United CoolAir VariCool VAV, AVW08, AVW60, AVW10, AVW12 Installation, Operation And Maintenance Manual

...

®

VariCool

VAV

Installation, Operation and Maintenance Manual

Effective August 2018

Water-Cooled and Chilled Water,

Variable Air Volume

Contents

Installation, Operation and Maintenance Manual

VariCool® VAV

Contents � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

Wiring Diagram � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

Important Notice� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Use of Symbols� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

General Information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

EQUIPMENT INSPECTION. . . . . . . . . . . . . . . . . . . . . . 6

HANDLING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

LOCATION AND CLEARANCES . . . . . . . . . . . . . . . . . . 6

UNIT DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

UNIT WEIGHT � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

UNIT INSTALLATION � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

Vibration Absorbers . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Refrigerant Connections . . . . . . . . . . . . . . . . . . . . . . . 10

Duct Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Water Piping / Water Flow . . . . . . . . . . . . . . . . . . . . . . 12

Water Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Recommended Field Installed Externally� � � � � � � � � � � 12

Condensate Drain Connection . . . . . . . . . . . . . . . . . . . 12

ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . 13

SINGLE POINT DISCONNECT (OPTION) . . . . . . . . . 13

SERVICE DISCONNECT. . . . . . . . . . . . . . . . . . . . . . . 13

Supply Air Temperature Sensor . . . . . . . . . . . . . . . . . . 14

Return Air Temperature Sensor (Option) . . . . . . . . . . . 14

Duct Mount Installation. . . . . . . . . . . . . . . . . . . . . . . . . 14

Wall Mount Installation . . . . . . . . . . . . . . . . . . . . . . . . . 14

Return Air Sensor Wiring . . . . . . . . . . . . . . . . . . . . . . . 15

Return Air RH Sensor (Option). . . . . . . . . . . . . . . . . . . 15

Outdoor Air Sensor (Option). . . . . . . . . . . . . . . . . . . . . 15

Duct Mount Installation. . . . . . . . . . . . . . . . . . . . . . . . . 15

Outdoor Air Sensor Wiring . . . . . . . . . . . . . . . . . . . . . . 15

Return Air RH Sensor (Option). . . . . . . . . . . . . . . . . . . 15

High Static Pressure Switch. . . . . . . . . . . . . . . . . . . . . 15

Remote Alarm Output (Option). . . . . . . . . . . . . . . . . . . 16

Remote Water Pump (Option) . . . . . . . . . . . . . . . . . . . 16

O/A Damper Control (Option). . . . . . . . . . . . . . . . . . . . 16

Smoke Detector/Fire Stat (Option). . . . . . . . . . . . . . . . 16

Remote On/Off Control (Option) . . . . . . . . . . . . . . . . . 16

SEQUENCE OF OPERATION . . . . . . . . . . . . . . . . . . . 16

MARVEL PLUS CONTROLLER. . . . . . . . . . . . . . . . . . 16

Maintenance Procedures� � � � � � � � � � � � � � � � � � � � � � � � 17

Filters� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

Cleaning The Water-Cooled Condenser� � � � � � � � � � � � 17

Blowers � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

Blower Motors� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

Blower Speed Adjustment � � � � � � � � � � � � � � � � � � � � � � � 18

Blower Bearing Lubrication� � � � � � � � � � � � � � � � � � � � � � 18

Belts� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

Refrigerant Systems� � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

Evaporator And Air-Cooled Condenser Coils � � � � � � � 19

Finned Coil Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Water Side Economizer Coil . . . . . . . . . . . . . . . . . . . . 20

Water Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Hard Start Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Checking Hot Gas Bypass Valve . . . . . . . . . . . . . . . . . 20

Adjustment Of Hot Gas Bypass Valve . . . . . . . . . . . . . 20

Sequence Of Operation Cooling - - Air-Cooled . . . . . . 21

Cooling - - Water-Cooled . . . . . . . . . . . . . . . . . . . . . . . 21

Cooling - - Chilled Water . . . . . . . . . . . . . . . . . . . . . . . 21

Heating (Other Than Heat Pump) . . . . . . . . . . . . . . . . 21

Heating (Heat Pump, Water Source) . . . . . . . . . . . . . . 21

Troubleshooting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

Limited Warranty � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

Limited Warranty for Hermetic Compressors � � � � � � � 27

Limited Warranty Condensing Section � � � � � � � � � � � � 28

Limited Warranty for Hermetic Compressors � � � � � � � 29

Air-Cooled Unit � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 30

Start-Up Procedures (R-410a Systems). . . . . . . . . . 30–31

Air-Cooled Unit � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 32

Water-Cooled Unit � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 34

Start-Up Procedures (R-410a Systems). . . . . . . . . . 34–35

Water-Cooled Unit � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 36

VARICOOL - Model Number Designation � � � � � � � � � � � 38

Subject to change without notice. 10.20-IM (0818)

3

Installation, Operation and Maintenance Manual

VariCool® VAV

Wiring Diagram

United CoolAir provides a wiring schematic for each unit produced. To retrieve the diagram for your unit please visit

www�unitedcoolair�com, on your computer or mobile device, scroll to the footer section or Home/industry-resources,

enter your serial number in the Serial Search eld and press return to retrieve your product-wiring diagram.

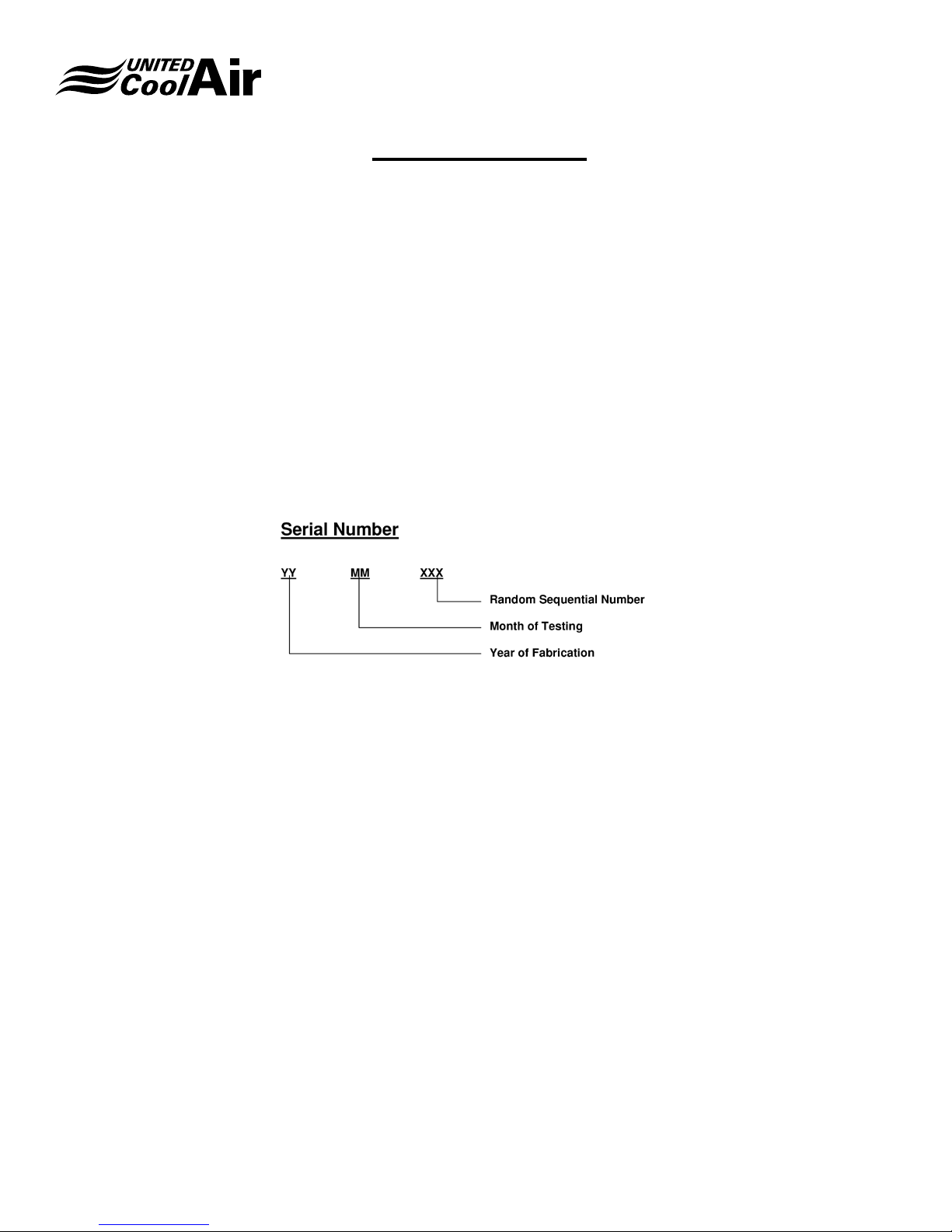

Your serial number is a combination of the year, month and sequential order of build date.

This action will return the Model number, Job Number and the wiring diagram for viewing as well as downloading.

NOTE: Only units shipped since November 2016 are available on the site, for older units please contact the factory directly

at 717-843-4311.

Subject to change without notice. 10.20-IM (0818)

4

Installation, Operation and Maintenance Manual

Important Notice

This manual is the property of the owner�

Please be sure to leave it with the owner when you leave the job�

VariCool® VAV

NOTE: If the unit design was ordered specic to the

application or installation, please refer to the Addendum

at the end of this product literature� The unit may have

features or options specic to this job or application so

please refer to the addendum for details� The addendum

will also list the specic United CoolAir Job Number

or eld reference Job Name. Examples of unit design

specic to unit ordered will include product dimensions,

special control sequences and remote condenser /

condensing sections�

Use of Symbols

This publication includes warnings, cautions and information icons that point out safety related issues or conditions as well

as other pertinent information relative to a safe installation, service or maintenance situation. The following icons should be

interpreted as follows:

ELECTRICAL

HAZARD

WARNING

The electrical hazard icon indicates the presence of an electrical hazard which

could result in electrical shock or death.

The warning icon indicates a potentially hazardous situation which could result

in death or serious bodily injury if not avoided.

CAUTION

INFORMATION

Subject to change without notice. 10.20-IM (0818)

The caution icon indicates a potentially hazardous situation which may result in

minor or moderate injury if not avoided.

The information icon indicates a situation that may result in equipment or

property damage. The information provided alerts the reader to relevant facts

and/or conditions.

5

Installation, Operation and Maintenance Manual

General Information

VariCool® VAV

VariCool units are cooling and optional heating systems

designed to effectively and efciently maintain tenant

occupied spaces within oor by oor building structures.

Each VariCool unit delivers continuous air ow at varied

air volumes and constant temperature to maintain tenant

occupied space settings through eld supplied VAV terminal

outlet boxes. Each unit is designed for optimal energy

efciency, reliability, IAQ, and lowered sound levels. Each

occupant then controls their specic zone by adjusting

temperature setting allowing the VAV terminal outlet box to

open to provide conditioned air. As the VAV box opens, the

VariCool automatically adjusts to maintain the systems static

pressure set point.

Multiple VariCool Systems may be networked together for

unit lead lag, back up/assist, and system rotation. Options

are available for linking each system through a facilities

Building Management System (BMS).

Each unit is shipped in two/three pieces (depends on model

size) for ease on movement to the location of installation.

EQUIPMENT INSPECTION

Upon receiving the unit, carefully inspect all sections for visible

or concealed interior/exterior damage. If damage occurred

during transit, contact the freight carrier immediately and le

a damage claim report. Inspect the unit data plate to verify

that the model unit that was ordered is the correct unit being

received. All accessory components for the application that

must be eld installed are shipped loose in one or several

boxes in the compressor section.

may be moved to the location of installation by crane, fork lift,

hand truck, or roller bars. Units are provided with lifting rings

for rigging and movement by crane. Spreader bars must be

used to protect section cabinet structure during movement.

Protection must be used so that damage to the cabinet

does not occur when using cables or slings. Be certain each

section is well supported when moving. When using dollies,

fork lifts, hand trucks, or roller bars, make sure the sections

base rails are well supported and the weight of the sections

are distributed evenly so that dropping or damage does not

occur during movement.

LOCATION AND CLEARANCES

The unit should be installed in an equipment room located

away from occupied tenant spaces. Careful consideration

should be taken during system layout and installation to allow

for minimum required service clearances for the VariCool

unit. Minimum clearances provided are worst case scenario.

If the clearances were less around the cooling coil section

and a cooling coil had to be replaced, it would be difcult to

maneuver the coil around the unit unless a service access

door(s) to the mechanical room were located next to the

VariCool’s cooling coil end. Figure 1 – Service Clearances

and Table 1 show minimum clearance requirements for each

model unit. If the unit has an optional water side economizer

coil, the distance for service clearance must be maintained

from the edge of the lter rack which will mount onto the

economizer section on larger units but DX cooling coil

on smaller units as the economizer coil will be mounted

internally on smaller systems.

HANDLING

Use extreme caution so that damage does not occur when

moving each section to the location of installation. The unit

Subject to change without notice. 10.20-IM (0818)

6

Installation, Operation and Maintenance Manual

VariCool® VAV

FIGURE 1 – Service Clearances

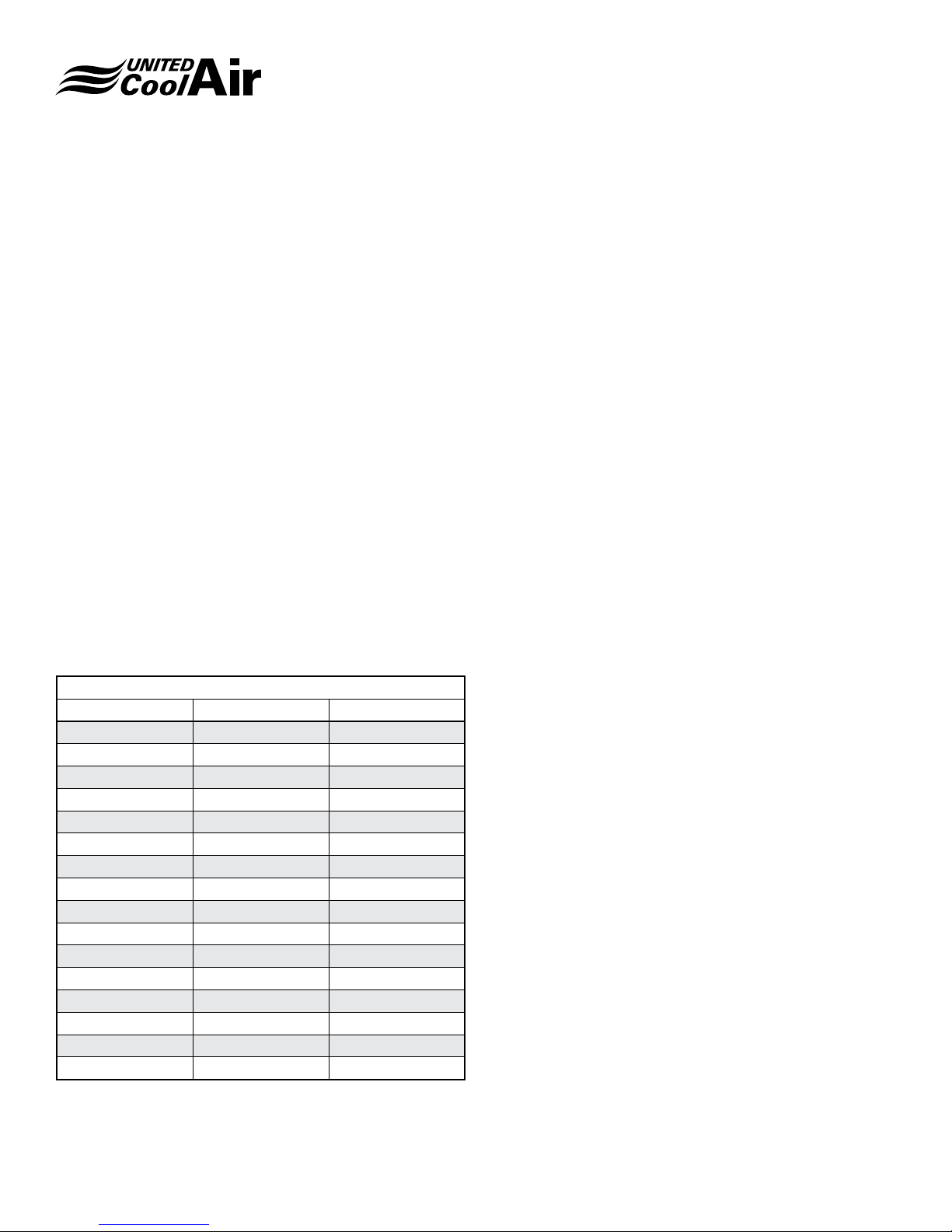

TABLE 1- SERVICE CLEARANCES

Unit Model (A) Dim (B) Dim

AV*8 – AV*16 30” 30”

AV*20-AV*30 42” 36”

AV*32-AV*60 50” 36”

UNIT DIMENSIONS

Figure 2 – Unit Dimensions and Table 2 show the dimensions

of each unit section. Note: If the System has the Water Side

Economizer Coil option, the unit will have a fourth section

that will be attached onto the Cooling Coil/Return Air Inlet

end of the unit. This has been labeled with the dimension

Tx on the diagram and it will vary depending on the lter

options desired.

Subject to change without notice. 10.20-IM (0818)

7

Installation, Operation and Maintenance Manual

VariCool® VAV

FIGURE 2 – Unit Dimensions

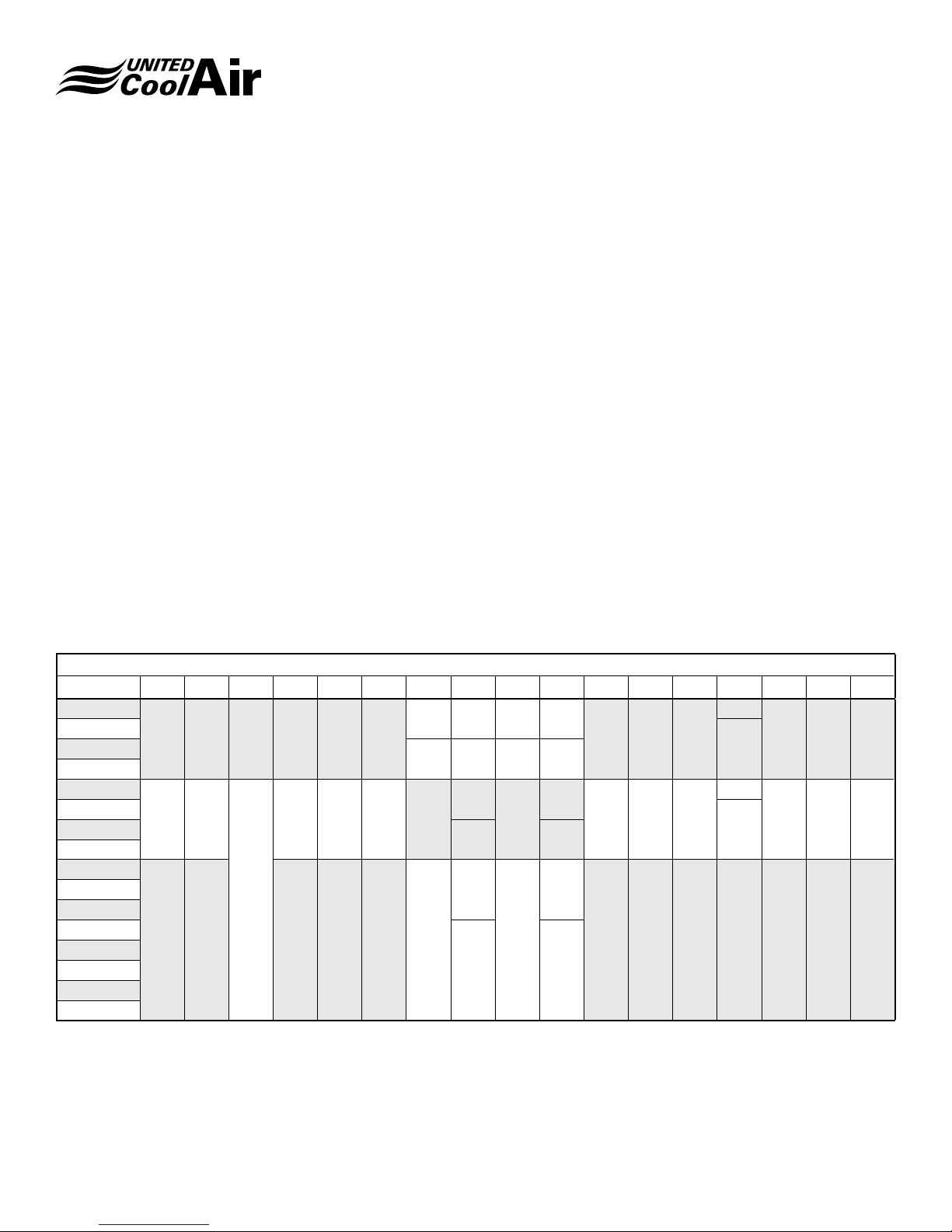

TABLE 2 – Unit Dimensions

MODEL A B C D E F G H I J K L M N P R S

AV*08

AV*10

AV*16

AV*20

AV*24

AV*30

68 68 32 32 38 30

80 80

35 48 32 20

16 26 8 21

18 32 7 18

36

7.5

44 18

AV*32

AV*36

AV*40

AV*44

AV*48

AV*52

35

98 100 52 62 36 30

42

11

52 24

AV*56

AV*60

Tx – Filter Rack dimensions are as follows:

T1 – 7” width when a standard 2” Filter is ordered

T2 – 9.5” width with extra ltration option includes a 2” plus 4” lter back to back

TBD TBD 21.5

22

TBD TBD 21

29

1.5 97 4 80 10.5 4.5 86

20

TBD 5 50

40AV*12

40

TBD 5 66

60AV*26

Subject to change without notice. 10.20-IM (0818)

8

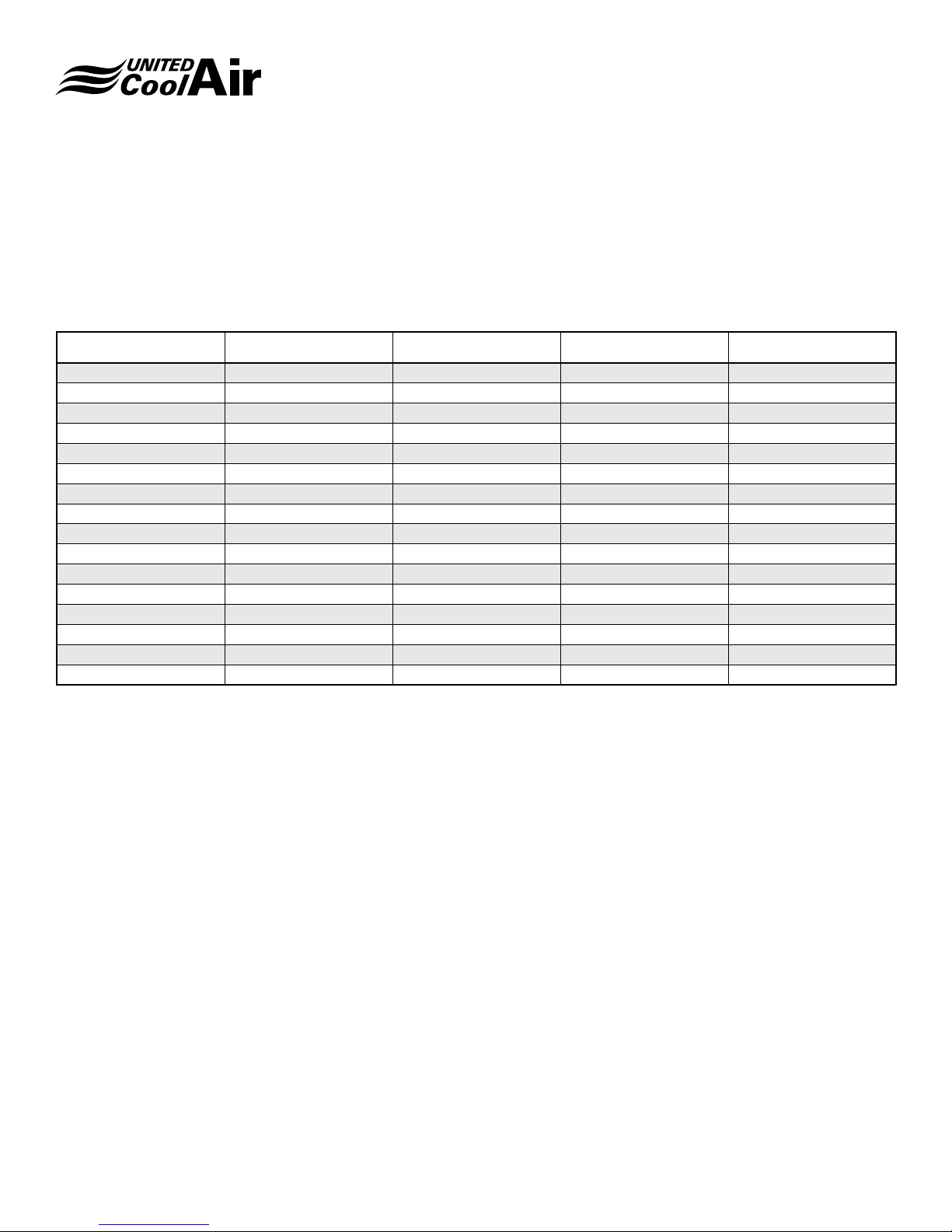

UNIT WEIGHT

Table 3 – Unit Weight shows the weights of each model. The

weight of each unit is listed as a standard VariCool without

options. Table 4 – Optional Component Weight references

the weights of each optional component or upgrade package.

MODEL BLOWER (lbs) EVAPORATOR (lbs) CONDENSER (lbs) TOTAL (lbs)

AVW08 588 521 592 1701

AVW10 617 550 642 1809

AVW12 699 562 732 1993

AVW16 757 619 796 2172

AVW20 1134 856 910 2900

AVW24 1270 954 1046 3270

AVW26 1305 954 1196 3455

AVW30 1305 989 1216 3510

AVW32 1735 1256 1697 4688

AVW36 1787 1325 1673 4785

AVW40 1805 1387 1847 5039

AVW44 1953 1422 1899 5274

AVW48 1953 1479 1942 5374

AVW52 2087 1489 2227 5803

AVW56 2155 1535 2247 5937

AVW60 2155 1593 2287 6035

Installation, Operation and Maintenance Manual

VariCool® VAV

When calculating the weight for each unit, the weight of each

optional component must be added to the standard VariCool

unit weight shown in Table 3.

Table 3 – Unit Weight

Subject to change without notice. 10.20-IM (0818)

9

Installation, Operation and Maintenance Manual

VariCool® VAV

UNIT INSTALLATION

Install the unit using the following procedures. Consideration

must be taken for proper condensate drain installation. Slight

elevation of the VariCool unit may be required for installation

of the condensate drain. Methods for elevating the VariCool

units are support rails, concrete pad(s), or spring isolators.

1� Once the unit’s sections have been moved to the

location of installation, locate the factory provided

mounting hardware, which has been pre-installed in the

holes where the sections will be connected together.

2� Using the appropriate size wrenches, remove the

mounting hardware and set in a safe location for

connecting the sections together during installation.

Vibration Absorbers

When installing the VariCool on a concrete pad, support

rails, or other methods other then spring isolation, use of

vibration absorbers is recommended to prevent transmission

of possible vibration.

3� Figure 3 – Vibration Pads shows the recommended

points for vibration absorbent pads (eld provided). We

recommend the use of a minimum 1” thick Neoprene

vibration absorbent pad under each point shown in

Figure 3. Models AV*09 through AV*16 only require the

pads under the corners only.

4� Place each vibration isolator into positions shown in

Figure 3, and then move the compressor and cooling

coil section into the location of installation being careful

not to damage the quick connect refrigerant piping.

5� Fasten the cooling coil section bottom half to the

compressor section using the mounting hardware

removed in Step 2.

6� Allow the hardware to remain only hand tight until the

Blower Section is installed.

INFORMATION

IMPORTANT: Before proceeding with

the installation of the Supply Air Blower

Section, we recommend connecting the

refrigerant quick connect connections

otherwise it may be difcult to make the

connections.

Refrigerant Connections

The DX Cooling Coil section refrigerant circuit is connected

to the compressor/condenser section using quick-connect

refrigerant connections. If the VariCool unit is a split system

with a Remote Air Cooled Condenser, refer to the section on

Split Systems. If the VariCool was ordered as a packaged

system, connecting refrigerant tubing will be fairly simple.

The quick connect ttings are self-sealing so they do not

permit refrigerant ow until they are completely tight. Follow

these steps for a packaged system:

7� Remove the caps on the quick connect refrigerant

lines.

8� Using a small amount of National 150 or 3G brand

refrigerant oil, lightly lubricate the threads of the

quick connect ttings. (5 to 6 droplets of oil are

recommended)

9� Align each quick connect tting and hand thread the

Female Quick Connect ttings onto the Male Quick

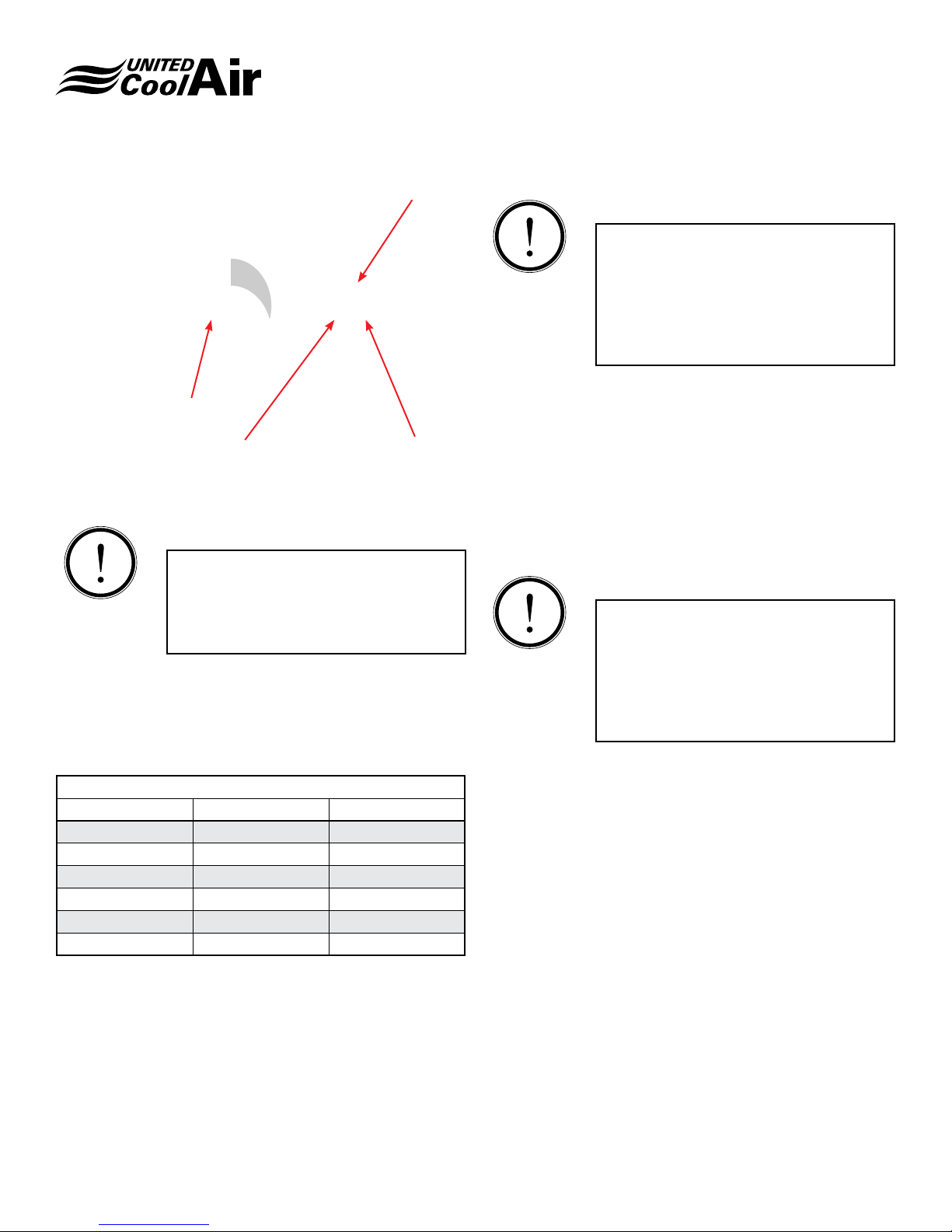

Connect ttings as shown in Figure 4 – Quick Connect.

FIGURE 3 – Vibration Pads

Subject to change without notice. 10.20-IM (0818)

10

Installation, Operation and Maintenance Manual

VariCool® VAV

Female Fitting

Clockwise Rotation

Apply oil to male threads

Male Fitting

FIGURE 4 – Quick Connect

INFORMATION

NOTE: Be certain to count the number

of complete thread rotations. Observe

the number of turns reference Table 6 to

determine how tight to make the quick

connect couplings

10� Continue to hand thread until slight resistance is

observed.

11� Once slight resistance is evident, continue to tighten

the ttings using appropriate size wrenches listed in

Table 5.

TABLE 5

QC-Size Wrench # Full Turns

3/8” 1-3/16” 6

1/2” 1-3/16” 6

5/8” 1-5/8” 7-3/4

3/4” 1-5/8” 7-3/4

7/8” 1-5/8” 8

1-1/8” 2” 8

12� If the quick connect still feels loose, tighten just a bit

more until complete resistance is evident.

INFORMATION

NOTE: Once tight, refrigerant should be

able to pass through the quick connect

couplings. If problems with low refrigerant

pressure appear during system startup,

double check the tightness of these quick

connect couplings as loose ttings will

restrain full refrigerant ow.

13� Move the Blower Section into position of installation

making sure the side that the blower can be seen will

mate up with the large opening in the Cooling Coil

Section.

14� Lift the blower section up onto the Compressor Section.

15� Use the remaining mounting hardware to connect the

Blower Section to the Cooling Coil Section.

16� Using the appropriate size wrenches, hand-tighten all

mounting hardware.

INFORMATION

Note: seismic isolators are shipped

completely locked into position. Once

the blower section is installed the spring

isolators adjusted to loosen the blower on

isolators. The blower should be allowed to

oat on the isolators approximately ½" to

1" side to side and back and fourth.

17� Once the supply air blower is installed, the spring

isolators under the supply air blower must be

loosened. It is the responsibility of the installing

contractor to loosen the spring isolators. These

isolators are tightened for shipping purposes only.

They must be loosened for proper operation.

Subject to change without notice. 10.20-IM (0818)

11

Installation, Operation and Maintenance Manual

VariCool® VAV

Duct Connections

A supply air plenum must be eld fabricated and attached

to the supply air outlet with a exible duct collar. Follow

appropriate guidelines for typical ducting installation.

Provide a duct length that is 3 to 4 times the diameter of

the plug fan wheel before making the rst transition. Provide

turning vanes when required. Attach the supply air plenum

Water Piping / Water Flow

As a standard, units shall have a shell and tube water cooled

condenser. The end plates of the shell and tube condenser

are fully removable for brush cleaning when soft deposits or

scale have formed internal to the condenser coil. Table 6 lists

the water ow and water pressure drops for each model unit.

Tube and tube water cooled condensers may be substituted.

Water Connections

Do not reduce water inlet and outlet connections as this will

restrain water ow and increase water pressure. The inlet

water line should have a strainer accessible for periodic

cleaning. Both the inlet and outlet water lines should have

eld installed water shut-off valves (Gate or Ball type valves).

The shutoff valves are required for maintenance, system

repairs, or long periods of system shut down.

TABLE 6 – Flow Rates/PSI Drop

Model GPM PSI

AVW8 24 4

AVW10 30 6

AVW12 36 7

AVW16 48 8

AVW20 60 6

AVW24 72 8

AVW26 78 10

AVW30 90 14

AVW32 96 8

AVW36 108 10

AVW40 120 6

AVW44 132 7

AVW48 144 8

AVW52 162 10

AVW56 168 12

AVW60 180 14

Recommended Field Installed

Externally

Condensate Drain Connection

Each VariCool unit has a condensate drain connection on

the Cooling Coil section. For systems with the Water Side

Economizer coil option, condensate drain connections are

provided

A condensate drain trap must be eld fabricated and

installed onto the 1" IPS drain connection. Each trap must

then be piped to a common waste drain. Refer to Figure

5 – Condensate Trap for reference dimensions. Units are

equipped with a 1" male IPS connection.

For systems with the Water Side Economizer coil option,

each individual section (Cooling Coil and Water Side

Economizer sections) must be piped individually with a

separate drain trap. Once each section has a drain trap, they

may be connected together by a tee and piped to a common

waste drain.

The depth of the condensate trap will vary due to the model of

the unit ordered and eld requirements. The purpose of the

trap is to neutralize the negative pressure created within the

blower cabinet. Refer to the order specications for external

static pressure (ESP) to calculate the depth required for the

“A” Dimension shown in Figure 5. The A Dimension must

equal or exceed the negative pressure developed by the

supply air blower. If it does not, the condensate will not drain

properly and may allow the drain pan to overow. The lower

leg of the trap must maintain a minimum depth of 3-1/2” to

maintain a water seal on during all operating conditions.

Plug each section’s (Cooling Coil and optional Water Side

Econo Coil) opposite side drain connection as shown.

Subject to change without notice. 10.20-IM (0818)

12

FIGURE 5 – CONDENSATE TRAP

ELECTRICAL CONNECTIONS

All electrical wiring must be in accordance with NEC (National

Electrical Code) and state and local building codes. Refer to

the specications section or the unit’s data tag for the unit’s

power requirements. The main power entrance for each

VariCool unit is located directly above the electrical box.

SINGLE POINT DISCONNECT (OPTION)

If the VariCool unit has through the door single point power

disconnect option, turn the disconnect switch to the ON

position.

SERVICE DISCONNECT

A eld installed fused single point power service disconnect

is required. Install the service disconnect in accordance

with NEC, State, and Local building codes. NEC guidelines

require the unit’s disconnect be installed within sight of the

unit.

A factory provided power block is installed internal to the

VariCool’s electrical control panel. Route the main power

wires in accordance with electrical codes to the eld provided

unit disconnect and terminate them on the line side of the

disconnect. Route the power wires from the Load side of

the eld provided service disconnect to the unit power block

inside the electrical panel.

A ground termination point is located within the VariCool’s

electrical control panel.

Installation, Operation and Maintenance Manual

VariCool® VAV

INFORMATION

NOTE: Conduit is not an acceptable

ground source. A separate ground conduct

must be connected from Earth Ground to

the factory supplied ground lug internal to

the unit.

SENSOR FIELD MOUNTING & WIRING

All sensors and optional components that must be eld

installed and wired to the electrical control panel must be

wired as shown on the electrical diagram provided with the

unit and the instructions listed below.

Static Pressure Transducer

The static pressure transducer is factory installed internal to

the main electrical panel and wired back to the main control

board. Pneumatic tubing (eld supplied) must be connected

from the “HIGH” connection to a point approximately 2/3rds

the distance down the straightest length of supply air ducting.

NOTE: Make certain there are no kinks in the pneumatic

tubing.

1� Drill a hole into the ducting at a right angle. Place

approximately 1/8” of the high pressure tube into the

duct at a right angle. The end of the pneumatic tubing

must be cut at and make a right angle for the tube to

pick up the correct air pressure reading.

2� Use a clamp to secure the tube to the ducting.

3� Make certain the end of the tube is cut ush at a 90

degree right angle. This tube must be located in

ambient air.

The static pressure transducer is preset to read from 0”

to 2.5” W.C. The VariCool’s controller will read the preset

conguration. If a lower pressure conguration is desired,

use the manufacturer’s provided literature to re-congure for

the sensor to read the desired lower pressure setting.

INFORMATION

NOTE: The VariCool’s controller for sensor

calibration must also be readjusted. This

is explained under sensor calibration in

the Marvel Plus controller section.

Subject to change without notice. 10.20-IM (0818)

13

Loading...

Loading...