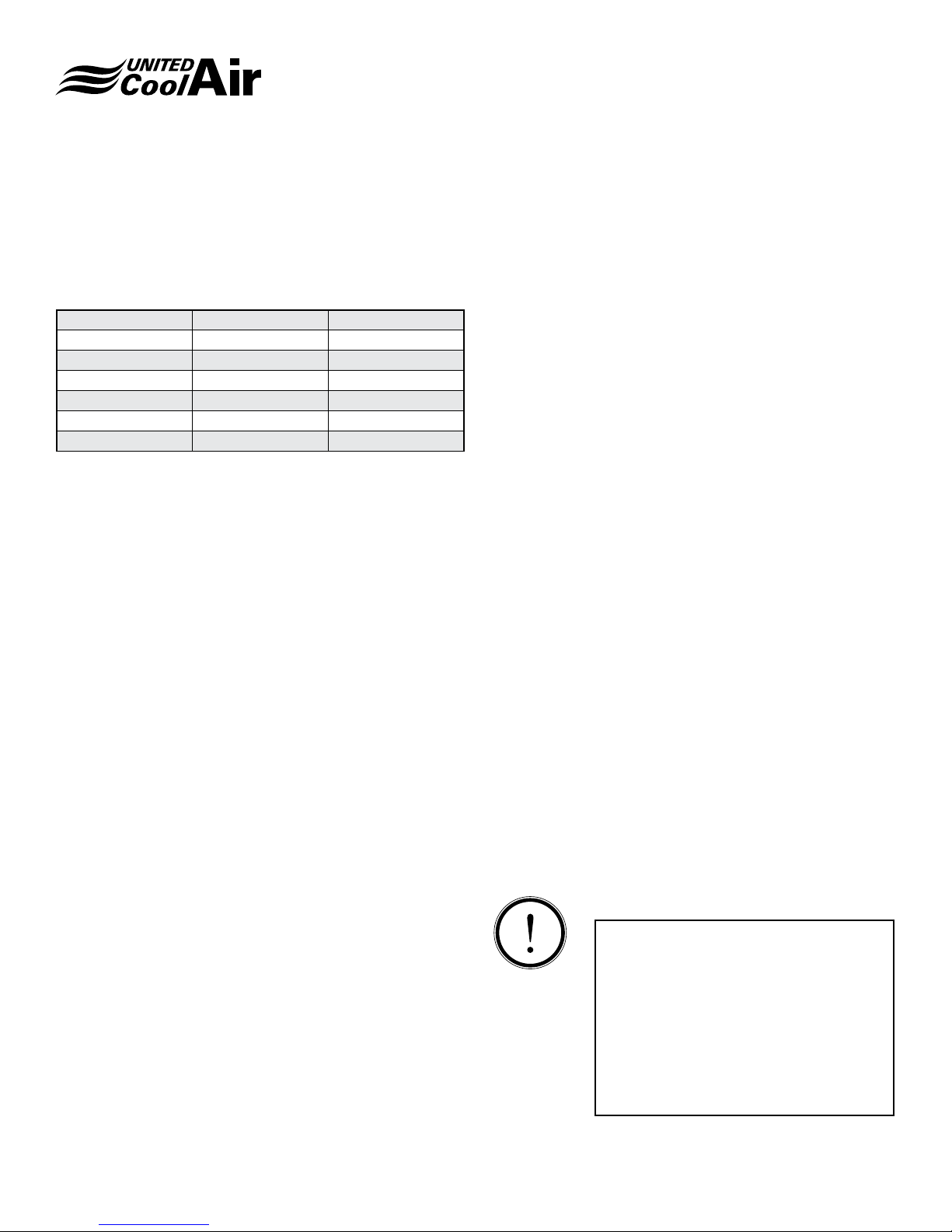

Wire Size1 AWG� Gauge

Note:

1� Solid, Class II copper wire

2� Based on a voltage drop of 1�2 volts per wire�

3� Total wire length is from unit to room thermostat, and

back to unit�

FIGURE 3: Control Wire Sizes

Select a location to install the thermostat to avoid vibration,

drafts, sun exposure, or internal heat sources� Use an inside

wall�

Split Systems

If the unit was ordered for a split system application each

section will contain male resealable refrigerant ttings. Install

the mating female ttings and eld supplied tubing per the

instructions that follow� Note that Optional Interconnect Kits

are required for each circuit and external Hot Gas Bypass

circuit�

Separation Of Sections

If the unit is to be installed as a split system, the following

steps must be carefully followed in performing the separation�

1� Remove evaporator access panel�

2� Using an open-end wrench and turning counter-

clockwise, disconnect the female half of the selfsealing couplings on both the suction and discharge

lines� These are located in the bottom left area of the

evaporator section� When there is a hot gas bypass

option, that connection is to the right of the self-sealing

coupling connections� There is one suction line, one

liquid line, and one hot gas by-pass line (option) for

each compressor�

22 20 19 18 16

40 120 150 190 305

Maximum Wire Length2 Feet

Subject to change without notice. 10.20-IM (0818)

9

Installation, Operation and Maintenance Manual

C13-Series

INFORMATION

Two circuit units have 2 groups of couplings�

It’s a good idea to label or mark the various

connections on both the evaporator

and condensing sections BEFORE

DISCONNECTING THE COUPLINGS to

eliminate the possibility of intermixing the

circuits when the interconnecting tubing

is installed� The suction and discharge

lines in the evaporator section will now

be dangling, be careful not to damage the

tubing connections� Do not disconnect the

male half of the self-sealing couplings,

which are still attached to the bulkhead of

the condensing section�

3� Remove the unit top tie piece*, removing only those

screws which attach the top piece to the two top

panels� (*If unit is already shipped split, these are not

included�)

4� Remove control box access panels from the evaporator

section and the condensing section by removing the

screws at the top and bottom of each access panel�

5� Disconnect and discard the wires which run between

the two internal control boxes� Single circuit units will

have two low voltage wires to be disconnected, dual

units will have 3 low voltage wires� See Wiring Diagram

on the inside of the evaporator control box access

panels for disconnecting power wiring�

6� Remove the two unit tie rails attached to the unit

mounting rails on each side of the unit�

7� Carefully pull the evaporator section away from the

condensing section�

8� Verify that the self-sealing couplings are completely

disengaged and not leaking refrigerant�

The sections may now be moved to their individual locations

for installation (either oor-mounted or hung).

Interconnecting Refrigerant Tubing

After the separated sections have been installed, the eld

supplied interconnecting tubing can be run, using the selfsealing couplings supplied in the optional interconnecting

tubing kit� For dual circuit units, two kits are supplied� It is

recommended that some refrigerant oil be placed on the

coupling threads (Item (10), Figure 5), to facilitate threading�

The following instructions apply:

1� Hand thread the female halves of the self-sealing

couplings (supplied with the interconnect tubing kit)

onto the male couplings (fastened to the unit, Item

(5), Figures 4 and 5)� Turn union nut (Item (11), Figure

5), approximately 1 to 1-1/2 turns� This is to make

sure that the interconnecting tubing will be routed and

brazed with the self-sealing couplings in their nal

proper location, so that there will be no difculty when

the nal coupling assembly is made.

2� If there is a hot gas bypass option, connect that

coupling the same way�

3� Run the interconnecting tubing required�

5

4

Figure 4: Disconnect/Connect Self-Sealing Coupling Figure 5: Install/Service Self-Sealing Coupling

Subject to change without notice. 10.20-IM (0818)

10

Coupling Threads

10

13

5

12

13

Metal

15

Seal

14

Rubber

Seal

4

11

Union Nut

Installation, Operation and Maintenance Manual

C13-Series

Always follow accepted industry practices for sizing lines

based on line length and elevation differences�

Max� total equivalent line length = 100 ft� (a)

Max� elevation difference between Evap� and Cond� = 40 ft�

(a) (b)

Tons Suction Line Liquid Line

2 Ton 3/4 1/2

3 Ton 7/8 1/2

4 Ton 1-1/8 1/2

5 Ton 1-1/8 5/8

6 Ton (2) 7/8 (2) 1/2

8 Ton (2) 1-1/8 (2) 1/2

a� Contact the factory for installations with elevation

differences greater than 40 feet or total equivalent

line lengths greater than 100 feet� Alternate line

sizes and specic refrigerant components may be

required�

b� If condensing section is 20 feet or more above the

evaporator include an oil separator for each circuit�

Systems not ordered from the factory to be installed as a

split system will contain Female Fittings on the evaporator

section� Interconnect kit(s) must be ordered indicating that a

Male / Female Kit is required�

United CoolAir Corporation’s C13-Series horizontal units are

provided with unique self-sealing ttings on the refrigerant

lines between sections. These ttings or couplings allow the

two-section unit to be separated and reconnected without

loosing refrigerant charge�

When installed as a split system, an interconnect kit is

required for each refrigerant circuit or hot gas bypass line�

If the unit is dened as a split system when ordered, the

ttings will be male ttings on both sections. The interconnect

kit will then consist of the matching female ttings. An

interconnect kit is required for the eld to connect refrigerant

lines between both sections� Refrigerant piping between the

sections is eld supplied.

The interconnect kit also contains four (4) Schrader ttings.

The installer can place at least one in each refrigerant line or

at the end of the refrigerant line� These enable the refrigerant

line to be evacuated and charged as needed based on size

and length�

In some situations, the desired refrigerant line size may

differ from the self-sealing tting size provided. The line size

should be reduced or enlarged at the self-sealing ttings as

necessary

The drawing below illustrates a typical piping arrangement

A� Male self-sealing ttings on unit sections

B� Refrigerant piping between sections (eld-supplied)

C� Female self-sealing ttings in interconnect kit (4)

D� Schrader ttings in interconnect kit (4)

A

Evaporator

Section

A

D

C

D

C

D

B

D

B

C

C

A

Condensing

Section

A

FIGURE 6: Guidelines for Interconnecting Tubing Sizing

5� Disconnect and discard the wires which run between

the two internal control boxes (Item (9), Figure 5)�

Single circuit units will have two low voltage wires to

be disconnected, dual and triple units will have 3 low

voltage wires� See Wiring Diagram on the inside of the

evaporator control box access panels (Item (7), Figure

3) for disconnecting power wiring�

6� Remove the two side cross-member angles (Item (1),

Figures 3 and 5; and Item (2), Figure 4)�

7� Carefully pull the evaporator section away from the

condensing section� Double check that the self-sealing

couplings are completely disengaged�

The sections may now be moved to their individual locations,

either oor-mounted or hung.

INFORMATION

NOTE: Installations may be made with

up to 100 feet equivalent line lengths by

installing the recommended tube sizes

(See Figure 6) and adding the necessary

additional refrigerant, R-410a for the

eld installed line set. (See Step 7, page

10)� For equivalent line lengths greater

than 100 ft�, contact the factory for line

sizing and additional refrigerant circuit

accessories required�

Subject to change without notice. 10.20-IM (0818)

11

Installation, Operation and Maintenance Manual

C13-Series

INFORMATION

IMPORTANT! On units with more than one

refrigerant circuit, be careful not to intermix liquid, suction and/or hot gas lines

of the various circuits� If the connections

were labeled before disconnecting the

couplings, this should not be a problem�

The 6 Ton and 8 Ton units have 2 circuits

(with 2 suction line couplings and 2 liquid

line couplings)�

CAUTION

When brazing tubing to the self- sealing

couplings, use a water-soaked wet rag,

running water bath or chill blocks on the

quick-connects to prevent overheating the

valves and damaging the seals� Always

apply heat toward the eld installed

refrigerant line� Do not apply heat toward

the coupling valve and seal�

INFORMATION

NOTE: The interconnect tubing kit (Figure

6) contains a sufcient number of Schrader

access valves to permit installation of one

Schrader in each end of both the liquid

and suction lines of the eld supplied

tubing� Each interconnecting line (suction,

liquid, or hot gas) must have at a minimum

one Schrader access tting. However for

short lengths of tubing, only one Schrader

in each line is necessary�

4� The suction line should be pitched downward to the

compressor, sloping approximately 1/4" every ten feet

to facilitate oil return�

5� “P” traps (eld supplied) are required for all suction

line risers every 15 feet� When the evaporator is above

the condensing section, an inverted “P” trap should be

incorporated as close as possible to the evaporator

(this minimizes oodback/oil slugging during the off

cycle)� If the condensing section is more than 40 feet

above the evaporator, consult the factory for specic

refrigeration components�

6� Install the Schrader valve ttings into the tubing before

brazing the couplings onto the ends of the tubing� Use

a 1/4" hole to mount the valve. Clean and debur the

tubing before doing any brazing to ensure that no chips

or debris are left in the refrigerant circuit� Remove the

Schrader valve cap and core before doing any brazing�

7� Leak check line sets with nitrogen at 500 psig� After

brazing the tubing to the self-sealing coupling halves,

evacuate each line to 300 microns� Check to make

sure that each line holds a vacuum after removal of the

vacuum pump (indicating no leaks) (micron level should

not go above 500 microns within 10 minutes)� Add the

appropriate charge of R- 410a Refrigerant using the

Schrader valves� Wipe off coupling seals and threaded

surfaces with a clean cloth to prevent the inclusion of

dirt or foreign material into the system (See Figure 5)�

Lubricate rubber seal (Item (14)) and metal seal (Item

(15)) in the male halves (Item (5)) with refrigeration

oil� Thread coupling halves together by hand to insure

proper mating of threads� Continue to hand-thread

each half-coupling to its mating half until resistance is

felt (approximately 1-1/2 to 1-3/4 turns)� Complete the

connection of the mating half-couplings with a wrench�

The suction line couplings will be totally engaged

after an additional 5-1/2 to 5-3/4 turns� The liquid line

couplings will be totally engaged after an additional

4-1/2 to 4-3/4 turns�

8� Refrigerant piping shall be insulated in accordance with

local codes and / or applicable ASHRAE Standards�

Insulation exposed to weather shall be suitable for

outdoor use� Provide protection from water and

shielding from solar radiation as necessary�

9� Add R-410A refrigerant to the system to compensate

for the additional interconnecting tubing as follows:

a� For 3/8" liquid line – add 0.6 oz. per foot

b� For 1/2" liquid line – add 1.2 oz. per foot

c� For 5/8" liquid line – add 1.8 oz. per foot

Subject to change without notice. 10.20-IM (0818)

12

Installation, Operation and Maintenance Manual

C13-Series

Single Package Unit Wiring

If the system is to be installed as a single package unit route

the low voltage wiring through the appropriate hole in the

condensing section� A single power supply can be routed

through the appropriate hole in the condensing section� The

unit is factory wired internally for the evaporator� Refer to the

unit data tag for power wiring minimum circuit ampacity and

maximum fuse size� Power wiring must be wired through

over current protective devices such as a circuit breaker or

fused disconnect as required by the National Electric Code�

A method to dis- connect main power such as a non-fused

service disconnect must be installed within sight of the unit�

Split System Wiring

If the unit was ordered for a split system application

(condensing section remote from the evaporator section)

each section will require separate power supplies� Route

these through the appropriate holes for each section� Power

wiring must be wired through over circuit protective devices

such as a circuit breaker or fused disconnect as required

by the National Electric Code� A method to disconnect main

power such as a non-fused service disconnect must be

installed within sight of the unit� Route the low voltage wiring

through the appropriate holes in the evaporator section� Run

the interconnecting low voltage wiring out of the evaporator

section and through the appropriate hole in the condensing

section�

INFORMATION

NOTE: Make sure to use the appropriate

gauge of low voltage wire based on the

total wire length so that no more than a

1�2 volt drop is experienced�

Duct Connection

It is recommended to use a ex collar or other means to

isolate any unit vibration from being transmitted to the duct

or structure�

Ductwork and plenums shall be insulated in accordance with

applicable ASHRAE standards or local codes�

Pressure Switches

High Pressure

This switch shuts the unit down in the event of excessive high

pressure in the discharge line� A manual reset is required at

the high pressure switch�

Low Pressure

This switch shuts the unit down in the event of excessive low

pressure in the suction line�

INFORMATION

NOTE: The low pressure switch(es) are

connected to lock-out relay(s)� If the unit

goes off on low pressure, the lock-out

relay(s) must be reset by switching the

thermostat to the “OFF” position and then

back to the “COOL” position� Refer to the

separate instructions for any units that

incorporate a microprocessor for control�

INFORMATION

NOTE: Microprocessor controlled units

do not incorporate a lock out relay�

After resolving the high or low pressure

situation reset the microprocessor as

required� Consult separate manual for

microprocessor control�

Water-Cooled Condensing Units

Water-Cooled Condenser

The condenser is a tube-in-tube, chemically-cleanable

conguration. The inner tube carries the water and the outer

tube the refrigerant�

Water Piping and Connections

Do not reduce the water pipe sizes from the factory

connections on the unit� Both the water inlet and outlet

of the condensing section should be equipped with eld

supplied shut off ball valves� This is needed for shutdown

of water supply during long periods of unit shutdown and/or

condenser removal, if required�

INFORMATION

The condensate drain line should not

be connected to the condenser outlet,

as ooding is likely to occur. Provisions

should be made for ease of piping cleaning

by using plugged tees at all turns, rather

than ordinary elbows�

Subject to change without notice. 10.20-IM (0818)

13

Installation, Operation and Maintenance Manual

C13-Series

Hook Up

Each refrigerant circuit requires 3 gallons per minute (GPM)

of water per ton of refrigeration� If the unit does not have

water regulating valves or head pressure control valves

eld supplied balancing valves may be required. For future

reference when cleaning is needed, record details on

temperatures entering and leaving the heat exchanger and

the pressure drop as a new installation during the initial unit

start-up� See “Cleaning The Water-Cooled Condenser” on

page 13�

Water Connection

Install and connect a fresh water strainer (eld supplied) to

the water inlet line� Strainer should be readily accessible for

periodic cleaning� Shut-off valves on both strainer inlet and

outlet are recommended to facilitate cleaning�

CAUTION

High inlet water temperature or low water

ow rate may result in nuisance tripping of

the high pressure switch�

CAUTION

Water-cooled units with a glycol cooling

uid will require a higher GPM / Ton ow

rate� Contact the factory for details�

Condensate Drain Connection

Units are equipped with two 3/4" IPS drains; one for the

evaporator condensate; one for the condensing section�

All units require evaporator section drains to be installed�

Heat pumps and water cooled condensing units also always

require the installation of a condensing section drain� Units

with air-cooled condensers need a condensing section drain

when units are installed in areas which may permit rain to

enter� It is EXTREMELY IMPORTANT that the lines attached

to these connections contain a trap, to ensure positive

draining� It is highly recommended that the trap be primed

with water prior to start-up�

The drain lines must be trapped because the coils are

located on the negative sides of the blowers� The purpose

of the condensate trap is to neutralize the negative pressure

created within the cabinet by the blower�

This negative pressure can vary from less than 1" up to 2"

column. The condensate trap must be of sufcient depth in

water column to permit the condensate to ow from the drain

pan (See Figure 7)�

The “A” dimension must equal or exceed the negative static

pressure developed by the supply air blower� If it does not,

the condensate will not drain properly and may overow the

drain pan. The trap must be at least 2-1/2" deep to maintain

a water seal under all operating conditions, especially during

blower start-up�

INFORMATION

NOTE: Optional Head Pressure Control

Valve(s) should be incorporated into the

unit circuit(s) if the cooling uid will be less

than 65°F

WARNING

Water cooled units are for use with

fresh water application only� Do not use

for brackish water or salt water unless

appropriate condenser has been installed

as an option�

Subject to change without notice. 10.20-IM (0818)

Unit

"A"

2-1/2"

Figure 7: Condensate Trap Installation

14

Loading...

Loading...